#MotorControlUnit

Explore tagged Tumblr posts

Text

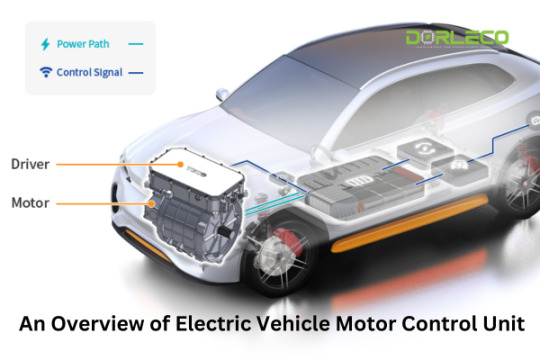

An Overview of Electric Vehicle Motor Control Unit

August 11, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Because of the technological advances made possible by electric motors and batteries, power conversion systems and motor control strategies that optimize efficiency and dependability have to be developed. These days, all of these features are included in the traction inverter, commonly referred to as the Vehicle Motor Control Unit (MCU).

The world’s need for electric cars, or EVs, has grown significantly in the last several years. One of the things boosting the popularity of electric cars is the government’s and automakers’ plan to transition from manufacturing internal combustion vehicles to electric and hybrid vehicles in a few years.

The advancement of lithium-ion battery technology, the dependability and accessibility of high-efficiency powertrain inverters, and the advancements made in engine management and electric motors are all responsible for the availability of EV technology and the reduction of range anxiety among consumers. Electric motors and batteries have facilitated technological advancements, necessitating the development of power conversion systems and motor control procedures that maximize reliability and efficiency.

These days, all of these features are included in the traction inverter, commonly referred to as the Vehicle Motor Control Unit (MCU).

DC versus AC motors

Two primary motor types are used in electric cars:

AC-powered engines:

A motor on alternating current (AC) has three phases and 240 volts. AC motors can also be utilized as a generator to recharge an electric vehicle’s batteries because of their regenerative nature. This motor also has the added benefit of faster acceleration and smoother running on uneven ground. Its cost is higher than that of DC motors, which is its primary disadvantage.

The two main types of AC motors are synchronous and asynchronous motors, also called induction motors. Induction motors can be relied upon, are reasonably priced, and require little maintenance, making them simple to use. In contrast, synchronous motors offer some advantages, including strong low-speed torque, small form factor, high power density, high efficiency, and low weight.

BLDC Motors:

These motors have several benefits over AC motors, such as longer speed ranges, noiseless operation, quicker dynamic reaction times, and more. They have an exceptionally high torque ratio relative to size, making them a great fit for EVs, which require high power density yet lightweight and small form factors.

Moreover, BLDC motors require incredibly intricate hardware and software control. AC motors can store energy for braking and release it for accelerating, but they require an appropriate DC-AC inverter. This restores the essential battery juice while enabling you to drive normally. Some DC systems are more costly and sophisticated than others because they can also accomplish that.

BLDC motors require more sophisticated reversing techniques than AC motors, which can be easily reversed by simply flipping the order of the two phases in the inverter.

Both BLDC and AC motors are viable choices for powering EVs, even though AC motors are preferred when performance and long-range are critical criteria. As with many other electronics applications, the key to this selection is to find the optimal balance between cost and performance.

Algorithms for motor control

While there are many other types of electric motors, we will focus on the AC and BLDC/PMSM DC motors that are commonly seen on electric vehicles (EVs). Consequently, the motor control algorithms used in EVs will depend on the kind of motor and control (open or closed loop). The latter requires the presence of sensors that can accurately determine the position of the motor at any given time.

Trapezoidal control is among the simplest types of BLDC motor control. Even though it’s quite popular and reasonably priced, it has a torque ripple problem when driving.

Sinusoidal control is generally considered to be an improvement over trapezoidal control. The main benefits of this control are less noticeable noise, higher torque at lower speeds, and more precise and seamless operation. To accomplish these, three currents are pushed into each of the three motor windings, and these currents vary smoothly and sinusoidally as the motor rotates. Precise rotor position measurement can be achieved using encoders or resolvers to provide smooth sinusoidal modulation of the motor currents while the motor rotates.

While sinusoidal control is very successful at low motor speeds, it becomes limited at high motor speeds due to an increase in the frequency of the sinusoidal signal. At high speeds, torque production decreases and efficiency diminishes.

Originally developed for AC motors, Vector Control, often known as FOC for Field Orientation Control, is the most advanced control method available today. An electric motor’s torque is influenced by the rotor and stator fields, and it is greatest when they are orthogonal.

The FOC approach aims to replicate the orthogonal relationship present in an AC or BLDC motor. A two-orthogonal component, FOC stands for variable frequency control of the stator in a three-phase motor. One component is the torque, which is determined by the motor speed and the location of the rotor; the other is the magnetic flux produced by the stator.

