#MachineShop

Explore tagged Tumblr posts

Text

I've clocked in with people who tried to stab me the night before & the office was never involved

I don't need a carpet walker to protect me at this place cuz HR's protections end @ the parking lot

Someone please explain to me how to exist as a girl in a man's world, obviously I'm doing it wrong

It remains that the most dangerous part of what I do for work has nothing to do with the machines

It's the men there that haunt me after I go to bed at night, wondering if tomorrow I might lose a leg

It isn't possible to lock & tag out a malicious co worker, but machines are much more predictable

#short poem#late night poems#poemsociety#late night writing#poems on tumblr#spilled poetry#late night thoughts#late night poetry#femaleintrades#female mechanic#machineshop

2 notes

·

View notes

Text

Types of Mandrel for Different Machining and Manufacturing: A Complete Guide

In the world of precision machining and manufacturing, mandrels play a silent but vital role. Whether you're working with metal, drilling operations, or even jewelry design, the mandrel is a go-to tool for holding, supporting, or shaping a workpiece during fabrication.

But what exactly is a mandrel, and why does it matter so much?

A mandrel, also referred to as an arbor, is a cylindrical or tapered rod used to secure workpieces or tooling components during machining. Instead of clamping directly to the machine’s chuck, the workpiece is mounted on the mandrel, which provides better balance, accuracy, and stability. This is especially crucial for items that are delicate or irregular in shape.

Why Use a Mandrel?

Mandrels allow for:

Improved workholding when a chuck or faceplate isn’t suitable

Higher precision in rotating the workpiece around its true center

Reduced deflection or misalignment during machining operations

Types of Mandrels You Should Know

There are many variations of mandrels, each designed for specific tasks:

1. Solid Mandrel: A plain, tapered cylindrical bar ideal for standard, symmetrical workpieces.

2. Step Mandrel: Features stepped diameters for holding parts with different hole sizes. Great for versatile operations.

3. Gang Mandrel: Used to hold multiple hollow workpieces at once—perfect for speeding up production.

4. Collar Mandrel: Has two fixed collars to grip large workpieces with diameters over 100 mm.

5. Screwed Mandrel: Includes a threaded end to securely hold parts with internal threads.

6. Cone Mandrel: Features a sliding cone to adjust for different workpiece diameters, useful for varying inner diameters.

7. Expanding Mandrel: Uses a tapered arbor and split bush design to expand and grip the inside of hollow parts tightly.

8. Ring Mandrel (Triblet): Popular in jewelry, this tapered tool is used to size, form, and shape rings accurately.

How Mandrels Improve Manufacturing

They help in forging and reshaping delicate pieces (especially in jewelry).

Ensure the workpiece rotates concentrically for precision.

Reduce errors and tool wear caused by unstable setups.

Support advanced operations like boring, grinding, or finishing.

From metal lathe operations to intricate ring making, mandrels are indispensable. Their role in securing workpieces and ensuring flawless rotation cannot be overstated. With so many types available, choosing the right mandrel for your application can significantly improve both quality and efficiency.

For a deep dive into specifications, design differences, and use cases, check out the full article here: Types of Mandrel for Machining and Manufacturing

#Mandrel#LatheTools#MachiningBasics#ManufacturingTech#PrecisionMachining#MachineShop#Metalworking#ToolTalk#CraftWithLathe#WorkshopGear#JewelryMaking#LatheMandrel#MachiningTools#SolidMandrel#EngineeringTips

0 notes

Text

Advanced Machining NW Inc "We're not just a machine shop, we're a solutions provider."

www.AdvancedMachiningnw.com

#metalFabrication #PlasticMachining #MetalIndustries #MachineShop #MachiningManufacturer #prototypemaching #stainlesssteelmachining #cncmachining

#metalFabrication#PlasticMachining#MetalIndustries#MachineShop#MachiningManufacturer#prototypemaching#stainlesssteelmachining#cncmachining

0 notes

Text

The Best Time to Buy Machine Shop Equipment at Auctions

Timing is everything when it comes to scoring great deals at machine shop auctions. The best opportunities often arise at the end of the fiscal year or during economic slowdowns, when businesses offload surplus equipment. Watch for seasonal trends and industry liquidations to maximize value and find top-tier machinery at competitive prices.

0 notes

Text

Knife Grinder Machine: Precision Sharpening for Optimal Performance

In the constantly changing world of woodwork and plywood manufacturing, how efficient your equipment is determines the quality of the finished product. One of the key tools that help in this is the knife grinder machine, a vital tool that maintains sharpness and accuracy in your cutting tools. Whether you're making plywood, veneers, or other wood products, making a good investment in a top-quality knife grinder machine can significantly improve your level of production quality and minimize downtime, resulting in a more streamlined operation.

