#RenewableEnergyTech

Explore tagged Tumblr posts

Link

0 notes

Text

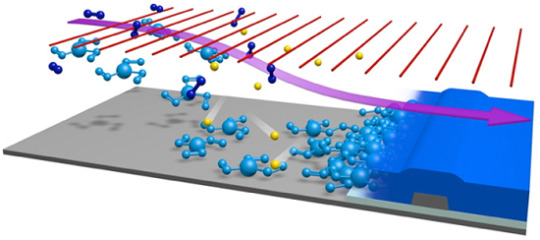

Beyond Silicon: How Longer-Lasting Perovskite Could Revolutionize Renewable Energy

Solar energy has always been an important part of renewable energy sources. The traditional polymer silicone panels, however, have their own performance and lifespan limitations, slowing down the progression of solar technology. While panels are widely used, there are efficiency constraints, and enormous costs and energy are required in their manufacturing. Perovskites, a new class of materials,…

0 notes

Text

Impact of Semiconductor and Electronics Industry on U.S. Chemical Vapor Deposition Market

The U.S. chemical vapor deposition market was valued at USD 4.15 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.6% from 2024 to 2030. This growth is attributed to technological advancements in the semiconductor industry, increasing demand for high-performance and energy-efficient devices, and the growing need for miniaturized semiconductor components are some of the key driving factors. Additionally, the rise in the adoption of CVD in various applications such as data storage, solar products, and cutting tools is also contributing to the market growth. However, the market’s expansion is not without challenges. Factors such as high equipment costs and the need for skilled labor can potentially hinder market growth.

For More Details or Sample Copy please visit link @: U.S. Chemical Vapor Deposition Market

The U.S. CVD market is characterized by rapid technological advancements and a high degree of innovation. Ongoing advancements in CVD techniques, such as plasma-enhanced CVD and atomic layer deposition, are driving the market. Significant research and development investments are being made by industry players and research institutions to develop innovative deposition processes, materials, and applications.

The chemical vapor deposition equipment segment dominated the U.S. market in 2023. This dominance can be attributed to the extensive use of CVD equipment in various industries, including semiconductors, electronics, and solar panels. The equipment is used to deposit thin films and coatings on substrates, which are essential in the manufacturing of semiconductors and other electronic components. The high demand for these components, driven by the growing electronics and semiconductor industries, has led to a significant market share of the CVD equipment segment.

The semiconductor & microelectronics segment dominated the U.S. market in 2023. The high market share is attributed to the increasing demand for high-quality and high-performance materials in the aerospace and defense sectors has been a significant driver for using CVD technology. Furthermore, in the U.S., rising demand for miniaturized and high-performance electronic devices has propelled the adoption of CVD for thin-film deposition of semiconductors and insulating materials.

Gain deeper insights on the market and receive your free copy with TOC now @: U.S. Chemical Vapor Deposition Market

List of key players in U.S. Chemical Vapor Deposition Market

Veeco Instruments Inc.

IHI Ionbond AG

Applied Materials Inc.

OC Oerlikon Corporation AG

ULVAC Inc.

CVD Equipment Corporation

Lam Research Corporation

#ChemicalVaporDeposition#CVDMarket#USMarketTrends#ThinFilmTechnology#AdvancedManufacturing#ElectronicsManufacturing#BiomedicalCoatings#AerospaceTechnology#RenewableEnergyTech#IndustrialCoatings

0 notes

Text

A solar panel manufacturing ERP optimizes efficiency through automation of planning production, managing inventory, and coordinating processes. It allows tracking in real time using UID/barcodes, integrating quality control, and simplifying lamination, framing, and assembly. ERP maximizes packaging, finished goods management, and warehouse functions as well. With digitization of these 8 major procedures, solar manufacturing ERP enhances supply chain efficiency, reduces costs, and supports scalability toward a future energy sustainability. Optimize your solar panel production with the best ERP software for solar manufacturing and enhance process automation.

