#Pipe Stress Analysis & Designing Software

Text

How Work Implementation is done using Pipe Stress Analysis & Designing Software?

From the Engineering perspective Pipe Stress Analysis & Designing Software Is a very in demand and crucial software which is used by the piping engineers in the analysis and modelling of Complex pipe structures . CSI Plant develops high Quality and advanced piping software which gives Engineers a variety of new features which helps them in Calculating the amount of Stress in the piping system and advanced analysis can be done which ensures the secure operation of pipes in various working industries like power generation plants and in oil and gas industries.

0 notes

Text

Your Engineering Potential with Piping Design Courses in Chennai

As industrial projects grow in scale and complexity, the demand for well-trained piping design professionals continues to rise. Whether it’s the oil and gas industry, power plants, or chemical facilities, piping design plays a critical role in ensuring safety, efficiency, and reliability. For those in Chennai looking to advance their careers in this specialized field, Conserve Academy offers an industry-leading piping course in Chennai that provides comprehensive training for aspiring engineers and designers.

The Role of Piping Design in Industrial Projects

Piping design is about more than just connecting pipes; it involves complex calculations, software modeling, and compliance with industry standards to ensure fluid transport systems work seamlessly within industrial plants. Conserve Academy’s piping design and drafting course in Chennai is tailored to give students a solid understanding of all these aspects and prepare them for the challenges of real-world projects.

Course Highlights

The piping design courses in Chennai at Conserve Academy offer a blend of theoretical knowledge and practical experience. Here’s what you’ll learn:

Fundamentals of Piping Engineering:

Introduction to piping materials, valves, fittings, and layout design.

Understanding fluid flow, pressure drops, and stress analysis in piping systems.

Working with industry codes and standards to ensure safety and efficiency.

Advanced Software Training:

Hands-on experience with PDMS, SP3D, and AutoCAD, which are widely used in piping design.

3D modeling of piping layouts for industrial plants, ensuring accuracy in design.

Software skills that allow you to create piping designs that integrate seamlessly with other engineering disciplines.

Drafting and Documentation:

Learn how to create detailed 2D drafts from 3D models.

Isometric, orthographic, and spool drawings to guide fabrication and installation.

Documentation skills necessary for project approval and execution.

Real-World Applications:

Apply your knowledge to actual industry projects, learning to solve complex design challenges.

Gain insights into the operational needs of industries like petrochemical, oil & gas, and power generation.

Certification and Career Advancement

Completing the piping design certification course in Chennai gives you a valuable credential recognized across industries. Whether you’re a fresh graduate or a working professional looking to upgrade your skills, this certification will open doors to high-demand roles in piping engineering.

Why Choose Conserve Academy?

Experienced Instructors: Learn from professionals with extensive industry experience in piping design and engineering.

Cutting-Edge Software: Gain hands-on experience with the latest design software used by top engineering firms.

Job-Ready Training: The piping design courses in Chennai emphasize practical training to ensure you are job-ready upon course completion.

Networking Opportunities: Benefit from Conserve Academy’s industry connections, which can help you land your dream job.

Career Opportunities After Certification

With industries increasingly relying on skilled piping professionals, there are ample job opportunities for graduates of the piping design and drafting course in Chennai. Some of the roles you can explore include:

Piping Designer

Piping Engineer

Project Engineer

CAD Designer

The certification provides you with the knowledge and skills to work in industries such as oil & gas, petrochemicals, water treatment, and more.

Conclusion

The piping design certification course in Chennai at Conserve Academy is your gateway to mastering one of the most critical engineering disciplines. With a focus on both software skills and real-world applications, this course equips you for success in today’s fast-paced industrial landscape. Whether you’re looking to enhance your current career or start fresh in the world of piping design, Conserve Academy provides the tools and training you need.

Enroll now and take the first step toward becoming a certified piping design expert!

#piping course in chennai in chennai#piping design and drafting course in chennai#piping design certification course in chennai#piping design courses in chennai in chennai

0 notes

Text

The Role of Pipe Stress and Pipe Stress Analysis in Industrial Safety

Industrial piping systems are vital to the functionality of various sectors, including oil and gas, chemical processing, and power generation. However, these systems are constantly exposed to internal and external forces that can lead to failure if not properly managed. Understanding Pipe Stress and conducting Pipe Stress Analysis are essential practices for ensuring the safety, efficiency, and longevity of these systems.

What is Pipe Stress?

Pipe Stress refers to the forces exerted on a pipe due to factors such as pressure, temperature changes, fluid dynamics, and external loads. These forces can cause the pipe to deform, bend, or even rupture if not appropriately managed. Managing Pipe Stress is crucial in the design and operation of piping systems to avoid failures that could result in downtime, safety hazards, or environmental damage.

The most common source of Pipe Stress is thermal expansion. As the temperature of the fluid inside the pipe changes, the pipe material expands or contracts. Without proper design considerations, this thermal movement can generate stress that leads to system damage. Additionally, the internal pressure of the fluid or gas within the pipe exerts stress on the pipe walls, which can weaken the structure over time if not accounted for in the system’s design.

The Importance of Pipe Stress Analysis

Pipe Stress Analysis is the process of evaluating the stresses in a piping system to ensure that it can handle the forces it will encounter during operation. This analysis is critical for identifying potential weak points and implementing solutions to prevent failures. By performing Pipe Stress Analysis, engineers can predict how a piping system will behave under different conditions and make necessary adjustments to enhance the system’s safety and efficiency.

The primary goal of Pipe Stress Analysis is to ensure that the piping system can withstand the various stresses it will face during its operational life. This includes accounting for factors such as temperature fluctuations, pressure changes, mechanical loads, and environmental forces. By analyzing these factors, engineers can design systems that are both robust and reliable, minimizing the risk of failures and ensuring long-term operational success.

Methods of Pipe Stress Analysis

There are several methods used in Pipe Stress Analysis, depending on the complexity of the system and the specific requirements of the project:

Hand Calculations: For simpler systems, basic hand calculations can provide a rough estimate of the stresses involved. This method is useful for initial assessments but may not be sufficient for more complex systems or those exposed to dynamic forces.

Software Tools: Modern engineering software such as CAESAR II and AutoPIPE are widely used for detailed Pipe Stress Analysis. These tools allow engineers to model complex piping systems and simulate various operating conditions, providing a comprehensive analysis of potential stress points.

Finite Element Analysis (FEA): FEA is an advanced method that breaks down the piping system into smaller elements and analyzes each one individually. This approach provides a highly detailed understanding of how stresses are distributed throughout the system, making it ideal for critical or high-risk projects.

