#Rail Electrical Connectors

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

Powering the Future of Railways: A Comprehensive Guide to Connectors for Railway Traction

In the context of global advancements towards sustainable and efficient transportation alternatives, there is a notable resurgence in the prominence of railways. The utilisation of railways as a primary means of transportation for both passengers and freight is on the rise, mostly due to the advantageous environmental attributes and cost-efficiency associated with this method of transport. The complex technology that drives modern railway systems is crucial for their performance, with a key element being the connectors employed for railway propulsion. Reliability you can depend upon. Elevate your railway systems with premium railway traction connectors manufactured and supplied by Radiant Enterprises - one of the distinguished Railway Traction Connectors manufacturers in India!

This thorough guide aims to provide an in-depth analysis of railway traction connectors, examining their importance, various types, advantages, and potential prospects in the future. A comprehensive grasp of these connectors is imperative for individuals engaged in the railway sector, as they assume a crucial function in propelling the advancement of trains and cultivating an environmentally friendly transportation infrastructure.

The Importance of Railway Traction Connectors:

This thorough guide aims to provide an in-depth analysis of railway traction connectors, examining their importance, various types, advantages, and potential prospects in the future. A comprehensive grasp of these connectors is imperative for individuals engaged in the railway sector, as they assume a crucial function in propelling the advancement of trains and cultivating an environmentally friendly transportation infrastructure.

Types of Railway Traction Connectors:

· Pantographs:

Pantographs represent the prevailing form of connectors employed in electric trains. The pantographs, located on the train's roof, establish a connection with the overhead wires, facilitating the transfer of electrical power to the train. Contemporary pantographs are outfitted with advanced sensors and control systems, enabling them to adjust to fluctuating voltage levels and maintain a consistent power provision.

· Third Rail Collectors:

The utilisation of a third rail as a power source is observed in certain railway systems, where trains derive electrical energy from an additional rail positioned adjacent to the tracks. Third-rail collectors are dynamic connectors that establish an electrical connection by sliding and making contact with the third rail. This approach is commonly observed in specific urban transport networks owing to its straightforwardness and economical nature.

Benefits of Advanced Railway Traction Connectors:

· Enhanced Efficiency:

Contemporary connections utilised in railway traction systems are engineered with the objective of minimising power losses during gearbox, hence leading to enhanced energy efficiency. The achievement of efficient power transmission results in a decrease in energy consumption and a reduction in operating expenses for railway operators.

· Reliability and Safety:

The utilisation of premium materials and cutting-edge engineering in the production of connectors guarantees a dependable and secure electrical linkage, hence enhancing reliability and safety. This improves the dependability and security of railway operations, hence mitigating the likelihood of power disruptions and incidents.

· Reduced Maintenance:

Connector designs that are more advanced sometimes possess self-cleaning capabilities, hence aiding in the prevention of the accumulation of dirt, debris, and ice on the contact surfaces. The implementation of this self-cleaning technology results in a reduction in maintenance demands and a decrease in downtime, hence enhancing operational availability.

· Sustainability:

The utilisation of electric trains, which are fueled by renewable energy sources, plays a substantial role in mitigating greenhouse gas emissions and addressing the issue of climate change. The utilisation of high-quality traction connectors is of paramount importance in expediting the acceptance and implementation of sustainable transportation systems.

The Future of Railway Traction Connectors:

The ongoing progress of technology will inevitably lead to the further development of railway traction connectors. Transform railway electrification with the advanced Railway Traction Connectors supplied by Radiant Enterprises. Request a sample today!

· Smart Connectivity:

The integration of the Internet of Things (IoT) and Industry 4.0 has led to the expectation that railway traction connectors will contain intelligent functionalities. The utilisation of real-time data monitoring and analytics has the potential to facilitate predictive maintenance, hence enhancing the efficiency and durability of the connectors.

· Lightweight and Durable Materials:

The field of material science has the potential to facilitate the creation of connector materials that possess both lightweight properties and exceptional durability. This may potentially result in a reduction in the overall weight of trains, hence enhancing their energy efficiency.

· High-Speed Rail:

The global demand for high-speed rail networks is experiencing a notable increase. In order to facilitate the operation of faster trains while ensuring safety and efficiency, future traction connectors will be required to accommodate elevated levels of voltage and current.

· Wireless Charging:

Wireless charging technology is now being investigated by researchers as a potential solution for trains. Potential future connectors have the potential to integrate wireless charging capabilities, hence obviating the necessity for direct physical contact between the train and the power source.

Final Thoughts:

The railway industry is positioned to assume a crucial role in influencing the trajectory of sustainable transport in the future. In order to realise this vision, the utilisation of modern technology, such as railway traction connectors, will play a pivotal role. As we progress, allocating resources towards research and development in order to create inventive and dependable connector solutions will not only propel the future of railway systems but also make a significant contribution towards a more environmentally friendly and efficient global landscape. The ongoing advancement of connector technology holds promise for the development of a more environmentally sustainable and interconnected railway system that will benefit future generations. Explore the optimal solution for your railway projects. Explore a diverse range of railway traction connectors offered by Radiant Enterprises - one of the trusted Railway Traction Connectors manufacturers in India!

#Railway Traction Connectors Manufacturers in India#Railway traction connectors#electrical#business#electrical company#electrical industry#smart grid sensor#rail insulator#railway#railway technology companies#train operating companies#locomotive#tramways#third rail#cable connector

10 notes

·

View notes

Text

Enhance Efficiency and Flexibility with DIN Rail Mounted Terminal Blocks in India

Introduction:

In today's rapidly evolving industrial landscape, efficient and reliable electrical connections are crucial for ensuring smooth operations. DIN rail mounted terminal blocks have emerged as a preferred solution for creating secure and organized electrical connections in a wide range of applications. With their versatility, durability, and ease of installation, these terminal blocks have gained immense popularity among professionals in India. In this blog post, we will explore the benefits and applications of rail mounted terminal blocks and highlight their importance in the Indian industrial sector.

