#PowertrainModelling

Explore tagged Tumblr posts

Text

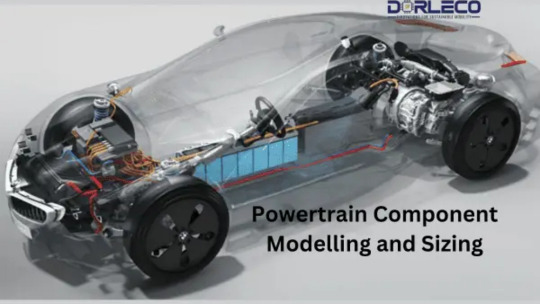

Powertrain Component Modelling and Sizing

Introduction

The dynamic automotive sector is depending more and more on virtual engineering and digital simulations to satisfy strict performance, efficiency, and regulatory requirements. The core of a vehicle’s design is the powertrain, which is the collection of elements that are accountable for generating and distributing power to the wheels. In order to achieve the best possible balance between performance, fuel efficiency, cost, and emissions, powertrain component modelling and size are crucial, regardless of the powertrain’s configuration — internal combustion engine (ICE), hybrid, or entirely electric. The systematic technique, advantages, difficulties, and prospects for powertrain component modelling and sizing in the automotive engineering process are all examined in this blog.

1. Understanding the Powertrain Component

Determining the vehicle’s intended use and performance goals is the first step in any powertrain development cycle. This fundamental stage lays the groundwork for component-level specifications and architectural choices.

Vehicle Type: EV, hybrid, commercial vehicle, sports car, or passenger car.

Performance metrics: include top speed, gradeability, towing capacity, and desired acceleration (0–100 km/h).

Compliance goals include safety regulations, fuel economy requirements, pollution regulations, and sustainability goals.

A thorough comprehension of these factors guarantees that the finished powertrain design complies with regulatory standards and market expectations.

2. Powertrain Architecture Selection

The type of vehicle and its intended use have an impact on the strategic choice of powerplant layout. Among the primary categories are:

Engine Internal Combustion (ICE)

Powertrain Hybrid (PHEV, HEV)

Electric Vehicles with Batteries (BEV)

Electric Vehicles using Fuel Cells (FCEV)

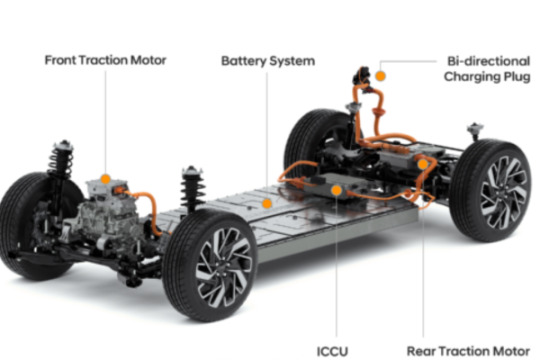

Core elements such the engine, electric motor, battery, gearbox, and control units must interact differently in each architecture. For downstream modelling, it is crucial to map the component interaction and energy flow paths at this point.

3. Modelling at the Component Level

Modelling engines

Modelling for ICE-based systems includes:

Creation of torque-speed curves

Mapping of fuel consumption

Emissions modelling and thermal behaviour

To model operating circumstances, assess combustion efficiency, and investigate transient responses, advanced programs such as GT-Power, AVL Cruise, or MATLAB/Simulink are used.

1.Modelling Transmissions

In this context, the gearbox connects wheel torque and engine power, while modelling helps determine:

Ideal gear ratios

Timing and logic for gear changing

Losses brought caused by inertia and friction

Reactivity and driveability

Single-speed gearboxes are frequently used in electric vehicles; nonetheless, efficiency and thermal considerations are still crucial.

2. Modelling Electric Motors and Batteries

In systems that are electrified:

Electric Motor: Efficiency mapping, torque-speed characteristics, inverter management, and the possibility of regenerative braking are all included in the simulations.

