#SHELL AND TUBE HEAT EXCHANGER

Text

Advancing Biofuel Efficiency: Precision Equipments' Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers

As the global focus shifts toward energy transition and decarbonization, developing countries like India face the dual challenge of rapidly growing energy demand and dwindling fossil fuel resources. To address this, the Government of India is promoting the production of biofuels such as ethanol, aiming for energy self-sufficiency and reduced reliance on fossil fuels.

The Role of Biofuel in Modern Energy Solutions:

Biofuels, including ethanol, can be utilized directly or blended with fossil fuels to reduce emissions and fossil fuel dependency. Notably, biofuels like ethanol boast a higher octane number than gasoline, ensuring complete combustion within engine cylinders and contributing to lower emissions.

Innovative Production Techniques:

Biofuel production leverages a novel, sulfur-free bio-solvent in a closed-loop cycle with water, enhancing sustainability through full recovery and minimal chemical input. This process not only offers significant cost savings but also aligns with sustainable practices by minimizing environmental impact.

Precision Equipment's Contribution to Biofuel Industry:

Precision Equipments specializes in manufacturing top-quality biofuel heat exchangers for cooling, reheating processes, and handling exhaust or flue gases. Our products serve a broad range of industries, including:

Biodiesel

Bioethanol

Biogas

And more biofuel production sectors.

Benefits of Bio-Fuels Heat Exchangers:

Our bio-fuels heat exchangers offer numerous advantages:

Reduction in CO2 emissions, supporting global decarbonization goals.

Production of bio-chemical byproducts that lessen environmental impact.

More energy-efficient than fossil fuels with fewer chemical processes.

Non-food-based production that does not affect human habitation.

Critical Role in Biofuel Production Processes:

Heat exchangers are crucial in various stages of biofuel production, including pre-treatment, fermentation, distillation, dehydration, stillage dewatering, and evaporation. Precision Equipments designs shell and tube heat exchangers specifically for biofuels, capable of handling hazardous fluids like bio-solvents and furfural. Constructed from materials such as duplex and super duplex stainless steels & non-ferrous metals, these exchangers often feature fixed tube sheets or thick wall expansion bellows for critical operating conditions.

Expertise and Reliability:

Since 1981, Precision Equipments has been a leader in manufacturing shell and tube heat exchangers for biofuels, adhering to international codes and standards like ASME, API, & TEMA, and meeting strict quality control measures. Our extensive experience ensures that we continue to deliver high-quality and high-performance heat exchangers for nationally important projects.

Conclusion:

Shell and tube heat exchangers from Precision Equipments play a pivotal role in enhancing the efficiency and sustainability of biofuel production processes. By improving operational reliability and reducing environmental impact, our solutions help propel the biofuel industry forward. For those in the biofuel industry looking to upgrade their production capabilities, Precision Equipments offers a range of solutions tailored to meet diverse needs.

Contact Precision Equipments today to explore our biofuel treatment systems and discover how our expertise can benefit your production requirements.

0 notes

Text

Cannabis companies use shell and tube heat exchangers in oil extraction and processing. Discover their many benefits in this profitable industry.

#shell and tube type heat exchanger#shell and tube heat exchanger supplier#shell and tube heat exchanger

0 notes

Text

#air cooled heat exchanger#shell and tube heat exchanger#heat exchangers#u tube bundle heat exchanger#finned tube heat exchanger

0 notes

Text

Shell and Tube Heat Exchanger

Looking for reliable solutions in heat exchange technology? CEPL specializes in the design and manufacturing of high-efficiency shell and tube heat exchangers. Our expert team ensures top-quality engineering services tailored to your industrial needs, optimizing performance and energy efficiency. Trust CEPL for innovative and cost-effective solutions in the field of shell and tube heat exchangers. Contact us today to learn more about how we can support your projects and enhance your operational efficiency.

0 notes

Text

WHAT ARE THE ADVANTAGES OF SHELL-AND-TUBE HEAT EXCHANGERS

Heat exchangers are widely used in a variety of industries and their main purpose is to transfer heat from one fluid to another. In the power generation plant, in order to generate electricity, the heat exchangers transfer heat from steam to water. In the petrochemical and refining industry, heat exchangers transfer heat from one process stream to another. This helps in controlling temperature and in recovering heat.

