#Round Automatic Label Dispenser

Explore tagged Tumblr posts

Text

Sticker Labelling Machine - High-Speed Sticker Labeller Best Price, Manufacturers & Explorer | Brothers Pharmamach

Whether you’re packaging pharmaceuticals, cosmetics, food products, or consumer goods, having the right sticker machine is essential to maintain production speed and ensure accurate branding. One such essential piece of equipment is the Sticker Labelling Machine — and Brothers Pharmamach stands as a trusted name among the top labelling machine manufacturers in India and across global markets.

What is a Sticker Labelling Machine?

A sticker labelling machine is a type of industrial labeling equipment that applies self-adhesive labels to a wide range of containers, bottles, jars, and packages. These labels can contain product names, barcodes, batch numbers, expiry dates, ingredients, and branding elements. The machine ensures consistent application, enhancing the aesthetic appeal and traceability of the product.

Sticker Labelling Machines are available in various configurations based on speed, container shape, label position, and automation level. From semi-automatic models to high-speed sticker machines, they cater to diverse industrial needs.

Why Choose a High-Speed Sticker Labeller?

When you're handling large-scale production, time is money. Investing in a high-speed sticker labeller can drastically reduce labeling time and boost your overall productivity. These machines are engineered to handle thousands of labels per hour with exceptional accuracy and minimal downtime.

Key benefits of high-speed sticker machines:

Increased Throughput: Suitable for large-volume production lines.

Precision & Consistency: Labels are applied without wrinkles or misalignment.

Reduced Labor Costs: Automation minimizes manual intervention.

Integration-Friendly: Can be easily integrated with other packaging line equipment.

Smart Controls: Advanced machines come with touchscreen HMIs and PLCs for easy operation and monitoring.

Applications Across Industries

Brothers Pharmamach's sticker labelling machines are used extensively across multiple sectors, including:

Pharmaceutical Industry: For labeling vials, ampoules, bottles, and cartons with essential information.

Cosmetics and Personal Care: For tubes, bottles, and jars of varying shapes and sizes.

Food & Beverages: For applying labels on jars, cans, bottles, and pouches.

Chemical Industry: For labeling bottles with safety warnings, batch numbers, and product details.

Agro & Fertilizers: For accurately labeling containers with regulatory and branding information.

Features to Look for in a Sticker Labelling Machine

Choosing the right sticker machine depends on your specific operational needs. Here are some features to consider while selecting:

Label Application Type: Depending on whether the label is to be placed on the top, side, wrap-around, or front and back, different machine configurations are available. Brothers Pharmamach offers custom solutions to match your labeling requirement.

Automation Level: While Semi-Automatic Machines are suitable for smaller operations, high-speed fully automatic machines are ideal for mass production lines. They come with automated container feeding, label dispensing, and label placement.

Container Compatibility: From flat containers to round bottles, square jars, and irregularly shaped packages, the machine should be compatible with your product's container shape.

Speed and Output Capacity: Speed varies from model to model. A high-speed sticker labeller can label up to 300 containers per minute, making it a preferred choice for fast-moving production lines.

Label Accuracy and Sensing: Equipped with advanced sensors, these machines ensure perfect label placement. They can detect the presence of a label, container, or missing labels to reduce waste and prevent mislabeling.

Automatic Sticker Labelling Machine: Many high-end models include an Automatic Sticker Labelling Machine that tracks the number of labels applied, helping with inventory control and quality assurance.

Build Quality and Compliance: Machines should be made from high-grade stainless steel and should comply with industry standards such as GMP and CE. This ensures long-lasting performance and regulatory compliance.

Why Choose Brothers Pharmamach?

Brothers Pharmamach is one of the leading labelling machine manufacturers known for its innovative, durable, and high-precision sticker labelling machines. With decades of expertise and a global presence, Brothers Pharmamach has established itself as a pioneer among manufacturing companies in India and beyond.

Salient Features of Brothers Pharmamach Machines:

User-friendly design with touch screen interfaces

Microprocessor-based or PLC-based control systems

High-speed label dispensing for unmatched productivity

Servo motor-driven systems for accurate label positioning

Flexible design for compatibility with various container types

Custom-built solutions tailored to client requirements

Quick changeover and minimal maintenance

Whether you are a startup in the cosmetics industry or a well-established pharma company, Brothers Pharmamach provides cost-effective and robust solutions with best price sticker machine options without compromising on quality.

Our Range of Sticker Labelling Machines

Here’s a quick look at some of the most popular models offered by Brothers Pharmamach:

Automatic Round Bottle Labelling Machine: Ideal for applying wrap-around labels on round containers. Can be integrated with bottle turntables and shrink tunnel systems.

Front and Back Labelling Machine: Used to label the front and back surfaces of flat and oval bottles simultaneously.

High-Speed Ampoule and Vial Labelling Machine: Perfect for the pharmaceutical industry. Offers precision labeling at speeds exceeding 200 containers per minute.

Top-Side Sticker Labelling Machine: For labeling cartons, pouches, and caps from the top. Commonly used in FMCG and food industries.

Automatic Label Counting Machine Integration: Equipped with inbuilt counting functionality to keep track of the number of labels applied.

Industrial Labeling Equipment Built to Last

The industrial nature of the equipment means it must withstand 24/7 operation under harsh factory conditions. At Brothers Pharmamach, machines are engineered with quality components, rugged structures, and modular parts to ensure longevity, safety, and superior performance.

Every component – from rollers to motors to control systems – is carefully selected and tested. These machines are built with high-precision technology to minimize waste, reduce changeover time, and enhance operational efficiency.

Competitive Pricing with High ROI

Finding the best price sticker machine doesn’t mean compromising on features. Brothers Pharmamach ensures its range of sticker machines delivers the best value for your investment. With competitive pricing, minimal maintenance, and unmatched reliability, your return on investment is assured.