Field Oriented management uses two techniques to manage torque and flux separately:

Direct FOC: From flux estimation or measurement, the rotor flux angle is directly determined.

Indirect FOC: The slip calculations and the available speed are used to deduce the rotor flux angle. When using a dynamic model of an AC induction or BLDC motor, vector control can be computed with the use of intricate algorithms and knowledge of the terminal current and voltages. However, this method requires a lot of processing power to use well.

Vector-based motor control has the natural benefit of being able to control multiple AC, PM-AC, or BLDC motors using the same scheme. The FOC technique allows brushless motors to reach up to 95% efficiency, which is efficient within the maximal speed range. Its accuracy and precise control also allow the motor speed to be decreased to almost 0 rpm.

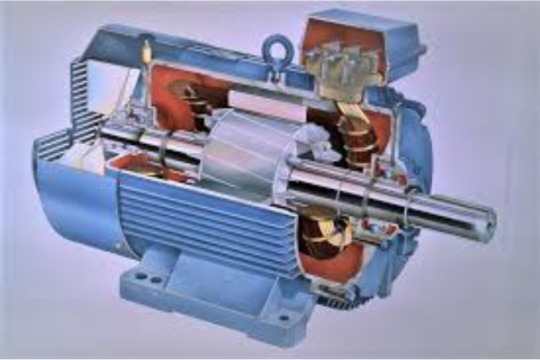

Figure 1 is an example diagram for a three-phase BLDC motor control. Six power transistors are involved, one for each of the three phases, or three half-bridges altogether. Three PWM signals are typically used to activate them, and an MCU or integrated driver IC controls the timing and sequence of these signals. The microcontroller receives positional feedback from three Hall sensors. An analogous picture that illustrates how to control an AC induction motor is picture 2. Here, an accurate encoder interface provides the position feedback.

Sensor versus Vehicle Motor Control Unit without sensors

BLDC motors are more challenging to operate and require an understanding of the rotor position and mechanism to commutate the motor because they are not self-commutating. Measurement of the motor speed and/or motor current and a PWM signal to control the motor speed and power are two more prerequisites for closed-loop speed control.

BLDC motors achieve absolute position sensing by detecting the rotor position with specific position sensors. Consequently, costs increase and the number of cables increases. By using the motor’s back-emf (electromotive force) to estimate the rotor position, sensor-free BLDC control does away with the requirement for position sensors. For low-cost variable speed applications like fans and pumps, sensor-less control is crucial. Sensor-less control is also necessary for compressors that use BLDC motors, including those in refrigerators and air conditioners.

Position sensors are available in three main types:

Hall-effect sensors reduce design complexity and are cheap. Yet, their resolution is subpar when compared to other sensors.

Encoders are expensive and require digital processing.

Resolvers: Digital processing must be used to obtain the optimal resolution.

Resolvers and encoders are typically used in high-precision motor control applications in the automotive and industrial industries.

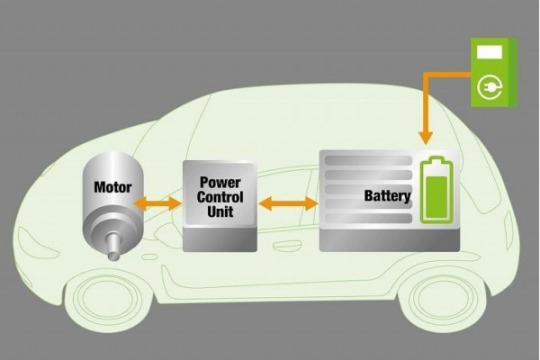

Motor control unit

The batteries, which are DC power sources, and the motor (AC or BLDC) are interfaced with each other by an electrical module known as the Motor Control Unit (MCU). Its main duty is to control how fast and how much acceleration the EV experiences when the throttle is applied.

The following are some of an MCU’s primary responsibilities:

Control the motor’s torque and speed. Switch the engine on and off. Reverse the motor’s direction. brakes that produce energy again. When the motor is braking, it acts as a generator since the back-emf it produces is higher than the DC supply voltage to the MCU. This potential difference causes current to flow from the motor to the battery through the Vehicle Motor Control Unit.

The Vehicle Motor Control Unit uses a range of safety measures, including the following, to protect EV components:

Overvoltage: this occurs when the input battery voltage exceeds permissible limits.

Under voltage: If the MCU operates below the lower voltage cutoff, it will drain the battery more fully and may result in a thermal runaway that could destroy the cells permanently or result in a decrease in performance.

Overcurrent: If the Vehicle Motor Control Unit detects an overcurrent, it will cut off the battery supply. It does this continuously.

Overheating: as with the previous point, this happens when the internal temperature of the motor controller goes above a safe threshold.