Key Considerations in Pipe Stress Analysis

When conducting Pipe Stress Analysis, several key factors must be considered to ensure the safety and reliability of the piping system:

Material Selection: The materials used in a piping system must be carefully chosen based on their ability to withstand the stresses they will encounter. Different materials have varying strengths, flexibilities, and resistances to stress, which must be accounted for in the design process.

Temperature Effects: Temperature changes can cause significant stress within a piping system due to thermal expansion and contraction. Accurate thermal analysis ensures that the system can accommodate these changes without compromising its structural integrity.

Pressure Conditions: The internal pressure of the fluid or gas inside the pipe creates stress on the pipe walls. Proper pressure analysis ensures that the system can handle these forces without failing.

Support and Restraint Design: Proper placement of supports and restraints is crucial for distributing the weight and forces within the system, minimizing stress concentrations. Pipe Stress Analysis helps determine the optimal locations for these supports.

Compliance with Industry Standards: Adhering to industry codes and standards, such as ASME B31.3 or B31.1, is essential for ensuring the safety and reliability of piping systems. Pipe Stress Analysis ensures that the system meets these regulatory requirements.

Applications of Pipe Stress Analysis

Pipe Stress Analysis is a critical process across a wide range of industries, each with its unique challenges:

Oil and Gas: In the oil and gas industry, pipelines transport fluids over long distances and through harsh environments. Pipe Stress Analysis ensures that these pipelines can handle the pressures, temperatures, and external forces they encounter.

Chemical Processing: Chemical plants often involve piping systems that transport corrosive or hazardous materials. Pipe Stress Analysis ensures that these systems can handle the stresses imposed by chemical reactions, temperature fluctuations, and pressure variations.

Power Generation: Power plants rely on complex piping systems to transport steam, water, and other fluids. Pipe Stress Analysis ensures that these systems can operate safely under high-pressure and high-temperature conditions.

Benefits of Proper Pipe Stress Analysis

Effective Pipe Stress Analysis offers several key benefits:

Improved Safety: By identifying and addressing potential failure points, Pipe Stress Analysis reduces the risk of accidents and enhances overall safety.

Increased Reliability: Proper analysis ensures that piping systems can handle the stresses they will encounter, reducing the likelihood of failures and improving reliability.

Cost Efficiency: Preventing system failures through Pipe Stress Analysis helps avoid costly repairs, operational downtime, and potential environmental damage.

Conclusion

In conclusion, understanding Pipe Stress and conducting thorough Pipe Stress Analysis are essential for designing and maintaining safe, efficient piping systems. By accurately predicting how these systems will respond to different forces and conditions, engineers can create systems that minimize the risk of failure and ensure long-term reliability.

For more detailed insights and expert discussions on Pipe Stress and Pipe Stress Analysis, visit this Twitter discussion. Staying informed about the latest techniques in piping engineering is vital for ensuring the success of your projects

1 note

·

View note

Text

Looking for Expert Piping Design Services?

We offer comprehensive piping design and engineering services using the best piping design software. Our expertise includes pipe design, pipe stress analysis, and process piping design. We specialize in piping CAD, piping drafting, and structural piping. Our team delivers precise Piping & Instrumentation Diagrams (P&IDs) and top-notch piping design engineering services. Discover what piping design truly is with Edanbrook’s expert solutions.

0 notes

Text

Transforming Civil Engineering: The Impact of CAD on Design and Efficiency

Introduction

Computer-Aided Design (CAD) has revolutionized civil engineering, transforming how projects are planned, designed, and executed. This technological tool has not only enhanced design accuracy but also improved the efficiency and productivity of civil engineering projects. CAD's applications in civil engineering span drafting, modeling, analysis, and project management, making it indispensable in modern civil engineering practices.

What is CAD?

CAD refers to the use of computer technology for design and design documentation. CAD software replaces manual drafting with an automated process. Engineers, architects, and construction professionals use CAD software to create precision drawings or technical illustrations in 2D or 3D, which can be used to build and manufacture complex structures and systems.

Historical Perspective and Evolution

The introduction of CAD software in the late 1960s constituted a significant technological leap for design disciplines. Initially, CAD systems were predominantly used in aerospace and automotive industries due to their high cost and operational complexities. By the 1980s, as computer technology became more accessible and user-friendly, CAD applications began to significantly influence the field of civil engineering. This transition marked a shift from traditional drafting methods to a more integrated and dynamic approach to design and construction.

Applications of CAD in Civil Engineering

CAD drafting has become a fundamental component in civil engineering, offering a range of applications that enhance the planning, design, and execution of various projects. Here’s a more detailed look at these applications:

1. Architectural Design

CAD drafting is extensively used in the creation of architectural plans, including the layout of buildings, structures, and other facilities. It allows for precise measurements and detailed representations of spaces, helping architects and engineers optimize design aesthetics and functionality. This application ensures that every architectural element is perfectly scaled and aligned according to project specifications.

2. Structural Engineering

In structural engineering, CAD drafting is crucial for designing the skeleton of buildings and other structures. It helps engineers calculate the correct dimensions, strengths, and materials needed to ensure safety and compliance with building codes. CAD models can simulate how structures withstand stresses and strains, helping to predict potential failure points and reinforce them in advance.

3. Road and Highway Design

CAD drafting simplifies the complex task of designing roads and highways. It allows engineers to map out precise routes, considering topography, traffic flow, and environmental impacts. CAD tools enable the creation of 2D and 3D models of road systems, which include details such as lane specifications, intersections, and access points, ensuring optimal traffic management and safety.

4. Utilities and Pipeline Design

For projects involving water supply, sewage systems, and pipelines, CAD drafting is indispensable. It provides detailed schematics and installation plans that help manage the extensive network of pipes and conduits required in these systems. CAD ensures these utilities are efficiently integrated into the overall project plan, avoiding conflicts and ensuring compliance with environmental standards.

5. Land Development and Site Planning

CAD drafting aids in the comprehensive planning and development of land. This includes plotting out land divisions, designing landscape elements, and planning the placement of buildings and other structures. CAD tools help civil engineers and planners assess the best use of a site, taking into account geographical data and zoning laws, which are crucial for sustainable development.

6. Environmental Engineering

In environmental engineering, CAD drafting is used to design solutions that mitigate environmental impacts. This can include everything from erosion controls and stormwater management systems to the remediation of contaminated sites. CAD models help engineers visualize and simulate environmental systems and their interactions with human-made structures, enhancing the effectiveness of environmental protection measures.

7. Surveying

CAD is crucial in surveying for capturing and analyzing geographical data. This data informs all phases of civil engineering projects, from initial planning to final construction. CAD software helps in creating detailed site models from the survey data, providing a precise base for all further engineering work.