Additionally, the machines are designed to grow with your business. As your production line expands, your industrial labeling equipment can be easily upgraded or integrated into a complete automated line.

Custom Solutions for Every Need

Every industry has its own unique labeling requirements. Whether you need tamper-proof labelling, transparent labels, promotional stickers, or multilingual labeling, Brothers Pharmamach provides tailored solutions based on your exact needs.

From machine layout to label type, automation level, and integration with upstream/downstream equipment, we ensure everything fits your production line perfectly.

After-Sales Support and Service

What sets Brothers Pharmamach apart from other labelling machine manufacturers is their commitment to customer satisfaction. Comprehensive support includes:

Installation and commissioning assistance

Operator training

Spare parts availability

Preventive maintenance and service contracts

Remote troubleshooting and technical guidance

This commitment makes us a trusted partner for numerous companies across pharmaceutical, food, chemical, and cosmetic sectors.

Ready to Upgrade Your Labeling Line?

Discover the full potential of automation with Brothers Pharmamach’s industry-leading sticker labelling machines and high-speed sticker labellers. Whether you're starting a new line or upgrading an existing setup, our expert team will guide you to the best solution tailored for your business — at the best price.

Contact Brothers Pharmamach today to explore our complete range of labeling machines and industrial labeling equipment. Get in touch now for a free consultation or quote!

For more info: https://www.brothers.in/

Email ID: [email protected]

Phone: 9825300706

Location: Plot No. 2, phase II, GIDC, Vatva, Ahmedabad 382445. Gujarat india

#sticker machine#sticker Labelling machine#High-Speed Sticker Machine#High-Speed Sticker Labeller#manufacturing companies#automatic label counting machine#Industrial Labeling Equipment#Best Price Sticker Machine#Labelling Machine Manufacturer

0 notes

Text

Sticker Labeling Machine Manufacturers: Custom Solutions for Every Industry

In the rapidly moving environment of product packaging, one can never provide enough stress on the need for speed, accuracy, and reliability in labeling. With so many industries involved, including pharmaceutical, food and beverage, cosmetics, and chemicals, sticker labeling machine manufacturers fulfill their end of the demands. With businesses gearing toward automation and compliance, selecting the right sticker labeling machine manufacturer becomes an added strategic decision affecting productivity, quality, and brand reputation.

What is the Role of Sticker Labeling Machine Manufacturer?

Sticker labeling machine manufacturers are engaged in the design and production of machines that ensure the automatic application of self-adhesive labels onto all sorts of containers. The machines are built in such a manner that they can apply labels onto products ranging from tiny vials and ampoules to huge bottles and jars. The main objective remains to accurately apply each label quickly and consistently, with little to no human error, thereby increasing throughput.

Types of Sticker Labeling Machines

The manufacturing companies present an array of sticker labeling machines to meet every packaging requirement:

Automatic Sticker Labeling Machine: These sticker labeling machines are made for high-speed, high-volume operations in which hundreds of containers can be labeled per minute. Such machines find their best use in instances where the demand for efficiency and accuracy are very high.

Bottle Labeling Machine: Being specifically designed for round, flat, oval, and square bottles, these machines can label any bottle smoothly, regardless of its shape or material.

Front and Back Labeling Machines: These systems label both the fronts and backs of containers in just a single pass, allowing for greater productivity of items that require dual labeling.

Wrap-Around Labeling Machine: These machines provide cylindrical bottles with a wrap-around label and are mostly used for beverages and pharmaceuticals.

Custom Labeling Solutions: Custom solutions are offered by the top manufacturers to address any unusual container designs, label sizes, and production requirements.

Learn more, How Sticker Labeling Machines Improve Efficiency in Packaging

Key Features Offered by Leading Manufacturers

The leading sticker labeling machine manufacturers put all advanced technologies in and the user interface depending on the operations:

Label dispenser with microprocessor control: Ensures labels are positioned with precision, hence reducing wastage.

Sensor-equipped systems: These sense the position of bottle and labels for exact application.

Servo and stepper motor drives create smooth and synchronized movement to label consistently even at high speeds.

PLC and touchscreen controls for operators to change settings, observe workings, and diagnose problems.

Adjustment without tools allows fast changeovers from one product to another or from one label size to another, reducing downtime.

Durability: Machines are typically constructed from stainless steel, ensuring durability, and conforming to hygiene standards laid down for food and pharma sectors.

Industries Benefiting from Sticker Labeling Machines

Pharmaceuticals: Exactly labeled to comply with regulatory requirements for traceability of vials, ampoules, and bottles.

Food & Beverage: High-speed bottle labeling machines are used to aid mass production and branding.

Cosmetics & Personal Care: Labeling solutions are customizable to accommodate various packaging designs and materials.

Chemicals & Agrochemicals: The machines are very sturdy to endure harsh conditions and are capable of labeling different containers.

Why Choose a Reputable Sticker Labeling Machine Manufacturer?

Choosing a trusted sticker labeling machine manufacturer guarantees:

Constant Quality: Machines are manufactured to international standards, giving them reliable performance and requiring little maintenance.

Customization: Machines can be customized by manufacturers according to requirements of a particular production, specific container shapes, and specific materials of labels.

After-Sales Support: Comprehensive service, training, and provision of spare parts ensure long-term operational goals.

Cost-Efficiency: By use of advanced automation, further saving on labor cost and increasing output, provides rapid rate of return.

Bottle Labeling Machine: A Fine Look

An indispensable part of the packaging lines of beverage, pharmaceutical, and cosmetic industries, labeling machines treat bottles of all shapes-rounded, flat-sides with different capacities and speeds. PLC control systems and servo-based label dispensers combined with sensor/alignment systems make sure the sticker labels are perfectly placed on bottles even at speeds of 100 bottles/minute.

