#PrefabBuilding

Explore tagged Tumblr posts

Text

Why Sandwich PUF Panels Are the Future of Modern Construction

In the world of modern construction, Sandwich PUF panels have become a game-changer, offering builders and developers unmatched advantages in insulation, durability, and speed. Whether you are considering roofing or wall solutions, Sandwich PUF insulated panels provide reliable performance in a variety of industrial and commercial projects.

What Are Sandwich PUF Panels?

Using sandwich PUF panels for roofs or walls means faster installation, time savings and reduced labour costs compared to traditional materials. The panels’ excellent insulation properties help reduce energy consumption – an important factor in today’s environmentally conscious world.

Benefits of Sandwich PUF Panel Roofing and Walls

Using Sandwich PUF Panels for roofing or walls means faster installation compared to traditional materials, saving time and reducing labor costs. The panels’ excellent insulation properties help reduce energy consumption — a crucial factor in today’s environmentally conscious world.

The durability of these panels also ensures long-lasting protection against weather, pests, and corrosion, making them perfect for warehouses, cold storage, factories, and commercial buildings.

EPACK Prefab: Leading Sandwich PUF Panel Manufacturer

As a reliable Sandwich PUF Panel manufacturer, EPACK Prefab offers a wide range of customized prefabricated sandwich panels to meet diverse construction needs. Their state-of-the-art manufacturing ensures precision, quality, and quick turnaround times, helping customers across India build smarter and faster.

From sandwich roof PUF panels to wall systems, EPAC Prefab offers solutions designed to optimize thermal performance while maintaining structural integrity.

Why Choose Prefabricated Sandwich Panels?

Prefabrication means these panels are constructed off-site under controlled conditions, ensuring consistent quality and minimal waste.This method also speeds up construction timelines and improves safety on site.

For industries aiming to efficiently upgrade their infrastructure, Sandwich PUF panels offer a durable, cost-effective alternative to traditional building materials.

Final Thoughts

As the demand for high-performance, energy-efficient building materials continues to grow, Sandwich PUF panels are emerging as a reliable option for roofing and insulation needs. EPACK Prefab continues to innovate as a leading sandwich panel manufacturer, providing premium solutions that support the future of construction in India.

Read More - Why You Should Use Sandwich Panels in Prefab Construction Projects

#SandwichPufPanels#SandwichPufPanelRoofing#SandwichPufInsulatedPanels#SandwichRoofPufPanel#SandwichPufPanelManufacturer#SandwichPanelManufacturer#PrefabricatedSandwichPanels#EPACKPrefab#EnergyEfficientConstruction#PrefabBuilding

1 note

·

View note

Text

Ibiuna House, Ibiuna, Brazil,

Rodrigo Ohtake Architect,

Manufactured by sysHaus,

Paul Clemence Phottography

#art#design#architecture#minimal#interior design#interiors#retreat#luxury lifestyle#prefabhomes#prefabricated#prefabconstruction#prefabbuildings#ibiuna#brazil#rodrigo ohtake#syshaus#paul clemence#cabin

612 notes

·

View notes

Text

Welcome to My Tumblr Profile!

This profile is dedicated to showcasing the future of construction with Pre-engineered Buildings (PEB) and Prefabricated Structures. Here, you’ll find insights on innovative building techniques, the benefits of modular and prefab construction, and how EPACK Prefab is at the forefront of this revolution.

Did you know that PEB technology can cut construction time by 30-50%, allowing large-scale projects like warehouses, offices, and schools to be built quickly and efficiently? Stay tuned for more about our projects and the amazing ways prefab buildings are changing the industry.

Follow us for updates on PEB technology, sustainable construction, and how EPACK Prefab is leading the way in transforming commercial construction.

2 notes

·

View notes

Text

Strong and Smart: Prefabricated Industrial Sheds by Multi Decor India

When it comes to industrial infrastructure, durability and speed matter. Multi Decor India’s prefabricated industrial shed offers a smart solution that combines both. Engineered for strength and designed for quick installation, these sheds are ideal for warehouses, factories, and logistic centers.

What sets these sheds apart? Their flexibility and cost-efficiency without compromising on quality. Whether you’re expanding your industrial space or setting up a new facility, these prefab sheds make the process simpler and faster.

Explore the full range built to support your business growth with reliable, long-lasting structures.

