#Precautions for safe use of circuit breakers

Explore tagged Tumblr posts

Text

An article "Some common problems about circuit breakers" was published

An article "Circuit protection dry goods: Some common problems about circuit breakers" was published today Original address: https://www.dhsic.com/news/148

#Circuit protection#Dry goods#Circuit breakers#Common problems with circuit breakers#Types of circuit breakers#Definition of circuit breakers#How to choose the appropriate specifications of circuit breakers#Installation and wiring methods of circuit breakers#Daily maintenance points of circuit breakers#Common types of circuit breaker failures#Precautions for safe use of circuit breakers#Application example guide of circuit breakers#New technologies for smart circuit breakers#How to choose circuit breakers

0 notes

Text

Learning Variable Frequency Drive for 3-Phase Motor: Simplified Guide

Electric motors are everywhere — in buildings, factories, and even in residential homes. Whether you are a technician, engineer, or simply interested, this tutorial will help you learn what a variable frequency drive (VFD) is, how it functions, and why it is so precious.

What is a Variable Frequency Drive (VFD)?

A variable frequency drive (VFD) is an electrical drive device that controls the speed and torque of an electric motor. It does its job by adjusting the frequency and voltage of the power supplied to the motor. Essentially, a VFD enables you to increase or decrease the speed of the motor as needed.

When we are referring to a variable frequency drive for a 3-phase motor, we are talking about a VFD that controls three-phase motors, which are extensively used in industrial machinery, pumps, fans, conveyors, and HVAC equipment.

How Does a VFD Work?

The grid power is generally of a constant frequency (such as 50 Hz in India). A 3-phase motor driven straight off this supply will always operate at the same speed. But suppose you want the motor to be slower or faster

A VFD consists of three principal components:

Rectifier—It converts AC (alternating current) to DC (direct current).

DC Bus—Stores the DC energy.

Inverter—Converts the DC to AC of frequency and voltage that varies.

Advantages of a VFD

There are many reasons why industries like to utilize a VFD in their 3-phase motors:

1. Energy Saving

A motor running at full speed when it doesn’t need to waste electricity. This can cut power bills dramatically.

2. Longer Motor Life

VFDs start and stop motors smoothly, whereas traditional motor starters create a sudden jerk, which sooner wears out parts. With a VFD, the motor is easier to run, leading to longer life.

3. Process Control

Certain processes, like conveyor belts or pumps, need precise control of speed. A variable frequency drive for a 3-phase motor gives operators smooth control of the speed, improving production quality.

4. Reduced Maintenance

With fewer mechanical parts (like valves or dampers), there’s less wear and tear.

5. Increased System Efficiency

Achieving optimum motor performance and matching it with the process requirement, a VFD can do the job of maximizing the overall efficiency of your system.

Applications

Variable frequency drives for 3-phase motors are widely available in most locations, including:

HVAC Systems—Control fans and compressors.

Water Pumps—Control flow and pressure based on demand.

Conveyor Systems—Monitor movement speed for maximum operation.

Elevators and Escalators—Provide a smooth start-stop ride.

Selecting the Right VFD

Selecting the right variable frequency drive for a 3-phase motor is vital for performance and safety. Have a look at these considerations:

Input Voltage: Make sure the VFD is for your supply voltage (typically 230V, 415V, etc.).

Environment: Will it be used in dusty, hot, or wet environments? Then you might need an IP-rated enclosure.

Features: VFDs can have built-in displays, communication ports, or even programmable logic.

Installation Tips

Proper installation ensures the VFD functions safely and efficiently. Here are some simple tips:

Follow Manufacturer Instructions: Always read the manual thoroughly.

Use Correct Wiring: Use shielded cables to avoid electrical noise.

Ventilation: VFDs generate heat. Ensure there is good airflow or place fans if needed.

Earthing and Protection: Earth the system properly and use circuit breakers or fuses.

Safety Precautions

Even though VFDs are safe, their improper handling is dangerous. Always follow these safety precautions:

Turn off all power during maintenance.

Wait for a few minutes for capacitors to discharge.

Never touch live terminals or wires.

Correctly train staff before using or maintaining the VFD.

Future Trends in VFD Technology

Technology is always evolving. Modern VFDs today come with intelligent capabilities:

IoT Connectivity: Remotely monitor and control VFDs via mobile apps or computers.

Self-Diagnostics: Certain VFDs are capable of detecting faults and issuing warnings before things go wrong.

Energy Monitoring: Sophisticated drives can estimate and display real-time energy savings.

As industries trend towards automation and sustainability, variable frequency drive for 3-phase motor demand is likely to increase.

Conclusion

Using a variable frequency drive for a 3-phase motor is one of the smartest ways to control motor performance, save energy, and improve system reliability. Whether you’re managing a factory, a building, or a commercial setup, adding a VFD to your 3-phase motor setup is a cost-effective and eco-friendly decision Originally Published Here:-https://nmagroup.in/variable-frequency-drive-for-3-phase-motor-guide/

0 notes

Text

DIY vs. Electrical Repairs by Professionals: What You Need to Know

When it comes to electrical repairs at home, Homeowners often face the dilemma of whether to undertake electrical repairs themselves or seek professional assistance. While some minor repairs can be safely handled with basic knowledge, others pose serious risks and require expert intervention. In this guide, we’ll help you understand when to roll up your sleeves and when to reach out to a qualified electrician.

Understanding DIY Electrical Repairs

For those proficient with tools, DIY electrical repairs may seem like a viable option. Simple tasks, such as replacing electrical switches or changing a fuse, can be managed without professional help. However, it is important to keep in mind that even these tasks involve risks, so adherence to DIY electrical repair safety tips is essential.

Safe DIY Electrical Repairs

Replacing an Electrical Switch by Yourself – A malfunctioning switch can be replaced with a new one, such as a piano type switch, which enhances both functionality and aesthetics.

