#shell and tube heat exchanger manufacturers

Link

Large process plants such as refineries or petrochemical plants where the process fluid is heated or cooled by passing through tubes within a shell. The shell and Tube Heat Exchanger in Singapore are usually made of metal while the tubes are made of either metal or composite materials.

#shell and tube heat exchanger#shell and tube heat exchanger advantages#shell and tube heat exchanger manufacturers

0 notes

Text

Applications of Shell and Tube Heat Exchangers

As industries continue to prioritize energy efficiency and sustainability, heat exchangers have become essential components in many processes. Among the various types of heat exchangers available, shell and tube heat exchangers stand out for their versatility and effectiveness. At Sungov Engineering, we understand the importance of efficient heat transfer in maximizing process efficiency and reducing energy costs. But have you ever wondered why shell and tube heat exchangers remain a popular choice in a world of ever-evolving technology? Despite the emergence of newer designs, shell and tube heat exchangers remain a go-to solution for many applications. Let’s explore the reasons behind their enduring popularity and why they may still be the best choice for your process.

Reliable and Efficient Shell and Tube Heat Exchangers

Shell and tube heat exchangers are a reliable and efficient solution for a wide range of applications due to their design and benefits. The shell and tube heat exchanger design enables effective heat transfer between two fluids, making them a popular choice for industrial heat exchanger manufacturers. They come in various tube heat exchanger types, including U-tube, straight tube, and double pipe, to suit different application requirements.

One of the primary benefits of shell and tube heat exchangers is their versatility. They can handle a wide range of temperatures, pressures, and flow rates, making them suitable for a variety of industrial processes. They can operate at high temperatures and pressures, making them ideal for use in processes such as oil refining, chemical processing, and power generation. They can also be used in low-temperature applications, such as cooling and air conditioning systems.

Another significant benefit of shell and tube heat exchangers is their ease of maintenance, repair, and upgrade. The modular design of the tube bundle allows for easy replacement of damaged tubes, and the shell can be opened for cleaning and inspection. Additionally, the customization options available with shell and tube heat exchanger manufacturers like Sungov Engineering help to tailor to specific applications.

The shell and tube heat exchangers are a further cost-effective option when compared to other heat exchanger designs. The simplicity of the shell and tube heat exchanger design and the ease of maintenance contribute to their cost-effectiveness, making them an attractive option for businesses seeking to reduce costs.

Shell and Tube Heat Exchanger: Benefits

We have listed a few benefits of using a shell and tube heat exchanger in your processes:

Shell and tube heat exchanger design: The design of a shell and tube heat exchanger allows for high heat transfer efficiency due to its large surface area. Additionally, the design allows for multiple fluids at different temperatures, making it versatile for various applications.

Industrial heat exchanger manufacturers: Many manufacturers specialize in shell and tube heat exchangers, meaning that there is a wide range of options to choose from. This results in a highly competitive market and a better chance of finding an exchanger that fits specific needs.

Tube heat exchanger cleaning: One of the key benefits of shell and tube heat exchangers is their easy maintenance. The removable tubes make cleaning and replacing them straightforward, which can prolong the lifespan of the exchanger and improve efficiency.

Shell & tube heat exchanger types: There are various types of shell and tube heat exchangers available, such as U-tube, double pipe, and spiral exchangers. This allows for customization and adaptation to specific applications.

To sum it all up, the benefits of shell and tube heat exchangers include high thermal efficiency, versatility in fluid types, durability, easy maintenance, compact size, and cost-effectiveness.

In conclusion, shell and tube heat exchangers are an incredibly versatile and efficient solution for a wide variety of industrial applications. With their unique design, these heat exchangers allow for high heat transfer efficiency, making them an ideal choice for applications where heat exchange is critical. Industrial heat exchanger manufacturers offer a range of shell and tube heat exchanger types, providing options for customization to fit specific applications. Furthermore, the easy maintenance and cleaning of these exchangers help to prolong their lifespan and improve their efficiency. In addition to their high thermal efficiency, shell and tube heat exchangers offer various benefits such as versatility, durability, compact size, and cost-effectiveness. As a result, these heat exchangers are widely used in industries such as oil and gas, chemical processing, food and beverage, and power generation. In short, the shell and tube heat exchanger design is a versatile and efficient solution for various industrial heat exchange applications, and their numerous benefits make them a worthwhile investment for companies looking to improve their heat transfer processes. Contact Sungov Engineering today and see how we can help you with your shell and tube heat exchanger requirements.