#SolarManufacturingERP#ERPforSolarIndustry#SolarPanelProduction#ManufacturingAutomation#ERPSystem#RenewableEnergyTech#SmartManufacturing#SolarPanelEfficiency#QualityControlERP#SupplyChainOptimization#GreenEnergySolutions#ProcessAutomation#SolarIndustryGrowth#InventoryManagementERP

0 notes

Text

ERP for Solar Panel Manufacturing: Revolutionizing Efficiency and Productivity

The renewable energy industry, especially solar power, has grown to such an extent over recent years. On this part, manufacturers of solar panels are encountering different challenges associated with production, inventory, supply chain optimization, and meeting regulatory satisfaction for demand of sustainable energy solutions. Therefore, those enterprises begin to look on the ERP system as means to help improve the manufacturing processes to an efficient competition.

Enterprise resources planning (ERP) is the term that defines holistic software solutions that consolidate and control within an organization itself all the primary business processes, from production, inventory, finance, procurement, and sales, to human resources. In solar panel manufacturing scenarios, an ERP system would automate processes effectively, provide real-time information, and promote collaboration across various departments.

Benefits of Implementing ERP in Solar Panel Manufacturing

Optimized production planning Solar panel manufacturing involves a lot of processes, from obtaining raw material, such as silicon, to photovoltaic cell assembly. An ERP system allows a manufacturer to develop an optimized production schedule, while also ensuring efficient resource allocation, maximum uptime, and completion of production objectives. Integrated production planning allows manufacturers to follow each batch's status, thereby optimizing machine utilization and avoiding bottlenecks.

Real-time inventory management Generally, raw materials, components, and finished products must be managed in solar panel manufacturing. An ERP system provides manufacturers with transparent views on the current status of inventories in real-time. Automation of stock updates assists greatly in preventing stockoverkills and stockouts, which are both cost-effective-loss items. Most importantly, it manages the supply chain much better with such features as supplier performance monitoring and optimization of reordering points.

Better Quality Assurance Quality is critical in the production of solar panels, as the tiniest defects can negatively affect the manifestation and life span of these products. With the capability of ERP solutions, manufacturers would be able to institute quality checks by tracking raw materials, documenting tests, and complying with industry standards. The integrated reporting in ERP allows manufacturers to remedy quality issues with speed and great accuracy, therefore helping to ensure even more product consistency.

Streamlined Supply Chain Management The solar panel manufacturing supply chain is, for the most part, global and includes thousands of suppliers, transportation providers, and governing bodies. ERP solutions enable a centralized system of managing the holistic supply chain organization from the start of order processing to shipment tracking and supplier performance. The transparency helps manufacturers manage disruptions before they affect lead times and delays.

Cost Control and Financial Management As the cost of production has seen a considerable increase, solar panel manufacturers are pressured to manage their costs without compromising on quality. But through ERP systems, cost control becomes more manageable, more efficient, and potentially much more profitable. The implication here is that they can minimize operating losses through increased expenditure control, budgetary control, and production costing.

Compliance and Reporting The renewable energy industry is mostly governed by various regulatory bodies, environmental standards, and safety regimes. ERP systems help manufacturers comply with these regulations through the automation of reporting, tracking of certifications, and maintenance of associated documentation. The inbuilt compliance capabilities in ERP systems allow manufacturers to generate reports to meet industry standards, thereby minimizing the risk of penalties and non-compliance-related concerns.

Data-Driven Decision Making Solar panel manufacturers operate in a highly competitive and dynamic environment, where making data-driven decisions is crucial. ERP systems provide comprehensive analytics tools that allow manufacturers to gain insights into key performance indicators (KPIs), such as production efficiency, sales performance, customer satisfaction, and supply chain reliability. These insights empower decision-makers to take proactive steps toward continuous improvement and long-term growth.

ERP Modules in Solar Panel Manufacturing

Generally, an effective ERP comprises the following modules for solar panel manufacturing:

Manufacturing Module This module manages the production processes: work order, production scheduling, inventory management, and quality control so that all production operations are optimized for better efficiency and productivity.