State of charge (SOC), voltage-current profiles, thermal performance, capacity decline, and charging/discharging behaviour are all included in the models of batteries.

Consequently, these components play a vital role in enabling accurate range estimation and supporting effective hybrid control schemes.

3. Control System Modelling

To that end, modern cars use intelligent control algorithms to regulate the flow of torque and energy. Key elements include:

Distribution of power in hybrid automobiles

Energy management systems for batteries (BMS)

Control of traction and stability

Regenerative braking and torque vectoring

Furthermore, control system modelling optimises real-time responses by ensuring smooth interaction between physical components.

4. Component sizing and optimisation

Each component is guaranteed to be neither overdesigned nor underutilised with proper dimensions. Engineers optimise variables like

Engine displacement and output torque

Maximum power and continuous motor rating

C-rate and battery capacity

Gear ratios for transmissions

The proper trade-offs between performance, efficiency, cost, and packing can be achieved with the aid of optimisation technologies (such as genetic algorithms and experiment design).

5. Compatibility and System Integration

The powertrain must function as a cohesive system in addition to its individual performance. Important integration factors consist of:

Thermal control of the battery, inverter, and engine.

Packaging and weight distribution to maintain vehicle dynamics

Features of NVH (Noise, Vibration, Harshness)

Compatibility of mechanical and electrical interfaces

Therefore, ignoring these elements may lead to inefficiencies, reliability issues, or dissatisfied clients.

6. Performance Validation Through Simulation

Subsequently, once components are designed and scaled, system-level simulations are conducted to validate the full powertrain component across real-world scenarios.

Urban driving cycles, such as the FTP-75 and WLTP

Profiles of highway loads

Simulations of hill climbing or towing

Conditions for idle-stop and regenerative braking

Engineers can create control methods and identify bottlenecks early in the process with the help of simulation technologies (such as MATLAB, dSPACE, and IPG Carmaker).

7. Physical Testing and Prototyping

Although simulation offers a theoretical starting point, physical testing is still necessary:

Prototype vehicle builds

Engine test beds and dynamometers for the chassis

Tests of endurance and durability

Prior to mass production, these tests ensure system robustness by validating predictions and identifying unforeseen mechanical, thermal, or ergonomic concerns.

8. Cost Analysis and Compromises

Additionally, a high-performance Powertrain Component needs to be profitable. Cost modelling includes:

Complexity of manufacturing and material selection

Tooling expenses and supplier availability

Implications for warranty and maintenance

In addition, simulations help identify cost-effective solutions without sacrificing critical performance parameters.

9. Iterative Refinement

In practice, the development process is rarely linear; instead, several design iterations are driven by insights gained from simulation, testing, and consumer feedback.

Modifying component specifications

Control logic revision

Power split or thermal load rebalancing

Consequently, this iterative loop ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

10. Records and Adherence

As a result, this iterative loop not only streamlines development but also ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

Logs from simulations and technical reports

Design specifications and the bill of materials

Safety requirements and emissions certifications

Design decision traceability

Proof of due diligence throughout the development process is necessary to comply with international rules (such as those set forth by the EPA, CARB, and UNECE).

Benefits of Powertrain Component Modelling and Sizing:

✔ Performance Enhancement

Fine-tuning for certain objectives, such as high torque, quick acceleration, or fuel economy, is possible through simulation.

✔Enhanced Productivity

Appropriate size improves energy efficiency on both ICE and EV platforms by preventing overdesign and lowering internal losses.

✔ Saving Money

Furthermore, by avoiding needless overspecification, manufacturers can effectively reduce manufacturing and material costs without compromising quality.

✔ Emissions Management

As a result of precise engine mapping and electric system optimisation, CO₂ and NOₓ emissions are significantly reduced.

✔ Predictive Knowledge

Prior to costly tooling and prototyping, simulations identify possible failure areas or inefficiencies.

✔ Personalisation

The architecture and Powertrain Component flexibility made possible by early modelling is advantageous for a variety of vehicle types, including haul trucks and two-wheelers.

