#PipeStressAnalysis

Explore tagged Tumblr posts

Text

What is Pipe Stess Analysis?

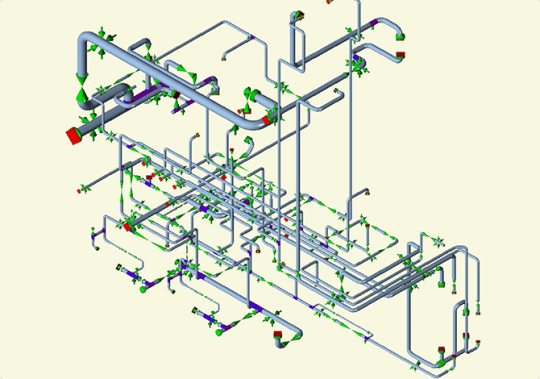

Pipe Stress Analysis is an engineering process used to evaluate the effects of forces such as internal pressure, temperature variations, weight, and external loads on a piping system. It ensures that pipes can withstand these stresses without failure, excessive deformation, or leakage, maintaining safety and operational efficiency.

Why is Pipe Stress Analysis Important?

Prevents pipe failure, leakage, or rupture due to thermal expansion, vibration, or mechanical loads.

Ensures compliance with industry standards such as ASME B31.3, B31.1, API 570.

Helps in optimizing support locations to minimize excessive stress and deflections.

Reduces maintenance costs by identifying potential issues early.

Types of Stresses in Piping Systems

Primary Stress – Caused by internal pressure and weight (e.g., pipe self-weight, fluid weight).

Secondary Stress – Due to thermal expansion/contraction, leading to bending or displacement.

Dynamic Stress – Caused by seismic activity, vibrations, water hammer, or wind loads.

Pipe Stress Analysis Methods

Manual Calculations – Based on empirical formulas (used for simple piping layouts).

Finite Element Analysis (FEA) – A detailed simulation for complex stress scenarios.

Software Tools – Industry-standard tools like CAESAR II, AutoPIPE, ROHR2, and ANSYS for precise stress calculations.

Industries That Require Pipe Stress Analysis

Oil & Gas Pipelines

Power Plants (Nuclear, Thermal, Renewable Energy)

Chemical & Petrochemical Plants

HVAC Systems

Pharmaceutical & Water Treatment Plants

Would you like a more detailed breakdown of pipe stress analysis software, industry standards, or case studies?

Visit our website:

Why is Pipe Stress Analysis Important?

Prevents pipe failure, leakage, or rupture due to thermal expansion, vibration, or mechanical loads.

Ensures compliance with industry standards such as ASME B31.3, B31.1, API 570.

Helps in optimizing support locations to minimize excessive stress and deflections.

Reduces maintenance costs by identifying potential issues early.

Types of Stresses in Piping Systems

Primary Stress – Caused by internal pressure and weight (e.g., pipe self-weight, fluid weight).

Secondary Stress – Due to thermal expansion/contraction, leading to bending or displacement.

Dynamic Stress – Caused by seismic activity, vibrations, water hammer, or wind loads.

Pipe Stress Analysis Methods

Manual Calculations – Based on empirical formulas (used for simple piping layouts).

Finite Element Analysis (FEA) – A detailed simulation for complex stress scenarios.

Software Tools – Industry-standard tools like CAESAR II, AutoPIPE, ROHR2, and ANSYS for precise stress calculations.

Industries That Require Pipe Stress Analysis

Oil & Gas Pipelines

Power Plants (Nuclear, Thermal, Renewable Energy)

Chemical & Petrochemical Plants

HVAC Systems

Pharmaceutical & Water Treatment Plants

Would you like a more detailed breakdown of pipe stress analysis software, industry standards, or case studies?

