#PowerDistribution

Explore tagged Tumblr posts

Text

Powering the Utility Sector with GIS Innovation | CyberSWIFT

In today’s fast-evolving energy landscape, reliable and efficient utility management is critical. At CyberSWIFT, we empower utility providers with user-friendly, cost-effective GIS solutions designed to optimize every layer of their operations — from asset management and consumer indexing to network mapping and energy audits.

Read more at https://www.cyberswift.com/in/industries/gis-for-electric-utilites

Our expertise includes:

✅ High-precision DGPS surveys for electrical distribution and transmission ✅ Real-time GIS mapping for power networks and substations ✅ Spatial data analysis for load flow, fault tracing, vegetation management, and more ✅ Consumer indexing & door-to-door surveys for accurate demand planning ✅ Meter Data Acquisition Systems (MDAS) for centralized data access ✅ Facility Management Services (FMS) for proactive asset monitoring ✅ Land use and corridor mapping to support sustainable transmission network planning

CyberSWIFT has proudly contributed to national initiatives like R-APDRP, delivering GIS-backed solutions in states including West Bengal and Manipur.

From substation to socket, we provide the geospatial intelligence to make utility infrastructure smarter, more transparent, and more resilient.

#GIS#UtilityMapping#PowerDistribution#ElectricUtility#DGPS#CyberSWIFT#EnergyAudit#SmartGrid#AssetManagement#MDAS#FacilityManagement#ConsumerIndexing

0 notes

Text

IEC Standard for Underground Cable Laying

The IEC standard for underground cable laying is essential for safe, reliable, and efficient installation of electrical systems. Underground cables are widely used in modern cities, industries, and infrastructure projects. Proper installation helps prevent faults, reduces maintenance costs, and enhances safety. The International Electrotechnical Commission (IEC) provides globally accepted guidelines for these practices.

IEC Standard for Underground Cable Laying The main goal of the IEC standard for underground cable laying is to ensure cables are installed properly without mechanical damage, overheating, or interference. It covers various aspects including trench dimensions, cable protection, spacing, backfilling materials, and installation techniques. Following the right standards is important not just for operational efficiency but also for compliance with legal and insurance requirements. Engineers and technicians must understand these details thoroughly.

Importance of Following IEC Standard for Underground Cable Laying

Compliance with the IEC standard for underground cable laying is critical for several reasons. It ensures electrical safety, mechanical protection, and environmental security. It reduces chances of cable failure due to moisture, temperature changes, chemical attacks, or physical damages. When installation is done poorly, it often leads to frequent cable faults, fire hazards, and costly repairs. Thus, strict adherence to the standards protects the investment made in infrastructure projects. Proper underground cable laying also supports standard earthing systems, reducing touch and step potentials which enhances personal and equipment safety.

Main IEC Standards Referenced for Underground Cable Laying

The IEC standard for underground cable laying is not a single document but refers to several standards collectively. Some important ones include: IEC StandardTitlePurposeIEC 60364-5-52Electrical installations of buildings – Selection and erection of electrical equipment – Wiring systemsLaying procedures and mechanical protectionIEC 60287Electric cables – Calculation of the current ratingDetermining cable size considering thermal conditionsIEC 60502-1Power cables with extruded insulation and their accessories for rated voltages from 1 kV to 30 kVCable construction and installation guidelinesIEC 60079-14Electrical installations in explosive gas atmospheres – Design, selection and erectionSpecial guidelines for hazardous areas These standards work together to ensure successful cable installations. They are also linked with other topics like IEC Standard for Hazardous Area Classification where explosive environments require special attention.IECStandard, #UndergroundCableLaying, #ElectricalEngineering, #CableLaying, #IECStandards, #CableInstallation, #UndergroundCabling, #ElectricalInfrastructure, #CableManagement, #PowerDistribution, #ElectricalSafety, #PowerCables, #InfrastructureDevelopment, #EnergyDistribution, #SmartGrid Read the full article

#CableInstallation#CableManagement#ElectricalCabling#ElectricalEngineering#ElectricalStandards#IECStandard#Infrastructure#PowerCables#powerdistribution#UndergroundCableLaying

0 notes

Video

youtube

Nuclear Power Plant Feed outs: A Quick Dive! #sciencefather #nuclearpower #researcher