What are DIN Rail Mounted Terminal Blocks?

DIN rail mounted terminal blocks are electrical connectors that provide a convenient and standardized method for connecting and distributing power or signals in industrial control systems. These blocks are specifically designed to be mounted on DIN rails, which are widely used for organizing and securing electrical components in control panels, switchgear cabinets, and equipment enclosures.

Benefits of DIN Rail Mounted Terminal Blocks:

Space-saving and Modular Design: DIN rail mounted terminal blocks feature a compact design that allows for optimal use of available space. Their modular construction enables easy customization and expansion as per the specific requirements of an application, making them highly adaptable.

Secure and Reliable Connections: These terminal blocks ensure secure and reliable connections, thanks to their robust construction and advanced connection technologies. They provide a sturdy grip on wires and facilitate excellent contact, minimizing the risk of loose connections and electrical failures.

Easy Installation and Maintenance: With their tool-less and user-friendly design, DIN rail mounted terminal blocks simplify installation and maintenance procedures. The snap-on mounting feature of these blocks allows for quick and hassle-free assembly, reducing overall downtime during system installation or upgrades.

Enhanced Safety: Rail mounted terminal blocks adhere to stringent safety standards and offer features like finger-safe design, which prevents accidental contact with live components. This ensures the safety of both the equipment and the personnel working with them.

Applications of DIN Rail Mounted Terminal Blocks:

Industrial Automation: Rail mounted terminal blocks are extensively used in industrial automation systems, where they serve as a vital component for connecting sensors, actuators, motors, and other devices. These blocks provide a reliable interface for transmitting power and signals between various control elements.

Power Distribution: DIN rail mounted terminal blocks play a crucial role in power distribution systems, allowing for easy and organized connection of power supply lines to different equipment. They enable efficient energy management and facilitate the distribution of power to multiple devices within a control panel.

Building Automation: In building automation systems, DIN rail mounted terminal blocks provide a convenient solution for connecting various electrical components, such as lighting controls, HVAC systems, security systems, and more. Their modular design allows for easy integration and maintenance of these systems.

Rail Mounted Terminal Blocks in India:

The Indian industrial sector is witnessing significant growth, and the demand for reliable electrical connectivity solutions is higher than ever. Rail mounted terminal blocks have gained traction in India due to their versatility and ability to meet the diverse requirements of industries ranging from manufacturing to infrastructure development. Manufacturers and suppliers in India offer a wide range of DIN rail mounted terminal blocks, catering to different voltage and current ratings, wire sizes, and connection types.

Conclusion:

Rail mounted terminal blocks have revolutionized the electrical connectivity landscape in India, providing efficient, secure, and organized solutions for various industrial applications. Their space-saving design, ease of installation, and robust construction make them indispensable for creating reliable connections in control systems and power distribution networks. As the industrial sector continues to thrive in India, the importance of DIN rail mounted terminal blocks as a key component in electrical installations cannot be overstated. By embracing these advanced terminal blocks, Indian industries can enhance efficiency, reduce downtime, and ensure safe and reliable operations.

#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India#Power BusBar Terminal#Finger Safe Power Terminal blocks#Barrier Terminal Block Manufacturer in India#electrical wire termination technology#manufacturer#terminal block#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#DIN rails channels#digital voltmeter#digital ammeter#power and signal#current transformer#railway#renewable energy#elmex#electrical company#electrical industry

2 notes

·

View notes

Text

Electrical terminal blocks, crimping terminal, What is a DIN terminal block

Automotive Connectors SZ 16 STAMP CONT SKT REEL OF 4000

#Connectors#Terminal Blocks#DIN Rail Terminal Blocks#1062-16-0722#TE Connectivity#electrical terminal blocks#crimping terminal#what is a DIN terminal block#phoenix terminal blocks#terminal block wire#Types of Terminal Blocks#barrier strip

1 note

·

View note

Text

The New Stäubli Modular Connector Lightweight – Evotrak lite

The New Stäubli Modular Connector Lightweight – Evotrak lite

Stäubli Showcased the New Modular Connector Lightweight at InnoTrans – Evotrak lite

Stäubli Electrical Connector launches the EvoTrak lite for versatile, adaptable electrical connections between the main functions of the rail vehicle electrical traction chain. During this year’s InnoTrans, the new modular lightweight EvoTrak lite was showcased to the public for the first time. The response was…

View On WordPress

#AC#bi#Connectors#Connectors for Busbars#CTA#db#design#EC#electri#Environment#era#GA#gr#Hani#InnoTrans#innovation#International#IT#Light Rail#Light Rail Vehicles#LRV#LTA#MAN#Mechan#NEC#News#NS#RAI#Rail Electrical Connectors#Rolling Stock

2 notes

·

View notes

Text

Automatic Platform Gates Market Size, Share, Forecast 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Automatic Platform Gates Market Share: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Automatic Platform Gates Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automatic Platform Gates Market?

The global automatic platform gates market size reached US$ 795.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,657.7 million in 2032, exhibiting a growth rate (CAGR) of 8.1% during 2024-2032.

What are Automatic Platform Gates?

Automatic platform gates are safety barriers installed at train station platforms designed to enhance passenger safety and prevent accidents by managing access to the tracks. These gates automatically open and close in coordination with train schedules, guiding passengers to stay behind the safety line and preventing unauthorized access to the track area. Featuring sensors and sophisticated control systems, automatic platform gates help reduce the risk of falls and accidents while improving station efficiency and crowd control.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1923

What are the growth prospects and trends in the Automatic Platform Gates industry?