The Use of Knife Grinder Machines in Plywood Production

Plywood production has several stages which entail accurate cutting and trimming. The cutting knives involved in these operations experience wear and tear over time, causing them to lose their performance. A knife grinder machine is specifically created to sharpen the knives and make them as precise as they were when new, so they can perform at optimal levels. By keeping your knives sharp, you are able to keep your equipment running smoothly and consistently, producing cleaner cuts and less waste.

Why Knife Grinding Machines Are Important

The significance of having a good knife grinder machine in your plywood production plant cannot be overemphasized. Here are some of the most important advantages:

1. Improved Cutting Accuracy: Knife grinder machines are made to sharpen blades with extreme accuracy. With well-sharpened knives, the cutting process is smoother, leading to less wastage and more precise cuts.

2. Reduced Downtime: When your cutting knives lose their edge, production comes to a standstill, resulting in expensive downtime. Sharpening with a knife grinder machine at regular intervals keeps your knives sharper for longer and minimizes replacements and repairs.

3. Cost Efficiency: Spending in a high-quality grinder machine for knives is worth it in the long term. Keeping your knives at their best will help you prolong the life of your knives, save you money on replacement knives, and lower the cost per unit of plywood production.

4. Improved Productivity: Sharp blades translate to reduced resistance while cutting through materials, leading to quicker and more effective production times. A well-serviced knife grinder machine helps your knives remain sharp and prepared for work, allowing your facility to maintain the pace.

5. Quality and Safety: Dull blades can result in irregular cuts, poor product quality, and unsafe conditions for the operators. Using the precision honing provided by a knife grinder machine, you reduce these hazards and enhance your products' quality and safety.

Features of a Perfect Knife Grinder Machine for Plywood Manufacturers

When selecting a knife grinder machine for your plywood production plant, there are a number of things to consider. Here are some features to consider:

1. Precision Grinding Capabilities: The machine should be capable of sharpening your knives to the highest level, so that the cutting edges are aligned perfectly for optimal performance.

2. Ease of Use: An easy-to-use interface and minimal controls allow operators to keep the machine in good condition without much training or technical expertise.

3. Durability: With the stresses of plywood manufacturing, the knife grinder machine needs to be constructed to withstand heavy use, with quality materials and components that can take repeated use.

4. Versatility: An effective knife grinder machine must be capable of sharpening different types of knives employed across different stages of the plywood production process. Such versatility enables greater flexibility and fewer periods of downtime between sharpening.

5. Efficient Operation: Find a machine that is efficient, using minimal power while producing exceptional results. Efficiency is responsible for ensuring productivity without unnecessary expenditure.

Conclusion

For plywood producers, knife grinder machines are a vital component of the manufacturing process. They keep cutting tools sharp, efficient, and safe, resulting in improved product quality, less downtime, and increased overall efficiency. By selecting a high-quality machine that provides precision, reliability, and simplicity, you can be sure that your manufacturing processes are smooth and at peak performance.

Invest in a knife grinder machine today and unleash the full potential of your plywood machinery and feel a significant difference in your operations!

If you’re looking for a leading manufacturer of plywood machinery, look no further. Our advanced knife grinder machines are designed to meet the highest standards of precision and performance, helping your business stay ahead of the competition. Contact DNH Engineers today to learn more about how our solutions can enhance your plywood production. Visit www.dnhengineers.com for more details.

#KnifeGrinderMachine#PrecisionSharpening#OptimalPerformance#KnifeSharpening#CuttingTools#UpgradeYourTools#ToolMaintenance#SharpKnives#Woodworking#Metalworking#PrecisionTools#DIYProjects#MachineShop#SharpeningServices#BladeMaintenance#EfficientTools#Craftsmanship#ProfessionalSharpening#IndustrialEquipment#HobbyistBytes

0 notes

Text

Learn How to Sharpen Knives with Expert Techniques

Check out the Bearded Sharpener and his channel for expert tips on knife sharpening tools and blade maintenance!

At The Bearded Sharpener, we focus on quality, offering the best sharpening tools backed by top-notch customer service.

Whether you're learning how to sharpen knives or refining your knife sharpening techniques, we’ve got you covered with tools we trust ourselves.

Our channel is perfect for knife sharpening beginners looking to elevate their skills.

Follow us to see the complete sharpening process and keep your blades in top shape!

Connect with us & Follow our journey on social media for the latest updates and more!

