#Roll Forming Machine India

Explore tagged Tumblr posts

Text

#roll forming machine#Hydraulic Decoiler Machine#Hydraulic Decoiler Machines#Hydraulic Decoiler Machine in India#Hydraulic Decoiler Machine in Faridabad#Hydraulic Decoiler Machine in Haryana#Hydraulic Decoiler Machine in Delhi NCR#Hydraulic Decoiler Machines Manufacturers

2 notes

·

View notes

Text

Shape with Confidence – Advanced C Channel Roll Forming by Jugmug

In today’s age of industrial precision and structural performance, C channel profiles are more than just pieces of metal—they are the backbone of strong, dependable frameworks. At the heart of these robust profiles lies the C Post Channel Roll Forming Machine, and no one understands this better than Jugmug RollForming. With years of engineering expertise, Jugmug has become a name synonymous with precision forming, durability, and customer-focused innovation.

What Is a C Channel Roll Forming Machine?

A C Channel Roll Forming Machine, also known as a C Post Roll Former, is used to manufacture C-shaped steel sections from metal coils. These profiles are widely used in:

Construction (purlins, wall studs)

Industrial shelving

Cable tray supports

Solar panel mounting structures

Automotive and transportation frames

The forming process ensures accurate dimensions, clean edges, and consistent shapes, which are critical for structural stability and assembly efficiency.

Why Jugmug RollForming?

With a heritage of craftsmanship and a passion for innovation, Jugmug RollForming has revolutionized how industries view roll forming. Here's why Jugmug leads the pack in C Channel Roll Forming:

1. Precision Engineering

Jugmug’s machines are designed using advanced CAD/CAM systems and assembled with CNC-manufactured components. The result is ultra-precise forming even at high speeds, with tolerance control up to ±0.5mm.

2. Heavy-Duty Build Quality

Built with rugged structural frames, hardened rollers, and wear-resistant shafts, these machines are engineered for long-term, high-volume performance without breakdowns.

3. High-Speed Automation

Equipped with PLC control systems, servo motors, and hydraulic punching/cutting, Jugmug’s C Post machines reduce human error and improve productivity. The touchscreen HMI makes operation simple and intuitive.

4. Customization on Demand

Every business has unique needs. Jugmug provides tailor-made C channel forming machines, whether you require:

Variable sizes and gauges (1.2 mm to 3 mm)

Manual or fully automatic operation

In-line punching, embossing, or logo marking

Quick-change cassette design for multiple profiles

Applications of C Channel Profiles

The C profiles manufactured using Jugmug’s machines find applications in:

Construction

Used as wall studs, roof purlins, girts, and base plates due to their load-bearing capacity and resistance to warping.

Solar Panel Mounting

C channels are widely used to fabricate the structural framework for solar PV systems.

Automotive Chassis & Framework

Because of their strength-to-weight ratio, C channels are ideal for reinforcing vehicle bodies and cargo enclosures.

Racking & Storage Systems

Industrial shelving systems often rely on C profiles for their modular, load-bearing structure.

Customer Success Stories

Jugmug RollForming has delivered its C channel machines across India and globally. Many manufacturers in the solar, automotive, construction, and logistics sectors report:

30% increased output

Reduced material wastage

Quick ROI (within 12-18 months)

Minimal downtime

After-Sales Support & Training

Jugmug doesn’t stop at selling the machine—it partners with you throughout the journey. Their post-sale support includes:

Installation & operator training

Preventive maintenance plans

Spare parts availability

Remote troubleshooting support

Annual servicing packages

Their team of qualified engineers is just a call away, offering pan-India coverage and global service reach.

Green Manufacturing with Jugmug

In alignment with sustainability goals, Jugmug machines are designed to optimize energy usage and reduce raw material waste. The machines feature:

Servo-driven motors for low energy consumption

Smart sensors for real-time quality control

Eco-friendly hydraulic systems

By adopting Jugmug’s forming systems, manufacturers not only boost output but also reduce their carbon footprint.

Conclusion: Shape with Confidence

When strength, accuracy, and speed matter, Jugmug RollForming’s C Channel Roll Forming Machine delivers with unmatched precision. Whether you are scaling up production or entering new markets, Jugmug ensures your foundation is strong—both literally and technically.

Shape your future with confidence—partner with Jugmug RollForming.

#C channel roll forming machine#C post forming machine manufacturer#C profile making machine India#Jugmug RollForming machines#Structural roll forming equipment#Roll forming machine for solar structures#Best C channel machine in India

0 notes

Text

Samosas, Sockets & Strategic Sarcasm

Previous Chapter - [Tumblr/Ao3] A/N: If you came here for plot, sorry. Today we have samosas, sockets, and semi-functional serotonin. It’s a slice-of-life palate cleanser—just you, the interns, and one possibly haunted coffee machine. (PS: This chapter is low on corporate trauma, high on found family with bad coping skills. Enjoy. Or rage. Both valid.)

You weren’t supposed to go.

You didn’t do field visits anymore—not after the last one ended with a warehouse fire, a broken AC unit, and Sukuna getting banned from Rajiv Chowk, Delhi's Shibuya.

But then Yuji barged into your office at 9:04 AM with a clipboard, a nervous smile, and a hot Americano held out like a peace treaty.

“Ma’am,” he said, sheepishly, “you’re on today’s site roster.”

You didn’t look up. “I’m not.”

Junpei peeked in behind him. “The vendor sent us a message. They deep-cleaned the toilet because they heard our CEO’s coming.”

Yuji added, “They even put phenyl. The good kind.”

You stared at them. Blinked once. “Phenyl is not a reason to relocate me.”

“But field’s fun!” Yuji insisted. “And we’re testing the new Insta-friendly brew-pod machine in Sector 63. Kokichi said it has ‘aesthetics.’”

You sipped your coffee. “…Fine. But if I see a single chipkali, I’m burning the building.”

Ten minutes later, you were in the backseat of a half-broken company SUV with five interns and a playlist titled “Corporate Chokehold: Vol. 3.”

Nobara—operations intern, nails like switchblades, temper like Delhi traffic—turned to face everyone with the confidence of a woman who’d fought her landlord and won.

“Okay,” she said, turning around in the front seat like a substitute teacher on Red Bull. “I made everyone playlists. You’re not allowed to complain.”

“Why is mine titled ‘Girlboss But Screaming’?” you asked.

“Because it fits,” said Kokichi, deadpan.

Yuji fist-bumped him. Junpei laughed. Megumi—stoic, folded into the corner like a cat in human form—just shook his head and turned up the AC.

They were chaos. Loud, all under 25, too eager, too caffeinated to be safe. And they worshipped you in the way only juniors who’ve never seen their boss cry over payroll do.

The test café was unfinished—concrete, cables, and the faint smell of damp walls and desperation. You walked in, heels clicking, sunglasses still on, sipping your cappuccino like it was a press statement.

“Where’s the machine?” you asked, already regretting this.

Junpei pointed at the corner. “They said the plug shorted. Again.”

You sighed. “Amazing. We’re launching India’s first AI-enabled coffee pod dispenser in a haunted PG.”

While they fussed over wires and breakers, you sat on a dusty crate, stared at the ceiling and contemplated leaving your own company.

Then Megumi appeared, holding out a samosa like a silent offering.

No words.

Just... samosa.

You blinked. “I didn’t say I was hungry.”

“You skipped breakfast,” he muttered, not looking at you. “You’re mean when you’re hungry.”

“Are you my PA now?”

“No. But HR won’t let me file another grievance.”

You took it. Grudgingly.

Nobara plopped down beside you, sipping warm Limca from a reused paper cup.

“You’re not scary once you stop yelling,” she said.

“Do you want to be unemployed?”

She grinned. “Nah. I’m unionising the interns.”

Then Kokichi walked into a spiderweb and screamed like a news anchor caught in an MLM scandal.

Yuji tripped on a paint bucket.

Junpei, god bless him, tried to climb a rickety shelf and brought down a full crate of cups.

And you… laughed.

Real laughter. The kind that started in your stomach and rolled out before your brain could censor it.

Megumi blinked. “Did you just—glitch?”

“Shut up.”

The terrace was where you crashed next, everyone sweaty and slightly bleeding. The tea was watery, the sandwiches stale, and the sun kept threatening to murder everyone in linen.

You didn’t mind.

Nobara came back with a spreadsheet crumpled under one arm.

“Ma’am,” she said, quieter this time. “Do you think I’m good enough to go full-time?”

You looked at her.