Inventory and Supply Chain Management This module monitors inventory levels, raw material orders, vendor management-all to help optimize inventory turnover and ensure that materials are available for production.

Sales and Order Management This module supports customer order input, demand forecasting, and shipment tracking so that customers will know when to expect their orders and receive quality products.

Financial Management This module brings together all financial accounting: budgeting, financial reporting, cost-tracking, and profit analysis. It lets the manufacturers keep financial control and make informed decisions regarding investments.

Customer Relationship Management CRM provides manufacturers with the tools to track customer interactions, manage sales leads, and enhance customer service. The role it plays is crucial in retaining a good customer relationship, enhancing sales performance, and managing after-sales service.

HR management It is critical in solar panel manufacturing employing a skilled workforce. With an ERP, HR will be able to maintain employee data, manage payroll, track shifts worked, and optimize workforce deployment for production.

Maintenance and Asset Management Solar panel manufacturing involves specialized machinery and equipment. With the help of an ERP, they can keep track of maintenance schedules and avoid machine downtime while ensuring that all their assets work at peak efficiency.

The Future of Solar Panel Manufacturing with ERP Systems

ERP systems are revolutionizing the solar panel manufacturing industry by allowing manufacturers to handle production, supply chains, product quality, and meeting regulatory requirements with the aid of these tools. It would provide solar panel manufacturers with the right tools to improve operational efficiency, cut costs, raise customer satisfaction, and push for overall business growth.

As the renewable energy market continues to grow, the adoption of ERP systems by solar panel manufacturers will become increasingly important to remain competitive, meeting demands for solar energy, and contributing to a more sustainable future.

#SolarPanelManufacturing#ERPforManufacturing#RenewableEnergyTech#ManufacturingAutomation#SolarEnergy#SmartManufacturing#SupplyChainOptimization#GreenEnergySolutions#ProductionEfficiency#SustainableManufacturing#SolarPowerInnovation#ERPforRenewableEnergy#EnergyManagement#SolarIndustryTechnology

0 notes

Text

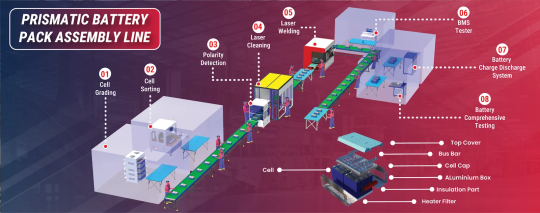

Explore the high-performance prismatic battery pack assembly line designed for precision and scalability. This cutting-edge solution is ideal for EVs and energy storage, ensuring quality and efficiency at every step.

#PrismaticBatteryPack#BatteryAssemblyLine#EVManufacturing#EnergyStorageSolutions#BatteryTechnology#SustainableEnergy#ElectricVehicles#GreenTech#BatteryInnovation#SmartManufacturing#AutomationInBatteries#CleanEnergy#EVBatteryProduction#RenewableEnergyTech

0 notes

Text

New Chip Revolutionizes Signal Processing and Computation More information: https://www.blogger.com/blog/post/edit/7484431261636362440/8936949549086094242 For Enquiry: [email protected] Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

0 notes

Text

Solutions for High-Pressure Hydrogen Storage

Hydrogen storage is one component of the hydrogen economy that is crucial. Because of its extreme flammability and low density, hydrogen needs to be stored in a solid state or at low temperatures. There exist multiple alternatives for storing hydrogen, each with pros and cons of their own.

Download - https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Compressed Hydrogen Storage: Compressed hydrogen storage is the most widely used and widely accepted method of storing hydrogen. This method compresses hydrogen gas, which is then stored in high-pressure tanks. The tanks can be constructed out of metal or composite materials. The storage pressure range is 350–700 bar; greater pressures result in greater storage capacity. Compressed hydrogen storage is useful for stationary applications such as industrial operations, backup power, and refueling stations. Unfortunately, due to their size and weight, the tanks cannot be utilized in mobile applications.