#cuttingtools#ductwork#engineer#engineers#fab101#fabrication#fabricator#fabshop#homemachineshop#hvachacks#hvacr#instamachining#instamachinist#machineshop#machinetools#machining#machinist#machinistsofinstagram#manualmachining#manualmachinist#mechanicalengineer#mechanicalengineering#metalwork#metalworker#metalworking#sheetmetalfab#sheetmetalworker#steelfab

0 notes

Text

Parts of CNC Machine for Precision Manufacturing

Petron Thermoplast delivers high-quality parts of CNC machine that meet the exact specifications. Whether you need custom machined components for the automotive, aerospace, or medical sector, we have the expertise and cutting-edge equipment to support your manufacturing needs.

Visit Website - https://petronthermoplast.com/cnc-machining/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#cncmachining#manufacturing#machining#engineering#cncmilling#machinist#milling#cncmachine#machineshop#fabrication#cncmachinist#tools#metalworking#cncmill#welding

0 notes

Text

Discover the Best Machinery in Tirupur with Eagle Graphics 💼⚙️

In the heart of the bustling industrial hub of Tirupur, having the best machinery in Tirupur is key to staying competitive. At Eagle Graphics, we provide top-tier equipment, from RFID Machines to Printing Machines, ensuring your business operates at its best. Whether it's garment production, labeling, or cutting, we’ve got the best machinery in Tirupur to suit your needs. 🌟

Best RFID Machines in Tirupur 📡📦

When it comes to the best RFID Machines in Tirupur, Eagle Graphics leads the market with cutting-edge technology like RFID Tags, RFID Labels, and RFID Stickers. Our solutions ensure seamless operations for your tracking needs.

Best Label Printing Machines in Tirupur 🏷️🖨️

For those seeking the best label printing machines in Tirupur, our lineup includes the powerful HY Label Printing Machine and the precise VERTEX Ultrasonic Cutting Machine. These machines deliver unmatched quality and efficiency.

Best Printing Machines in Tirupur 🖨️🎨

Eagle Graphics offers the best printing machines in Tirupur, including Digital Printing Machines, Offset Printing Machines, and Screen Printing Machines. Whether you're printing textiles or paper, we have the solution.

Best T-shirt Printing Machines in Tirupur 👕🖌️

For garment makers, our best T-shirt printing machines in Tirupur provide vibrant, durable results. We offer Heat Transfer Printing Machines and Screen Printing Machines to elevate your production.

Best Cutting Machines in Tirupur ✂️🔪

Precision is vital in cutting, and Eagle Graphics delivers the best cutting machines in Tirupur, including Die Cut Machines, Laser Cutting Machines, and Hangtag Cutting Machines for flawless results.

Best Imported Machinery in Tirupur 🌍🚢

Looking for international quality? We provide the best imported machinery in Tirupur, featuring top-notch equipment like Cardboard Pasting Machines, Hy Folding Machines, and more to meet your production standards.

HY and VERTEX Machines in Tirupur 🛠️🏭

Our HY and VERTEX machines in Tirupur are designed to handle the most demanding tasks. From HY Label Printing Machines to VERTEX Encoding and Ultrasonic Cutting Machines, we offer robust, efficient solutions.

Conclusion 🎯

For the best machinery in Tirupur, trust Eagle Graphics to supply high-quality, reliable equipment. From RFID Machines and Printing Machines to Cutting Machines and Imported Machinery, we are your one-stop destination for all machinery needs. Contact us today to elevate your production! 🚀

1 note

·

View note

Text

Optimize Manufacturing Efficiency with Cosmos Automation’s digiFAC Solution

Say goodbye to manual data processing and embrace streamlined operations with Cosmos Automation. The digiFAC system gathers real-time machine data directly from your equipment, unlocking maximum asset potential and driving productivity to new heights. With instant insights, manufacturers can make swift, data-driven decisions that optimize efficiency, reduce downtime, and enhance overall performance. Stay ahead in today's fast-paced industry landscape by transforming your manufacturing processes with Cosmos Automation’s digiFAC, ensuring you remain competitive while minimizing operational costs.

#cnc machine manufacturer in gujarat#cnc machine manufacturer india#cnc machine suppliers in india#best cnc machines in india#cnc machine companies in india#automation#machineshop#shopfloor#manufacturer#productivitybooster#industry#machinedata

0 notes

Text

If you're worried about where to buy a Chowmein-Making Machine near you, Look no further! Just visit Maabharti Industries Pvt Ltd, Get more accurate and relevant information about Chowmein-Making Machine. Get in touch with us at +91 7595938888 or Email us now [email protected]

#chowmeinmachine#chowmeinmakingmachine#chowmeinmachineinindia#chowmeinmachinekolkata#chowmeinmakingmachinenearme#automaticchowmeinmakingmachine#chowmeinmakingmachinemanufacturer#chowmeinmakingmachineforsale#manufacturer#exporter#machine#machinery#industrial#industry#machineshop#machineforsale#industrialmachine#manufacturingmachine#maabharti#maabhartipvtltd#bharti#maabhartiindustriespvtltd#MAABHARTIINDUSTRIESPVTLTD#maabhartiindustriesprivatelimited

