#Programmable Logic Controller Panels

Explore tagged Tumblr posts

Text

PLC Based Panels

A PLC control panel is required for any industrial, manufacturing, or production process application that demands versatile, dependable, and cost-effective automation control (PLC full form is Programmable Logic Controller). These control panels, also known as PLC Automation Panels, provide an advantage over traditional relay-based systems because of their smaller size, simplicity of logic adjustment, methods of remote connections, and technological developments.

PLC panels are used in a wide range of electronic and electrical circuit fittings for a wide range of applications that may be generally classified into three categories: Wind turbine panels, compressor control panels, incinerators, boilers, chillers, spray driers, HVAC panels, and other applications are covered by OEM control panels. The number of I/O points is the essential criterion when selecting modular processors. Each PLC processor will be restricted to a certain number of I/O modules. Memory size (for data storage or programme storage) and performance are other crucial considerations when choosing CPUs (scan time depends on the processor). The programme's size is determined by the complexity of the control issue and the programmer's competence and style. Milestones Switchgears Pvt. Ltd. is an Indian maker of PLC panels.

0 notes

Text

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

Introduction

In today’s fast-moving industrial world, being physically present on the shop floor every hour of the day is neither practical nor necessary. Thanks to modern PLC Panels, plant managers and engineers can now monitor and control their operations from virtually anywhere.

This is where remote monitoring comes in—a game-changing feature that turns your PLC Panel into a smart control center for your entire plant.

What is Remote Monitoring in PLC Panels?

Remote monitoring allows real-time access to your PLC Panel’s data through cloud-based platforms or networked software systems. It enables you to:

View machine status live

Monitor performance metrics

Receive alerts and diagnostics

Control start/stop operations remotely

Whether you’re at another site, at home, or travelling, you can manage your plant operations with just a laptop or smartphone.

Benefits of Remote Monitoring with PLC Panels

Real-Time Oversight Instantly check the status of equipment and production without being on-site.

Faster Problem Resolution Receive immediate alerts for faults, so downtime can be minimized.

Cost Savings Reduce the need for constant physical supervision and travel between sites.

Improved Decision-Making Access to live data helps you make informed decisions quickly.

Enhanced Safety Monitor high-risk processes remotely, minimizing exposure for workers.

Ready to take control from anywhere? Partner with a reliable PLC Panel Manufacturer to implement secure, remote-ready automation systems.

Key Features to Look For in Remote-Ready PLC Panels

Ethernet and Wi-Fi Connectivity Enables seamless data transfer between your PLC and remote devices.

Cloud Integration Support Compatible with platforms like MQTT, OPC UA, or custom dashboards.

Secure Access Protocols SSL encryption, VPN access, and password protection keep your system safe.

User-Friendly Interfaces Easy-to-use mobile or web apps that show real-time visualizations.

SCADA or HMI Compatibility Gives a centralized view with alarms, trends, and historical data logs.

Industries That Benefit the Most

Water Treatment Plants – Monitor pumps, levels, and chemical dosing remotely

Renewable Energy Farms – Supervise solar or wind operations from central control

Cold Storage Units – Keep track of temperature and humidity offsite

Manufacturing Units – Detect faults or delays without halting production

Agricultural Automation – Manage irrigation or feeding schedules remotely

How to Get Started

Collaborate with an experienced Programmable Logic Controller Panel Manufacturer who can:

Customize the panel with remote access modules

Integrate your system with cloud services

Train your team to monitor and control remotely

Ensure top-level cybersecurity protocols are in place

Conclusion

Remote monitoring with PLC Panels is no longer a luxury—it’s a necessity in a digital-first industrial world. It saves time, boosts productivity, and enhances control like never before. To enable this, choose a PLC Panel Manufacturer that delivers smart, secure, and remote-ready solutions tailored to your industry.

Control your plant from anywhere—talk to a trusted PLC Panel Manufacturer and upgrade your operations today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Using PLC Panels in HVAC Automation for Commercial Buildings

#plc electrical panel#plc#electrical panel#plc panel#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

### Report on the Ancient Cogitator

#### Found in the Depths of Mars

**By the Omnissiah’s Grace, Servant of the Machine God, Tech Priest Dominus Pdep Eith**

---

**Date: M39.305**

**Subject: Cogitator Designation – Unknown**

---

In the year of the Omnissiah M42.305, an expedition into the subterranean vaults beneath the surface of Mars did yield a most wondrous find: an ancient cogitator of unknown origin, long lost to the sands of time. This device, encrusted with the dust of millennia, hath been identified through the holy rites of tech-retrieval as a device of remarkable antiquity. By the will of the Machine God, I do hereby present a thorough account of its features and internal layout.

#### External Features

The exterior of this venerable cogitator doth present itself in a rectangular form, wrought from a durable metal alloy that hath withstood the ravages of countless ages. The surface is adorned with an array of switches and lights, each one a testament to the artisanship of ancient tech-priests. The face of the cogitator is dominated by a control panel, bedecked with a myriad of toggle switches, rotary controls, and luminescent indicators.

- **Dimensions:** Approximately three feet in height, two feet in width, and a foot in depth.

- **Material:** Sturdy alloy, resistant to corrosion and wear.

- **Interface:** An array of manual switches and indicator lights for direct interaction.

#### Internal Layout

Upon delving into the inner sanctum of the cogitator, the sacred architecture reveals itself in a manner most intricate. The internal layout is a marvel of ancient engineering, exhibiting a modular design that doth allow for ease of access and maintenance by those initiated in the rites of tech-repair.

- **Processing Unit:** The heart of the cogitator, the Central Processing Unit (CPU), is a compact assembly of transistors and circuits. It doth operate at a clock speed of 1 MHz, a relic by today’s standards, yet a marvel of its time.

- **Memory:** The cogitator doth possess a core memory of 4,096 words, each word being twelve bits in length. This magnetic core memory is both robust and reliable, providing swift access to data.

- **Input/Output Modules:** The cogitator is equipped with various I/O modules, allowing for the connection of peripheral devices. These modules are interfaced via a backplane, a unifying structure of interconnecting circuits.

- **Power Supply:** The power sanctum of the cogitator is a robust unit, designed to convert and regulate energy, ensuring the smooth operation of the cogitator’s components.

#### Operational Characteristics

The operational rites of the cogitator are governed by a series of machine instructions, simple yet powerful in their execution. The instruction set architecture is designed to perform a variety of computational tasks with efficiency and precision.