Resetting a Tripped Circuit Breaker – If a breaker trips, it can be safely reset after identifying and addressing the cause of the issue.

Changing a Light Fixture – This is a manageable task, provided proper safety precautions are taken.

DIY Electrical Repair Safety Tips

Turn Off the Power – Always switch off the main power supply before handling any electrical accessories.

Use Insulated Tools – These reduce the risk of electrical shocks.

Avoid Overloading Circuits – Distributing electrical loads appropriately is critical to preventing hazards.

Recognize Your Limits – If uncertain about a repair, seek professional assistance.

When to Call a Professional

While certain electrical fixes can be managed, others should be handled exclusively by qualified and licensed professionals to prevent potential dangers, such as electrical fires or serious injuries associated with work.

Electrical Repairs That Require an Expert

Rewiring Your Home – This complex task must comply with stringent safety codes.

Upgrading Electrical Panels– Handling high-voltage systems presents significant risks and should be performed by an expert.

Fixing Faulty Wiring – Symptoms such as flickering lights, frequent power interruptions, or burning odors necessitate immediate professional intervention.

The Advantages of Professional Electrical Services

Enhanced Home Electrical Safety – Professionals ensure all electrical work adheres to safety standards.

Compliance with Electrical Regulations – Licensed electricians follow legal safety codes and best practices.

Long-Term Efficiency and Reliability – Expertly handled electrical repairs offer durability and optimal functionality.

While DIY electrical repairs can be cost-effective and rewarding, understanding one’s limitations is crucial for maintaining home electrical safety. Simple tasks such as replacing an electrical switch or installing a piano type switch can be performed with care, but complex electrical issues should always be entrusted to professionals. Precision Electricals strongly advocates for prioritizing safety over cost savings—because when it comes to electricity, precision and expertise are indispensable.

#electrical safety#electrical switches manufacturers#electrical switches#electric repair safety tips

0 notes

Text

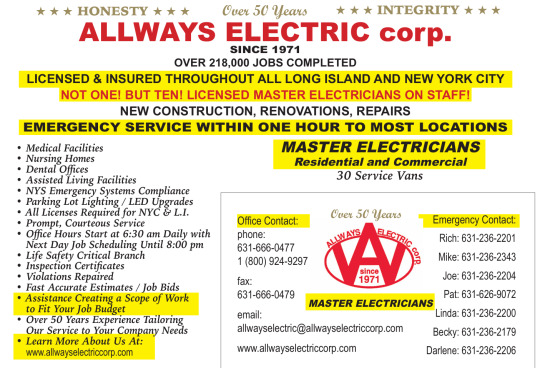

Residential Electrical Wiring in Long Island: A Comprehensive Guide to Mastering the Basics

Residential Electrical Wiring in Long Island: A Comprehensive Guide to Mastering the Basics

From the top resource for residential electrical wiring on Long Island, greetings! Understanding the intricacies of electrical wiring is crucial for both functionality and safety, whether you're building a new house or renovating an existing one. In this book, we'll go over everything you need to know to become an expert in residential electrical wiring on Long Island.

Understanding Electrical Wiring for Residential Properties

Learn the fundamentals of electrical wiring in Long Island homes by embarking on an expedition. We can assist you with everything from basic concepts to advanced techniques.

Why Safe Electrical Wiring Is Important

Find out why proper electrical wiring is necessary for residential buildings. Purchasing high-quality electrical wiring is crucial for several reasons, such as guaranteeing effectiveness, security, and adherence to regulations.

Key Elements of a Residential Electrical System

Examine the essential components of home electrical systems. Effective wiring requires an understanding of a variety of components, including outlets, switches, and circuit breakers.

Electrical Wiring Codes and Regulations for Long Island

Stay informed about the latest electrical codes and regulations in Long Island. Following these rules is essential to ensuring safety and averting potential legal issues.

Types of Wiring Suitable for Residential Properties

Look at the various types of wiring commonly used in residential structures. To make informed decisions, weigh the benefits and drawbacks of several options, such as copper-clad aluminum and aluminum and copper wire.

Methods for Electrical System Planning and Design

Learn the importance of meticulous design and planning when it comes to electrical wiring. Numerous factors, including as load calculations, circuit design, and the placement of outlets and fixtures, affect how safe and efficient an electrical system is.

Safety Procedures for Electrical Wiring Installation

Prioritize safety during the electrical wiring installation process. By using the appropriate tools and equipment and following safety protocols, precautions can help prevent accidents and injuries.

Common Electrical Wiring Errors to Avoid

Avoid common risks that could compromise the safety and functionality of your electrical system. Be aware of these flaws to ensure a smooth and error-free wiring process.

FAQs

Is it necessary to hire a professional electrician for residential wiring projects?

While DIY electrical work may seem tempting, hiring a licensed electrician is highly recommended to ensure safety and compliance with regulations.

What factors should I consider when choosing electrical wiring materials?

Factors such as durability, cost, and compatibility with your home's electrical system should be taken into account when selecting wiring materials.

How often should residential electrical systems be inspected?

It's advisable to schedule regular inspections by a qualified electrician to detect any potential issues and ensure the continued safety and performance of your electrical system.

Can I upgrade my home's electrical system to meet increased power demands?

Yes, upgrading your electrical system may be necessary if you're adding new appliances or experiencing frequent power disruptions. Consult with a licensed electrician to assess your needs and make appropriate upgrades.

What are the signs of electrical problems in residential properties?

Signs such as flickering lights, tripped circuit breakers, and burning odors indicate potential electrical issues that should be addressed promptly by a professional electrician.

Are there any government incentives or rebates available for upgrading residential electrical systems?

Depending on your location and specific circumstances, there may be government incentives or rebates available for energy-efficient upgrades to your home's electrical system. Consult with local authorities or utility companies for more information.

