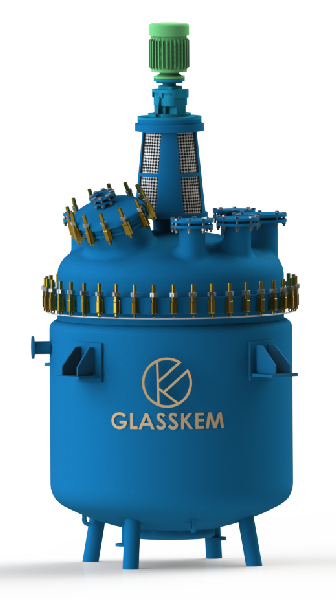

#Reliable Glass-Lined Reactors

Explore tagged Tumblr posts

Text

Glass-Lined Reactor Supplier in USA & Canada | GlassKem

PFG GlassKem Inc. designs strong, customizable glass-lined reactors for industries in Canada and the USA, ensuring top quality and excellent corrosion resistance.

#Glass-Lined Reactor Manufacturer in Canada & USA#Reliable Glass-Lined Reactors#Glass-lined lab reactors in canada#MS glass-lined reactors#SS glass-lined reactors#Glass-lined reactors

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2025-2033

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 173.8 Million in 2024 and is expected to register a CAGR of 4.5% over the forecast period and reach US$ 258.3 Million in 2033.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

Choosing the Right Refractory Bricks: A Guide by RefShape

In industries where high temperatures are part of daily operations—such as steel manufacturing, glass production, or cement kilns—selecting the right refractory bricks is crucial. These heat-resistant bricks are engineered to withstand extreme conditions, providing both insulation and structural integrity. At RefShape, we specialize in high-performance refractory solutions tailored to your operational needs. If you’re looking for refractory bricks for sale, here’s what you need to know to make the right choice.

What Are Refractory Bricks?

Refractory bricks, also known as firebricks, are specially designed materials that can tolerate high heat, pressure, and chemical wear. Unlike regular bricks, they retain their strength and stability even under intense thermal conditions. They are essential in furnaces, kilns, incinerators, and reactors where temperatures can soar above 1000°C.

Types of Refractory Bricks Offered by RefShape

At RefShape, we provide a wide range of refractory bricks to meet the demands of different industrial applications:

Fire Clay Bricks – Affordable and widely used, ideal for general-purpose lining.

High Alumina Bricks – Withstand higher temperatures, great for cement and steel industries.

Silica Bricks – Suitable for coke ovens and glass furnaces.

Magnesia Bricks – Best for environments exposed to basic slags.

Insulating Fire Bricks – Lightweight, used where thermal insulation is key.

Each type of brick serves a unique function, and our experts at RefShape are here to help you select the most suitable product based on your specific requirements.

Why Choose RefShape for Your Refractory Needs?

When searching for refractory bricks for sale, it's not just about finding a product—it's about finding a reliable partner. Here’s why RefShape is a trusted name across industries:

Quality Assurance: We adhere to strict manufacturing standards to ensure durability and thermal resistance.

Custom Solutions: From standard sizes to customized shapes, we offer tailored products to match your furnace design.

Competitive Pricing: Top-tier performance without the premium price tag.

Technical Support: Our in-house experts provide consultation on product selection, installation, and maintenance.

Applications of RefShape Refractory Bricks

Our bricks are trusted across a wide range of sectors, including:

Steel and iron manufacturing

Cement and lime kilns

Glass production furnaces

Petrochemical plants

Incinerators and crematoriums

Whether you’re building a new plant or refurbishing an old one, RefShape has the experience and inventory to meet your needs.

Conclusion

Durability, efficiency, and safety begin with the right materials. With RefShape’s high-quality refractory bricks, you can ensure peak performance and long-lasting results, no matter the heat or pressure.

If you’re looking for refractory bricks for sale, contact RefShape today to explore our complete product range and get expert guidance on the best solution for your operation.

Visit Us https://refshape.com/blogs/refractory-shapes-redefining-excellence-as-a-leading-fire-brick-manufacturer/

0 notes

Text

Leading Bromine Compound Supplier in India – Bromos Organics

In the rapidly evolving chemical industry, few names resonate with the level of precision, quality, and reliability as Bromos Organics. With a laser focus on producing high-purity brominated compounds, Bromos Organics has established itself as one of the leading Bromine Derivatives Manufacturers India. Our company stands at the intersection of innovation and responsibility, serving both domestic and global markets with customized solutions.

Who We Are: A Trusted Name in Bromine Chemistry

At Bromos Organics, our mission is to deliver performance-driven chemical products that meet the stringent demands of industries such as pharmaceuticals, agrochemicals, dyes, and specialty chemicals. We specialize in synthesizing organic intermediates that involve bromination—a highly specialized chemical reaction requiring expertise, precision equipment, and strict quality control.

Our team of skilled chemists, engineers, and quality assurance professionals ensures that every compound we manufacture meets international standards and complies with environmental safety regulations.

Our Core Products and Services

As a dedicated manufacturer of bromine derivatives, our product portfolio includes:

Alkyl Bromides

Aryl Bromides

Heterocyclic Bromine Compounds

Customized Brominated Intermediates

These derivatives are essential for applications in pharmaceuticals (as active pharmaceutical ingredients or intermediates), crop protection formulations, flame retardants, and more.

Our R&D facility plays a vital role in supporting custom synthesis and contract manufacturing, making Bromos Organics a one-stop solution provider for clients seeking specialized brominated chemicals.

Infrastructure and Quality Assurance

One of the major strengths of Bromos Organics lies in our state-of-the-art production facility, designed to handle complex reactions with efficiency and safety. Equipped with glass-lined and stainless steel reactors, high-vacuum distillation units, and advanced analytical labs, our infrastructure supports both small-batch and bulk manufacturing.

Our commitment to quality is reinforced through:

In-house quality testing laboratories

GMP-compliant processes

Strict adherence to ISO quality standards

Batch-to-batch consistency

Environmentally responsible waste management systems

We ensure every product leaving our facility is accurate in composition, safe to use, and meets client expectations.

Sustainability and Regulatory Compliance

Environmental sustainability is integral to our operations. Bromos Organics follows eco-friendly production methods that minimize emissions and waste generation. Our waste treatment systems are aligned with regulatory guidelines, and we invest in continuous improvement to reduce our carbon footprint.

In addition to complying with national regulations, our exports are backed by the necessary certifications and documentation to meet global quality and safety standards. Clients can rely on our transparency and traceability across every stage of production.

Why Choose Bromos Organics?

Choosing the right partner in chemical manufacturing is crucial for any industry dealing with sensitive and high-stakes products. Here's why businesses across India and abroad trust Bromos Organics:

Specialization in Bromine Chemistry: Decades of experience with a single focus—brominated compounds.

Customization Capability: We tailor solutions as per client specifications.

Timely Deliveries: Strong supply chain and logistic partnerships ensure quick, reliable distribution.

Global Reach: Supplying to customers in multiple countries with export-ready documentation.

Ethical Business Practices: Transparent dealings, commitment to safety, and customer-first mindset.