- **Instruction Set:** Comprising a minimalistic set of operations, including basic arithmetic, logic, control flow, and data manipulation instructions.

- **Programming:** The cogitator is programmable via electro-arcana script, each instruction directly corresponding to a machine operation.

- **Performance:** While humble by the standards of our current sacred machinery, the cogitator performs its designated tasks with admirable fidelity and speed.

#### Conclusion

In the name of the Omnissiah, the rediscovery of this ancient cogitator doth enrich our understanding of the ancient ways. This cogitator, a relic of a bygone era, stands as a testament to the ingenuity and craftsmanship of those who came before us. As we venerate the Machine God, let us continue to unearth and study such treasures, that we may preserve the sacred knowledge and further the glory of the Adeptus Mechanicus.

By the will of the Omnissiah and the blessings of the Machine God, this report is thus concluded.

**Ave Deus Mechanicus.**

7 notes

·

View notes

Text

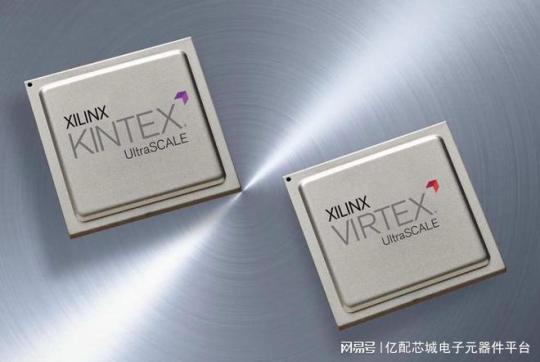

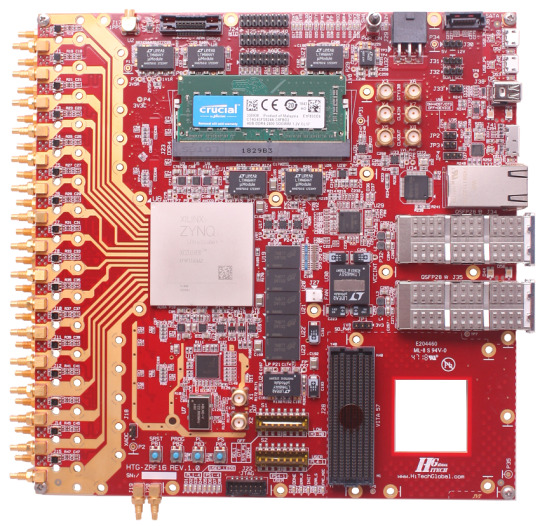

Beginner's learning to understand Xilinx product series including Zynq-7000, Artix, Virtex, etc.

Xilinx (Xilinx) as the world's leading supplier of programmable logic devices has always been highly regarded for its excellent technology and innovative products. Xilinx has launched many excellent product series, providing a rich variety of choices for different application needs.

I. FPGA Product Series

Xilinx's FPGA products cover multiple series, each with its own characteristics and advantages.

The Spartan series is an entry-level product with low price, power consumption, and small size. It uses a small package and provides an excellent performance-power ratio. It also contains the MicroBlaze™ soft processor and supports DDR3 memory. It is very suitable for industrial, consumer applications, and automotive applications, such as small controllers in industrial automation, simple logic control in consumer electronics, and auxiliary control modules in automotive electronics.

The Artix series, compared to the Spartan series, adds serial transceivers and DSP functions and has a larger logic capacity. It achieves a good balance between cost and performance and is suitable for mid-to-low-end applications with slightly more complex logic, such as software-defined radios, machine vision, low-end wireless backhaul, and embedded systems that are cost-sensitive but require certain performance.

The Kintex series is a mid-range series that performs excellently in terms of the number of hard cores and logic capacity. It achieves an excellent cost/performance/power consumption balance for designs at the 28nm node, provides a high DSP rate, cost-effective packaging, and supports mainstream standards such as PCIe® Gen3 and 10 Gigabit Ethernet. It is suitable for application scenarios such as data centers, network communications, 3G/4G wireless communications, flat panel displays, and video transmission.

The Virtex series, as a high-end series, has the highest performance and reliability. It has a large number of logic units, high-bandwidth serial transceivers, strong DSP processing capabilities, and rich storage resources, and can handle complex calculations and data streams. It is often used in application fields with extremely high performance requirements such as 10G to 100G networking, portable radars, ASIC prototyping, high-end military communications, and high-speed signal processing.

II. Zynq Product Series

The Zynq - 7000 series integrates ARM and FPGA programmable logic to achieve software and hardware co-design. It provides different models with different logic resources, storage capacities, and interface numbers to meet different application needs. The low-power consumption characteristic is suitable for embedded application scenarios such as industrial automation, communication equipment, medical equipment, and automotive electronics.

The Zynq UltraScale + MPSoC series has higher performance and more abundant functions, including more processor cores, larger storage capacities, and higher communication bandwidths. It supports multiple security functions and is suitable for applications with high security requirements. It can be used in fields such as artificial intelligence and machine learning, data center acceleration, aerospace and defense, and high-end video processing.

The Zynq UltraScale + RFSoC series is similar in architecture to the MPSoC and also has ARM and FPGA parts. However, it has been optimized and enhanced in radio frequency signal processing and integrates a large number of radio frequency-related modules and functions such as ADC and DAC, which can directly collect and process radio frequency signals, greatly simplifying the design complexity of radio frequency systems. It is mainly applied in radio frequency-related fields such as 5G communication base stations, software-defined radios, and phased array radars.

III. Versal Series

The Versal series is Xilinx's adaptive computing acceleration platform (ACAP) product series.

The Versal Prime series is aimed at a wide range of application fields and provides high-performance computing and flexible programmability. It has high application value in fields such as artificial intelligence, machine learning, data centers, and communications, and can meet application scenarios with high requirements for computing performance and flexibility.

The Versal AI Core series focuses on artificial intelligence and machine learning applications and has powerful AI processing capabilities. It integrates a large number of AI engines and hardware accelerators and can efficiently process various AI algorithms and models, providing powerful computing support for artificial intelligence applications.

The Versal AI Edge series is designed for edge computing and terminal device applications and has the characteristics of low power consumption, small size, and high computing density. It is suitable for edge computing scenarios such as autonomous driving, intelligent security, and industrial automation, and can achieve efficient AI inference and real-time data processing on edge devices.