#IndustrialShed#PrefabricatedSheds#MultiDecorIndia#IndustrialConstruction#WarehouseSolutions#PrefabBuildings#IndustrialInfrastructure

0 notes

Text

🏭 A New Era of Sandwich Panel Manufacturing Begins in South India

India’s infrastructure and industrial construction landscape is evolving rapidly — and at EPACK Prefab, we’re proud to be at the forefront of this transformation.

We’re excited to announce the launch of our state-of-the-art Continuous Sandwich Panel Manufacturing Facility in South India. Designed for scale, speed, and quality, this advanced plant is built to meet the growing demand for high-performance insulated panels used across various sectors — from warehousing and cold storage to modular buildings and clean rooms.

🌟 Why Continuous Panel Manufacturing Matters

Unlike batch production, which is time-consuming and prone to inconsistencies, a continuous sandwich panel line allows for:

Seamless, high-speed production

Stronger adhesive bonding between layers

Uniform insulation thickness and density

Reduced waste and improved quality control

These advantages result in faster project completion, greater structural integrity, and long-term energy savings for clients.

🔧 What We’re Producing at This Facility

Our new line supports the production of a wide variety of panel types and configurations to suit diverse industrial needs:

🔹 Panel Types:

Wall & Roof Panels – with PIR, PUF, or Rockwool core

Cold Room Panels – Double Groove design for thermal efficiency

Hidden Screw Wall Panels – Sleek finish with no visible fasteners

Camlock Panels – For quick modular assembly

EPS & Glasswool Panels – Available for specialized use

This facility will not only streamline delivery timelines but also help businesses in Bengaluru, Chennai, Hyderabad, and across South India set up faster and scale smarter.

📸 Inside Our Manufacturing Line

📦 Where Our Panels Are Used

Our panels serve a wide range of use cases:

Industrial warehouses and logistics parks

Temperature-controlled cold storage buildings

Prefabricated clean rooms for pharma and food industries

Modular factory units and PEBs

Prefab offices and commercial spaces

Each panel is manufactured under stringent quality protocols to meet thermal performance, fire resistance, and structural load standards.

📞 Get in Touch

Looking to build faster with world-class insulated panel solutions?

🔗 Explore our panel systems: https://www.epack.in/sandwich-panel-manufacturing 📧 Email us: [email protected] 📱 Call us: +91 8130444466

📢 Closing Note

At EPACK Prefab, we believe innovation in construction starts with manufacturing excellence. This new facility is more than just an expansion — it’s a step forward in building smarter, faster, and more sustainably.

Stay tuned as we roll out high-performance panel solutions made with precision, speed, and purpose — right here in South India.

Read More - Why You Should Use Sandwich Panels in Prefab Construction Projects

#ContinuousPanelLine#SandwichPanelsIndia#SouthIndiaInfrastructure#ModularConstruction#PUFPanels#MadeInIndia#ConstructionInnovation#InsulatedPanels#PrefabBuildings#EPACKPrefab

0 notes

Text

Best Site Office Containers in Dubai – Smart, Affordable Workspace Solutions

Time, cost and space efficiencies are key in Dubai’s rapid construction and development sector. Whether you are constructing a skyscraper in Downtown Dubai or planning a pop-up site in Jebel Ali, needing and having a ready-made, flexible and reliable workspace is a given. This is where site office containers in Dubai enters the scene — a contemporary answer to the region’s fast-evolving commercial and industrial domains.

What Are Site Office Containers?

Site office containers are suitable for rugged use and made out of shipping containers or build in prefab modules, that are then converted into fully functional and perfect use of office. These mobile office trailers are ideal for use as construction site offices, project management units, or temporary management units for construction sites, oilfields, meeting rooms, sales offices, and any other commercial use.

These boxes are designed to be comfortable, sturdy and stretchable. Available options include basic cabins to fully air-conditioned office set-up, complete with toilets and furniture, which is perfect for Dubai’s extreme weather conditions and ever-changing infrastructure.

0 notes

Text

The Rise of Prefabricated Structures Manufacturers

In the ever-evolving construction world, prefabricated structures are swiftly gaining traction as a game-changing solution. At the heart of this transformation are prefabricated structures manufacturers, who are revolutionizing how buildings are designed, assembled, and delivered.

What Are Prefabricated Structures?

Prefabricated (or prefab) structures are buildings or components that are manufactured in a factory setting and then transported to the construction site for assembly. Unlike traditional construction, which happens entirely on-site, prefab methods leverage off-site fabrication for faster, cleaner, and more efficient project completion.

