#megawatt wind turbine blade

Text

9201A/B Epoxy Resin Helps the Development of Wind Power Industry

Epoxy resin is widely used in wind power, electronic and electrical, chemical anti-corrosion, aerospace, rail transportation, machinery manufacturing, ship transportation and other fields due to its strong adhesion, good corrosion resistance, strong electrical insulation and high mechanical properties.

The series of epoxy resin products for wind turbine blades mainly include vacuum infusion resin, hand lay-up resin and mold resin, etc., which have the characteristics of good mechanical properties, fatigue resistance, high and low temperature resistance, excellent mechanical properties, rapid prototyping, and typhoon resistance.

YQXPOLYMER 9201A/B epoxy resin is a product developed to meet the development needs of "lightweight" and "large-scale" wind turbine blades. YQXPOLYMER 9201A/B is an epoxy resin curing agent system specially designed for megawatt wind turbine blades, and it has long operating time and excellent mechanical strength and DNV certified.

Epoxy resin has excellent mechanical properties, chemical stability and corrosion resistance, and can be used as blade structural parts, connectors and coatings for wind power generation. In the supporting structure, skeleton and connectors of the blade, epoxy resin can provide high strength, high stiffness and fatigue resistance to ensure the stability and reliability of the blade. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of the blades, reduce the vibration noise of the blades, and improve wind power generation efficiency.

The application of epoxy resin in wind turbine blade coating is also very critical. By coating epoxy resin on the blade surface, the wear resistance and UV resistance of the blade can be improved, and the service life of the blade can be extended. At the same time, it can also reduce the weight and resistance of the blades and improve the efficiency of wind power generation.

Epoxy resin needs to be used in many aspects of the wind power industry, with a wide range of applications. Currently, among the blade materials for wind power generation, epoxy resin is mainly used in wind turbine blades, the core component of the front end of wind turbines. It is used to make the main beams, shells, webs, blade molds and blade trailing edge bonding.

Due to the development needs of "lightweight" and "large-scale" wind turbine blades, the material properties of epoxy resin can optimize the basic parameters such as strength, stiffness and dynamic fatigue of wind turbine blades, making the wind turbine blades lighter, with longer service life, better maintenance performance and shorter maintenance cycle.

The epoxy resin curing agent contributes particularly crucially to the performance of the wind turbine blade system. Only curing agents with good structural properties can effectively enhance the overall strength of the epoxy resin and thereby enhance the blade strength. In addition, curing agents also have an important impact on process control of blade manufacturing. If the viscosity of the curing agent is too high, it will be difficult to operate. If the reaction speed is too fast, the opening time will be too short. During the curing process of the blade, the reaction will be exothermic and smoke will be emitted, posing risks to the operation. YQXPOLYMER 9201A/B has low mixing viscosity, excellent fiber wettability, long gel time and operable time, low exothermic peak, and excellent comprehensive mechanical properties after curing.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy resin curing agent system#wind power#megawatt wind turbine blade#wind turbine blade#wind turbine blade coating#curing agent

0 notes

Text

The world's first full-scale timber wind turbine has started turning in Sweden, with a tower built by wood technology company Modvion.

The 105-metre-tall tower, located in the region of Skara, is Modvion's first commercial wind turbine tower, and follows on from a smaller 30-metre-high demonstration project the company completed in 2020.

While its rotor blades and generator hub are made of conventional materials, the tower is made of laminated veneer lumber (LVL), a type of engineered wood made of thin veneer strips glued together and often used for beams and load-bearing building structures.

forces of a turning turbine, it is much more environmentally sustainable to build with than the currently used steel.

While wind power plays an important role in providing the world with green renewable energy, there are still ample carbon emissions created during their construction — in part because of the steel towers.

Modvion describes its wood towers as reducing the carbon emissions from wind turbine construction by over 100 per cent, due to the combination of a less emissions-heavy production process and the carbon storage provided by trees.

"Our towers, just in the production of them, they emit 90 per cent less than a steel tower that will do carry the same work," Modvion chief financial officer Maria-Lina Hedlund told Dezeen. "And then if you add the carbon sequestration, then you actually end up with a minus — so a carbon sink. This is great if we want to reach net zero energy production, and we need to."

Hedlund, who is also an engineer, describes LVL as having a construction "similar to carbon fibre", with strips of veneer just three millimetres thick sandwiched and glued together, giving it a high strength-to-weight ratio.

This lightness is a benefit, reducing the amount of material needed overall. With a heavy material, there is a "bad design spiral", says Hedlund, as the weight of the tower itself adds to the load that it needs to carry.

And while some LVL has all their veneer strips facing in the same direction, Modvion uses its "own recipe" specifying the directions of the fibres, improving the material's performance even more.

The production process involves timber boards being made to order in a standard LVL plant and then delivered to Modvion's factory. There, they are glued together into larger modules and bent into a rounded form in a step called lamination, and then very precisely machined to fine-tune the shape.

"In the wood industry, you usually see centimetre tolerances, while we are in the sub-millimetre scale," said Hedlund.

The modular nature of LVL construction addresses another problem Modvion has observed with steel: that with turbines getting ever bigger to give more power, it's becoming impossible to transport steel towers to site.

They are built as essentially large cylinders and transported by truck, but the base diameter desired for the tallest towers is getting to be taller than some bridges and roads can allow.

"We're now reaching a point where they will not get through anymore," said Hedlund. "So we will see a transition in the wind power industry to modular construction, because this is the way to get them there. And one of the big advantages of building in the material we do is that it's naturally built modular."

While steel could also be built modular, it would require bolts rather than glue to join it together on site, which Hedlund says is a disadvantage.

"Bolts are not very nice when you have so much dynamic loading, because it will loosen over time," she said. "So first of all, you have to have to put them in place which is a lot of work, and then you have to also service them over the lifetime."

The Skara turbine has a capacity of two megawatts, which represents the maximum power output the turbine can achieve under ideal conditions. This is a bit lower than the average capacity for new turbines built in Europe.

On the outside, the tower has a thick white coating that makes it look similar to steel, and it's rotor blades and generator hub, which are not supplied by Modvion, are made of conventional materials like fibreglass. This may change in the future, however, with another company, Voodin Blades, working on the technology for wooden blades.