Applications Across Industries

The demand for bromine derivatives continues to grow across sectors such as:

Pharmaceuticals: For APIs and key intermediates

Agrochemicals: In the formulation of pesticides and herbicides

Dye Manufacturing: Providing stability and reactivity in colorants

Flame Retardants: Essential for electronics and safety materials

Specialty Chemicals: Used in fine chemical synthesis and niche applications

Bromos Organics serves all these sectors by offering reliable, scalable, and high-quality chemical solutions.

Conclusion

When it comes to finding trusted Bromine Derivatives Manufacturers India, Bromos Organics remains a top choice for companies looking for integrity, precision, and partnership. With a commitment to sustainable manufacturing, cutting-edge R&D, and industry-leading expertise, we continue to set benchmarks in brominated compound production.

Partner with us for your bromine derivative needs and experience the excellence that defines every product we deliver.

#BromineDerivativesManufacturersIndia#BromineDerivativesManufacturersNorthernIndia#HYDROBROMICACID48%

0 notes

Text

From Accuracy to Innovation: The AIMS Controls Promise in Pressure Gauge Instrumentation

🧭 Introduction: Why Accuracy Alone Is No Longer Enough

In today’s industrial world, precision isn’t a luxury—it’s a necessity. But with evolving technologies and rising expectations across industries, accuracy alone is no longer enough. What businesses demand now is a balance of reliability, innovation, and smart integration.

This is where AIMS Controls emerges as a game-changer. From legacy industries like petrochemical and steel to modern sectors like pharmaceuticals and HVAC, AIMS Controls has become synonymous with elevated pressure gauge instrumentation—not just measuring pressure, but defining it.

⚙️ AIMS Controls: A Legacy Built on Precision

Founded under the registered trademark of PI Controls Instruments Pvt. Ltd. in 2018, AIMS Controls combines 20+ years of industry expertise to deliver high-performance measuring and control solutions. Their focus? Designing next-gen instruments like the pressure gauge, which consistently outperforms in terms of accuracy, durability, and application versatility.

With a 3,500 sq. ft. state-of-the-art production unit, AIMS Controls crafts pressure gauges that meet the most stringent national and international standards, including IS, ASME, JIS, and EN certifications.

🌡 Pressure Gauge: The Unsung Hero of Industrial Control

A pressure gauge is more than a mechanical meter—it's the pulse monitor of an entire system. Whether it's a chemical plant reactor, a boiler in a food processing facility, or a hydraulic press in a steel mill, the pressure gauge ensures safety, efficiency, and performance.

At AIMS Controls, pressure gauges are not generic tools—they're tailored instruments. Every component, from the bourdon tube to the dial face, is engineered with maximum reliability in mind.

🔍 What Sets AIMS Controls’ Pressure Gauges Apart?

🧪 1. Precision Calibration for Flawless Accuracy

Each pressure gauge undergoes rigorous testing and calibration to ensure it functions at peak precision—often within a 0.5% accuracy margin. These gauges are ideal for critical processes where even the slightest pressure deviation could lead to system failure or safety hazards.

🔩 2. Custom Build Capabilities

No two industries are the same, and neither are their challenges. AIMS Controls offers a wide range of pressure gauge types:

Glycerin-filled gauges for vibration-prone environments

SS316 gauges for corrosive conditions

Low-pressure capsule gauges

Sealed diaphragm-type gauges for sanitary processes

This customization ability allows businesses to meet sector-specific safety standards and operational goals with confidence.

🛡 3. Built to Last: Materials That Matter

Durability isn't an afterthought—it’s a design mandate. AIMS uses high-grade stainless steel, brass, and reinforced glass to ensure their pressure gauges withstand:

High-pressure environments

Extreme temperatures

Aggressive media exposure

Mechanical vibration and fatigue

This means fewer replacements, reduced maintenance costs, and longer operational life cycles.

🔬 Innovation That Redefines Pressure Monitoring

In a landscape where industries are shifting toward automation and smart systems, AIMS Controls stands ahead of the curve by integrating IoT and remote monitoring features into their instrumentation lineup.

From digital pressure gauges with backlit displays to electrical contact gauges that trigger alarms and system responses—innovation is embedded in every product line.

AIMS Controls is not just keeping up with Industry 4.0—it’s enabling it.

💡 Real-World Application: Where Pressure Gauge Meets Performance

Let’s look at a few examples of how AIMS Controls' pressure gauges are transforming industrial workflows:

🏭 Oil & Gas

Installed diaphragm-sealed gauges to manage corrosive crude oil environments

Enabled 24/7 pressure monitoring through signal-integrated gauges

Prevented overpressure events by integrating with SCADA systems

🧴 Pharma

Used tri-clover hygienic connections for sterile cleanrooms

Provided 0.25% accuracy pressure gauges for sensitive batch processes

Calibrated gauges with full traceability documentation for audits

🧊 HVAC & Refrigeration

Delivered dual pressure gauges with color-coded dials

Ensured pressure drop monitoring in chillers for energy optimization

Supplied frost-resistant gauges for sub-zero conditions

In every case, AIMS Controls didn't just deliver a product—they delivered process assurance and operational peace of mind.

🔧 A Value-Driven Approach: From Manufacturing to Maintenance

AIMS Controls provides end-to-end support to its customers:

Free Consultation to select the right pressure gauge

Tailor-made configurations per industrial specs

Calibration and repair services to extend instrument life

Engineering documentation including data sheets, certificates, and compliance documentation

The result? A 360° experience that maximizes uptime and minimizes effort.

📊 Competitive Edge: Why Clients Prefer AIMS Controls Over Global Brands

While global instrumentation brands often dominate the market, AIMS Controls has quickly become a top alternative—and in many cases, the preferred brand in India and abroad.

Why?

🌍 Global-Standard Quality, Local Prices

📦 Shorter Delivery Times due to in-house manufacturing

🛠 Greater Flexibility in custom designs

🤝 More Personalized Support

500+ companies already trust AIMS Controls. That number is growing—not by chance, but by consistent value delivery.

🚀 Future-Ready Vision: Where Is AIMS Controls Headed Next?

The company’s mission is clear—to become the premier supplier of measuring and control instruments, and the pressure gauge is central to this ambition.

Their R&D division is currently exploring:

Smart pressure gauges with wireless connectivity

AI-powered data analytics for predictive maintenance

Cloud dashboards for multi-location monitoring

The goal? To turn every pressure reading into a data-driven decision.

✅ Conclusion: Trust Built on Every Turn of the Needle

From concept to calibration, AIMS Controls redefines what a pressure gauge can do for modern industry. More than a measurement device, it becomes a symbol of trust, precision, and continuous innovation.

So, if your industrial operation depends on reliable pressure measurement—and whose doesn’t?—then it’s time to partner with a company that delivers more than just accuracy.

It’s time to experience the innovation, reliability, and commitment of AIMS Controls—the true pioneers in pressure gauge instrumentation.