In short, Xilinx's product series are rich and diverse, covering various application needs from entry-level to high-end. Whether in the FPGA, Zynq, or Versal series, you can find solutions suitable for different application scenarios, making important contributions to promoting the development and innovation of technology.

In terms of electronic component procurement, Yibeiic and ICgoodFind are your reliable choices. Yibeiic provides a rich variety of Xilinx products and other types of electronic components. Yibeiic has a professional service team and efficient logistics and distribution to ensure that you can obtain the required products in a timely manner. ICgoodFind is also committed to providing customers with high-quality electronic component procurement services. ICgoodFind has won the trust of many customers with its extensive product inventory and good customer reputation. Whether you are looking for Xilinx's FPGA, Zynq, or Versal series products, or electronic components of other brands, Yibeiic and ICgoodFind can meet your needs.

Summary by Yibeiic and ICgoodFind: Xilinx (Xilinx) as an important enterprise in the field of programmable logic devices, its products have wide applications in the electronics industry. As an electronic component supplier, Yibeiic (ICgoodFind) will continue to pay attention to industry trends and provide customers with high-quality Xilinx products and other electronic components. At the same time, we also expect Xilinx to continuously innovate and bring more surprises to the development of the electronics industry. In the process of electronic component procurement, Yibeiic and ICgoodFind will continue to provide customers with professional and efficient services as always.

4 notes

·

View notes

Text

Forming the Future: Exploring Double Deck Compression Technology

In the evolving world of materials processing and component manufacturing, efficiency, precision, and space optimization are critical to staying competitive. Enter the Double Deck Compression Forming Machine—an advanced piece of industrial equipment designed to significantly boost productivity in high-volume compression molding operations. This dual-level system is revolutionizing the way manufacturers approach composite material forming by doubling throughput without doubling floor space.Get more news about double deck compression forming machine,you can vist our website!

What Is a Double Deck Compression Forming Machine?

This specialized machine features two vertically aligned forming decks within a single press framework, allowing simultaneous molding operations at two levels. It is primarily used in compression molding—an established method for shaping thermoset and thermoplastic composites—where heat and pressure are applied to form materials into predetermined shapes.

Each deck operates independently or synchronously, depending on the production requirement. The technology is widely used in the automotive, aerospace, household goods, and construction sectors, where high precision and scalability are essential.

Key Components and Operation

The machine typically includes:

Upper and Lower Press Units: Each equipped with its own mold set and hydraulic system. These units apply controlled pressure and heat to shape the material.

Heating Plates: Designed to reach and maintain specific temperatures suitable for curing composite materials.

Advanced PLC Control Systems: Programmable Logic Controllers (PLCs) allow operators to monitor and manage individual cycles for each deck in real time.

Safety and Interlock Systems: Ensure both levels function safely during concurrent operations.

Advantages of the Double Deck Configuration

The defining feature of this machine—two mold decks—translates into several strategic advantages:

Double the Output: Two molds running simultaneously mean a significant increase in production without proportional increases in labor or factory floor requirements.

Space Efficiency: Stacked operation utilizes vertical space, making it ideal for workshops or factories where horizontal expansion is limited.

Energy Optimization: Shared hydraulic and control systems lower overall energy consumption per unit produced.

Flexible Operation: The decks can run similar or different molds, allowing manufacturers to diversify production without additional equipment.

Cost Savings: Enhanced throughput and reduced footprint ultimately lead to lower cost per part.

Application in Modern Industries

In automotive manufacturing, for example, the double deck compression forming machine is used to produce lightweight yet strong components like interior panels, battery enclosures for electric vehicles, and underbody shields—all from composite materials. The aerospace industry uses it to form parts that require both high-performance materials and repeatable manufacturing cycles. Even consumer goods industries apply this technology for molding plastic or fiber-reinforced products at scale.

Technological Trends and Innovations

Modern iterations of these machines are integrating smart manufacturing features, including:

IoT Monitoring: Real-time data collection and remote diagnostics.

Servo-Driven Hydraulics: For improved pressure control and energy efficiency.

Quick Mold Change Systems: Reducing downtime between production runs.

Human-Machine Interfaces (HMIs): Touchscreen interfaces that enhance user control and training efficiency.

Conclusion

The Double Deck Compression Forming Machine stands at the intersection of innovation and practicality. By enabling simultaneous operations in a compact footprint, it empowers manufacturers to meet increasing demand without compromising on quality or efficiency. As industries continue to seek scalable, eco-conscious production methods, this machine proves to be a versatile and future-ready asset on the modern factory floor.

0 notes

Text

Who is the Best Electrical and Instrumentation Supplier in Bahrain?

If you’re working on an industrial, commercial, or even a residential project in Bahrain, finding a reliable electrical and instrumentation supplier in Bahrain can make a huge difference in terms of project efficiency, safety, and long-term reliability. Whether you’re dealing with automation, power distribution, control panels, or industrial sensors, choosing the right supplier is crucial.

What Does an Electrical and Instrumentation Supplier Do?

An electrical and instrumentation (E&I) supplier provides the essential components needed to power, control, and automate systems. These include:

Electrical cables, switches, and circuit breakers

Control panels and automation equipment

PLCs (Programmable Logic Controllers)

Sensors and transducers

Industrial lighting solutions

Calibration and testing equipment

In Bahrain’s rapidly growing infrastructure and industrial sectors, high-quality E&I components are in demand for everything from oil & gas projects to smart building developments.

Why Local Expertise Matters in Bahrain

Working with a local electrical and instrumentation supplier in Bahrain has several advantages:

Faster delivery times: No long wait for overseas shipments

Compliance with local standards: Bahrain follows specific safety and regulatory guidelines

Support and service: A local supplier can offer on-site support, technical guidance, and even after-sales service

Cost-effective solutions: Minimizing shipping and customs costs

What to Look for in a Trusted Supplier?

If you’re on the hunt for a reliable electrical and instrumentation supplier in Bahrain, consider the following criteria:

Authorized distributor for major global brands

Large inventory and fast turnaround

Engineering support and technical consultation

Proven experience with local and international projects

Positive customer reviews and a reputation for reliability

Whether you’re setting up a control system for a manufacturing plant or installing safety instruments in a refinery, partnering with the right electrical and instrumentation supplier in Bahrain is key. Make sure you work with a company that understands both the technical and regulatory requirements of the Bahraini market.