The automatic platform gates market growth is driven by various factors and trends. The market for automatic platform gates is expanding as a result of growing safety standards and increased demand for improved passenger security at train stations. The adoption of these gates is driven by technological advancements and the need for better accident prevention and crowd management. Factors fueling market growth include stricter safety regulations, the expansion of rail networks, and the integration of smart technologies for enhanced operational efficiency. Key regions contributing to this growth are North America, Europe, and Asia-Pacific, where infrastructure investments and developments in public transportation are boosting the use of these advanced safety systems. Hence, all these factors contribute to automatic platform gates market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Full Height Platform Gates

Half Height Platform Gates

Portable Platform Gates

By Technology:

Sensor-based Gates

RFID-based Gates

Barcode-based Gates

Others

By Application:

Railway Stations

Metro Systems

Bus Stations

Airports

Others

By End-Use:

Transportation Authorities

Railway Operators

Metro Operators

Bus Operators

Airport Authorities

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Faiveley Transport

Nanjing Kangni Mechanical & Electrical Co., Ltd.

ST Electronics

Japan Transport Engineering Company

Gilgen Door Systems AG

DURAG GROUP

KG Technologies

Shanghai Sanei Elevator Co., Ltd.

WECO Electrical Connectors Inc.

Kaba Gallenschütz GmbH

Larsen & Toubro Limited

MEA Group

Tanabe Corporation

Wabtec Corporation

Thales Group

View Full Report: https://www.reportsandinsights.com/report/automatic-platform-gates-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Automatic Platform Gates Market share#Automatic Platform Gates Market size#Automatic Platform Gates Market trends

0 notes

Text

Enhance Your Space with Jaquar Bathroom Accessories

Jaquar is renowned for its exceptional quality and comprehensive range of bathroom products. At Maruthi Ceramics, we proudly showcase Jaquar’s extensive collection, offering customers access to top-tier sanitary solutions that blend functionality with aesthetic appeal. Founded with a commitment to innovation and excellence, the Jaquar brand has consistently set benchmarks in the industry since its inception. The brand’s dedication to crafting superior bathroom products is evident in every facet of its offerings, from faucets and showers to water closets and bathtubs. Each Jaquar product is uniquely designed to enhance the bathroom experience, combining cutting-edge technology with elegant design.

Why Jaquar Bathroom Accessories?

Give your bathroom the same care and attention as any other room in your home. Suppose you are searching for the best bathroom accessories in Bangalore, Jaquar is the best choice and take a glimpse at the wide range of bathroom accessories available at Maruthi Ceramics. These accessories are essential for outfitting your bathroom. Jaquar’s bathroom fittings are budget-friendly and offer excellent value for your investment! When choosing bathroom accessories, Jaquar emerges as the preferred choice for several compelling reasons. Not only does Jaquar prioritize eco-efficiency, but it also integrates advanced electrical protection features into its products. This commitment ensures that every installation not only enhances convenience but also promotes sustainability.

What sets Jaquar apart is its dedication to inclusivity. The brand offers a range of bathroom shower accessories designed to be disability-friendly, ensuring that everyone can access and enjoy their products with ease. This thoughtful approach underscores Jaquar’s commitment to creating solutions that cater to diverse needs and preferences. From essential bath and shower accessories to sophisticated sanitaryware and bathtub fittings, Jaquar covers all aspects of bathroom enhancement. Each product is crafted with meticulous attention to detail and quality, reflecting Jaquar’s reputation for excellence in both design and functionality.

Jaquar guarantees superior quality across its entire range of bathroom accessories. Whether you’re seeking stylish faucets, efficient showers, or elegant bathtub accessories, Jaquar products stand out for their durability, aesthetic appeal, and user-friendly features. Every item is engineered to deliver exceptional performance while complementing the overall ambiance of your bathroom space.

By choosing Jaquar, customers can rest assured that they are investing in products that meet and exceed expectations. With a focus on innovation and customer satisfaction, Jaquar continues to set industry standards, ensuring that each purchase enhances both the functionality and aesthetics of your bathroom.

Bathroom Accessories from Jaquar

Jaquar offers a comprehensive range of bathroom accessories and bathroom fixtures designed to enhance functionality, style, and comfort across various needs and preferences. From bath accessories to sanitaryware essentials, each Jaquar product reflects meticulous craftsmanship and innovation.

Bath Accessories: Jaquar’s bath accessories encompass a wide array of products aimed at elevating your bathing experience. Whether you’re looking for a corner glass shelf, grab bar, single towel rail, towel holder, etc, Jaquar provides options that combine aesthetic appeal with practicality.

Shower Accessories: Enhance your shower experience with Jaquar’s range of shower accessories. From luxurious shower pipes to Shower shower arms, Jaquar ensures that every shower is a rejuvenating experience.

Sanitaryware Accessories: Jaquar’s sanitaryware accessories include essential components like Vario bend, WC PAN Connector, Rack Bolt for WC, Inlet and Outlet Gasket, Wax Seal. Each piece is crafted with superior materials and ergonomic design, offering reliability and comfort for everyday use.

Bathtub Accessories: Turn your bathtub into a luxurious spa experience with Jaquar’s bathtub accessories.Explore options such as Drain Pipe, Drain Pipe with Overflow System, Headrest Sophi, Headrest Comfort, Base Europa Kit for Bathtubs, Atlas Frame that enhance relaxation and functionality.