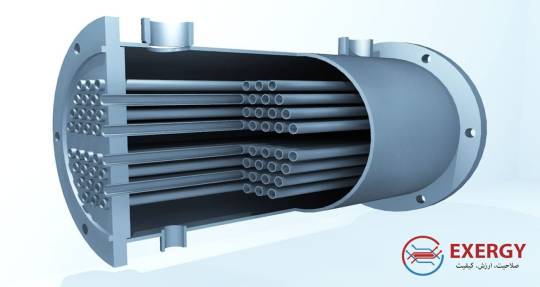

What is a Shell and Tube Heat Exchanger?

Shell & Tube Heat exchanger consists of a cylindrical shell with a series of parallel tubes that helps in transferring thermal energy from one fluid to another. When one fluid flows through tubes, the other flows around them in the shell. A metal tube sheet separates the fluids to prevent fluid mixing, while the baffles placed inside the shell enhances the heat transfer between the fluid streams. The tube walls enable the transfer of heat from one fluid to another. Used for both heating and cooling, shell and tube heat exchanger is largely dependent on the design and the application for which it is used. Sungov Engineering is among the leading industrial heat exchange manufacturers who manufacture shell and tube heat exchangers that meet ASME Section VIII Division 1 and TEMA standards.

What is the Shell & Tube Heat Exchanger Types?

The shell and tube heat exchanger types is usually based on the configuration and design of tubes, the flow arrangements and the number of passes. Shell and tube exchangers are also built depending on the temperature requirements and corrosiveness of the fluids and based on this, various materials such as stainless steel, aluminum, copper are selected. The following lists the common types of shell and tube heat exchangers:

Single-Pass Shell and Tube Heat Exchanger: The fluid in this type flows through tubes in a single pass.

Multi-Pass Shell and Tube Heat Exchanger: The fluid flows through tubes in multiple passes thus increasing heat transfer surface. This enables the overall efficiency of the exchanger.

U-tube Heat Exchanger: The tubes in this kind of heat exchangers are bent in a U-shape. One end is in the shell, while the other in the shell outlet. One fluid runs through the tubes, and the other fluid flows over the tubes (through the shell) to transfer heat between the two fluids. This kind of heat exchangers are used in situations when one of the fluids have corrosive nature and could cause damage to the heat exchanger.

Floating-Head Heat Exchanger: This kind of shell and tube heat exchanger is built to keep one end of the tubes free in order to help them contract or expand with the change of temperature. The other end is fixed. This kind is generally used for applications that involve high-pressure.

Fixed-Tube Sheet Heat Exchanger: The tubes in this kind of heat exchanger are fixed and cannot be removed for cleaning or maintenance.

Spiral Heat Exchanger: In this type, the tubes are wound into a spiral shape, with one fluid flowing inside the tubes and the other fluid flowing outside the tubes.

Plate And Shell Heat Exchanger: This kind of heat exchanger makes use of metal plates instead of tubes. One fluid flow in between the plates, while the other outside the plates.

What are the Benefits of Shell and Tube Heat Exchangers?

The shell and tube heat exchanger benefits are as follows.

Versatility: The shell and tube heat exchangers can accommodate many fluid types including those that are viscous and corrosive. This makes this heat exchanger perfect for a wide variety of applications

Durability: Shell and tube heat exchangers are usually composed of durable and strong materials that can tolerate various conditions

Competency: The high heat transfer rate makes this a great choice in a wide variety of applications

Reduced Downtime: The shell and tube heat exchangers enable better cleaning and maintenance thereby reducing work stoppage

Cost Effective: In comparison to other heat exchangers, the shell and tube heat exchanger is a low-cost option

High Pressure Competence: With their ability to operate at high pressures, the shell and tube heat exchangers are appropriate for high-pressure applicationsScalability: Shell and tube heat exchangers are available in a range of sizes and can be easily scaled up or down to meet the changing needs of a process.

0 notes

Video

undefined

tumblr

Water to water heat exchangers are responsible for exchanging heat between waste water and freshwater. The heat transfer process between the liquids does not involve direct contact or mixing of the two. If you are looking for the best quality Water Heat Exchanger then you should contact AIC Heat Exchanger - which offers Complete Heat Transfer Solutions.

#aicheatexchangers#DoubleWall#heat exchanger#water to water heat exchanger#Double Wall Heat Exchanger#shell and tube heat exchangers#brazed plate heat exchangers#Shell and Tube Heat Exchanger#Heat Exchanger Manufacturer#heat exchangers market#USA

0 notes

Link

Large process plants such as refineries or petrochemical plants where the process fluid is heated or cooled by passing through tubes within a shell. The shell and Tube Heat Exchanger in Singapore are usually made of metal while the tubes are made of either metal or composite materials.