In conclusion

Congratulations for making the first move toward mastering residential electrical wiring on Long Island! The dependability, efficiency, and safety of your home's electrical system may be ensured with the correct knowledge and by following best practices. Prioritize safety at all times and consult a qualified electrician before starting any complex wiring jobs.

#Electrical Wiring Residential Long Island#Electric Repair Service Long Island#24 hour Electrician Long Island

0 notes

Text

Expert Tips for Landscape Lighting Repair in Pennsylvania

Picture this: a cozy evening in Pennsylvania, your garden illuminated by soft, warm lights highlighting its natural beauty. Landscape lighting not only enhances the look of your home but also boosts security and curb appeal. However, when your outdoor lighting system falters, it can be frustrating and unsafe. That’s where this guide comes in.

You're in the right place if you're a Pennsylvania homeowner dealing with flickering lights, broken fixtures, or system malfunctions. This blog will guide you through the importance of landscape lighting, teach you how to tackleLandscape lighting repair work safely and provide a step-by-step guide to fixing everyday problems.

Plus, we’ll share maintenance tips to maximize your system's lifespan and local resources to help you find professional support.

Why Landscape Lighting is Vital

Landscape lighting is more than decorative. It transforms outdoor spaces into inviting areas, deters intruders, and increases the usability of your yard at night. However, Pennsylvania’s varied climate—its icy winters, humid summers, and occasional storms—can affect outdoor lighting systems. Common issues include:

Corroded wires due to moisture.

Damaged fixtures from temperature fluctuations or falling debris.

Burnt-out bulbs or faulty LEDs.

Tripped circuit breakers caused by bad weather.

Knowing how to repair these issues will save you time and money and ensure that your yard always looks its best.

Safety First: Essential Repairs Start With Precautions

Before reaching for your toolbox, preparing for a safe repair process is essential. Landscape lighting repair involves electricity, so safety should always be your priority.

Turn Off the Power: Always cut the power to your lighting system at the breaker or control panel before handling wires or fixtures. Always use a voltage tester to ensure no electrical current is present.

Wear Protective Gear: Gloves and safety glasses protect you from electrical shocks and debris.

Check the Weather: Avoid working on your outdoor lighting system during rain or extreme weather conditions. Moisture can be dangerous when combined with electrical systems.

Inspect for Wildlife: Check for nests, bugs, or small critters that may have taken up residence around your light fixtures.

Keep Tools Dry: Always use insulated tools and ensure your workspace is dry and secure.

Following these precautions will create a safe repair environment and avoid unnecessary mishaps.

Step-by-Step Guide to Landscape Lighting Repair

To troubleshoot and fix common landscape lighting issues in your yard, follow these steps:

Step 1: Check the Power Source

Begin by confirming the issue isn’t a power outage or disconnected system:

Inspect the breaker box for tripped circuits.

Confirm that the transformer is plugged in and your timer or control panel is functioning correctly.

If the problem isn’t with the power source, move on to the lighting system.

Step 2: Replace Burnt-Out Bulbs or Faulty LEDs

If some lights are dim or completely out, the issue might be with the bulbs:

Remove the bulb carefully and inspect for signs of damage or burnout.

Replace with a new bulb of the same wattage or the appropriate LED replacement. Ensure it is seated securely.

Step 3: Repair or Replace Damaged Wires

Pennsylvania’s harsh winters and unpredictable storms often lead to corroded or chewed wires:

Locate the damaged area using a voltage tester.

Strip the wire ends, reconnect them, and secure them with electrical tape or waterproof connectors.

If damage is excessive, replace the whole section of the wiring.

Step 4: Clean and Seal Corroded Fixtures

Fixtures exposed to the elements can develop rust or blockages:

Disassemble the fixture and clean it with mild soap and water.

Apply a silicone sealant to prevent future corrosion.

Step 5: Address Timer or Control Panel Issues

If your lights won’t turn on, the control system may be at fault:

Reset the manual timer or intelligent control app.

Replace batteries or address faulty connections within the control panel.

Step 6: Test the System

Once all repairs are complete, restore power and test your system to ensure everything works correctly.

Brighten Up Your Yard Today

Fixing your landscape lighting doesn’t have to be intimidating. By following this guide and taking a step-by-step approach, you’ll soon have your Pennsylvania yard looking just as magical as it deserves. A little effort goes a long way, whether repairing a single light or adjusting your entire system.

And remember, if things feel overwhelming, professional help is just a phone call away. Keep your outdoor spaces well-lit, beautiful, and safe all year round.

#landscape lighting repair#landscape lighting installation#landscape lighting installers near me#landscape lighting repair near me#landscape light installers near me#landscape lighting services

0 notes

Text

How to Handle a Broken Bulb While You Clean Up

Like a scene from a suspenseful movie, a broken bulb can create an unexpected mess and potential hazards in your home. Before you jump into cleanup mode, it’s vital to understand the right steps to guarantee your safety and prevent further accidents. With the right approach, you can turn an unfortunate situation into a manageable task. But where do you start? Let’s break down the essential steps you need to take.

Key Takeaways Ensure safety by wearing thick gloves and clearing the area of pets, children, or hazards before starting the cleanup. Turn off the power at the circuit breaker to prevent electrical accidents while handling the broken bulb. Use a broom and dustpan to collect larger shards, and damp paper towels for tiny fragments to avoid injury. Dispose of all collected pieces in a sturdy, puncture-resistant bag and follow local hazardous waste disposal guidelines. Consider calling a professional if the cleanup feels overwhelming or if the broken bulb contains hazardous materials. Assessing the Situation

When you find a broken bulb, it’s crucial to assess the situation quickly to prevent any injuries.

First, take a moment to observe your surroundings. Verify there are no pets or children nearby who could accidentally step on the shards.

Next, identify the type of bulb; some may contain hazardous materials. If you’re in a public space, alert others to the danger.