Conclusion:

In conclusion, this overview of electric vehicle motor control provides a comprehensive understanding of the key components and characteristics that dictate how the electric motors in these cars function. Electric vehicles are crucial for reducing carbon emissions and raising energy efficiency as the automobile industry shifts to more sustainable and ecologically friendly forms of mobility.

The motor control systems — which comprise inverters, motor controllers, and several sensor types — that have been discussed form the basis of electric vehicle propulsion. The intricate relationships between these components ensure optimal efficacy, security, and performance when the car is driving. Additionally, as technology advances, motor control algorithms get better and better, providing electric car users with better acceleration, regenerative braking, and overall driving experiences.

#autonomousvehicle#MotorControlUnit#Powertrainmodelling#VCU#EVSoftware#evCODE#ADASCode#VCUSupplier#VCUManufacturer

0 notes

Text

#FRIWO#manufacturer#electromobility#motorcontrolunit#growth#electricvehiclesnews#electricvehicles#evnews

0 notes

Text

An Overview of Electric Vehicle Motor Control Unit

January 31, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Electric motors and batteries have produced technological results that have necessitated the development of power conversion systems and motor control strategies that maximize efficiency and dependability. These days, the traction inverter, also known as the Motor Control Unit (MCU), incorporates all these functions.

The demand for electric vehicles, or EVs, has increased dramatically in the world recently. The government and automakers’ decision to switch from producing internal combustion vehicles to electric and hybrid vehicles within a few years is one of the factors contributing to the increasing popularity of electric automobiles. The development of lithium-ion battery technology, the accessibility and dependability of high-efficiency powertrain inverters, and the advancements made in engine control and electric motors have all contributed to the accessibility of EV technology and the reduction of range anxiety among users. Electric motors and batteries have produced technological results that have necessitated the development of power conversion systems and motor control strategies that maximize efficiency and dependability.

These days, the traction inverter, also known as the Motor Control Unit (MCU), incorporates all these functions.

DC versus AC motors

In electric cars, two main types of motors are utilized:

Motors AC. An AC motor is a three-phase motor that runs at 240 V and is powered by alternating current. AC motors can also be utilized as a generator to replenish an EV’s battery because of their regenerative characteristic. This motor also has the benefit of greater acceleration and smoother operation on uneven surfaces. The primary disadvantage is that it is more expensive than DC motors.

Asynchronous motors, often known as induction motors, and synchronous motors are the two primary kinds of AC motors. Induction motors are dependable, inexpensive, and easy to operate (they don’t require a lot of maintenance). Conversely, synchronous motors have several benefits, such as low weight, small form factor, high power density, high efficiency, and strong low-speed torque.

BLDC Drives. Compared to AC motors, these motors provide several advantages, including faster dynamic reaction times, noiseless operation, greater speed ranges, and more. They are an excellent fit for EVs, which need high power density but lightweight and tiny form factors, because of their extremely high torque ratio about size.

Moreover, BLDC motors need highly sophisticated hardware and software control. AC motors can recover energy from braking and release it during acceleration, although they do require an appropriate DC-AC inverter. This makes it possible to restore necessary battery power while driving normally. Certain DC systems are more costly and sophisticated because they can also accomplish that.

In contrast to AC motors, which can be easily reversed by simply switching the order of the two phases in the inverter, BLDC motors require more complex reversing techniques.

Although AC motors are favored when performance and long-range are severe requirements, BLDC and AC motors are good options for powering EVs. Finding the ideal balance between cost and performance is crucial in this decision, just like it is in many other electronics applications.

Algorithms for motor control

While there are many various kinds of electric motors, we will concentrate on the ones that are typically seen on electric vehicles (EVs), such as AC and BLDC/PMSM DC motors. Therefore, the type of motor and control (open or closed loop) will determine the motor control algorithms utilized in EVs. For the latter to be possible, sensors that can precisely determine the motor’s position at any given time must be present.

One of the most basic forms of BLDC motor control is trapezoidal control. Despite being highly affordable and well-liked, it has a torque ripple issue when commuting.

Typically, sinusoidal control is regarded as the advancement from trapezoidal control. Reduced audible noise, increased torque at lower speeds, and more accurate and smoother functioning are the primary advantages of this control. The three motor windings are driven with three currents that fluctuate smoothly and sinusoidally as the motor turns to achieve these outcomes. Encoders or resolvers can be used to measure the rotor position accurately, which is necessary to provide smooth sinusoidal modulation of the motor currents as the motor rotates.

Because the sinusoidal signal frequency increases at high motor speeds, sinusoidal control, while highly effective at low motor speeds, becomes limited. Efficiency declines and torque production is reduced at high speeds.