Accessories for Disability-Friendly Bathrooms: Jaquar is committed to inclusivity with its range of disability-friendly bathroom accessories. These include grab bars that ensure everyone can experience a safe and comfortable bathing experience.

Washroom Accessories: Complete your washroom with Jaquar’s assortment of accessories like Hand Dryers, Soap Dispensers, Paper Towel Dispensers. These items are designed to complement any bathroom decor while offering practical solutions for storage and organization.

Conclusion

Experience unparalleled luxury with Jaquar sanitary products, exclusively available at Maruthi Ceramics. With conveniently located showrooms across Bangalore, including Indiranagar, Rajaji Nagar, Lavelle Road, Banaswadi, and JP Nagar, we ensure easy access to top-quality products and exceptional service. At Maruthi Ceramics, we are committed to your satisfaction, offering a diverse range of high-end bathroom accessories to elevate your living spaces. Whether you’re renovating your bathroom, kitchen, or any other area of your home, we provide the perfect solutions to meet your needs and preferences.

Our showrooms are a haven for those seeking the finest in bathroom accessories. Beyond Jaquar, we proudly feature superior brands such as Toto, Hansgrohe, Axor, Delta, Brizo, Grohe, Viking, and Easy Drain. Each brand is renowned for its exceptional quality, innovative designs, and lasting durability, ensuring that your bathroom not only looks stunning but also functions seamlessly. Visit Maruthi Ceramics today to explore our extensive collection and transform your space with the best bathroom accessories on the market. Our knowledgeable staff is ready to assist you in finding the perfect products to suit your style and requirements. Discover the difference that premium bathroom accessories can make and enjoy a new level of elegance and comfort in your home.

0 notes

Text

Outdoor LED strip lights

Outdoor LED strip lights are a popular choice for enhancing the ambiance and functionality of outdoor spaces. Here are some key features and considerations for choosing outdoor LED strip lights:

Key Features

Weatherproofing: Look for waterproof or weatherproof LED strip lights (rated IP65, IP67, or IP68) to ensure they can withstand rain, snow, and other outdoor conditions.

Brightness: Consider the lumens rating to ensure the lights are bright enough for your needs. Some applications may require brighter lights, while others might benefit from a softer glow.

Color Options: LED strip lights come in various colors, including single-color and RGB (color-changing) options. RGB lights often come with remote controls or smartphone apps for easy customization.

Length and Flexibility: Ensure the strip lights are long enough to cover the desired area. They should also be flexible to conform to different shapes and surfaces.

Power Source: Check whether the lights are battery-operated, solar-powered, or need to be plugged into an electrical outlet. Solar-powered options are eco-friendly and can be easier to install.

Installation: Look for strip lights that come with adhesive backing or mounting clips for easy installation. Some products may also include additional hardware for more secure mounting.

Applications

Deck and Patio Lighting: Enhance the ambiance and safety of your deck or patio by installing LED strip lights along railings, under seating, or around the perimeter.

Garden and Pathway Lighting: Illuminate pathways, garden beds, or landscape features to create a beautiful nighttime garden.

Outdoor Events and Parties: Use color-changing LED strip lights to add a festive touch to outdoor gatherings and events.

Architectural Accents: Highlight architectural features like columns, steps, or pergolas with discreet and elegant lighting.

Tips for Installation

Plan the Layout: Measure the area and plan the layout before purchasing to ensure you get the right length and number of strips.

Secure Connections: Use waterproof connectors and ensure all connections are secure to prevent water damage and ensure reliable operation.

Test Before Installing: Test the lights to ensure they work properly before final installation.

Follow Safety Guidelines: Adhere to the manufacturer's installation guidelines and local electrical codes to ensure safe installation.

Our website is an excellent source for additional details.

battery led strip lights

moon and stars night light

0 notes

Text

Cummins CM850/CM2850 Engine Fault Code 2311 Low Power Error Solution

Cummins CM850 and CM2850 engine fault code 2311,Electronic Fuel Injection Control Valve Circuit - Condition Exists. Fuel pump actuator circuit resistance too high or too low.

Cummins insite 8.9.2

Cummins inline 6

Circuit Description

The circuit is a pulse width modulation (PWM) driver in the ECM that controls the fuel pump pressurizing assembly 1. The fuel pump pressurizing assembly 1 is grounded in the ECM. The ECM varies the current to this valve to provide the correct fuel flow to the high-pressure pump based on engine operating conditions. The fuel pump pressurizing assembly 1 valve is a normally open valve. High circuit resistance can cause fuel pressure to be higher than commanded at light loads and Fault Code 1911 can be logged.

Component Location

The fuel pump pressurizing assembly 1 valve is located on the engine mounted fuel pump housing.

Use the following procedur for a detailed component location view. Refer to Procedure 100-002 in Section E.

Shop Talk

If this fault code occurs during road test, verify that all connectors are clean and free of corrosion before replacing components. This fault code can become active for any of the following reasons: Fuel pump pressurizing assembly 1 high resistance

Engine harness high resistance

Loose, worn, or corroded connectors or pins

Fuel pump pressurizing assembly 1 with low internal resistance

Fuel pump pressurizing assembly 1 or engine harness that has shorted to ground

Intermittent circuit failures that cause the fuel pressure to exceed the fuel rail pressure relief valve opening pressure.

If an intermittent electrical circuit problem of the fuel pump pressurizing assembly 1 circuit exists, it is possible for the fault code to become active then inactive during normal engine operation. For example, if a poor connection causes an intermittent open or short circuit, the normally open valve will open in a fraction of a second, while the circuit is faulty causing the fuel rail pressure relief valve to open. Following the event that caused the fuel rail pressure relief valve to open, the ECM will attempt to reset the fuel rail pressure relief valve, provided the fuel pump pressurizing assembly 1 circuit is not still failed.