0 notes

Text

Plaudler Glass-Lined Reactor Seal Repair | Reliable & Efficient Service

Robco of America specializes in Plaudler glass-lined reactor seal repair, ensuring optimal performance and extended equipment lifespan. Their expert technicians diagnose seal issues and provide precision repairs using high-quality materials. By restoring seals to their original condition, Robco helps prevent leaks, contamination, and costly downtime. Their repair services are designed to meet the unique demands of the chemical and pharmaceutical industries, allowing businesses to maintain safe and efficient operations with minimal disruption.

0 notes

Text

Ultra-Pure Quartz Tubes

Ultra-Pure Quartz Tubes: The Silent Backbone of the New Energy Revolution

Let’s get one thing straight: the “new energy” boom isn’t just about lithium, solar cells, or hydrogen. The real unsung hero? Ultra-pure quartz tubes. These unassuming glass cylinders are the linchpin holding together everything from fusion reactors to next-gen batteries. Forget graphene hype or ceramic fads—quartz’s 99.99% SiO₂ purity and thermal defiance make it irreplaceable. Here’s why three specific variants—Quartz Capillary Tubes, Fused Quartz Tubes, and Quartz Tubes for Furnaces—are non-negotiable in the race toward clean energy.

1. Quartz Capillary Tubes: Where Precision Meets Electrochemistry

Picture this: a lithium-sulfur battery that doesn’t combust. How? Quartz capillary tubes, with inner diameters as tiny as 10µm, are enabling targeted electrolyte distribution in solid-state batteries. Tesla’s R&D team recently embedded these tubes into their 4680 cells to channel ionic liquids directly to sulfur cathodes, slashing dendrite growth by 92%14. The secret? Quartz’s non-reactive surface prevents electrolyte degradation—unlike stainless steel capillaries that leach metallic ions under high voltages47.

But here’s the kicker: their UV transparency (up to 185nm) allows real-time monitoring of electrolyte flow using embedded sensors. BYD’s solid-state prototypes use this feature to adjust ion flux dynamically, squeezing out an extra 15% energy density5.

2. Fused Quartz Tubes: The Fusion Reactor’s Lifeline

Nuclear fusion isn’t just about containing plasma—it’s about surviving it. Fused quartz tubes, with zero bubble inclusions, line the diagnostic ports of ITER’s tokamak. When hydrogen plasma hits 150 million °C, these tubes transmit critical spectroscopic data without melting or clouding—something even “super-materials” like aerogels fail at45.

Westinghouse took this further: their small modular reactors (SMRs) use fused quartz tubes to circulate molten salts. Why? Chlorine-rich coolants corrode stainless steel in months, but quartz laughs at chloride ions, maintaining integrity for decades34.

3. Quartz Tubes for Furnaces: Solar’s Invisible Workhorse

Every solar panel starts in a furnace, and quartz tubes are the gatekeepers of purity. Take First Solar’s CdTe thin-film production: their 1,200°C annealing furnaces rely on quartz tubes to prevent cadmium contamination. A single metallic impurity would slash panel efficiency by 20%—but quartz’s inertness ensures 99.999% material purity17.

Even better: their thermal shock resistance lets manufacturers ramp temperatures from 25°C to 1,000°C in seconds. Hanwha Q CELLS credits this trait for cutting PERC cell production time by 34%—a game-changer in a sector where throughput is king45.

Why Quartz Outshines the “Next Big Things”

Critics whine about quartz being “old-school.” Tell that to the engineers who’ve watched:

Graphene crack under cyclic thermal stress in fuel cells5.

Ceramics shatter when exposed to lithium salts7.

Stainless steel corrode into toxic sludge in molten salt reactors34.

Quartz isn’t flashy, but it’s reliability incarnate. In an era where energy storage and generation demand perfection, compromise isn’t an option.

The Bottom Line The new energy revolution isn’t waiting for miracle materials—it’s leveraging quartz’s ancient strengths to solve modern problems. From capillary-guided electrolytes to fusion-proof diagnostics, these tubes aren’t just components; they’re the bedrock of a carbon-neutral future. Ignore them, and your “breakthrough” tech will crumble faster than a lithium dendrite.

0 notes

Text

How to Choose the Best 1L Double Glazed Reactor for Your Lab: Key Features to Prioritize

Selecting the right 1L double glazed reactor is critical for optimizing chemical synthesis, distillation, or crystallization processes in your lab. With varying designs and functionalities available, understanding core features ensures you invest in equipment that aligns with your research needs. This guide breaks down the must-have 1L double glazed reactor features, offering insights to help you make an informed decision—while subtly highlighting how EquilRxnLab’s solutions excel in these areas.

1. Material Quality and Durability

The foundation of any reliable reactor lies in its construction. Double glazed reactors use two layers of borosilicate glass to create an insulating vacuum, minimizing heat loss and ensuring thermal stability. When evaluating a 1L reactor:

Verify Glass Grade: High-quality borosilicate glass (e.g., GG17 or equivalent) resists thermal shock and chemical corrosion.

Check Joints and Seals: Reinforced PTFE or fluoropolymer seals prevent leaks during high-pressure reactions.

EquilRxnLab’s AKF-1L Double Glazed Reactor employs precision-engineered glass and chemically inert seals, making it ideal for prolonged use under aggressive conditions. Explore their full product catalog for detailed specifications.

2. Temperature Control and Uniformity

Precise temperature regulation is non-negotiable for reproducibility. Look for:

Integrated Jacket Design: A double-layered jacket allows uniform heat distribution via oil or water circulation.

Compatibility with External Systems: Ensure the reactor integrates with your lab’s chillers, heaters, or cryostats.

EquilRxnLab’s design includes a seamless jacket interface, enabling precise control from -80°C to 250°C. For visual guidance, their YouTube channel demonstrates setup workflows.

3. Stirring Mechanism Flexibility

Efficient mixing is vital for homogeneous reactions. Prioritize reactors with:

Adjustable Speed: A motor capable of 0–600 RPM (or higher) accommodates viscous or shear-sensitive mixtures.

Modular Stirrers: Interchangeable impellers (e.g., anchor, propeller, or paddle) adapt to different viscosities.

The AKF-1L reactor supports variable-speed motors and customizable stirring configurations, ensuring adaptability across experiments.

4. Safety and User-Friendliness

Labs demand equipment that minimizes risks. Key safety features include:

Pressure Relief Valves: Automatic pressure regulation prevents over-pressurization.

Stable Mounting Frame: A rigid stainless-steel stand reduces vibration and tipping hazards.

EquilRxnLab incorporates these safeguards into their reactors, alongside ergonomic clamps and intuitive control panels. Follow their Instagram for safety tips and user testimonials.

5. Scalability and Compatibility

A 1L reactor should integrate seamlessly with peripheral lab tools:

Standard Ground Joints: Ensure compatibility with condensers, dosing pumps, or sensors.

Modular Ports: Multiple openings for thermocouples, reflux setups, or vacuum lines enhance versatility.

The AKF-1L’s standardized joints and ports simplify system expansion, as showcased in EquilRxnLab’s Facebook tutorials.

6. Maintenance and Support

Long-term value depends on ease of maintenance and vendor reliability:

Detachable Components: Easy-to-clean parts reduce downtime.