Carefully note where the largest pieces lie, so you can clean them up efficiently later.

Remember, it’s important to stay calm and composed; your ability to house cleaning company handle the situation will help others feel safe too.

Ensuring Your Safety

When dealing with a broken bulb, your safety comes first.

Make sure you wear protective gear, clear the area of any hazards, and use the right tools to handle the situation.

Taking these precautions will help prevent injuries and make the cleanup process smoother.

Wear Protective Gear

To guarantee your safety while handling a broken bulb, it’s crucial to wear protective gear that minimizes the risk of injury.

By taking this precaution, you not only protect yourself but also set a good example for others around you.

Here are four items to keep in mind:

Safety Glasses: Shield your eyes from tiny glass shards.

Gloves: Use heavy-duty gloves to protect your hands from cuts.

Closed-Toe Shoes: Wear sturdy shoes to safeguard your feet from potential punctures.

Long Sleeves: Opt for long-sleeved clothing to cover your arms from sharp edges.

Clear the Area

Before you start cleaning up a broken bulb, it’s essential to clear the area around it.

Confirm to remove any nearby items that could get in the way or become damaged. This includes furniture, rugs, and any delicate decorations.

If you’re in a shared space, kindly inform others to stay clear until you’ve finished the cleanup. This guarantees everyone’s safety and helps prevent injuries.

Use Proper Tools

Once you’ve cleared the area, gather the right tools to confirm your safety during the cleanup.

Having the proper equipment not only protects you but also assures you can serve others effectively by preventing further accidents.

0 notes

Text

Is It Safe to Reset a Tripped Breaker Yourself?

Power loss due to a tripped circuit breaker is a typical household problem. Most homeowners who face electrical maintenance in Calicut tend to ask if it's safe to reset a breaker by themselves. Resetting a breaker might be easy, but it's important to know when it's safe—and when you need to hire a professional.

What Causes a Circuit Breaker to Trip?

Circuit breakers are made to safeguard your home's electrical system from overloads or short circuits. They will automatically trip if they sense an issue, including:

Too many appliances plugged into a single circuit

A malfunctioning appliance pulling too much current

Short circuits or ground faults

Wiring problems or moisture exposure

It's necessary to know what caused the breaker to trip before resetting it.

How to Safely Reset a Breaker

If you're sure the problem isn't recurring, use these steps to reset your breaker safely:

Turn off or unplug the appliances in the affected circuit.

Find your breaker panel and locate the switch in the "off" or middle position.

Solidly throw it over into the "off" position, and then back into "on."

This might restore power. But if the breaker trips again right away, stop and call a pro.

When You Shouldn't Reset It Yourself

If resetting the breaker is a regular job, there might be a more critical problem. Repeatedly tripping breakers can signal overloaded circuits, worn-out wiring, or faulty appliances. These are cases that need to be inspected and repaired by a professional electrician.

Never try a reset if you observe:

Burning odors or smoke

Sparks from outlets or the panel

Visible wire or breaker damage

Conclusion

Reloading a tripped breaker can be safe if done properly and judiciously. But repeated tripping or damage indicators are warning signs. For professional analysis and dependable electrical maintenance in Calicut, rely on the experts at Fixail. Your safety is worth taking extra precautions.

#ElectricalService#Electrician#ElectricalRepairs#LightingSolutions#SafeElectricity#EnergyEfficiency#ElectricalMaintenance

0 notes

Text

Arc Flash Study

ETAP (Electrical Transient Analyzer Program) is a powerful software tool widely used for performing arc flash analysis as part of comprehensive electrical safety studies. Its advanced capabilities make it a preferred choice among engineers and safety professionals aiming to comply with NFPA 70E and IEEE 1584 standards. An arc flash study using ETAP helps identify potential electrical hazards, calculate incident energy levels, and determine the appropriate Personal Protective Equipment (PPE) requirements for safe work practices.

The arc flash analysis process in ETAP begins with building a detailed model of the electrical power system. This model includes essential data such as system voltage, fault current, protective device settings, conductor lengths, and equipment ratings. ETAP’s intuitive interface allows users to accurately represent the electrical network and input necessary parameters.

Once the model is complete, ETAP performs short-circuit calculations to determine the available fault currents at various system nodes. The software then calculates the incident energy levels and arc flash boundaries for each equipment location. These calculations are based on the methodologies outlined in IEEE 1584, ensuring that the results are both accurate and industry-compliant.

One of the most significant advantages of ETAP is its ability to generate detailed arc flash reports and labeling. The software automatically produces equipment-specific labels that display critical information such as incident energy, arc flash boundary, and required PPE categories. These labels help workers quickly understand the necessary safety precautions before performing any maintenance or operational tasks.

ETAP also offers coordination analysis to ensure that protective devices are properly set to minimize arc duration and reduce incident energy levels. By optimizing relay settings and breaker configurations, ETAP helps reduce arc flash risks and enhances overall system safety.

Regular arc flash studies using ETAP are essential for maintaining up-to-date safety practices, especially when system modifications or upgrades occur. Implementing ETAP’s arc flash analysis capabilities ensures that facilities remain compliant with safety regulations while protecting personnel from hazardous arc flash incidents.

0 notes

Text

How do I fix flickering lights in my Monmouth home?

Flickering lights can be more than just an annoyance – they could signal serious electrical issues in your Monmouth home. This guide will help you diagnose and resolve lighting problems safely and effectively.