Modvion was founded in 2016 by university peers David Olivegren and Otto Lundman. While its current focus is wind turbines, it is dedicated to wooden technology more broadly, and Hedlund told Dezeen that the team believes it has "the world's strongest joint for timber construction", which could also be put to other uses.

Another recent milestone for wind power came in the form of a wind-powered cargo ship, which had been retrofitted with two 37.5-metre-tall sails.

4 notes

·

View notes

Photo

Global Wind Day

Global Wind Day is celebrated on June 15 every year. It’s an international event to raise awareness regarding the importance of wind energy and the power it holds to change the world, improve energy systems, and decarbonize economies. Investing in wind energy means spending less money on fossil fuel imports, resulting in a smaller carbon footprint and minimized CO2 for cleaner air on our planet. On this day, we learn not just about how wind power leads to a greener planet, but also about job creation and employment opportunities for many people.

History of Global Wind Day

The history of wind energy as a power source traces back thousands of years. As early as 5,000 B.C., Egyptians had already been using wind power to propel their boats on the Nile River. This was improved upon by the Chinese in 200 B.C. as they invented wind-powered water pumps. Furthermore, people from the Middle East and Persia discovered windmills with woven-reed blades to grind grain with more speed and less manpower, which eventually led to more efficient food production.

It wasn’t until the 1st century A.D. that Heron of Alexandria created the windwheel. According to historians, this was the first recorded wind-driven wheel to power a machine. It included a small windmill that powered a piston that forces air through the organ pipes. According to records, it made a sound like that of a flute.

In the Middle Ages, windmills became a popular device in Pakistan, Afghanistan, and Iraq. They were used to pump water and grind sugarcane, which eventually boosted their grist milling industry. This technology was ultimately brought to Northwestern Europe in 1180 and became a popular tool to grind flour — a system that still exists up to date.

In the late 1800s and early 1900s, colonists brought windmills to the United States. Homesteaders and ranchers installed thousands of water pumps and small wind-electric generations in Western America.

The possibilities of wind power were further explored due to oil shortages in the 1970s. This forced everyone to find an alternative source of energy to generate electricity. Due to this scarcity, the U.S. federal government installed thousands of wind turbines in California to encourage the use of renewable energy sources. By 2020, the U.S. share of electricity generation via wind power grew to 8.4% — a huge spike compared to the 1990s 1%.

Global Wind Day timeline

1st Century A.D. The First Wind-Powered Machine

Greek engineer Heron of Alexandria discovers the first wind-driven wheel that powers a machine.

1180s Vertical Windmills

Northwestern Europe uses vertical windmills to grind flour.

1900s 2,500 Windmills Reaches 30 Megawatts

About 2,500 windmills in Denmark produce a combined power of 30 megawatts used to grind grains and pump water.

1970s Global Oil Shortage

The global oil shortage leads people to explore wind energy in a more advanced manner to be an alternative to electricity.

1980s Wind Turbines in California

The U.S. Federal Government installs thousands of wind turbines in California in support of renewable energy sources.

Global Wind Day FAQs

What are the types of wind energy?

The three main types of wind energy are utility-scale wind, offshore wind, and distributed wind.

What are four manufacturers in the world that uses wind turbines?

Vestas (Denmark), Siemens Gamesa (Spain), Goldwind (China), and General Electric (U.S.)

Which country uses the most wind power?

China uses the most wind power, generating approximately 236,402 megawatts in 2019 alone.

How to Observe Global Wind Day

Fly a kite outside

Attend seminars about wind energy

Take it to social media

This may sound like a simple activity, but flying a kite outside is an effective way to explain to your kids how wind energy works. Discuss how wind power propels the kite to stay afloat in the air. It’s also a great bonding activity that’s both fun and educational.

In an era where the climate crisis is peaking, wind energy is the future. Attend seminars on Global Wind Day to learn about the benefits and new technologies of wind energy as an alternative power source. Educating yourself is key.

Raise awareness about wind energy and its benefits on social media. Share scholarly articles or Global Wind Day event pages to your newsfeed. Use the hashtag #GlobalWindEnergy and keep your friends and family in the loop about one of the most pivotal solutions to decarbonizing the planet.

5 Interesting Facts About Wind Energy

The wind industry solves employment problems

The first modern turbine

Commercial turbines are powerful

The largest wind turbine

It doesn’t need water

The wind industry employs 650,000 people in different capacities around the world.

The first modern turbine was built in Vermont, U.S.

One commercial wind turbine can provide power to 600 homes.

The largest wind turbine was created in Hawaii, which stands 20 stories tall and each blade is as long as a football field.

Wind energy is the only power source that doesn’t need water.

Why Global Wind Day is Important

It’s for the good of the planet

It raises awareness

Wind energy is cost-effective

With the rise of global warming and other crises, wind energy is one solution to help lessen pollutants. Its long-term effects are advantageous to the new generation and to the generations that will come after.

People need to be proactive in highlighting the benefits of wind energy so that companies, governments, and other industries will adopt this technology as an alternative power source. The only way to make them proactive is to raise awareness. Education is key.

Global Wind Day helps us support the cost-effectiveness of wind energy. It’s one of the lowest-priced energy sources known today, which could potentially lower federal taxes.

Source

#Spring Valley#Nevada#Appalachian Mountains#Somerset County#landscape#countryside#nature#Somerset Wind Farm#Oregon#USA#Shepherds Flat Wind Farm#Middelgrunden Wind Turbine Cooperative#Denmark#Copenhagen#wind turbines#original photography#travel#vacation#15 June#GlobalWindDay#Pennsylvania#flora#forest#Atlantic Ocean#world day#international day#energy source

7 notes

·

View notes

Text

Offshore wind turbines are becoming an increasingly popular source of renewable energy, as they harness the power of wind in the open ocean to generate electricity. In this article, we will explore the size, capacity, and operation of offshore wind turbines, as well as the role that workers play in maintaining them.

Offshore wind turbines are typically much larger than onshore turbines, as they need to withstand more extreme weather conditions and generate more electricity to justify the cost of installation. The largest offshore wind turbines currently in operation are over 200 meters tall, with blades that can span up to 100 meters in length. These massive turbines can generate up to 12 megawatts of electricity each, which is enough to power thousands of homes.

