#SimulationDrivenDesign

Explore tagged Tumblr posts

Text

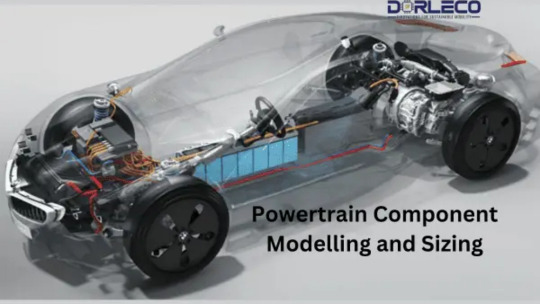

Powertrain Component Modelling and Sizing

Introduction

The dynamic automotive sector is depending more and more on virtual engineering and digital simulations to satisfy strict performance, efficiency, and regulatory requirements. The core of a vehicle’s design is the powertrain, which is the collection of elements that are accountable for generating and distributing power to the wheels. In order to achieve the best possible balance between performance, fuel efficiency, cost, and emissions, powertrain component modelling and size are crucial, regardless of the powertrain’s configuration — internal combustion engine (ICE), hybrid, or entirely electric. The systematic technique, advantages, difficulties, and prospects for powertrain component modelling and sizing in the automotive engineering process are all examined in this blog.

1. Understanding the Powertrain Component

Determining the vehicle’s intended use and performance goals is the first step in any powertrain development cycle. This fundamental stage lays the groundwork for component-level specifications and architectural choices.

Vehicle Type: EV, hybrid, commercial vehicle, sports car, or passenger car.

Performance metrics: include top speed, gradeability, towing capacity, and desired acceleration (0–100 km/h).

Compliance goals include safety regulations, fuel economy requirements, pollution regulations, and sustainability goals.

A thorough comprehension of these factors guarantees that the finished powertrain design complies with regulatory standards and market expectations.

2. Powertrain Architecture Selection

The type of vehicle and its intended use have an impact on the strategic choice of powerplant layout. Among the primary categories are:

Engine Internal Combustion (ICE)

Powertrain Hybrid (PHEV, HEV)

Electric Vehicles with Batteries (BEV)

Electric Vehicles using Fuel Cells (FCEV)

Core elements such the engine, electric motor, battery, gearbox, and control units must interact differently in each architecture. For downstream modelling, it is crucial to map the component interaction and energy flow paths at this point.

3. Modelling at the Component Level

Modelling engines

Modelling for ICE-based systems includes:

Creation of torque-speed curves

Mapping of fuel consumption

Emissions modelling and thermal behaviour

To model operating circumstances, assess combustion efficiency, and investigate transient responses, advanced programs such as GT-Power, AVL Cruise, or MATLAB/Simulink are used.

1.Modelling Transmissions

In this context, the gearbox connects wheel torque and engine power, while modelling helps determine:

Ideal gear ratios

Timing and logic for gear changing

Losses brought caused by inertia and friction

Reactivity and driveability

Single-speed gearboxes are frequently used in electric vehicles; nonetheless, efficiency and thermal considerations are still crucial.

2. Modelling Electric Motors and Batteries

In systems that are electrified:

Electric Motor: Efficiency mapping, torque-speed characteristics, inverter management, and the possibility of regenerative braking are all included in the simulations.

State of charge (SOC), voltage-current profiles, thermal performance, capacity decline, and charging/discharging behaviour are all included in the models of batteries.

Consequently, these components play a vital role in enabling accurate range estimation and supporting effective hybrid control schemes.

3. Control System Modelling

To that end, modern cars use intelligent control algorithms to regulate the flow of torque and energy. Key elements include:

Distribution of power in hybrid automobiles

Energy management systems for batteries (BMS)

Control of traction and stability

Regenerative braking and torque vectoring

Furthermore, control system modelling optimises real-time responses by ensuring smooth interaction between physical components.

4. Component sizing and optimisation

Each component is guaranteed to be neither overdesigned nor underutilised with proper dimensions. Engineers optimise variables like

Engine displacement and output torque

Maximum power and continuous motor rating

C-rate and battery capacity

Gear ratios for transmissions

The proper trade-offs between performance, efficiency, cost, and packing can be achieved with the aid of optimisation technologies (such as genetic algorithms and experiment design).

5. Compatibility and System Integration

The powertrain must function as a cohesive system in addition to its individual performance. Important integration factors consist of:

Thermal control of the battery, inverter, and engine.

Packaging and weight distribution to maintain vehicle dynamics

Features of NVH (Noise, Vibration, Harshness)

Compatibility of mechanical and electrical interfaces

Therefore, ignoring these elements may lead to inefficiencies, reliability issues, or dissatisfied clients.

6. Performance Validation Through Simulation

Subsequently, once components are designed and scaled, system-level simulations are conducted to validate the full powertrain component across real-world scenarios.

Urban driving cycles, such as the FTP-75 and WLTP

Profiles of highway loads

Simulations of hill climbing or towing

Conditions for idle-stop and regenerative braking

Engineers can create control methods and identify bottlenecks early in the process with the help of simulation technologies (such as MATLAB, dSPACE, and IPG Carmaker).