Hair a mess. Eyes sharp. Posture slightly slumped from lifting cartons. Trying. Really trying.

You took a sip of your warm Nimbooz and said, “You’re annoying. But you’re sharp. You’ll get there.”

She beamed. Not giddy. Not grateful. Just... understood.

“Don’t get used to compliments. You will report to Toji; he’s not good with those,” you added. “Prepare for gym talk and protein packets in the mailroom.”

She groaned. “Fuck. Okay.”

Yuji kicked her lightly. Kokichi stole her Limca.

Somewhere, Junpei was doodling on the café walls.

And you just sat there. Under the ugly Delhi sun. Sipping flat soda with people who made your startup feel... bearable.

You didn’t think about investor Gojo fumbled.

Didn’t think about the deck Suguru hadn’t submitted. Didn’t stress about Sukuna, Toji and Nanami’s burner Twitter accounts ratio-ing investors.

You just existed.

No rage. No ego. No debt spiral-induced existentialism.

You just sat.

“Hey,” Yuji whispered suddenly, leaning close. “You okay?”

You blinked. “Why wouldn’t I be?”

“I dunno,” he said. “You always look like you’re one payroll error away from homicide. But today you looked... okay.”

You bit back a smile. “I’ll deduct your salary for that.”

“Totally fair.”

At some point, Nobara put on a second playlist. Kokichi started sketching another prototype. Megumi cleaned a data sheet with a pen he didn’t borrow from Nanami for once. Junpei made samosa jokes. Yuji asked you about the machine specs with genuine curiosity.

And none of them asked you about the boys.

Because they didn’t care who you were at IIM. They cared about who you were now.

And right now, you were just their boss. Their shark. Their war general.

And they’d follow you to hell if it came with free WiFi and quarterly bonuses.

By 4 PM, the machine still wasn’t fixed. Kokichi had duct-taped a fire hazard into existence. Megumi declared it “mostly safe.”

You stared at it. “If this explodes, I’m blaming all of you.”

“Noted,” said Kokichi.

Yuji saluted.

Back in the car, you sat in the middle seat.

Yuji offered you half his KitKat. You took it. No words.

Megumi put on lo-fi beats.

Junpei snored softly.

Kokichi fell asleep with his laptop still open.

Nobara took a selfie. Captioned it: “We tested nothing. But we had fun.”

You rolled your eyes and added a like. Quietly.

Back at the office, no one said anything when you walked in with paint on your pants and samosa oil on your hand.

Toji was wrestling Ino for some reason.

Sukuna blinked at you. “Did you... go outside?”

You ignored him.

Suguru appeared from behind a ficus. “You smell like fresh cement. Lovely.”

Nanami raised an eyebrow when you dropped a working brew-pod schematic on his desk.

“Prototype worked?”

“No,” you said.

Gojo watched you walk past.

Slightly confused. Slightly soft-eyed.

You didn’t look back.

Walked straight to your cabin. Sat down.

Opened Slack. Typed:

Field update: It’s not about the damn coffee. It’s about the team. The real one.

Also, budget a new fuse box. Kokichi set the last one on fire.

–CEO

And hit send.

You didn’t hate today.

Because you didn’t feel tired.

You felt... fine.

---

A/N: Tell me which intern you'd unionise with. Be honest. Also— Did the samosa scene make you soft? Did Yuji's KitKat offering hit your lizard brain like it hit mine? Do you think the machine passed QA, or are we all collectively lying on Slack? Talk to me in the comments. I’m running this startup with bad mental health and vibes. I need your emotional Google Map reviews. 😌

Next Chapter - The Utahime Fallout - [Tumblr/Ao3]

All Works Masterlist

#jujutsu kaisen#jjk#nanami kento#gojo satoru#kento nanami#jjk x reader#jujutsu kaisen x reader#satoru gojo#toji fushiguro#ino takuma#geto suguru#suguru geto#ryomen sukuna#sukuna ryomen#jjk fic#takuma ino#jjk crack#satoru gojo x reader#gojo x you#suguru x reader#sukuna x reader#nanami x reader#megumi#kokichi muta#mechamaru#nobara#junpei

11 notes

·

View notes

Text

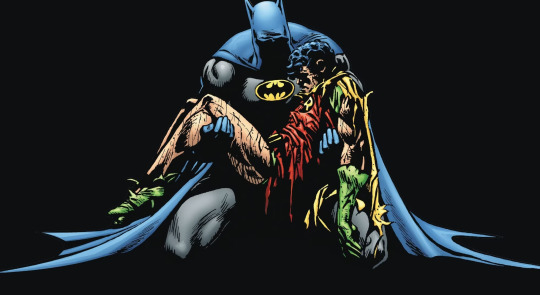

Spider-Man: Across the Spider-Verse: I may have activated my own trap card

Spoilers for a movie that's two months old and also out on home release.

So, Miles, Gwen, Pavitr (Spider-India), and Hobie (Spider-Punk) all seem to have modern left-wing politics, though Gwen's got edited out. Hobie's introduction specifically says he hates "fascists", which carries over from the original comics.

By the time Hobie came around, I assumed he was just another poser, cooler than the hero rival character, expressing generic leftie politics, and his punk ethos wasn't sincere.

Which is exactly what the writers wanted me to think.

Not only is Hobie perfectly sincere about being anti-authoritarian, but he's been helping Miles since before they even met. He's been blatantly stealing junk from the Spider Society to build his own universe-jumping watch, and disguising it as petty vandalism.

He even tries to talk Miles out of trying to join the Spider-Society before the reveal that Miles himself is an anomaly, and the SS (geddit?) tries to detain Miles.

When Hobie says he's against authoritarianism, he really means it.

Speaking of the left-wing politics, Miles has a "#BLM" pin on his bag. It's very visible while he sits next to his dad.

Who's a cop.

(TANGENT: A few years ago, someone drew a stupid, very bad comic where Spider-Man (Peter Parker) was a) black, b) hated cops, and c) assaulted and subdued riot cops when they asked him for help.

That the comic didn't even show the riot cops were wrong. We were just supposed to assume they deserve to be left to the mercy of an angry mob.

Also, in this comic, Uncle Ben was killed by a cop, not a random thug who Spidey could've stopped but chose not to. Which makes me wonder how that would shake out.

It's kind of weird for someone to look at a character who's about personal responsibility to an unhealthy degree, and use him to express their collectivist anti-cop terrorism fantasies. That, or they didn't think through their fantasies.)

During Spider-India's opening, Miles says "I love Chai Tea!" And Pavitr goes on a rant about how "Chai" means "tea". Later on, The Spot says he's been on a "journey of self-discovery", and Pavitr basically says he's racist.

Which is a tad ironic, because Spot is literally white. And also because Pavitr is the one making the racist assumptions.

And I personally go to a church - in England - that has a lot of non-white non-British people. Mostly Africans. And me, of course. I wonder if any Asians ever went on a journey of self discovery to South London.

And I don't just mean as a cab driver.

"Wait, SYABM, didn't you move to the UK for self-discovery?"

W-well, yes, partially.

Aside: I made the mistake of watching a Youtube video with the Chai Tea joke, and then I looked at the comments.

One guy said "tfw when Twitter users write a movie". An idiot (with much more upvotes) said "bro out here wanting blatant racism in movies".

...When the whole point of the joke is that the racism is not blatant.

It's only "blatant" if you're insufferably Twitterized. There are loads of redundant phrasings in English, like "ATM machine", and words often shift when they're adopted from other languages.

Also, "I dislike this joke" is not the same as "I want racism in this movie", when the "racism" in the movie is only there so it could be mocked.

One of the issues with putting real world movements in worlds that are drastically different - it's one of the main selling points of the franchise - is that it may seem odd that those movements exist in very similar form to the IRL version.

For example, Miles supports BLM in both his video game, and this. Which makes me think "did Trayvon Martin get shot in Florida? How about Mike Brown? Wouldn't the existence of supervillains throw things into a new perspective?"

Did I mention the giant George Floyd-style "REST IN POWER" mural to Miles' dead uncle? I cringed at that in the Wakanda Forever trailer, and I rolled my eyes at it here.

Floyd wasn't a saintly martyr, he was an unlucky violent thug.

Also, Aaron was a supervillain killed by another bad guy who nearly destroyed the city, not a cop.

Also, this is at a party to celebrate how Miles' dad is about to be promoted. Assuming Floyd died and the 2020 protests/riots also happened in Miles' universe, then it seems a tad tasteless to have a mural inspired by an anti-cop movement overlooking it, even if the party is not full of cops.

Spider-India lives in "Mumbattan".