These structures range from modular homes and office buildings to complex industrial warehouses and railway shelters. The flexibility and scalability of prefabricated construction make it a top choice for modern infrastructure demands.

Role of Prefabricated Structures Manufacturers

Prefabricated structures manufacturers are the backbone of this industry. Their role extends beyond mere production — they are deeply involved in:

Design & Engineering: Utilizing CAD and BIM technologies to create precise, customizable designs.

Material Selection: Choosing high-quality steel, aluminum, composites, or concrete to suit project needs.

Fabrication & Quality Control: Manufacturing components in controlled environments, ensuring consistent quality and reduced waste.

Logistics & Installation: Coordinating the transportation and on-site assembly with precision and safety protocols.

Benefits Delivered by Manufacturers

Faster Project Completion By prefabricating components simultaneously with site preparation, manufacturers help reduce overall project timelines significantly.

Cost Efficiency Factory production minimizes labor costs and material waste, providing cost-effective solutions.

Superior Quality & Durability Controlled factory conditions allow for higher precision, structural strength, and weather-resistant construction.

Sustainability Prefab methods reduce environmental impact through waste reduction, energy efficiency, and use of sustainable materials.

Customizability Manufacturers offer tailored solutions for varied applications, from temporary shelters to permanent commercial buildings.

Key Applications of Prefabricated Structures

Industrial Warehouses Quick to erect and highly durable, prefab warehouses meet the needs of fast-growing industries and logistics companies.

Railway Infrastructure Prefabricated shelters and station components enhance passenger comfort while meeting stringent safety standards.

Commercial & Exhibition Halls Large spans without internal columns make prefab ideal for events, showrooms, and temporary exhibits.

Residential Housing Affordable and quick to build, modular homes are addressing housing shortages worldwide.

The Future of the Industry

With advances in automation, robotics, and sustainable materials, the prefab construction market is expected to grow rapidly. Manufacturers are integrating smart technologies into structures, offering IoT-enabled buildings with improved energy management and user experience.

As urbanization continues and demand for faster, greener building methods grows, prefabricated structures manufacturers are well-positioned to lead the charge in reshaping how we build.

Conclusion

Prefabricated structures manufacturers are no longer just suppliers — they are strategic partners in modern construction. With their innovation, efficiency, and commitment to quality, they are helping developers, governments, and private enterprises build smarter, faster, and more sustainably.

#prefabricated#prefabricated structure#prefabbuildings#peb#pre engineered building manufacturers#prefab#prefabconstruction

1 note

·

View note

Text

Vogue Engineering Services Pakistan is a trusted leader in designing, manufacturing, and maintaining temperature-controlled cold storage rooms and warehouses for various industries. Our cold rooms (also known as cool rooms or chiller rooms) provide walk-in storage with precise temperature control, ensuring optimal preservation of products such as fruits, vegetables, beverages, flowers, meat, seafood, pharmaceuticals, and fresh foods. Rely on our expertise to safeguard the quality of your products with durable, energy-efficient cold storage solutions. Visit our website at https://vogue-engineering.com

#cold storage#buildings#manufacturer#modren home#prefab#prefabbuildings#prefabconstruction#prefabricated#steel buildings#steel fabrication

1 note

·

View note

Text

What You Need to Know About Industrial Building Construction

Buildings for industrial use are among the most important contributions of the commercial building industry. These buildings are a very important part of economic activity, where factories, warehouses, and production plants can freely produce and distribute goods. We at EPACK Prefab know how industrial building construction can be complex and that the best approach is needed to make your project a successful one.

Below, we discuss the major factors of industrial building construction and how EPACK Prefab delivers top-quality solutions for your industrial projects.

Types of Industrial Buildings

An industrial building is a kind of commercial property designed for production, manufacturing, storage, or distribution purposes. These structures form the backbone of industrial operations, housing the equipment, machinery, and storage required for large-scale production. Industrial buildings include warehouses, factories, research centers, and specialized facilities such as cold storage and telecom centers.

EPACK Prefab’s Expertise in Industrial Building Construction

Our expertise in industrial building construction enables EPACK Prefab to deliver structures that meet the needs of modern industries. Whether it’s for manufacturing, storage, or research, we can provide a facility tailored to your operations.

