#Rotary Indexing Table

Explore tagged Tumblr posts

Text

Boost CNC Precision with 4th Axis Rotary Tables Today!

Upgrade your CNC machining with 4th Axis Rotary Tables. Discover features, benefits, and integration tips to boost precision, speed, and productivity. This in-depth guide covers the features, functions, and integration suggestions for 4th-axis CNC rotary tables. Whether you are an OEM or enthusiast trying to improve your CNC device, knowing how to leverage a rotary table can unlock the next stage of operational excellence.

0 notes

Video

youtube

Rotary Indexing Table Automatic Orbital Riveting Machines

0 notes

Text

0 notes

Text

Counting on Precision: Rotary Contactors in American Manufacturing

In factories across the USA, production lines often combine high-tech automation with tried-and-true mechanical devices. One unassuming component that engineers continue to count on for accuracy is the rotary contactor. It may not flash or beep, but this simple device plays a big role in keeping counts and measurements spot-on – from tallying product units to gauging lengths of material. Let’s explore how a rotary contactor enhances production precision and why it remains a staple in American manufacturing.

Old-School Gadget, Modern-Day Reliability

Rotary contactors have been around for decades, long before today’s digital sensors and IoT-enabled devices. Yet, many U.S. factories still rely on them because of one simple reason: they work, and they work practically anywhere. In an age where high-tech sensors can sometimes glitch due to electrical noise or require complex setup, a rotary contactor offers a refreshingly simple and foolproof solution. It doesn’t need a power supply to do its basic job of counting; a rotating shaft and a magnet or cam inside do all the work to close a switch at just the right moment. This means even if your production floor is dusty, hot, or subject to electrical interference, the contactor keeps on clicking away reliably. American manufacturers have learned that mixing a bit of old-school tech with modern automation can actually boost reliability – the rotary contactor is often that dependable backup that ensures the counts keep coming even when fancier systems hiccup.

Counting Rotations, Lengths, and More

When people hear “rotary contactor,” they often think of simply counting rotations – like how many times a machine arm goes around. And indeed, that’s a core use: for example, counting each revolution of a shaft to know how many cycles a machine has completed. But rotary contactors can do more than just count turns. Pair one with a measuring wheel, and suddenly you have a device that can measure length of material. This is a common trick in industries like textiles, paper, or metal fabrication in the USA: as a sheet or strip of material moves, the wheel turns and the contactor clicks off pulses corresponding to distance. It’s a straightforward way to track how many feet or meters of material have been fed or processed – essentially acting as a basic flat material measuring machine without needing elaborate electronics. Of course, for ultra-precise length measurements or higher resolution, many might opt for advanced encoders. But if one pulse per unit of length is enough, a rotary contactor with a wheel gets the job done with minimal fuss.

Real-World Examples Across the USA

In real-world operations, rotary contactors quietly contribute to accuracy in various ways. Imagine a paper mill in the USA Northeast: as giant rolls of paper are wound, a contactor counts each rotation of the spool. After a set number of turns (translating to a specific length of paper), it signals a cutter to slice the roll at just the right point. Or picture a Midwest packaging plant where a contactor tracks each cycle of a rotary indexing table, ensuring every station (filling, capping, labeling) has completed its task in sync – any missed beat and the contactor would alert operators. Even small workshops benefit: a custom machine builder in the USA might install a rotary contactor on a piece of legacy equipment to give it a simple counting capability without overhauling the entire system. These examples show how from coast to coast, this device adapts to needs both big and small, providing a layer of assurance that “yes, that rotation happened” or “that length of material passed by” when it’s supposed to.