The people who settled the Manhattan area were originally Indian. But the other type of Indian. The Indians we're not supposed to call Indians anymore.

The name "Manhattan" is even Native American.

The first permanent settlement was Dutch. Then the English got it. I guess the English could've shipped Indians to the other side of the world and eventually ceded the area to them, or maybe in this world India was a world-conquering superpower and Mumbattan is the result of...importing Native Americans?

Which would make Pavitr's complaint that "the British stole all of our stuff and put it in their museums" seem a tad hypocritical.

Of course, since I wrote all that, someone reminded me that Pavitr explicitly says the joint is in India.

"SYABM," you say, "you're overthinking this."

Yes, I am. Because the filmmakers didn't think it through. If you want to use ha-ha-funny to make a serious point, you invite examination of that point.

Miles (as Spidey) now works with his dad, though he disguises his voice. At one point, Miles tells his father that men bottle up mental health issues.

This is true (and ironic, considering Miles is hiding who he is from Jeff), but it's not the first time I've seen some progressive work try to address men's issues in an very awkward way. At least here, it's played for comedy.

Also, seems a tad hypocritical coming from a guy who wears a "#BLM" pin in the presence of his cop father.

Also, if you work the timeline, that would mean Miles was about 7 or 6 when BLM started. Which means he's gone most of his life knowing nothing else.

There was a controversy over a "protect trans kids" trans flag in Gwen's room, which was apparently edited out.

IMO, it seems a tad strange for a girl who feels estranged from everyone in her world to join a social movement, but what do I know? Maybe it was there before then.

Some people came to the extremely logical conclusion that Gwen herself is trans. Even though she's distinctly physically feminine and possibly too young for puberty blockers depending on Earth 65′s laws.

Like the "oh great, it's Liv" shippers, people are reaching really hard to see what they want to see.

Some people have said that Gwen's issues with her dad and herself seem awfully similar to the issues LGBTQIA2S+ kids go through.

Gee, it's not like, y'know, feeling estranged from one's family is a common theme in fiction about teenagers and superhero, and the whole "superpowers = minority" thing has been done to death for most of the past century.

Perhaps most notably - and clumsily - in X-Men.

youtube

I'm not saying this wasn't the intended subtext. I'm saying if it was, it would just be really, really cliche.

There's this recurring theme of people telling miles "how [his] story is supposed to go".

When he's at a meeting with his parents and his guidance counselor, the lady says his story of being a black-Latino son of an immigrant would sound great in the college application letters. His mom is a tad miffed, given that they're a) solidly middle class, and b) as a Puerto Rican, she considers herself American.

Miguel (Spider-Man 2099) doesn't want Miles in the multiversal council of Spiders, because Miles was bitten by the radioactive spider from a different universe. Which is why his local Spider-Man died, and the spider's home dimension has no Spider-Man.

Also, Miguel is fixated on "canon events". The idea that there are certain things, especially tragedies, that have to happen to Spiders, or their entire universe falls apart.

And he knows this, because he tried to take over for a version of him that got shot dead by a thug. Tried to raise his daughter.

And he watched as the universe collapsed in front of him.

So he's projecting his own guilt onto Miles, a tad.

According to TVtropes and other sources, this was actually about the people who didn't accept Miles as a replacement Spidey, possibly out of racism.

Yeah, that's real hard-hitting topical meta-commentary about a character who debuted 12 years ago. 8 years when the first movie came out.

I'd also like to point out that despite stereotypes of comic book fans, certain minority successors to banner superheros have been fairly well-received. Like Jaime Reyes, or Cassandra Cain.

(Note: I wrote that before the Blue Beetle movie came out. And flopped.)

And, of course, loads of people like Miles specifically because he's a minority Spidey, which is also racist, just from the other direction. In fact, a lot of his fans seem to forget the "Latino" part of "Afro-Latino". From what little I've seen of Miles early comics, they did actually put strong emphasis on his race.

I also suspect the filmmakers may be misinterpreting the usual successor knee-jerk reactions

as racism. If you're using an established brand name for your new hero, you're creating some expectations.

Also, you know the most popular meme about regular Spidey that I see? That Marvel's writers just keep making him suffer and don't want him to actually develop. Which would kinda make Marvel closer to Team Miguel than Team Miles.

Miles also gripes that Miguel is letting "some algorithm" tell him what to do. While I agree with the sentiment, I'd like to point out that, again, Miles supports BLM.

A movement popularized by an algorithm.

A movement made up of narratives and assumptions.

A movement which has never proven a single incident was because of racism.

During the big chase scene, we see a Spider girl in a wheelchair, aka Sun-Spider. She's from the comics. Same initiative that gave us "Web-Weaver".

Who is, of course, an extremely effete gay fashion designer Spidey. I kinda like his outfit, though the Spider-eyes with eyelashes is a little too far.

And Sun-Spider seems exactly like a character a stereotypical 90s executive and focus group would come up with. Down to the backward baseball cap.

(Turns out she's Dayn Broder's actual Spider-Sona.)

Also, while I was looking up that one black and white Spider who said "nowhere to run" (Metro-Spider, played by record producer Metro Boomin [/sic]), I found out that Aunt May's full name is "Maybelle", not just "May". TIL.

There's a bit of a double standard with this version of Spider-Woman, who's black and pregnant. -People in the movie - including Peter B - regularly point out how Peter B endangering his infant daughter Mayday by taking her along with him. But for some reason, nobody says a word about Jessica, who's an active-duty stunt-biking superhero.

Even regular motorbiking can be dangerous for pregnant women.

In fact, the movie portrays this as heroic and impressive. When Gwen sees Jess is preggos, she asks if Jess can adopt her.

Not to mention the whole "afro and hoop earrings" thing, which seem like a bad idea for a type of hero who often gets into melee combat, even with Spider-Sense.

Yes, I'm aware that female heroes, including the Spider-Ladies, often have exposed hair. It's a genre convention. Incidentally, it was nice to see Batwoman wore a detachable decoy wig in the comics. Some bad guy tries to grab it in a fight? It comes right off.

Also, Jess doesn't have much actual character.

Being pregnant is not a character trait. In fact, her only real traits are basically "cool but stern sassy mentor", to contrast with Peter B. -Incidentally, someone on TVtropes pointed out the double standard. And when I saw the page again, a page-camper had deleted it, with no explanation.

Guess they couldn't stand someone pointing out the flaws of their waifu.

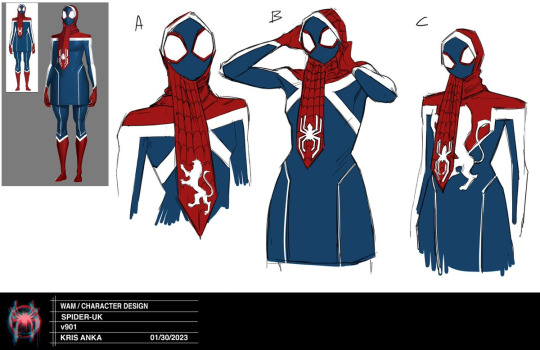

(One) Spider-UK in this movie is Muslim. I know she's Muslim because she wears a Spider-themed headdress. Note that regular Marvel 616 has a muslim lady Spider-UK, but her name is Zarina Zahari and she doesn't wear a hijabi.

(Also, she could be mistaken for Ms. Marvel.)

ms marvel.jpg

You might be thinking "wait, isn't a headdress impractical in a melee fight? Doesn't it give your enemy something to grab?" Yes, it is.

But so are Jess's earrings, afro, and being pregnant, so clearly there's a lot of artistic license going on.

Maybe it's partially tearaway, like Batman's cape.

I gotta wonder about the religious rules of wearing a head covering over a mask that *already* covers your entire head. Did she go see her imam and go "Okay, I have a really weird question..."

Come to think, Spidey is usually slim, but a lot of lady Spideys in this movie seemed to have wide hips. Including muscular ladies. Kris Anka's concept art goes really hard on wide hips. I don't know why. Stronger, faster character reads during the big chase?

I guess Spiders could be expected to have strong legs.

BOTTOM LINE:

I liked the movie overall, though the progressive bits made me roll my eyes a little. I...want to see the third one, with reservations.

79 notes

·

View notes

Text

Chaiwala Shop, 41025 Fremont Blvd, Fremont, CA 94538

Monument Shopping Center is very lively at night with lights and signs that remind me of being in India. Several newish eateries opened in this shopping center this year, including Chaiwala Shop. Most of the patrons of this shopping center are Indian.