Designing electrical feed outs for hard-core components in nuclear power plants ⚡🏭 is a critical task that demands the highest levels of precision, reliability, and safety. These feed outs serve as the lifeline for essential systems such as reactor control, emergency shutdown mechanisms, and cooling systems 🛠️❄️, which must remain operational under all circumstances—including extreme events like earthquakes, fires, or loss of power. Engineers must consider factors like radiation shielding ☢️, thermal insulation 🔥, and electromagnetic interference protection to ensure uninterrupted power delivery. Redundancy, physical separation, and rigorous testing are incorporated into the design to prevent single-point failures 🚫🔌. Materials selected for cabling and connectors are often resistant to radiation and heat, ensuring long-term durability and performance. Ultimately, the feed out design is not just a matter of engineering—it’s a cornerstone of nuclear safety and regulatory compliance 📋✅.

Natural Scientist Awards

Nomination Link: https://naturalscientist.org/award-nomination/?ecategory=Awards&rcategory=Awardee

Visit Our Website 🌐naturalscientist.org

Contact us [email protected]

Get Connected Here:

LinkedIn: https://www.linkedin.com/in/natural-scientist-466a56357/

Blogger: https://naturalaward.blogspot.com/

Instagram: https://www.instagram.com/natural_scientist/

Pinterest: https://in.pinterest.com/research2805/_profile/

Youtube: https://www.youtube.com/@NaturalScientistAwards

Facebook: https://www.facebook.com/profile.php?id=61574191899176

#youtube#sciencefather#naturalscientistawards#researchawards#nuclearpower#electricalengineering#nuclearplant#powerdistribution#safetyengineering#reactors#engineeringdesign#nuclearsafety#nuclear#engineeringresearch#powerplant#nuclearengineering#electricalsystems#electrical#researchanddevelopment#energysystems#criticalinfrastructure#researcher#scientist#engineer

0 notes

Text

Trusted Switchgear Manufacturers in India & Electrical Accessories Experts – HPL India

HPL India is one of the leading switchgear manufacturers in India , delivering advanced and reliable electrical solutions across the country. As prominent electrical accessories manufacturers , HPL India offers a wide range of products including switches, sockets, MCBs, and more. Known for quality and durability, HPL is also a top provider of wires and cables, designed for safety and high performance. Whether you're looking for dependable switchgear manufacturers in India or trusted electrical accessories manufacturers, HPL India is your one-stop destination for comprehensive electrical solutions, including premium wires and cables.

Visit for more info: HPL Electric & Power Limited

Address: 1/20, Asaf Ali Road, New Delhi - 110002

Email: [email protected]

Phone: +91-11-23234411

#SwitchgearManufacturersInIndia#ElectricalAccessoriesManufacturers#WiresAndCables#HPLIndia#ElectricalSolutions#PowerDistribution#SmartElectricals#HighQualityWiring#IndustrialElectricals#ElectricalSafety

0 notes

Text

#datacenter#datacenterconstruction#missioncritical#datacenterdesign#serverroom#datacenterbuild#itinfra#colocation#hyperscale#edgecomputing#datacenterengineering#criticalinfrastructure#uptime#modulardatacenter#cloudinfrastructure#techinfrastructure#datacenterproject#lowlatency#scalableinfrastructure#datacenterexperts#redundancy#datacentermaintenance#powerdistribution#coolingsystems#datacentersolutions

0 notes

Text

Solid State Transformer Market Innovations: Transforming Energy Grids with High-Efficiency Power Conversion

The global energy landscape is undergoing a profound transformation driven by increasing demand for renewable energy integration, smart grid development, and advancements in power electronics. Among the emerging technologies shaping this new era is the solid state transformer market, a next-generation power conversion device poised to revolutionize electrical grids. The Solid State Transformer market is projected to grow significantly over the coming years as utilities, industries, and infrastructure sectors seek smarter, more efficient power distribution solutions.

What is a Solid State Transformer?

A Solid State Transformer is an advanced type of electrical transformer that replaces conventional copper and iron-based transformers with semiconductor components, high-frequency transformers, and control circuitry. Unlike traditional transformers that rely solely on magnetic induction, SSTs offer intelligent, bidirectional control of power flow, voltage regulation, and frequency conversion. These capabilities make them ideal for interfacing with decentralized energy sources, electric vehicle (EV) chargers, and complex smart grid architectures.

There are three main types of SSTs:

Distribution SSTs – For medium-voltage distribution networks.

Power SSTs – For high-voltage transmission and grid-level applications.