Easy Integration with Modern Systems

Another reason rotary contactors remain relevant is how easily they integrate with modern counting and control systems. The output of a rotary contactor is just an electrical contact closure (basically like a momentary button press), which nearly any counter, PLC, or industrial controller can accept as an input. This means you can connect a rotary contactor to a digital counter display, a programmable logic controller, or even into a PC-based data acquisition system with minimal hassle. It acts as a simple sensor that provides a dependable “tick” each time an event occurs. Many facilities in the USA pair these contactors with electronic counters or PLC programs to trigger actions – for example, stopping a machine after a certain count, or displaying the throughput count on a screen for operators. In essence, the rotary contactor bridges the gap between the mechanical world and the digital world: you get the ruggedness of a mechanical device and the intelligence of modern electronics working together. It’s a relationship that keeps production data flowing smoothly.

Conclusion: In summary, the rotary contactor exemplifies how classic engineering can complement modern manufacturing. Its presence on factory floors across the United States is a testament to its reliability and utility. When precision counts (literally!), having a rotary contactor in the mix can make all the difference in keeping operations smooth and counts accurate. So whether you're troubleshooting an existing line or designing a new system, don't overlook this proven solution. To learn more about rotary contactors and explore a full range of industrial automation tools, you can visit our main website anytime. Sometimes, a little old-school ingenuity is just what your high-tech production line needs to stay on the cutting edge.

0 notes

Text

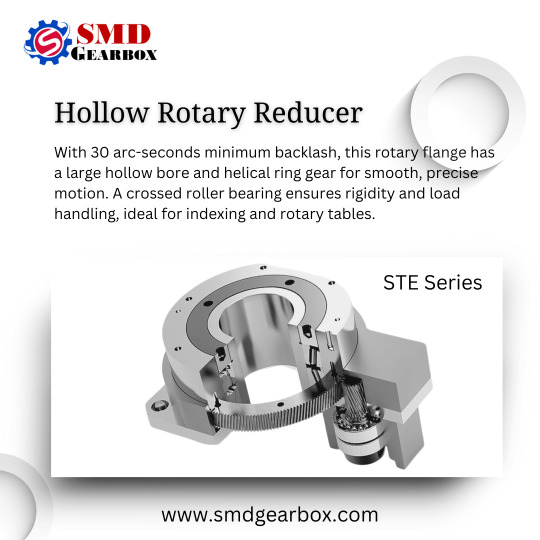

SMD Hollow Rotary Gearbox – Compact, High-Torque & Precision Control

SMD's Hollow Rotary Reducer features a helical ring gear for smooth, precise motion, while its high-capacity crossed roller bearing ensures rigidity and supports heavy axial loads for reliable performance.

Here are some key advantages of the Hollow Rotary Gearbox: Advantages:

Hollow Bore Design: Large hollow rotary flange allows easy wiring or shaft integration.

Precision & Low Backlash: Offers a minimum backlash of 30 arc-seconds for high-accuracy positioning.

Versatile Gear Reduction: Compatible with planetary or right-angle gearheads for higher reduction ratios.

Ideal for Rotary Applications: Perfect for indexing tables and rotary table applications.

Experience superior control and efficiency with our Hollow Rotary Reducer.

0 notes

Text

Precision Rotation Tables - Velmex Inc

Precision Rotation Tables: Enhancing Accuracy in Motion Control

Precision rotation tables, also known as rotary tables or indexing tables, are essential components in various industrial and scientific applications. They are designed to provide precise angular positioning, enabling accurate control over rotational movements in manufacturing, research, and automation systems.

What Are Precision Rotation Tables?

Precision rotation tables are mechanical devices that allow for controlled rotation around a single axis. They can be manually operated or motorized, depending on the level of precision required. These tables are commonly used in CNC machining, metrology, robotics, and optical applications where exact angular positioning is critical.

Key Features and Benefits

High Accuracy and Repeatability: Precision rotation tables are engineered to achieve tight tolerances, often within arc-seconds, ensuring consistent and repeatable positioning.

Load Capacity: They can support various load sizes, from lightweight optical components to heavy industrial machinery, without compromising accuracy.

Versatility: Available in different configurations, such as worm gear, direct drive, and air-bearing tables, they cater to diverse applications requiring different levels of precision and speed.