8. Project Documentation

Every civil engineering project requires comprehensive documentation, from initial designs and specifications to as-built drawings and maintenance plans. CAD drafting systems facilitate the creation of these documents, ensuring they are accurate and up-to-date. This supports project management and execution and ensures compliance with legal and regulatory requirements.

9. Integration with BIM

CAD drafting is often integrated with Building Information Modeling (BIM) systems, representing a further evolution of traditional CAD. BIM incorporates detailed information about every component of a building or structure, creating a more dynamic 3D modeling process that spans the entire lifecycle of a project. This integration enhances collaboration among all stakeholders, improving the decision-making process throughout the project's phases.

CAD drafting in civil engineering is pivotal for achieving precision, efficiency, and effectiveness in project implementation. It supports a range of critical activities, from the foundational planning stages to the detailed final design and maintenance plans, embodying a central tool in the civil engineering field.

Read our blog for more information: https://www.gsourcedata.com/blog/how-cad-improves-design-effectiveness-and-work-output

#gsourcetechnologies#architecturedesigns#engineeringdesigns#cadservices#caddrafting#civil engineering

1 note

·

View note

Text

Transforming Engineering with Advanced Design Services: ACS Baroda’s Comprehensive Solutions

In the dynamic field of engineering, design and innovation are paramount to success. ACS Baroda Services stands at the forefront of this evolution, offering a suite of advanced engineering design services that encompass 3D design, piping engineering, and service engineering. This article explores the unique approach and comprehensive solutions provided by ACS Baroda, highlighting how they are redefining engineering standards and meeting the diverse needs of their clients.

The Importance of Engineering Design Services:

Engineering design is the cornerstone of any successful project. It involves conceptualizing, planning, and executing designs that meet specific functional, aesthetic, and safety criteria. Effective design services can significantly enhance the efficiency, sustainability, and overall performance of engineering projects. In an era where precision and innovation are critical, ACS Baroda Services offers a competitive edge with their specialized design capabilities.

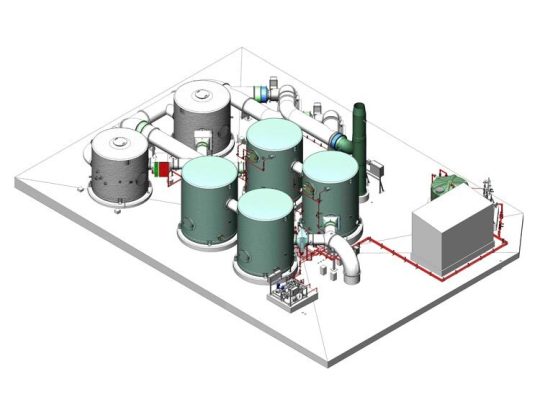

3D Design Services:

One of the most transformative aspects of modern engineering is the utilization of 3D design services. ACS Baroda Services leverages state-of-the-art 3D modeling software to create detailed and accurate representations of projects before they are built. This approach offers several benefits:

Enhanced Visualization:

Clients can see a realistic, three-dimensional view of their projects, making it easier to understand complex designs and make informed decisions.

Improved Accuracy:

3D models reduce errors by providing precise measurements and detailed views from multiple angles, ensuring that every aspect of the design is accounted for.

Streamlined Modifications:

Changes to the design can be quickly implemented and visualized, facilitating a more efficient design process and reducing costly revisions during construction.

Effective Communication:

3D models serve as a powerful communication tool among stakeholders, including engineers, architects, and clients, ensuring everyone is aligned and understands the project scope.

Piping Engineering:

Piping engineering is a critical component of many industrial projects, particularly in sectors like oil and gas, chemical processing, and water treatment. ACS Baroda Services specializes in providing comprehensive piping engineering solutions that include:

Design and Layout:

Detailed piping layouts are created to ensure optimal flow and efficiency. This includes the design of pipe routes, selection of materials, and integration with other systems.

Stress Analysis:

Piping systems are subjected to various stresses due to temperature changes, pressure, and mechanical loads. ACS Baroda conducts thorough stress analysis to ensure the integrity and safety of the piping network.

Compliance and Standards:

All designs adhere to industry standards and regulations, ensuring that the piping systems are safe, reliable, and compliant with legal requirements.

Installation and Maintenance:

In addition to design, ACS Baroda provides support for the installation and ongoing maintenance of piping systems, ensuring long-term performance and durability.

Service Engineering:

Service engineering encompasses a broad range of activities aimed at optimizing the functionality and efficiency of engineering systems. ACS Baroda offers specialized services in this area, including:

System Integration:

Ensuring that various engineering systems work seamlessly together is crucial for the overall success of a project. ACS Baroda’s expertise in system integration ensures that all components function harmoniously.

Performance Optimization:

Through advanced analysis and testing, ACS Baroda identifies opportunities to enhance system performance, reduce energy consumption, and improve overall efficiency.

Maintenance and Support:

Ongoing maintenance and support services are provided to ensure the continued reliability and performance of engineering systems. This includes regular inspections, troubleshooting, and updates as needed.

Custom Solutions:

Recognizing that each project is unique, ACS Baroda offers customized engineering solutions tailored to meet the specific needs and challenges of their clients.

Unique Approach of ACS Baroda Services:

What sets ACS Baroda Services apart is their commitment to innovation, quality, and client satisfaction. Here are some key aspects of their unique approach:

Client-Centric Focus:

ACS Baroda places a strong emphasis on understanding the needs and goals of their clients. This client-centric approach ensures that the solutions provided are not only technically sound but also aligned with the client’s vision and objectives.

Expert Team:

The team at ACS Baroda comprises highly skilled professionals with extensive experience in various engineering disciplines. Their expertise allows them to tackle complex challenges and deliver superior results.

Cutting-Edge Technology:

ACS Baroda leverages the latest technology and tools in their design and engineering processes. This includes advanced 3D modeling software, simulation tools, and analytical instruments that enhance accuracy and efficiency.

Sustainable Practices:

Sustainability is a core value at ACS Baroda. They strive to implement eco-friendly practices in their designs, promoting energy efficiency, resource conservation, and environmental stewardship.

Comprehensive Services:

From initial concept development to final implementation and maintenance, ACS Baroda offers a comprehensive suite of services that cover every stage of the project lifecycle. This end-to-end approach ensures consistency, quality, and seamless execution.

Case Studies:

To illustrate the impact of ACS Baroda’s engineering design services, here are a few case studies:

Oil and Gas Project:

ACS Baroda was tasked with designing a complex piping system for an oil and gas processing facility. Utilizing advanced 3D design tools, they created a detailed model that optimized pipe routing and minimized material usage. The project was completed ahead of schedule, and the client reported significant cost savings and enhanced operational efficiency.