Liquid Hydrogen Storage: Hydrogen gas must first be cooled to its boiling point (-253˒°C) in order for it to liquefy before being kept in insulated tanks. Compressed hydrogen storage has a higher energy density than liquid hydrogen storage. However, because it requires cryogenic temperatures, the tanks must be well insulated to avoid boil-off and venting. Although liquid hydrogen storage is not ideal for general applications due to its high cost and complexity, it is often used in space applications and some specialized ones, such as high-performance automobiles.

Metal Hydride Storage: Metal hydride storage involves the utilization of metal alloys that possess the capacity to both absorb and release hydrogen gas. Often utilized lightweight metals for creating metal alloys are magnesium, titanium, or aluminum. The low operating pressure, safety, and enormous storage capacity of metal hydride storage are just a few advantages. The high cost and high temperature required for hydrogen to be released from the alloys are disadvantages. Metal hydride batteries are useful for portable devices, backup power systems, and small fuel cells.

Chemical Hydrogen Storage: Chemical hydrogen storage uses materials with the ability to release hydrogen gas when activated. Among the substances, which can be either organic or inorganic, are sodium borohydride, ammonia borane, and formic acid. Chemical hydrogen storage has the advantages of high storage capacity, low operating pressure, and portability. The compounds' disadvantages are their high cost, byproduct production, and catalyst requirement for hydrogen release. Chemical hydrogen storage has use in small fuel cells, backup power systems, and portable electronics.

Storage is a crucial link in the hydrogen supply chain. It allows hydrogen to be produced and delivered to the consumption site during off-peak hours. The choice of hydrogen storage methods is influenced by the different applications, energy density, safety, and cost considerations.

The primary objectives of continuing research and development are cost reduction and increased hydrogen storage efficiency.

High-Pressure Hydrogen Storage

High-Pressure Hydrogen Storage is crucial for hydrogen-based energy systems, particularly for fuel cell vehicles, industrial operations, and energy storage. The following information relates to high-pressure hydrogen storage.

Importance of High-Pressure Storage: Given its low volumetric energy density, hydrogen gas needs to be compressed in order to acquire a sizable storage volume for a number of uses. Storage at high pressure is one of the finest solutions to this issue.

Storage Technologies: High-pressure hydrogen storage solutions include gas cylinders, composite overwrapped pressure vessels (COPVs), and tube trailers. These technologies are used in many fields, depending on the specific requirements and applications.

Safety Considerations: Hydrogen storage at high pressure raises numerous safety issues. Containment systems must abide by stringent safety rules to prevent leaks or ruptures since hydrogen is extremely flammable.

Advantages: The ability to store more hydrogen in a given area, speedier refueling for hydrogen-powered cars, and simpler design are only a few advantages of high-pressure storage over cryogenic storage.

Challenges: A significant challenge may be the energy required for compression. Furthermore, the strain and fatigue caused by cyclic loading must be tolerated by the materials used to construct high-pressure storage systems.

High-pressure hydrogen storage is crucial to the hydrogen economy because it enables the safe and efficient storage and transportation of hydrogen for a range of applications, which is necessary for the pursuit of cleaner and more sustainable energy solutions.

Hydrogen Storage Materials

The development of technologies and systems based on hydrogen energy is heavily dependent on Hydrogen Storage Materials. These materials are used to store and release hydrogen in an efficient and secure manner. The following information explains the materials used to store hydrogen:

Hydrogen Storage Mechanisms:

There are several ways to store hydrogen, including chemisorption (chemical bonding), physisorption (physical adsorption), and mixtures of these methods. While choosing a material, consideration is typically given to the planned storage capacity, release kinetics, and thermodynamic considerations.

Types of Hydrogen Storage Materials:

Metal Hydrides: These compounds are known as metal hydrides; they are composed of metal atoms combining with hydrogen. Sodium alanate (NaAlH4), magnesium hydride (MgH2), and complex metal hydrides are a few examples. Metal hydrides have a relatively large capacity to hold hydrogen, which is released at ambient temperature.