#industrial heat exchanger manufacturers#shell & tube heat exchanger types#shell and tube heat exchanger benefits#shell and tube heat exchanger design#tube heat exchanger cleaning

0 notes

Text

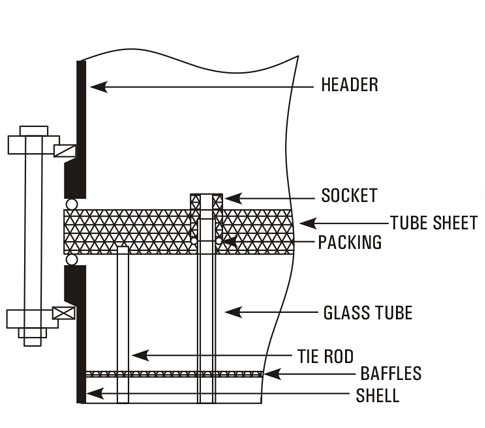

Best Graphite Tube Heat Exchanger | Goel Scientific | Canada

We Serve the Best, Long Lasting Glass Heat Exchanger & Coil Condenser, Glass Shell & Tube Manufacturers, Goel Scientific Glass Canada, USA Quebec Ontario Alberta

#Best#Top#We Serve the#Long Lasting Glass Heat Exchanger & Coil Condenser#Glass Shell & Tube Manufacturers#Goel Scientific Glass Canada#USA Quebec Ontario Alberta

0 notes

Text

Rahul Engineering Global Private Limited is a reputable engineering company based in Pune, India. With a strong commitment to innovation and quality, the company has established itself as a leading provider of industrial solutions, specializing in the manufacturing of Shell & Tube Type Heat Exchangers. With a dedicated team of skilled professionals and state-of-the-art facilities, Rahul Engineering Global Private Limited delivers reliable, efficient, and customized heat exchange solutions to clients across various industries.

#Shell & Tube Type Heat Exchangers#heat exchangers Manufacturer#Titanium Heat Exchanger#Shell and Tube Type Evaporators in Pune#Shell and Tube Type Evaporators in India#Shell and Tube Type Coolers In Pune#Shell and Tube Type Coolers In India.

0 notes

Text

Shell & Tube Type Heat Exchangers in Pune India | Rahul Engineering Global

#Shell & Tube Type Heat Exchangers#heat exchangers Manufacturer#Titanium Heat Exchanger#Shell and Tube Type Evaporators in Pune#Shell and Tube Type Evaporators in India#Shell and Tube Type Coolers In Pune#Shell and Tube Type Coolers In India.

0 notes

Text

Types of Shell and Tube Heat Exchangers: A Comparative Analysis for Industrial Applications

Heat exchangers play an important role in various industrial processes. They help in the efficient transfer of heat between two fluid streams. The versatility and efficiency of shell and tube heat exchangers make them one of the most popular types of heat exchangers. If you also want to know more about it then read further. We will tell you about the various types of shell and tube heat exchangers commonly used in industries. Their features, applications, and benefits, we have covered everything in this blog.

Furthermore, if you need high-quality heat exchangers. Then get it from a reliable shell and tube heat exchanger manufacturer or supplier.

Fixed Tube Sheet Heat Exchangers

The most common and simple type of shell and tube heat exchangers are the Fixed tube sheet heat exchangers. They have a stationary tube bundle which is attached to a rigid shell, where the tube sheet is welded or bolted to the shell. If the temperature and pressure difference between the two fluids is relatively small. Then, these heat exchangers are the best option. These heat exchangers are widely used in HVAC systems, chemical processing plants, and power generation facilities.

U-Tube Heat Exchangers

U-tube heat exchangers, as the name suggests, have U-shaped tubes. these tubes allow for thermal expansion. One end of the U-shaped tube bundle is fixed to the tube sheet and the other end is free to move within the shell. This design allows the tubes in U-tube heat exchangers to expand and contract as the temperature changes. This makes U-tube heat exchangers perfect for handling high differences in temperature. They are commonly used in applications such as steam condensers, oil coolers, and process heating.

Floating Head Heat Exchangers

Floating head heat exchangers offer enhanced flexibility by allowing the floating tube sheet to move within the shell. This feature enables the expansion and contraction of the tubes without exerting excessive stress on the tube sheet. Floating head heat exchangers are suitable for applications involving high temperature and pressure variations. They find extensive use in oil refineries, chemical plants, and petrochemical industries.

Conclusion

Understanding the different types of shell and tube heat exchangers is necessary for industrial applications. Each type offers unique advantages depending on the specific requirements of the process. By choosing the appropriate type of heat exchanger, industries can optimize heat transfer enhance system performance, and improve overall operational efficiency.