Manufacturing Trends in Sticker Labeling Machines

Integration with Smart Manufacturing: Modern machines integrate IoT connectivity for real-time monitoring and data analytics.

Sustainability: The focus for manufacturers is towards energy-efficient designs and compatibility with eco-friendly label materials.

Versatility: More and more machines are becoming modular in order to be modified rapidly for new products or new packaging formats.

Conclusion: Aim Technologies-Your Trustworthy Sticker Labeling Machine Maker

Choosing a trustworthy sticker labeling machine manufacturer puts Aim Technologies in a category by itself. They offer a full range of automatic sticker labeling machines and bottle-labeling machines serving pharmaceuticals, food and beverage, and chemical lines. An abiding commitment to innovation, quality, and customer satisfaction ensures that clients receive the latest state of art labeling solution designed to fit their very own requirements. When it comes to sticker labeling machine manufacturers, Aim Technologies is the name a business would want to associate for precision, efficiency, and long-term value.

0 notes

Text

Top 5 Features to Look for in Pharmaceutical Packaging System

Pharmaceutics carry critical importance in human life. Every practice involved in this healing industry requires meticulous operation. From the course of treatment to the dosage measures and storage, every aspect is managed with the utmost precision. This precision is well reflected in keeping all the drugs from damage and contamination. How is this precision attained?

Pharmaceutical packaging plays a vital role in attaining precision in keeping all the drugs undamaged and uncontaminated. It deals with every process along the way starting from the primary packaging to end-of-line operations and warehousing. Considering the stakes and stringent regulatory standards, the manufacturers must operate with an efficient packaging system that ensures the safety, integrity, and efficacy of medicines.

How do you, as a manufacturer, ensure the functionality of a pharmaceutical packaging system? Below are the features to look for that'll help you make the ideal choice.

1. High Precision and Sterility

Precision is paramount in the Pharma Industry. Accurate dosage quantities are crucial to maintaining uniformity. Precise Pharmaceutical Packaging Solutions efficiently manage this uniformity, maintain regulatory standards, and prevent wastage.

Nichrome’s high-precision automated solutions from powder jar filling machines to carton packing machines, are designed for tablets, capsules, powders, injectables, gels and liquids and are equipped with advanced filling and sealing technologies that eliminate the scope of errors and ensure consistent packaging quality.

2. Versatile Packaging Solutions

The Pharma Industry deals with a diverse range of product forms that require various packaging formats like sachets, blister packs, bottles, etc. Versatile packaging solutions avail the adaptability to changing pharmaceutical needs and enhance the flexibility of production. This indeed makes it a valuable investment.

At Nichrome, we offer single-point convenience with versatile packaging solutions for both primary and secondary packaging. From granulation to filling and capping, Nicrome's innovative and integrated packaging systems cover all the bases to deliver well-rounded solutions like tin packing machines, powder filling machines and much more.

3. Pharmaceutical Packaging System with Track and Trace Solutions

The services of packaging solutions aren't limited to just packaging operations. There are several other challenges such as counterfeiting and supply chain transparency. To overcome these the track and trace solutions ensure that every packed product can be identified, verified and traced throughout the transport.

Nichrome Data Over Internet (NDOIT) offers partial or complete track-and-trace solutions right from the raw material stage to retail sales with software operations, cloud storage including real-time data and even the complete hardware i.e. packaging system for seamless product identification and tracking.

4. End-of-Line Efficiency

Automated systems for secondary and end-of-line packing processes such as cartoning machines, labelling and palletizing machines help reduce the operation time and scope for manual errors. This automation streamlines the logistics and distribution of products, maintaining the quality and ensuring the final packaging stage operations run smoothly.

Nichrome's end-of-line packaging machines are engineered to provide businesses with enhanced operational efficiency. We offer customized solutions like Automatic Case Erector, Automatic Pallet Dispensing, Collation, Multiple Line Configuration Integration, and Stretch Wrapping. Along with secondary packaging and palletizing, Nichrome is a leading shrink wrapping machine manufacturer in India that provides advanced case-packing and bottle-packing solutions. With end-to-end pharmaceutical packaging solutions, we are dedicated to simplifying and accelerating packaging operations.

5. Cost-Effective Solutions

Cost-effectiveness holds equal importance as the high-quality standards in the Pharma Industry. Manufacturers can effectively waive off a good amount of costs by eliminating the investment in labour costs with automation, energy-efficient systems and low-maintenance designs.

This cost control could be achieved with Nichrome’s innovative yet cost-effective solutions tailored to pharmaceutical needs. We have aided many businesses in reducing their reliance on human labour with automated and integrated packaging systems, helping them save some hefty costs in the pharmaceutical packaging requirements and leading them to enhanced cost efficiency.

Nicrome's End-to-End Innovative Pharmaceutical Packaging Solutions for Healthier Tomorrow

A reliable pharmaceutical packaging system must prioritise precision, versatility, traceability, efficiency, and cost-effectiveness. These features not only help manufacturers maintain compliance and enhance productivity but also ensure the safety and satisfaction of end-users.

Nichrome's pharmaceutical packaging solutions reflect each of these must-haves and how! We provide an integrated packaging system that covers end-to-end pharmaceutical packaging solutions starting from product handling, primary, secondary, and end-of-line packaging operations to warehousing and track and trace solutions. With unparalleled quality, sterility, and our commitment to 'Safety First', we ensure our packaging solutions abide by the industry standards. At Nicrome, we don't just serve as the packaging partners, but as allies of the Pharmaceutics contributing to a healthier future.