Water Treatment Plant:

For a large-scale water treatment plant, ACS Baroda provided comprehensive service engineering solutions, including system integration and performance optimization. The result was a highly efficient plant that exceeded regulatory standards and operated with reduced energy consumption.

Manufacturing Facility:

In a project for a manufacturing facility, ACS Baroda’s 3D design services enabled the client to visualize and refine their production layout. This led to improved workflow, increased production capacity, and a safer working environment.

Conclusion:

ACS Baroda Services stands out in the engineering industry for their innovative design solutions, technical expertise, and commitment to client satisfaction. By offering advanced 3D design, piping engineering, and comprehensive service engineering, they provide clients with the tools and support needed to achieve exceptional project outcomes. Whether it’s a large-scale industrial project or a specialized engineering challenge, ACS Baroda is dedicated to delivering excellence and driving success through their unique and comprehensive engineering design services.

#engineering_design_services#3d_design_services#design_and_engineering#piping_engineering#service_engineering

0 notes

Text

What is Different types of CADD formats

WHAT ARE THE DIFFERENT CADD FORMATS

CADD FORMATS

There are several different CADD formats. The most recognized CADD formats include 2D drawings and 3D wireframe, surface, and solid models. In general, 2-D drawings and 3-D solid models are the most common CADD formats currently used in the industry. Three-dimensional surface models are also widely used, but often for specific applications. Three-dimensional wireframe models are rare in the current industry. Software specifies the CADD format, which usually focuses on a certain process such as 2-D drawing or 3-D solid modeling.

However, some systems offer tools for working in a variety of formats or the ability to use drawing or model content created in a different format. For example, you can often develop a 2D drawing from 3D model geometry or build a 3-D solid model from 3-D surface model geometry. A software add-on or separate application is sometimes required to work with multiple CADD formats.

Beyond the Basics: A Granular Look at CADD Formats

While the article rightly mentions 2D drawings and 3D models (wireframe, surface, solid) as the primary CADD formats, let's delve deeper into their characteristics:

- 2D Drawings: The workhorse of many industries, 2D drawings offer a familiar and efficient way to represent designs. They excel in:

- Manufacturing & Construction: Standard format for conveying precise dimensions and details.

- Simple Designs: Ideal for quick projects that don't require significant revisions.

- Annotation & Communication: Effective for adding notes, dimensions, and other project-critical information.

- 3D Wireframe Models: These skeletal representations depict designs using lines and curves to connect points in 3D space. While less common today, they can be useful for:

- Conceptualization & Early Design Stages: Providing a basic framework for visualizing initial design ideas.

- Rapid Prototyping: Laying the groundwork for creating physical models.

- 3D Surface Models: A step up from wireframes, these models capture a design's outer "skin" using mathematically defined surfaces. They find application in:

- Organic Shapes & Complex Geometry: Representing curved and freeform elements effectively.

- Visualization & Aesthetics: Creating realistic renderings for presentations or marketing purposes.

- 3D Solid Models: The crown jewel of CADD formats, solid models represent a design as a complete, volumetric entity. This allows for:

- Advanced Analysis & Simulation: Performing stress analysis, calculating weight and volume, and simulating real-world behavior.

- Detailed Design & Manufacturing: Creating highly accurate models for downstream processes like CNC machining or 3D printing.

- Collaboration & Assembly: Facilitating seamless integration of different design components.

Understanding these distinctions empowers you to choose the right format for the job.

CHOOSING A CADD FORMAT

Several factors influence CADD software and format selection. Design and drafting practices and specific project requirements are primary considerations. Two-dimensional drawings are often required because they are the standard format in manufacturing and construction.

The figure shows a 2-D structural detail required for building construction. In addition, 2-D drawing is effective for a project that is quick to design, does not require extensive revision, and does not require advanced visualization, simulation, and analysis. Three-dimensional solid modelling is a better solution when a complex project requires extensive revision and when advanced visualization, simulation, and analysis are required. A 3-D representation of a design can help overcome visualization problems and produce a realistic, testable product model.

The figure shows a multidiscipline 3D model of a building providing structural, electrical, HVAC, and piping layouts. A combination of CADD formats and software may prove most effective for a project when applied correctly. Bringing the advantages of each CADD format together maximizes product design flexibility and effectiveness.

Collaboration and communication during a project also influence CADD software and format selection. Everyone involved in a project must be able to use a common CADD format or be able to convert data to a usable format easily. Costs are another important factor to consider when choosing a CADD software and format. For example, advanced 3-D solid modelling software is generally more expensive than 2-D drafting software. Operating a new or different CADD system also requires training and time to learn. Training is an expense and takes time from projects that produce income. A more capable CAD format, such as 3D solid modeling, is extremely cost-effective for some users, especially over time, but others will never benefit from the initial costs of the software and training. Several additional factors also influence selecting CADD software and format, including choosing a product and a format that is a known industry standard for project requirements, software stability and usability, the availability and effectiveness of support and training, and personal preference.

Beyond the List: Advanced CADD Format Considerations

The realm of CADD formats extends beyond the basic types mentioned earlier. Here's a glimpse into some specialized options:

- Neutral Formats (DXF, STEP): These formats allow data exchange between different CAD software programs, promoting interoperability.

- Point Cloud Data: Captured from 3D scanners, point clouds represent objects as a collection of data points, providing a highly detailed representation of physical objects that can be integrated into CAD models.

- Additive Manufacturing Formats (STL, AMF): Used for 3D printing, these formats translate CAD models into a format compatible with 3D printers for physical fabrication.

Understanding these advanced formats expands your design toolbox, allowing you to leverage the power of CADD for a wider range of applications.

Conclusion

CADD formats are more than just file extensions; they are the building blocks of your design workflow. By understanding their nuances and selecting the right format for your project needs, you can optimize your design process, enhance collaboration, and ultimately achieve superior design outcomes.

Australian Design & Drafting Services provides excellent service for CAD Design and Drafting. Contact Us for more info.

Read the full article

0 notes

Text

Future Trends in Piping Stress Analysis Services

As technology continues to evolve, the field of piping stress analysis services is also undergoing significant changes. Some of the future trends in this industry include:

1. Digital Twin Technology: Digital twin technology allows engineers to create virtual replicas of physical assets, such as piping systems, and monitor their performance in real-time. By integrating digital twin technology into piping stress analysis services, engineers can improve the accuracy and efficiency of their analyses.

2. Artificial Intelligence: Artificial intelligence (AI) and machine learning are being used to enhance the capabilities of piping stress analysis software. AI algorithms can analyze large datasets, identify patterns, and make predictive recommendations to improve the design and performance of piping systems.