If you are in need of a reliable shell and tube heat exchanger manufacturer or supplier, Pragya Associates is dedicated to providing high-quality products. As a trusted shell and tube heat exchanger manufacturer, we prioritize quality and performance in every product we deliver. We design and manufacture heat exchangers using advanced techniques and materials. Furthermore, we ensure their durability, thermal efficiency, and long-term reliability. As a result, our heat exchangers meet industry standards and customer expectations.

#shell & tube heat exchanger#shellandtubeheatexchangersindia#shell and tube heat exchanger types#shell and tube heat exchanger supplier#shell and tube heat exchanger manufacturer

0 notes

Text

0 notes

Text

Shell And Tube Heat Exchanger Manufacturers In India | Oil Cooler Heat Exchanger Manufacturers In India

Phoenix Industries at a Glance

We Are Leading Shell And Tube Heat Exchanger Manufacturers In India, Oil Cooler Heat Exchanger Manufacturers In India .Heat Exchangers Are Used In Variety Of Industries Like Oil And Gas Industries, Chemical Industries, Power Industries, Marine Applications, Defense Industry For Desired Applications.

Phoenix Industries is an ISO 9001:2015 certified company that has been designing and manufacturing shell and tube type heat exchangers, Sealant Injection Grease Fittings, High Pressure Instrumentation Valves, Heat Exchangers, Precision Machined Components and Sub-assemblies for Oil and Gas Industries, Chemical Industries, Power Industries, & Marine Applications, Foundries for the last 22+ years.

Our founder Mr. Sachin Kulkarni is an epitome of experience and motivates his robust team to perform above expectations. The company is being managed by promoters who have the required technical and financial expertise and they work in synchronization with a dedicated team of engineers and technocrats to excel in everything they do.

We believe in ‘KAIZEN’ a Japanese principle of quality management which enables us for continuous improvement of our products and services, and hence maintaining ‘TOTAL QUALITY MANAGEMENT (TQM)’. We assure you the ‘Best’ quality product with ‘excellent’ services using precision machines and latest technology at most competitive prices.

#oil cooler heat exchanger manufacturers in india#Shell And Tube Heat Exchanger Manufacturers In India

0 notes

Text

Rahul Engineering Global provides India's Best best Shell & Tube Type Heat Exchangers. We offer different types of Products such as heat exchangers Manufacturer, Titanium Heat Exchanger.

#Shell & Tube Type Heat Exchangers#heat exchangers Manufacturer#Titanium Heat Exchanger#Shell and Tube Type Evaporators in Pune#Shell and Tube Type Evaporators in India#Shell and Tube Type Coolers In Pune#Shell and Tube Type Coolers In India.

0 notes

Text

Heat Exchanger Manufacturer In India

Shell and Tube Heat Exchanger

A Shell and Tube Heat Exchanger consists of a Shell and either improved surface tubes for high thermal performance

or traditional plain tubes.

Our Galaxyprocess industries heat exchanger manufacturer plant is strongly supported by an in-house design facility

that is outfitted with the newest design codes and software, as well as a welding development department that can

construct a manufacturing method for any new material.

A shell and tube heat exchanger is a type of heat exchanger that consists of a shell (or housing) and a bundle of tubes. It is one of the most common and widely used heat exchanger designs due to its versatility and efficiency. Shell and tube heat exchangers are used in a variety of industrial applications for transferring heat between two fluids, typically a hot fluid and a cold fluid, while keeping them physically separated.

• The basic construction of a shell and tube heat exchanger involves a cylindrical shell that contains a bundle of tubes. The shell has two main fluid chambers: one for the hot fluid and another for the cold fluid.

The tubes are typically made of materials such as copper, stainless steel, or titanium, and they are arranged in a parallel or helical pattern within the shell.

• The hot fluid flows inside the tubes, while the cold fluid flows through the shell space surrounding the tubes.

Heat is transferred from the hot fluid to the cold fluid through the tube walls. The tube walls act as the heat

transfer surface, allowing efficient heat exchange between the two fluids.

• To enhance heat transfer, the tube side of the heat exchanger may have various types of internal enhancements,

such as fins or turbulators, which increase the surface area available for heat transfer.

These enhancements promote turbulence and improve heat transfer efficiency.

• Shell and tube heat exchangers can be designed with different configurations, including fixed tube sheet,

floating head, and U-tube designs. The choice of configuration depends on factors such as operating conditions,

ease of maintenance, and the specific requirements of the application.

• Advantages of shell and tube heat exchangers include their ability to handle high-pressure and high-temperature

applications, their resistance to thermal stress, and their versatility in accommodating a wide range of fluids.