#pharma packaging#integrated#intergratedpackagingsolutions#pharmaceutical packaging solutions#Automatic Case Erector#Nichrome Data Over Internet (NDOIT)

0 notes

Text

Round Bottle Labeling Machine

Round Bottle Labeling Machine or bottle self adhesive sticker labeling machine is simple mechanism linear design machine to label bottles, jars, cans, tins & other containers. Bottle labeler can label PET, glass, plastic, aluminium, metal & tin containers. This equipment incorporates modern Micro Processor Control Label Dispensing mechanism with sensing system for Label and Product. Specially designed electronic and mechanical system to apply transparent (No Look) Labels on bottles at very high speed using optional special label sensing system. Interestingly no change parts/format parts requires for changing one size to another size of bottle.

Automatic bottle labeler available in India, with unique single point synchronized speed control system. Machine also available with optional Turn Table for Feeding of containers for online transfer of containers from Capping/Inspection machine to labeling and online transfer of labeled bottles to packing conveyor/inspection system, This system helps for continues labeling operation for bottles.

Machine can be supplied with Optional Toughened (Tampered) Glass or Acrylic Safety Cabinet. Machines having required all basic features as a standard fitment to match the current market needs and also saves cost and time. Adinath range of sticker labelers can be attached to bottle liquid and powder filling lines. Machine also called as pharmaceutical labeling machine, glass bottle labeler, plastic bottle labeling machine and syrup bottle sticker labeling machine.

0 notes

Text

Brothers Pharmamach Sticker Labelling Machines and Powder Filling Machine

Brothers Pharmamach has been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing industry in India. Brothers Pharmamach, the largest Manufacturers & Exporter of Pharmaceutical and Labelling Machinery in India is a result of a merger between some of the leading brands such as BHAVANI & AMBICA Labelling.

Sticker Labelling Machine Manufacturer

The largest Manufacturers & Exporter of Sticker labelling machines are essential in various industries for applying labels to products, ensuring accurate and efficient packaging.

Automatic sticker labelling machine

sticker labelling machine for bottle

round bottle sticker labelling machine

hologram sticker labelling machine

Ampoule Sticker Labelling Machine

Rotary Bottle Sticker labelling machine

label applicator label dispenser security

label applicator tax label applicator

Tube labelling machine

Powder Filling Machine Manufacturer

The largest Manufacturers & Exporter of Powder filling machines are crucial in industries that handle powdered products, such as pharmaceuticals, food, and chemicals.

automatic dry syrup filling machine

dry syrup filling machine

dry syrup powder filling line

dry syrup filling and sealing machine

Linear auger powder filling machine

For More Details Click here : https://www.brothers.in

0 notes

Text

Achieve precision and speed with our Top Label Applicator, designed for top and bottom side labeling with unparalleled quality. The SBSL-300 Vial Sticker Labeling Machine is fully automatic, user-friendly, and packed with advanced features, including a microprocessor-controlled label dispensing system and the latest sensing technology. It’s perfect for labeling round vials, small bottles, and various round objects, handling up to 300 units per minute. With a built-in system to detect label length and a single-point synchronized speed control, this machine minimizes downtime and maximizes efficiency. Ideal for glass, plastic, PET, HDPE, PP, and more, it’s the ultimate solution for your labeling needs.

For more details, visit - https://www.bhagwatilabeling.com/products/top-label-applicator-top-labeller-machine-top-sticker-labeling-machine/

0 notes

Text

Sticker Labelling Machine Manufacturer, Supplier & Exporter

In packaging industries, sticker labelling machine is used to apply labels on products and containers, bottles, vials, injections, tubes etc. Labels are found on almost every item for sale like packs and bottles an many more. As labelling plays a very important role in manufacturing and packaging industries. Now a days Labels are stickered through labelling machines, types of Labeling machines have a huge demand amongst the industries.

We are manufacturer Supplier of many different types of sticker labelling machines. It is based on their features and as per clients applications.

Types of Labeling machines

Automatic sticker labelling machine Label applicator Label dispenser Sticker labelling machine for bottle Round bottle sticker labelling machine Semi Automatic sticker labelling machine

For More Types of Labeling Machines Visit: https://www.brothers.in https://www.brothers.in/sticker-labelling-machine.html

0 notes

Text

Linear Motion Products for Automation

Automation is a market where industrial linear motion products are used in large numbers. You can find CSK products in the smallest most simple machine to the largest and most complex system imaginable. In short, wherever there is a need in a machine to push, pull, lift, tilt, turn or move something CSK has a suitable product. Typical areas include:

Robots and manipulators

Pressing, cutting and gluing

Printing and scanning

Packaging, palletizing and dispensing

Welding, soldering and drilling

Automatic warehouses

Measuring and supervision

Assembly

Linear Motion Robotics

CSK's linear motion automation products play a vital role in factory automation, enabling precise and controlled linear motion in various applications. They optimize factory automation systems by offering advantages such as high precision, smooth operation, reliability, and compact design. Here is an all-round interpretation of the application of CSK's linear motion products in factory automation:

1. Robotic Systems:

- Linear Guides: Linear guides are extensively used in robotic systems to facilitate smooth and accurate linear motion for robot arms, gantries, and other moving components. CSK's linear guides ensure precise positioning, stability, and repeatability, enhancing the overall performance and productivity of robotic systems.

- Ball Screws: Ball screws convert rotary motion into linear motion and are employed in robot actuators for precise and controlled movement. CSK's ball screws offer high precision, low backlash, and efficient power transmission, contributing to accurate and reliable robotic operations.

2. Material Handling and Conveying:

- Linear Motion Systems: Linear motion systems, including linear guides, ball screws, and linear actuators, are utilized in material handling and conveying systems. CSK's linear motion products enable smooth and efficient linear motion for conveyors, lifting mechanisms, and transfer systems, optimizing the movement of materials within the factory.