Understanding Flickering Light Causes

1.Common Electrical Issues

Potential reasons for flickering lights include:

Loose light bulb connections

Voltage fluctuations

Overloaded circuits

Aging electrical systems

Faulty light fixtures

Wiring problems

2. Simple Troubleshooting Steps

Initial checks to perform:

Tighten light bulb connections

Check for loose lamp plugs

Verify light switch functionality

Inspect visible wiring

Test different light fixtures

3. Voltage-Related Problems

Voltage issues can cause persistent flickering:

Normal voltage range: 120 volts

Acceptable fluctuation: ±5%

Significant variations indicate serious problems

Use voltage meter for precise measurements

4. Circuit Overload Indicators

Signs of overloaded electrical circuits:

Lights dim when appliances turn on

Frequent circuit breaker trips

Multiple devices on same circuit

Older home electrical systems

Limited circuit capacity

5. Professional Diagnostic Techniques

Advanced detection methods:

Thermal imaging

Circuit load analysis

Comprehensive electrical inspection

Advanced diagnostic equipment

Professional voltage testing

Potential Risks of Ignored Flickering Lights

Electrical fire hazards

Property damage

Increased energy consumption

Potential short circuits

Compromised electrical safety

DIY Safety Precautions

Turn off power before inspection

Use proper safety equipment

Avoid complex repairs

Consult professionals for major issues

Never ignore persistent problems

When to Call an Electrical Professional

Immediate professional help needed if:

Widespread flickering occurs

Burning smell detected

Visible wire damage

Frequent circuit breaker trips

Older home electrical system

Unexplained electrical issues

Prevention Strategies

Regular electrical maintenance

Annual home electrical inspections

Update aging electrical systems

Install modern circuit breakers

Use surge protectors

Monitor electrical load

Monmouth-Specific Considerations

Historic home wiring challenges

Seasonal electrical stress

Local building code compliance

Regional electrical infrastructure

Protect Your Home from Electrical Hazards!

Don't let flickering lights compromise your home's safety. Contact All Seasons Monmouth Handyman for expert electrical diagnostics and repair services today!

0 notes

Text

AULTEN COPPER Mainline Voltage Stabilizer for Home 5 KVA Heavy Duty

What is Voltage Fluctuation at Home?

Voltage fluctuation at home refers to sudden and irregular changes in the electrical voltage supplied to your appliances. These fluctuations can manifest as sudden increases (surges) or decreases (sags) in voltage, which can be caused by factors like power grid issues, electrical storms, faulty wiring, or heavy appliances switching on and off. These fluctuations can cause appliances to malfunction, overheat, or even break down over time, leading to expensive repairs or replacements.

Causes of Voltage Fluctuations in Homes

Power Grid Issues: Power plants sometimes experience disturbances due to demand spikes or technical failures, which can lead to voltage fluctuations reaching homes.

Weather Conditions: Storms, lightning, and other extreme weather events can cause temporary power interruptions or fluctuations in the supply voltage.

Electrical Overloads: When too many appliances are connected to a single circuit, the power load can exceed its capacity, resulting in voltage drops or surges.

Faulty Wiring or Connections: Old, damaged, or improperly installed wiring can cause inconsistent voltage supply, resulting in fluctuations.

Appliance Switching: Large appliances like air conditioners or refrigerators switching on and off can cause a temporary dip or spike in voltage, affecting other devices in the home.

Impact of Voltage Fluctuations on Home Appliances

Voltage fluctuations can have serious consequences for household electronics and appliances:

Damage to Sensitive Electronics: Computers, TVs, and other sensitive devices can suffer from data loss or permanent damage if exposed to fluctuating voltage for extended periods.

Reduced Lifespan of Appliances: Even minor voltage fluctuations over time can shorten the lifespan of devices, causing them to wear out faster than expected.

Inefficiency: Appliances may not operate at their optimal capacity during voltage fluctuations, leading to poor performance and higher energy consumption.

How to Protect Your Home from Voltage Fluctuations

To protect your home appliances from the harmful effects of voltage fluctuations, you can:

Use a Voltage Stabilizer: A voltage stabilizer regulates the incoming voltage to ensure it remains within a safe range, offering protection for sensitive appliances.

Install Surge Protectors: These devices protect against sudden spikes in voltage, especially from lightning or power surges, preventing damage to electronics.

Regular Electrical Maintenance: Ensure your home’s electrical wiring and circuit breakers are in good condition by having them checked regularly by a professional.

Conclusion

Voltage fluctuations are a common issue in many homes, but with the right precautions, you can minimize their impact. Using a voltage stabilizer, surge protector, and ensuring proper electrical maintenance will safeguard your appliances, improving their performance and extending their lifespan.

#voltage fluctuation at home#best stabilizer for home 5kva price#3kva stabilizer price#Aulten stabilizer

0 notes

Text

How to Handle an Electrical Emergency Before an Electrician Arrives in Red Deer

Electrical emergencies can occur at any time, and knowing how to respond quickly and safely is crucial. Whether it’s a power outage, sparking wires, or an electrical fire, understanding the necessary steps can protect both people and property. When facing such situations, contacting emergency electrical services should be your top priority, but in the meantime, here’s what you can do to manage the situation effectively.

1. Assess the Situation

Before taking any action, evaluate the severity of the electrical issue. If you notice burning smells, smoke, or exposed wires, it’s essential to stay calm and act cautiously. Avoid touching anything that appears damaged or sparking.

2. Turn Off the Power

If it’s safe to do so, switch off the main power supply at the circuit breaker to prevent further damage or hazards. This step is particularly important if there is flooding or exposed wiring involved.

3. Stay Away from Electrical Fires

In the event of an electrical fire, never use water to extinguish it, as this can cause electrocution. Instead, use a Class C fire extinguisher or smother the flames with a fire blanket if the fire is small and manageable.

4. Avoid Direct Contact

If someone has been electrocuted, do not touch them directly, as the current may still be active. Instead, turn off the power and use a non-conductive object such as a wooden stick to move the person away from the electrical source before calling emergency services.

5. Unplug Faulty Appliances

If a malfunctioning appliance is causing sparks or excessive heat, unplug it immediately if it’s safe. Avoid using it until a professional electrician inspects and repairs the issue.