✔ Superior Energy Organisation

Reliability and range are directly impacted by efficient battery and power management systems, particularly in EVs and hybrids.

✔ Reduced Market Time

Virtual iterations make faster development cycles possible as opposed to conventional build-and-test loops.

✔ Dependability

Moreover, stress analysis and thermal modelling ensure durability, which in turn lowers warranty claims and enhances brand recognition.

✔ Attention to Regulations

By ensuring early compliance with international safety and emissions standards, manufacturers can significantly reduce the need for costly redesigns later in the development cycle.

Difficulties with Powertrain Component Sizing and Modelling

Despite its strength, this strategy has drawbacks: Model Complexity: It takes knowledge and computing power to accurately simulate multi physics systems. Data Reliability: Reliable input data is necessary for model accuracy, which frequently necessitates rigorous physical testing for calibration. Integration Difficulties: Maintaining balance between electrical, mechanical, and control systems is difficult. Dynamic Operation Limits: Unexpected real-world circumstances are not always taken into account by models. Cost of Software Tools: Smaller businesses cannot afford the sophisticated simulation suites. Rapid Technological Changes: As EVs advance quickly, current models may become outdated. Real-World Parameter Uncertainty: It is challenging to accurately forecast traffic, temperature, and driver behaviour.

Conclusion

At the forefront of contemporary vehicle engineering is the modelling and sizing of powertrain components. In a cutthroat market, they enable automakers and suppliers to create vehicles that are effective, legal, and perform well. Engineers may unlock better ideas while cutting down on time, expense, and environmental effect by combining virtual simulations with actual testing. Modelling techniques will only become more crucial as the sector continues its transition to electrification and autonomous systems. Experts anticipate that future developments in digital twins, AI-driven simulations, and cloud-based co-simulation platforms will further push the limits of accuracy and effectiveness. Powertrain modelling and sizing are essentially strategic enablers of innovation, performance, and sustainability in mobility when used with insight and rigour.

#Dorleco#EVEngineering#PowertrainModelling#AutomotiveInnovation#VCU#CANDisplay#BatteryManagement#SimulationDrivenDesign#ElectricVehicles#MobilitySolutions#FutureOfTransport#EngineeringExcellence#DigitalEngineering

0 notes

Text

An Overview of Electric Vehicle Motor Control Unit

August 11, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Because of the technological advances made possible by electric motors and batteries, power conversion systems and motor control strategies that optimize efficiency and dependability have to be developed. These days, all of these features are included in the traction inverter, commonly referred to as the Vehicle Motor Control Unit (MCU).

The world’s need for electric cars, or EVs, has grown significantly in the last several years. One of the things boosting the popularity of electric cars is the government’s and automakers’ plan to transition from manufacturing internal combustion vehicles to electric and hybrid vehicles in a few years.

The advancement of lithium-ion battery technology, the dependability and accessibility of high-efficiency powertrain inverters, and the advancements made in engine management and electric motors are all responsible for the availability of EV technology and the reduction of range anxiety among consumers. Electric motors and batteries have facilitated technological advancements, necessitating the development of power conversion systems and motor control procedures that maximize reliability and efficiency.

These days, all of these features are included in the traction inverter, commonly referred to as the Vehicle Motor Control Unit (MCU).

DC versus AC motors

Two primary motor types are used in electric cars:

AC-powered engines:

A motor on alternating current (AC) has three phases and 240 volts. AC motors can also be utilized as a generator to recharge an electric vehicle’s batteries because of their regenerative nature. This motor also has the added benefit of faster acceleration and smoother running on uneven ground. Its cost is higher than that of DC motors, which is its primary disadvantage.

The two main types of AC motors are synchronous and asynchronous motors, also called induction motors. Induction motors can be relied upon, are reasonably priced, and require little maintenance, making them simple to use. In contrast, synchronous motors offer some advantages, including strong low-speed torque, small form factor, high power density, high efficiency, and low weight.