CSK's linear motion systems provide high load capacity, low friction, and precise positioning, ensuring reliable and efficient material handling. They contribute to increased throughput, reduced downtime, and improved overall productivity in factory automation.

3. Assembly and Testing Equipment:

- Linear Actuators: Linear actuators, such as electric cylinders or linear stages, are used in assembly and testing equipment for precise positioning, pushing, or pressing components during the manufacturing process. CSK's linear actuators offer accurate and controlled linear motion, ensuring precise alignment, reliable testing, and consistent assembly quality.

- Linear Bearings: Linear bearings are employed in assembly and testing equipment to support and guide the movement of components or testing probes. CSK's linear bearings provide smooth and low-friction linear motion, contributing to the accuracy and repeatability of assembly and testing processes.

4. Packaging and Labeling Machines:

- Linear Motion Systems: Linear motion systems, including linear guides and ball screws, are employed in packaging and labeling machines for precise and controlled linear motion. CSK's linear motion products enable accurate positioning of packaging materials, products, or labeling mechanisms, ensuring precise and efficient packaging processes.

CSK's linear motion drive systems offer high positioning accuracy, smooth operation, and high-speed capabilities, enhancing the productivity and accuracy of packaging and labeling machines. They contribute to reduced errors, improved packaging quality, and increased production throughput.

0 notes

Link

We are leading Manufacturer of Label Roll Dispenser Machine. These label printing machine is also known as batch coding machine. Also we Confirmation Label Dispensers, Label Rewinder for our consumer internal use. Coated structure with adjustable height, M.S. base, with Suitable Label Wrap Around system. We have been also manufacturing Slitter Rewinder Machine for different industry. For More Information Visit Our Website: krishnaengineeringworks.com or Contact Our Sales Team: [email protected]

#Label Roll Dispenser Machine#Manual Label Dispenser#Automatic label Dispenser#Industrial Automatic Label Dispenser#Semi-Automatic Label Dispenser#Stainless Steel Automatic Label Dispenser#Mild Steel Manual Label Dispenser#High Speed Label Dispenser#Round Automatic Label Dispenser#Auto Label Dispenser#Batch Coding Machine#Heavy Duty Label Dispenser#High Quality Semi-Automatic Sticker Label Dispenser

1 note

·

View note

Text

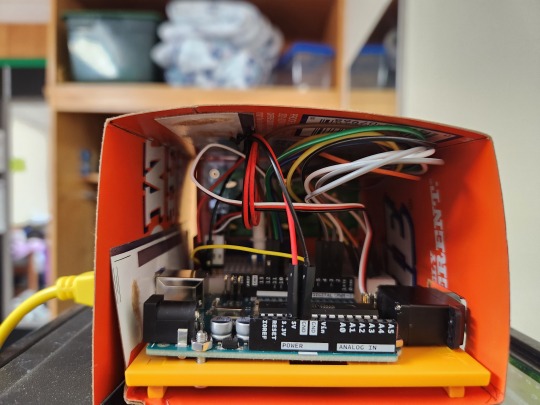

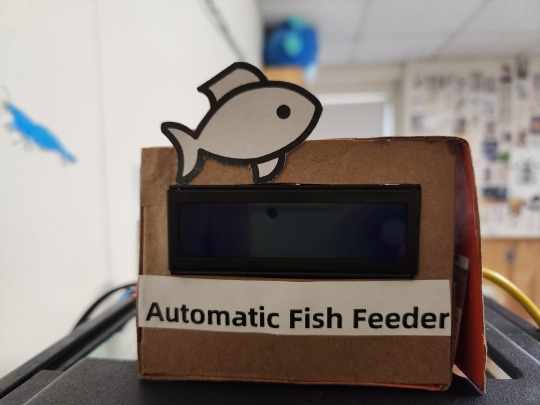

Project 14 - Automatic Fish Feeder

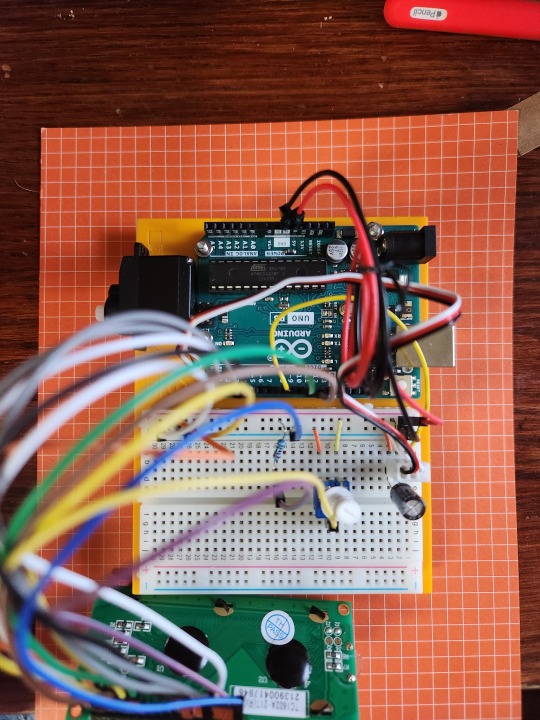

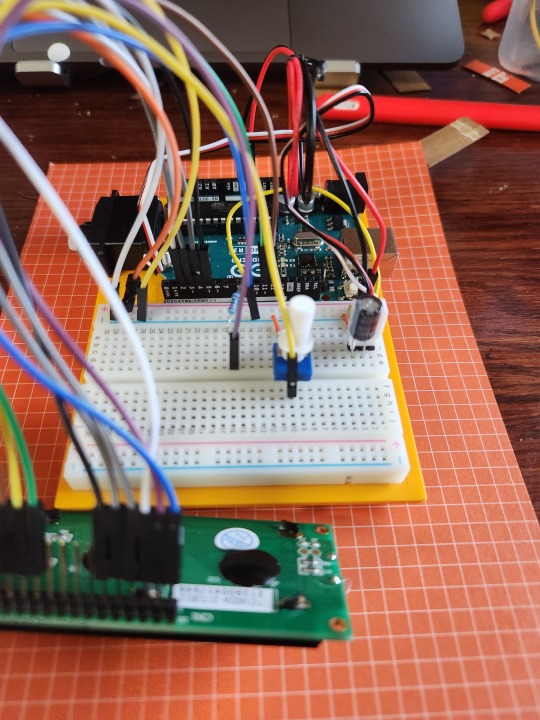

Since the class has completed all the assignments from the Arduino projects book, we're moving onto more advanced projects we came up with on our own for the rest of the semester.