#shell and tube heat exchanger#shell and tube heat exchanger advantages#shell and tube heat exchanger manufacturers

0 notes

Text

Shell and Tube Heat Exchanger: An Introduction

Are you familiar with the concept of a heat exchanger? It's a device that transfers thermal energy between two fluids. And if you're particularly interested in this technology, then you've likely come across Shell and Tube Heat Exchangers. These types of heat exchangers have been around for over 150 years, but they're still widely used today due to their effectiveness and reliability. If you're looking to learn more about these amazing machines, then keep reading! This blog post is your definitive guide to the fascinating world of shell and tube heat exchangers - an introduction like no other.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a type of heat exchanger that is commonly used in industrial applications. It consists of a shell, which is a large cylindrical vessel, and a bundle of tubes that run through the shell. Heat is transferred between two fluids that flow through the shell and the tubes, respectively.

How Does a Shell and Tube Heat Exchanger Work?

In a shell and tube heat exchanger, the two fluids flow in opposite directions. The fluid that needs to be heated or cooled flows through the tubes, while the other fluid flows through the shell. As the fluids flow through the tubes and the shell, heat is transferred from one fluid to the other through the walls of the tubes.

Types of Shell and Tube Heat Exchangers

There are several types of shell and tube heat exchangers, including:

Fixed Tube Sheet Heat Exchanger: This is the simplest type of shell and tube heat exchanger, where the tube sheet is fixed and cannot be removed.

U-Tube Heat Exchanger: In this type of heat exchanger, the tube bundle is bent into a U-shape, allowing for easy maintenance and cleaning.

Floating Head Heat Exchanger: In a floating head heat exchanger, the tube bundle is removable, making it easy to clean and maintain.

Applications of Shell and Tube Heat Exchangers

Shell and tube heat exchangers are commonly used in a variety of industrial applications, including:

Chemical Processing: Shell and tube heat exchangers are commonly used in chemical processing plants to heat or cool fluids.

Oil and Gas: Shell and tube heat exchangers are used in oil refineries and gas processing plants to transfer heat between fluids.

HVAC: Shell and tube heat exchangers are used in HVAC systems to transfer heat between air and water.

Advantages of Shell and Tube Heat Exchangers

Efficient heat transfer

Can handle high-pressure applications

Can handle a wide range of fluids and temperatures

Conclusion

Why use a shell and tube heat exchanger? Shell and tube heat exchangers are an important component in many industrial applications. They provide efficient heat transfer between two fluids, making them ideal for use in chemical processing, oil and gas, and HVAC systems. While they can be expensive to manufacture and install and can be difficult to clean and maintain, the advantages of shell and tube heat exchangers make them a valuable asset in many industrial settings. So, whether you're designing a new industrial process or looking to improve an existing one, consider the benefits of a shell and tube heat exchanger.

4 notes

·

View notes

Text

Best Graphite Tube Heat Exchanger | Goel Scientific | Canada

We Serve the Best, Long Lasting Glass Heat Exchanger & Coil Condenser, Glass Shell & Tube Manufacturers, Goel Scientific Glass Canada, USA Quebec Ontario Alberta

#Best#Top#We Serve the#Long Lasting Glass Heat Exchanger & Coil Condenser#Glass Shell & Tube Manufacturers#Goel Scientific Glass Canada#USA Quebec Ontario Alberta

0 notes

Text

Cubic Block Graphite Heat Exchanger

omega graphite is a Leading company for Manufacturers and suppliers of Cubic Block Graphite Heat Exchanger, Cubic block type graphite heat exchangers consist of cube-shaped graphite blocks assembled and bolted together. Each cubic block consists of two sets of holes, one set of holes axially carrying the corrosive process to adjacent blocks. We are the best manufacturer, supplier of cubic block type graphite heat exchangers in Mumbai, India, UAE and Saudi Arabia, Brazil. media while another set of holes runs perpendicular to the axial holes carrying the service media. Heat transfer occurs by conduction through the graphite material that separates the two sets of pores. Cubic block heat exchangers are available in horizontal and vertical mounting designs.

Call Us: +919820045787 | Email Us: [email protected] | Visit Our Website: https://www.omegagraphite.com/

#graphite#cubic block graphite heat exchanger#cylindrical block graphite heat exchanger#shell & tube graphite heat exchanger#graphite powder#graphite condensers

0 notes

Text

Shell & Tube Heat Exchanger Market Size, Share, Latest Trends, and Growth Research Report 2024-2036

A comprehensive analysis of the Shell & Tube Heat Exchanger Market Size, Share, Latest Trends, and Growth Research Report 2024-2036 provides an accurate overview and thorough analysis of the market industries in the present and the future. This report provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry. It provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry.