BLDC Motors:

These motors have several benefits over AC motors, such as longer speed ranges, noiseless operation, quicker dynamic reaction times, and more. They have an exceptionally high torque ratio relative to size, making them a great fit for EVs, which require high power density yet lightweight and small form factors.

Moreover, BLDC motors require incredibly intricate hardware and software control. AC motors can store energy for braking and release it for accelerating, but they require an appropriate DC-AC inverter. This restores the essential battery juice while enabling you to drive normally. Some DC systems are more costly and sophisticated than others because they can also accomplish that.

BLDC motors require more sophisticated reversing techniques than AC motors, which can be easily reversed by simply flipping the order of the two phases in the inverter.

Both BLDC and AC motors are viable choices for powering EVs, even though AC motors are preferred when performance and long-range are critical criteria. As with many other electronics applications, the key to this selection is to find the optimal balance between cost and performance.

Algorithms for motor control

While there are many other types of electric motors, we will focus on the AC and BLDC/PMSM DC motors that are commonly seen on electric vehicles (EVs). Consequently, the motor control algorithms used in EVs will depend on the kind of motor and control (open or closed loop). The latter requires the presence of sensors that can accurately determine the position of the motor at any given time.

Trapezoidal control is among the simplest types of BLDC motor control. Even though it’s quite popular and reasonably priced, it has a torque ripple problem when driving.

Sinusoidal control is generally considered to be an improvement over trapezoidal control. The main benefits of this control are less noticeable noise, higher torque at lower speeds, and more precise and seamless operation. To accomplish these, three currents are pushed into each of the three motor windings, and these currents vary smoothly and sinusoidally as the motor rotates. Precise rotor position measurement can be achieved using encoders or resolvers to provide smooth sinusoidal modulation of the motor currents while the motor rotates.

While sinusoidal control is very successful at low motor speeds, it becomes limited at high motor speeds due to an increase in the frequency of the sinusoidal signal. At high speeds, torque production decreases and efficiency diminishes.

Originally developed for AC motors, Vector Control, often known as FOC for Field Orientation Control, is the most advanced control method available today. An electric motor’s torque is influenced by the rotor and stator fields, and it is greatest when they are orthogonal.

The FOC approach aims to replicate the orthogonal relationship present in an AC or BLDC motor. A two-orthogonal component, FOC stands for variable frequency control of the stator in a three-phase motor. One component is the torque, which is determined by the motor speed and the location of the rotor; the other is the magnetic flux produced by the stator.

Field Oriented management uses two techniques to manage torque and flux separately:

Direct FOC: From flux estimation or measurement, the rotor flux angle is directly determined.

Indirect FOC: The slip calculations and the available speed are used to deduce the rotor flux angle. When using a dynamic model of an AC induction or BLDC motor, vector control can be computed with the use of intricate algorithms and knowledge of the terminal current and voltages. However, this method requires a lot of processing power to use well.

Vector-based motor control has the natural benefit of being able to control multiple AC, PM-AC, or BLDC motors using the same scheme. The FOC technique allows brushless motors to reach up to 95% efficiency, which is efficient within the maximal speed range. Its accuracy and precise control also allow the motor speed to be decreased to almost 0 rpm.

Figure 1 is an example diagram for a three-phase BLDC motor control. Six power transistors are involved, one for each of the three phases, or three half-bridges altogether. Three PWM signals are typically used to activate them, and an MCU or integrated driver IC controls the timing and sequence of these signals. The microcontroller receives positional feedback from three Hall sensors. An analogous picture that illustrates how to control an AC induction motor is picture 2. Here, an accurate encoder interface provides the position feedback.

Sensor versus Vehicle Motor Control Unit without sensors

BLDC motors are more challenging to operate and require an understanding of the rotor position and mechanism to commutate the motor because they are not self-commutating. Measurement of the motor speed and/or motor current and a PWM signal to control the motor speed and power are two more prerequisites for closed-loop speed control.

