#Sheet Crimping Curve Machine

Explore tagged Tumblr posts

Text

#roll forming machine#Sheet Crimping Curve Machine#Sheet Crimping Curve Machines#Sheet Crimping Curve Machine in India#Sheet Crimping Curve Machine in Faridabad#Sheet Crimping Curve Machine in Haryana#Sheet Crimping Curve Machine in Delhi NCR

1 note

·

View note

Video

youtube

Sen Fung was established in 1963 as a professional manufacturer of roll forming machines and is the leading manufacturer and exporter of roll forming machines in Taiwan. We are using COPRAR and AUTO CAD softwares for roller design.With more than half a contury of experience and strict quality control, our products meet European CE and International Standards. Products Include Roofing, Tile Sheet, Ceiling T-Bar, Partition Beam, Floordeck, Door Frame, Purlin,Stainless Steel Pipe and Flooring Deck Equipments......etc. Address: No. 131.Sec 3,Zhongshan N.Rd. Danshuei Township,Taipei Country 251,Taiwan Tel:+886-2-26220000 Fax:+886-2-26252086 E-mail:[email protected] Website: http://www.senfung.com

Please check our other videos: High Speed Corrugated Roofing Sheet Roll Forming Machine Corrugated Roofing Sheet Roll Forming Machine Floor Decking Roll Forming Line C&Z Purlin Pre-cut/Punching/Size Adjustable Roll Forming Machine C&Z Purlin Roll Forming Machine Double-Layer Roll Forming Machine Stud & Track Roll Forming Machine Storage Racking Roll Forming Machine Rack Beam Roll Forming Machine Storage Upright Roll Forming Machine Guardrail Roll Forming Machine T-Bar Roll Forming Machine Door Frame Roll Forming Machine Roofing Tile Roll Forming Machine Uncoiler/Decoiler More Videos

#curving machine#crimping machine#roofing sheet crimping machine#bending machine#roll forming machine#roll forming line#Cold Roll Forming Machine#Rollformer#Roll Forming#roll forming machine manufacturers

0 notes

Video

tumblr

Corrugated sheet roll forming machine Will be sent to Ireland. HANGZHOU ROLL FORMING TECHNOLOGY CO., LTD Website: www.hzrollforming.com #machine #Guardrail #Gutter #Downspout #pipe #DOOR #Tube #roof #tiles #panel #shutters #CableTray #AG #Ridge #Slitting #Decoiler #Recoiler #Upender #Stackmaster #Curving #Crimping #Purlin #doorframe #windowframe #Doubllayer #rollformingmachine #coldrollformingmachine #rollformingline

0 notes

Text

Knit fabrics are constructed by interloping one or more sets of yarns

Common examples of apparel utilizing weft knitted fabric are socks. Knitting is a more versatile manufacturing process, as entire garments can be manufactured on a single knitting machine, and it is much faster than weaving. However, due to the looping, more yarn is required to manufacture a knitted garment than a comparable woven garment. Thus any cost savings gained in manufacturing speed are offset by the higher materials cost.

Knits are comfortable fabrics, as they adapt to body movement. The loop structure contributes to elasticity beyond what is capable of the yarns or fibers alone. A knit fabric is prone to snagging, and has a higher potential shrinkage than a woven fabric. The loop structure also provides many cells to trap air, and thus provides good insulation in still air. Knits are not typically very wind- or water-repellent.

Knit fabrics are composed of intermeshing loops of yarns. There are two major types of knits: weft knits and warp knits, as illustrated in Fig. 4.7. In weft knits, each weft yarn lies more or less at right angles to the direction in which the fabric is produced, and the intermeshing yarn traverses the fabric crosswise. In warp knits, each warp yarn is more or less in line with the direction in which the fabric is produced, and the intermeshing yarn traverses the fabric lengthwise. Similar to the way that woven fabrics have warps and wefts, knit fabrics have courses and wales, which lie in the crosswise and lengthwise direction, respectively. However, unlike woven fabrics, courses and wales are not composed of different sets of yarns; rather are formed by a single yarn.

Weft blend knitted fabrics are produced predominantly on circular knitting machines. The simplest of the two major weft knitting machines is a jersey machine. Generally, the terms circular knit and plain knit refer to jersey goods. The loops are formed by knitting needles and the jersey machine has one set of needles. Typical fabrics are hosiery, T-shirts, and sweaters.