The menu includes ten kinds of chai, available hot or iced, snacks, coffee, badam masala, pink milk, fresh juices, refreshers, shakes, Maggi masala, Indian burgers, Indian pizza, and Indian sandwiches, etc.

Cardamom masala ($4.50, hot): creamy and sweet. It was sweeter than I expected, but did taste handcrafted. I could see the spices and even the film that sometimes forms on top

Bun maska ($4): a soft round bun (looked like a hamburger bun and tasted like the rolls they use for pav bhaji), split and slathered with butter and cream. It’s sweet and buttery. It was okay. Very simple.

The shop is open late and has free wi-fi but it’s not cozy or comfortable. The chairs are hard. They leave the door open and it’s cold outside and cold and drafty inside. The lights are far too dim and the machine that they use to brew chai seems very noisy.

3.5 out of 5 stars

By Lolia S.

#Chaiwala Shop#chai shop#tea shop#chai#Indian snacks#Indian pizza#Indian sandwiches#free wi-fi#Fremont

2 notes

·

View notes

Text

Are you looking for DIN 2379 Steels for your Cold Work Steel projects?

Virat Special Steels is one of the most reputable Tool Steel & Die Steel and Mold Steel Suppliers in India.

DIN 2379 steel is Cold Work Steel with High Carbon High Chromium contents. Its very applicable for cold stamping or forming dies industries. DIN 2379 steel, also known as X153CrMoV12 material, is a high carbon chromium molybdenum vanadium cold-work tool steel.

Let’s dive into the details: Chemical Compositions:

Carbon ©: 1.45-1.60%

Silicon (Si): 0.10-0.60%

Manganese (Mn): 0.20-0.60%

Chromium (Cr): 11.0-13.0%

Molybdenum (Mo): 0.70-1.00%

Vanadium (V): 0.70-1.00%

Virat Special Steels is the leading Supplier & Stockiest of Din 2379 Steel. DIN 2379 steel is Cold Work Steel with High Carbon High Chromium contents. The Quality with high wear resistant and toughness properties due to Vanadium addition of 0.90% . Normally it supply condition is an Annealed and will offer hardness to reach 57-59 HRC.

It can be machinable in the annealed condition. DIN 2379 is the superior steels than D3 due to high alloys properties.

Applications: DIN 2379 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting Threading Dies, stamping tools Etc.

Learn more: https://www.viratsteels.com/din-2379.html

Learn from pdf: https://www.viratsteels.com/pdf/cold-steels/2379.pdf

Any queries feel free to contact us : Email us:[email protected] or call us:+91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#ToolSteel#SteelTrades#MetalIndustry#DIN2379#cold work steel

2 notes

·

View notes

Text

Discover the Power of Aluminium Sheets: Lightweight, Durable, and Sustainable—Inox Steel

Inox Steel is a trusted name among Aluminium Sheet Manufacturers in India, delivering top-quality aluminium products for a wide range of industrial and commercial applications. As a leading Aluminium Sheet Supplier, we understand the growing demand for lightweight, corrosion-resistant, and durable materials across sectors such as construction, transportation, electronics, packaging, and more. Our aluminium sheets combine innovation with excellence to meet the highest quality standards and performance expectations.

Understanding Aluminium Sheet

Aluminium Sheets are flat-rolled products created by passing aluminium slabs through heavy rollers to achieve the desired thickness. They typically range from 0.2 mm to 6 mm in thickness, with variations above 6 mm classified as plates and below 0.2 mm as foils. Available in various grades, finishes, and tempers, aluminium sheets are suited for a wide range of functional and aesthetic applications.

Leading Aluminium Sheet Manufacturers in India offer products that comply with global standards, catering to different industrial needs. Common alloys such as 1100, 3003, 5052, and 6061 are used by almost every Aluminium Sheet Manufacturer to ensure high strength, formability, and corrosion resistance.

Advantages That Make a Difference

Durability Meets Versatility Aluminium sheets are built to last. They resist rust, environmental damage, and chemical exposure, making them ideal for outdoor and high-wear applications. Despite their durability, these sheets are easy to form, cut, and weld.

Weight Efficiency That Delivers Weighing significantly less than steel, aluminium sheets reduce structural load and transportation costs. Using an Aluminium Sheets Weight Chart helps engineers and fabricators calculate loads and plan for structural efficiency without compromising strength.

Visual Appeal with Functional Design With a range of finishes—such as anodised, brushed, or mirror-like polish—Aluminium Sheet not only serves a functional purpose but also offers a modern appearance. Architects and designers often use it in interior decor and facade systems.

Excellent Formability for Custom Solutions Aluminium sheets can be bent, rolled, or shaped without losing structural integrity. This makes them ideal for customised components in machinery, signage, packaging, and consumer products.

Eco-Friendly and Fully Recyclable Aluminium is among the most recycled materials in the world. Using recycled aluminium saves up to 95% of the energy required to produce it from raw ore, making Aluminium Sheet a sustainable choice for green manufacturing practices.

Where Aluminium Sheets Make an Impact

1. Industrial Manufacturing Used in equipment housings, panels, and machine parts, aluminium sheet provides a dependable material that balances strength and formability in factory settings.

2. Building and ConstructionAluminium Sheet Suppliers provide sheets for cladding, insulation panels, roofing systems, and more. Their weather resistance and aesthetic flexibility make them ideal for modern infrastructure projects. Builders often rely on the Aluminium Angles Weight Chart to select the right materials.

3. Automotive and TransportationFrom vehicle body panels and trailer sides to train and aircraft skins, aluminium sheet helps manufacturers reduce vehicle weight, improve fuel efficiency, and meet emissions targets. Weight estimation using tools like the Aluminium Pipe Weight Chart is critical in this sector.

4. Electrical and Electronics Due to its conductivity and thermal dissipation properties, aluminium sheet is used in casings, heat sinks, and enclosures for electronic equipment.

5. Packaging and Consumer Products Aluminium sheets are used in the production of beverage cans, cosmetic containers, and food trays. They offer excellent hygiene, non-toxicity, and recyclability.

Choosing the Right Aluminium Sheet for Your Needs

When selecting aluminium sheet, consider:

Application environment (indoor, marine, structural)

Required strength and formability

Surface finish needs

Alloy and temper specifications

Trusted sourcing from an experienced Aluminium Sheet Supplier

If you're located in Gujarat, working with an Aluminium sheet supplier in Ahmedabad can ensure faster delivery and personalised service. Many regional manufacturers offer tailored solutions to meet construction and industrial demands efficiently.

Conclusion:

Aluminium sheets from Inox Steel India offer the perfect combination of strength, lightness, and sustainability, making them an essential material across industries. With a strong presence as an Aluminium Sheet Supplier in India, we are committed to delivering superior-quality products that meet diverse application needs. Whether you're building infrastructure, manufacturing equipment, or designing consumer goods, our aluminium sheets provide unmatched performance and reliability.

#AluminiumSheetManufacturersinIndia#AluminiumSheetManufacturer#AluminiumSheet#AluminiumSheetSupplier

0 notes

Text

Pouch Filling Machine: The Definitive Guide for Modern Packaging Solutions

What is a Pouch Filling Machine? A pouch filling machine is an automated packaging system designed to fill pre-formed pouches with liquid, powder, granules, or paste-based products. These machines are engineered to perform multiple tasks such as pouch feeding, product dosing, filling, sealing, coding, and sometimes even cutting or perforating—all in a single streamlined process.

Pouch filling machines are critical to ensuring speed, hygiene, product integrity, and cost efficiency in modern production lines.

Types of Pouch Filling Machines

Vertical Form Fill Seal (VFFS) Machines These machines form pouches from a roll of film, fill them vertically, and then seal them. Ideal for products like snacks, rice, sugar, and detergents.

Horizontal Form Fill Seal (HFFS) Machines Pouches are formed horizontally, making them perfect for solid and fragile items like biscuits, chocolates, and wrapped confectionery.

Pre-Made Pouch Filling Machines These handle pre-formed pouches (like doypacks or zipper bags), filling and sealing them. They are widely used for liquids, sauces, oils, and ready-to-eat foods.

Rotary Pouch Filling Machines Known for their compact design and high speed, rotary machines handle all pouch filling stages in a circular layout, offering consistent performance and versatility.