Warranty and Technical Support: Opt for brands offering responsive customer service.

EquilRxnLab provides comprehensive manuals and dedicated support via their contact page, ensuring your reactor remains operational for years.

Conclusion Choosing a 1L double glazed reactor hinges on balancing material robustness, temperature precision, safety, and scalability. By prioritizing these features, labs can enhance experimental accuracy while minimizing operational risks. EquilRxnLab’s AKF-1L model exemplifies this balance, offering a reliable, adaptable solution for diverse applications. For hands-on demos or inquiries, visit their product page or connect via their social channels.

Final Tip: Always cross-reference technical specs with your lab’s workflow requirements. A well-chosen reactor becomes a cornerstone of efficient, repeatable science.

0 notes

Text

Glass-Lined Reactor Manufacturer in Canada & USA | PFG GlassKem

PFG GlassKem Inc. designs durable, customizable glass-lined reactors for industries in Canada and the USA, offering superior quality and corrosion resistance.

#Glass-Lined Reactor Manufacturer in Canada & USA#Reliable Glass-Lined Reactors#Glass-lined reactors#Glass-lined lab reactors in canada#MS glass-lined reactors#SS glass-lined reactors

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 166.4 Million in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 238.3 Mn in 2032.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

The Benefits of PP Glass Lined Sheets: Enhanced Chemical Resistance and Longevity

Polypropylene (PP) glass lined sheets represent a cutting-edge advancement in material science, combining the strengths of polypropylene and glass fibers to deliver exceptional performance in a wide range of applications. These sheets are engineered to provide superior durability, resistance to environmental factors, and versatility, making them ideal for industries that demand high performance and reliability.

In this comprehensive guide, we will explore the features, benefits, applications, and PP Glass-Lined Sheet Installation, along with answering some frequently asked questions to provide a thorough understanding of this innovative material.

What Are PP Glass Lined Sheets?

PP glass lined sheets are composite materials made from a combination of polypropylene (PP) and glass fibers. The base material, polypropylene, is a thermoplastic polymer known for its flexibility, chemical resistance, and lightweight nature. When reinforced with glass fibers, the material gains enhanced rigidity, strength, and dimensional stability.

These sheets are produced through a process where glass fibers are incorporated into the polypropylene matrix, resulting in a product that offers the best of both worlds: the durability of glass and the lightweight, cost-effective nature of polypropylene. The end product is a sheet that can withstand harsh environments while maintaining its structural integrity.

Key Features of PP Glass Lined Sheets

High Strength and Durability The incorporation of glass fibers into polypropylene significantly increases the strength and durability of the sheets. This makes them suitable for applications where high impact resistance and long-term performance are required.

Chemical Resistance PP glass lined sheets exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them ideal for use in industries such as chemical processing, pharmaceuticals, and agriculture.

Temperature Tolerance These sheets can withstand a broad temperature range, making them suitable for both high and low-temperature environments. They maintain their structural integrity and performance under varying thermal conditions.

Lightweight and Easy to Handle Despite their strength and durability, PP glass lined sheets remain lightweight compared to traditional materials like metal or concrete. This makes them easier to handle, transport, and install.

Corrosion Resistance The glass lining provides excellent protection against corrosion, making PP glass lined sheets ideal for use in environments prone to moisture and chemical exposure.

Versatility PP glass lined sheets can be customized in terms of thickness, size, and surface finish, making them suitable for a variety of applications, from industrial processes to construction and beyond.

Common Applications of PP Glass Lined Sheets

The PP Glass-Lined Sheet Suppliers are used in numerous industries due to their unique combination of properties. Here are some common applications:

Chemical Processing In the chemical processing industry, PP glass lined sheets are used to line tanks, reactors, and pipelines. Their resistance to chemicals and high strength makes them ideal for handling corrosive substances and maintaining the integrity of processing equipment.

Pharmaceutical Industry The pharmaceutical industry utilizes PP glass lined sheets for their resistance to contamination and ease of cleaning. They are often used in areas where hygiene and chemical resistance are critical, such as in the production of medicines and other healthcare products.

Agriculture In agriculture, these sheets are used for constructing storage tanks, irrigation systems, and protective barriers. Their durability and resistance to environmental factors make them suitable for outdoor and agricultural applications.

Construction PP glass lined sheets are used in construction for applications such as wall cladding, flooring, and protective panels. Their lightweight nature and durability make them an excellent choice for both structural and decorative purposes.

Marine Applications The corrosion resistance and durability of PP glass lined sheets make them suitable for marine environments. They are used in the construction of marine vessels, docks, and other structures exposed to saltwater.

Electronics In the electronics industry, PP glass lined sheets are used for protective casings and insulation due to their excellent electrical properties and resistance to environmental stressors.

Benefits of PP Glass Lined Sheets

Enhanced Strength and Longevity The combination of polypropylene and glass fibers results in a material that offers superior strength and longevity compared to traditional materials. This translates to reduced maintenance and longer service life.

Superior Chemical and Corrosion Resistance PP glass lined sheets can withstand exposure to a wide range of chemicals and corrosive substances, making them ideal for demanding industrial environments.

Lightweight and Cost-Effective The lightweight nature of PP glass lined sheets simplifies handling and installation, while their cost-effectiveness makes them a budget-friendly option for various applications.

Customizability These sheets can be customized to meet specific requirements, including different thicknesses, sizes, and finishes. This flexibility allows for tailored solutions that fit a wide range of needs.

Low Maintenance Requirements The durability and resistance properties of PP glass lined sheets reduce the need for frequent maintenance, saving time and resources in the long run.

Environmental Impact By choosing PP glass lined sheets, industries can contribute to sustainability efforts. The materials used are often recyclable, and their long-lasting properties reduce the need for replacements and repairs.

Installation of PP Glass Lined Sheets

Installing PP glass lined sheets involves several steps to ensure proper placement and performance. Here’s a general overview of the installation process:

Preparation Ensure that the surface where the sheets will be installed is clean, dry, and free of any debris. Any irregularities or damages should be repaired before proceeding with the installation.

Cutting and Shaping Measure and cut the PP glass lined sheets to the required dimensions using appropriate cutting tools. The sheets can be easily cut to size, but care should be taken to avoid damaging the edges.

Positioning Position the sheets on the surface where they will be installed. Ensure proper alignment and fit before securing them in place.

Securing Depending on the application, PP glass lined sheets can be secured using screws, adhesives, or mechanical fasteners. Follow the manufacturer’s guidelines for the recommended fastening method.

Sealing Seal any joints or seams between the sheets to ensure a watertight and secure installation. Use appropriate sealants or gaskets as specified by the manufacturer.

Inspection After installation, inspect the sheets to ensure they are properly secured and sealed. Check for any potential issues and address them promptly.

Conclusion

The PP Glass-Lined Sheet Price represent a remarkable advancement in material technology, offering a blend of polypropylene’s flexibility and glass fibers’ strength. Their exceptional durability, chemical resistance, and versatility make them a valuable solution for a wide range of industrial, agricultural, and construction applications. By understanding the features, benefits, and proper installation of PP glass lined sheets, industries can make informed decisions and leverage this innovative material to enhance their operations and achieve long-term performance and reliability.