Porous Materials: Activated carbon, covalent organic frameworks, and metal-organic frameworks (MOFs) are among the porous materials that can adsorbe hydrogen using physisorption techniques. They have a wide surface area and can be modified for storing hydrogen.

Thermodynamics and Kinetics: The thermodynamics of hydrogen storage materials must be understood in relation to the energy changes caused by hydrogen adsorption and desorption. Kinetics deals with the speeds of these processes. Good thermodynamic and kinetic properties are desirable for materials used in practical hydrogen storage devices.

Operating Conditions: Materials for storing hydrogen may need a variety of operating environments. Some materials may require heating, while others can work at ambient temperature. Gaining an understanding of and honing these factors are necessary for practical implementation.

Challenges and Research: The objective of current research is to develop materials with improved properties such as increased storage capacity, faster kinetics, and lower operating temperatures for the storage of hydrogen. Reversibility, cost, and safety issues must all be addressed before these materials be employed extensively.

The category of hydrogen storage materials includes a wide range of compounds with varying capacities, operating circumstances, and storage procedures. These materials are crucial for the development of hydrogen-based energy systems, and research and development efforts are ongoing to improve their efficacy, safety, and utility.

Hydrogen Fuel Storage

Fuel storage for hydrogen-based energy systems and technologies is essential. Hydrogen needs to be stored carefully and efficiently in order to be used in combustion engines or fuel cells. The following information relates to the fuel storage for hydrogen:

Hydrogen Storage Methods:

Gaseous Hydrogen Storage: With this method, hydrogen is stored as a gas at pressures typically between 350 and 700 bar (5,000 and 10,000 psi) in high-pressure containers. Lightweight materials such as metal alloys or composite materials are commonly employed in these containers in order to ensure their survival under high pressure.

Liquid Hydrogen Storage: Liquid hydrogen is stored at very low temperatures roughly 253°C or -423°F. Gaseous hydrogen has a lower energy density than liquid hydrogen, but gaseous hydrogen requires cryogenic storage tanks, which can be huge and energy-intensive to maintain.

Metal Hydride Storage: Certain metal hydrides possess the ability to absorb and release hydrogen gas in a reversible manner. Because they offer a compact and safe method of storing hydrogen, they are suitable for both fixed and mobile power generation.

Chemical Hydride Storage: Sodium borohydride and ammonia borane are examples of chemical hydrides that can hold hydrogen. They release hydrogen when heated or in the presence of a catalyst. Chemical hydrides are used in applications like backup power systems.

Liquid Organic Hydrogen Carriers (LOHCs): The reversible binding and release of hydrogen is a property of organic compounds called LOHCs. For the mobile storage and transportation of hydrogen, these carriers are extremely well-suited.

The hydrogen economy, which enables the practical use of hydrogen in a range of applications, depends critically on hydrogen fuel storage. The ideal storage solution will depend on the specifics of the application and the need for efficiency, portability, and safety. The advancement of hydrogen storage technology is the aim of ongoing research and development.

Leading businesses that focus on hydrogen storage systems include the following:

Air Liquide: Air Liquide offers a variety of hydrogen storage solutions, including bulk storage tanks, tube trailers, and compressed gas cylinders.

Linde: Linde offers a range of hydrogen storage solutions, including high-pressure gas cylinders, tube trailers, and cryogenic storage tanks.

Hexagon Purus: Type 4 tanks are strong and lightweight composite high-pressure hydrogen storage tanks that are the specialty of Hexagon Purus.

McPhy Energy: Two hydrogen storage solutions offered by McPhy Energy are solid-state hydrogen storage and hydrogen refueling stations.

Plug Power: Plug Power offers fuel cell hydrogen storage alternatives in addition to metal hydride-based storage systems.

Worthington Industries: Worthington Industries offers a variety of hydrogen storage systems, compressed gas cylinders and bulk storage tanks being only two.

Chart Industries: Chart Industries is a specialist in building cryogenic storage tanks, which have the capacity to hold large amounts of hydrogen at low temperatures.

Hydrogenics: Two hydrogen storage solutions offered by Hydrogenics are hydrogen refueling stations and compressed gas cylinders.