Integration with Automation Systems: Modern precision rotation tables can be easily integrated with computer-controlled systems, enhancing efficiency in automated processes.

Applications of Precision Rotation Tables

CNC Machining: For precise cutting, drilling, and milling operations, allowing complex geometries and multi-axis machining.

Metrology: In coordinate measuring machines (CMMs) for accurate measurement of angles and dimensions.

Robotics: For the precise movement and positioning of robotic arms in assembly lines.

Optics and Photonics: In laser systems and telescopes where fine angular adjustments are crucial.

Choosing the Right Precision Rotation Table

When selecting a precision rotation table, consider factors such as load capacity, rotational speed, accuracy requirements, and environmental conditions. Motorized tables offer higher precision and automation capabilities, while manual tables are suitable for simpler tasks.

Conclusion

Precision rotation tables are indispensable tools in industries that demand high levels of accuracy and control. By enabling precise angular positioning, they contribute significantly to the efficiency, quality, and innovation of modern technological processes.

#lead screws#xy table stepper motor#inductive rotary encoders#national petrographic#joystick motor control#rotary table controller#motorized positioning tables#motorized xy system#measuring counters

0 notes

Text

The Best Practices for High-Volume, Precision Machining

Those who manufacture parts for the automotive, defense and industrial industries (among others) are increasingly turning to world-class machine shops that offer a high-volume, precision machining service in addition to a host of supplementary, value-added services.

If you are in search of a new machining partner who can help you reduce cycle times and contain costs, look for one that offers cutting-edge equipment – including both multi-spindle and rotary transfer machines – and a variety of additional services – like secondary operations, vertical integration and in-house engineering, tooling and automation.

An overview of the equipment, services and processes to look for is presented below.

Multi-Spindle Machining

As the name suggests, multi-spindle machines use multiple spindles machine parts. The spindles perform distinct tooling operations on an individual part at the same time. Multi-spindle machines work accurately and efficiently – and are ideally suited to complex, high-volume primary operations. Because of this, they are commonly relied upon to machine parts used in safety-critical applications.

Multi-spindle machining is flexible and can either be conventional or fully CNC programmable depending on your product needs and specifications.

Rotary Transfer Machining

Rotary transfer machines use various machining stations surrounding a large indexing table to manufacture parts. Rotary transfer machining capabilities include external and internal recessing, drilling, milling, cross-drilling, boring, turning, threading, tapping, and broaching. Once a cycle is complete, the table rotates and delivers the part to the next machining station.

Rotary transfer machines are customizable and commonly used for intricate metalworking jobs. Like multi-spindle machines, rotary transfer machines work quickly – and are, impressively, capable of machining very complex components in seconds. They are frequently used to create high volumes (generally in the millions) of complex parts that demand precision.

Secondary Operations

In addition to multi-spindle and rotary transfer machines, look for a machining partner that offers a multitude of essential secondary operations, including:

Interior (ID) and outer diameter (OD) grinding

Deburring using robotics, electro-chemical deburring (ECD), tumbling, and media blasting

Coin and leak testing

Lapping

Blasting for texture

Sub-assembly

Heat treatment

100% automated inspection

When secondary operations and machining are executed by the same partner, it eliminates the time and costs associated with transportation. As an added benefit, your team won’t have to spend as much time or as many resources managing various vendors and overseeing multiple projects.

Vertical Integration

To further accelerate turn times and drive costs down, look for a machining partner who maintains partnerships with local service providers. Vertical (or near-vertical) integration allows machinists to expedite logistics for most high-volume, precision applications – like machined automotive parts.

In-House Engineering, Tooling & Automation

A machining partner with an in-house design engineering team can increase the efficiency and cost-effectiveness of machining high-volume, precision parts. By custom designing solutions – and not relying on off-the-shelf solutions – your machining partner can meet exacting needs quickly.

The most valuable partner will have a dedicated team of engineers who create custom EDM technology, CNC tooling grinding, and other tools – and offer custom-built automation equipment and inspection automation.