Following any event that opens the fuel rail pressure relief valve, the fuel rail pressure relief valve will regulate the fuel pressure at approximately 900 bar [13,053 psi]. If the ECM is still capable of controlling fuel pressure, the following will occur: The measured fuel pressure will reduce to 600 bar [8702 psi] as the ECM prepares to seat the fuel rail pressure relief valve.

Once pressure is 600 bar [8702 psi] and engine speed is greater than 1200 rpm, the ECM will momentarily close the fuel pump pressurizing assembly 1. This action will reduce the fuel rail pressure (to less than 20 bar [290 psi] for a fraction of a second) so that the fuel rail pressure relief valve will reset. At light engine loads, especially if the engine is sped while the driveline is not engaged, engine power interruption will be noticeable while the ECM attempts to reset the fuel rail pressure relief valve.

Once the ECM detects that the fuel rail pressure relief valve is reset, normal engine operation will resume and Fault Code 2311 will become inactive.

https://www.car-auto-repair.com

0 notes

Text

Connecting the Dots: Exploring Different Types of Wire Terminal Connectors

Wire terminal connectors are essential components in electrical and electronic systems, providing secure and reliable connections between wires and devices. With a variety of types available, each designed for specific applications and environments, understanding the different wire terminal connector types is crucial for efficient wiring and connectivity. Let's delve into the various types of wire terminal connectors and their unique characteristics.

1. Ring Terminals

Ring terminals, also known as ring connectors or eyelet terminals, are one of the most common types of wire terminal connectors. They feature a ring-shaped metal terminal that is crimped or soldered onto the stripped end of a wire. Ring terminals are used for securing wires to terminal blocks, studs, or screws, providing a secure and durable connection that can withstand vibrations and mechanical stress.

2. Spade Terminals

Spade terminals, also called fork terminals or blade terminals, have a flat, spade-shaped metal terminal that is crimped onto a wire. They are designed to be inserted into terminal blocks, connectors, or screw terminals for quick and easy connections. Spade terminals are available in various sizes and styles, including insulated and non-insulated versions, to accommodate different wire gauges and applications.

3. Bullet Connectors

Bullet connectors, also known as bullet terminals or barrel connectors, feature cylindrical metal terminals that are crimped onto wires. They are commonly used for quick and reliable connections in automotive wiring, electrical appliances, and low-voltage applications. Bullet connectors come in male and female pairs, allowing for easy mating and disconnection of wires.

4. Quick-Disconnect Terminals

Quick-disconnect terminals, also called quick-connect terminals or push-on terminals, are designed for rapid and tool-free wire connections and disconnections. They feature a male or female terminal that can be easily pushed onto a corresponding terminal or stud. Quick-disconnect terminals are commonly used in automotive wiring, electrical appliances, and industrial equipment for fast and convenient installations and repairs.

5. Butt Connectors

Butt connectors, also known as splice connectors or wire joiners, are used to join two wires end-to-end. They feature a cylindrical metal tube with insulation and crimping ends that securely hold the wires together. Butt connectors are available in insulated and non-insulated versions, with heat-shrinkable options for added protection and durability in harsh environments.

6. Terminal Blocks

Terminal blocks are modular connectors that provide a convenient way to connect multiple wires or components. They consist of insulated blocks with metal terminals or screws where wires can be attached. Terminal blocks come in various configurations, including barrier strips, DIN rail-mounted blocks, and PCB-mounted blocks, making them versatile for different wiring applications in control panels, machinery, and electrical enclosures.

7. Pin Terminals

Pin terminals, also called male disconnect terminals, feature a pin-shaped metal terminal that is crimped onto a wire. They are designed to be inserted into female disconnect terminals or receptacles for electrical connections. Pin terminals are commonly used in automotive wiring, electrical appliances, and industrial equipment for secure and reliable connections that can be easily disconnected for maintenance or repairs.

8. Ferrule Terminals

Ferrule terminals, also known as wire ferrules or cord end terminals, are used to terminate stranded wires before insertion into terminal blocks or connectors. They feature a metal sleeve that is crimped onto the stripped end of a wire, providing a secure connection and preventing wire strands from fraying or coming loose. Ferrule terminals are available in insulated and non-insulated versions for different applications.

Conclusion

Wire terminal connectors are essential components in electrical and electronic systems, providing reliable connections that are crucial for proper functionality and safety. From ring terminals for secure wire attachments to quick-disconnect terminals for fast and tool-free connections, the variety of wire terminal connector types allows for efficient wiring and connectivity in various applications. Understanding the characteristics and applications of these connectors is essential for technicians, engineers, and DIY enthusiasts to ensure proper installations, repairs, and maintenance of electrical and electronic systems.

0 notes

Text

Ensuring Reliability and Safety: The Importance of Quality Traction Converters and Connectors in Railways

Introduction

The modern railway industry is evolving at a rapid pace, with advancements in technology playing a crucial role in enhancing efficiency, sustainability, and safety. Among the many components that contribute to the seamless functioning of a railway system, traction converters and connectors stand out as vital elements. This blog explores the significance of quality railway traction converter manufacturer and railway traction connector manufacturer in ensuring the reliability and safety of railway operations, with a specific focus on manufacturers in this domain.

Railway Traction Converters: The Powerhouses of Rail Mobility

Railway traction converters manufacturers play a pivotal role in the electrification of trains. These devices are responsible for converting electrical power from the grid into the appropriate form for the efficient and controlled movement of trains. As the demand for electrified rail systems grows, the role of railway traction converters manufacturers becomes increasingly critical.