Offshore wind turbines are typically installed on floating platforms or fixed foundations that are anchored to the ocean floor. Maintenance workers access the turbines via boats or helicopters, as they are often located in remote and hard-to-reach areas. Workers typically undergo specialized training to work on offshore wind turbines, as the environment can be hazardous and challenging.

The maintenance of offshore wind turbines is crucial to their longevity and performance. Workers are responsible for inspecting and repairing the turbines on a regular basis, ensuring that they are running smoothly and efficiently. This can include tasks such as blade repair, electrical maintenance, and cleaning the turbines to remove debris and prevent corrosion.

Despite the challenges of working on offshore wind turbines, many workers find the work to be rewarding and fulfilling. The development of the offshore wind industry has created new job opportunities in areas such as engineering, manufacturing, installation, and maintenance. In addition, offshore wind turbines are helping to reduce our dependence on fossil fuels and combat climate change, making the work even more meaningful.

In conclusion, offshore wind turbines are a vital source of renewable energy that are capable of generating large amounts of electricity. They are typically much larger than onshore turbines and require specialized maintenance and inspection. Workers play a crucial role in ensuring the safety and efficiency of offshore wind turbines, and the development of the industry has created new job opportunities in a variety of fields. As we continue to transition to a cleaner and more sustainable energy future, offshore wind turbines will undoubtedly play a crucial role in meeting our energy needs.

7 notes

·

View notes

Text

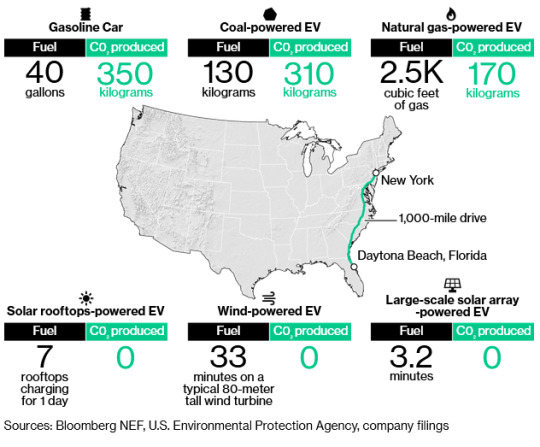

New Yorkers looking to escape the winter chill by driving to Daytona Beach, Florida, would use about 40 gallons of gasoline to traverse the 1,000 miles in a Chevrolet Impala.

Switch that gas guzzler out for an electron-eating EV and the equation changes. A Tesla Model S traveling the same distance would need power generated by about 2,500 cubic feet of natural gas, 286 pounds of coal or 33 minutes of blades spinning on a giant offshore wind turbine to make the same journey.

Gas Guzzlers to Electron Eaters

Electric vehicles have a wide range of fuel mileage options

As electric vehicles slowly become a bigger part of the global automobile fleet, questions about mileage and fuel efficiency are going to become more apposite. While there are multiple variables that can affect electric vehicle energy consumption, a Bloomberg NEF analysis illustrated some ballpark estimates to give drivers a better picture of what’s happening underneath the hood.

Coal

Taking that same 1,000-mile road trip in an electric vehicle that needs 33 kilowatt-hours of energy to travel 100 miles, like a Tesla Model S, would require about 286 pounds (130 kilograms) of coal to be burned at the local power plant. Modern coal plants only convert about 35 percent of the fuel’s energy into electricity, and about 10 percent of that electricity could be lost as it travels along power lines.

Even with all those losses, the electric vehicle road trip is still better for the climate than driving a gasoline-powered car. Burning that much coal would release about 310 kilograms of carbon dioxide into the atmosphere, compared with 350 kilograms by the 40 gallons of gasoline. Even though coal tends to emit more pollutants than oil for the amount of energy it generates, the efficiency of the electric vehicle, which recharges its battery with every brake, more than makes up the difference.

Natural Gas

A natural gas power plant producing the same amount of electricity would need to burn about 2,500 cubic feet of the fuel, enough to fill a small apartment in Hong Kong or a master bedroom in Dallas. Gas plants are more efficient than coal, typically converting about half the fuel’s energy into electricity. It’s also much cleaner, emitting just 170 kilograms of carbon dioxide for the 1,000-mile journey.

Solar

When it comes to charging electric vehicles with solar power, size matters. A typical 10-kilowatt rooftop array would need about seven days to create enough electricity for a 1,000-mile journey, as clouds and darkness mean it only operates at about 20 percent of its capacity on an average day.

Scale up to a photovoltaic power station, though, and it would take a matter of minutes, not days. At a modest-sized solar field like the 25-megawatt DeSoto Next Generation Solar Center in Florida, the average daily output would produce enough electricity for a 1,000-mile drive in less than four minutes.

Wind

Wind is a similar story, with different sizes of turbines producing different amounts of electricity. Take the Vestas V90-2.0 MW, an 80-meter tall behemoth that can be found swirling on the plains of West Texas, among other locations. Just one of these turbines, and wind farms are usually planted with dozens of them, produces enough electricity in a day to power a 1,000-mile trip every 33 minutes.

Calculating carbon emissions from wind and solar is a bit trickier. Neither emit any carbon dioxide in the course of producing electricity on a daily basis. But unless they’re paired with adequate energy storage -- and most existing renewable generation isn’t -- carbon-emitting generation has to make up for them whenever the sun isn’t shining or the wind isn’t blowing.

2 notes

·

View notes

Text

Brazil faces dilemma: endangered macaw vs. wind farm

A wind farm in northeastern Brazil sounds like a welcome climate-friendly energy solution, but it is causing controversy over another kind of environmental worry: the impact on the endangered Lear's macaw.

Home to more than 90 percent of Brazil's booming wind-power industry, the northeast is known for strong, steady winds that President Luiz Inacio Lula da Silva wants to harness to power a green-energy revolution.

The region has drawn the interest of French renewable energy company Voltalia, which broke ground in 2021 on a 28-turbine, 100-megawatt wind farm in semi-arid Canudos county, in the state of Bahia.