0 notes

Text

Bottle Filling Machine: Comprehensive Guide to Boost Productivity and Precision

What is a Bottle Filling Machine?

A bottle filling machine is specialized equipment designed to fill bottles of various sizes and shapes with liquids, semi-liquids, or even powders. These machines streamline the bottling process, ensuring uniformity, speed, and accuracy across the production line. They can be manual, semi-automatic, or fully automatic depending on production needs and budgets.

Types of Bottle Filling Machines

1. Gravity Bottle Filling Machines

Ideal for low-viscosity, free-flowing liquids such as water, juices, and spirits, these machines allow liquid to flow into bottles using gravitational force. Cost-effective and low-maintenance, they're perfect for startups and small batch producers.

2. Overflow Bottle Filling Machines

These machines ensure precise fill levels, making them ideal for transparent containers where aesthetics matter. Overflow fillers are commonly used in cosmetic, personal care, and beverage industries.

3. Piston Bottle Filling Machines

Designed for high-viscosity or chunky liquids like sauces, honey, creams, and gels, these machines use a piston to draw and dispense the product. They offer unmatched volumetric accuracy.

4. Pressure Bottle Filling Machines

These are used when product flow needs assistance, especially with thick or dense liquids. Pressure fillers are found in industrial chemical and oil production lines.

5. Vacuum Bottle Filling Machines

Best suited for small volume and precision applications, especially in the perfume or essential oil sectors, vacuum fillers prevent product spillage and ensure exact filling.

Applications of Bottle Filling Machines

Food and Beverage Industry

From carbonated drinks to ketchup and cooking oils, bottle filling machines ensure hygiene, safety, and regulatory compliance in high-speed food processing environments.

Pharmaceuticals and Healthcare

Accuracy and contamination prevention are crucial. Bottle filling machines here come with HEPA filters, sterile filling zones, and anti-bacterial contact parts.

Cosmetics and Toiletries

For products like lotion, shampoo, face creams, and perfumes, filling machines must maintain product integrity. Features such as foam control and gentle handling are vital.

Chemicals and Lubricants

These machines handle flammable, corrosive, and heavy-duty fluids. With explosion-proof enclosures and corrosion-resistant parts, they're built for extreme conditions.

Key Features of Modern Bottle Filling Machines

1. Multi-Container Compatibility

Modern machines can adjust for various bottle sizes, shapes, and materials, from glass to PET and HDPE plastic.

2. Nozzle Customization

Options include anti-drip, shut-off, or bottom-up nozzles for foamy or corrosive products. Multi-head systems speed up production significantly.

3. Speed and Throughput

Machines can handle anything from 10 bottles per minute (for small setups) to 500+ bottles per minute in industrial operations.

4. Integrated Capping and Labeling

Some systems offer integrated solutions for filling, capping, sealing, and labeling—eliminating the need for multiple machines and ensuring seamless automation.

5. Programmable Logic Control (PLC)

Machines come with touchscreen HMI panels, allowing operators to store multiple recipes, monitor performance, and automate diagnostics.

Advantages of Using a Bottle Filling Machine

Enhanced Productivity: Automates repetitive tasks and fills multiple bottles simultaneously.

Reduced Wastage: Precision filling means minimal product loss.

Hygiene and Safety: Closed systems reduce contamination risks.

Scalability: Easily upgradeable to accommodate future business growth.

Regulatory Compliance: Helps meet FDA, GMP, or ISO standards with traceability and documentation features.

Selecting the Right Bottle Filling Machine

Step 1: Know Your Product

The viscosity, temperature, and chemical composition of your product determine the appropriate filling mechanism.

Step 2: Identify Bottle Type

Consider dimensions, cap styles, and materials. Machines should be adaptable to your container specs.

Step 3: Determine Output Requirements

What’s your daily or hourly bottle output? Choose between manual, semi-automatic, or fully automatic systems.

Step 4: Budgeting

Balance your initial investment against long-term benefits like speed, accuracy, and maintenance costs.

Maintenance Tips for Longevity and Efficiency

Daily Cleaning: Avoid product build-up and contamination.

Monthly Calibration: Maintain accuracy for compliance and quality.

Lubricate Moving Parts: Prevent mechanical wear and tear.

Replace Worn Components: Keep spare parts like gaskets, seals, and nozzles handy.

Train Operators: A knowledgeable team can identify issues early and avoid production delays.

0 notes

Text

Revolutionizing Food Production with the Automatic Mayonnaise Making Machine

In today’s fast-paced food industry, precision and consistency are non-negotiable. That's where the automatic mayonnaise making machine plays a crucial role. Designed to meet the high demands of commercial kitchens and large-scale food factories, this machine automates the entire mayonnaise production process—right from emulsifying to mixing ingredients. Traditional methods are no longer viable for businesses aiming for scale, hygiene, and cost-efficiency. The use of an industrial mayonnaise mixer ensures not only uniformity in texture but also accelerates production, helping manufacturers meet rising market demands. As a result, more brands are investing in reliable mayonnaise processing equipment to gain a competitive edge and maintain quality standards.

The automatic mayonnaise making machine stands out due to its advanced mixing technology and hygienic stainless steel build. Hygiene is a major concern in food production, and that’s why machines constructed from stainless steel are preferred—they are corrosion-resistant, easy to clean, and comply with food safety regulations. Moreover, many manufacturers now integrate AI-powered control panels that allow operators to adjust temperature, speed, and timing without manual effort. This not only reduces labor but also ensures that the consistency of the final product remains intact every single time. Leading suppliers of commercial mayonnaise mixing machines have observed a sharp increase in demand as restaurants, cloud kitchens, and FMCG companies turn to automated solutions to boost productivity and maintain recipe uniformity.

What further enhances the efficiency of an automatic mayonnaise making machine is its ability to process large batches without compromising on quality. Equipped with high-speed mixing blades and automated dosing systems, these machines can produce hundreds of liters of mayonnaise per hour. This makes them indispensable in large-scale production environments like condiment factories and industrial kitchens. Alongside, the incorporation of programmable logic controllers (PLC) allows the equipment to operate with minimal human supervision, reducing the chances of errors. With features like vacuum mixing and temperature control, these machines outperform older systems and even some modern manual alternatives. No wonder the mayonnaise processing equipment segment is rapidly evolving, offering customizable solutions for different production needs.