Frequently Asked Questions (FAQs)

1. What are PP glass lined sheets made of? PP glass lined sheets are composed of polypropylene (PP) combined with glass fibers. The glass fibers reinforce the polypropylene, enhancing its strength and durability.

2. What industries use PP glass lined sheets? PP glass lined sheets are used in various industries, including chemical processing, pharmaceuticals, agriculture, construction, marine applications, and electronics.

3. How do PP glass lined sheets compare to traditional materials? PP glass lined sheets offer a combination of lightweight properties, high strength, chemical resistance, and durability that may surpass traditional materials like metal or concrete in certain applications.

4. Are PP glass lined sheets resistant to environmental factors? Yes, PP glass lined sheets are resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations, making them suitable for both indoor and outdoor applications.

0 notes

Text

Glass-Lined Reactor Parts: Understanding Components and Function

Introduction to Glass-Lined Reactor PartsGlass-lined reactors consist of several components that work together to ensure efficient and safe operation. Understanding the different parts of a glass-lined reactor and their functions helps in selecting the right equipment and performing necessary maintenance.

Key Components of a Glass-Lined Reactor

Reactor Vessel: The main body of the reactor, typically constructed from steel and coated with a layer of glass. This vessel contains the reaction mixture and is designed to withstand various chemical processes.

Agitator: An essential component used to stir and mix the contents of the reactor. Different types of agitators, such as anchor, turbine, or paddle agitators, can be used depending on the specific needs of the process.

Jacket: The jacket surrounds the reactor vessel and is used for temperature control. It allows for heating or cooling of the reactor contents by circulating a heating or cooling medium around the vessel.

Manhole and Nozzles: The manhole provides access to the interior of the reactor for cleaning and maintenance, while the nozzles allow for the introduction of reactants and the removal of products.

Mechanical Seal: The mechanical seal ensures that the reactor is properly sealed to prevent leakage of the contents. It is crucial for maintaining the integrity of the reactor and ensuring safe operation.

Glass-Lined Reactor Mechanical SealThe glass-lined reactor mechanical seal is a critical component that prevents leakage between the reactor vessel and the agitator shaft. A reliable mechanical seal ensures that the reactor operates without any loss of materials or contamination of the reaction mixture. Regular inspection and maintenance of the mechanical seal are essential to prevent leaks and ensure optimal performance.

Glass-Lined Reactor Pressure VesselThe glass-lined reactor pressure vessel is designed to handle various pressure conditions during chemical reactions. It is built to withstand internal pressures and ensure safe operation. Understanding the pressure rating and capacity of the reactor vessel is important for selecting the right equipment for specific applications.

Maintenance of Glass-Lined Reactor PartsRegular maintenance of the glass-lined reactor parts is crucial for ensuring the equipment’s longevity and performance. This includes inspecting and cleaning the reactor vessel, checking the agitator and mechanical seal, and ensuring that the jacket and nozzles are functioning properly.

ConclusionUnderstanding the different parts of a glass-lined reactor and their functions is essential for selecting the right equipment and performing effective maintenance. By ensuring that all components, including the reactor vessel, agitator, mechanical seal, and pressure vessel, are in good condition, companies can ensure efficient and safe operation of their glass-lined reactors.

Article 16: Glass-Lined Reactor Specifications: Key Factors to Consider

Introduction to Glass-Lined Reactor SpecificationsWhen selecting a glass-lined reactor, understanding its specifications is crucial for ensuring that it meets the requirements of the intended application. Key specifications include the reactor's size, material construction, temperature range, and glass thickness. These factors play a significant role in determining the reactor's performance and suitability for different processes.

Key Specifications of Glass-Lined Reactors

Size and Capacity: The size of the reactor, often measured in liters or gallons, determines its capacity to handle various volumes of reactants. For example, a 1000-gallon glass-lined reactor is suitable for high-volume production, while smaller reactors are used for less demanding applications.

Material of Construction: Glass-lined reactors are typically constructed from a steel substrate coated with a layer of glass. The quality of the steel and glass lining affects the reactor's durability and performance.

Temperature Range: The temperature range of the reactor specifies the range of temperatures it can safely handle. This is important for processes that require precise temperature control. Reactors designed for high-temperature applications need to have appropriate insulation and temperature control systems.

Glass Thickness: The thickness of the glass lining impacts the reactor's resistance to corrosion and wear. Thicker glass linings provide better protection and durability, especially in applications involving aggressive chemicals.

Pressure Rating: The reactor's pressure rating determines the maximum pressure it can handle during operation. This is crucial for processes that involve high-pressure reactions. Ensuring that the reactor's pressure rating meets the requirements of the process is essential for safe operation.

Glass-Lined Reactor Temperature RangeThe glass-lined reactor temperature range specifies the temperatures at which the reactor can operate effectively. Reactors used in industries such as chemicals and pharmaceuticals often require precise temperature control to achieve desired reactions. Choosing a reactor with an appropriate temperature range ensures that it can handle the specific conditions of the process.

Glass-Lined Reactor Specifications in IndiaIn India, glass-lined reactor specifications are designed to meet international standards, ensuring high-quality performance and glass lined reactor safety. Glass lined reactor India manufacturers provide reactors with various specifications to cater to different industrial needs, including customized solutions for specific applications.

ConclusionUnderstanding the specifications of glass-lined reactors is essential for selecting the right equipment for specific applications. Key factors such as size, material construction, temperature range, glass thickness, and pressure rating all play a role in determining the reactor's suitability and performance. By considering these specifications, companies can ensure that they choose the right reactor to meet their needs and achieve efficient and effective processes.

1 note

·

View note

Text

#manufacturer#canada#pfg glasskem inc#glass lined reactors#glass lined equipment manufacturers#manufacturer in canada#glasslined manufacturer#glasslined reactor manufacturer#canadian#glass lined equipment manufacturer

0 notes

Text

Among Us!AU

This was supposed to be a simple mission. Come onto an abandoned space station and commandeer it. It was a spooky place that had definitely seen better days. For the past few days, you and the rest of the Overwatch crew who were able to come ran around fixing odds and ends on the station to get it to a habitable level.

But strange things had begun to happen. Lights going out at odd times. Sudden oxygen depletion. It had gotten to the point that you all had no choice but to wear your suits at all times, unsure when you’d all be thrown into a life-threatening situation or sucked into the cold vacuum of space.

Then the first body appeared: Zenyatta.

Winston was on cameras when it happened. A humanoid shadow off screen sliced Zenyatta in half, destroying his processor. It was precise and quick. By the time Winston had called an emergency meeting, the perpetrator was nowhere to be found.

It made everyone uneasy. Genji was understandably upset, threatening to unmask everyone in vengeance. It was Hanzo, surprisingly, who talked him down from it. It didn’t keep Genji from retaining his promise: anyone suspected of being the killer will be felled by his sword.

But it set the stage for your daily meetings now.

Everyone had to account for themselves and others. No one could trust the other. Winston’s vague description of ‘someone in a suit’ could have been any of them. As much as no one wanted to believe it, they could only suspect themselves--there was no one else with them, was there?