Traction SSTs – Used in electric trains and other transportation systems.

Market Drivers

The growth of the Solid State Transformer market is being propelled by several key factors:

1. Renewable Energy Integration: The global shift toward renewable energy sources, such as solar and wind, creates a need for smarter grid components capable of managing variable power inputs. SSTs are uniquely suited for this task, as they can rapidly adapt to fluctuating power levels and enable two-way communication with energy sources.

2. Smart Grid Development: As utility companies invest in digitizing power grids, the demand for devices that support real-time monitoring, fault detection, and load balancing increases. SSTs provide these functionalities, making them vital components of smart grids.

3. Electric Vehicle Infrastructure: The rise of EVs requires an upgraded charging infrastructure that can handle high power levels efficiently and safely. SSTs can play a critical role in fast-charging stations by converting and distributing power effectively while managing grid stability.

4. Space and Weight Constraints: In applications like aerospace, military, and marine sectors, size and weight are critical. SSTs offer compactness and high efficiency, making them a preferred alternative to bulky traditional transformers.

Market Challenges

Despite their promise, several challenges hinder the widespread adoption of SSTs:

High Initial Costs: The advanced semiconductor components used in SSTs are costly, making the upfront investment higher than traditional transformers.

Thermal Management: SSTs generate significant heat, and effective thermal management is essential to ensure long-term reliability.

Standardization Issues: The lack of universal standards for SST implementation can slow down market penetration.

Technological Complexity: Maintenance and operation require specialized skills, which can limit adoption in less developed regions.

Regional Outlook

North America and Europe are leading the way in SST development due to robust investment in smart grids, renewable energy, and research initiatives. The United States, in particular, has several pilot projects demonstrating SST applications in utilities and EV charging stations.

Asia-Pacific is expected to witness the fastest growth, fueled by rapid urbanization, expanding industrial bases, and large-scale renewable energy deployment in countries like China, India, and Japan.

Middle East & Africa and Latin America are also gradually adopting SST technology, particularly in regions looking to modernize aging grid infrastructure and improve energy access.

Key Market Players

Some of the leading companies in the Solid State Transformer market include:

ABB Ltd. – One of the pioneers in SST development with a focus on grid applications.

Siemens AG – Actively involved in smart grid and transformer innovations.

General Electric – Working on SSTs for both grid and transportation systems.

Mitsubishi Electric Corporation – Investing in SST research for industrial and utility use.

Schneider Electric – Offering digital power solutions integrated with SST technology.

Startups and research institutions are also playing an increasingly important role, pushing the boundaries of SST capabilities with new materials and designs.

Future Outlook

The Solid State Transformer market is still in its early stages, but the potential is vast. With continued advancements in wide-bandgap semiconductors (like SiC and GaN), manufacturing costs are expected to decrease, making SSTs more commercially viable. Governments and utilities embracing energy decentralization and electrification will further accelerate demand.

By 2030, the market is expected to transition from pilot projects and niche applications to more widespread deployment. As the world moves toward more resilient, flexible, and sustainable energy systems, Solid State Transformers are likely to be at the heart of this transformation.

Conclusion: The Solid State Transformer market reflects the growing need for smart, adaptable power infrastructure. While challenges remain, the combination of technological innovation and market demand positions SSTs as a cornerstone of the future energy grid.

#SolidStateTransformer#PowerDistribution#SmartGrid#RenewableEnergy#EnergyEfficiency#PowerElectronics

0 notes

Text

Aerial Bunched Cables (ABC) offer safer, more reliable, and cost-effective power distribution. With lower losses and minimal maintenance, they are ideal for rural, urban, and challenging terrains. Their flexibility makes them perfect for evolving cityscapes. Choose ABC for efficient and uninterrupted power supply!