The storage of hydrogen has proven to be a major technical barrier to the widespread use of hydrogen as fuel. Some major problems with hydrogen storage are as follows:

Low energy density: The energy density of hydrogen is lower per unit volume than that of conventional fuels such as gasoline and diesel. This suggests that in order to store the same amount of energy as conventional fuels, more hydrogen must be stored.

Storage at high pressures: Hydrogen must be compressed to extremely high pressures in order to acquire the energy density required for practical application. This poses a safety risk due to the extreme pressure that could result in leaks and explosions.

Cryogenic storage: Hydrogen can also be stored by cooling it to very low temperatures and turning it into a liquid state. Unfortunately, this means that very low temperatures (-253˂°C) are required, which complicates and increases the cost of the storage process.

Material compatibility: Gas can cause embrittlement and corrosion in certain materials, so materials that are compatible with hydrogen must be used to build storage tanks and pipes.

Cost: It is still somewhat expensive to store hydrogen when compared to other fuels. The cost of high-pressure tanks, materials compatible with hydrogen, and cryogenic storage could raise the overall cost of storing hydrogen.

Hydrogen storage system problems must be resolved before hydrogen can be used as a fuel on a large scale. New, affordable, high-energy-density hydrogen storage technologies are the aim of current research and development.

Read More - https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-storage-solution

#HydrogenStorageSolutions#HighPressureHydrogen#CleanEnergyStorage#HydrogenInnovation#RenewableEnergyTech#HydrogenInfrastructure#PressureVesselTech

0 notes

Text

Transparent OLED Roofing: $4.5B → $15.2B (2034) | CAGR 12.9%

Transparent OLED Roofing Market is projected to grow from $4.5 billion in 2024 to $15.2 billion by 2034, with a CAGR of 12.9%. This cutting-edge building-integrated photovoltaic (BIPV) technology merges organic light-emitting diodes (OLEDs) with transparent photovoltaic layers, transforming rooftops into energy-generating surfaces without obstructing natural light.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10778 &utm_source=SnehaPatil&utm_medium=Article

Transparent OLED roofing utilizes flexible, ultra-thin organic semiconductor materials that emit customizable light while simultaneously harvesting solar energy. Unlike conventional solar panels, OLED-based roofs offer high transparency, lightweight structures, and superior design flexibility, making them ideal for smart buildings, urban skylines, and sustainable homes.

Recent advancements in perovskite solar films, quantum dot enhancement, and AI-powered energy management have significantly improved efficiency, longevity, and adaptive control. These next-gen roofing solutions not only reduce carbon footprints but also integrate with smart grids, IoT-enabled energy systems, and off-grid power applications for maximum sustainability.

With the push toward net-zero energy buildings and carbon-neutral urbanization, transparent OLED roofing is set to redefine modern architecture, making structures both self-sufficient and aesthetically advanced

#TransparentOLED #SmartRoofing #OLEDTechnology #SolarRoofing #NextGenSolar #BuildingIntegratedPV #GreenConstruction #SolarArchitecture #FutureOfBuildings #TransparentSolarCells #PerovskiteSolar #QuantumDotTech #OLEDInnovation #EnergyHarvestingRoofing #SelfSustainingBuildings #NetZeroArchitecture #SmartBuildingSolutions #AIInEnergy #SolarPoweredRoof #SustainableUrbanization #RenewableEnergyTech #ElectroactiveMaterials #ThinFilmSolar #SmartGlassTech #FutureOfConstruction #CarbonNeutralDesign #IoTForBuildings #AdvancedMaterials #SolarWindows #PlasmonicNanotechnology #OLEDGlass #AdaptiveEnergySystems #EcoFriendlyBuildings

0 notes

Text

Top 5 Ways ERP Optimizes Solar Panel Manufacturing

Solar panel manufacturers are under pressure to work towards high efficiency, low-cost products, and improved quality, given that the demand for renewable energy is increasing. Solar manufacturing ERP is transforming the industry by standardizing and streamlining processes and also providing better supply chain management while ensuring compliance with the industry's standards.