But the project soon came under attack when it emerged that the enormous turbines, with their 120-meter (nearly 400-foot) diameter blades -- a known threat to birds in flight -- were being built in a nesting region for the Lear's macaw, a bright blue parrot also known as the indigo macaw, or by its scientific name Anodorhynchus leari.

Continue reading.

#brazil#politics#environmentalism#animal rights#brazilian politics#renewables#energy#mod nise da silveira#image description in alt

3 notes

·

View notes

Text

Renewable Drones Market Analysis by Size, Share, Growth, Trends (2024-2032)

Introduction

A comprehensive overview of the Renewable Drones market is recently added by UnivDatos Market Insights to its humongous database. The Renewable Drones market report has been aggregated by collecting informative data of various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Renewable Drones market. The Renewable Drones market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Renewable Drones market at the global and regional levels.

The recent covid-19 pandemic in 2019 took the world by a storm. The pandemic brought the world to a standstill. All industries have suffered some form of loss due to the pandemic. In addition to this the pandemic has also cost many lives. Till date there have been 177,470,620 covid-19 cases in the world and 3,839,931 deaths. Most nations around the world were affected by the pandemic which not only took lives but also took away jobs. The pandemic caused a huge economic burden all around the world with most industries bearing some form of loss. The Renewable Drones industry also saw a slowdown during the pandemic as the industries were shut and production was affected.

Request for Sample of the report browse through - https://univdatos.com/report/renewable-drones-market/get-a-free-sample-form.php?product_id=6285

Market Overview

The Renewable Drones Market is expected to grow from US$ billion in 2020 to US$ XX billion in 2027 with a lucrative CAGR. The key reasons for this are that data can be collected almost 50 times faster with the help of drones. Solar farms are large parks and so manual check takes a long amount of time, whereas with the help of drones equipped with an appropriate thermal camera the detection can be made much faster. For example, usually wind turbines are inspected manually either by climbing or hanging down by a rope, which apart from being unsafe is also time consuming. With the help of drones this can be changes and data can be collected much more efficiently and in much less time. With the help of a drone 1 wind turbine (with 3 blades) can be inspected in 40 minutes. With the help of drones, solar and wind farm inspections are more accurate, faster, and more economical. This is expected to boost the renewable drones market in the coming times.

Based on type, the renewable drones market is segmented into Multirotor and Fixed wing. Amongst type, the multirotor segment of the renewable drones market was valued at US$ XX billion in 2020 and is likely to reach US$ XX billion by 2027 and is growing at a CAGR of XX% from 2021-2027. Multirotor drones have various advantaged over fixed rotor drones like performing vertical takeoffs and landings. They do not need much space to take flight, can maneuver around objects and can hover mid-flight, which allows for easy inspection, modeling, and mapping. Wind turbine inspection costs can minimize by 40% with the help of drones.

Based on solution, the renewable drones market is segmented into End-to-end solution and Point solution. Amongst solution, XX accounted for a market valuation of US$ XX billion in 2020 and is expected to reach US$ XX billion by the year 2027, at a CAGR of XX% over the analyzed period. End-to-end solutions includes everything from data analysis, accessories, reports etc. for the client such that nothing must be supplied from the outside. According to NREL researchers an average of 4 megawatts per square kilometer (about 10 megawatts per square mile) of area is required by windmills.

Based on end-user, the renewable drones market is segmented into solar and wind. The solar segment is further sub segmented into Solar PV and Solar CSP. The solar segment generated revenue of US$ XX billion in 2020 and is expected to grow at a CAGR of XX% during the forecast period to reach a market valuation of US$ XX billion by 2027F. Solar farms are growing at a tremendous rate around the world as the solar cell technology is becoming more efficient and governments are realizing the potential of solar energy. Siemens Gamesa for Trianel Windkraftwerk Borkum II GmbH & Co. maintained and provided service for its Trianel Windpark Borkum II. This involved the servicing and maintenance of 32 Senvion 6.33 MW turbines.

COVID-19 Impact

The recent covid-19 pandemic in 2019 took the world by a storm. The pandemic brought the world to a standstill. All industries have suffered some form of loss due to the pandemic. In addition to this the pandemic has also cost many lives. Till date there have been 177,470,620 covid-19 cases in the world and 3,839,931 deaths. Most nations around the world were affected by the pandemic which not only took lives but also took away jobs. The pandemic caused a huge economic burden all around the world with most industries bearing some form of loss. The Renewable Drones industry also saw a slowdown during the pandemic as the industries were shut and production was affected.

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analysing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Renewable Drones market. The leading players have been analysed by using research methodologies for getting insight views on global competition.

For a detailed analysis of the Solution in the Renewable Drones Market browse through - https://univdatos.com/report/renewable-drones-market/get-a-free-sample-form.php?product_id=6285

Conclusion

Additionally, the report provides detailed initiatives that are being taken in the field of renewable drones, globally. The report provides a detailed analysis of regions including North America (the U.S, Canada, and Rest of North America), Europe (Germany, France, Spain, Italy, UK, and Rest of Europe), Asia-Pacific (China, Japan, India, Australia, and Rest of Asia-Pacific), and the Rest of the World. Asia Pacific dominated the market in 2020, with XX% share. DJI Enterprise, Terra Drone, AgEagle Aerial Systems, DroneDeploy, Parrot Group, ABJ Drones, DRONE VOLT Group, Airpix, Sitemark, and Skylark Drones are some of the prominent players operating in the Renewable Drones market. Several M&As along with partnerships have been undertaken by these players to make Renewable Drones as cost-effective and as widely available as possible.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Website - https://univdatos.com/

0 notes

Text

Big Tech’s appetite for energy is just about visible from the east coast of Scotland. Some 12 miles out to sea sits a wind farm, where each of the 60 giant turbines has blades roughly the length of an American football field. The utility companies behind the Moray West project had promised the site would be capable of generating enough electricity to power 1.3 million homes once completed. That was before Amazon stepped in.

In January, Amazon announced it had struck a deal to claim more than half the site’s 880 megawatts of output, part of its ongoing attempt to slake its unquenchable thirst for power. As the world’s biggest companies race to build the infrastructure necessary to enable artificial intelligence, even remote Scottish wind farms are becoming indispensable.