BLDC motors achieve absolute position sensing by detecting the rotor position with specific position sensors. Consequently, costs increase and the number of cables increases. By using the motor’s back-emf (electromotive force) to estimate the rotor position, sensor-free BLDC control does away with the requirement for position sensors. For low-cost variable speed applications like fans and pumps, sensor-less control is crucial. Sensor-less control is also necessary for compressors that use BLDC motors, including those in refrigerators and air conditioners.

Position sensors are available in three main types:

Hall-effect sensors reduce design complexity and are cheap. Yet, their resolution is subpar when compared to other sensors.

Encoders are expensive and require digital processing.

Resolvers: Digital processing must be used to obtain the optimal resolution.

Resolvers and encoders are typically used in high-precision motor control applications in the automotive and industrial industries.

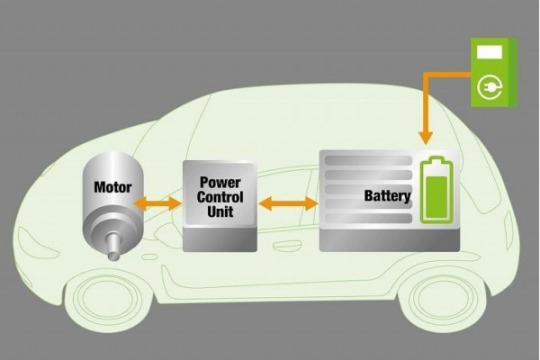

Motor control unit

The batteries, which are DC power sources, and the motor (AC or BLDC) are interfaced with each other by an electrical module known as the Motor Control Unit (MCU). Its main duty is to control how fast and how much acceleration the EV experiences when the throttle is applied.

The following are some of an MCU’s primary responsibilities:

Control the motor’s torque and speed. Switch the engine on and off. Reverse the motor’s direction. brakes that produce energy again. When the motor is braking, it acts as a generator since the back-emf it produces is higher than the DC supply voltage to the MCU. This potential difference causes current to flow from the motor to the battery through the Vehicle Motor Control Unit.

The Vehicle Motor Control Unit uses a range of safety measures, including the following, to protect EV components:

Overvoltage: this occurs when the input battery voltage exceeds permissible limits.

Under voltage: If the MCU operates below the lower voltage cutoff, it will drain the battery more fully and may result in a thermal runaway that could destroy the cells permanently or result in a decrease in performance.

Overcurrent: If the Vehicle Motor Control Unit detects an overcurrent, it will cut off the battery supply. It does this continuously.

Overheating: as with the previous point, this happens when the internal temperature of the motor controller goes above a safe threshold.

Conclusion:

In conclusion, this overview of electric vehicle motor control provides a comprehensive understanding of the key components and characteristics that dictate how the electric motors in these cars function. Electric vehicles are crucial for reducing carbon emissions and raising energy efficiency as the automobile industry shifts to more sustainable and ecologically friendly forms of mobility.

The motor control systems — which comprise inverters, motor controllers, and several sensor types — that have been discussed form the basis of electric vehicle propulsion. The intricate relationships between these components ensure optimal efficacy, security, and performance when the car is driving. Additionally, as technology advances, motor control algorithms get better and better, providing electric car users with better acceleration, regenerative braking, and overall driving experiences.

#autonomousvehicle#MotorControlUnit#Powertrainmodelling#VCU#EVSoftware#evCODE#ADASCode#VCUSupplier#VCUManufacturer

0 notes

Text

Powertrain Component Modelling and Sizing

August 8, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Modeling and sizing the components is one of the most crucial steps in designing a vehicle’s powertrain component system. A car’s powertrain, which typically consists of the engine, transmission, and other related components, significantly impacts the vehicle’s performance, economy, and overall functionality. Below is a synopsis of the process:

1. Describe the needs for the vehicle:

Establish the type of vehicle and its intended use, such as a truck, an electric car, or a passenger automobile.