Advancements in Traction Converter Technology

Leading manufacturers in the field of railway traction converters are at the forefront of innovation. They constantly strive to develop converters that are not only more efficient but also environmentally friendly. The integration of cutting-edge technologies, such as regenerative braking systems and advanced power electronics, contributes to the reduction of energy consumption and environmental impact.

Reliability Challenges and Solutions

Ensuring the reliability of traction converters is paramount for the uninterrupted operation of rail services. Manufacturers invest significantly in research and development to address challenges related to overheating, voltage fluctuations, and system failures. Robust testing procedures and quality assurance measures are implemented to guarantee the reliability of these critical components.

Railway Traction Connectors: Linking Efficiency and Safety

Railway traction connectors play a crucial role in ensuring the seamless transmission of power between various components of the rail system. These connectors serve as the interface between the traction converter and the train, facilitating the efficient transfer of electrical energy for propulsion.

Key Considerations in Connector Design

Manufacturers specializing in railway traction connectors prioritize several key considerations in their design and production processes. These include factors such as durability, weather resistance, and ease of maintenance. The harsh operating conditions that railways often face, including exposure to extreme weather and mechanical stress, necessitate connectors that can withstand such challenges without compromising performance.

Innovations in Connector Technology

In response to the evolving needs of the railway industry, manufacturers are continually innovating their connector designs. The integration of smart technologies, such as sensor-equipped connectors capable of real-time monitoring, enhances the safety and reliability of railway operations. These innovations contribute to the prevention of malfunctions and enable proactive maintenance measures.

Post Insulator for Railways: Ensuring Electrical Isolation and Safety

Post insulators for railways are critical components in railway electrification systems, providing electrical insulation and preventing current leakage. They play a crucial role in ensuring the safety of both passengers and railway personnel.

Importance of Quality Insulators

Railway electrification systems are subject to high voltage, and the quality of post insulators is paramount in maintaining electrical isolation. High-quality insulators prevent flashovers and electrical breakdowns, reducing the risk of accidents and disruptions. Manufacturers specializing in post insulators for railways adhere to stringent quality standards to meet the safety requirements of modern rail systems.

Challenges in Insulator Performance

The performance of post insulators can be affected by various factors, including environmental conditions, pollution, and mechanical stress. Manufacturers address these challenges through the use of advanced materials and coatings that enhance insulator resistance to environmental factors. Ongoing research and development efforts focus on improving the longevity and reliability of post insulators.

Choosing the Right Manufacturers: A Key to Reliability and Safety

Selecting reliable and experienced manufacturers is crucial for railway operators looking to ensure the longevity and safety of their electrified rail systems. Whether it is traction converters, connectors, or post insulators, the expertise and commitment of manufacturers significantly impact the performance of these components.

Key Criteria for Manufacturer Selection

Railway operators should consider several key criteria when choosing traction converter, connector, and post insulator manufacturers. These include a proven track record, adherence to industry standards, the use of advanced technologies, and a commitment to continuous improvement. Collaborating with reputable manufacturers enhances the likelihood of deploying systems that meet or exceed safety and reliability expectations.

Conclusion

In conclusion, the reliability and safety of railway systems depend heavily on the quality of traction converters, connectors, and post insulators. Manufacturers in these domains play a critical role in advancing technology to meet the evolving needs of the railway industry. As electrification becomes more prevalent, ensuring the highest standards in the design, production, and maintenance of these components is essential for the seamless, efficient, and safe operation of rail networks worldwide.

#Post Insulator For Railways#Railway Traction Converter Manufacturers#India#Railway Traction Connectors Manufacturers#railway#third rail#locomotive#tram#metro#railway engine

7 notes

·

View notes

Text

Step-by-step installation instructions of Submersible Pumps

Installing a submersible pump requires careful planning and adherence to safety guidelines to ensure proper operation and longevity. Here's a step-by-step guide to installing a submersible pump:

Step-by-Step Installation Instructions

1. Preparation

Read the Manual: Carefully read the pump’s installation and user manual provided by the manufacturer.

Safety Gear: Wear appropriate safety gear such as gloves, safety goggles, and non-slip footwear.

Inspect Equipment: Inspect the pump and all components for any visible damage or defects.

Tools and Materials: Gather all necessary tools and materials, including pipe wrenches, Teflon tape, electrical tape, pipe fittings, a torque arrestor, and safety rope.

2. Check the Well/Borehole

Clean the Well: Ensure the well or borehole is clean and free of debris.

Measure Depth: Measure the total depth of the well and the static water level to determine the required length of drop pipe and electrical cable.

3. Assemble the Pump and Accessories

Attach the Discharge Pipe: Connect the appropriate length of discharge pipe to the pump’s discharge outlet. Use Teflon tape on threaded connections to ensure a watertight seal.

Install the Torque Arrestor: Attach a torque arrestor to the discharge pipe just above the pump to prevent movement and damage due to pump start-up torque.

Connect the Safety Rope: Securely attach a safety rope to the pump, ensuring it is long enough to reach the top of the well.

4. Electrical Connections

Check Voltage and Phase: Ensure the pump’s voltage and phase match the power supply.

Splice the Cable: If needed, splice the electrical cable to the pump’s motor leads using waterproof connectors or a heat-shrink splice kit. Make sure the connections are secure and waterproof.

Install the Control Box: If required, install the pump control box near the power supply.

5. Lower the Pump into the Well

Attach Guide Rail (if applicable): Install a guide rail or centralizers to keep the pump centered in the well.

Lower the Pump: Slowly lower the pump into the well, using the safety rope and discharge pipe. Avoid dropping or allowing the pump to hit the sides of the well.