Visit https://inclinedengg.com/pipe-stress-analysis/

#pipestressanalysis#3d modeling#blender3d#3d model#pipe stress analysis#inclined engineering#Piping Design

1 note

·

View note

Text

Pipe Stress Analysis: Integrating Sustainability into Piping Design Practices. Integrating sustainability into pipe stress analysis is vital for modern engineering practices. By adopting eco-friendly materials and optimizing designs, we can minimize environmental impact while ensuring piping systems remain robust. Techniques like thermal expansion management and efficient load distribution not only enhance safety but also reduce resource consumption. This approach fosters resilience against climate challenges, aligning with industry trends towards sustainability. Emphasizing sustainable practices in piping design ultimately leads to safer, more efficient systems. #Sustainability #PipeStressAnalysis #EcoFriendlyEngineering #PipingDesign #GreenEngineering For more insights, visit: https://inclinedengg.com/pipe-stress-analysis/

0 notes

Text

#PipingDesignEngineering#pipingdesign

#PipelineDesignEngineering

#ProcessDesignEngineering

#PipeStressAnalysis

#AdvancePipingEngineering

#OffshoreEngineering

#SafetyEngineering

#processpiping

#pipingdesgin

#pipingengineer

#pipinginterview

#PipingLayout#oil#gas#power#installation

#PipingDesignEngineering#pipingdesign#PipelineDesignEngineering#ProcessDesignEngineering#PipeStressAnalysis#AdvancePipingEngineering#OffshoreEngineering#SafetyEngineering#processpiping#pipingdesgin#pipingengineer#pipinginterview#PipingLayout#oil#gas#power#installation

2 notes

·

View notes

Link

The Best Pipe Stress Analysis Consultant in Toronto, Ontario, Canada. by Meena Rezkallah, P.Eng. Call us now for a free quote.

0 notes

Photo

اطلاق نسخة جديدة من البرنامج الاشهر في مجال تحليل اجتهادات المواسير CEASER II V12 من Hexagon PPM بتحسينات جديدة. للمزيد https://hxgn.biz/2M3Z5x0 We're excited announce the release of CAESAR II v12, the industry standard for #pipestressanalysis. The new version includes improvements to efficiently build, assess and report on piping systems in accordance with more than 35 #internationalpipingcode standards and many environmental and equipment guidelines. #pipinganalysis #HexagonPPM https://hxgn.biz/2M3Z5x0 #TeqniaSci #قناة_تقنية https://www.instagram.com/p/CB8fvwWJNIx/?igshid=18waxwt4lg4wo

0 notes

Link

It is also known as Custom programming, bespoke programming or customized programming which is used to program that is uncommonly produced for some particular association or other client.

#PipingLayout#ProcessDesign#ProcessPlantDesign#OilAndGasProjects#PipeStressAnalysis#PipingDesign#DetailedDesign#StorageTankDesign#BasicEngineering#PipeRouting#3dPlantDesign#ElectricalDesign

1 note

·

View note

Link

Silicon Engineering Consultants Ltd has specialized expertise in building, plan, development and testing of pipes and funneling instruments and their arrangement inside the structures. Our Key services includes Plumbing Piping Engineering Services, Plumbing Piping Drafting, Pipe Stress Analysis, 3D Modeling throughout New Zealand. https://goo.gl/mSqCME

#PlumbingPipingEngineering#PipeStressAnalysis#3DModeling#PlumbingDrawing#PlumbingPipingDesignOutsourcing#PipeCorrosionMitigation#MEP#MEPEngineering

0 notes

Link

Are you looking for a reliable partner for the #StressAnalysis of the #piping system at your plant or refinery ? Rishabh Engineering, has a proven track record in providing #PipeStressAnalysis services using CAESAR II.