1 note

·

View note

Text

0 notes

Text

Benefits of Using an Index Table in Machining

An index table is a crucial component for achieving high precision and versatility in machining processes. Designed to enable efficient part positioning and multiface machining, index tables are indispensable for modern manufacturers. At SilverCNC, we offer premium-quality rotary and index tables tailored for various CNC applications.

1. Enhanced Precision

By enabling exact workpiece placement, index tables guarantee accurate machining of intricate geometries. Multiple settings are no longer necessary, which lowers errors and guarantees consistency.

2. Increased Efficiency

By enabling multi-face machining in a single setup, index tables save valuable time and reduce machine downtime. This time-saving procedure reduces project lead times and increases productivity.

3. Versatile Machining Capabilities

With an index table, you can easily machine parts with intricate shapes, angles, and features. It supports both rotational and angular adjustments, offering flexibility for various machining tasks.

4. Improved Workflow Automation

Modern index tables can integrate with CNC systems, enabling automatic positioning and toolpath execution. This results in a smooth and effective workflow and a reduced need for manual intervention.

5. Reduced Material Waste

Precise indexing reduces errors and misalignment, preventing material waste. This promotes environmentally friendly production methods in addition to economic savings.

6. Enhanced Tool Access

An index table provides optimal access to different workpiece faces, reducing tool interference and enabling the use of shorter, more stable tools for better results.

Why Choose SilverCNC Index Tables?

At SilverCNC, our index tables are built for durability, accuracy, and adaptability to meet the demands of modern machining. Whether you’re working on small components or large-scale parts, our rotary and index tables provide unmatched performance and reliability.

Explore how an index table can elevate your machining operations. Visit https://tinyurl.com/2nfwshne and call now at +86 180 9892 0890 or email us at [email protected] to find the perfect solution for your needs!

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/pneumatic-rotary-indexing-table-market/

0 notes

Text

0 notes

Text

Common misconceptions about CNC rotary tables

CNC rotary tables are essential tools in modern machining that help improve precision, save time, and boost productivity. Yet, many people across the Indian manufacturing sector still carry outdated ideas or incorrect assumptions about them. Whether you’re running a small workshop, an MSME unit, or a large-scale factory, understanding the truth about CNC rotary tables can help you make better investments and achieve higher efficiency. Let’s clear the air and bust the 14 most common myths about CNC rotary tables.

0 notes

Text

Unlocking High-Speed Efficiency with URQ-HS 4th Axis CNC Rotary Tables

In the ever-evolving landscape of industrial manufacturing, the need for speed, rigidity, precision, and reliability has never been great. Addressing these demands, the URQ-HS Series High-Speed CNC Rotary Tables are offering unparalleled performance for high-volume production. Designed to excel in industries such as Aerospace, Automotive and Agriculture for tool manufacturing, these rotary tables redefine efficiency and precision in machining operations.

High-Speed Indexing & Quick Acceleration

Time is money in manufacturing and the URQ-HS Series ensures no second is wasted. Engineered with a Dual Lead Worm Gear Mechanism, this Rotary Table delivers rapid indexing and precise, repeatable positioning. By significantly reducing cycle time, it boosts productivity and minimizes downtime, making it an indispensable asset for mass production. The quick acceleration capability ensures smooth transitions between machining operations, further enhancing overall efficiency. This feature is particularly valuable in industries that require rapid yet accurate positioning to meet tight production schedules.

Compact & Lightweight Design

Space and weight considerations are critical in machining environments. The URQ-HS Series is 30% lighter and more compact than traditional models, offering enhanced acceleration and precision. This compact design not only optimizes space utilization but also improves production efficiency, making it a smart choice for facilities with high demands and limited space. The lightweight construction also reduces strain on the machine, prolonging its lifespan while maintaining high levels of performance. Manufacturers benefit from a system that is not only powerful but also adaptable to a variety of production setups.