3. Cloud Computing: Cloud computing offers a scalable and cost-effective platform for running complex simulations and analyses. By leveraging cloud-based tools and resources, engineers can conduct piping stress analysis services more efficiently and collaborate with team members in remote locations.

4. Sustainability: With a growing focus on sustainability and environmental impact, piping stress analysis services are increasingly incorporating considerations for energy efficiency, carbon footprint, and lifecycle assessment Piping Isometrics Services. Engineers are exploring ways to optimize piping systems for sustainability while ensuring safety and reliability.

5. Augmented Reality: Augmented reality (AR) technology is being used to visualize piping systems in 3D space and overlay stress analysis results onto physical objects. By incorporating AR into piping stress analysis services, engineers can enhance their understanding of complex systems and make informed decisions.

Overall, the future of piping stress analysis services is bright, with exciting technological advancements and trends on the horizon. By staying up-to-date with these developments and embracing innovation, companies can benefit from more reliable, efficient, and sustainable piping systems in the years to come.

1 note

·

View note

Text

Key Factors to Consider When Choosing a Piping Design Partner

In the world of industrial projects and infrastructure development, a crucial component that often remains unseen but plays a significant role is piping engineering. Piping design and engineering form the backbone of various industries, ensuring the smooth flow of fluids and gases within a facility. The success of any project heavily depends on the expertise of the piping design partner you choose. In this article, we'll delve into the key factors you should consider when selecting a piping design company to ensure seamless operations and project success.

Expertise and Experience:

When it comes to piping design and engineering, experience matters. Look for a company with a proven track record in handling diverse projects across different industries. An experienced piping design partner will have a deep understanding of various materials, codes, regulations, and best practices. This expertise ensures that your project will be designed efficiently and in compliance with industry standards.

Comprehensive Services:

Piping design and engineering encompass a wide range of activities, from conceptual design to detailed engineering and construction support. A reputable piping design company should offer comprehensive services that cover every phase of the project. This includes feasibility studies, process design, equipment selection, stress analysis, and more. Choosing a partner that can handle the entire spectrum of piping design will streamline your project and reduce potential coordination challenges.

Advanced Technology and Tools:

In the modern world, technology plays a vital role in enhancing the efficiency and accuracy of piping design and engineering. Look for a company that utilizes cutting-edge software and tools for 3D modeling, simulation, and analysis. Advanced technology not only ensures precise design but also enables better visualization and collaboration throughout the project lifecycle.

Flexibility and Customization:

Every project is unique, and your piping design partner should be able to tailor their solutions to your specific needs. A flexible company can adapt to changes and evolving requirements, ensuring that the final design aligns with your project goals. Clear communication and a willingness to accommodate modifications are signs of a reliable piping design partner.

Commitment to Safety and Compliance:

Safety is paramount in any engineering project, and piping design is no exception. Your chosen partner should have a strong commitment to safety protocols and industry regulations. Ask about their approach to risk assessment, safety procedures, and quality control. A company that prioritizes safety will contribute to the overall success and longevity of your project.

Client References and Reviews:

One of the most reliable ways to assess the capabilities of a piping design partner is by checking their client references and reviews. Make contact with former customers to learn more about their experiences.Positive feedback and successful project outcomes indicate a trustworthy and capable partner.

Conclusion:

Piping design and engineering are essential components of industrial projects, ensuring the efficient movement of fluids and gases within a facility. When selecting a piping design partner, consider factors such as expertise, comprehensive services, advanced technology, flexibility, commitment to safety, and client references. The right partner will not only contribute to the success of your project but also provide innovative solutions that optimize performance and minimize risks. By making an informed choice, you set the stage for a seamless and successful project execution in the world of piping design and engineering.

#Piping Engineering#Piping Design & Engineering Services#Piping Design Engineering Services#Piping design and engineering

0 notes

Text

Why is the importance of Pipe Stress Analysis & Designing Software ?

With the help of our highly developed piping softwares the work of the engineers has become easy as everything can be predefined and a great plan strategy can be made according to which the work execution can be done. Our organisation named CSIESPL is the exclusive partner of computers and structures , we provide marketing and technical support for all types of Engineering work and projects. Pipe Stress Analysis and Designing software is used in determining the force and load capacity when stress is applied to a piping system. This software has helped engineers a lot and made their work easy and flexible.

0 notes

Text

Leveraging Little P.Eng. Engineering's Piping Stress Analysis Services using Bentley Autopipe

Leveraging Little P.Eng. Engineering's Piping Stress Analysis Services using Bentley Autopipe (littlepeng.com)

The field of mechanical engineering has evolved over time, becoming a linchpin of industrial and infrastructural development. Today, we focus on a game-changer in piping stress analysis – Little P.Eng. Engineering, and its impressive implementation of Bentley Autopipe, a leading-edge tool designed for optimized performance and precision in pipe stress analysis.

In the world of engineering, piping stress analysis is a critical discipline, necessary to ensure the integrity and safety of piping systems in various industrial environments. One company that stands out in providing this service is Little P.Eng. Through the use of advanced tools such as Bentley Autopipe, Little P.Eng. Engineering offers premier piping stress analysis services, which we will explore in-depth in this article.

vimeo

Piping Stress Analysis: A Crucial Engineering Concern

The safety, efficiency, and durability of industrial processes largely depend on the health of the piping systems. Piping stress analysis is a crucial engineering process that helps to ensure the structural integrity of piping systems. It assesses the potential stress points in a pipe system to prevent failures, leakages, and consequent safety hazards. In a rapidly evolving industry, companies seek service providers who can offer precise, efficient, and cost-effective solutions. This is where Little P.Eng. Engineering comes into the picture.

Little P.Eng. Engineering: Pioneers in Piping Stress Analysis

Headquartered in Canada, Little P.Eng. Engineering has earned a reputation for delivering high-quality engineering services, specializing in piping stress analysis. With a highly skilled team of professional engineers, they leverage their extensive experience to serve a wide range of industries, from oil and gas to chemical and power generation.

What sets Little P.Eng. Engineering apart is their commitment to accuracy, efficiency, and client satisfaction. They utilize top-notch tools and software, like Bentley Autopipe, to conduct precise and comprehensive analyses.

Little P.Eng. Engineering: Revolutionizing Piping Stress Analysis Services

Little P.Eng. Engineering, a renowned engineering consulting firm, is known for its advanced and comprehensive piping stress analysis services. The company combines years of experience, technical expertise, and state-of-the-art software tools to deliver accurate and reliable solutions for a wide range of industrial applications.

At Little P.Eng. Engineering, the professionals understand the critical role of thorough stress analysis in preserving the integrity and performance of piping systems. They have mastered various software and tools that aid in precision analysis, and one such tool they use is Bentley Autopipe.