0 notes

Text

Pipe Stress Analysis: The Significance of Support Systems in Piping Design Pipe Stress Analysis is crucial for ensuring the integrity of piping systems, particularly regarding support systems. Properly designed supports help manage thermal expansion, vibrations, and static loads, preventing failures. Recent trends emphasize the use of advanced software for dynamic load assessments and compliance with industry standards. Effective support design not only enhances safety but also optimizes system performance, reducing maintenance costs. Understanding these elements is vital for engineers in oil and gas, petrochemical, and power generation sectors. #PipeStressAnalysis #PipingDesign #EngineeringSafety #SupportSystems #IndustrialPiping For more information, visit: https://inclinedengg.com/pipe-stress-analysis/

0 notes

Text

Pipe Stress Analysis: Challenges Faced in High-Temperature Applications High-temperature applications present unique challenges in pipe stress analysis. As temperatures increase, pipes expand, leading to significant thermal stresses that can compromise system integrity. Engineers must address issues like thermal fatigue, buckling, and material degradation. Effective analysis requires advanced techniques such as finite element analysis to model stress distributions accurately. Maintaining safety and efficiency is crucial, especially in industries like petrochemicals and power generation. Proactive stress management ensures reliable operation and compliance with industry standards. #PipeStressAnalysis #HighTemperatureChallenges #ThermalFatigue #FiniteElementAnalysis #EngineeringSafety For more information, visit: https://inclinedengg.com/pipe-stress-analysis/

1 note

·

View note

Text

The Role of Pipe Stress Analysis in Piping Design Pipe stress analysis is essential in piping design, ensuring safety and reliability in various industries. By assessing the impact of thermal expansion, pressure fluctuations, and external loads, engineers can prevent failures and leaks. This analysis is crucial for maintaining structural integrity, optimizing performance, and adhering to industry standards. Recent trends emphasize its role in enhancing operational efficiency and minimizing downtime. As industries evolve, integrating advanced simulation tools into pipe stress analysis becomes increasingly vital for sustainable practices. #PipeStressAnalysis #PipingSafety #EngineeringDesign #StructuralIntegrity #OperationalEfficiency For more insights, visit https://inclinedengg.com/

0 notes

Text

Piping Design Engineering with AutoCad offline/online training @ACEPiping Institute | +91-8143508300

#PipingDesignEngineering#pipingdesign#oil#gas#power#installation#pipelines#pipecoating#pipebending#pipewelding#leakdetection#processpiping#pipingdesgin#pipingengineer#pipinginterview#PipingLayout#PipelineDesignEngineering#ProcessDesignEngineering#PipeStressAnalysis#AdvancePipingEngineering#OffshoreEngineering#SafetyEngineering

0 notes

Photo

Little p.eng. for engineering services proudly presents the Apega permit to practice. #piping #Engineering #engineeringservices #engineeringcompany #engineeringfirm #pipestressanalysis #meena_rezkallah meenadevelopment.ca (at Canada) https://www.instagram.com/p/CD2_ySZAmZr/?igshid=mw1quboprkgl

#piping#engineering#engineeringservices#engineeringcompany#engineeringfirm#pipestressanalysis#meena_rezkallah

0 notes

Link

#ProcessPlantDesign#PipingDesign#ProcessDesign#DetailedDesign#BasicEngineering#ElectricDesign#PressureVesselDesign#ChemicalPlantDesign#PipeStressAnalysis#StorageTankDesign

1 note

·

View note

Link

Process Plant Design gives different structures and improvements as indicated by Client's needs or requirements. It can be used for the most part centers in process structure, detail design, developments and Project Management of huge scale Project.

#ProcessPlantDesign#PipingDesign#ProcessDesign#DetailedDesign#BasicEngineering#ElectricDesign#PressureVesselDesign#ChemicalPlantDesign#ElectricalDesign#PipeStressAnalysis#StorageTankDesign#3dPlantDesign

1 note

·

View note

Link

Instrumentation & Control permits ongoing estimation and control of procedure factors like dimensions, stream, weight, temperature, pH, and moistness.

#ProcessPlantDesign#PipingDesign#ProcessDesign#DetailedDesign#BasicEngineering#ElectricDesign#PressureVesselDesign#PipeStressAnalysis

0 notes