Pneumatic & Hydraulic Clamping

For precision machining, stability is key. The URQ-HS Series features robust pneumatic and hydraulic clamping mechanisms, providing secure and stable holding of the Rotary Axis. With clamping torque ranging from 500 to 1100 Nm (hydraulic at 30 bar) and 300 to 450 Nm (pneumatic at 5 bar), it ensures unwavering stability, eliminating unwanted movement during operations and guaranteeing high-quality results. The dual clamping options allow users to choose the best system for their specific applications, ensuring flexibility and reliability across various machining tasks.

IP65 Protection

With an IP65 protection, these Rotary Tables are built to resist dust and water ingress, ensuring reliable performance even in harsh industrial environments. This level of protection reduces the risk of damage from external contaminants, allowing the equipment to operate at peak efficiency over extended periods. Furthermore, the robust design reduces maintenance requirements, saving time and costs for manufacturers and contributing to a lower total cost of ownership.

Easy Installation

Ease of integration is a standout feature of the URQ-HS Series. Its user-friendly design simplifies servo motor mounting and electrical routing, with streamlined cable and conduit arrangements. This reduces installation time and minimizes errors, allowing operators to focus on production with minimal setup hassle. The intuitive design also makes it easier for technicians to perform adjustments, ensuring that the Rotary Table remains a versatile component in dynamic production environments.

Advanced Applications

The versatility of the URQ-HS Series extends to advanced applications in high-precision industries. Aerospace manufacturers, for instance, require exceptional accuracy to produce complex components that adhere to strict tolerances. Similarly, automotive and agricultural sectors benefit from the high-speed and precise capabilities of these rotary tables, enabling them to produce durable and reliable tools. This adaptability ensures that the URQ-HS Series is not limited to a single type of production but can cater to a broad range of industrial needs.

The URQ-HS Series High-Speed CNC Rotary Tables represent a leap forward in machining technology. By combining high-speed indexing, compact design, robust clamping, and industrial-grade durability, these rotary tables empower manufacturers to achieve new heights of productivity and precision. The easy installation process and advanced features make them suitable for a wide range of applications from aerospace to agriculture. Whether tackling high-volume production or intricate machining tasks, the URQ-HS Series is the ultimate solution for demanding industrial environments, providing exceptional value and performance.

0 notes

Text

0 notes

Text

Scream!AU Prolog

word count: 1.8k

warnings: murder, blood, weapons, cursing, yk, horror shit, Adam being Adam

note: uh this is just the prolog so I'm sorry if it's not super interesting or very good I haven't written in a long time but I've had this AU eating away at my brain so yeah. it'll be an Adam x OC thing too btw but I'm hoping to get a character sheet out of her first 💪

☆•°☆•°☆•°☆•°☆•°☆•°☆•°☆•°☆•°☆•°

Drip drip drip

The knobs of the shower turned off with a loud squeak as the water cut off completely. A feminine hand, slender and poised, found the metal handle on the side of the shower door. It slid it open gently while billows of foggy plumes escaped before Lililth Magne stepped out into the luxury bathroom.

Cool marble pressed against the bottom of well pedicured feet as the woman made her way in front of a floor length silver mirror. It was as steamy as the rest of the room and using the edge of her towel she had wrapped around herself, she wiped a small circle into the glass.

The circle gave way to a face that was more stunning than the entire bathroom despite its current lack of makeup, high end serums and creams.

Lilith met her own eyes, observing her face for just a moment before she dried herself off completely and slid on a deep purple silk robe over her porcelain skin.

She turned to the sink to apply her twenty-step skincare routine when she could hear the distant ringing of the home phone down the hall. Lilith let out a small sigh, setting down the small container of moisturizer that she was about to use before she opened the door.

Normally, she would’ve shouted for Charlotte to get it or maybe one of her maids, but her daughter had left the house hours ago and the maids departed shortly before she went to the bathroom to unwind. Wrapping the robe tighter around herself, she walked elegantly down the hallway to a small dark oak end table that held a ringing landline phone.