Common Types of Industrial Buildings

Various industrial buildings serve specific sectors. Below are some popular types: 1. Distribution Centers and Warehouses: These buildings are primarily used for the storage and distribution of goods. Featuring high ceilings and large spaces, they include tall racking systems and loading docks for transportation vehicles. EPACK Prefab specializes in constructing durable warehouses that optimize storage capacity. 2. Manufacturing Facilities: Heavy industrial buildings contain capital-intensive equipment necessary for production processes. These facilities require specialized power supplies, ventilation, and exhaust systems. EPACK Prefab ensures all safety and operational standards are met during construction. 3. Light Manufacturing Facilities: Light manufacturing buildings are less equipment-intensive and cater to industries such as electronics, textiles, and furniture manufacturing. EPACK Prefab offers flexible construction solutions that are cost-effective and energy-efficient for these operations. 4. Cold Storage Facilities: Cold storage buildings are critical for industries dealing with perishable goods. EPACK Prefab designs energy-efficient cold storage solutions that maintain the necessary temperature, ensuring your products remain in top condition. 5. Telecom and Data Centers: These facilities house data servers and equipment essential for telecommunications and IT companies. EPACK Prefab designs telecom spaces and data centers with high-security measures, proper ventilation, and energy-efficient systems.

Industrial Building Trends:

The industrial construction landscape is always evolving. Below are some key trends shaping the industry: Increased Demand for Warehouses: The rise of e-commerce has driven the need for larger warehouses. EPACK Prefab designs and builds warehouses that cater to the growing logistics industry, offering optimized storage solutions that improve operational efficiency. Growth in Cold Storage Solutions: With rising demand in the food and pharmaceutical sectors, there’s an increasing need for cold storage facilities. EPACK Prefab constructs state-of-the-art cold storage buildings to meet these growing requirements. Multistory Warehouses: In cities with limited land availability, multistory warehouses are becoming more popular. EPACK Prefab provides innovative multistory warehouse designs that maximize space while minimizing costs.

The Industrial Building Construction Process

The construction of an industrial building is a complex process involving multiple stages. Here’s an overview of the key stages: 1. Planning: Planning is the most crucial stage in industrial building construction. EPACK Prefab collaborates closely with clients to understand their requirements, assess the site, and create a project plan that outlines timelines, budgets, and material specifications. 2. Design: Industrial building design requires specialized expertise to accommodate heavy equipment, airflow requirements, and safety protocols. EPACK Prefab ensures every facility’s design adheres to regulatory standards and meets the client's operational needs. 3. Pre-Construction: Pre-construction involves securing permits, site preparation, and sourcing materials. EPACK Prefab manages the entire process, ensuring that everything is ready before construction begins. 4. Construction: During the construction phase, the building components are assembled, and all systems such as HVAC, plumbing, and electrical are installed correctly. EPACK Prefab focuses on safety and efficiency, completing projects on time and within budget. 5. Post-Construction: After construction is complete, the facility undergoes thorough inspections to ensure all systems function as intended. EPACK Prefab offers post-construction support to resolve any issues and ensure the building meets the client’s needs.

Why Choose EPACK Prefab for Industrial Building Construction?

EPACK Prefab has a proven track record of delivering high-quality industrial buildings that meet the needs of modern businesses. With a team of experienced engineers and architects, EPACK Prefab ensures each project is completed with precision and efficiency. Whether you need a manufacturing plant, warehouse, or cold storage facility, EPACK Prefab offers cost-effective, durable, and functional solutions. Backed by years of experience in industrial building construction, EPACK Prefab is committed to helping businesses succeed by providing reliable, energy-efficient, and customized building solutions. Contact us today to learn how we can assist with your industrial building project.

Read More: How Important is it to Assess the Long-term Benefits of Prefabricated Steel Buildings?

#IndustrialBuilding#IndustrialConstruction#WarehouseConstruction#ManufacturingFacilities#ColdStorageSolutions#PrefabConstruction#EPACKPrefab#IndustrialShed#CommercialConstruction#TelecomCenters#DataCenters#FactoryBuildings#IndustrialBuildingDesign#IndustrialBuildingSolutions#MultistoryWarehouses#PrefabBuildings#IndustrialWarehouse#ColdStorageFacility#ConstructionTrends#IndustrialArchitecture#BuildingSolutions