Applications Across Industries Food & Beverage Fruit juices, milk, water, ketchup, sauces, oil, spices, flour, snacks, grains

Use of food-grade contact parts, anti-drip nozzles, and nitrogen flushing for extended shelf life

Pharmaceutical & Nutraceutical Oral liquids, powders, capsules, herbal supplements

Requires adherence to GMP and FDA standards

Cosmetic & Personal Care Lotions, shampoos, gels, creams, serums

Need high viscosity handling and anti-leak sealing

Chemical & Agrochemical Liquid pesticides, fertilizers, and industrial chemicals

Involves corrosive resistance materials like SS316L or PTFE coatings

Key Features of Modern Pouch Filling Machines

Servo-Driven Dosing System Allows precise product fill levels with minimal variation, enhancing consistency.

Touchscreen HMI with PLC Control Offers easy recipe changes, fault diagnostics, and real-time performance data.

Automatic Pouch Detection The machine detects pouch presence and alignment before initiating filling.

Nitrogen Flushing Used to remove oxygen from the pouch, increasing product shelf life.

Zipper Opening and Closing Mechanism Essential for resealable pouches such as those used for dry fruits, coffee, and snacks.

High-Speed Operation Modern machines can fill up to 120 pouches per minute, depending on pouch size and product type.

Advantages of Using a Pouch Filling Machine Hygienic Packaging: Contactless filling and sealing in a clean environment

Reduced Labor Cost: Fully automated lines require minimal manpower

Higher Output: Consistent speeds and reduced downtime boost production

Versatile Packaging: Can handle stand-up, flat, zipper, gusseted, or spouted pouches

Enhanced Brand Appeal: Clean, wrinkle-free sealing with clear date coding

Minimal Wastage: Drip-proof nozzles and accurate dosing reduce overfilling or spillage

Top Considerations Before Buying

Product Type Is it a powder, granule, paste, or liquid? Each needs different dosing systems (auger filler, piston filler, volumetric cup filler, etc.).

Pouch Format and Size Ensure the machine supports your pouch type: flat, stand-up, zipper, three-side seal, or four-side seal.

Production Volume Calculate your expected pouches per hour and match it with the machine's speed.

Space Availability Rotary machines are compact, while VFFS may need vertical clearance.

Compliance and Certifications Machines for food and pharma should follow GMP, ISO 22000, or FSSAI standards.

Estimated Pricing in India (2025) Machine Type Price Range (INR) Capacity (Pouches/Min) Manual Pouch Filler ₹70,000 – ₹1.5 lakh 10–20 Semi-Automatic Machine ₹1.5 – ₹4 lakh 20–40 Automatic VFFS Machine ₹5 – ₹18 lakh 30–100 Rotary Pre-Made Pouch Filler ₹20 lakh – ₹1 crore+ 60–120

Prices depend on machine materials, number of filling heads, pouch size, and customization.

Top Indian Manufacturers of Pouch Filling Machines Nichrome India Ltd.

Durga Packaging Machine

Uflex Limited

Sampack India Pvt. Ltd.

Mamata Machinery Pvt. Ltd.

These companies offer end-to-end solutions including pouch making, filling, sealing, and after-sales support with installation and operator training.

Common Accessories and Integrations Coding Machines (Inkjet/thermal) for MRP & date

Weighing Systems

Checkweighers and Metal Detectors

Nitrogen Flushing Units

Pouch Pick-and-Place Robots

Pouch Counting and Batching Units

Routine Maintenance Tips Lubricate moving parts every 15 days

Calibrate dosing systems monthly

Replace sealing jaws annually or as needed

Inspect sensors and PLC connections for moisture or dust

Clean nozzles and product pathways daily

Future of Pouch Filling Technology AI-Powered Fill Accuracy Adjustment

Self-Cleaning Filling Valves

Real-Time Batch Tracking

Smart HMI Panels with Cloud Storage

Recyclable Pouch Compatibility

Conclusion A pouch filling machine is an indispensable part of modern packaging automation. Whether you’re in the food, pharma, cosmetic, or chemical industry, the right machine can significantly improve productivity, reduce human error, and increase your product’s market appeal. With rising consumer demand for flexible and eco-friendly packaging, investing in the right pouch filling solution ensures long-term operational success and brand growth.

0 notes

Text

Versatile Solutions for Racking & Shelving – Slotted Angle Machines by Jugmug

In today’s fast-paced industrial environment, storage efficiency and structural versatility are vital. From warehouses to retail stores, slotted angles play a pivotal role in supporting robust racking and shelving systems. At the forefront of manufacturing innovation stands Jugmug Rollforming, a name synonymous with precision engineering and customized roll forming solutions. Among their most popular offerings is the Slotted Angle Roll Forming Machine, crafted to meet the dynamic needs of modern fabrication units.

Why Slotted Angles?

Slotted angles are L-shaped steel profiles with pre-punched slots, designed to create a variety of support structures. These components are widely used for:

Storage racks

Warehouse shelving

Custom-made frameworks

Light-duty structural assemblies

The ability to bolt and assemble without welding makes slotted angles a favorite in industries requiring modular design, ease of assembly, and cost-effective scalability.

Jugmug Rollforming: Excellence in Every Slot

Jugmug Rollforming has earned a reputation for delivering high-performance, precision-built roll forming machines. Their Slotted Angle Roll Forming Machine is a result of deep industry experience, robust engineering, and an understanding of end-user challenges. Whether you're a mass producer of slotted angles or a custom profile manufacturer, Jugmug's solutions offer unmatched efficiency, accuracy, and reliability.

Key Features of Jugmug’s Slotted Angle Roll Forming Machine

High-Speed Production

Jugmug’s roll forming line delivers fast and seamless production from coil to finished profile. With line speeds of up to 10–15 meters per minute, manufacturers can scale operations without compromising on quality.

Adjustable L-Shape Design

The machine is optimized for producing standard L-shape slotted angles with variable widths, heights, and slot patterns. Whether it's light-duty angles for retail racks or heavy-duty ones for industrial shelves, Jugmug’s machines handle it all.

Automatic Punching System

Integrated hydraulic or mechanical punching units ensure accurate and repeatable slot placement. The slot pattern can be customized using CNC-controlled die systems, giving manufacturers the flexibility to meet diverse client needs.

Coil Handling to Cut-to-Length

From decoiling to roll forming and final cut-to-length shearing, the complete slotted angle profile line is automated. Jugmug provides options for manual or fully automatic stacking systems.

Smart Control Systems

Equipped with PLC-based control panels, the system allows users to set parameters like length, number of slots, and batch quantity. Minimal human intervention reduces error and improves production consistency.

Applications of L Shape Slotted Angle Manufacturing Machine

The L shape slotted angle manufacturing machine by Jugmug Rollforming is used in producing profiles for:

Pallet racking systems

Light and medium-duty shelving units

Support frameworks for electrical panels

Mezzanine floor structures

Modular display units

These machines are also widely used by OEMs, steel fabrication units, storage solution providers, and logistics infrastructure developers.

Customization & Support

Jugmug Rollforming understands that no two clients are the same. That’s why they offer:

Profile customization as per client drawings

Slot pattern variations with modular tooling design

Material adaptability – compatible with GI, MS, SS, or CR steel

Installation & training support worldwide

Their engineers collaborate closely with each client to tailor the machine according to production volume, material thickness, profile dimensions, and punching needs.

Why Choose Jugmug for Your Slotted Angle Profile Line?

Made in India – Trusted Worldwide

Proudly designed and manufactured in India, Jugmug’s machines are trusted by businesses across Asia, Africa, Europe, and the Middle East.

Sturdy Construction

With heavy-duty base frames, hardened rollers, and precision gearboxes, Jugmug machines are built for long-term durability and low maintenance costs.

After-Sales Support

Jugmug Rollforming provides unmatched after-sales services, including remote diagnostics, spare parts supply, and on-site support when required.

Cost Efficiency

By investing in Jugmug’s slotted angle machines, manufacturers reduce labor dependency and wastage, thereby increasing production yield and profitability.

Conclusion

If your business is focused on racking, shelving, or structural frameworks, investing in a slotted angle roll forming machine is a strategic move. And when it comes to choosing the right manufacturing partner, Jugmug Rollforming offers the perfect blend of technology, performance, and service.

#slotted angle shelving machine#L shape slotted angle machine#storage rack shelving machine#L shape slotted angle manufacturing

0 notes

Text

#roll forming machine#PUF Panel Side Bending Machine#PUF Panel Side Bending Machines#PUF Panel Side Bending Machine in India#PUF Panel Side Bending Machine in Faridabad#PUF Panel Side Bending Machine in Haryana#PUF Panel Side Bending Machine in Delhi NCR

1 note

·

View note

Text

What Makes Four Roll Plate Bending a Game-Changer in Fabrication?