In this blog, we explore the top five ways ERP optimizes solar panel manufacturing :

Production Automation for Maximum Efficiency : Solar panel production encompasses various durations of procedures; raw materials preparation, assembly, and testing all involve one or another preceding procedure. ERP for the solar industry integrates processes and automates many functions while reducing manual errors and delays in production. With the real-time data tracking capabilities, manufacturers can optimize workflows, allocate resources, and enhance production speed altogether, equating to increased output.

Real-time Inventory Management : Inventory management is essential. An efficient process ideally minimizes instances of materials shortages and surplus stock. ERP for solar manufacturers gives real-time visibility into the inventories of the materials used across procurement, not just raw materials but also finished product inventories too. Manufacturers will thus maintain optimum stock levels with minimal chances of waste, hence going a long way in effecting cost efficiencies.

Enhancing Supply Chain Visibility : The manufacturing of solar panels depends on a complex supply chain, from suppliers to logistics providers and distributors. ERP solutions provide complete supply chain visibility; thus, aiding manufacturers in tracking shipments, managing vendor relationships, and optimizing procurement. The automation of supply chain operations scales down delays and manages disruptions successfully. With such assurance, production runs smoothly.

Reduced Costs With More Efficient Use of Resources : Cost control in the manufacturing of solar panels is vital. ERP software would allow manufacturers to do production cost analysis, resource allocation optimization, and point out areas where costs can be reduced. Since wastage of materials is reduced, energy management bettered, and financial automation enabled by ERP, the profit margin can only increase, given that production standards are maintained.

Quality Control and Regulatory Compliance : Strict standards of quality and environmental specifications must be met by almost all solar panels. ERP for the solar industry integrates quality control systems, ensuring rigorous testing and adherence to regulatory requirements for every solar panel produced. It minimizes the risk of defects, recalls, and penalties thanks to automated compliance tracking, and maintains the brand reputation of manufacturers within the sector.

Conclusion

Implementing ERP in solar manufacturing, adds excellent production efficiency, enhances inventory management, streamlines supply chain operations, drives down costs, and ensures regulatory compliance. As the solar industry continues to thrive, implementing ERP solutions will become quintessential for manufacturers to withstand increasing competition and growing global demand.

#SolarManufacturing#ERPforSolar#SolarIndustryERP#RenewableEnergyTech#SolarPanelProduction#SmartManufacturing#ERPforEnergySector#SolarTechSolutions#SupplyChainOptimization#GreenEnergyManufacturing

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

0 notes

Text

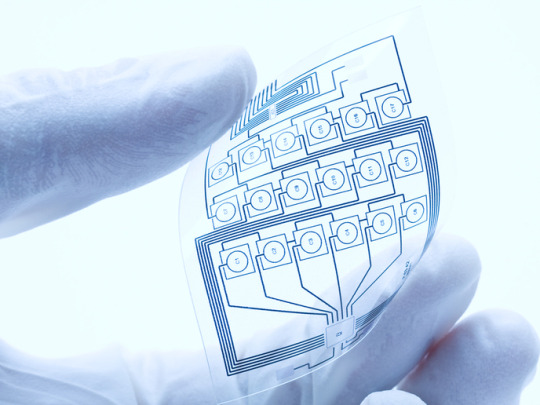

Lowering the barrier for innovation in flexible electronic components

More information: https://www.blogger.com/blog/post/edit/7484431261636362440/7118660735529769743

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration#Nomination Link :https://x-i.me/emcnom#Get Connected Here:#==================#Facebook : https://www.facebook.com/profile.php?id=61556074815651#Twitter : https://twitter.com/PencisE28647#Pinterest : https://in.pinterest.com/electronicconference/

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected]

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WorldElectronicConference#ElectronicsInnovation#GlobalTechGathering#SemiconductorSummit#DigitalSystemsForum#TelecomTechTalk#RenewableEnergyTech#InnovationExchange#NetworkingEvent#TechCollaboration

1 note

·

View note