Bentley Autopipe: An Industry-Standard Tool

When it comes to piping stress analysis, Bentley Autopipe is an industry-standard software. It's a comprehensive and advanced computational tool that simulates the behavior of piping systems under a variety of loads, ensuring the safety and efficiency of these systems. Bentley Autopipe allows engineers to evaluate stresses, sagging, and loads to prevent potential problems such as pipe failure, leaks, and vibrations.

Bentley Autopipe: An Unparalleled Tool for Pipe Stress Analysis

Bentley Autopipe is a highly sophisticated tool that streamlines piping stress analysis. This software suite allows for the comprehensive and efficient modeling of piping systems, offering a multitude of capabilities to handle a vast array of complex scenarios.

Bentley Autopipe provides seamless integration with CAD design tools, allowing for easy model imports and modification. The software provides a vast library of international design codes, making it adaptable for projects globally. Its powerful computational abilities facilitate precise analysis of temperature, pressure, weight, and seismic loads on the piping system.

Exceptional Services at Little P.Eng. Engineering with Bentley Autopipe

Little P.Eng. Engineering’s services utilizing Bentley Autopipe are second to none. With this tool, they can offer detailed and precise piping stress analysis, identifying potential issues and providing solutions that meet industry standards and regulations. They specialize in areas such as static and dynamic analysis, model analysis, seismic analysis, and thermal analysis.

1. Static and Dynamic Analysis

In static analysis, Little P.Eng. Engineering's team evaluates the stress on piping systems from loads such as pressure, temperature, weight, and others. Dynamic analysis involves assessing the system's response to dynamic loads like wind, seismic events, and operational transients. The use of Bentley Autopipe ensures that these assessments are accurate, enabling them to design reliable and durable systems.

2. Model Analysis

Model analysis is crucial for understanding the overall behavior of the piping system. Using Bentley Autopipe, Little P.Eng. Engineering's engineers create detailed and precise 3D models, enabling them to visualize and analyze the system from different perspectives. This approach allows them to spot potential weak points and implement measures to enhance the system's overall performance and safety.

3. Seismic Analysis

Seismic analysis is especially vital for piping systems in regions prone to seismic activity. Little P.Eng. Engineering's use of Bentley Autopipe allows them to simulate seismic loads and evaluate the system's response, thereby ensuring that the system can withstand seismic events without failure.

4. Thermal Analysis

Thermal stresses can cause significant issues in piping systems. With Bentley Autopipe, Little P.Eng. Engineering's engineers can simulate thermal conditions and assess the system's response to temperature changes. This ensures that the system can manage thermal expansion and contraction effectively without causing undue stress or damage.

Harnessing the Power of Bentley Autopipe: Little P.Eng. Engineering's Strategy

The experts at Little P.Eng. Engineering employ Bentley Autopipe to analyze various critical factors that may affect the stability, performance, and longevity of piping systems. They effectively leverage the advanced features of Bentley Autopipe to predict potential failures and implement effective preventative measures.

Little P.Eng. Engineering considers various stress types such as thermal, pressure, deadweight, and occasional loads in its analysis. They use Bentley Autopipe to ensure that all potential stress points meet the standards set by the applicable design codes. Additionally, they perform dynamic analysis for situations involving wind, earthquake, and other transient loads, providing an all-encompassing stress analysis service that keeps safety as a priority.

Key Benefits of Choosing Little P.Eng. Engineering for Piping Stress Analysis Services

With Little P.Eng. Engineering at the helm of your piping stress analysis, you get:

Precision: The use of Bentley Autopipe ensures high-precision modeling and analysis, predicting stress points accurately.

Experience: Leveraging their extensive experience, the professionals at Little P.Eng. Engineering can analyze complex piping systems efficiently.

Compliance: Little P.Eng. Engineering's service ensures compliance with international standards, as Bentley Autopipe incorporates a broad spectrum of global design codes.

Risk Mitigation: The comprehensive analysis reduces the risk of system failure, enhancing safety and reliability.

Trusted Expertise from Little P.Eng. Engineering

In the realm of piping stress analysis, the future is here with Little P.Eng. Their adept use of Bentley Autopipe has enhanced their service delivery, making them a preferred choice for businesses globally. For any industry that depends on robust and efficient piping systems, engaging the expert services of Little P.Eng. can be a pivotal step towards ensuring system longevity and operational safety.

With the support of tools like Bentley Autopipe, Little P.Eng. Engineering continues to demonstrate their unwavering commitment to providing top-tier piping stress analysis services. Their emphasis on safety, reliability, and efficiency ensures that their clients receive practical solutions that meet the demands of their operations.

In a world where infrastructure integrity is paramount, partnering with a reliable service provider like Little P.Eng. Engineering gives you premium pipe stress analysis services.

Tags:

Pipe Stress Analysis Services

Meena Rezkallah

Pipe Stress Analysis

Pipe Stress Analysis Company

Engineering Services

Little P.Eng.

Piping Stress Analysis

Piping Stress Analysis Services

Compliance

Safety

Piping System

Risk Mitigation

Bentley

Autopipe

Bentley Autopipe

Precision

Piping Stress Analysis Company

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Pipe Stress Analysis Services#Meena Rezkallah#Pipe Stress Analysis#Pipe Stress Analysis Company#Engineering Services#Little P.Eng.#Piping Stress Analysis#Piping Stress Analysis Services#Compliance#Safety#Piping System#Risk Mitigation#Bentley#Autopipe#Bentley Autopipe#Precision#Piping Stress Analysis Company#Vimeo

0 notes

Text

Your Engineering Skills with Piping Modeling Courses in Chennai

Piping systems are a crucial element of industrial facilities, and as industries like oil and gas, power plants, and chemical processing expand, the demand for professionals proficient in piping modeling is increasing. For engineers looking to specialize in this field, Conserve Academy’s piping modeling course in Chennai provides the ideal platform to enhance your expertise.

Why Piping Modeling is Important

Piping modeling is a critical aspect of plant design, ensuring efficient and safe layouts for complex piping systems. This involves using advanced software to create accurate 3D models that simulate the real-world flow of liquids and gases within a facility. Conserve Academy’s piping modeling and drafting course in Chennai provides a thorough understanding of the design process, from conceptualization to drafting.

What You Will Learn

The piping modeling courses in Chennai at Conserve Academy are designed to offer comprehensive training, covering all essential aspects of piping design and modeling. The course focuses on:

Core Concepts of Piping Design:

Introduction to piping systems, materials, and components.

Understanding fluid dynamics and stress analysis within piping networks.

Compliance with industry standards and safety regulations.

Advanced 3D Modeling Techniques:

Training on industry-standard software like PDMS, SP3D, and AutoCAD.