Rib knitting machines have a second set of needles at approximately right angles to the set found in a jersey machine. They are used for the production of double-knit fabrics. In weft knits, design effects can be produced by altering needle movements to form tuck and miss stitches for texture and color patterns, respectively. Instead of a single yarn, several yarns can be used in the production of these structures. This increases the design possibilities.

‘Loop’ is the basic unit of knit fabric. As illustrated in Fig, 4.7a, in weft knits, a loop, called a needle loop, consists of a head and two legs, and the section of yarn connecting two adjacent needle loops is called the sinker. In warp knits, the needle loop is divided into overlap and underlap, as illustrated in Fig. 4.7b. Each loop in a printed fabric is a stitch. Alternative to fabric count for woven fabrics, cut (or gauge) and stitch density are used to represent the closeness of the intermeshing loops. Cut or gauge indicates the number of knitting needles per unit length along the crosswise or lengthwise direction. The greater the number, the closer together the loops are to each other. Stitch density is the number of stitches per unit area, obtained by multiplying the number of courses per inch (25 mm) by the number of wales per inch (25 mm). Like woven fabrics, a knit fabric also has a technical face and a technical back and can differ in appearance on each side. The technical face is the side where the loops are pulled toward the viewer. Knit fabric also has an effect side, which is intended to be used outermost on a garment or other textile product. In some cases, the technical face and the effect side are the same; but in others, they are opposite.

Gel Knit® fabric is a small diameter weft knitted tube. This is knitted on a small diameter circular knitting machine with the provision for the positive feeding of two separate yarns. Positive feeding is used to ensure the good quality assurance required for a medical product.

The main yarn that is knitted is a staple (spun) yarn of cellulose. This may be any normal cellulosic textile material such as cotton or a number of different reconstituted cellulose materials such as lyocel or viscose. As will be described later in this paper, the cellulose is the precursor material since it will be chemically converted after knitting into the Gel forming material.

The second yarn is a very thin continuous filament nylon which acts as reinforcement and holds the fabric together after the Gel has been formed and the Gel forming yarn has lost all form and stability. The total nylon content of the fabric is about 10%.

Warp knit fabric is similar to that of a woven fabric in that yarns are supplied from warp beams. The fabric is produced, however, by intermeshing loops in the knitting elements rather than interlacing warps and wefts as in a weaving machine. Warp knitted fabric is knitted at a constant continuous width. This is achieved by supplying each needle with a yarn (or yarns) and all needles knit at the same time, producing a complete course (row) at once. It is also possible to knit a large number of narrow width fabrics within a needle bed width to be separated after finishing. In comparison with weft-knit structures, warp knits are typically run-resistant and are closer, flatter and less elastic.

The two common warp-knit fabrics are tricot and raschel (Fig. 10.9). Tricot, solely composed of knit stitches, represents the largest quantity of warp knit. It is characterized by fine, vertical wales on the surface and crosswise ribs on the back. Tricot fabrics may be plain, loop-raised or corded, ribbed, cropped velour or patterned designs. It is commonly used for lingerie owing to its good drapability. It is used for underwear, night-wear, dresses, blouses and outerwear.4 Tricot fabric is used in household products such as sheets and pillowcases. It is also be used for upholstery fabrics for car interiors.Most warp cotton stripe jersey knit fabrics tend to curl, including the most important type known as Jersey stitch (in the USA) or Locknit stitch (in the UK). If they receive appropriate heat treatment, synthetic warp knit fabrics do not curl. In dyeing, finishing, cutting and sewing garments, it helps to know the face and back of the fabric and its curling propensity. When a greige nylon Jersey stitch fabric is put on a table technically upright (having the loop side up), the top and bottom edges of the fabric will curl upwards or towards the loop side or technical face. However, the side edges will curl under the fabric towards the float or technical backside of the fabric.

If nylon Jersey stitch fabric is heat set it will not curl, but if that fabric is laid on the table technically upright and it is pulled sideways on the top edge of the fabric, the fabric will curl towards the loop side. There are some warp knit structures that will not curl in the greige state.Plain warp-and weft-knitted structures are not commonly used for composite applications due to their inherent anisotropy in the wale and course directions. This causes the fabric preform to roll up on itself making handling and manufacturing more difficult. This problem is solved by using weft-knit structures such as the 1 × 1 rib and milano rib, which exhibit balanced properties because of their through-thickness symmetry. However, the highly curved fibre architecture, or crimp, present in these and any knitted structure, means that composites produced using these structures exhibit relatively poor mechanical performance. Characteristics of high conformability and low strength make them ideally suited to producing semi-structural complexly shaped components.