Define the essential performance metrics, such as maximum velocity, acceleration, and towing capability.

Consider the law’s limitations, environmental regulations, and fuel economy goals.

2. Architecture of the Powertrain:

Select from an electric powertrain component architecture, fuel cell, hybrid, or internal combustion engine.

Explain the interactions between the different components of the powertrain and the energy flow that occurs inside the system.

3. Modeling Components:

Modelling Engines

Use simulation tools to model the engine’s performance characteristics, such as torque, power, and fuel consumption.

Consider issues such as engine economy, emissions, and heat control.

4. Modeling Transmissions:

To optimize gear ratios for performance and fuel efficiency, model the transmission system.

Consider factors such as gearbox efficiency, driveability, and shift times.

Electric motor and battery modeling (for hybrid and electric vehicles):

Model an electric motor’s torque-speed characteristics.

Consider output power, voltage, and capacity while modeling the battery system.

5. Modeling Control Systems:

Use control algorithms to manage energy flow, power distribution, and system performance.

Consider vehicle stability control, energy regeneration, and torque vectoring concepts.

6. Sizing and Optimization:

Dimensioning of Components

Establish the correct dimensions and specifications for each powertrain component based on the needs of the vehicle.

Optimize variables such as engine displacement, electric motor power, and battery capacity.

7. Integrity & Compatibility:

Make sure the powertrain functions as a single cohesive unit.

Consider factors such as heat management, weight distribution, and packing restrictions.

8. Validation of Performance:

Playback:

Use simulation tools to confirm the overall functioning of the Powertrain Component system under various operating conditions.

Iterate and refine the design in light of the simulation’s results.

9. Testing of prototypes:

Build functional prototypes to confirm the simulation’s findings in practical situations.

Based on test results, modify the components of the powertrain.

10. Evaluation of Costs:

Consider the budgetary impact of the chosen powertrain components.

Cost considerations ought to be weighed against effectiveness and efficiency.

11. Iterative Methodology:

Iterations are a common part of powertrain development. Modify the design in response to feedback, testing, and simulation results.

12. Documentation and Compliance:

Keep records of the design decisions, testing outcomes, and specifications. Verify that the pertinent laws and regulations are being followed.

Advantages of Modeling and Sizing Powertrain Components

When constructing a car, there are numerous benefits to modeling and sizing the powertrain components. Here are a few key advantages:

1. Performance Optimization:

Thanks to modeling, engineers can simulate and assess the performance of individual Powertrain components as well as the system as a whole.

Sizing ensures optimal performance in terms of power production, efficiency, and overall functionality by properly matching components.

2. Enhancing Efficiency:

By accurately replicating the components of the powertrain, engineers can discover solutions to improve efficiency, reduce energy losses, and maximize fuel economy.

Precise component sizing minimizes over- or under-sizing by optimizing the Powertrain Component for the particular requirements of the vehicle.

3. Lowering Expenses:

Engineers can determine the most economical configuration of Powertrain components using simulation and sizing.

Cutting down on over-specification can save costs for materials, manufacture, and the entire vehicle production process.

4. Reduction of Emissions:

Internal combustion engines emit fewer pollutants thanks to the optimization of the combustion process made possible by precise modeling.

5. Analysis of predictability:

Through modeling, engineers can predict how the Powertrain Component will perform in various operating conditions without the need for physical prototypes.

This ability to foresee issues ahead of time speeds up the design process and makes it feasible to recognize and address any issues early on.

6. Personalization for Specific Uses:

Modeling and sizing facilitate powertrain modification for a range of vehicle types and applications.

Whether the vehicle is meant to be a high-performance sports car, a fuel-efficient commuter car, or a heavy-duty truck, the powertrain can be built to meet specific needs.

7. Enhanced Energy Management (in Electric and Hybrid Cars):

Modeling aids in the energy management strategy’s optimization in electric and hybrid cars. This covers controlling the distribution of power overall, regenerative braking, and battery charging and discharge.