The caller ID was unknown but the Magne’s always made a point to answer them, their business partners weren’t the most legal or well known most of the time.

Lilith grabbed the phone from its place on its rotary, clearing her throat slightly before she raised it to her perfect lips and spoke.

“Lilith Magne, what is it?”

There was no point in being kind or friendly to the unknown numbers, they usually weren’t kind to her either.

A deep chuckle came from the other end of the phone, deep and raspy.

“Not one for friendly greetings are you?”

The voice wasn’t like any she had heard before, unfamiliar down to the way the caller's breath was slightly ragged and excited.

Lilith smirked, letting out a small hum as she twirled the phone chord between her index and middle finger.

“My apologies, I wasn’t aware you were calling for that.”

A few months ago, her husband and she had both decided to reopen their relationship. It had been open prior to their daughter's birth but had decided to close it shortly after she was born due to keeping her safety in mind but now her daughter was no longer living with them. Since then plenty of their business connections had called to have some fun with either of the Magne’s.

The caller laughed again as Lilith swiped her finger across a shelf that was positioned by the small table, frowning at the dust that had begun to form. She would have to tell a maid tomorrow.

“What else would I be calling for, baby? I’m a man with needs.”

Lilith hummed in acknowledgment as she rubbed her fingers together, ridding herself of the dust she would have to have cleaned up later before she walked into a nearby room. She sat down on a plush chaise, the coily chord of the phone stretched with her as she draped her legs across the velvety fabric.

“I’m a bit busy at the moment.” She told him, disinterested and interested at the same time.

The man laughed again and the crackle of leather sounded as he moved on the other end.

“Busy? Busy doing what?”

The blonde woman looked around the room, giving an excuse to whatever she laid eyes on first, which happened to be an antique bookcase in the corner.

“Reading.”

She stood up and crossed the room to the bookcase, grabbing the first book that seemed interesting before she scanned the cover. Turning it over in her hands, she opened her mouth again to speak but the man beat her to it.

“H.P. Lovecraft?” He asked, “I didn’t take you for a horror kind of gal.”

Lilith blinked, looking down at the book in her hands for a dumb moment. How did he know what she was reading?

She swallowed thickly, “Who doesn’t love a good scary story?” Lilith answered, her voice as confident and silky as it always was. She had gotten quite good about having such a demeanor when dealing with clients who caught her red handed. Somehow she always managed to get her way out of it though.

Lilith slid the book back into its spot as she tried to discreetly look around her space for any signs of someone watching her.

The man spoke again but his words fell on deaf ears as she saw a door that had previously been closed, cracked open just barely.

Someone was inside her house.

“...Isn’t that right?” He asked, his question forcing her to zone back in.

Without the slightest clue of what he had just asked her she merely agreed, leaving the room and walking back to the small table that held the holder for the glossy rotary phone.

“Well I would like to return to my book.” She told him, maybe a bit too abruptly. “Good night.”

Before he could even respond she slammed the phone down, letting out a breath she hadn’t known she had been holding. Lilith stood in silence with herself, debating the best course of action before she left the hallway and made her way to the main room where the security system was controlled from.

With shaky hands, she input the password into the small wall device, arming the system before dropping her hand. It wasn’t much use if someone was inside with her but it made her feel safer.

As soon as the system was armed, the phone rang again.

This time the glowing blue light from the more modern landline signaled a call was coming in before it started. It glared at her from across the room and she froze like a deer in headlights.

Again, there was no caller ID and it did not make her want to answer it this time.

It rang and rang and rang before it stopped and Lilith’s shoulders sagged in relief.

She took a few steps back, letting her back hit the wall before she sighed loudly but her peace was interrupted once more.

It rang again, this time somehow louder than the last and she let out a small sob. SHe urged herself to pick it up, dragging her feet over to the receiver to pick it up.

She held the phone with a shaky hand, pressing the accept call button slowly before she raised it to her ear.

Before she could even talk the man was snarling into the phone.