Vector Control (abbreviated FOC, for Field Orientation Control) was first created for AC motors and is currently the most sophisticated control technique on the market. The torque in an electric motor is dependent on the stator and rotor fields, and it reaches its maximum when they are orthogonal.

Replicating the orthogonal relationship found in an AC or BLDC motor is the goal of the FOC technique. FOC, or variable frequency control of the stator of a three-phase motor, is a two-orthogonal component. The torque, which is based on the motor speed and the rotor’s position, is one component and the magnetic flux generated by the stator is the other.

Two methods are used by Field Oriented Control to control torque and flux independently:

Direct FOC: The rotor flux angle is computed directly from flux estimation or measurement.

Indirect FOC: The slip calculations and available speed are used to indirectly determine the rotor flux angle.

Using complex algorithms and knowledge of the terminal current and voltages, vector control can be computed when utilizing a dynamic model of an AC induction or BLDC motor. Nevertheless, the application of this technique necessitates a high level of processing resources.

One inherent advantage of vector-based motor control is the capability to control many AC, PM-AC, or BLDC motors using the same scheme. Brushless motors that use the FOC approach can achieve up to 95% efficiency, which is efficient within their maximum speed range. Additionally, because of its accuracy and tight control, the motor speed may be lowered to nearly 0 rpm.

An analogous figure illustrating the control of an AC induction motor can be found in Figure 2. Here, a precise encoder interface provides the position feedback.

Motor Control Unit: sensor versus sensorless

Because BLDC motors are not self-commutating, they are more difficult to handle and require knowledge of the rotor position and mechanism to commutate the motor. Two more requirements for closed-loop speed control are the measurement of the motor speed and/or motor current and a PWM signal to regulate the motor speed and power.

Absolute position sensing is achieved by BLDC motors by using specialized position sensors to detect the rotor position. Costs increase and there are more wires as a result. By estimating the rotor position using the motor’s back-emf (electromotive force), sensorless BLDC control does away with the requirement for position sensors. For low-cost variable speed applications like fans and pumps, sensorless control is crucial. Sensorless control is also necessary for compressors used in air conditioning units and refrigerators that use BLDC motors.

Position sensors come in three primary varieties:

Hall-effect sensors are inexpensive and simplify designs. But when measured against other sensors, their resolution is poor.

Encoders: they need digital processing and are costly.

Resolvers: the best resolution is achieved at the expense of digital processing.

Motor control unit

An electrical module called the Motor Control Unit (MCU) serves as an interface between the motor (AC or BLDC) and the batteries, which are DC power sources. Its primary responsibility is to regulate the EV’s acceleration and speed in response to throttle input.

An MCU’s primary responsibilities include the following:

Regulate the speed and torque of the motor.

Turn on and off the engine

Turn the motor backward.

Brakes that regenerate energy. Because the back-emf produced by the motor is greater than the DC supply voltage to the MCU, the motor functions as a generator when it is braking. Through the Motor Control Unit, current flows from the motor to the battery as a result of this potential difference.

The Motor Control Unit implements a variety of safety strategies to safeguard EV components, such as:

Overvoltage: this is the result of the input battery voltage going above its bounds.

Under voltage: Should the Motor Control Unit function below the lower voltage threshold, it would draw greater currents from the battery, perhaps leading to a thermal runaway that could cause irreversible damage to the cells or a decline in performance.

Overcurrent: The Motor Control Unit continuously checks the current level and cuts off the battery supply if it detects an overcurrent.

Overheating: similar to the preceding point, this occurs when the motor controller’s internal temperature rises above a safe level.

Conclusion :

To sum up, this overview of electric vehicle motor control offers a thorough grasp of the essential elements and features that determine how these cars’ electric motors operate. As the automotive sector transitions to more environmentally friendly and sustainable modes of transportation, electric vehicles are essential for lowering carbon emissions and increasing energy efficiency.

The core of electric vehicle propulsion is made up of the motor control systems that have been mentioned, which include inverters, motor controllers, and different types of sensors. When a vehicle is operating, the complex interactions between these parts guarantee maximum effectiveness, safety, and performance. Furthermore, technological developments keep improving motor control algorithms, giving owners of electric vehicles improved acceleration, regenerative braking, and overall driving experiences.

To solve issues like range anxiety, advancements in battery technology, and infrastructural development, the shift to electric transportation calls for continuous research and development. The industry is ready to overcome these obstacles and increase the accessibility and appeal of electric vehicles to a wider range of consumers as motor control systems for electric vehicles advance.

To summarise, comprehension of electric vehicle motor control is essential for researchers, engineers, and enthusiasts alike as we jointly strive towards a more environmentally friendly and sustainable future in the transportation sector. Undoubtedly, the continuous advancements and enhancements in electric vehicle motor control will facilitate the extensive integration of electric vehicles and ultimately lead to a more ecologically conscious and clean automotive landscape.

0 notes