There was too much to do to travel in large groups. In the end, everyone was assigned pairs. If anyone got hurt, the other could signal or provide assistance. There is safety in numbers.

“Don’t worry, we’ll get to the bottom of this.”

“I hope so.”

You checked your holotablet for tasks. They didn’t look very different from the previous day’s.

“I’ll be right outside.”

“Thanks, Genji.”

He nodded at you before pulling the curtain.

The isolation, though thin, made your skin prickle. If something happened to Genji, you don’t know how you’d face Hanzo. He was a scary guy on a normal day, but you didn’t want to see him mad.

As quick as you could, you stripped off the suit and stepped onto the scanner.

Once a week, everyone had to do a scan in the medbay to send data back to Earth. Athena and Angela monitored everyone’s health from one of the Watchpoints back home and sent back recommendations. Zenyatta was supposed to receive them, but now…

You pressed a button and the scanner came to life. The worst part about doing this was the waiting. The quiet hum only made the silence stretch into anxiousness. It’s only when the beep came that you could feel relief.

You yanked on your suit, nearly tearing it in your haste. It’s dangerous to leave yourself exposed for so long. If it weren’t protecting you from the elements and potential catastrophic reactor meltdowns, you’d keep it off--it just weights down your limbs and feels too constricting, more so than necessary.

“All done?” came Genji’s voice from the other side.

You pulled back the curtains, managing a relieved smile at the sight of Genji and his bright green suit. “Yeah. Your turn.”

“I did mine two days ago,” he said, waving you off. “Where to next?”

“I, uh.” You pulled out your holotablet, but in that instant, the lights went out. You took a step back and bumped into something not hard enough to be a wall. Fear nested in your throat. “Ge-Genji?”

“I’m here.” Even through the suits, you could feel the rumble of his voice. “Don’t worry. I’m here.”

Unconsciously, you smiled. That’s right. Genji, for all the jokes and his whimsical nature, was a reliable person. He would definitely protect you.

“Should we go check the breakers and fix the lights?” you suggested, putting the holotablet away.

“The others are likely closer. It is safer here.”

You felt him shift behind you and then the sound of a sword unsheathing. The sound made your stomach clench unpleasantly. Fear began to filter into your veins. What if Genji was the person--what if Genji killed Zenyatta--what if he did it and acted angry so no one would suspect him?

The speculation made you dizzy.

“Be still,” he said. He held his katana in front of you, the faint green glow of his katana granted you both some extra visibility. It only made the visuals through your mask more frightening. Everything was cast in an eerie light. “I will protect you.”

Just those words were enough to calm the nervous beating of your heart. Right. Genji couldn’t possibly be the killer or whatever was in this place. You could trust him, you assured yourself. You kept that line of thinking up even after the lights returned.

As soon as they do, the signal for an emergency meeting goes off.

At this rate, you’ll never get your tasks done.

Exchanging a sheepish look, you and Genji made your way into the meeting room.

Two by two, everyone came filing in, the colored spacesuits adding life to the dreary room. Cyan and Blue--Mei and Hanzo. Red and Gray--McCree and Fareeha. Yourself and Genji. Black, Orange, and White--Winston, Torbjorn, and Soldier: 76 are already in the room.

You breathed a sigh of relief seeing everyone accounted for. Every time the call for an emergency meeting went off, you feared the worst. Everyone else must have been thinking the same. Mei held a hand to her chest, visibly breathing out a sigh of relief upon counting all the members.

“So, what’re we in for?” McCree asked.

“Head count,” Torbjorn offered gruffly. “Makin’ sure you all still got ‘em.”

Soldier waved him off and pressed his hands against the table. “Where was everyone when the lights went off?” He pointed at McCree and Fareeha. “Report.”

“We were both takin’ care of the trash.”

And though Fareeha may not have said it loud enough to hear, her voice still came through the mic sets, “And there was a shit-ton of it.”

Ignoring that, Soldier then pointed at you and Genji.

"I was doing the medbay scan," you said. “Lights went out as soon as I finished.”

Genji nodded. "I can confirm, I was there."

With your alibi established, they moved onto the next person until all alibis were heard. Everyone's worried expressions visible through the small window of their suits. You were, too.

Winston raised his hand as though to adjust his glasses, but bumped into his helmet instead. He gave a little laugh before he cleared his throat. “Right. With that out of the way, we have some new information. It appears to be some sort of lifeform that is able to, ah, control people.”

Blue’s head--Hanzo--snapped up. “Control people? How?”

“We don’t know. There is simply not enough information to determine whether this life form kills and takes over the body, in essence, replacing them, or if it is simply controlling our bodies and leaving the victim alive.”

Mei put both hands over her helmet where her mouth would be. “Does that mean the person might not even know they’re the killer?”

“It’s quite possible. But again,” Winston rushed to say before the clamor in the room could reach unrestrainable levels, “we simply do not have enough information to work off of. We are still not dismissing the possibility of an outsider. And absurd as it may sound, maybe even a shapeshifter.”

The last part fizzled out as though the communicator didn’t want to relay such a nonsensical theory. But it would be entirely possible. In that case, no one would know who to trust.

“We again recommend keeping your partner in your sights at all times, if possible. Notify the rest if you suspect anything suspicious. You are all dismissed. Please continue with your tasks.”

There was some hesitation before the groups dispersed, everyone whispering to each other. You and Genji were no different.

As you did your tasks, you both pondered the nature of whatever it was you were facing. A shapeshifter? A doppleganger? A parasitic creature? Whatever it was, Genji swore to put it at the end of his blade.

By the time you were done with your tasks, it was ‘night’. Even with Genji helping, there were just too many things to be done in the station. It’s a given considering just how long it has been abandoned, but you really didn’t expect this much work out of it.

Even Genji requested for a short break.

“I’ll get us some tea,” you offered. The cafeteria was just a short ways away from your rooms anyway. You’re sure nothing will happen in the meantime.

“Thank you.” The fact that Genji didn’t even try to offer to come with you only gave away just how exhausted he must be. With the death of his master and now being suspicious of everyone on the space station, you couldn’t even imagine.

The cafeteria was huge and so very empty. Dying here would probably be the worst way to go. If you couldn’t find the perpetrator, were you all going to die in space where no one could hear you scream or mourn your death? Where you’d have to be thrown out into the empty embrace of space without ever returning home?

You shook yourself free of the oncoming existential crisis, grabbing two mugs and some stale teabags from the cabinets. You had to focus on the tasks at hand. Tasks make the day go by faster. And the faster the days went by, the faster you could all get the hell off this space station and go home where you didn’t have to suspect your fellow teammates of being shapeshifting, human-eating aliens—

“You’re alone?”

You shouted, nearly jumping out of your skin. You spun around and there was Gray--Fareeha. Your eyes darted back and forth. When did she sneak up on you?

“Fareeha! Um. What brings you here?”

“Where’s your partner?” she asked suspiciously, crossing her arms. Her tone immediately sent goosebumps up and down your skin.