“You think you can just hang up bitch?” He growled, voice sinister. “Your tacky little security system doesn’t mean shit to me. Not when I’m already so close to your polished ass I can smell your fuckass perfume.”

Lilith instinctively grabbed a knife out of the block, hunching over behind the kitchen island as she held the phone still.

“What do you want?” She asked, voice quivering.

There was a thump from inside the main room and she shrank up into herself further, clenching the phone until her knuckles turned white.

“What do I want?” The man asked, the voices doubled now due to his proximity. “Nothing you can give me. You’re a practice run.”

A hand slammed down on the kitchen island and the voice and person behind her laughed maniacally at her body jolting.

Lilith dropped the phone, standing up straight and leaned back against the counter.

The man was dressed in all black aside from his mask that had wicked neon yellow eyes and a matching sinister smile. It remained unmoving as he spoke, hanging up his own phone and pocketing it somewhere deep within his robes.

Lilith didn’t stay long enough to find out, dropping her knife with a clatter before she bolted from the kitchen back down the hallway she had just come.

“Stay away from me!” She shrieked, nearly tripping over her silk robe as she rushed through the now cold and horrifying halls of her home. The masked man laughed loudly, “I’ll give you a head start!”

Lilith didn’t like how confident he sounded and she ran to her shared room, slamming the door shut and locking it before she threw her dresser on the ground in front of it. It landed with a loud bang and she panted heavily, looking around wildly for something to defend herself with.

There was an assortment of… “weapons” around but she wasn’t sure she wanted to have her last stance be with a paddle. She ran to her bedside dresser, fumbling with the drawer as she pulled it out and rummaged through it until she found what she was looking for. Her fingertips touched cool metal and she pulled out a small silver pistol with a soft triumphant ‘aha’.

“What’s that supposed to do?” A new voice came and Lilith barely had time to spin around and register the words before a knife plunged its way into her side. She let out a choked gasp that changed into a shout as the blade was twisted and thrusted deeper inside her.

The gun fell from her hands and clattered onto the floor along with the drip of crimson blood that spattered near it soon after.

Lilith turned her gaze to her attacker, a different masked figure but a similar mask nonetheless. Instead of neon yellow it was silver with an ‘x’ over the eye. This person was shorter and slender, more agile than that guy in her kitchen.

Lilith held a hand to her wound, croaking out a small sound before the knife was forcefully removed just as harshly as it had been pushed in.

“AHH!” She screamed, looking down to see the crimson blood flow out and stain her robes. She could feel it dribble down her side and her leg from inside her clothing as she fell to the floor just in time to witness the man from earlier slide through her window like it was nothing.

“Can you finish this? Didn’t expect this to take so long.” The man asked, standing beside the other person and looking down at a dying Lilith with what she could only assume was a cold and uncaring expression.

The person nodded, taking their gaze away from Lilith to respond.

“Yeah, go shower. You’ll be late.”

Lilith ignored their conversation, searching for her silver pistol with bleary eyes.

“What about you? You’ll be even late-”

BANG BANG

“FUCK!” The man screamed as the bullets grazed his bicep and he instinctively grasped it. Both of their attentions snapped back to the dying blonde woman.

"This is going to be such a pain in the ass.." he grumbled, inspecting the damage.

“Finish her whore ass off.” He instructed with a snarl, clenching his wound.

The silver mask nodded, raising their arm up with the knife.

Lilith's eyes widened.

“Buh-bye, bitch."

#cw murder#hazbin hotel adam#hazbin hotel lilith#hazbin hotel lute#scream!au hazbin#cw blood#cw violence#odettes writing

0 notes

Text

SMD Hollow Rotary Reducer – STE Series: Perfect for High Load & Accurate Indexing

The large hollow rotary table enables efficient wiring and piping, while its simple, reliable design supports direct attachment and easy repeat origin returns, ideal for indexing and rotary table applications.

Enhance your motion control systems with the SMD Hollow Rotary Reducer

0 notes