Secure the Discharge Pipe: Once the pump is at the desired depth, secure the discharge pipe at the wellhead. Ensure the pipe is properly supported to prevent strain on the pump.

6. Final Electrical Connections

Connect to Power Supply: Connect the electrical cable to the power supply, following local electrical codes and standards. Ensure all connections are tight and waterproof.

Grounding: Properly ground the pump to prevent electrical hazards.

7. Test the Installation

Initial Test: Turn on the power and allow the pump to run briefly to check for proper operation. Monitor the pump for any unusual noises, vibrations, or leaks.

Check Flow and Pressure: Verify that the pump is delivering the expected flow rate and pressure. Adjust as needed according to the pump’s specifications.

8. Complete Installation

Secure the Wellhead: Seal and secure the wellhead to prevent contamination.

Monitor Performance: Periodically check the pump’s performance, especially during the initial few days of operation, to ensure everything is working correctly.

Safety Precautions

Electrical Safety: Always turn off the power supply before making any electrical connections or adjustments.

Handling: Handle the pump carefully to avoid damage to the motor or pump components.

Professional Assistance: If you are unsure about any part of the installation, seek assistance from a professional or a licensed contractor.

By following these steps, you can ensure a safe and effective installation of your submersible pump, leading to reliable performance and extended service life. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

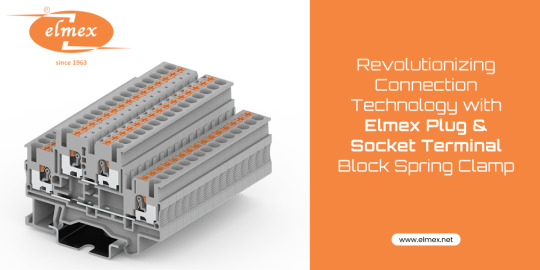

Revolutionizing Connection Technology with Plug & Socket Terminal Block Spring Clamp

Elmex is a leading name in the field of electrical connection technology, and their plug and socket terminal block spring clamps are one of their most innovative offerings. These spring clamps have revolutionized the way electrical connections are made, providing a secure and reliable connection that is easy to install and maintain.

One of the key advantages of Elmex plug and socket terminal block spring clamps is their ease of use. Unlike traditional screw terminals, which require manual tightening and loosening, these clamps use a spring mechanism to create a tight, secure connection with minimal effort. This makes installation and maintenance much faster and more efficient, which is especially important in large-scale industrial applications.

Another advantage of Elmex plug and socket terminal block spring clamps is their reliability. The spring mechanism ensures a consistent level of contact pressure, which minimizes the risk of loose or intermittent connections. This is particularly important in applications where the connection must remain stable and secure over a long period of time, such as in power distribution systems.

Elmex plug and socket terminal block spring clamps are also highly versatile. They can be used with a wide range of wire sizes and types, making them suitable for a variety of applications. In addition, they can be easily mounted on a DIN rail or panel, providing flexibility in installation.

Elmex plug and socket terminal block spring clamps are also designed with safety in mind. They are made from high-quality, flame-retardant materials that meet industry safety standards. This ensures that they can be used in even the most demanding environments without compromising safety.

In conclusion, Elmex plug and socket terminal block spring clamps are a game-changer in the field of electrical connection technology. Their ease of use, reliability, versatility, and safety make them an ideal choice for a wide range of industrial and commercial applications. If you are looking for a secure and efficient way to make electrical connections, Elmex plug and socket terminal block spring clamps are the way to go.

#Plug & socket terminal block spring clamp#Micro terminal block spring clamp#Panel mounted terminal blocks spring clamp India#Component housing block spring clamp#Spring loaded terminal blocks#spring loaded terminal connector#spring type terminal block#solar pv panel junction box India#solar pv branch connector India#electrical wire termination technology#manufacturer#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#digital voltmeter#digital ammeter#power and signal#current transformer#renewable energy#electrical company

4 notes

·

View notes

Text

Brass C21000 Round Bars Exporters in India

In the realm of industrial materials, brass has always held a significant place due to its durability, workability, and excellent resistance to corrosion. Among the various grades of brass, C21000 is particularly notable for its strength and versatility. When it comes to sourcing high-quality Brass C21000 round bars, Siddhgiri Tubes stands out as a leading exporter in India. This blog delves into why Siddhgiri Tubes is the preferred choice for brass round bars and explores the unique qualities of Brass C21000.

Understanding Brass C21000

Brass C21000, also known as Commercial Bronze, is an alloy composed primarily of copper (about 90%) and zinc (about 10%). This particular composition imparts several advantageous properties:

Corrosion Resistance: Brass C21000 exhibits superior resistance to corrosion, making it ideal for applications in harsh environments.

Strength and Ductility: This alloy combines strength with excellent ductility, enabling it to be formed into various shapes without compromising its structural integrity.

Aesthetic Appeal: With a warm, golden hue, Brass C21000 is also favored in decorative applications where visual appeal is essential.

Applications of Brass C21000 Round Bars

Thanks to its exceptional properties, Brass C21000 round bars find applications across a multitude of industries:

Architecture: Used in decorative elements, railings, and architectural hardware.

Electrical: Employed in electrical connectors and terminals due to its excellent conductivity.

Marine: Utilized in marine hardware and fittings, benefiting from its resistance to saltwater corrosion.

Automotive: Integral in the manufacturing of various automotive components, including radiator cores and heat exchangers.

Siddhgiri Tubes: Commitment to Quality and Excellence

As a premier exporter of Brass C21000 round bars, Siddhgiri Tubes has earned a reputation for delivering high-quality products that meet stringent industry standards. Here’s why they are a trusted name in the market:

Precision Manufacturing: Siddhgiri Tubes employs advanced manufacturing processes to ensure that each round bar meets exact specifications and tolerances.