To sum it up, the automatic mayonnaise making machine has become a cornerstone of efficient food processing. As consumer demand for mayonnaise and similar condiments grows, so does the need for reliable, scalable, and hygienic solutions. With a variety of models available—from compact units for small businesses to fully automated systems for industrial use—there’s something for every level of production. Thanks to innovations in commercial mayonnaise mixing machine design and improvements in automation, manufacturers can now enjoy faster turnaround, consistent product quality, and reduced operational costs. Whether you're starting a condiment line or upgrading your current setup, investing in a top-tier industrial mayonnaise mixer made from stainless steel is a smart, future-ready choice. Tags: commercial mayonnaise mixing machine mayonnaise processing equipment industrial mayonnaise mixer stainless steel mayonnaise machine

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

High-Speed Candy Wrapping Machine by Dhiman Industries

Dhiman Industries presents a revolutionary solution for the confectionery sector with its high-speed candy wrapping machine, designed to streamline and elevate the packaging process of candies in commercial production lines. Engineered with advanced automation and built for long-term performance, this high-speed candy wrapping machine reflects the brand’s legacy of precision, innovation, and reliability in sweet manufacturing equipment. The machine ensures maximum operational efficiency while reducing manual intervention, making it ideal for manufacturers seeking high-output candy production with consistent wrapping quality.

This high-speed candy wrapping machine from Dhiman Industries is meticulously crafted to handle various candy shapes and sizes with ease, from square and rectangular to round and oval forms. It boasts a dynamic feeding system that aligns candies with exactitude, preparing them for the synchronized wrapping mechanism that operates seamlessly even at high speeds. Every mechanical motion within the machine is optimized for durability and minimal downtime, allowing production teams to meet large-scale orders without compromising on wrapping aesthetics or sealing integrity.

One of the defining advantages of this high-speed candy wrapping machine is its adaptability across wrapping materials such as wax paper, aluminum foil, cellophane, and laminated films. This multi-material compatibility opens possibilities for customized packaging based on branding, preservation needs, and target markets. The machine's quick-change tooling system further allows operators to switch formats rapidly, reducing idle time during product transitions. Whether wrapping butter candies, fruit toffees, or center-filled treats, the machine delivers consistent results at impressive speeds.

At the heart of the Dhiman high-speed candy wrapping machine is its electronic control panel, powered by programmable logic controllers (PLC). This intelligent interface allows real-time monitoring of machine status, speed regulation, wrapping cycle synchronization, and fault detection alerts for smooth operation. Additionally, sensor-based feeding and cutting systems ensure that each candy piece is wrapped with precision, reducing material wastage and enhancing the final presentation of the product. These integrated smart systems make the machine not only efficient but also user-friendly and safe to operate.

The robust stainless-steel construction of the machine guarantees hygiene, resistance to corrosion, and easy maintenance. It complies with international food-grade safety standards, ensuring candies remain uncontaminated throughout the wrapping process. Cleaning and servicing are simplified with modular components and accessible design, reducing long-term maintenance efforts and operational interruptions. Moreover, the compact footprint of the machine makes it suitable even for factories with limited floor space, while still delivering industrial-scale output.

With speeds exceeding several hundred wraps per minute, this high-speed candy wrapping machine empowers manufacturers to scale their business without additional manpower or complex logistics. The machine also incorporates automatic feeding conveyors and waste collection systems, creating a closed-loop process that enhances productivity while maintaining cleanliness in the workspace. Noise reduction technology further ensures a quieter operation, contributing to a more pleasant working environment for factory staff.

Dhiman Industries has always prioritized precision engineering and customer-centric design in its machinery, and this candy wrapping machine is a true embodiment of that vision. The machine can be tailored with optional attachments such as embossing rollers for branding, date coding modules, and customized cutting knives for specific edge finishes. These value-added features help brands stand out in competitive markets by enhancing the packaging’s visual appeal and information accuracy. The machine's scalability also allows integration with downstream packaging systems like carton box fillers and shrink-wrapping units, completing the full production cycle.

Training and support provided by Dhiman Industries further add to the overall value of the machine. Clients receive installation assistance, operator training, maintenance guides, and access to a responsive technical support team that ensures continuous performance and peace of mind. The company’s commitment to after-sales service makes it a trusted partner for businesses looking to invest in reliable high-speed wrapping technology for long-term growth.

In conclusion, the high-speed candy wrapping machine by Dhiman Industries is a game-changing solution for the confectionery industry. It brings together speed, accuracy, hygiene, and smart automation in one compact, efficient, and adaptable system. For manufacturers aiming to improve their production capacity, reduce labor dependency, and deliver attractively wrapped products to the market, this machine stands as the perfect investment. Dhiman Industries continues to set benchmarks in confectionery machinery, and this innovative high-speed candy wrapping machine reinforces its leadership in delivering performance-driven solutions for modern candy production lines.

0 notes

Text

Using PLC Panels in HVAC Automation for Commercial Buildings

Introduction

In modern commercial buildings, controlling temperature, air flow, and ventilation efficiently is crucial. Manual systems are no longer enough. Today, PLC Panels are widely used to automate HVAC (Heating, Ventilation, and Air Conditioning) operations, ensuring comfort, energy savings, and reliability.

Let’s understand how PLC Panels make HVAC systems smarter and more efficient.

Role of PLC Panels in HVAC Automation

Precise Temperature Control PLC Panels monitor room temperature and automatically adjust heating or cooling units.

Ventilation Management They control air circulation based on occupancy or air quality sensors.

Energy Optimization PLC logic reduces power usage by switching off unnecessary equipment or reducing loads during off-peak hours.

Humidity Regulation Integrated sensors can maintain ideal humidity levels in indoor spaces.

Fault Detection PLC Panels instantly detect errors and send alerts, preventing bigger breakdowns.

Make your building smarter and greener—consult a reliable PLC Panel Manufacturer for energy-efficient HVAC automation.