For more details, visit- https://www.capitalcables.co.in/wires-cables/aerial-bunched-cables

#capitalcables#AerialBunchedCables#ABCCables#PowerDistribution#SafeElectricity#ReliablePower#CostEffectiveCables#UrbanInfrastructure#RuralElectrification

0 notes

Text

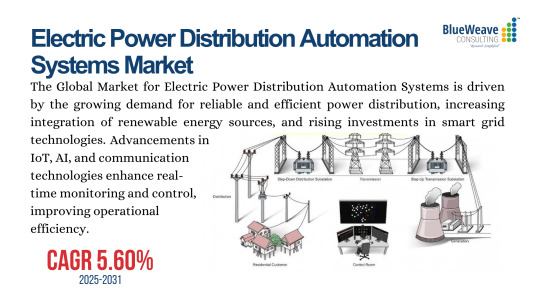

Electric Power Distribution Automation Systems Market size by value at USD 31 billion in 2024. During the forecast period between 2025 and 2031, BlueWeave expects Global Electric Power Distribution Automation Systems Market size to boom at a significant CAGR of 5.60%, reaching a value of USD 44.3 billion by 2031. The Global Market for Electric Power Distribution Automation Systems is driven by the growing demand for reliable and efficient power distribution, increasing integration of renewable energy sources, and rising investments in smart grid technologies. Advancements in IoT, AI, and communication technologies enhance real-time monitoring and control, improving operational efficiency. Additionally, government regulations promoting energy efficiency and the need to reduce transmission losses propel market growth. The increasing adoption of distributed energy resources and rising electricity demand further support the expansion of Global Electric Power Distribution Automation Systems Market in the coming year.

Sample: https://www.blueweaveconsulting.com/report/electric-power-distribution-automation-systems-market/report-sample

#BlueWeave#Consulting#Marketforecast#Marketresearch#EnergyEfficiency#SmartGridTechnology#EnergyManagement#PowerDistribution#EnergyInnovation

0 notes

Text

What are the applications of tubular poles in urban infrastructure?

Tubular poles play a vital role in modern urban infrastructure, offering durability and versatility in street lighting, signage, and power distribution. Discover their key applications and why they are a preferred choice for urban development. Read More

0 notes

Text

Compact Sub-Station: Efficient Power Solutions for a Smarter Future

In today's fast-paced world, reliable and efficient power distribution is critical for industries, urban infrastructure, and commercial spaces. A Compact Sub-Station (CSS) serves as a game-changing solution, offering space-saving, high-performance energy distribution tailored to modern needs.

What is a Compact Sub-Station?

Compact Sub-Station is a complete electrical distribution system containing the vital parts such as transformers, circuit breakers, and switchgear combined into one encased system. The compact and weather-resistant structure, with excellent efficiency, is ideal for limited-space areas that can provide trouble-free power supply with less maintenance.

Why Use Compact Sub-Stations?

1. Space Optimization

Conventional power plants need plenty of space and infrastructure. CSS, on the other hand, is a compact, self-sustained system, which makes it ideal for cities, industrial sites, and off-grid areas.

2. Enhanced Safety & Reliability

Housed in a sturdy metal or polymer case, CSS systems provide greater safety from electrical failures, environmental exposure, and outside interferences. This results in safer and more reliable power distribution.

3. Cost-Effective Installation & Maintenance

In contrast to traditional substations that involve significant civil work, a Compact Sub-Station is factory-assembled, saving installation time and related expenses. Its modular construction also allows for simple maintenance and upgrades.

4. Energy Efficiency & Sustainability

CSS solutions today include energy-efficient transformers, minimizing power loss and encouraging sustainable energy consumption. Most are also compatible with renewable energy sources, paving the way for a cleaner future.

Applications of Compact Sub-Stations

Compact Sub-Stations find applications in many industries, including:

• Industrial Plants – Offering problem-free power delivery in factories.

• Commercial Complexes – Serving smooth power distribution to shopping complexes, offices, and skyscrapers.

• Renewable Energy Projects – Facilitating solar and wind farms with credible energy distribution.

• Construction Sites – Offering transient but effective power solutions.

Future of Compact Sub-Stations

As urbanization and industrialization are expanding, the requirement for smaller, efficient, and intelligent power solutions will continue to increase. Incorporation of IoT and AI-driven monitoring systems will further optimize the efficiency and predictive maintenance of CSS, allowing real-time monitoring while ensuring power supply without interruptions.

For organizations looking for economical, space-saving, and dependable power distribution, investing in a Compact Sub-Station is the best option. Not only does it guarantee efficient operation, but it also supports a green and energy-efficient tomorrow.

If you are searching for tailored Compact Sub-Station solutions, our organization provides high-quality, long-lasting, and advanced power solutions specifically designed to cater to your needs. Get in touch with Pavika Power Equipment today to find out how we can power your future!.Call or visit www.pavikapowerequipment.in today.