My first project is an Automatic Fish Feeder! This one is designed to release one feeding 12 hours after starting. Perfect for a weekend away to keep your fish happy!

expand the post to see how to make it. This one is really long since I'm sharing how I built everything as well as some of my thought processes.

Needed Materials:

Electronic parts:

• LCD

• 220 Ohm resistor

• Servo

• Potentiometer

• Capacitor

• Long Male/Female wire extenders

Building materials:

• Thin cardboard (I used a soda can box)

• Glue stick

• Bobby pin

• Adhesive dots

• Electric tape

• Printed decorations (Optional, just for aesthetics)

How It's Made:

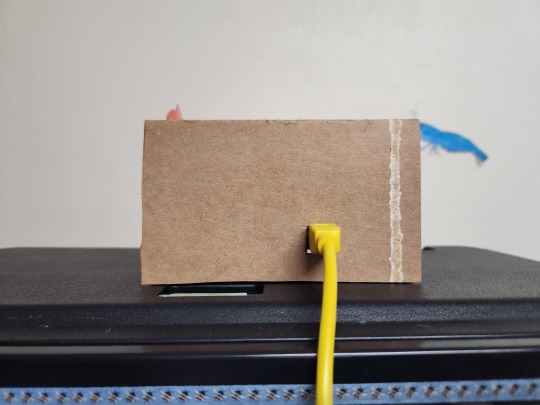

Using thin cardboard as my main building material, I traced the footprint of the Arduino + breadboard base and eyeballed how tall the sides should be. I'll include measurements below so you don't have to guess like I did. I also made sure to leave room for the servo to poke out as well as a spot for the power cable to be plugged in.

I used an adhesive dot to stick the servo to plastic base my Arduino is on.

the front panel is a separate piece of cardboard. I traced the LCD's footprint onto the front and cut it out with a knife. The thin cardboard wasn't strong enough to hold the weight of the screen, so I made a second front panel and glued it to the first. I also left room around the edges when I was cutting out so I would have surface area to glue things together.

The food receptacle is traced from a pencil sharpener I had on hand, so I'll include the measurements in my mockup for your pleasure. It's just a rectangle with an open top and bottom. Just for fun, I glued a little strip of colorful cardboard to the bottom edge of the box.

For the trap door on the bottom of the food bin, I traced the bottom of the rectangle and cut out two. Cut the wavy leg off a bobby pin. Glue the remaining straight leg between the two cut outs, make sure it's off center(as seen in picture X). Use electric tape to secure the rounded part of the bobby pin to the little servo arm. Stretch the tape as you put it on to make sure it's secure.

Finally, I spiced up the outside of the build with some labels and pictures. I have a small thermal sticker printer, but any printed or hand written markings will do. I stuck the fish image to a cardboard scrap and cut it out before gluing it above the LCD. Having it come off the edge of the box adds a lot of visual interest to an otherwise boring build.

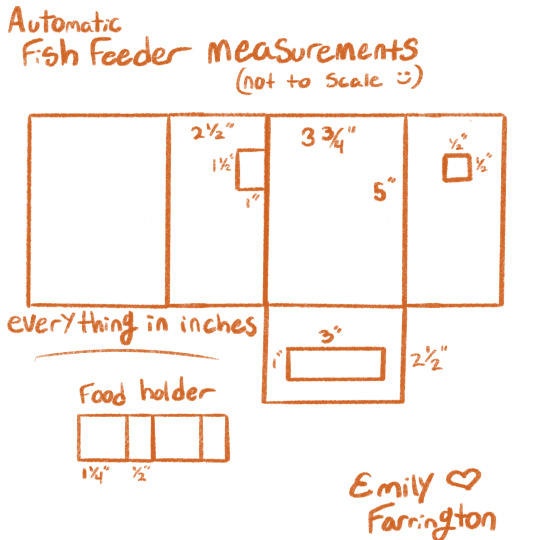

Graphic of build plus measurements:

Board:

The Code:

Once the Arduino turns on, it starts counting up until the dispense time - start time = 0. Then the servo will rotate it's arm to 180° and dump the food into your fish tank. The LCD screen will display a welcome message before showing the time remaining until the food gets dispensed. For the demonstration, I changed the code to dump the food after 10 seconds and display the time remaining in seconds. You can comment that out and comment in the 12 hour pre programmed time if you want to actually use this build.