They are commonly used in industries such as petrochemical, power generation, chemical processing, HVAC, and

refrigeration.

• However, shell and tube heat exchangers also have some limitations. They tend to be larger and heavier compared

to other heat exchanger types, and they may require more space for installation. Additionally, they can be more

expensive to manufacture and maintain compared to other designs.

• Overall, shell and tube heat exchangers are widely used due to their effectiveness in transferring heat between

fluids while maintaining a high level of reliability and safety in various industrial applications.

#heat exchanger#shell and tube heat exchangers#construction#industries#galaxyprocess industries#heat exchanger manufacturer in india#heat exchanger manufacturer company in pune#articulate material

1 note

·

View note

Text

Heat Exchanger Manufacturers in Coimbatore | 9443428975

Our Heat Exchanger Manufacturers in Coimbatore is unique design provides more efficient and dependable performance than traditional shell and tube heat exchangers. Heat Exchanger Technology is a package of architecture that improves heat transfer and minimizes pressure drops while improving heat transfer surface area and reducing harmful vibration. Areas where fouling might develop and limit efficient heat transmission surface area are eliminated to offer true value to every single product Gireesh heat exchangers best understand your industry, attend to the needs of your business, and are committed to making our technologies and practices better all the time. Our products come from experienced personnel that is equipped with a complete range of facilities to chemically clean, UV crack test and refurbishes any plate heat exchanger. Additionally, it offers a wide range of parts, upgrades, and servicing for any cooling tower. Our new product range includes an extensive variety of heat transfer equipment

including but not limited to; heat exchangers, cooling towers, condensers, evaporators, radiators, coolers, and heat recovery economizers. Your unique requirements are what drive us, service is our passion. We just happen to sell great heat exchangers in the city! Gireesh heat exchanger is the only plate heat exchanger provider in Coimbatore with a purpose-built Assembly Unit for gasket plate heat exchangers. We strive to manufacture and fast supply at a competitive price without compromising on quality for your industrial requirement.

#heat exchanger manufacturer in Coimbatore#chiller manufacturer in coimbatore#cooling tower manufacturer in Coimbatore#plate heat exchanger manufacturer in Coimbatore#Shell and Tube heat exchanger manufacurer in Coimbatore#Oil Chiller Manufacurer in Coimbatore#heat exchanger in Coimbatore

0 notes

Text

https://www.phoenix.ind.in/oil-cooler-heat-exchanger-shell-and-tube-manufacturer-supplier-india.php

#shell and tube type heat exchangers#heat exchangers manufacturer#oil cooler heat exchanger manufacturer#supplier#exporter#india

0 notes

Text

Heat Exchangers Retubing excellent service available at Jay Steel Corporation

Jay Steel Corporation provides excellent Heat Exchanger Retubing service. Evacuating the tube or restarting the system helps in retubing heat exchangers conventionally. Lubricating and oiling tubes of heat exchangers are crucial for making them smooth functioning after prolonged use. We understand that machines need servicing and repairing work from time to time. As a result, we offer them through our skilled experts. Each retubing report is systematically mentioned, and it is promptly delivered to the customer.

#Repair and retubing of heat exchangers#heat exchanger retubing service#condenser retubing suppliers#shell and tube heat exchanger retubing procedure#titanium heat exchanger manufacturer

0 notes

Text

Shell and Tube Heat Exchanger manufacturer & dealers | Goel Scientific | Canada

We Serve the Best, Long Lasting Shell and Tube Heat Exchanger, Shell and Tube Heat Exchanger Products, manufacturer, Goel Scientific Canada USA

#Best#Top#We Serve the Long Lasting Shell and Tube Heat Exchanger#Shell and Tube Heat Exchanger Products#manufacturer#Goel Scientific Canada USA

0 notes

Text

Kinam Engineering Industries - A heat exchanger specialist from India, are among the leading manufacturers of Shell & Tube Heat Exchangers (STHE) from India. Manufactured in exotic materials like Hastealloy, Titanium, Duplex,Monel, Inconel, Nickel 200, Super Duplex and Nickel.

0 notes

Text

Best heat exchanger manufacturer in Nashik

Are you looking for heat exchanger manufacturer in Nashik? We provide best quality, customized and genuine industrial heat exchanger manufacturers in Nashik. We are committed to deliver excellent customer service at a reasonable price.

#heat exchanger manufacturer in nashik#heat exchanger manufacturer in maharashtra#heat exchanger supplier#heat exchanger#plate heat exchanger manufacturers#spiral heat exchanger manufacturers#shell & tube heat exchanger manufacturers

1 note

·

View note