In the world of metal fabrication, precision, efficiency, and repeatability are key elements for success. Among the various methods and machines used in the industry, four roll plate bending has emerged as a true game-changer. Whether you're working with mild steel, stainless steel, or even alloys, this bending technology significantly improves the way industries approach metal forming. In this in-depth guide, we'll explore what makes four roll plate bending revolutionary and why it's rapidly becoming the preferred method for businesses globally, especially for any heavy engineering company in India looking to stay ahead of the curve.

Understanding Four Roll Plate Bending Technology

At its core, four roll plate bending is a process that uses a machine for bending metal with four rolls: two central (pinch) rolls and two side rolls. This configuration allows the material to be fed into the machine, clamped, and bent in a single pass—streamlining the fabrication process like never before.

Unlike three roll systems, the four roll system offers pre-bending and rolling in one continuous operation. The top and bottom rolls hold the plate securely, while the side rolls shape it precisely. This advanced control ensures greater consistency and fewer defects.

Key Advantages of Four Roll Plate Bending

1. Enhanced Precision and Accuracy

With CNC (Computer Numerical Control) integration, four roll systems provide pinpoint accuracy. The plate is gripped tightly between the top and bottom rolls, minimizing slippage. This ensures the final product meets exact specifications every time—a critical factor for sectors like aerospace, defense, and high-precision construction.

2. Superior Material Handling

Handling large and heavy plates can be challenging and risky. Four roll bending machines offer better material control and can process larger and thicker materials with ease. This makes them a preferred choice for any heavy engineering company in India involved in infrastructure, shipbuilding, or energy projects.

3. Time and Labor Efficiency

In traditional three-roll systems, operators often need to reinsert the metal for pre-bending and final shaping. In contrast, the four roll machine completes the job in one seamless operation. This results in higher throughput and significantly lower labor costs.

4. Automation and CNC Integration

Modern four roll systems are integrated with automation capabilities. Operators can store multiple programs, reducing the need for manual adjustments. For businesses aiming to scale or standardize production, this feature is a massive advantage.

5. Versatility in Applications

Whether it's rolling small-diameter tubes or large structural components, four roll machines can handle it all. From cylindrical tanks and silos to complex geometries, this equipment delivers unmatched versatility.

How It Outperforms Traditional Bending Technologies

While three roll machines are still in use, they lack the efficiency, control, and ease of operation offered by four roll machines. The need for manual repositioning increases the chance of error and elongates the cycle time. On the other hand, the four roll machine for bending metal automates the bending sequence and improves workflow, making it the go-to solution for modern manufacturers.

Additionally, four roll machines are safer for operators. With fewer manual interventions required, the risk of injury is minimized. This makes them ideal for large-scale operations and workshops aiming to uphold rigorous safety standards.

The Role of Hydraulic Systems in Four Roll Machines

The most efficient and powerful four roll machines available today are hydraulic plate bending machines. Hydraulic pressure allows for uniform force distribution, resulting in consistent bends across the entire sheet. The hydraulic system also contributes to a longer machine life and reduced maintenance costs.

A hydraulic plate bending machine offers:

Higher pressure for bending thick or hardened materials

Precise control of each roll’s movement

Consistent performance over long production runs

For industries where durability and reliability are crucial, such as automotive, oil and gas, and marine, the hydraulic system proves indispensable.

Use Cases and Industry Applications

1. Infrastructure Development

Large-scale infrastructure projects often require massive rolled components for bridges, tunnels, and railways. A four roll machine for bending metal can produce these parts with accuracy and speed, allowing contractors to meet deadlines without compromising on quality.

2. Shipbuilding and Marine Engineering

Curved plates are integral to ship hulls and offshore platforms. Four roll bending ensures smooth, defect-free curves, enhancing structural integrity and performance.

3. Energy Sector

Whether it's wind towers or pressure vessels for oil refineries, the energy sector relies heavily on reliable bending technology. A hydraulic plate bending machine ensures that thick, high-tensile materials are formed without warping or cracking.

4. Manufacturing and Fabrication Shops

General fabrication companies benefit from the versatility of four roll machines. They can handle a variety of materials and thicknesses, making them ideal for custom jobs and prototyping.

5. Aerospace and Defense

These sectors demand utmost precision and reliability. Four roll bending machines deliver consistent results, ensuring components meet stringent industry standards.

Choosing the Right Machine: Key Features to Consider

When selecting a four roll machine for bending metal, consider the following features:

Roll Diameter and Material: Larger rolls handle thicker materials better. Rolls made from hardened steel or alloy last longer.

Bending Length Capacity: Ensure the machine can accommodate the sheet sizes you typically work with.

Control Systems: Opt for CNC systems for better automation and repeatability.

Hydraulic Power: A strong hydraulic plate bending machine ensures durability and smoother operation.

Safety Features: Emergency stop buttons, safety guards, and overload protection are essential.

Partnering with a reputed heavy engineering company in India can also help you source the best equipment tailored to your requirements.

Maintenance and Operational Best Practices

To keep your four roll bending system in top shape:

Regular Lubrication: Keeps moving parts functioning smoothly

Routine Inspections: Identify wear and tear early

Training for Operators: Reduces operational errors and prolongs machine life

Software Updates: Keep the CNC system updated for better performance

Long-term efficiency depends on proactive care, and many a heavy engineering company in India offers maintenance services to ensure minimal downtime.

Future Trends in Four Roll Plate Bending

The future of plate bending is being shaped by automation, AI integration, and digital monitoring. Smart sensors now track roll pressure, sheet thickness, and material type in real time, allowing for instant adjustments. These innovations are making four roll machines even more reliable and user-friendly.

Additionally, sustainability is becoming a priority. New models are designed for energy efficiency and lower environmental impact. If you're investing in a hydraulic plate bending machine, looking for eco-friendly features could benefit your operation in the long run.

Final Thoughts

The adoption of four roll plate bending is transforming the fabrication landscape. From enhanced accuracy and speed to safety and automation, this technology checks all the boxes. Whether you're an independent fabricator or part of a heavy engineering company in India, upgrading to a four roll machine for bending metal can drastically improve your production quality and capacity.

With the added strength and control offered by a hydraulic plate bending machine, businesses can confidently take on complex and large-scale projects. As the demand for precision and customization in metal forming continues to grow, four roll plate bending stands out as an indispensable asset in any modern fabrication setup.

0 notes

Text

Essential Exercise Accessories to Boost Your Workout Routine

It’s not just about big machines — sometimes, the smallest tools deliver the biggest fitness gains. Whether you're a beginner or advanced athlete, the right exercise accessories can take your workouts to the next level.

In this post, we’ll break down the must-have exercise accessories for any home or commercial gym, and show you why Energie Fitness is your go-to source for premium fitness gear in India.

What Are Exercise Accessories?

Exercise accessories are compact tools and fitness aids that enhance your training. They improve form, increase intensity, and support recovery. Common accessories include:

Resistance Bands

Foam Rollers

Yoga Mats

Skipping Ropes

Push-Up Bars

Balance Balls

Wrist Straps and Lifting Belts

Why Add Accessories to Your Routine?

Versatility You can train strength, cardio, mobility, and flexibility using just accessories.

Portability Perfect for travel, small apartments, or even outdoor workouts.

Injury Prevention Tools like resistance bands or foam rollers help activate muscles and recover faster.

Cost-Effective Get a full-body workout without spending big on bulky machines.

Top Exercise Accessories from Energie Fitness

Energie Fitness offers a wide selection of exercise accessories that are ideal for both home users and gyms:

Resistance Bands – For mobility, stretching, and strength training 👉 Explore Bands

Yoga Mats – Non-slip and cushioned for yoga, pilates, and floor workouts

Balance Balls – Improve core strength and posture

Skipping Ropes – Burn calories fast with a full-body cardio tool

Exercise Balls & Accessories – Improve core stability and control 👉 Check Accessories

All products are designed with durability, comfort, and performance in mind.

Best Workouts Using Accessories

Resistance Band Squats & Rows

Core Balance Ball Crunches

Yoga Flow with Mats & Blocks

Speed Skipping Circuits

Foam Rolling for Muscle Recovery

Whether you’re doing HIIT, strength training, or flexibility work, the right accessories elevate every session.

Final Thoughts

Accessories may seem small, but they bring big results. From improving your mobility to adding variety to your workouts, these tools are essential in every fitness setup.

Visit Energie Fitness today to shop high-quality, affordable exercise accessories trusted by gyms, athletes, and home fitness lovers across India.