Video:

youtube

Schematics:

and a picture of my fish because I love him so much. His name is Horatio

2 notes

·

View notes

Text

etiketleme

Labeling (etiketleme) provides information on the components from the piece. If you're a small business, this is the Labeling Machine you've been in search of. If you're inside the packaging organization then you need to be conscious from the numerous needs of fast production. Across the past decades, this business has provided handle strategies to a range of well-known organizations from different market sectors. It can be properly famous for by no means limiting with the quality of their goods and extremely affordable prices in the market. The models are produced in agreement using the international standards of good quality. It's a long lasting Machine, and provides you with several years of dependable assistance. Labeling Machine (etiketleme makinesi) increase the full production procedure and decrease the producing expenses. Jar Labeling Machines are ideal for Labeling containers of a variety of distinctive forms, sizes and materials like window and plastic material. Semi automatic Labeling Machine would work for your little scale businesses. Your Labeling Machine gives you an expert product that you could be pleased with. The sticker label Machine (etiket makinesi) should be simple to use, having a small little bit of upkeep fee and it needs to be in line with the absolute most updated modern technology. The Easy Labeler Labeling Machine should be able to assist you to construct your succesful small business. A brand dispenser will opt for the brand off its liner along with dispense it to the package in the obligatory condition accurately with no individual intervention. Labeling bottles has been a overwhelming undertaking for a good whilst now. The vial or phial, as it's otherwise known as, is a little bottle especially for water treatment. Labeling are often challenging to peel and implement. It had been created to use several labels to round parallel sided storage containers. It is supposed to utilize a couple of tags to cylindrical plastic-type or metal pipes. Labels enjoy a substantial part in the packaging of the piece. Labeling supply client information in regards to the merchandise and business which helps the company to create a company image in consumers imagination and clients by letting them make proper selection based upon their condition. They could be applied from several ways by using a suitable Machine. Apart from the logistics business, the labeling can also be employed in product packaging of program goods. It can be positioned on the compartment quickly when it will probably be sensed from the compartment detector. Easily removed product or service tags will have to link till they are eliminated. Labeling is able to be achieved yourself or via sticker label Machine (etiket makinesi). Customized wrapping is definitely an evolutionary use of modern-day supplies. Some enable you to change the manifestation of your own content label having a frame around the text message. It can be easy to also enjoy coloration! The color coordinating case is enormously utilized in a tremendous number of sectors in which colour is a big aspect of high quality of items according to international norms. There are lots of spots exactly where you are able to obtain your Labeling Machine ( etiketleme makinesi) from. There are certain things that you must be mindful with for all those time prior to acquiring it. 5, It is really not tough to use and modify. A few are briefed here. Examine the information on each model to find out its capabilities so you obtain the one that matches your expectations. You might opt for what kind of create you want based on your requirements. The capability to make a unique label configuration is really a successful source.

1 note

·

View note

Text

Front back and top side labeling machine

Automatic front and back sticker labeling machine is a fully automatic labeling machine that is sturdy and used to apply sticker labels on the front and back of bottles of various shapes and sizes. Packagers can leverage this machine to apply sticker labels on the front and back of oval, rectangular, square and round bottles. With a processor controlled label dispensing system, a sensing system and a unique single point synchronized speed control system, the machine offers high productivity. It can offer a production output as high as 120 labels per minute. There is no need to manually feed and store label length data. Understandably, our automatic two side front and back labeling machine eliminates the need of retrieving data, making changes and restarting the machine.

Adinath’s automatic two side front and back labeling machine comprises a touch screen for enhanced accessibility. Owing to its precise technology and VFDs, the machine makes precise labeling on single side or double side a breeze.

#Automatic front and back sticker labeling machine#fully automatic labeling machine#automatic two side front and back labeling machine

0 notes

Text

Commonly used labeling methods and advantages and disadvantages of automatic labeling machines

Nowadays, many industries have achieved automation. Fully automatic labeling machines are playing an increasingly important role in the packaging industry. The emergence of fully automatic labeling machines has basically replaced the time-consuming and labor-intensive problems of manual labeling. Although there are many types of labeling machines on the market, they are always the same. There are three main methods: friction method, blowing method and suction method. The accumulated experience allows us to summarize the advantages of the three labeling methods of the labeling machine. shortcoming.

1. The principle of suction adhesion: when the label paper of the automatic labeling machine is separated from the conveyor belt, it is pulled onto the vacuum pad and connected to the end of the mechanical device. Install and stretch the automatic labeling machine until the label touches the product, it will shrink and stick to the product. This method has the advantage of high precision and is mainly used in the labeling process of difficult packaging products. The disadvantage is that the labeling speed is relatively slow and the labeling quality is not very good.

https://www.gst-automation.com/uploads/allimg/20221126/1-221126152S1336.jpg

2. The principle of air blowing method: It has been improved on the basis of the inhalation method. The difference is that the appearance of the vacuum pad remains the same and the label is fixed on the vacuum grid, which is a flat surface that covers the top of the entire surface. Hundreds of small round holes. The small round hole is used to keep the air jet. This type of air ejector blows a constricted flow of air at very high pressure to move the label on the vacuum grid and adhere it to the product. This method has the advantages of high precision and high reliability. The disadvantage is that the process is complicated and the cost is high.

3. Principle of rubbing method: When marking, when the outside of the label is pasted on the package, the product will be removed immediately. In this fully automatic labeling machine, the method is only successful if the package passing speed differs from the label dispensing speed. It is also a technology that requires continuous operation, so its labeling efficiency is greatly improved, and it is mainly used in fast, automated medical packaging production lines. When the label of the automatic labeling machine is pasted on the outside of the product, the product will immediately remove the label. The advantage of this method is that the speed of label distribution through the automatic labeling machine and the speed of label distribution. If the two speeds are constant, the labeling is highly accurate, otherwise it will affect the accuracy of the labeling machine.

https://www.gst-automation.com/News/266.html

0 notes

Text

Sticker Labelling Machine Manufacturer, Supplier & Exporter

Brothers Pharmamach, the largest manufacturers & exporter of Pharmaceutical and Labelling Machinery in India.