Request Free Sample Copy of this Report @

Report findings provide valuable insights into how businesses can capitalize on the opportunities provided by these dynamic market factors. It also provides a comprehensive overview of the major players in the industry, including their product offerings, contact and income information, and value chain optimization strategies. Furthermore, it offers an in-depth analysis of the leading businesses in the industry based solely on the strength of their business plans, product descriptions, and business strategies.

Key Findings

Shell & Tube Heat Exchanger Market has experienced significant growth in recent years, driven by factors such as increasing consumer demand and technological advancements.

The market segmentation analysis revealed several key segments, including Material, Classification and End-Use each with unique characteristics and growth potential.

Regional analysis highlighted the strong performance of Shell & Tube Heat Exchanger Market in regions such as North America, Europe, and Asia-Pacific, with emerging markets showing promising growth opportunities.

Analyzing the Shell & Tube Heat Exchanger Market

A thorough understanding of the Shell & Tube Heat Exchanger Market will provide businesses with opportunities for growth such as customer acquisition, enhancements to their services, and strategic expansions.

By incorporating market intelligence into their operations, businesses can anticipate changes in the economy, assess the effect these factors may have on their operations, and create plans to counteract any negative effects.

Market intelligence helps organizations stay ahead of the curve through insights into consumer behavior, technological advancements, and competitive dynamics.

Using Shell & Tube Heat Exchanger Market data can provide organizations with an edge in the competitive market and establish prices and customer satisfaction levels.

In a dynamic market environment, business validation helps companies develop business plans and assures their long-term survival and success.

What are the most popular areas for Shell & Tube Heat Exchanger Market?

The North American continent includes Canada, Mexico, and the United States.

The European Union is made up of the United Kingdom, France, Italy, Germany, the Republic of Turkey, and Russia.

The Asia-Pacific region is comprised of China, Japan, Korea, India, Australia, Vietnam, Thailand, Indonesia, and Malaysia.

The region of Latin America, which includes Brazil, Argentina, and Columbia

In addition to Africa, the Middle East includes South Africa, Egypt, Nigeria, Saudi Arabia and the United Arab Emirates.

Report highlights include:

There is a 360-degree synopsis of the industry in question in this study, which encompasses all aspects of the industry.

The report presents numerous pricing trends for the keyword.

Additionally, the report includes some financial data about the companies included in the competitive landscape.

The study enumerates the key regulatory norms governing the keyword market in developed and developing economies.

Additionally, the keyword report provides definitions of the market terms referred to in the document for the sake of convenience.

Future Potential

In the keyword research report, various primary and secondary sources are used to describe the methodology of conceptualizing the study. It has been discussed in the study what the scope of the report is and what elements it contains in terms of the growth spectrum of the keyword. The document also includes financial data of the companies profiled, along with the current price trends of the keyword.

Access our detailed report at@https://www.researchnester.com/reports/shell-tube-heat-exchanger-market/5819

0 notes

Text

The Crucial Role of Shell and Tube Heat Exchangers in Industrial Processes

Shell and Tube Heat Exchangers are unsung heroes in industrial processes, regulating temperatures, enhancing energy efficiency, and facilitating condensation and vaporization. Precision Equipments, a leading manufacturer, provides tailored solutions for industries like Oil & Gas, Petrochemicals, and Energy. With extensive experience, high-capacity manufacturing, and a commitment to quality, Precision Equipments ensures processes run smoothly and efficiently while conserving energy. Their expertise in High-Pressure Shell and Tube Heat Exchangers makes them a trusted partner for global industrial needs.

0 notes

Text

Get Premium Shell and Tube Heat Exchangers from Valutech

Looking for top-notch shell and tube heat exchangers for your industrial needs? Look no further than Valutech. These premium products are constructed from high-quality materials, including carbon and stainless steel, titanium, and nickel alloys.

0 notes

Text

0 notes

Text

shell & tube heat exchanger

مبدل حرارتی پوسته و لوله به عنوان یک فناوری حرارتی پرکاربرد، با ساختار خاص و امکانات عالی خود در انتقال حرارت مورد توجه صنایع مختلف قرار گرفته است. بهوسیله ترکیبی از مهندسی دقیق و انتخاب مواد مناسب، این نوع مبدل حرارتی در بهینهسازی فرآیندهای حرارتی و افزایش بهرهوری تأثیر مثبت دارد.