Quality Assurance: Rigorous quality control measures are in place to guarantee the integrity and performance of the brass round bars. Each batch undergoes thorough testing for chemical composition, mechanical properties, and dimensional accuracy.

Global Standards: The company adheres to international standards such as ASTM, ASME, and DIN, ensuring that their products are suitable for global applications.

Customer-Centric Approach: Understanding the unique needs of their clients, Siddhgiri Tubes offers customized solutions, timely deliveries, and competitive pricing.

Sustainability: Committed to sustainable practices, the company ensures that their manufacturing processes are environmentally friendly, reducing waste and conserving resources.

Why Choose Siddhgiri Tubes?

Choosing Siddhgiri Tubes as your Brass C21000 round bar supplier comes with several advantages:

Expertise and Experience: With years of experience in the industry, Siddhgiri Tubes possesses in-depth knowledge and expertise, enabling them to cater to diverse industrial requirements.

Comprehensive Inventory: A vast inventory ensures that clients can procure the needed materials without delays, supporting efficient project timelines.

Reliable Logistics: Strong logistics and distribution networks ensure that the products reach clients safely and promptly, no matter where they are located globally.

In the competitive market of industrial materials, Siddhgiri Tubes has established itself as a leader in exporting Brass C21000 round bars from India. Their unwavering commitment to quality, precision, and customer satisfaction makes them the preferred choice for industries worldwide. Whether for architectural, electrical, marine, or automotive applications, Siddhgiri Tubes provides reliable solutions that meet the highest standards of performance and durability. For those seeking top-notch Brass C21000 round bars, Siddhgiri Tubes is the name you can trust.

For More Information :

Email : [email protected]

Call Us : +91-22674-96251 | +91-97734-70471

0 notes

Text

Top Quality Panel Board Accessories in Dubai, UAE | Trans Light Electricals

At Trans Light Electricals, we offer a comprehensive range of panel board accessories in Dubai, UAE, tailored to meet the diverse needs of our customers. Our extensive selection includes DIN Rail Channels, End Clamps, DMC Bus Bar Supports, Insulator Conical Series, PVC Grommets, Panel Locks, Swing Handles, Hinges, Filters, Document Holders, PBT Spacers, Neutral Link Breaks, PVC Trunkings, and Porcelain Connectors.

Our accessories are lightweight, corrosion-free, and ROHS compliant, ensuring easy installation and high workability. Designed to provide optimal surge protection and support for overloaded panels, they are suitable for various applications in control panels and machine tools. Trust Trans Light Electricals for reliable solutions that enhance the safety and efficiency of your electrical installations.

To know more -

1 note

·

View note

Text

9201A/B Epoxy Resin Helps the Development of Wind Power Industry

Epoxy resin is widely used in wind power, electronic and electrical, chemical anti-corrosion, aerospace, rail transportation, machinery manufacturing, ship transportation and other fields due to its strong adhesion, good corrosion resistance, strong electrical insulation and high mechanical properties.

The series of epoxy resin products for wind turbine blades mainly include vacuum infusion resin, hand lay-up resin and mold resin, etc., which have the characteristics of good mechanical properties, fatigue resistance, high and low temperature resistance, excellent mechanical properties, rapid prototyping, and typhoon resistance.

YQXPOLYMER 9201A/B epoxy resin is a product developed to meet the development needs of "lightweight" and "large-scale" wind turbine blades. YQXPOLYMER 9201A/B is an epoxy resin curing agent system specially designed for megawatt wind turbine blades, and it has long operating time and excellent mechanical strength and DNV certified.

Epoxy resin has excellent mechanical properties, chemical stability and corrosion resistance, and can be used as blade structural parts, connectors and coatings for wind power generation. In the supporting structure, skeleton and connectors of the blade, epoxy resin can provide high strength, high stiffness and fatigue resistance to ensure the stability and reliability of the blade. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of the blades, reduce the vibration noise of the blades, and improve wind power generation efficiency.

The application of epoxy resin in wind turbine blade coating is also very critical. By coating epoxy resin on the blade surface, the wear resistance and UV resistance of the blade can be improved, and the service life of the blade can be extended. At the same time, it can also reduce the weight and resistance of the blades and improve the efficiency of wind power generation.

Epoxy resin needs to be used in many aspects of the wind power industry, with a wide range of applications. Currently, among the blade materials for wind power generation, epoxy resin is mainly used in wind turbine blades, the core component of the front end of wind turbines. It is used to make the main beams, shells, webs, blade molds and blade trailing edge bonding.

Due to the development needs of "lightweight" and "large-scale" wind turbine blades, the material properties of epoxy resin can optimize the basic parameters such as strength, stiffness and dynamic fatigue of wind turbine blades, making the wind turbine blades lighter, with longer service life, better maintenance performance and shorter maintenance cycle.

The epoxy resin curing agent contributes particularly crucially to the performance of the wind turbine blade system. Only curing agents with good structural properties can effectively enhance the overall strength of the epoxy resin and thereby enhance the blade strength. In addition, curing agents also have an important impact on process control of blade manufacturing. If the viscosity of the curing agent is too high, it will be difficult to operate. If the reaction speed is too fast, the opening time will be too short. During the curing process of the blade, the reaction will be exothermic and smoke will be emitted, posing risks to the operation. YQXPOLYMER 9201A/B has low mixing viscosity, excellent fiber wettability, long gel time and operable time, low exothermic peak, and excellent comprehensive mechanical properties after curing.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy resin curing agent system#wind power#megawatt wind turbine blade#wind turbine blade#wind turbine blade coating#curing agent

0 notes