To help increase mechanical performance, insert yarns can be placed between the planes of loops in either the warp or weft direction. The technique can be used for both warp-and weft-knitted fabrics which allow the insert yarns to remain perfectly straight, giving a greater yarn to fabric translational strength. This results in an increase in the composite stiffness and strength along the insert direction. Warp-and weft-knitted fabrics with inlay yarns are termed unidirectional knitted fabrics and the incorporation of insert yarns in two directions creates biaxial knitted fabrics.

8.4.1 Multiaxial warp knits

Multiaxial Warp Knit (MWK) fabric is a further development of this idea by utilising layers of insertion yarns for the in-plane reinforcement and warp stitch yarns for the through-thickness reinforcement. They consist of one or more parallel layers of yarns held together by a warp knit loop system. Theoretically, as many layers as preferred can be used but typical commercially available machines only allow four layers (Du and Ko, 1996). The purpose of the knit loops is to hold the layers of unidirectional yarns together, but it has also been proven to be the key to increasing the damage tolerance of the material (Zhou et al., 2005).

These types of knitted structure are termed non-crimp structures and can be produced in a single knitting process (Du and Ko, 1996). They are particularly suitable for thin to medium thickness parts. The combination of the warp-knitted structure and non-crimp yarns means they have the ability to conform to complex shapes as well as the potential to meet the demands of primary load bearing applications.

MWKs have evolved through structural modifications of warp-knitted fabrics and are predominantly fabrics with inlay yarns in the warp (90°), wale (0°) and bias (± θ°) directions. Warp, weft and bias yarns are held together by a chain or tricot stitch through the thickness of the fabric (Du and Ko, 1996). Layers of 0° need to be placed somewhere other than the top or bottom layer to ensure structural integrity. The amount of fibre and the orientation of the inlay yarns can be controlled, which is advantageous for preform engineering. As a result, the insert yarns are made from a much higher linear density yarn than the stitch yarns, since they form the load-bearing component of the fleece fabric structure (Du and Ko, 1996). Figure 8.4 shows the configuration of the chain and tricot MWK structures.Yarns in a simple weft-knitted structure, as shown in Figure 11.13a, lack the long continuous paths found in woven fabrics and there would be stress concentrations where yarns cross one another. This limits their mechanical performance, but as shown in Chapter 3, they do have applications as composites. In the free state, the knit fabric shows a low resistance to extension and shear, with accompanying area change, until the yarns jam together. This means that they are easily draped into complex shapes.

0 notes

Text

Some Known Facts About Metal Roofing Installation - The Family Handyman.

Corrugated roof covering panels can be made from aluminum, galvanized steel (G-60, or G-90 steel), galvalume coated steel, and also stainless-steel. When going with a long long-term economical service, galvalume steel provides an optimum combination of price effectiveness and product long life and also integrity. When coated with a Kynar covering, corrugated roof can offer significant power savings and certify for LEED structure credit scores, issued by United States eco-friendly building council.

Corrugated steel roof covering panel presented over is LEED certified, inexpensive roofing solution for business and also industrial usages. It is light weight, provides solar reflectivity, as well as great thermal emmitance, which will certainly assist maintain the structure cool. The drawback of utilizing corrugated roof such as 5 v crimp, R panels, and also U panels, is that all corrugated roof covering systems come with subjected bolts.

As you can see in a representation above, corrugated 36 inch R panels are set up using a 4 inch overlap at a 32 inch mark. The subjected bolts (usually galvanized steel screws shade matched to the panel, and also combined with special rubber washing machines for water-tightness are needed) are installed 12 inches on center, and after that with 16 inches on facility, creating a 12 and also 16 inches overlap.

Throughout the years corrugated roof have actually gained from lots of aesthetic as well as roof covering integrity system particular renovations, which now makes it a considerable choice to standard asphalt shingle roofings that enter into land fills after 15 years of solution. Although steel roof covering is extra expensive than asphalt tile, corrugated roofing is rather budget-friendly compared to standing seam.

The Facts About Introduction To Metal Corrugated Roofing Sheets - Garvin ... Revealed

youtube

youtube

Nevertheless, remember, that steel roof with subjected fasteners might need re-tightening some every ten years or so. Additionally, ought to you determine to invest in a corrugated roof, I suggest that you select light weight aluminum, or galvalume steel corrugated roofing system covered with Kynar 500 covering, not the inexpensive acrylic paint surface, which will certainly discolor swiftly.