0 notes

Text

Base Oil SN150 Supplier at Buoyancy Impex Private Limited

In today’s fast-paced industrial landscape, high-performance lubricants and oils are essential for machinery and automotive efficiency. Among these, Base Oil SN150 plays a crucial role. When it comes to sourcing premium-grade base oil, Buoyancy Impex Private Limited stands as a trusted Base Oil SN150 Supplier, offering consistent quality, timely delivery, and unmatched reliability.

Whether you're in the automotive, manufacturing, or lubricants sector, finding a dependable partner for your base oil needs is vital. Buoyancy Impex not only ensures superior product standards but also brings years of expertise to meet your bulk and customized requirements.

What is Base Oil SN150?

Base Oil SN150 is a light neutral paraffinic base oil used in a wide range of lubricant formulations. It is typically derived from petroleum through a solvent refining process. Known for its excellent thermal stability, oxidation resistance, and viscosity, SN150 serves as a primary component in:

Automotive engine oils

Industrial lubricants

Hydraulic fluids

Greases and specialty oils

With a low pour point and optimal viscosity index, SN150 base oil is ideal for blending with additives to create high-performance lubrication solutions.

High-Quality SN150 Base Oil from Buoyancy Impex

At Buoyancy Impex Private Limited, quality is non-negotiable. As a reputable SN150 base oil supplier, we ensure that every batch undergoes rigorous quality checks to meet international industry standards.

Key Features of Our Base Oil SN150:

Excellent oxidation stability

Low volatility and minimal impurities

Superior viscosity-temperature performance

Good solvency for additives

Consistent product specifications

Available in virgin and recycled grades

We provide SN150 in bulk and drum packaging options based on customer preferences, ensuring flexibility and convenience.

Applications of Base Oil SN150

The versatility of SN150 makes it a key ingredient across multiple sectors. Here’s where it plays a critical role:

1. Automotive Sector

SN150 is used as a base for manufacturing motor oils, transmission fluids, and gear lubricants due to its clean burning and high temperature stability.

2. Industrial Machinery

It serves as the backbone for various lubricants required in compressors, hydraulic machines, turbines, and pumps.

3. Metalworking Fluids

Base Oil SN150 is essential in forming, cutting, and rolling applications, helping in efficient heat dissipation and friction reduction.

4. Greases & Additive Blends

This base oil provides a perfect foundation for manufacturing greases and customized lubrication additives for niche industries.

Why Choose Buoyancy Impex Private Limited?

Buoyancy Impex Private Limited is more than just a base oil supplier—we are your growth partner in the lubricants and petrochemical supply chain. Here's what makes us stand out:

✅ Premium Product Quality

We supply only refined, tested, and certified SN150 base oil, ensuring optimal performance in every application.

✅ Global Export Network

We serve clients across India, the Middle East, Africa, and Southeast Asia, with a strong logistics and distribution network for seamless exports.

✅ Recycled & Virgin Options

Offering both recycled SN150 base oil for cost-effective solutions and virgin SN150 for high-grade applications, we meet diverse customer needs.

✅ Flexible Packaging & Delivery

Choose from ISO tanks, drums, or flexi-bags. Our team ensures on-time and secure deliveries that meet your schedule.

✅ Competitive Pricing

With long-standing supplier relationships and bulk capacity, we offer cost-effective base oil SN150 without compromising on quality.

✅ End-to-End Support

From product selection to documentation and shipping assistance, our expert team ensures a smooth procurement process.

Commitment to Sustainability

At Buoyancy Impex, we believe in responsible sourcing and sustainable practices. Our recycled SN150 base oil is processed with advanced refining technologies, reducing environmental impact while maintaining industry performance benchmarks. Sustainability and quality go hand in hand in everything we do.

Client Testimonials

“Buoyancy Impex has been our go-to supplier for SN150. Their product consistency and fast turnaround times have helped us maintain production without delays.” – Industrial Lubricant Manufacturer, UAE

“We switched to their recycled base oil SN150, and it has met all our performance parameters at a much more affordable cost.” – Automotive Oils Distributor, India

Conclusion

When it comes to Base Oil SN150 Supplier, Buoyancy Impex Private Limited is the name industries trust. With a firm commitment to quality, sustainability, and customer satisfaction, we offer unparalleled service in the global base oil market.

Whether you need bulk quantities, specific viscosity grades, or tailor-made logistics solutions, Buoyancy Impex ensures a seamless, reliable, and value-driven partnership.

FAQs

1. What is the minimum order quantity for Base Oil SN150?

We accommodate both small and bulk orders. Minimum order quantities can vary depending on packaging—contact us for details.

2. Do you supply both virgin and recycled SN150 base oil?

Yes, we offer both types. Virgin for high-spec industrial uses, and recycled for cost-efficient applications.

3. Where do you export SN150 base oil?

We export globally, with key markets in India, UAE, Africa, and Southeast Asia.

4. Is your SN150 compliant with international standards?

Absolutely. All our base oils meet ASTM specifications and undergo stringent QC checks.

5. Can you assist with export documentation?

Yes, we handle all necessary documentation, customs formalities, and shipping coordination for smooth international deliveries.

Partner with Buoyancy Impex Private Limited – your trusted source for premium Base Oil SN150 that powers industries forward.

1 note

·

View note

Text

What is MS Pipe? Benefits, Types & Industrial Applications

Introduction

Mild Steel (MS) Pipes are among the most widely used steel products in the construction and manufacturing sectors. Known for their strength, affordability, and versatility, MS pipes are used in water pipelines, infrastructure, fabrication, and industrial projects across India and globally.

In this article, Udhhyog explains what MS Pipe is, its core benefits, various types, and major industrial applications in 2025.

What is MS Pipe?

MS Pipe refers to pipes made from Mild Steel, a low-carbon steel alloy (typically 0.05%–0.25% carbon). This low carbon content makes MS pipes easier to weld, shape, and fabricate without compromising structural strength.

They are typically used for:

Conveying fluids like water, oil, and gas

Structural support in construction

Machinery frameworks

Automobile components

MS pipes come in various forms: round, square, and rectangular, and can be coated (galvanized) for rust resistance in harsh environments.

Key Benefits of MS Pipe

Cost-Effective MS Pipes are significantly cheaper than stainless steel or alloy pipes, making them ideal for budget-sensitive projects.

High Weldability Due to low carbon content, MS pipes are easily weldable using standard techniques, ideal for on-site work.

Customizable Sizes & Thickness Available in a wide range of sizes, wall thicknesses, and lengths for different load-bearing needs.

Good Ductility & Malleability Can be bent or formed into various shapes without cracking.

Recyclable & Sustainable Mild steel is 100% recyclable, supporting eco-friendly construction practices.

Corrosion Protection (Optional) When galvanized or coated, MS pipes gain significant rust resistance.

Types of MS Pipes

There are several types of MS pipes, categorized based on manufacturing process and shape:

1. MS ERW Pipe (Electric Resistance Welded)

Made by welding edges of steel plates

Cost-effective and used in structural & low-pressure fluid transport

Available in round, square, and rectangular profiles

2. MS Seamless Pipe

Manufactured without any welds

Withstands high pressure and temperature

Used in power plants, oil refineries, chemical industries

3. MS Square Pipe

Ideal for frames, fencing, and furniture

Preferred in architectural and civil engineering projects

4. MS Rectangular Pipe

Used in door frames, railings, truck bodies

Offers flat surfaces for mounting and structure

Industrial Applications of MS Pipes

MS pipes are crucial across various sectors:

✅ Construction

Used in columns, beams, scaffolding, gates, and temporary structures

Offers strength and support with minimal weight

✅ Water & Sewage Pipelines

Common for transporting water and wastewater

Compatible with both urban and rural plumbing

✅ Automotive

Used in chassis, roll cages, and structural components

Lightweight with sufficient rigidity for vehicle frameworks

✅ Agriculture

Borewell casings, irrigation pipelines, and greenhouse structures

✅ Furniture & Fabrication

Frames for chairs, tables, storage racks, and workstations

Welds easily and offers long-lasting durability

✅ Oil & Gas

MS seamless pipes used for petroleum and natural gas pipelines

Pressure-resistant and corrosion-protected when coated

✅ Industrial Machinery

Machine frames, conveyors, ducts, and supports in factories

Standard Sizes & Thicknesses

MS Pipes are available in nominal bore (NB) sizes ranging from 15mm to 300mm with wall thicknesses from 1.2mm to 10mm.Size (NB)Outer DiameterWall ThicknessCommon Use15mm21.3 mm2.0 mmResidential plumbing50mm60.3 mm3.2 mmConstruction & scaffolding100mm114.3 mm4.0 mmIndustrial pipelines

Price of MS Pipes in India [2025]

MS Pipe prices vary by location, size, brand, and quantity. Here is a general estimate:

Price per kg: ₹55 to ₹75

Price per meter: ₹40 to ₹220 (based on size & thickness)

🔹 Get accurate pricing and bulk quotes from Udhhyog, a trusted MS pipe supplier in India.