6. Evacuate If Necessary

If the electrical emergency presents an immediate danger, such as a major fire or risk of explosion, evacuate the building and call emergency services for assistance. Do not attempt to resolve the issue on your own in such situations.

7. Call a Professional Electrician

Once you have taken the necessary precautions, contact a licensed electrician to assess and repair the issue. Prompt action can prevent further damage and ensure the safety of your home or business.

Conclusion

Handling an electrical emergency requires a calm and methodical approach to minimize risks and protect your property. By following these steps, you can prevent further hazards until professional help arrives. For expert assistance, trust a residential electrician in Red Deer from Bryant’s Electrical Ltd. to provide reliable and timely solutions for all your electrical needs.

#emergency electrician#commercial electrician#red deer electrician#residential electrical repair red deer

1 note

·

View note

Text

5 Tips to Prevent Air Conditioner Fire Hazards

Air conditioners are vital appliances for maintaining comfort, especially during the hot summer months. However, they can also pose fire hazards if not properly maintained and handled. From electrical malfunctions to overheating, various risks can turn a seemingly harmless unit into a potential fire hazard. Thankfully, many of these are avoidable with proper care and precaution. With this, here are some essential tips to ensure your air conditioning Sydney system operates safely and efficiently, helping you reduce the chance of a fire in your home or business.

Regular Inspections

Air conditioners are essential for comfort in many homes and businesses, but like any electrical appliance, they carry the risk of fire if not properly maintained. Regular inspections are one of the most effective ways to prevent potential fire hazards related to air conditioning units. These inspections ensure that all components of the air conditioning system are functioning properly and that safety protocols are in place.

Remember that the compressor and fan motors in an air conditioning system are critical components that can overheat if not properly maintained. If the motors become clogged with dust or debris, they can overheat, increasing the risk of a fire. Regular inspections include cleaning and lubricating these parts to ensure they are working efficiently and safely. A buildup of dust and debris can also impede airflow, causing the unit to work harder than necessary, which can lead to overheating. By keeping these components clean and well-maintained, you reduce the chances of overheating and potential fire hazards.

Clean Filters Frequently

The air filter's primary function is to catch particles and prevent them from reaching sensitive components like the evaporator coils. Over time, the filter can accumulate dust, dirt, and other debris, which causes it to become clogged. When this happens, airflow through the system is reduced. This reduction in airflow causes the air conditioner to work harder to cool the space, which can lead to overheating of various components, such as the compressor or the motor. Overheated parts, particularly electrical ones, increase the risk of short circuits, sparking, or even fires. Regular cleaning or replacement of the air filter ensures that air can flow freely through the system, reducing the chances of overheating and mitigating fire hazards.

Proper Installation

If the wiring is not installed according to the manufacturer’s guidelines or local electrical codes, it can lead to overheating, electrical shorts, or even sparks that can ignite a fire. Good thing a professional technician ensures that all electrical connections are securely and correctly made, using the appropriate gauge wires and circuit breakers. Proper grounding of the unit is also critical, as improperly grounded units can increase the risk of electrical shocks or fires. By adhering to safety standards, a properly installed air conditioner reduces the possibility of electrical faults that could lead to fire hazards.

Keep Flammable Materials Away

In the unfortunate event of an air conditioner malfunction leading to a fire, having flammable materials in close proximity can cause the fire to spread rapidly. Cluttered areas around the unit can exacerbate a fire by providing extra fuel that allows the flames to grow uncontrollably. On the other hand, keeping the area around the air conditioning unit clear of materials such as plastic containers, paper towels, or cleaning rags reduces the chances of a small fire turning into a larger disaster.

Call a Professional for Repairs

Parts of the air conditioner, such as the fan motor, capacitor, or compressor, may wear out or fail. If these components are not replaced promptly, they can lead to overheating or electrical failure, increasing the risk of fire. A professional technician is trained to identify worn-out or faulty parts that may not be immediately obvious to the homeowner.

Also, in some air conditioning systems, especially those that include heating capabilities, gas leaks can pose significant fire risks. If there is a problem with the gas line or combustion chamber, it could lead to an explosion or fire. A professional technician is equipped to inspect the entire system, including any heating components, for leaks or gas-related issues.

Incorporating these preventative tips into your regular air conditioner maintenance routine can reduce fire hazards. Always remember that air conditioners are complex appliances that require attention and respect for their potential dangers. By taking these proactive steps, you extend the lifespan of your unit and protect your home from unnecessary fire risks. Stay vigilant, keep up with regular maintenance, and be aware of the signs of any potential issues to keep your air conditioning system safe and reliable.

0 notes

Text

Basic Electrical Safety Tips for Home

Electrical safety is crucial to prevent accidents, injuries, or damage to your home. At SK Electricals, your trusted electrical contractors in High Wycombe, we recommend following a few simple precautions to reduce the risks associated with electricity. Always ensure that your wiring is up to code, avoid overloading outlets, and regularly inspect electrical appliances for damage. Keep water away from electrical devices, use proper extension cords, and never attempt DIY repairs unless you're qualified. Install smoke detectors and circuit breakers to enhance safety. These basic electrical safety tips from SK Electricals help keep your home secure while promoting a safe and comfortable living environment.

0 notes

Text

The Risks of DIY Electrical Panel Repair in Antelope: Why You Should Trust the Experts at Hagan Electric

When it comes to electrical systems, safety should always be a top priority. While the idea of saving money by tackling electrical repairs on your own might seem appealing, DIY electrical panel repair can lead to serious risks, especially when working with complex systems like your electrical panel. At Hagan Electric, we understand the importance of maintaining a safe, functional electrical system, which is why we strongly recommend leaving electrical panel repair to the professionals. In this article, we’ll highlight the risks associated with DIY electrical panel repair and why it’s essential to call in experts like us to ensure your home in Antelope, stays safe and efficient.