The panel provided over, is V-- 5 crimp panel, with exposed fasteners. It can actually be made use of for domestic roof covering tasks. V 5 Crimp roof panel, as well as its installation (materials and labor) is instead cost effective when compared to standard domestic steel roof such as steel roof shingles, trembles, ceramic tiles, and standing seam roofing.

I got ta say uyouguys are really fantastic. I received my order today, earlier after that anticipated. Whatever was spot on. And also thanks to your impressive do it yourself video clips, that I have actually supervised and over, I have constructed a beautifu L carport by myself worth over 10 thousand bucks for less after that 4.

For many years, home owners have counted on the application of corrugated roof covering sheets made from steel to secure their residences from varying climate components. Nevertheless, as increasingly more makers ventured in the production of this kind of roof covering, their quality as decreased significantly for many years hence leaving them with a bad track record.

Indicators on 7/8" Corrugated Metal Roofing And Metal Siding. Buy Direct ... You Should Know

Fortunately, constant technological improvements have presented a way to enhance their quality without racking up their cost. They are currently consisted of light-weight overlapping metal plates that can currently be cheaply mass-produced. Corrugated metal roof materials sold these days are surprisingly resilient, and are capable of holding up against consistent direct exposure to unsafe outside components.

If you are considering setting up corrugated steel roofs in your house, it is essential that you gauge the size of your roof https://www.fema.gov/media-library-data/20130726-1706-25045-9347/chapter8.pdf to establish the number of steel sheets you really need. Those that will certainly be employing roofing contractors won't need to stress over getting roofing measurements given that they will be the one to do it for you.

Step the size, size and slope of the roof covering to aid you compute how many roofing sheets you have to obtain. Once you have actually determined the variety of steel roof sheets that you require, you might now begin canvassing the rate of corrugated metal sheets from various roof manufacturers. Compare as well as contrast the estimate that you have actually collected to determine which one offers the most effective as well as most affordable bargain.

When selecting the roof sheets, you need to keep in mind of the kind of corrugation utilized in them. Majority of metal roof covering sheets include curved and also bumpy appearance that correspond those used in plastic ranges. An additional popular corrugation pattern seen in steel roofing sheets is the settled form, which is preferably utilized for roofing decks.

Corrugated Installation And Technical Guide - Amerilux ... Things To Know Before You Buy

Yet overall, corrugated roofing sheets are a superb option for protecting varying kinds of structures as well as residence structures. They are normally affordable as well as are exceptionally long-lasting. Post Resource .

youtube

0 notes

Text

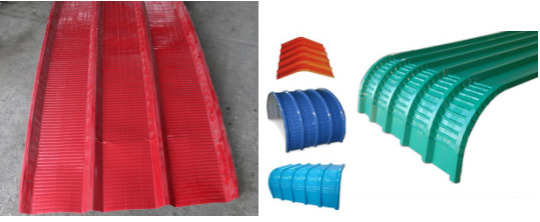

Roofing sheet crimping machine

Roofing sheet crimping machine can produce crimping sheet which used for the edge of roofing sheet or for some shed for bike or others. It is also called curving machine or bending machine. In addition, it has two types: motor crimping machine and hydraulic crimping machine. Hydraulic crimping machine allows you to bend sheet at any degree and you can set the bending degree in PLC. As to the motor crimping machine or electrical crimping machine, it is powered by motor. It only can crimp one type as the molds of the electrical bending machine only support one type but the price is quite lower.

Here are some finished product of crimping sheet

Features of crimping roofing sheet

1. Stylish and attractive design, giving the appearance of a traditional roof tile 2. Resistant to frost, heat, hail and gales, 100% waterproof, due to the lateral run-off channel on each sheet for several models 3. Raw material can be of different colors with elegant and noble looking Widely used as the garden like factory, hotel, exhibition, villa, civil construction

Parameters of roofing sheet crimping machine

Suitable material: color galvanized steel coil 2. Thickness of raw material: 0.3-0.7mm 3. Yield strength of material: 235MPa 4. Working speed: 8-10m/minute 5. Step distance: adjustable according to requirement (≥250mm) 5. Uncoiler loading capacity: max capacity: 5000kg 6. Controlling system: PLC with the best brand 7. Power: 3+3kW 8. Voltage: 380V 50Hz 3 phases 9. Cutting way: motor drive or hydraulic drive 10. Machine's size: about 2x1.5x1.4m (depend on final design) 11. Total weight: 2.2 tons

Features of roofing sheet crimping machine:

1. Precise forming 2. High-solid forming stand guarantees the goods and uniform high-quality of final product 3. Operating automatically minimizes the tolerance of cutting length

The application of crimping roofing sheet

Our products are widely used in various industrial factory, beauty spot, holiday village building, hotel, exhibition, easy steel building manufacturing, and have features such as nice appearance and durable.