Why Choose MS Pipe from Udhhyog?

✔️ ISI Certified & Tested Products

✔️ Competitive Rates for Retail & Bulk

✔️ Wide Range of Shapes & Sizes

✔️ Custom Orders & Timely Delivery

✔️ Serving PAN India with Reliable Service

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of MS Pipes?

A: With proper coating, MS pipes can last 15–25 years depending on environment and application.

Q2: Are MS Pipes suitable for drinking water?

A: Yes, if the pipes are galvanized or food-grade coated.

Q3: What is the difference between MS and GI Pipes?

A: GI (Galvanized Iron) is zinc-coated MS pipe for corrosion resistance.

Q4: Can MS pipes be used for gas transport?

A: Yes, but only under low pressure and if coated or seamless type is used.

0 notes

Text

Top Round Bar Manufacturer in India Delivering Premium Solutions

Nova Steel Corporation is a significant Manufacturer of round bars in India. We specialize in producing high-quality round bars that meet stringent standards. These Round Bars come in a variety of sizes, forms, and dimensions, and may be modified to meet our clients' exact needs. Our high-quality Round Bars are ideal for steel manufacturing facilities, the petrochemical industry, fire suppression systems, synthetic businesses, shipping and delivery companies, and other uses. As a leading Round Bar manufacturer, we provide a diverse range of Round Bar solutions to meet a variety of needs.

Range of Materials and Types of Round Bars

Round bars are solid cylindrical rods produced through processes like hot rolling, cold drawing, or forging. These bars are widely used across industries for their strength, precision, and versatility. We offer round bars in a wide variety of materials and types to suit different application needs:

Stainless Steel – Excellent corrosion resistance, suitable for marine and chemical industries

Carbon Steel – High strength and durability, widely used in construction and machinery

Alloy Steel – Enhanced toughness and performance for demanding environments

Aluminum & Brass – Lightweight and resistant to corrosion, ideal for electrical and decorative applications

Our product range includes Hot-Rolled Round Bars for general structural use, Cold-Drawn Round Bars for precision applications, Forged Round Bars for heavy-duty requirements, and Polished Round Bars for aesthetic and engineering needs.

We also manufacture and supply specialized grades such as 2014 T6 Aluminium Round Bars, known for their high strength and excellent machinability, making them suitable for aerospace and defense applications. In addition, we offer Round Bars, which are widely used in transport, marine, and structural components due to their exceptional corrosion resistance and weldability. For applications requiring enhanced strength and corrosion resistance, our Duplex Steel Round Bars deliver outstanding performance under high-pressure and temperature conditions. These advanced-grade bars further strengthen our standing as one of the leading Stainless Steel Round Bars Manufacturers in India.

Industrial Applications of Round Bars

As a trusted Round Bars Supplier in India, we serve a wide range of industries with round bars designed for durability and performance. These bars play a vital role in sectors such as:

Construction – Used for reinforcement, support beams, and structural frames

Machinery and Equipment – Integral in shafts, bolts, fasteners, and precision parts

In addition to the above, round bars are used in automotive systems for making engine parts and axles, and in the electrical sector, especially when made from copper or aluminum, for power transmission components. Their easy machinability and availability in diverse grades make them suitable for both large-scale manufacturing and custom fabrication tasks.

We are recognized as a reliable Round Bars Supplier in Hyderabad, Bangalore, Chennai, Mumbai, and Gujarat, ensuring quick delivery and consistent stock availability throughout India. Whether you require general-purpose bars or specialized solutions like 6061 T651 Aluminium Round Bars, our inventory and supply capabilities support varied project requirements across sectors.

Why Choose Nova Steel Corporation

With a commitment to engineering excellence and timely service, we stand out as a preferred Round Bar manufacturer in India. Our round bars go through strict quality checks to ensure dimensional accuracy, mechanical strength, and surface finish consistency. Whether your project demands high-load performance or decorative appeal, we offer the right material and finish options to match. As one of the top Stainless Steel Round Bars Manufacturers in India, our focus remains on delivering not just products, but long-term performance and value.

Conclusion

Nova Steel is not only a prominent Round Bar manufacturer but also a dependable Round Bar supplier. Our strong manufacturing capabilities, wide material selection, and national supply network position us as a one-stop destination for all-around bar needs. We also offer helpful resources like the MS Sheet Weight Chart to support project planning and execution. Partner with us for quality, reliability, and performance you can trust.

0 notes

Text

Paper Machine Headbox Market 2025

The global Paper Machine Headbox market was valued at US$ 235.32 million in 2023 and is anticipated to reach US$ 288.92 million by 2030, witnessing a CAGR of 3.92% during the forecast period 2024-2030.

Europe market for Paper Machine Headbox is estimated to increase from $ 159.09 million in 2023 to reach $ 191.02 million by 2030, at a CAGR of 3.71% during the forecast period of 2024 through 2030.

Get a free Report : https://www.intelmarketresearch.com/download-free-sample/293/paper-machine-headbox

China market for Paper Machine Headbox is estimated to increase from $ 42.32 million in 2023 to reach $ 56.42 million by 2030, at a CAGR of 4.87% during the forecast period of 2024 through 2030.

Japan market for Paper Machine Headbox is estimated to increase from $ 8.06 million in 2023 to reach $ 8.46 million by 2030, at a CAGR of 2.01% during the forecast period of 2024 through 2030.

A paper machine headbox is an essential component of the papermaking process, responsible for distributing a consistent and controlled flow of pulp onto the forming fabric or wire. This creates a uniform paper sheet with the desired characteristics.

The headbox works by receiving low-consistency pulp stock from the machine chest and then evenly dispersing it onto the forming fabric or wire. It contains a slice and perforated roll to assist in the formation of the paper.

The major global manufacturers of Paper Machine Headbox include Valmet, Voith, ANDRITZ, Huazhang Technology, Bellmer, Kobayashi Engineering Works, A.Celli Group, ST Macchine, Xi'an Weiya Papermaking Machinery, Allimand, Toscotec S.p.A. (Voith), Zhuji ZhongTai Paper Machinery, Dazhi Paper Machinery, Parason, Jiangsu Xinnuo Track Technology, Weifang Synchronous Papermaking Technology, etc. In 2023, the world's top five vendors accounted for approximately70.88% of the revenue.

Report Scope

This report aims to provide a comprehensive presentation of the global market for Paper Machine Headbox, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Paper Machine Headbox.

The Paper Machine Headbox market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Paper Machine Headbox market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Paper Machine Headbox manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, production, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation By Company

Valmet

Voith

ANDRITZ

Huazhang Technology

Bellmer

Kobayashi Engineering Works

A.Celli Group

ST Macchine

Xi'an Weiya Papermaking Machinery

Allimand

Toscotec S.p.A. (Voith)

Zhuji ZhongTai Paper Machinery

Dazhi Paper Machinery

Parason

Jiangsu Xinnuo Track Technology

Weifang Synchronous Papermaking Technology

By Type

Open Type Headbox

Air-cushioned Headbox

Hydraulic Headbox

By Application

New Installation

Renovation and Replacement

Production by Region

Europe

China

Japan

Consumption by Region

North America

U.S.

Canada

Asia-Pacific

China

Japan

Korea

India

Southeast Asia

Europe

Germany

France

UK

Russia

Italy

Rest of Europe

Latin America

Mexico

Brazil

Rest of Latin America

Middle East and Africa

Middle East

Africa

FAQs: Paper Machine Headbox Market Overview and Trends 1. What is the current value of the global Paper Machine Headbox market?

The global Paper Machine Headbox market was valued at US$ 235.32 million in 2023.

2. What is the projected size of the Paper Machine Headbox market by 2030?

The market is anticipated to grow to US$ 288.92 million by 2030, with a compound annual growth rate (CAGR) of 3.92% from 2024 to 2030.

3. What is driving the growth of the Paper Machine Headbox market?

Key growth drivers include:

Increasing demand for high-quality paper production.

Technological advancements in paper-making machinery.

The growing paper and packaging industries across global markets.