Key Benefits in Commercial Settings

Consistent indoor climate for employees or customers

Reduced electricity bills

Easy monitoring through a central HMI or SCADA

Custom schedules based on working hours or seasons

Remote access for quick adjustments or diagnostics

Industries and Spaces Benefiting from PLC HVAC Panels

Office buildings – Automated comfort settings and load balancing

Shopping malls – Precise control for multiple zones

Hospitals – Strict temperature and air quality requirements

Hotels – Personalized room settings and centralized management

Educational institutions – Smart use of energy in classrooms and labs

Why You Need a Skilled PLC Panel Manufacturer

A good Programmable Logic Controller Panel Manufacturer will:

Customize the PLC for your building’s size and layout

Integrate it with your existing HVAC setup

Ensure compliance with energy standards

Provide user-friendly controls and after-sales support

Conclusion

Automation of HVAC systems through PLC Panels is a smart investment for any commercial building. It brings comfort, control, and savings—without the hassle of manual systems. Partner with a trusted PLC Panel Manufacturer to get a tailored solution for your building’s specific needs.

Keep your building cool, comfortable, and cost-efficient—choose a dependable PLC Panel Manufacturer today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

#plc electrical panel#plc#plc panels#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes

Text

Can Industrial Electrical Services Support Automation and Control Systems?

Automation is the backbone of modern manufacturing and processing industries. It helps businesses save time, reduce errors, and boost efficiency. But behind every automated system is a skilled team providing the right industrial electrical services. These services are essential for setting up the power and control systems that allow automation to run smoothly.

Electricians work with systems like programmable logic controllers (PLCs), sensors, and automated machines. Their job is to make sure each part is correctly connected, receives enough power, and communicates with other parts of the system. Without proper electrical setup, even the most advanced automation tools won’t work reliably.

How electricians help install, wire, and maintain equipment

Professional electricians play a key role in every stage of an automation project. First, they help with planning—choosing the right layout and ensuring the system fits the building’s design and power capacity. Then comes the hands-on work: installing cables, connecting machinery, setting up control panels, and testing the system.

Once everything is up and running, industrial electrical services also include ongoing maintenance. Regular checks help spot potential issues before they cause downtime. Whether you’re building a new plant or upgrading existing equipment, having qualified electricians on your team is essential to get the most from your automation investment.

Do I Need an Industrial Electrician Sydney Based for Local Automation Projects?

Importance of choosing local expertise

If you’re setting up or upgrading an automated system in NSW, choosing a local industrial electrician sydney makes good sense. Local electricians are familiar with regional safety codes, energy requirements, and industry trends. They can also coordinate more easily with other local contractors and respond faster when needed.

Beyond convenience, working with a nearby expert means better project management. Communication is faster, site visits are easier to schedule, and support is available without long delays. This is especially important when deadlines are tight or when changes need to be made mid-project.

How a trusted industrial electrician sydney can assist with fast response and ongoing service

Automation systems don’t run on a 9-to-5 schedule—and neither should your electrical support. When things go wrong, you want help fast. A trusted industrial electrician sydney can provide same-day service or 24/7 call-outs to handle faults, malfunctions, or breakdowns.

But the support doesn’t stop after installation. Sydney-based electricians can also help with routine inspections, system upgrades, and staff training. Having a local partner ensures your automation system stays up-to-date, safe, and efficient over time.

What Types of Automation Can Be Installed During an Industrial Fit-Out?

Examples of automated systems: conveyors, PLCs, robotic arms

Automation isn’t one-size-fits-all. During an industrial fit-out, a wide range of systems can be installed to suit your operation. These might include automated conveyors for moving goods, robotic arms for packaging or welding, or computer-controlled machines for assembly and testing.

Electricians help install and integrate programmable logic controllers (PLCs), which act as the brains behind these machines. PLCs manage input and output devices, read sensors, and carry out programmed actions. With the right setup, your plant can run faster, safer, and more efficiently.

How automation is integrated during an industrial fit-out

An industrial fit-out is the perfect time to introduce or upgrade automation. Electricians work alongside builders and project managers to ensure all electrical systems support current needs and future expansion. They plan cable routes, power supply points, and ventilation for heat-sensitive equipment.

This process involves careful coordination. The electricians must know the layout of every machine, where control stations will be placed, and how much power each piece will need. Proper integration ensures that when the automation system is turned on, everything runs like clockwork from day one.

How Do Electricians Help Set Up Control Panels and PLC Systems?

What is a PLC and why it matters for automation

A Programmable Logic Controller (PLC) is like the brain of an automation system. It’s a small but powerful computer that tells machines what to do. Whether it’s turning on a motor, adjusting pressure, or stopping a conveyor belt, the PLC handles it based on pre-set instructions. And none of it works without the help of professional industrial electrical services.

A qualified electrician installs, wires, and programs these PLCs as part of your automation setup. They ensure the system responds to real-time data from sensors and operates in a safe, predictable way. With well-programmed PLCs, your facility can run smarter with less manual input.

How industrial electrical services manage control wiring and system logic

Control wiring is the foundation of any successful automation system. Electricians route cables from sensors, switches, and equipment back to the control panel and the PLC. They make sure every connection is secure, labelled, and compliant with safety standards.

Industrial electrical services also involve logic testing to ensure the PLC runs each operation correctly. If the system is too slow, too sensitive, or not responding, your electrician can adjust it. The result is a control system that’s reliable, responsive, and tailored to how your business operates.

Can I Get Affordable Electrical Services for Automation Projects?

What affects the cost of automation setup

The cost of automation can vary depending on your site size, system complexity, and the type of machines you’re using. Installing a full automation line with robotic arms, PLCs, and control systems will naturally cost more than upgrading a conveyor or adding new sensors. That said, getting affordable electrical services doesn’t mean compromising on quality.

Labour, material, and equipment costs will all affect your quote. So will the timing of the project—weekend or after-hours installs usually cost more. However, working with the right provider can help you plan more efficiently and avoid unexpected charges.

Tips to find affordable electrical services without cutting corners

To get good value, start by looking for a provider with broad expertise and a clear pricing structure. Choose companies that specialise in automation and have experience with industrial fit-out projects. This ensures they understand your needs and can recommend cost-saving solutions, like energy-efficient components or modular installations.

One trusted option is ES4U, a reliable electrical services company offering a full range of support. Whether you need an industrial electrician, commercial electrician, emergency electrician, or complete industrial fit-out, they’ve got you covered. With ES4U, you can expect expert service that fits your budget—without cutting corners on safety or quality.

What Ongoing Support Is Needed for Automated Systems?

Why regular maintenance and checks are essential

Once your automation system is up and running, it still needs care. Regular checks help catch small problems before they turn into major issues. Loose wires, worn components, or software glitches can slow down production or even shut it down completely. This is why scheduled maintenance is a core part of professional industrial electrical services.