In Europe last year, $79.4 million was spent on new data center projects, according to research firm Global Data. Already in 2024, there are signs that demand is accelerating. Today Microsoft announced a $3.2 billion bet on Sweden data centers. Earlier this year, the company also said it would double its data center footprint in Germany, while also pledging a $4.3 billion data center investment for AI infrastructure in France. Amazon announced a network of data centers in the state of Brandenburg as part of a $8.5 billion investment in Germany, later dedicating another $17.1 billion to Spain. Google said it would spend $1.1 billion on its data center in Finland to drive AI growth.

As the tech giants rush to build more data centers, behind the scenes there is panic around how to power them. Microsoft, Meta and Google all plan to be net zero before 2030, while logistics-heavy Amazon has targeted 2040. In pursuit of that aim, the past decade has seen those companies hoover up renewable energy contracts with wind or solar companies. But all these projects rely on electricity grids, which are buckling under increased demand for clean energy. That’s forcing the tech giants to think about their energy-intensive futures and consider how they might operate their own off-grid power empires, outside the system.

“There is a recognition that as power demand increases, the industry will have to find alternative energy sources,” says Colm Shorten, senior director of data center strategy at real estate services company JLL, explaining that server farms are increasingly looking for “behind-the-wire” power supply, whether that's gas or diesel generators or more innovative technology such as green hydrogen.

Data centers need power for two primary purposes. The first is to power the chips that enable computers to run algorithms or power video games. The second is to cool the servers, to stop them from overheating and cutting out. Initiatives such as using liquid to cool the chips instead of air are expected to make modest energy savings. But forecasts still expect data centers’ demand for power to as much as double by 2026, according to the International Energy Association, thanks in part to the demands of artificial intelligence.

For the past five years, tech companies have been on an increasingly frenzied shopping spree for renewable contracts known as power purchase agreements (PPAs), which can enable data center operators to reserve power from a wind farm or solar site before the projects have even been built. In Denmark, there are solar farms paid for by Meta. In Norway, there are wind farms bankrolled by Google. As early adopters of these types of deals, tech companies have helped fuel Europe’s now-thriving PPA market, says Christoph Zipf, spokesperson at WindEurope. This month, Microsoft struck the world’s biggest renewables energy deal, signing a $10 billion contract for clean power across Europe and the US.

Yet renewables still need to run through the electricity grid, which is becoming a bottleneck—especially in Europe, as a surge of renewable producers try to connect to feed green transition demand across a multitude of sectors. “We're going to run into energy constraints," Meta CEO Mark Zuckerberg predicted on a podcast in April. At Davos this year, OpenAI CEO Sam Altman also warned that the status quo was not going to be able to provide AI with the power it needed to advance. “There's no way to get there without a breakthrough,” he said at a Bloomberg event.

Grid operators are essentially saying the same thing. Ireland’s state-owned electricity provider Eirgrid cited grid problems when it imposed an effective moratorium on Dublin data centers two years ago. When the municipality of Amsterdam introduced a similar pause, the Dutch Data Center Association, an industry group, hit back. “The current grid congestion in North Holland is blocking the growth of the data center sector,” it said in a statement.

In the search for space on the grid, data centers are being pushed into parts of Europe where their arrival is more conspicuous, risking backlash from the smaller communities when they show up. That trend is already visible in Germany, according to Simon Hinterholzer, researcher at Germany’s Borderstep Institute for Innovation and Sustainability. “In the past, the large majority of new data centers were being built in Frankfurt,” he says. “This has completely changed in the last two or three years.” He points to a 300-megawatt data center being built in the small town of Wustermark, as well as Amazon’s latest investment into Brandenburg, the region bordering Berlin where more than 70 turbines were installed last year.

To cope long-term, there are more calls for data centers to find ways to survive off-grid. “The size of AI projects are getting bigger and bigger, reaching up to 1 gigawatt of power, which cannot be supplied by the traditional power grids,” says Ricardo Abad, founder of data center Quark, which is working on a new site with an unnamed partner in Spain that will be able to generate its own power through on-site solar and wind power. These types of on-site projects are technically still connected to the grid—in case they want to offload excess power—but they have the ability to operate independently, he says.

The same year Dublin announced restrictions on data centers, Amazon also opened its largest-ever on-site solar farm, spanning the roof and car park of its fulfillment center in Seville, Spain. Google’s head of data center location strategy in Europe has also expressed interest in on-site renewables for its next generation of server farms. Microsoft and Meta denied running any projects that are entirely off-grid. But in Dublin, Microsoft is building a data center alongside its own backup gas power plant, meaning the site can keep running even if the grid operator kicks it off.

But Big Tech is really in search of clean energy ideas—even if those ideas are still in their very early stages. “In the future, technologies like advanced nuclear reactors, renewable energy sources, and energy storage solutions will be crucial in making this possible,” says Kilian Wagner, an expert in sustainable digital infrastructures at German digital association Bitkom. OpenAI’s Altman is already an investor in Helion Energy, an American nuclear fusion company that has also agreed to provide Microsoft with 50 megawatts of electricity from its first fusion nuclear plant, once operational. In the US, Microsoft has already been experimenting with hydrogen fuel cells, touting them as a form of emission-free power back-up.

What server farms going off-grid would mean for the rest of us is unclear. By going it alone, Big Tech firms could strike gold in their search for the clean energy source of the future. Until they figure it out, they’re stuck with the grid.

0 notes

Text

World's first 16-megawatt offshore wind turbine installed in SE China

No more global energy crisis

The last blade of a giant offshore wind turbine successfully completed docking at a height of 100 meters in southeast China's Fujian Province.

This 16-megawatt wind turbine installed is the largest that has been put into installation in the world thus far.

0 notes

Text

China Launches World's Largest Offshore Wind Turbine

China's Three Gorges Energy has successfully connected the world's largest offshore wind turbine to the grid. MingYang Smart Energy designed the massive turbine, named the MySE 16-260. It has a rotor diameter of 260 meters and stands on a tower 152 meters high. The motor section and generator component weigh 385 tons on their own. The three 123-meter-long blades add an extra 54 tons to the total weight.