#CompactSubStation#EfficientPowerSolutions#PowerEfficiency#SustainableEnergy#SmartGrid#RenewableEnergy#EnergyStorage#CleanEnergy#PowerDistribution#GridReliability#EnergyInnovation#ElectricInfrastructure#RenewablePower#EnergyManagement#PowerSolutions#EcoFriendly#UtilitySolutions#Microgrid#EnergyFuture

0 notes

Text

Powering Cities & Industries: The Role of Pad-Mount Transformers

Introduction

Reliable and efficient power distribution is essential for cities and industries to function smoothly. Pad-Mount Transformers play a crucial role in delivering safe, underground, and space-saving power solutions. These transformers are designed for urban areas, industrial zones, and commercial buildings, where traditional pole-mounted transformers may not be suitable.

What Are Pad-Mount Transformers?

Pad-Mount Transformers are self-contained, tamper-proof transformers installed at ground level. They are enclosed in weather-resistant cabinets and designed for underground power distribution networks. This makes them ideal for areas where safety, space efficiency, and aesthetics are priorities.

These transformers are widely used in urban power grids, residential communities, industrial plants, and renewable energy projects. They ensure consistent voltage regulation, enhanced safety, and lower maintenance costs.

Why Are Pad-Mount Transformers Important?

✅ Safe & Secure Power Distribution

Their locked, tamper-proof enclosures prevent unauthorized access, ensuring public safety.

✅ Compact & Space-Saving Design

Since they are installed at ground level and connected to underground power lines, they save space and improve aesthetics.

✅ Reliable & Energy Efficient

Designed for high efficiency and minimal energy loss, these transformers improve overall power distribution reliability.

✅ Low Maintenance & Durable

Built with corrosion-resistant materials, Pad-Mount Transformers require minimal maintenance and have a long operational life.

✅ Suitable for Industrial & Commercial Use

These transformers are widely used in factories, business complexes, data centers, hospitals, and urban infrastructures.

Key Features of Pad-Mount Transformers

Engineered to meet international standards, these transformers offer: ✔ Fully enclosed, tamper-resistant design ✔ Optimized for underground distribution networks ✔ Highly efficient voltage regulation ✔ Oil-cooled & dry-type options available ✔ Customizable voltage and power ratings ✔ Eco-friendly design with low noise levels

The demand for high-quality transformers is increasing as cities and industries shift towards safe and efficient power solutions. With advanced insulation, cooling technology, and voltage control, these transformers provide maximum energy savings and operational safety.

The Growing Demand for Pad-Mount Transformers

As urbanization expands, underground power networks are becoming the preferred choice for modern infrastructure. The need for reliable power, reduced environmental impact, and better grid performance has led to a surge in demand for efficient and high-performance transformers.

With industries focusing on smart energy management, these transformers help achieve better load handling, improved grid stability, and long-term cost efficiency.

Conclusion

Pad-Mount Transformers are a smart, secure, and sustainable solution for modern power distribution. Their compact design, high efficiency, and low maintenance requirements make them ideal for cities and industries alike. As more regions adopt underground power infrastructure, the demand for advanced transformer solutions continues to rise, ensuring safer and more efficient energy management for the future.

🔗 Contact us today to learn more about our advanced transformers!

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#PadMountTransformer#PadMountTransformerInCoimbatore#PadMountTransformerManufacturersInCoimbatoreIndia#PadMountTransformerManufacturersExportersInCoimbatoreIndia#PowerDistribution#EnergyEfficiency#IndustrialTransformers#SmartGridSolutions#UndergroundPower#ReliableEnergy#ElectricalInfrastructure#CompactPowerSolutions#SafeEnergyDistribution#SustainablePower#VoltageRegulation#UrbanEnergySolutions#HighEfficiencyTransformers#GridStability#LowMaintenanceTransformers#RenewableEnergyIntegration