The Complexity of Electrical Panel Systems

Your electrical panel is the central hub of your home’s electrical system, responsible for distributing electricity to various circuits and appliances. It’s a critical component that requires technical knowledge and experience to repair or replace. Unlike simpler home repairs, electrical panels involve high-voltage connections, intricate wiring, and safety protocols that can be difficult for the average homeowner to understand.

DIY enthusiasts may attempt electrical panel repairs to save on labor costs, but handling electrical work without the proper training can lead to severe consequences. Here are some of the risks associated with DIY electrical panel repair:

1. Electrical Shock and Injury

The most immediate and obvious risk of attempting electrical panel repair yourself is the potential for electrical shock. Even if the power is turned off, there are still components within the panel that can hold a charge. Without the right knowledge and precautions, you could be at risk of serious injury or even death. An experienced electrician knows how to safely manage the electricity in the panel and ensure that no part of the system is dangerous to touch.

2. Fire Hazards

Electrical panels are designed to prevent overloads and short circuits, which can cause fires. If you make an error while repairing the panel—such as miswiring or improperly installing a breaker—you could inadvertently create a fire hazard. A faulty electrical panel can overheat, sparking a fire in your home. With DIY repairs, the risk of making a mistake increases, which could have devastating consequences for both your property and your safety.

3. Voiding Your Homeowner’s Insurance

Many insurance policies require homes to adhere to local electrical codes and regulations. If you attempt DIY electrical panel repairs, you risk violating these codes, which could result in your homeowner’s insurance being voided. In the event of a fire, electrical damage, or another accident related to electrical failure, your insurance may refuse to cover the costs, leaving you financially responsible for repairs and damages. Hiring a licensed professional ensures that your repairs are done to code and that you’re fully protected.

4. Inaccurate Diagnosis of the Problem

Electrical panel issues can stem from a variety of sources, including faulty wiring, damaged breakers, or outdated components. Without a trained eye, it can be difficult to accurately diagnose the root cause of the problem. A professional electrician will be able to quickly identify the issue and provide a targeted solution, saving you time and frustration. DIY repairs, on the other hand, may not resolve the underlying problem and could potentially make the situation worse.

5. Potential for Long-Term Damage

Electrical systems are complex, and even a small mistake during DIY repairs can lead to long-term damage. Misconnections, improper installation, or using the wrong components can cause lasting issues, including inefficient energy use, unreliable power supply, and even permanent damage to appliances and electronics in your home. Professional electricians ensure that repairs are done correctly the first time, preventing any further damage to your electrical system.

Why Trust Hagan Electric for Your Electrical Panel Repairs?

At Hagan Electric, we’ve been serving Antelope, CA, homeowners for years, providing top-quality electrical services with a focus on safety, reliability, and customer satisfaction. Our team of licensed and experienced electricians is trained to handle even the most complex electrical panel repairs, ensuring that your home’s electrical system is safe and up to code.

By choosing Hagan Electric, you’ll benefit from:

Expert Technicians: Our team has extensive knowledge and experience working with electrical panels, so we can quickly identify and resolve issues.

Safety Assurance: We prioritize safety in every job, adhering to the highest safety standards to protect both your home and our technicians.

Compliance with Local Codes: We ensure that all repairs and installations comply with Antelope’s local electrical codes, keeping your home safe and your insurance valid.

Guaranteed Work: We stand behind the quality of our work, offering guarantees on all our services to give you peace of mind.

Don’t Risk Your Safety—Call Hagan Electric Today!

Electrical panel repairs are not a DIY project you should take on lightly. The risks involved can be costly, dangerous, and even life-threatening. Instead of attempting electrical repairs yourself, trust the experts at Hagan Electric to get the job done right the first time. Whether you’re dealing with a malfunctioning electrical panel, frequent circuit breaker tripping, or need an upgrade, we’re here to help.

Contact Hagan Electric today to schedule a consultation or emergency electrical panel repair service around Antelope area. Call us or visit our website to get started! Keep your home safe and powered with Hagan Electric’s professional electrical services.

Hagan Electric

8149 Hearth Pl, Antelope, CA 95843

(916) 858-9487

0 notes

Text

Insulated Tools: The Defender Against Electric Dangers

Safety when working with electricity is never an option; it is a must. One of the best tools for safety against electric dangers is using insulated tools. Specifically designed to protect users from electric shock, these are essential tools used by electricians, engineers, and even DIYers who operate regularly with live electrical systems. We would discuss the importance of insulated tools, their features, applications, and why Krishan Brothers' range of insulated tools is such a great option for anyone working in electrical environments.

What Are Insulated Tools?

Special hand tools with an insulating layer through which current does not flow; they cannot flow through the tool to a human being when handling them. In fact, tools have high voltage ratings of up to 1,000 volts, as well as the ability to live circuits with safety while being used for all purposes at the workplace and in homes.

Important Insulated Tool Attributes

Strong Grade of Isolation

The insulated tools are abrasion-resistant and block electrical currents, keeping their users safe.

Ergonomics

The tools are ergonomic in construction; they are made to feel comfortable and efficient, with little fatigue if used for extended periods. In addition, the tool is firmly gripped.

Durability

These tools are created from strong materials and can be used in rough environments without breaking down easily.

Variety

Insulated tools have a variety ranging from pliers and cutters up to screwdrivers, wrenches, etc.

Safety Standards Compliance

Tools such as those from Krishan Brothers are made up to international safety standards for safe and trouble-free operation.

Applications of Insulated Tools

1. Electricity Maintenance

For electricians working on the circuit repair, changing breakers, or even installation of wires, insulated tools ensure that risk-free handling is there for the live circuits.

2. Industrial Applications

In factories and industrial premises where routine live equipment maintenance is always conducted, insulated tools provide personnel with added comfort for handling risky operations.