“He wasn’t feeling all himself, so he’s resting. I’m making him tea,” you said quickly.

“You’re not supposed to move without each other.”

“I know, I just thought--you know, we’re just across the hall.”

She sighed in exasperation. “I can’t believe you. I’m coming with you until you have your partner back. Safety in numbers, right?”

You smile weakly. “Right.”

She waited patiently for you to finish making the tea and then nodded at the doorway even though no one was there. “Jesse. Let’s go.”

From behind the wall, McCree came out and gave you the tip of a phantom hat. “Escort mission, eh?”

“Hey, McCree.”

“Howdy. Let’s get this show on the road, shall we?” He bowed dramatically at you, sweeping his hands at the door. “After you.”

Even in such tense situations, he hasn’t lost his flair. You couldn’t help but smile. “Thanks.”

No sooner did the three of you step outside the room did the lights go out.

Fareeha growled. “Again!?”

“Guess we gotta go fix the lights.”

Someone--probably Fareeha--grabbed your wrist. “Wha—?”

“Gotta go fix the lights first. Then we bring you back to your partner.”

You could only follow whoever was pulling at your hand, unable to see more than just a few inches beyond your helmet. You don’t even know where you’re going or how they’d know where they were going for that matter.

But eventually, the grip on your hand disappeared. The sounds of footsteps faded away. In fact, everything faded away. No lights, no sound. Nothing. It was as though the vacuum of space was condensed onto your being, reality slipping away from you in inches.

The sound of a buzzer snapped you back into reality like a bubble popping. The lights were back on. You were standing in front of Genji’s room, on the other side of the cafeteria where you exited with your cups of tea. You looked around. How did you get here? Odd. You felt odd. You felt...full. Satisfied?

A voice--Soldier’s voice--crackled in your suit’s headset, choked up and reluctant.

“Dead body found. It’s...Fareeha.”

---

In case it’s not incredibly clear, which it isn’t, you’re the imposter and Genji isn’t. I’ve also only played the game a handful of times and watched a dozen youtube videos on it.

Originally it was supposed to be revealed that it’s Reaper who is controlling you ala symbiote-style. If I included it, I thought it would end up being a multi-chaptered thing and I wasn’t ready for that. But to tie up loose ends, Reaper was turning off the lights via your tablet without you noticing. Genji is sus of you. Everyone is sus of Genji. You were able to do the medbay scan because Reaper was in your suit which you took off.

15 notes

·

View notes

Text

The Island of Maravu - Chapter 2

The Island of Maravu

Chapter 2 - The Bunker

Pairing: Starker AU (Peter is 22)

Rated: Overall: E / Chapter: T

Status: WIP

Summary: The Avengers are in shambles and Tony Stark just needs to get out from under the fallout. So, he does what every genius, billionaire, playboy, philanthropist does - he buys an island. Maravu is just the escape Tony is looking for until one morning a beautiful young man arrives with secrets and a smile that makes Tony’s broken heart beat again.

Some Tags: AU, A little angst, Smut and Fluff is the goal here people but I can’t just do that apparently without backstory and plot. No real trigger warnings that I can think of unless water or storms are an issue for you. If you run into something I didn’t think of, let me know.

Chapter 1

~~~~~~~~~~

The birds hated him. They were in cahoots. Thirty-three days on Maravu and the birds woke him up before the sun every freaking morning. Tony stirred, rolled over and scowled at the open window. They were at it again.

He groaned and put a pillow over his head.

"Friday, play something loud."

"Playing your Something Loud playlist," Friday said. Tony rolled his eyes, noting the amusement in her voice before the opening guitar riff of Def Leppard's Photograph blasted through the speakers.

The cabin, a simple, but cozy one-room affair with a fireplace, sofa, kitchenette and dining room table, suited him perfectly. One of the two luxury items he'd insisted upon, besides Friday and the technical upgrades he'd made, was the queen-sized bed that dominated the bedroom area of the cabin. He'd have flown in a king if it would have fit. But even the queen was pushing it.

The cabin came equipped with an attached bathroom and shower. But Tony had grown accustomed to showering in the original, outdoor shower that ran using accumulated rainwater. Something about showering outside in the sun brought out the hedonist in him.

During his first week on Maravu, Tony installed a self-sustained arc reactor to solve the electricity problem and ensured they’d had fast reliable wi-fi. The plantation resumed operation the following week with Mr. Umbari as manager. Tony liked the huge mountain of a man. They worked well together and at the end of a long day, he often sought out his calming presence at the community fire that burned in the village's center courtyard most evenings.

They would talk about the day and share a drink before retiring. Tony liked to watch him talk, his expressive, deeply lined face and white, wiry hair and beard that stood up as though it had a mind of its own. Mr. Umbari had learned to speak English by watching episodes of old American shows like MASH and Happy Days and Tony found himself smiling when now and then he recognized a familiar phrase. When the reactor went live, Mr. Umbari had celebrated by giving Tony the double Fonzie thumbs before dragging him into a chest busting hug.

For the most part, the islanders didn't intrude on Tony’s solitude. Mr. Umbari was a fair and able leader, so Tony didn't get involved in the day to day operations unless they needed him. But periodically he'd be working in the lab he’d set up near his cabin and hear someone call out "Turaga Ni Kaukamea!" Tony would look outside to see someone emerge from the trees and request his assistance at the plantation.

Mr. Umbari addressed him as Mr. Stark even after Tony had invited him to call him by his first name. But the rest of the islanders called him Turaga Ni Kaukamea or sometimes just Kaukamea. Friday had translated it as basically Man of Iron.

So, they were aware of who he was. But no one ever asked to see the suit or wondered why he'd chosen to live on the island when it was clear his own house was in such disarray. They didn't bring it up at all. They expressed their gratitude in humble ways and treated him like anyone else on the island, which was perfect with Tony.

He peeked out from under his pillow to find that the sky has lightened into a midnight blue with the faint orange glow of dawn creeping up behind the windowsill.

"Okay, okay. Stop the music and start the coffee," he said, giving in. "And play me something tropical.”

"You do realize that the current temperature is 76 degrees with a humidity of 94%?" Friday asked as the sound of steel drums and ukulele began.

"My body still thinks it's December in New York, don't judge me," Tony snarked back, smiling when the coffee pot came to life. The rich aroma of the local blend infused his little cabin as the sun crested the horizon.

Tony threw back the sheet and stretched. He drew a deep breath and padded naked across the wood floor to the little kitchenette that consisted of the smallest stove he'd ever seen, a microwave, and a refrigerator that was straight out of the '70s in avocado green. The fanciest thing in the kitchen was his second luxury item – his beloved Concordia espresso machine.

He poured a cup into one of the chipped mugs that had come with the place and took it outside to the fire pit he'd built in the dooryard. His cabin was far enough away from the beach to be safe from the tide but close enough that his view from the fire was the perfect place to watch the sun come up. Tony lit the fire and settled into his camp chair with his coffee to do just that.

Although he tried to focus on his plans for the day, his mind wandered down paths he preferred to avoid. He tried not to spend his time worrying about the wayward Avengers, Rhodey, and the countless ways he had and continued to fail Pepper. But in those quiet moments when it was just him and the traitorous birds, Tony let it in.

He rubbed his chest. Like a phantom limb, it ached as it had for months after his last meeting with Steve.

And Barnes.

Tony sighed. Pepper had insisted he see a shrink after everything went down. He'd gone - a couple of times. But he still couldn't talk about it. Hell, he couldn't even think about it without igniting the flame of resentment and hatred. Logically he understood that Barnes had been brainwashed by Hydra. He was no more responsible for his actions than Clint had been for what he'd done when under the power of Loki's scepter.

Nevertheless, here Tony was. If Barnes were to materialize before him, Tony would probably try to bash his head in with a coconut.

Probably. Maybe.

Barnes may have the benefit of Tony’s doubt, the mind-controlled pass. But Steve...Cap…he’d made his choices all on his own. Tony oscillated between hope and fear that the big, stubborn man would get caught. He had no idea what he would say to the man if he ever saw him again. But he had the little burner phone Steve had mailed to Tony Stank tucked into his sock drawer nonetheless.

The temperature had risen just a little. On the horizon, Tony spied a rain cloud, one of those slow-moving clouds you could watch approach with its sheets of rain that blanketed the island at least once a day.

He frowned.

"Friday, what's the weather supposed to be like today?"

"Fair in the morning with severe thunderstorms rolling in at approximately 1:34 P.M."

"I suppose I should get started then," he said, gulping down the rest of his coffee. He put the mug in the sink and fished a fresh pair of shorts and a t-shirt from his dresser. It was time to check on the arc reactor.