Routine servicing includes inspecting PLCs, testing backups, checking safety features, and making sure sensors respond correctly. Even cleaning out dust from panels can prevent overheating or short circuits. With consistent attention, your system stays reliable, and you avoid costly downtime.

How electricians help prevent downtime in automated operations

Having a reliable industrial electrician sydney based—or nearby—is key. They can monitor the system and provide fast repairs if anything goes wrong. Some electricians even offer remote diagnostics or 24/7 call-outs for emergencies.

Ongoing support also includes upgrading outdated systems, improving energy efficiency, and making adjustments as your operation grows. With the right team on standby, your automation setup continues working hard without interruption.

Why Choose a Full-Service Provider Like Electrical for U for Industrial Projects?

Benefits of working with a team that handles installs, upgrades, and support

When you're managing a facility or running a factory, having one trusted team for everything makes life easier. A full-service provider like electrical for u can handle all parts of the project—from initial planning to installation and post-build support.

Instead of juggling multiple contractors, you get one point of contact for all your industrial electrical services. This means better coordination, faster delivery, and fewer mistakes. You can rely on one team to understand your systems inside and out, which is especially helpful for complex or evolving operations.

How electrical for u delivers complete solutions for automation

Whether you’re doing an upgrade, a full industrial fit-out, or installing new automated machinery, electrical for u can help. They offer complete services including data cabling, control panel design, PLC programming, and emergency call-outs.

Their electricians understand the demands of industrial spaces, and they bring both experience and flexibility to every job. With electrical for u, you get a solution that’s built for performance, safety, and long-term success.

#commercial electrician#electrical services#electrician for hire#electrician sydney#industrial electrician#electrician#emergency electrician#emergency electrical services#industrial fit-out#electrician near me

0 notes

Text

Why Are Contactors a Critical Component in Every Electrical System?

Understanding the Role of Contactors in Electrical Control

In the rapidly evolving field of industrial automation and power distribution, contactors have emerged as vital components that ensure seamless switching and safety in electrical circuits. Whether it’s for controlling motors, lighting systems, heaters, or capacitors, contactors act as the backbone for reliable and efficient electrical operations. Their ability to manage high-current loads while being controlled by low-voltage signals makes them indispensable in both commercial and industrial setups.

Contactors are electromechanical switching devices designed to make or break connections in a power circuit without manual intervention. They are engineered for durability, capable of handling multiple operations per minute and sustaining thousands of cycles over their lifetime.

How Do Contactors Function?

A contactor operates through the interaction of a coil and a set of contacts. When electrical current flows through the coil, it generates a magnetic field that pulls in the contacts, closing the circuit and allowing current to pass through. When the coil is de-energized, the magnetic field collapses, and a spring mechanism forces the contacts apart, breaking the circuit.

This action allows remote switching and automation of high-power devices using low-power control signals, which is especially beneficial in safety-critical and industrial environments.

Where Are Contactors Commonly Used?

Contactors find applications across numerous sectors, making them an integral part of electrical control systems:

Industrial automation panels for starting and stopping motors

HVAC systems to control compressors, fans, and blowers

Lighting circuits in commercial buildings and stadiums

Pumping systems in agriculture and wastewater management

Power factor correction equipment for capacitor switching

Heating control in industrial furnaces and ovens

What Are the Main Types of Contactors?

There are several types of contactors based on their design, application, and construction. Selecting the right type ensures optimal performance and longevity:

Electromagnetic Contactors: Operated via a magnetic coil and used in most general-purpose applications.

Definite Purpose Contactors: Tailored for specific equipment like HVAC units, offering cost-effective solutions with compact designs.

Vacuum Contactors: Ideal for medium to high-voltage applications, using vacuum-enclosed contacts to prevent arcing.

Solid-State Contactors: Utilize semiconductor devices for silent, fast switching without mechanical wear.

Knife Blade Contactors: Older, manually operated contactors mostly replaced by electromagnetic types in modern systems.

Key Features That Define a Quality Contactor

When investing in contactors, reliability and safety are paramount. High-quality contactors usually incorporate the following features:

High current and voltage ratings for handling industrial loads

Arc suppression technology to prevent contact welding and extend lifespan

Auxiliary contact options for signaling and interlocking

Thermal and magnetic overload protection integration

Modular design for easy installation and maintenance

What Are the Advantages of Using Contactors?

The use of contactors offers several significant benefits that contribute to efficiency, safety, and scalability in electrical systems:

Allow remote and automated switching of high-current devices

Minimize manual intervention, reducing operational risks

Improve the overall safety of electrical circuits by isolating control and power

Extend the lifespan of equipment by reducing electrical wear and tear

Enable integration with programmable logic controllers (PLCs) and timers for smart control

How to Choose the Right Contactor for Your Application?

Selecting the correct contactor depends on several application-specific parameters. Here's what to consider:

Voltage and current rating: Always choose a contactor that supports slightly higher values than your system’s maximum current and voltage.

Load type: Different contactors are optimized for resistive, inductive, or capacitive loads.

Control voltage: Ensure compatibility with the voltage used to activate the coil (e.g., 24V DC, 110V AC).

Frequency of operation: For frequent switching, select contactors rated for high endurance cycles.

Mounting method and size: Choose based on available panel space and standard configurations.

Certifications and compliance: Look for CE, UL, or IEC compliance, especially for commercial installations.

What Makes Contactors Different from Relays?

While both contactors and relays are switching devices, they differ mainly in power handling capabilities and design intent:

Contactors are designed for high-power applications, while relays are used in lower-current control circuits.

Contactors feature arc suppression systems and auxiliary contacts, while relays are generally simpler.

The contact spacing in contactors is more robust, ensuring safer operation under heavy loads.

The Role of Contactors in Safety and Automation

In environments where safety is non-negotiable, such as industrial manufacturing, data centers, or power plants, contactors play a pivotal role in:

Isolating faulty circuits to prevent equipment damage

Providing reliable system shutdowns during overloads or faults

Enabling seamless switching between power sources in backup systems

Facilitating energy efficiency by controlling non-essential equipment during peak hours

Future Trends and Innovations in Contactors

As industries move towards smarter and more energy-efficient systems, contactors are also evolving:

IoT-enabled contactors now allow remote monitoring and diagnostics

Energy-efficient coils reduce power consumption

Integration with smart grids for intelligent energy distribution

Enhanced arc suppression materials extend lifespan and reduce maintenance

These innovations ensure that contactors continue to support advanced automation systems and meet evolving industrial requirements.