Three Gorges Energy's giant turbine sweeps an area of approximately 50,000 square meters with every full turn. This is equivalent to the area of seven football pitches. With every turn, the turbine provides 34.2 kWh of energy to China's power grid. This means about 66 gigawatt-hours of energy per year.

World's Largest Offshore Wind Turbine

The giant turbine is located at the Fujian offshore wind farm in the Taiwan Strait. This location creates a natural wind tunnel effect, increasing the efficiency of the turbine. According to Three Gorges Energy, this area faces 7-level "near-strong wind" conditions with wind speeds of 51 kilometers per hour 200 days a year.

Typhoons frequently occur in this area, and the turbine's design enables it to withstand winds gusting up to 287 kilometers per hour. This provides a safety margin above the wind speed of 260 kilometers per hour, which represents the most severe condition recorded during the Tip Typhoon in 1979. However, it is difficult to predict what the future holds, as weather conditions are becoming increasingly unstable due to climate change.

It appears that offshore wind turbines will continue to grow. In January, the China State Shipbuilding Corporation began constructing an 18-megawatt turbine, and they are expected to announce a 20-megawatt turbine in the near future.

Read the full article

#China'sWindFarm#MySE16-260#OffshoreWindTurbine#RenewableEnergy#ThreeGorgesEnergy#WindEnergyInnovation

0 notes

Text

Birders Take Green Energy Project To OH Supreme Court

New Post has been published on https://www.ohenergyratings.com/blog/birders-take-green-energy-project-to-oh-supreme-court/

Birders Take Green Energy Project To OH Supreme Court

Owl’s Fair In Love And War Against Wind Farm

Ohio birders are taking a green energy project to court. Find out what the issues are and how this could affect future electricity rates.

A proposed wind turbine farm in northwest Ohio is ruffling bird watchers. The Emerson Creek Wind Project site lies 40 miles southwest of the Black Swamp Bird Observatory (BSBO). The BSBO hosts the annual Biggest Week In American Birding festival in May. While most birders back renewable electricity, many oppose this wind project. So, let’s look at why birders are taking a green energy project to the Ohio Supreme Court.

Wind Is A Great Asset For Green Energy

It’s no secret that green energy cuts carbon from fossil fuels, like natural gas. And after last year’s extreme price swings, Ohio electricity customers may find green energy burns less cash in their wallets. The proposed 73 wind turbine farm could create up to 950,000 megawatts per year. That output could power around one million homes every year. With electric demand rising, turning towards renewables would ease the state’s energy costs.

Why Is The Location Controversial

Ohio is home to many species of migratory birds. Birdwatching is a very popular hobby in Ohio, bringing in huge numbers of tourists each year. In 2011 alone, birdwatching brought in over $26 million dollars to Ohio towns on the coast of Lake Erie. However, birds don’t stay in one place. Even at 40 miles away, the wind farm could effect one of the state’s prime birdwatching spots. While some studies suggest turbine related bird deaths aren’t very high, the BSBO argues that the wind farm’s location does threaten the area’s birds. The group also dismissed the effectiveness of painting one blade black, adding it goes against FAA guidelines.

What’s Really The Situation With the Birds and The Blades?

According to the Audubon Society, bird-wind turbine collisions kill up to 500,000 birds per year. Although that number seems shocking, pet and building-related fatalities are in the billions. The problem is that adding a new renewable energy resource would help control electricity prices across the state. More importantly, it would reduce carbon emissions, which is good for both humans and birds. But while the site does lie directly in a migratory path, the turbines still present a threat to endangered birds. After all, when each member of a species is important to its survival, loosing just one can spell extinction. To be sure, it’s not an ideal trade off. So, researchers should carefully monitor the wind turbine effects on local bird populations.

Other Problems With The Green Energy Project

Birders aren’t the only people taking issue with the proposed wind turbine project. Local landowners worry about the unstable ground at wind farm’s site. The karst landscape is prone to washouts and sinkholes that could endanger both workers and turbines. However, the Ohio Power Sitting Board argues that construction could reduce these risks to man, turbine, and bird alike.

A Lost Cause or Lost Caws?

There is currently no news about the first court hearing from the Supreme Court. We’ll keep you posted if that changes for both sides of the story. If you’re looking to save on your electricity bill while you save the birds, don’t worry. You can check out the best plans in your area, including green ones, at www.ohenergyratings.com

0 notes

Text

How Wind Turbines Have Evolved

Over the millennia, humans have been using the wind to power various objects. In the 1st century AD, mathematician and engineer Heron of Alexandria created a windwheel, which he then used to make “flute-like noises.”

Wind power disappeared in the 7th century AD when we came across windmills in Iran that were used to pump water and grind flour. The discovery of electricity during the 1700s was the next significant development in our story.

In 1887, James Blyth became the first person to create a wind turbine that could power a house. His wind turbine was placed in the garden of a holiday cottage in Kincardine, Scotland. It was able to provide the electricity for the cottage’s lighting.

In July 1887, James Blyth built the first wind-powered structure in Scotland. His wind turbine, which measures 10 meters tall, was placed in his holiday cottage’s garden and was able to power the cottage’s lights. It was the first home in the world to benefit from wind power.

Blyth had offered the residents of Marykirk surplus electricity to light their main street, but they refused to accept it due to their belief that it was “the devil’s work.” In response, he built a wind turbine that was able to provide emergency power to an asylum in nearby Montrose.

Danish inventor and scientist Poul la Cour was a significant figure in the development of wind power. He was able to demonstrate the efficiency of wind turbines by designing them with fewer blades. He also discovered that regulators could be utilized to ensure that the energy supply was stable.

The 20th Century

During the 20th century, various companies and individuals started developing wind power technology at a utility-level level. The rapid pace of development was due to the combination of government incentives and material science. In the 1970s, the first commercial wind farms were established.

Cost of wind turbines

Offshore wind turbines are significantly more expensive than those installed onshore due to their logistics and challenges. The cost of producing 1 megawatt of electricity is computed by taking into account all of the capital expenditures involved.