1 note

·

View note

Text

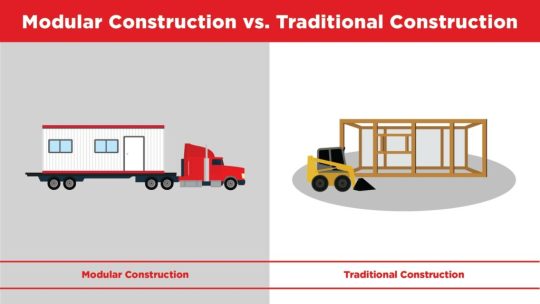

How Modular Construction is Revolutionizing the Building Industry

The global modular construction market size is expected to reach USD 162.40 billion by 2030, registering a CAGR of 7.5% over the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to growing infrastructural development and building activities in developing countries around the globe. Rapid urbanization and industrialization are expected to increase the number of new projects, primarily in the commercial and industrial building sectors. This is likely to fuel the growth of the modular construction industry across the globe. Increasing technological advancements in the building industry coupled with the advantages provided by modular construction such as reduced building schedule, reduced cost, greater flexibility, reuse, and less material waste are contributing to the product demand in the market.

The relocatable modular construction (RMC) market is expected to witness rapid growth as temporary housing for emergency and relief operations has gained popularity over the past decade. These buildings are made to be repurposed and transported to various building sites. Government initiatives and regulations toward sustainability and a green environment are expected to fuel the market growth over the forecast period.

Using wood in modular construction is advantageous due to its favorable properties as a material. Wood is used in modular construction to create exterior wall panels including additional layers for insulation, vapor barrier, siding, waterproofing, and drywall. Moreover, global concerns regarding sustainability and increasing awareness about wood as a building material among consumers are the factors likely to augment the growth of the market over the forecast period.

Growing commercial sector in Asia Pacific on account of rising penetration of multinational brands backed with favorable trade policies are expected to propel the market growth. Increasing construction of office spaces, shopping malls, lodging spaces and other utility spaces across the region are likely to provide a major boost to the adoption of modular construction.

The manufacturers of modular construction prefer to maintain strategic relationships with raw material suppliers in order to avoid disruptions in raw material supply. In addition, manufacturers do not depend on a single source to procure raw materials to ensure the steady supply of raw materials and avoid volatility in terms of sourcing, thereby limiting the bargaining power of suppliers.

Leading companies are implementing the latest modular construction techniques and solutions to drive innovation in the modular construction sector. For instance, in March 2017, Bureau Veritas, Setec Bâtiment, Agence Coste Architectures, and Bouygues Construction partnered to work on innovative Building Information Modeling (BIM) processes. These processes enable technical inspectors and health & security protection coordinators to assess buildings and structures directly based on the digital model and allows principal contractors to sign off directly on the same digital model.

For More Details or Sample Copy please visit link @: Modular Construction Market Report

Modular Construction Market Report Highlights

The permanent segment accounted for the largest revenue share of 64.1% in 2021. This is attributed to the several advantages of off-site construction such as high-quality control compared to traditional building methods.

The steel material segment accounted for a major share of 41.5% in 2022, owing to its characteristics due to which structural steel is used in building materials and can be welded into different shapes and grades.

The residential application segment was valued at USD 47.85 billion in 2022 and is further forecasted to grow rapidly by 2030. The residential application segment includes single-family houses, multi-story residential buildings, and rental housing properties. Modular construction is witnessing rapid adoption in residential applications on account of its ability to significantly reduce building costs and time.

The European region accounted for the largest revenue share in 2022 and is forecast to grow at a CAGR of 7.1% by 2030. The primary driving factor is expected to be the rising influx of migrants necessitating the building of temporary and permanent housing structures in the region.

Modular construction market is characterized by the presence of various established players with a strong financial base resulting in high barriers for new entrants in this market. High initial capital required for developing buildings with modular construction is expected to lower the threat of new entrants in the market.

Gain deeper insights on the market and receive your free copy with TOC now @: Modular Construction Market Report We have segmented the global modular constructionmarket report based on product, material, application, and region.

#ModularConstruction#SustainableBuilding#ConstructionInnovation#PrefabBuildings#ConstructionTrends#ModularArchitecture#OffsiteConstruction#BuildingEfficiency#ModularHousing#ConstructionTechnology#GreenConstruction#ModernBuildingMethods#ConstructionSolutions

0 notes

Text

From blizzards to summer heat, Missouri Portable Buildings delivers structures that endure.

Our portable shelters, temporary accommodations, and modular classrooms are designed to meet the challenges of real-world environments—no shortcuts, no compromises.