Final Thoughts

Contactors are far more than simple switches; they are the unsung heroes of modern electrical systems. By enabling safe, automated, and reliable control of power, they contribute significantly to operational efficiency across multiple industries. Whether you're running a high-capacity manufacturing unit, managing a data center, or installing a home automation system, the right contactor is a cornerstone of secure and scalable electrical design. For those aiming to enhance their system's reliability and control capabilities, investing in high-quality contactors is a smart and future-proof decision.

#Contactors#Enrgtech#electroniccomponents#electricalparts#electrical parts#technology#electronic components

0 notes

Text

Elettro ABS Junction Box IP 55/65 – The Most Advanced Protection For Your Electronics

In industrial and outdoor applications, safeguarding sensitive equipment against potential moisture, dust, and impact is a prerequisite. A failure in your enclosure can spell disaster in the form of costly short circuits, system downtimes, and expensive maintenance. That’s where Elettro’s ABS Junction Box IP 55/ 65 comes into play, a highly resilient weatherproof enclosure that guarantees electrical components are kept safe, optimally protected, and ever-durable.

Why You Should Consider An Electro Mechanical Housing With Enhanced Protection Rating

Managing elaborate automation systems, implementing solar power setups, or handling telecommunication hubs requires an electrical junction box that serves as a connective foundation. The integrity of external conditions should never compromise the protective seal this box offers ensuring dry and secure terminals, connections, and wirings.

Due to being made out of graded ABS, this Elettro’s product offers unmatched protection with extreme ease of installation. With certified IP rating, this Junction Box stands out and combines considerable form and functional reliability for both professionals and keen amateurs seeking longevity in their installations.

Key Points of Elettro ABS Junction Box IP 55/65

Shielded From Water and Dust IP55/65- The enclosure features absolute defense from solid particles such as dust and can withstand water immersion up to 1 meter for 30 minutes. This is excellent for harsh industrial areas and/or unpredictable outdoor locations.

Custom Built For Enduring Conditions- Crafted from premium Acrylonitrile Butadiene Styrene (ABS), this material is preferred for UV stable impact polymer that endures chemicals because of its impact resistance and chemical tolerance make it ideal for indoor and outdoor applications.

Requires Minimal Maintenance and Extremely Strong- Unlike standard plastic boxes, Elettro’s ABS junction box withstands much greater mechanical stress and prolonged exposure to elements while still maintaining its structure.

Tailored To Individual Needs, Multiple Sizes Offered- To accommodate various wiring and device protection needs, Elettro offers a range of size variants which enables you to select the box that fits your technical setup.

Mounting and Installation Made Easy- The user friendly locking mechanisms and the smooth surface for labeling or drilling extra holes aid with pre marked drilling locations for further labeling or marking, increasing ease of installation.

Eco friendly improved fire resistance materials used- Hardened rubber and other polymers help maintain the box's overall form while Electric Polymers aid in keeping the encased components from internal and external damage. WRAP 530 increases fire resistance, making the box much safer than alternatives.

Uses of The ABS Junction Box IP55/65

This junction box can be used for a variety of purposes and is ideal for residential, commercial, and industrial settings:

Industrial Automation Systems

Provides guard for programmable logic controllers (PLCs), relays, and terminal block assemblies.

Solar and Other Energy Systems

Applicable in outdoor solar cell (PV) connections and inverter installations.

Telecommunication Equipment

Carefully house vulnerable connectors, switches, and fiber optic splitters in outdoor networks.

Outdoor Lighting, Signage and Guarding

Stripping power and timers can be enclosed in garden flower beds, streets, and commercial sign boards.

Control Panels & Distribution Boards

Covers internal wiring from dust, insects, and tampering, keeping them protected.

Coastal and Marine Installations

Perfect for areas that are prone to salt water and require corrosion protection.

Why choose Elettro for Electrical Accessories?

For professionals in the industry along with engineers and electricians, Elettro has been and is a reliable supplier due to its quality electrical components. Their ABS Junction Box IP65 is manufactured to high standards with safety and ease of use in mind.

By purchasing from Elettro, you’re not purchasing a product but investing in safety, system durability, and most importantly, letting you rest easy.

Conclusion

Of all the existing options, Elettro’s ABS Junction Box IP55/65 is unmatched in reliability, weather resistance, and overall protection. This waterproof junction box is efficiently catered for both residential projects and expansive industrial sites, guaranteeing that the electrical systems are safeguarded from every angle.

0 notes

Text

Test Chamber Manufacturers in India

Ferrotek Equipment is a leading name among Test Chamber Manufacturers, offering a wide range of high-quality, precision-engineered testing chambers designed for accurate and reliable environmental simulations. Our test chambers are ideal for research laboratories, electronics industries, automotive sectors, pharmaceuticals, and various other industrial applications where controlled testing conditions are critical.

What is a Test Chamber?

A test chamber is a controlled enclosure used to simulate environmental conditions such as temperature, humidity, pressure, or corrosion. These chambers allow businesses to test the durability, performance, and reliability of their products under different environmental stresses. At Ferrotek Equipment, we specialize in designing test chambers that meet international quality standards while offering maximum precision and durability.

Our Range of Test Chambers Includes:

Temperature and Humidity Chambers

Stability Chambers

Thermal Shock Chambers

Salt Spray Chambers

Altitude Test Chambers

Vibration Test Chambers

Key Features of Our Test Chambers:

Accurate Environmental Control: Digital control panels with programmable logic for precise regulation of temperature, humidity, and other parameters.

High-Quality Construction: Made using corrosion-resistant stainless steel and insulated with advanced materials for efficiency and safety.

User-Friendly Interface: Easy-to-operate touch-screen panels with real-time monitoring and data logging capabilities.

Custom-Built Designs: We offer tailored solutions to suit the specific testing needs of different industries.

Energy-Efficient Operation: Designed for low power consumption without compromising on performance.

Compliance with Global Standards: All our test chambers are manufactured in compliance with relevant industry norms such as ISO and ASTM.

Applications of Our Test Chambers

Our products are widely used across multiple sectors, including:

Automotive – For testing vehicle components in extreme environmental conditions

Electronics – For evaluating performance of electronic circuits and devices

Pharmaceuticals – For long-term stability studies and packaging validation