Creation of detailed 3D models to simulate piping systems in industrial plants.

Ensuring coordination between piping systems and other structural components.

Drafting and Detailing:

Conversion of 3D models into 2D drafts for fabrication and installation.

Detailed isometric drawings and orthographic projections.

Ensuring piping layouts meet project specifications and quality standards.

Practical Industry Applications:

Hands-on projects simulating real-life piping design scenarios.

Case studies from industries such as oil refineries, power plants, and chemical plants.

Application of the latest technology and tools to solve design challenges.

Why Choose Conserve Academy?

Conserve Academy offers a highly specialized training program that equips you with both the technical skills and practical experience needed to excel in piping modeling. Key benefits include:

Expert-Led Training: All courses are taught by professionals with extensive industry experience, ensuring that you gain practical insights alongside theoretical knowledge.

Industry-Standard Software: The piping modeling certification course in Chennai ensures you are trained on software that is widely used by leading engineering firms, giving you a competitive edge in the job market.

Hands-On Learning: Real-world projects and assignments allow students to apply what they’ve learned in practical settings, preparing them for the challenges they’ll face in the field.

Career Advancement: Graduates of the piping modeling certification course in Chennai have strong job prospects, with opportunities to work in sectors such as petrochemicals, construction, and energy.

Career Opportunities

Completing the piping modeling courses in Chennai can open doors to exciting roles, including:

Piping Engineer

Piping Designer

CAD Engineer

Project Manager in piping design

With the growing demand for skilled piping professionals, this certification will boost your employability and set you up for success in the competitive engineering industry.

Conclusion

Investing in your future with Conserve Academy’s piping modeling course in Chennai can significantly enhance your career prospects. Whether you are looking to specialize in piping design or advance your current role, this course provides the knowledge, skills, and certification you need to stand out. Start your journey toward a rewarding career in piping modeling today.

For more information, visit Conserve Academy’s Piping Modeling Training Course in Chennai.

#piping Modeling in chennai in chennai#piping Modeling and drafting course in chennai#piping Modeling certification course in chennai#piping Modeling courses in chennai in chennai

0 notes

Text

Mechanical Engineer - Remote, USA oka4m9x1nucq

Bachelor's Degree in Mechanical Engineering - 7+ years of Oil and Gas experience - Develop project scopes, assist in proposal writing, writing technical reports, and performing engineering studies - Engineer O&G facility piping systems utilizing 3D design software such as Plant 3D, CADWorx - Strong understanding of ASME B31 piping codes.

Our flexible work options allow our employees to get the work/life balance they need to be productive employees, partners, parents, and contributing members of the community across the country. It’s a rare opportunity to get to shape the evolution of a company emerging in the AEC industry. Be a part of building the next great comprehensive consulting firm with business optimizing technology, environmental, energy, water, transportation, energy, and civil infrastructures.

We are seeking a highly motivated and experienced Mechanical Engineer with an Oil and Gas background or piping background to help us with our growing workload of oil & gas projects This position will be remote.

RESPONSIBILITIES:

Work with project managers and the mechanical design drafting team

Engineer O&G facility piping systems utilizing 3D design software

Perform pipe and valve sizing and material specifications

Develop and coordinate pipe routing and layouts with the design drafting team

Interpret vendor data sheets and P&IDs to create accurate 3Ddesign models

Determine specifications and locations of equipment and fittings

Familiar with ASME B31 piping codes

Work with the Process team to develop P&IDs

Perform site visits to assess, document, and report on existing conditions

Review isometrics, schematics, and P&IDs for accuracy

Develop project scopes, assist in proposal writing, writing technical reports, and performing engineering studies

Attends client meetings, communicating concerns and changes with the client

Writes project specifications (non-technical and technical sections)

Coordinate with the project team and other disciplines to incorporate design information and client standards into the construction documents

Familiar with Caesar II stress analysis is a plus

QUALIFICATIONS:

Experience with AutoCAD and 3D software design tools such as Plant 3D, CADWorx

Proficient with Microsoft Office software

Good writing, organization, and communication skills

REQUIREMENTS:

Bachelor's Degree in Mechanical Engineering

7+ years of Oil and Gas experience

We strive to develop new ways to increase diversity awareness within our organization. We recruit and reward our employees based on capability and performance — regardless of race, gender, sexual orientation, gender identity or expression, lifestyle, age, educational background, national origin, religion, or physical ability. For us, it is imperative to build balanced teams from all walks of life and we believe that a diverse workforce is a stronger workforce.

Read the full article

0 notes

Text

Best Plant Design Service Shalin Designs

We offer impeccable enlisted services:

Process Engineering Design Services

Piping Design Services

PDFs or process flow diagrams in 2D drafting.

Support for steel detailing.

Offer study for process simulation.

Preparing manuals for plant operation & maintenance.

P&ID or piping & instrument diagrams in AutoCAD.

Point Clouds to CAD conversion for intelligent P&ID.

3D CAD modeling for piping arrangements.

FEA or Finite Element Analysis for measurement of stress tolerance and flexibility.

Preparation of construction documents for piping system.

GA drawing generation.

Mechanical Design or Equipment Design Services

Mechanical Design or Equipment Design Services

Using FEA and CED we offer engineering analysis for thermal, fluid flow, and structural elements.

Detailed 2D CAD drawings for tanks and fittings including, tank, valves, & pressure vessels.

Detailed designs for fluid handling and pumping equipment, such as pumps & turbines, heat exchanging equipment, & separators.

Equipment for material handling like cranes, hoists, receivers, etc.

Equipment for power generation, such as burners, furnaces, and boilers.

Standard Software & Tools for Plant Design

We use AutoCAD Plant 3D for the creation of plant layout, machine arrangements, and mechanical specifications for plants.

MEP (Mechanical, Electrical, Piping) 3D modeling by using Revit MEP & SolidWorks

BIM (Building Information Modeling) by Revit BIM & Tekla software, like BIM, helps in the efficient space utilization in the plant.

We provide design support and validation for mechanical, hydraulic, and pneumatic operated equipment by using ANSYS Fluent & ANSYS Mechanical tools.

We use reverse engineering tools for equipment replacement and assist OEM for manufacturing.

CADWorx, PDS- Plant design software, AutoPLANT

PDMS – Plant design & Management software, Smart® 3D

We deliver top quality Plant Design services to our global clientele based out of the USA, UK, Canada, Australia, Europe, Singapore, Norway, Ireland UAE region. Now, it is time to partner with the right CAD plant design services and Shalin Designs is an unbeatable selection for a wise business like you!

2 notes

·

View notes

Text

Learn advanced techniques in piping stress analysis with industry-leading software through Caesar II Training. Participants typically learn about pipe stress analysis techniques, software functionalities, interpretation of results, and best practices in piping design and engineering.