The cost of producing 1 MW of electricity from onshore wind farms was £1.61 million in 2016-19. On the other hand, the cost of producing 1 MW of electricity from offshore wind farms was £4.49 million in 2016-19.

Size of wind turbines

The latest models from GE are known as the Haliade X-13 and the V236-15.0 MW. These wind turbines have 220-meter rotor blades and are capable of producing power at a rate of over 107 meters per blade. According to the company, the new models are designed to deliver industry-leading performance.

The future

Due to the increasing number of projects being developed offshore, the future of the wind power industry is secure. There are currently several areas of potential growth that can be addressed in the coming years.

0 notes

Text

Global Wind Day

Global Wind Day is celebrated on June 15 every year. It’s an international event to raise awareness regarding the importance of wind energy and the power it holds to change the world, improve energy systems, and decarbonize economies. Investing in wind energy means spending less money on fossil fuel imports, resulting in a smaller carbon footprint and minimized CO2 for cleaner air on our planet. On this day, we learn not just about how wind power leads to a greener planet, but also about job creation and employment opportunities for many people.

History of Global Wind Day

The history of wind energy as a power source traces back thousands of years. As early as 5,000 B.C., Egyptians had already been using wind power to propel their boats on the Nile River. This was improved upon by the Chinese in 200 B.C. as they invented wind-powered water pumps. Furthermore, people from the Middle East and Persia discovered windmills with woven-reed blades to grind grain with more speed and less manpower, which eventually led to more efficient food production.

It wasn’t until the 1st century A.D. that Heron of Alexandria created the windwheel. According to historians, this was the first recorded wind-driven wheel to power a machine. It included a small windmill that powered a piston that forces air through the organ pipes. According to records, it made a sound like that of a flute.

In the Middle Ages, windmills became a popular device in Pakistan, Afghanistan, and Iraq. They were used to pump water and grind sugarcane, which eventually boosted their grist milling industry. This technology was ultimately brought to Northwestern Europe in 1180 and became a popular tool to grind flour — a system that still exists up to date.

In the late 1800s and early 1900s, colonists brought windmills to the United States. Homesteaders and ranchers installed thousands of water pumps and small wind-electric generations in Western America.

The possibilities of wind power were further explored due to oil shortages in the 1970s. This forced everyone to find an alternative source of energy to generate electricity. Due to this scarcity, the U.S. federal government installed thousands of wind turbines in California to encourage the use of renewable energy sources. By 2020, the U.S. share of electricity generation via wind power grew to 8.4% — a huge spike compared to the 1990s 1%.

Global Wind Day timeline

1st Century A.D. The First Wind-Powered Machine

Greek engineer Heron of Alexandria discovers the first wind-driven wheel that powers a machine.

1180s Vertical Windmills

Northwestern Europe uses vertical windmills to grind flour.

1900s 2,500 Windmills Reaches 30 Megawatts

About 2,500 windmills in Denmark produce a combined power of 30 megawatts used to grind grains and pump water.

1970s Global Oil Shortage

The global oil shortage leads people to explore wind energy in a more advanced manner to be an alternative to electricity.

1980s Wind Turbines in California

The U.S. Federal Government installs thousands of wind turbines in California in support of renewable energy sources.

Global Wind Day FAQs

What are the types of wind energy?

The three main types of wind energy are utility-scale wind, offshore wind, and distributed wind.

What are four manufacturers in the world that uses wind turbines?

Vestas (Denmark), Siemens Gamesa (Spain), Goldwind (China), and General Electric (U.S.)

Which country uses the most wind power?

China uses the most wind power, generating approximately 236,402 megawatts in 2019 alone.

How to Observe Global Wind Day

Fly a kite outside

Attend seminars about wind energy

Take it to social media

This may sound like a simple activity, but flying a kite outside is an effective way to explain to your kids how wind energy works. Discuss how wind power propels the kite to stay afloat in the air. It’s also a great bonding activity that’s both fun and educational.

In an era where the climate crisis is peaking, wind energy is the future. Attend seminars on Global Wind Day to learn about the benefits and new technologies of wind energy as an alternative power source. Educating yourself is key.

Raise awareness about wind energy and its benefits on social media. Share scholarly articles or Global Wind Day event pages to your newsfeed. Use the hashtag #GlobalWindEnergy and keep your friends and family in the loop about one of the most pivotal solutions to decarbonizing the planet.

5 Interesting Facts About Wind Energy

The wind industry solves employment problems

The first modern turbine

Commercial turbines are powerful

The largest wind turbine

It doesn’t need water

The wind industry employs 650,000 people in different capacities around the world.

The first modern turbine was built in Vermont, U.S.

One commercial wind turbine can provide power to 600 homes.

The largest wind turbine was created in Hawaii, which stands 20 stories tall and each blade is as long as a football field.

Wind energy is the only power source that doesn’t need water.

Why Global Wind Day is Important

It’s for the good of the planet

It raises awareness

Wind energy is cost-effective

With the rise of global warming and other crises, wind energy is one solution to help lessen pollutants. Its long-term effects are advantageous to the new generation and to the generations that will come after.

People need to be proactive in highlighting the benefits of wind energy so that companies, governments, and other industries will adopt this technology as an alternative power source. The only way to make them proactive is to raise awareness. Education is key.

Global Wind Day helps us support the cost-effectiveness of wind energy. It’s one of the lowest-priced energy sources known today, which could potentially lower federal taxes.

Source

#Spring Valley#Nevada#Appalachian Mountains#Somerset County#landscape#countryside#nature#Somerset Wind Farm#Oregon#USA#Shepherds Flat Wind Farm#Middelgrunden Wind Turbine Cooperative#Denmark#Copenhagen#wind turbines#original photography#travel#vacation#15 June#GlobalWindDay#Pennsylvania#flora#forest#Atlantic Ocean#energy source#tourist attraction#landmark#Global Wind Day#Linden Wind Farm#Washington

1 note

·

View note

Text

Wind turbines are already skyscraper-sized – is there any limit to how big they will get?

- By Simon Hogg , Durham University , The Conversation -

In 2023, some 100 miles off the coast of north-east England, the world’s largest wind turbines will start generating electricity. This first phase of the Dogger Bank offshore wind farm development uses General Electric’s Haliade X, a turbine that stands more than a quarter of a kilometre high from the surface of the sea to the highest point of the blade tip.