We Provide a wide range of sticker labelling machine such as, Automatic sticker labelling machine, Label applicator, Label dispenser, Sticker labelling machine for bottle, Round bottle sticker labelling machine, Carton sticker labelling machine, Pouch sticker labelling machine, Twin head carton labelling machine, Two side flat bottle sticker labelling machine, Horizontal sticker labelling machine, Test tube sticker labelling machine, Vertical sticker labelling machine, Double side vertical sticker labelling machine, Self adhesive ampoule sticker labelling machine, Hologram sticker labelling machine, High speed roll to roll sticker labelling machine, Ampoule sticker labelling machine, Vial sticker labelling machine, High speed vial sticker labelling machine, Empty tube sticker labelling machine, Automatic label counting machine, Linear sticker labelling machine, Rotary bottle sticker labelling machine, Tube labelling machine, Empty tube labelling machine, Security label applicator, Tax label applicator, Lami tube labelling machine.

For More Details Click here : https://www.brothers.in

0 notes

Text

Labeling System Basics

Labeling systems are generally used to apply standard pre-printed labels over items, packages, cases, and Pallet loads for better product identification and better traceability. The CTM Labeling Systems employ laser-based label printers that produce crisp, legible labels and are ideal for use over a wide variety of materials. They are extensively used in the retail and distribution sectors for custom label applications. Moreover, they can be effectively applied on items like books, folders, CDs, DVDs, CDs/DVDs, VHS tapes, and even clothing to customize them for better product recognition. Also, these labels are ideal for addressing different issues related to product identification like shelf life, return, and security.

In addition, labeling systems make use of computer-based software to add, update, or delete information about the inventory. They can be used for product inventory control, product recall, inventory control, and for periodic product analysis. In fact, they can also be utilized to print barcodes on products for better customer service. The flexibility of these systems is widely seen in the form of user-friendly software that allows users to create, update and manage inventory using simple forms. Users can also add, delete, and edit human-readable information using barcode software.

Among the popular labeling systems used today are desktop label dispensers, handheld label dispensers, stand-alone labeling machines, automatic dispenser machines, and wireless label dispensers. All these dispensers have the following basic features: user-friendly features such as labels can be easily wiped off; multiple labeling trays can accommodate different types of products; labels can be printed in single or multiples; and an integrated design that enables convenient and fast operation. Furthermore, a wide range of labeling equipment is available. These include automatic label applicators, label printers, lamination machines, garment rollers, and many more. This makes it possible for companies to have complete control over their labeling process.

Label applicators are among the most important dispenser-type labeling system used today. This is because they provide for a quick, easy way of applying labels on containers. Applying labels in this way does not only help improve the quality of the products and make them easily recognizable by consumers but also improves storage container security. Automatic applicators for round containers can come with a variety of features including built-in screw threads, removable parts that can be secured to the bottom part of the container, and a threaded peg attached to the side. see here to get a detailed overview of this topic: https://en.wikipedia.org/wiki/Packaging_and_labeling.

Some other popular labeling systems include hazard communication systems and bio hazard communication systems. Hazard communication involves automatic triggering of safety devices when exposed to specific hazardous materials. These safety devices can be used in workplaces, including hospitals and manufacturing facilities, to warn employees of hazardous conditions or materials before an accident takes place.

Meanwhile, bio hazard communication involves using special labels that are affixed to the inside surface of round containers. These labels warn of the presence of certain substances or materials that are harmful to the user. When the product label for a round container is used in this manner, it is easy to identify the correct product. The CTM labeling systems can improve chemical identification. They also help in reducing injuries as a result of misidentification of chemicals and other dangerous substances.

0 notes

Text

Role Of Induction Cap Sealing Machine, Label Dispenser & Food Labeler In Different Industries

Shree Bhagwati is a reputed manufacturer of high-quality induction cap sealing machines, label dispensers, and food labelers. The advanced manufacturing infrastructure supports the organization in manufacturing highly efficient types of equipment.

These machines are extensively used in various industries including cosmetics, pharmaceuticals, food, health care, and many more. A brief introduction of some of the important types of equipment are mentioned below.

Induction Cap Sealing Machine

The induction cap sealing machine is known for its excellent sealing properties for bottles. This induction cap sealer prohibits any kind of spillage from the bottles due to its excellent capacity to preserve products for a long-term duration.

The induction sealers have been opted in major industries like petrochemicals, agrochemicals, confectionary industry, personal care, health care, and food and beverage sectors. Industries where packaging of fresh and flavoured milk bottles and various ghee and oil filling industries, the induction cap sealing machines have considerable demand.

Label Dispenser

Label dispensers are responsible for clear and proper labeling of products. They play an important role in resulting of high efficient production by saving time and resources. These label dispensing machines are used for labeling finished goods in the industry before the final packing. These dispensers of labels are mostly used for bottles and other similar containers.

The bottle label dispensers are sometimes also known by the name label applicators and can result in a high production rate. The labels dispensed by these machines have pre-applied adhesives on the backside that makes them easy to apply. The manual labeling process was once a tedious task but with the coming in of these label dispenser machines, the process has gradually taken speed and enhanced the quality of labeling.

Industries expecting large production rates like pharmaceuticals, pesticides, food & beverages, beauty products, and many more such sectors where round or containers of similar shapes need to be labelled make use of these label dispensers.

Food Labeler

With the increasing food industries, the demand for food labelers is constantly increasing. The food labeling systems are available in different variants depending upon the need of that particular industries. It includes fully automatic and semi-automatic labeling machines that can help in increasing the production rate of the food industries.

The food labelers manufactured at the facility of Shree Bhagwati Labeling stand out amongst other different labeling machines in the market due to their excellent features. These food labellers have high volume output and can prove efficient to save time and money. Most of the food labeling systems are suitable for different product container designs and can be customized as per the need of the industry.

Current Demand in Industries

In current times, the demand for machines has increased in industries looking to increase their production rate along with cost-cutting in labour expenses. Industries like the food sector, chemical sector, pharmaceutical sector, beverage industry, personal care products industry, beauty care industry, and many more such divisions have extensively invested in these machines.

youtube

0 notes