7. Physical Testing and Prototyping

Although simulation offers a theoretical starting point, physical testing is still necessary:

Prototype vehicle builds

Engine test beds and dynamometers for the chassis

Tests of endurance and durability

Prior to mass production, these tests ensure system robustness by validating predictions and identifying unforeseen mechanical, thermal, or ergonomic concerns.

8. Cost Analysis and Compromises

Additionally, a high-performance Powertrain Component needs to be profitable. Cost modelling includes:

Complexity of manufacturing and material selection

Tooling expenses and supplier availability

Implications for warranty and maintenance

In addition, simulations help identify cost-effective solutions without sacrificing critical performance parameters.

9. Iterative Refinement

In practice, the development process is rarely linear; instead, several design iterations are driven by insights gained from simulation, testing, and consumer feedback.

Modifying component specifications

Control logic revision

Power split or thermal load rebalancing

Consequently, this iterative loop ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

10. Records and Adherence

As a result, this iterative loop not only streamlines development but also ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

Logs from simulations and technical reports

Design specifications and the bill of materials

Safety requirements and emissions certifications

Design decision traceability

Proof of due diligence throughout the development process is necessary to comply with international rules (such as those set forth by the EPA, CARB, and UNECE).

Benefits of Powertrain Component Modelling and Sizing:

✔ Performance Enhancement

Fine-tuning for certain objectives, such as high torque, quick acceleration, or fuel economy, is possible through simulation.

✔Enhanced Productivity

Appropriate size improves energy efficiency on both ICE and EV platforms by preventing overdesign and lowering internal losses.

✔ Saving Money

Furthermore, by avoiding needless overspecification, manufacturers can effectively reduce manufacturing and material costs without compromising quality.

✔ Emissions Management

As a result of precise engine mapping and electric system optimisation, CO₂ and NOₓ emissions are significantly reduced.

✔ Predictive Knowledge

Prior to costly tooling and prototyping, simulations identify possible failure areas or inefficiencies.

✔ Personalisation

The architecture and Powertrain Component flexibility made possible by early modelling is advantageous for a variety of vehicle types, including haul trucks and two-wheelers.

✔ Superior Energy Organisation

Reliability and range are directly impacted by efficient battery and power management systems, particularly in EVs and hybrids.

✔ Reduced Market Time

Virtual iterations make faster development cycles possible as opposed to conventional build-and-test loops.

✔ Dependability

Moreover, stress analysis and thermal modelling ensure durability, which in turn lowers warranty claims and enhances brand recognition.

✔ Attention to Regulations

By ensuring early compliance with international safety and emissions standards, manufacturers can significantly reduce the need for costly redesigns later in the development cycle.

Difficulties with Powertrain Component Sizing and Modelling

Despite its strength, this strategy has drawbacks: Model Complexity: It takes knowledge and computing power to accurately simulate multi physics systems. Data Reliability: Reliable input data is necessary for model accuracy, which frequently necessitates rigorous physical testing for calibration. Integration Difficulties: Maintaining balance between electrical, mechanical, and control systems is difficult. Dynamic Operation Limits: Unexpected real-world circumstances are not always taken into account by models. Cost of Software Tools: Smaller businesses cannot afford the sophisticated simulation suites. Rapid Technological Changes: As EVs advance quickly, current models may become outdated. Real-World Parameter Uncertainty: It is challenging to accurately forecast traffic, temperature, and driver behaviour.

Conclusion

At the forefront of contemporary vehicle engineering is the modelling and sizing of powertrain components. In a cutthroat market, they enable automakers and suppliers to create vehicles that are effective, legal, and perform well. Engineers may unlock better ideas while cutting down on time, expense, and environmental effect by combining virtual simulations with actual testing. Modelling techniques will only become more crucial as the sector continues its transition to electrification and autonomous systems. Experts anticipate that future developments in digital twins, AI-driven simulations, and cloud-based co-simulation platforms will further push the limits of accuracy and effectiveness. Powertrain modelling and sizing are essentially strategic enablers of innovation, performance, and sustainability in mobility when used with insight and rigour.

#Dorleco#EVEngineering#PowertrainModelling#AutomotiveInnovation#VCU#CANDisplay#BatteryManagement#SimulationDrivenDesign#ElectricVehicles#MobilitySolutions#FutureOfTransport#EngineeringExcellence#DigitalEngineering

0 notes

Photo

Art by @iso.hedron Sonorous #bear #skull #growth #coral #houdini #sidefx #blender3d #3dartist #3dprinting #3dart #generativedesign #generativeart #algorithmicdesign #procedural #simulationdrivendesign #abstractart #art #artist https://www.instagram.com/p/Cc1HKF5KI9R/?igshid=NGJjMDIxMWI=

#bear#skull#growth#coral#houdini#sidefx#blender3d#3dartist#3dprinting#3dart#generativedesign#generativeart#algorithmicdesign#procedural#simulationdrivendesign#abstractart#art#artist

3 notes

·

View notes