If you placed one in London, it would be the third-tallest structure in the city, taller than One Canada Square in Canary Wharf and just 50 metres shorter than the Shard. Each of its three blades would be longer than Big Ben’s clock tower is tall. And Dogger Bank will eventually have nearly 300 of these giants.

Next up: an Eiffel-sized turbine? GE Renewable Energy / Facebook

Just two decades have passed since the UK’s first proper offshore wind farm was built off the coast of north Wales. Its turbines were each able to produce 2 megawatts (MW) of electricity in ideal conditions – considered huge at the time. In contrast, the Haliade X is able to produce 13MW of electricity, and 15MW turbines are only another year or two away.

So why are turbines increasing in size at such a rapid rate, and is there a limit to how big they can go? In short, the first answer is to reduce the cost of energy and the second is that there must be a limit – but nobody has put a number on it yet.

Big turbines, cheap electricity

Just five years ago, the offshore wind industry hoped to reduce its energy pricing to below £100 per megawatt-hour by 2020 from new projects in UK waters. Even at that level, projects would still have relied on government subsidies to make them economically viable, compared with other types of electricity generation.

But in fact, costs quickly reduced to the extent that offshore wind farm developers were soon committing to selling their electricity at much lower prices. Today, developers are building wind farms such as Dogger Bank where they have committed to prices below £50 per megawatt-hour. This makes offshore wind competitive with other forms of power generation, effectively removing the need for subsidy.

The major factor in reducing these costs was turbine size. Ever-larger turbines came to market faster than virtually everybody in the sector had expected.

Dogger Bank is ideal for offshore wind as the water is very shallow. When complete, the project will power 6 million UK homes. Dogger Bank Wind Farm

Blades cannot spin too fast

In theory, turbines can keep getting bigger. After all, a bigger blade extracts energy from the wind over a greater area as it rotates, which generates more electricity.

But there are some engineering constraints. One concerns erosion of the blades caused by them colliding with raindrops and sea spray. For current designs, the speed of the blade tips must be limited to 90 metres per second (which works out at just under 200mph) in order to avoid erosion. Therefore, as turbines get bigger and blades get longer, their rotors have to turn more slowly.

A consequence of having to slow the rotor down is that, to produce the same amount of power, the blades must deflect the wind to a greater extent. This results in greatly increased forces on the whole turbine. We can address these high forces, but only by increasing both turbine weight and cost. And that means the point at which the turbine becomes unprofitable – the point at which the extra cost is no longer worth it for the value of extra electricity generated – is reached much sooner than if the blade tips were allowed to go faster.

Also, as blades get longer they become more flexible. This makes it more difficult to keep the aerodynamics of the wind flow around them fully under control, and harder to ensure the blades do not strike the turbine tower under extreme wind conditions.

Logistical constraints

Engineering challenges like these can perhaps be solved in the longer term, though. This will mean that wind turbines are more likely to be limited in size by manufacturing, installation and operational issues, rather than any physical limit on the design of the turbine.

Just transporting blades and towers from factory to site and assembling the turbine when you get there presents huge challenges. Each of those Big Ben-sized blades must be shipped in one piece. This requires huge ports, giant vessels, and cranes that can operate safely and reliably far offshore. This is where the limit is most likely to come from.

You can see these limits in practice in the UK, which is surrounded by windy and shallow seas that are perfect for generating energy. Despite this, the UK is likely to miss its ambitious target to more than treble its offshore wind capacity by 2030.

This is not because of technology or lack of offshore sites. Rather, the industry will not be able to manufacture turbines quickly enough, and the port infrastructure and number of installation vessels, suitable cranes and workers with requisite skills is unlikely to be sufficient.

So if the UK is to maximise the benefit to its economy from what is, so far, a fantastic success story, the focus now needs to switch from pure cost reduction to developing workers’ skills and the offshore wind supply chain.

Turbines will get bigger, I am sure, but I suspect at a slower rate than we have seen in recent years. And if the turbines are deployed 100 miles offshore, will anybody care? After all, the public will not be there to see them.

Simon Hogg, Executive Director of the Durham Energy Institute, Durham University

This article is republished from The Conversation under a Creative Commons license. Read the original article.

--

Read Also

Bigger, better blades for wind turbines

#wind#renewable energy#renewables#green energy#wind turbine#engineering#energy#wind energy#offshore#uk#wind power#electricity#power generation

0 notes

Photo

Today’s Earth Week post focuses on wind energy, one of the most promising technologies to curb carbon emissions and address global warming in the coming decades. Approximately 314,000 wind turbines currently provide just 3.7% of global electricity, leaving ample opportunity for growth of both offshore and onshore wind farms. Wind farms use less than 1 percent of the land they occupy, allowing for greater land conservation and mixed-use like farming, while power generation takes place. Furthermore, when compared to fossil-fuel powered energy, wind produces significantly less emissions – coal’s carbon footprint is almost 90 times larger, while natural gas is 40 times larger.

Here is a collection of wind farm related Overviews from our collection:

__

With the incoming tide, streaks of sediment form around the turbines of the Donghai Bridge Wind Farm in Shanghai, China. This facility was the first commercial offshore wind farm in China and has the capacity to power 200,000 homes.

The Bayannur Wulanyiligeng Wind Farm in Inner Mongolia, China, consists of more than 200 wind turbines and can generate nearly 850,000 megawatt hours of power per year at full operation. This wind farm has the capacity to reduce carbon dioxide emissions by more than 760,000 tonnes annually.

Middelgrunden is a wind farm located 2.2 miles (3.5 km) offshore Copenhagen, Denmark in the Øresund Strait. The farm’s 20 turbines provide approximately 4% of the power for Copenhagen.

Blades for wind turbines are grouped together at a manufacturing facility in Little Rock, Arkansas, USA. Individual blades are transported from this facility to wind farms on top of trucks and then assembled on-site. For a sense of scale, the longest blades here are 350 feet (107 meters) long, or 1.3 times the length of a New York City block.

__

Source imagery: Maxar / Nearmap

231 notes

·

View notes