#heat exchangers#مبدل حرارتی#مبدل حرارتی پوسته و لوله#shell & tube heat exchanger#مبدل حرارتی شل تیوب#industry

1 note

·

View note

Text

Applications of Shell and Tube Heat Exchangers

As industries continue to prioritize energy efficiency and sustainability, heat exchangers have become essential components in many processes. Among the various types of heat exchangers available, shell and tube heat exchangers stand out for their versatility and effectiveness. At Sungov Engineering, we understand the importance of efficient heat transfer in maximizing process efficiency and reducing energy costs. But have you ever wondered why shell and tube heat exchangers remain a popular choice in a world of ever-evolving technology? Despite the emergence of newer designs, shell and tube heat exchangers remain a go-to solution for many applications. Let’s explore the reasons behind their enduring popularity and why they may still be the best choice for your process.

Reliable and Efficient Shell and Tube Heat Exchangers

Shell and tube heat exchangers are a reliable and efficient solution for a wide range of applications due to their design and benefits. The shell and tube heat exchanger design enables effective heat transfer between two fluids, making them a popular choice for industrial heat exchanger manufacturers. They come in various tube heat exchanger types, including U-tube, straight tube, and double pipe, to suit different application requirements.

One of the primary benefits of shell and tube heat exchangers is their versatility. They can handle a wide range of temperatures, pressures, and flow rates, making them suitable for a variety of industrial processes. They can operate at high temperatures and pressures, making them ideal for use in processes such as oil refining, chemical processing, and power generation. They can also be used in low-temperature applications, such as cooling and air conditioning systems.

Another significant benefit of shell and tube heat exchangers is their ease of maintenance, repair, and upgrade. The modular design of the tube bundle allows for easy replacement of damaged tubes, and the shell can be opened for cleaning and inspection. Additionally, the customization options available with shell and tube heat exchanger manufacturers like Sungov Engineering help to tailor to specific applications.

The shell and tube heat exchangers are a further cost-effective option when compared to other heat exchanger designs. The simplicity of the shell and tube heat exchanger design and the ease of maintenance contribute to their cost-effectiveness, making them an attractive option for businesses seeking to reduce costs.

Shell and Tube Heat Exchanger: Benefits

We have listed a few benefits of using a shell and tube heat exchanger in your processes:

Shell and tube heat exchanger design: The design of a shell and tube heat exchanger allows for high heat transfer efficiency due to its large surface area. Additionally, the design allows for multiple fluids at different temperatures, making it versatile for various applications.

Industrial heat exchanger manufacturers: Many manufacturers specialize in shell and tube heat exchangers, meaning that there is a wide range of options to choose from. This results in a highly competitive market and a better chance of finding an exchanger that fits specific needs.

Tube heat exchanger cleaning: One of the key benefits of shell and tube heat exchangers is their easy maintenance. The removable tubes make cleaning and replacing them straightforward, which can prolong the lifespan of the exchanger and improve efficiency.

Shell & tube heat exchanger types: There are various types of shell and tube heat exchangers available, such as U-tube, double pipe, and spiral exchangers. This allows for customization and adaptation to specific applications.

To sum it all up, the benefits of shell and tube heat exchangers include high thermal efficiency, versatility in fluid types, durability, easy maintenance, compact size, and cost-effectiveness.

In conclusion, shell and tube heat exchangers are an incredibly versatile and efficient solution for a wide variety of industrial applications. With their unique design, these heat exchangers allow for high heat transfer efficiency, making them an ideal choice for applications where heat exchange is critical. Industrial heat exchanger manufacturers offer a range of shell and tube heat exchanger types, providing options for customization to fit specific applications. Furthermore, the easy maintenance and cleaning of these exchangers help to prolong their lifespan and improve their efficiency. In addition to their high thermal efficiency, shell and tube heat exchangers offer various benefits such as versatility, durability, compact size, and cost-effectiveness. As a result, these heat exchangers are widely used in industries such as oil and gas, chemical processing, food and beverage, and power generation. In short, the shell and tube heat exchanger design is a versatile and efficient solution for various industrial heat exchange applications, and their numerous benefits make them a worthwhile investment for companies looking to improve their heat transfer processes. Contact Sungov Engineering today and see how we can help you with your shell and tube heat exchanger requirements.

#industrial heat exchanger manufacturers#shell & tube heat exchanger types#shell and tube heat exchanger benefits#shell and tube heat exchanger design#tube heat exchanger cleaning

0 notes