0 notes

Text

Advanced Machining NW Inc "Your vision, our precision" visit us now at www.AdvancedMachiningnw.com

#metalFabrication #PlasticMachining #MetalIndustries #MachineShop #MachiningManufacturer #prototypemaching #stainlesssteelmachining #cncmachining #steelmachining #aluminummaching

#metalFabrication#PlasticMachining#MetalIndustries#MachineShop#MachiningManufacturer#prototypemaching#stainlesssteelmachining#cncmachining#steelmachining#aluminummaching

0 notes

Text

The Cost-Effectiveness of Buying Used Machine Shop Equipment at Auctions

Buying used equipment through machine shop auctions offers significant cost savings compared to purchasing new machinery. These auctions often feature well-maintained tools at a fraction of the original price, allowing businesses to expand or upgrade without exceeding budget limits. It's a smart, budget-friendly way to access high-quality equipment while maximizing return on investment.

0 notes

Video

youtube

Ecotile - Solving Your Flooring Problems

#youtube#machineshop#flooringideas#industrialflooring#flooringexperts#tiles#flooringinstaller#flooring#warehouses#design#designerflooring#industialtiles#interlocking#manufacture#easyinstallation

0 notes

Text

Take your metal milling to the next level with JET Tools' premier lineup of Jet Milling Machines and accessories! 🛠️

https://www.penntoolco.com/jet/

Discover our wide range of high-quality Milling Machine benches, tools, and equipment, perfect for various Industrial Machinery and Manufacturing Tools applications.

Our products are designed to meet the needs of both hobbyists and seasoned professionals, ensuring that you have the right Workshop Equipment to streamline your workflow and elevate your projects.

Browse our collection to find the perfect milling machine for your needs. Shop now at JETTools.com! Connect with us & Follow our journey on social media for the latest updates and more!

#industry#instamachinist#machineshop#machining#machinist#machinistsofinstagram#manufacturing#measuring#measuringtools#metalwork#metalworking#metrology#qualitycontrol#automatic#automotiveindustry

1 note

·

View note

Text

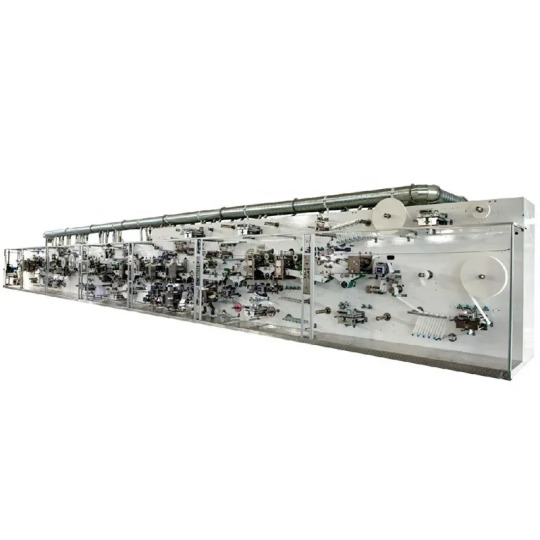

Top On Sale Product Recommendations! Professional 200-300Pcs/Min Sanitary Pad Machine Napkin Folding Machine China Sanitary Napkin Machines Original price: USD 127627.62 Now price: USD 127627.62 Click&Buy:

#Aliexpress#BeGouriStore#napkinmachine#napkinmachinefactory#napkin#napkins#napkinisms#napkinrings#napkinsketch#napkinholder#napkinfolding#napkinchallenge#napkindecoupage#machines#machineshop#machinesewing#machinestrong#machinesbrazil#machinesdelile#machineshoplife#machinesewnwigs#machinestitching#machinesforfreedom#sanitarynapkinmachine#sanitarynapkin#sanitarynapkins#sanitarynapkinsph#sanitarynapkinpouch#sanitarynapkinsindia#sanitarynapkinsforall

0 notes

Text

Explore Kolkata's Leading Lathe & Drill Machine Shop

Unlock precision engineering at its finest!

Discover Kolkata's premier destination for all your lathe and drill machine needs. Searching for top-notch lathe and drill machines in Kolkata? Look no further! Datre, the best lathe & drill machine shop in the city. With a reputation for quality and precision, they offer an extensive range of machinery to meet your industrial needs. Their dedicated team is committed to providing expert guidance, ensuring you make the right choice. Whether you're a professional or a hobbyist, Datre is your one-stop destination for high-quality lathe and drill machines.

For more information-

Website- datre.in

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III

South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

0 notes