#education#certification#training#onlinetraining#caesar2training#caesariitraining#caesariicertification#caesariicourse

0 notes

Text

Exploring Information Technology Career Opportunities with ACS Baroda Services

In today's fast-paced digital world, the field of Information Technology (IT) offers a plethora of career opportunities. Whether you're a fresh graduate, an experienced professional looking to transition into IT, or someone looking to upskill, the IT sector promises rewarding and dynamic career paths. ACS Baroda Services, a leading baroda job consultancy, specializes in connecting talent with top-tier IT and engineering roles. This comprehensive guide explores the various IT career opportunities, the role of ACS Baroda Services in facilitating these opportunities, and the training programs that can help you excel in your IT career.

The Booming IT Sector

The IT sector is one of the fastest-growing industries globally, and India is at the forefront of this growth. With advancements in technology and the increasing digitization of businesses, the demand for IT professionals is soaring. From software development and data analysis to cybersecurity and IT consulting, the career options are vast and varied. This booming sector not only offers high-paying jobs but also provides opportunities for continuous learning and career advancement.

IT Career Opportunities

Software Development

Roles: Software Developer, Web Developer, Mobile App Developer

Skills Needed: Programming languages (Java, Python, C++), software development methodologies (Agile, Scrum), problem-solving skills

Job Outlook: High demand across various industries, including tech companies, startups, and established corporations.

Data Science and Analytics

Roles: Data Scientist, Data Analyst, Business Intelligence Analyst

Skills Needed: Statistical analysis, data visualization, programming (R, Python), machine learning

Job Outlook: Increasing demand as businesses seek to leverage data for decision-making and strategic planning.

Cybersecurity

Roles: Security Analyst, Ethical Hacker, Cybersecurity Consultant

Skills Needed: Network security, encryption, risk management, ethical hacking

Job Outlook: Growing importance due to rising cyber threats and the need for robust security measures.

IT Consulting

Roles: IT Consultant, Systems Analyst, IT Project Manager

Skills Needed: Business analysis, project management, IT strategy, communication skills

Job Outlook: Strong demand for professionals who can bridge the gap between business needs and technological solutions.

Network and System Administration

Roles: Network Administrator, System Administrator, IT Support Specialist

Skills Needed: Network configuration, server management, troubleshooting, cloud services

Job Outlook: Essential roles in maintaining and managing IT infrastructure across organizations.

Engineering Career Opportunities

Civil Engineering

Roles: Structural Engineer, Project Manager, Site Engineer

Skills Needed: Structural analysis, project management, CAD software, knowledge of building codes

Job Outlook: Steady demand driven by infrastructure development and urbanization.

Mechanical Engineering

Roles: Design Engineer, Manufacturing Engineer, Maintenance Engineer

Skills Needed: CAD software, mechanical design, thermodynamics, materials science

Job Outlook: Opportunities in manufacturing, automotive, and aerospace industries.

Electrical Engineering

Roles: Electrical Design Engineer, Systems Engineer, Power Engineer

Skills Needed: Circuit design, power systems, control systems, renewable energy technologies

Job Outlook: Growing demand with the expansion of renewable energy projects and smart grid technology.

Chemical Engineering

Roles: Process Engineer, Chemical Engineer, Production Manager

Skills Needed: Chemical process design, safety management, thermodynamics, material science

Job Outlook: Opportunities in pharmaceuticals, petrochemicals, and environmental engineering.

Piping Engineering

Roles: Piping Designer, Piping Engineer, Stress Analyst

Skills Needed: Piping design, fluid dynamics, stress analysis, CAD software

Job Outlook: Key roles in industries such as oil and gas, power plants, and chemical processing.

ACS Baroda Services: Your Partner in Career Development

ACS Baroda Services is a premier job consultancy in Baroda, specializing in IT and engineering careers opportunities. Our mission is to bridge the gap between job seekers and employers, ensuring the right fit for both parties. Here’s how we can help you achieve your career goals:

Job Placement Services

Extensive Network: We have strong connections with leading companies in the IT and engineering sectors, providing access to exclusive job opportunities.

Personalized Matching: Our consultants work closely with candidates to understand their skills, interests, and career aspirations, ensuring a perfect match with potential employers.

Training and Development Programs

IT Job Training: We offer comprehensive training programs in software development, data science, cybersecurity, and more, designed to equip you with the skills needed to succeed in the IT industry.

Engineering Job Training: Our training programs for engineers cover various disciplines, including civil, mechanical, electrical, and piping engineering, focusing on both theoretical knowledge and practical skills.

Freelance Work Opportunities

Flexible Career Options: For those looking to work independently, we provide access to freelance projects in IT and engineering, allowing you to build a diverse portfolio and gain valuable experience.

Career Counseling and Support

Expert Guidance: Our experienced career counselors offer personalized advice and support, helping you navigate the job market and make informed career decisions.

Resume and Interview Preparation: We provide assistance with resume writing, interview preparation, and job search strategies to enhance your chances of success.

Unique Features of ACS Baroda Services

Customized Solutions

We understand that every job seeker and employer is unique. Our personalized approach ensures that we cater to the specific needs and goals of each client, providing customized solutions that deliver results.

Industry Expertise

Our team of consultants has deep industry knowledge and experience, enabling us to provide valuable insights and advice to both job seekers and employers. We stay updated with the latest trends and developments in the IT and engineering sectors to ensure our services remain relevant and effective.

Comprehensive Services

From job placement and training to career counseling and freelance opportunities, we offer a wide range of services to support your career journey. Our holistic approach ensures that you receive the support you need at every stage of your career.

Strong Employer Partnerships

We have established strong relationships with top companies in the IT and engineering sectors, allowing us to offer exclusive job opportunities that are not advertised elsewhere. Our employer partnerships also ensure that we have a deep understanding of their hiring needs and preferences.

Commitment to Excellence

At ACS Baroda Services, we are committed to delivering excellence in everything we do. Our focus on quality, integrity, and customer satisfaction sets us apart from other job consultancies and makes us a trusted partner in your career development.

Conclusion

The field of Information Technology offers a wealth of career opportunities for those willing to invest in their skills and professional development. With the right training and support, you can unlock your potential and achieve success in this dynamic industry. ACS Baroda Services is here to guide you every step of the way, providing expert advice, comprehensive training, and access to top job opportunities. Whether you're just starting your career or looking to make a transition, we have the resources and expertise to help you succeed. Choose ACS Baroda Services for a seamless and rewarding career in IT and engineering.

#career_placement_services#careers_in_IT#engineering_careers#IT_job_training#Engineering_job_training

0 notes