0 notes

Text

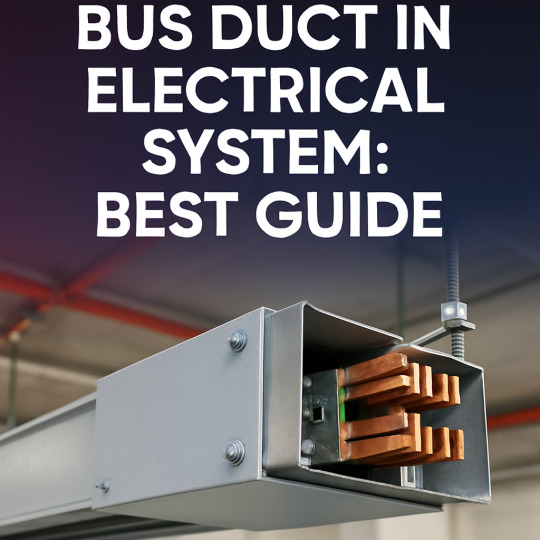

Bus Duct in Electrical System: Best Guide

The bus duct in electrical system is a critical component in modern power distribution. It offers a compact, flexible, and efficient method to carry large currents within buildings, factories, and power stations. Compared to traditional cabling, bus ducts provide higher safety, reduced power losses, and easier installation. These advantages make bus ducts popular in both commercial and industrial electrical infrastructures.

Bus Duct in Electrical System: Best Guide Understanding how a bus duct in electrical system works is essential for engineers, electricians, and facility managers. The system not only ensures effective power flow but also contributes to space optimization and improved energy efficiency.

What is Bus Duct in Electrical System

A bus duct in electrical system is a metallic enclosure that houses copper or aluminum bus bars. These bus bars are the conductors that carry electrical power from one point to another. The enclosure offers mechanical protection and electrical insulation. Bus ducts come into play especially when high current needs to be transferred over short to medium distances. They are ideal for applications that demand safety, reliability, and space-saving layouts. Bus ducts serve as alternatives to cable trays and conduit wiring systems. While cable systems are more common in residential installations, bus bar electrical solutions dominate in commercial and industrial setups due to their robust nature.

Technical Composition of Bus Duct in Electrical System

The bus duct in electrical system comprises the following primary components: Conductors (Bus Bars): These are typically made of copper or aluminum. They are the current-carrying elements and can be of different shapes – rectangular, round, or even flat. Insulation: The bus bars are insulated using air, epoxy resin, or other dielectric materials. This prevents short circuits and ensures operator safety. Enclosure: This is the metallic body made of aluminum or galvanized steel that protects the bus bars from mechanical damage and environmental exposure. Read More... #BusDuct, #ElectricalSystem, #PowerDistribution, #ElectricalEngineering, #BusDuctDesign, #IndustrialElectrical, #BusDuctInstallation, #ElectricalSafety, #EnergyDistribution, #BuswaySystem, #ElectricPower, #ElectricalPanel, #ElectricalComponents, #HVACSystems, #SubstationDesign Read the full article

#BusDuct#BusDuctInstallation#BusbarSystem#CableManagement#electricalcomponents#ElectricalEngineering#ElectricalSystem#Energytransmission#IndustrialPower#powerdistribution

0 notes

Text

How to Choose the Right Cable Gland Size for Optimal Performance

Choosing the correct cable gland size prevents issues like inadequate sealing and electrical failures. Learn about different cable glands, key selection factors, and expert-recommended steps for a secure fit. Ensure safe and efficient electrical installations with the right gland size.

#CableGlands#ElectricalSafety#IndustrialSolutions#CableManagement#EngineeringTips#PowerDistribution#AtlasMetal

1 note

·

View note

Text

Advanced Electrical Solutions by HPL India – Changeover Switch, Smart Meters India & Solar Cable

HPL India delivers reliable and efficient electrical products including the high-performance changeover switch, innovative smart meters India trusts, and durable solar cable for renewable energy applications. Designed to meet modern electrical needs, HPL's changeover switch ensures uninterrupted power supply, while their smart meters India range offers accurate energy monitoring and billing. Whether you're upgrading your system or going solar, HPL India provides quality solar cable solutions built for performance and longevity.

Visit for more info: HPL Electric & Power Limited

Address: 1/20, Asaf Ali Road, New Delhi - 110002

Email: [email protected]

Phone: +91-11-23234411

#BestElectricSwitchesInIndia#BestElectricalModularSwitchesInIndia#TransmissionCable#HPLIndia#ElectricalSolutions#ModularSwitches#ElectricSwitches#PowerDistribution#MadeInIndia#SmartHomes

0 notes

Text

Ring Main Unit Market Opportunity Analysis & Industry Forecast, 2024–2030

Ring Main Unit Market Overview:

Ring Main Unit Market size is estimated to reach $5.2 billion by 2030, growing at a CAGR of 8.0% during the forecast period 2024–2030.