3. Automobile Repairs

Modern vehicles are mainly electric and are hybrid or electric. Mechanics in this domain need insulated tools.

4. Household Revamp

For the do-it-yourselfers who take on electrical repair or installation, insulation tools would be the safest and most efficient way of conducting this kind of job.

Why Krishan Brothers Insulated Tools?

For over 60 years of manufacturing tools, Krishan Brothers has become a name that has entered every home. Its insulated tools are quality, safety, and innovation in making them stand tall among professionals and hobbyists. Here's why Krishan Brothers stands out from the rest:

Proven Track Record: decades of expertise in delivering high-quality tools that meet the stringent safety standards.

State-of-the-Art Facilities: Tools are manufactured with the use of the latest technology to be quite safe and highly ergonomically efficient.

From the simplest of tools to specific ones, Krishan Brothers satisfies diverse needs.

Technical and customer support is given by them also. This ensures the user peace of mind.

Safety Precautions While Using Insulated Tools

Regular inspection of tools

Cracks, wear, or damage in the insulation should be looked for before its use.

Voltage ratings

Use tools rated for the specific voltage you are working on.

Storage

Tools must be kept in a dry,, safe environment in order to preserve the insulating qualities of the tool.

Do Not Abuse

Use tools only for those applications to avoid damaging and sustaining safety standards.

Conclusion

That is insulated tools, rather a commitment to safety and efficiency than a financial decision. Whether you are an electrician, an industrial technician, or an enthusiastic do-it-yourselfer, these tools have provided the best defense against electrical hazards. Krishan Brothers' insulated tools stand out for every need—from quality insulation, ergonomic design, through to international safety standards compliance.

Armed with the very best in trade tools, Krishan Brothers would mean each time an insulated tool would reach you: safety, strength, and ingenuity.

Frequently Asked Questions (FAQs)

1. What are insulated tools for?

Insulated tools are to tackle live electrical circuits and systems without jolting electrical shock towards the human using them.

2. Do insulation tools make a big difference in do-it-yourself projects?

Yes, especially if your home improvement task does entail electricity. Insulated tools lower the chances of having an accident happen to you significantly.

3. How to take care of your insulated tool?

It shall be frequently monitored for signs of degradation and to be stored indoors and never employed on an application where it is is intended to be applied.

4. What is a tool's acceptable voltage rating so as it stands??

Most insulated tools are rated to 1,000 volts, but read the rating for each tool you use.

5. Why do you need insulated tools from Krishan Brothers?

This is because Krishan Brothers provides good, long-lasting tools meeting international standards for safety that may guarantee reliability and support.

About the Author

Ritika is a passionate blogger with more than five years of experience in producing engaging, high-quality content on various niches, including tools and equipment. She has over 3,000 blogs in her portfolio, and she combines creativity and thorough research to deliver informative and relatable content. Ritika's dedication to excellence ensures that her writing not only informs but also inspires her readers.

0 notes

Text

How to Drain a Washing Machine: A Step-by-Step Guide

A washing machine that won’t drain properly can be a frustrating issue. Whether it’s due to a clogged hose, a faulty pump, or a power failure, knowing how to manually drain your washer can save you time and prevent further damage. In this guide, we’ll walk you through simple steps to safely drain your washing machine and troubleshoot common issues.

Why Your Washing Machine Won’t Drain

Before jumping into the draining process, it’s helpful to understand why your washer might be holding water. Some common causes include:

Clogged Drain Hose – Lint, dirt, or small clothing items can block the hose.

Faulty Drain Pump – A damaged or clogged pump can prevent proper drainage.

Lid Switch Malfunction – If the lid switch is broken, the machine may not drain as a safety precaution.

Kinked or Blocked Hose – A bent or pinched hose can restrict water flow.

Power Failure – A sudden power outage may stop the washer mid-cycle, leaving water inside.

Now, let’s go through the steps to manually drain your washing machine.

Step 1: Unplug the Washing Machine

Before doing anything, disconnect the power to avoid electrical hazards. If your washer is hardwired, turn off the circuit breaker.

Step 2: Locate the Drain Hose and Filter

Most washing machines have a drain hose located at the back and a drain filter near the bottom front. Check your user manual if you’re unsure where these parts are.

Step 3: Use Gravity to Drain the Water

Place a large bucket or container near the drain hose.

Disconnect the drain hose from the wall or standpipe.

Let the water flow out naturally. If no water comes out, there may be a clog.

Step 4: Drain Through the Drain Filter (Front-Load Washers Only)

Open the access panel at the bottom front of the washer.

Place a shallow pan under the filter.

Unscrew the filter slowly and let the water drain out.

Clean the filter and remove any lint, coins, or debris.

Step 5: Check for Clogs

If your washer isn’t draining properly, inspect the drain hose and pump for clogs.

Use a flashlight to check inside the hose for blockages.

Run water through the hose to ensure it’s clear.

If the drain pump is clogged, remove debris carefully.

Step 6: Restart the Washing Machine

After draining, reconnect everything securely. Plug the washer back in and run a short drain/spin cycle to check if it’s working properly.

When to Call a Professional

If your washing machine still won’t drain, you may need a repair technician to fix issues like:

A damaged pump that needs replacement.

A faulty control board preventing drainage.

A severe blockage that requires professional tools to remove.

Preventing Future Drainage Issues

To avoid draining problems in the future: ✔️ Clean the drain filter every month. ✔️ Use a lint trap for small clothing items. ✔️ Avoid overloading the machine. ✔️ Check the drain hose for kinks or blockages regularly.

Final Thoughts

A washing machine that won’t drain can be stressful, but with the right steps, you can fix the problem yourself in most cases. By keeping your washer clean and well-maintained, you can prevent future drainage issues and keep your laundry routine running smoothly.

Do you have any other washing machine problems? Let us know in the comments!

0 notes