If you need a structure that’s mobile and reliable, we’ve got you covered.

📞 Call now: (417) 843-3102 🌐 Visit: www.missouriportablebuildings.com

#TemporaryStructure #PortableStorageUnit #PrefabBuilding #PortableCabins #PopUpBuilding #SiteOffice #IndustrialShed

#storage facilities#carports#green house#youtube#accounting#architecture#storage#tiny home#storage shed#storage solutions

0 notes

Text

Prefab vs. Traditional Construction: Which Is Better for On-Site Offices?

In the dynamic field of construction, there's a growing discussion about the merits of prefab versus traditional construction methods, especially when it comes to on-site offices. The decision between these two approaches holds substantial sway over a project's efficiency, cost-effectiveness, and environmental footprint. Let's take a closer look at the intricacies of prefab and traditional construction, shining a light on EPACK Prefab as a standout manufacturer and supplier in the industry.

Exploring Prefab Construction:

Prefab, or prefabricated construction, involves assembling building components at a dedicated manufacturing facility before transporting them to the construction site for final assembly. This method is known for its speed, cost-effectiveness, and reduced environmental footprint compared to traditional construction.

EPACK Prefab, a key player in the prefab construction sector, pioneering innovative, sustainable, and customizable solutions. Their prefab structures are engineered with precision, facilitating swift on-site assembly and significantly cutting down construction timelines.

Traditional Construction: Embracing Time-Honored Practices:

On the flip side, traditional construction embraces the age-old approach of on-site building, involving the delivery of materials to the location and the meticulous assembly of the structure, piece by piece. While this method has stood the test of time, it presents challenges, including extended construction periods and higher costs.

Advantages of Prefab Construction for On-Site Offices:

Rapid Construction: Prefab construction dramatically reduces project timelines. EPACK Prefab, with its cutting-edge manufacturing facilities, ensures that building components are ready for on-site assembly in a fraction of the time required for traditional construction.

Cost-Efficiency: The controlled environment of a prefab facility minimizes material waste and labor costs. EPACK Prefab's dedication to quality and efficiency translates into cost savings for clients without compromising structural integrity.

Tailored Design: Prefab construction allows for a high degree of customization. EPACK Prefab collaborates closely with clients to design structures that meet specific requirements, ensuring that on-site offices are tailored to the unique needs of each project.

Sustainability: Prefab construction inherently reduces environmental impact by optimizing material usage and minimizing construction waste. EPACK Prefab goes the extra mile by incorporating eco-friendly practices into its manufacturing processes.

youtube

EPACK Prefab: Setting the Gold Standard: As a leading prefab construction manufacturer and supplier, EPACK Prefab has earned accolades for its commitment to excellence. Their dedication to quality, innovation, and sustainability aligns seamlessly with the evolving needs of modern construction projects.

While both prefab and traditional construction methods have their merits, the undeniable advantages offered by prefab construction, especially with a reliable partner like EPACK Prefab, make it a compelling choice for on-site offices. The speed, cost-effectiveness, and sustainability of prefab construction are reshaping the construction landscape, and EPACK Prefab stands as a beacon of excellence in this transformative era.

Also Read: ARE PREFABRICATED SITE OFFICES USEFUL AND SHOULD YOU OPT FOR ONE?

#PrefabOffice#ModularConstruction#SiteOfficeSolutions#EPACKPrefab#PrefabDesign#ConstructionInnovation#OffsiteConstruction#PrefabBuilding#GreenConstruction#SustainableOffice#QuickBuild#PrefabTrends#OnSiteOffice#EcoFriendlyPrefab#TimeSavingConstruction#PrefabRevolution#SmartConstruction#Youtube

1 note

·

View note

Text

May the bond between brothers and sisters flourish.

Happy Bhai Dooj | Japline Infra

Japline Infra is one of the leading suppliers in the PEB business. We specially crafted and construct pre-assembled structures which incorporates retails and business, workplaces, site office, modern stockroom, medical services places and some more. We have full in house capacity from plan to execution which makes the single resource provider for a great many pre-assembled structures.