Request Sample :

RMUs offer enhanced safety features like arc-flash protection which drives their adoption in hazardous environments. Moreover, the modernization of power distribution infrastructure as well as adoption of renewable energy are driving the market. In addition, the increasing investment in power infrastructure is also driving the market.

The two major trends in the Ring Main Unit Market are the adoption of eco-friendly technologies and the integration of smart systems. Increasingly, ecofriendly advancements like Siemens’ F-gas free RMUs with climate neutral Clean Air insulation are coming to the fore. These solutions eliminate SF6 gases and reduce the carbon footprint of power distribution systems by an order of magnitude, while maintaining high efficiency and safety. Moreover, smart technologies are integrated into RMUs to make them intelligent solutions. A key enabler provided by digitalization is the remote monitoring, automated control and IoT connectivity of features as seen in ABB’s SafeLink RMUS. These capabilities improve operational efficiency, support predictive maintenance, and integrate easily with the modern decentralized grids. These trends, together, guarantee that RMUs satisfy increasing requirements for sustainability, reliability, and sophisticated functionality in power distribution.

COVID-19 / Ukraine Crisis — Impact Analysis:

COVID 19 pandemic heavily impacted Ring Main Unit (RMU) market by creating delays in manufacturing, supply chain issues and project delays. Reduced availability of the workforce and the slow pace of production of RMU components in the regions with strong dependence on imports due to lockdowns and restrictions. Key sectors such as industrial and commercial projects continued to demand less due to persisting economic uncertainties.

Russia Ukraine war also added to the RMU market by aggravating the supply chain problems and intensifying the energy security issues. This conflict disrupted global trade in all critical raw materials for RMU costs, such as copper and steel, and this state of inflation. At the same time, energy supply disruptions in Europe triggered investments in reliable and decentralized power systems.

Inquiry Before Buying:

Key Takeaways:

APAC Dominates the Market

APAC is the dominant region in the Ring Main Unit market driven by industrialization, growing demand for power and infrastructure development. Countries like China, India and Japan are heavily investing in expanding their power distribution networks to support growing electricity demand. According to the Central Electricity Authority, Government of India, India generated 1,949 TWh of electricity in FY 2023–24, with 1,734 TWh coming from utilities, and achieved a per capita electricity generation of 1,395 kWh, reflecting substantial energy demands. Additionally, the region’s focus on renewable energy integration with extensive wind and solar projects increases the deployment of RMUs for efficient power distribution. There is a need for reliable electrical systems, further fueling RMU demand. Moreover, APAC’s strong manufacturing base reduces production costs for RMUs, making them more accessible to local utilities and industries.

Gas Insulated Represent the Largest Segment

The Ring Main Units (RMUs) market is dominated by Gas-insulated RMUs which are characterized by a compact design, high efficiency, and ability to support reliable electricity distribution in urban areas with limited space. This trend is further underscored by the expansion efforts of Siemens India, which were announced on May 2024. Siemens will invest $3.95 million to enhance its gas insulated switchgear (GIS) production capacity by 23% which includes 22,000 feeders for its Ring Main Unit. The expansion will be phased over three years from 2024–25 and will be funded from internal accruals. Such investments demonstrate the increasing need for gas insulated RMUs, which are essential to modern power systems for switching, transformation, measuring and distributing electrical energy in a reliable and efficient way. Thus, gas insulated RMUs are a preferred choice to address the rising energy needs globally due to their scalability and performance.

Schedule A Call:

Industrial is the Largest Segment

The industrial sector is the largest application area for RMUs owing to its high demand for reliable and uninterrupted power supply. Industries such as manufacturing, mining, oil & gas and petrochemicals operate in environments where power outages can result in significant financial losses and operational downtime. RMUs are preferred in these settings due to their compact design, durability and enhanced safety features. Additionally, industries often require medium-voltage distribution systems where RMUs provide an ideal solution for efficient load management and fault isolation. The growing trend of automation and electrification in industrial operations further boosts the demand for advanced RMUs with smart monitoring and control capabilities. According to Aktif Elektroteknik, RMUs are essential components in power distribution particularly valuable in industrial applications and humid environments. These medium-voltage switchgear systems, compact yet powerful, ensure steady electricity flow and can quickly switch between power sources during repairs or emergencies, minimizing downtime.

Their versatility, low maintenance, and adaptability for indoor and outdoor installations make them indispensable for industrial use. With advancements in smart grid technology and renewable energy integration, RMUs continue to evolve, offering enhanced capabilities to support modern industrial operations. This makes them a cornerstone for ensuring operational continuity and energy efficiency in industries worldwide.