~~~~~~~~~~

"Boss, the Fiji Meteorological Society has issued a tropical storm warning with potential for rotation in this area and is expected it hit earlier than expected," Friday warned.

Tony crawled out from under the arc reactor's electronics panel and adjusted his glasses.

"How bad?" he asked, wiping his hands on a towel. He peered up at the doughnut-shaped reactor housing. The walls of the cave in which he'd built it flickered blue and purple as it purred softly.

There was a certain amount of poetic justice in this, he thought. He'd started this in a cave. And now here he was again, minus the car battery and armed guards. And this arc reactor was designed only to help.

Tony climbed a small set of metal stairs, freshly painted safety yellow, which led to the ground floor. He opened a set of doors and entered the circular antechamber where islanders could look through the reinforced glass at the arc reactor below. They'd installed bunker doors at the mouth of the cave for emergencies. But they were usually left open to the public. The reactor itself was locked and protected by Friday. No one entered without Tony's knowledge.

Outside, the palm trees swayed and here and there little puffs of dirt from the path twisted into the air with leaves and rocks. Tony had been in the reactor bunker for a few hours and the wind had picked up considerably.

"Radar indicates wind speed of approximately 22 miles per hour. No active rotation," Friday said.

Tony chewed his lip and considered the news. When he'd moved in, Mr. Umbari had gone over their storm preparedness plan. The island had a storm bunker for its inhabitants. As though he'd summoned the man, Mr. Umbari and his orange menace of a golf cart sped around the corner. He slid in next to Tony's red cart, barely missing the tail end as he turned the sharp corner. Tony chuckled and shook his head as Mr. Umbari unfolded his long legs and climbed out from under the orange and white striped canopy. He hurried toward the bunker as the first drops of rain plip-plopped against his yellow rain slicker. As soon as he saw Tony Mr. Umbari grinned and waved. Tony ushered him inside and hit the button to close the bunker doors.

"Mr. Stark. The boys said you were here," Mr. Umbari said, entering through the single door.

"Yeah, I was just checking on the reactor, giving her a tune-up. Friday says we've got a storm on the way?"

Mr. Umbari had been introduced to the AI and he seemed completely charmed by her.

He smiled at the ceiling. "Hello, Ms. Friday. Thank you for keeping Mr. Stark so informed."

"It's my pleasure, Sir," she answered in her pleasant Irish lilt earning a grin from Mr. Umbari.

"Unfortunately, Ms. Friday is correct, Sir. Since this is your first storm on the island, I wanted to make sure that you were safe."

"Thanks for your concern. I'll finish up here and go down to the cabin, batten down the hatches and be in the bunker in time for dinner, Dad." Tony smiled at the large man as he put away his tools."

Mr. Umbari laughed, deep and genuine. "Good, good. I'm glad to hear it. I hear that Skillet has already begun a pot of lamb stew for the occasion."

Tony's stomach growled at the thought of food and he realized he hadn't eaten yet today.

"Skillet's cooking?" Tony asked and Mr. Umbari grinned.

"If Skillet's in the kitchen I'm not gonna miss it," Tony said.

Kitchen wizard and culinary school dropout, Skillet worked the plantation to help pay off his student loans. But one meal at Skillet's table told Tony that the young Fijian was wasting his talents.

Tall, whip-thin, with long black curls he kept up in a messy bun most days, the kid could cook rings around the overpriced chefs at any of the five-star Manhattan restaurants. Tony had offered to pay his debt and set him up in a spot of his own, wherever he wanted. But Skillet turned him down every time.

Tony, being Tony, had been trying to come up with a loophole that kid would accept to no avail. But he had one final trick up his sleeve he planned to save until the right moment. As Tony's chef, Skillet would both pay down his debt and have his talents recognized by the top critics around the world at the events Tony threw. It was a win-win for both of them.

Mr. Umbari nodded, evidently pleased with Tony's response.

"Good. Good. I should go to make sure the animals are safe. I will see you there, my friend! Goodbye, Ms. Friday," he said.

Tony smiled, amused at the way the islanders treated everything with a relaxed acceptance. Even in the face of a potentially damaging storm, they prepared for a gathering of families.

"See you there."

~~~~~~~~~~

Tony stepped into the storm bunker and was immediately enveloped in the delicious aroma of stew and fresh bread. He breathed in deeply and looked around the room, impressed by the setup. The bunker looked like a basement with concrete walls and floors. A bar and small kitchen stood on the right side of the room where Skillet was working his magic. The left side was lined with padded seats. They'd made the cold, grey room into a warm and comfortable place to gather with tapestries on the walls, and woven rugs and pillows on the floors.

"Turaga ni kaukamea!" several children called and swarmed, reaching up to be held and tugging him toward the group of adults who sat at the tables lined up end to end in the center of the room.

"Oh hey!" he exclaimed when a little girl who couldn't be more than four climbed him like a palm tree. The adults laughed as she wrapped her arms around his neck. He sat down in one of the folding chairs and held her on his lap.

"Kaukamea, what are you building in your lab? Filipe says you have a ghost and you talk to it. Does it help you build things?" she asked.

"Who told you that?"

The little girl pointed to a boy with bronze skin and wide, curious eyes. He looked up at Tony in fascination from the safety of his mother's arms.

"Filipe?" Tony asked with a raised eyebrow. The boy nodded dramatically.

"And what's your name?" Tony asked the girl.

"Sara," she said.

"Nice to meet you, Sara and Filipe. It just so happens that I am currently working on some upgrades to the arc reactor technology that runs the island. Have you seen the new bunker?"

All the children nodded in unison.