If the electric components are sized appropriately, the car can achieve the necessary performance and range.

8. Shorter Time for Development:

The simulation-based design allows Powertrain Component iteration and refinement more quickly than traditional trial-and-error methods.

This reduces the overall development time of the vehicle.

9. Enhanced Durability and Reliability:

By using simulation, engineers can assess the mechanical and thermal stresses placed on powertrain components and make sure they are designed to withstand real-world scenarios.

Proper size of components aids in avoiding premature wear and failure.

10. Adherence to Regulations:

By applying modelling, engineers may design powertrains that comply with safety, fuel efficiency, and emissions laws.

This preventive measure enables manufacturers to avoid costly recalls and redesigns.

Disadvantages of Sizing and Modeling Powertrain Components

1. The complexity of the model:

Making realistic models of every part of the powertrain and their interactions can be challenging and time-consuming. For detailed modeling, a complete understanding of the thermodynamic and physical properties of the components is required.

2. Validation and Accuracy of Data:

The correctness of the simulation findings is mostly dependent on the caliber of the input data and the dependability of the mathematical models used. The validation of these models requires time-consuming and expensive real-world testing.

3. Integration Difficulties:

It can be difficult to integrate different powertrain components into a coherent system, particularly in hybrid and electric vehicles where many technologies (such as engines, electric motors, and batteries) must function seamlessly.

4. Conditions of Dynamic Operation:

Powertrains operate in a range of dynamic conditions. Severe weather patterns, sudden variations in load, and ephemeral behaviors could be too complex for size and modeling to capture.

5. Limited Simulation Scope:

Simulations are based on assumptions and simplifications. Certain aspects of driving in the actual world, like changing traffic patterns and road conditions, might not be sufficiently accounted for in simulations.

6. Simulation Software’s Initial Cost:

Purchasing and utilizing advanced simulation tools can be costly. It could be challenging for small or new enterprises with limited funding to get modern modeling software.

7. Human Factors and Experience Driving:

While modeling often focuses on technical aspects, it may overlook crucial features or the driver’s subjective experience. Probably, features like comfort, loudness, and vibration aren’t given enough consideration.

8. Rapid advancements in technology:

Technology is advancing quickly in the automotive industry, especially in the domains of electric and driverless cars. Models may become outdated due to new technologies, requiring constant changes.

9. Ambiguity in the parameters entered:

Many of the input characteristics utilized in modeling, such as environmental elements, traffic conditions, and driver behavior, can have a great deal of uncertainty. These uncertainties could affect how accurate the forecasts are.

Conclusion:

To sum up, engine component sizing and modeling are crucial to the design and development of contemporary cars. They come with several advantages as well as difficulties. The ability to simulate and improve the functioning of individual components as well as the entire drivetrain system results in more efficient, cost-effective, and low-emission solutions. Engineers can meet legal requirements and provide the best possible performance by tailoring the powertrain to a particular vehicle’s requirements.

It’s crucial to recognize the difficulties and restrictions this strategy has, though. A flawless simulation is unattainable due to the complex nature of modeling, difficulties with data validation and accuracy, and the dynamic working circumstances of automobiles. The complexity is increased by integrating different powertrain technologies, responding quickly to changes in the industry, and handling input parameter uncertainty.

It’s critical to strike a balance between simulation and in-person testing. Even while modeling speeds up the design process and offers insightful information, physical testing is still necessary to confirm simulation results and guarantee the powertrain’s dependability and safety under a variety of circumstances.

Powertrain modeling and sizing will probably become more important as the automotive industry develops, particularly in light of the developments in electric and autonomous car technology. Future vehicle powertrain design and development can be made more innovative and efficient by addressing some of the current issues through continued study, cooperation, and standardization. In summary, when applied wisely, powertrain component modeling and sizing are effective techniques that help engineers design cars that are not just cutting edge in terms of technology but also dependable, sustainable, and well-suited to a wide range of customer requirements.

0 notes