Demand for Uninterrupted Electricity in Critical Applications to Drive the Market

The demand for uninterrupted electricity in critical applications, such as medical facilities, data centers and manufacturing, is a significant driver for RMU installations. The rapid growth in global electricity demand is projected to increase by around 4% in 2024, up from 2.5% in 2023, which compounds this need, according to the IEA’s Electricity Mid-Year Update. This is the highest annual growth rate since 2007, except for exceptional rebounds following crises. As global electricity consumption grows, with a further 4% growth expected in 2025, consistent power supply is critical to the functioning of critical sectors. They expect renewables to expand rapidly, accounting for 30% of global electricity supply in 2023 and 35 percent in 2025. Though, strong electricity demand, in economies like India with 8% growth and China with over 6% growth TO ensures stable CO₂ emissions from coal reliance. This robust demand demonstrates the need for reliable RMU systems to maintain uninterrupted power to the energy intensive infrastructure of modern economies.

Buy Now:

Lack of Skilled Professionals to Hamper the Market

There is a shortage of skilled workers required for installation, operation and maintenance. RMUs involve sophisticated technologies including advanced circuit breakers, insulation systems and digital monitoring tools which demand expertise for effective handling. In developing countries, where power infrastructure development is accelerating, the gap between workforce capabilities and technological advancements is particularly pronounced. This skill deficit leads to delays in project implementation, suboptimal system performance and increased operational risks. According to TeamLease, this problem is very significant in the renewable energy sector, where there is a skill gap of nearly 1.2 million workers. Moreover, TeamLease Services states, the industry will need 1.7 million trained workers by 2027, which is when demand for skilled professionals is expected to rise by 26%. This is a similar challenge occurring in other power sector infrastructure sectors, including RMUs, where the shortage of skilled professionals not only slows down growth, but also raises concerns about the quality and reliability of systems deployed around the world.

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Ring Main Unit Market. The top 10 companies in this industry are listed below:

Siemens AG

Schneider Electric SE

Eaton Corporation Plc

ABB Ltd.

GE Vernova

Toshiba Corporation

CG Power and Industrial Solutions

CHINT Group

LS Electric Co., Ltd

Lucy Electric

For more Automation and Instrumentation Market reports, please click here

#RingMainUnit#RMU#ElectricalEngineering#PowerDistribution#Switchgear#MediumVoltage#SmartGrid#EnergyInfrastructure

0 notes

Text

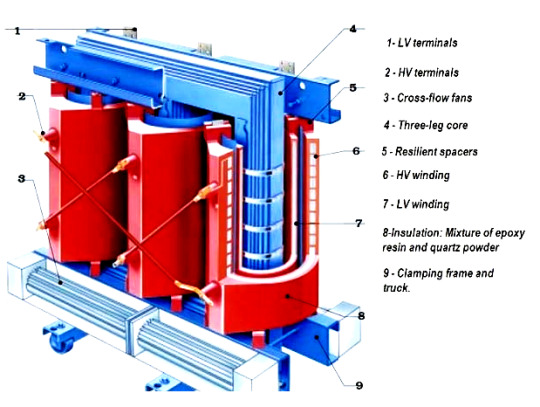

𝗣𝗼𝘄𝗲𝗿𝗶𝗻𝗴 𝘁𝗵𝗲 𝗙𝘂𝘁𝘂𝗿𝗲: 𝗧𝗵𝗲 𝗥𝗶𝘀𝗲 𝗼𝗳 𝗗𝗿𝘆 𝗧𝘆𝗽𝗲 𝗧𝗿𝗮𝗻𝘀𝗳𝗼𝗿𝗺𝗲𝗿𝘀 𝗶𝗻 𝟮𝟬𝟮𝟱 🔌

The Dry Type Transformer Market size is estimated to reach $10202.7 Million by 2030, growing at a CAGR of 6.3% during the forecast period 2024-2030.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞: 👉 https://tinyurl.com/4mu3hybr

As industries #worldwide shift towards sustainability, safety, and efficiency, the Dry Type #Transformer Market is gaining strong momentum. 🚀

#DryTypeTransformer#EnergyEfficiency#SmartGrids#SustainableEnergy#RenewableEnergy#PowerDistribution#MarketTrends

0 notes