Get in touch with our experts now:

📱: +91-9310247567 📧: [email protected] 🌐: www.japlineinfra.com 🏠: A-14 & 15, Meerut Rd Industrial Area, Ghaziabad, UP-201003

#steelstructure #prefabricatedbuilding #preengineeredbuilding #peb #pebmanufacturer #japlineinfra #construction #steelbuildings #manufacturing #design #buildings #realestate #prefabbuilding #happybhaidooj#customdesign #smartbuilding #japlineinfra #bhaidooj2024

0 notes

Text

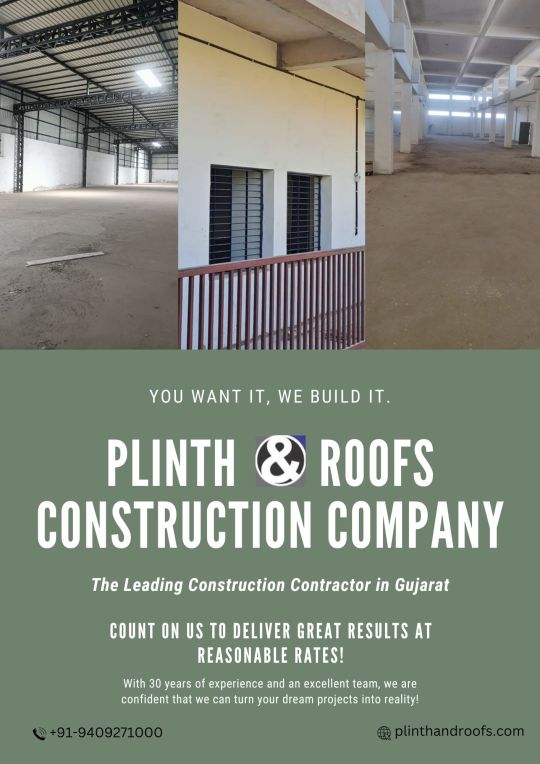

Industrial Construction & Fabrication in Naroda Ahmedabad

At Plinth & Roofs, we specialize in providing comprehensive turnkey solutions for industrial construction projects. With a proven track record of delivering high-quality, efficient, and cost-effective solutions, we are your trusted partner from concept to completion.

Services Offered By Plinth & Roofs

1.Design and Engineering 2.Construction and Project Management 3.Civil and Structural Construction 4.Mechanical Systems 5.Electrical Systems 6.Industrial Structural Fabrication 7.Industrial Shed Manufacturer 8.Heavy Structural Fabrication

Whether you're planning a new industrial Construction Project, upgrading existing infrastructure, or seeking maintenance services, Plinth & Roof is your trusted partner. Contact us today to discuss your project requirements and discover how we can bring your vision to life.

#IndustrialConstruction

#IndustrialShed

#IndustrialFactory

#Industrialgodown

#Industrialwarehouse

#structure

#shedManufacturer

#PEBShed

#Prefabricatedshed

#prefabbuilding

Call:+91-9409271000 Web: https://plinthandroofs.com/industrial-shed-construction/

#building construction#factory construction#industrial fabrication#industrialconstruction#peb manufacturers#youtube#warehouseconstruction#construction#industrialshedmanufacture#factoryconstructionexperts

0 notes

Text

Why Pre Engineered Buildings in India Are the Smart Choice | Multi Decor India

Pre engineered buildings in India are transforming the way industries build — offering speed, durability, and cost savings all in one package. Designed with precision and assembled quickly, these structures fit perfectly for warehouses, factories, and commercial spaces.

Multi Decor India leads the way in delivering these advanced building solutions tailored to your needs. Their expertise ensures your project is built to last without compromising on quality or time.

Explore how these innovative buildings are shaping modern construction by visiting Pre Engineered Buildings in India.

Thinking about upgrading your workspace or storage? Contact Multi Decor India today for expert advice and custom solutions. Visit: Contact Multi Decor India

0 notes

Text

Container Homes in Dubai The Future of Sustainable Living

In a city that is all about the next big thing when it comes to futuristic skyscrapers and extravagant living, the latest trend is surprisingly cheap and easy to build – homes made from industrial shipping containers. With the rise of urban living and skyrocketing land prices, shipping container homes are a popular choice for both those looking for local accommodations as well as builders looking for a creative and affordable building materials. In this blog post, we’re going to take a look at the advantages, legality, pricing, design, and future prospects of shipping container homes in Dubai.

What Are Container Houses?

Container houses are homes built by stacking and welding together secondhand shipping containers. The steel contraptions that previously held goods, are converted into livable spaces with insulation, ventilation, windows, doors, and even fancy fittings. The homes are modular and stackable and can be used for permanent living as well as temporary housing.

0 notes