Here is a video of the machine for your reference:

youtube

If you want to know more detail information about this machine, please feel free to contact with us.

Email: [email protected]

Whatsapp: +8615127755788 and +8613733275488

1 note

·

View note

Text

Little Known Facts About Metal Fab Shop

Introduction Steel construction includes the making of metal frameworks and parts by controling the raw material-- normally structural steel and sheet metal-- with a variety of procedures. The term covers a broad range of tasks, from sheet metal fabrication for construction projects, to machined parts and bespoke items for manufacturers. Workshops that are experts in metal manufacture are http://northsidesteelwork.ie/balustrades known as 'fab stores'. Regular processes involved in metal construction include: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching. As soon as the components have been made, they could have to be constructed. Setting up may entail welding, binding with adhesives, riveting, crimped joints or threaded fasteners. The parts or settings up may then be treated by a process of sandblasting, priming, powder or painting finish, if needed. The ended up item ought to subject to cautious evaluation to guarantee it follows the specification prior to leaving the fab shop. Cutting

youtube

The wanted shape can be developed by getting rid of unwanted material from a block of metal, in a process known as machining. Steel is cut as called for utilizing different devices, including: Saws Industrial saws such as band saws and big circular saws could cut steel in straight-lines. Angle grinders are portable power devices fitted with an unpleasant disc used for cutting, brightening and grinding. Shears Shears are industrial makers, that been available in a large range of configurations and dimensions, efficient in reducing sheet steel of different densities. They operate in similarly as a set of scissors, with opposing blades, one being fixed and the various other relocating an angled levering movement. Different kinds of shears include: Hand shears: Also known as 'aviation snips', these are straightforward, hands-on tools used to reduce slices of metal. Power shears: These can cutting sheet metal quickly and with less handbook initiative. Nonetheless, most are not able to reduce complex forms or tight radii and so tend to lose product. Throatless shears: These are hand-operated and make use of a hinged blade that swings to reduce metal lying on https://www.washingtonpost.com/newssearch/?query=metal fabrication a fixed surrounding blade. These are capable of cutting in straight lines or shapes and minimise waste product. Plasma and laser cutters High definition plasma reducing strategies are utilized to accomplish elaborate forms. With the integration of computer helped layout and computer system aided manufacturing, the cutting process can be achieved flawlessly, with minimal waste. Bending The flexing steel can be accomplished by a couple of strategies: The most basic approach is kind flexing, in which metal is curved over an edge or form located under the metal. This can be done manually or with tools such as hammers and forming dollys to bend steel around the Additional info required shape. Metal brakes are one of the most common http://northsidesteelwork.ie technique of achieving clean, exact bends. The Click for source procedure involves placing the metal on a flat, gated surface, clamping a flat bar in addition to it, and raising the gated portion to bend the steel to the desired angle. Shrinking One of the most common techniques of shrinking steel consist of: Putting: A simple technique that entails requiring metal with each other in between a gap or folding steel over at the sides. Shrinker: This is a lever-operated device with moving distinctive jaws that grasp sheet steel from the bottom and leading and compel it together gently. Certain locations can be very carefully worked to diminish as required. This is a more accurate yet slower approach. Warmth diminishing: This entails heating an over-stretched area with a blowtorch till it is almost red hot, as the metal shrinks when it cools. Diminishing discs can be put on angle grinders that use friction to produce warmth. Stretching The most typical methods of stretching steel include: Hammer and dolly: This is the simplest strategy and involves holding an object behind the metal and striking the opposite with a hammer, compeling the metal to press and stretch. Cot: This is a mechanically-operated device just like the shrinker, that puts metal between 2 flat-textured jaws which draw it apart slowly. English wheel: This method uses wheels that roll back and forth over the flat metal. Welding The most typical approaches of welding metal to create bigger and more complicated parts include: Oxy-acetylene welding This is the earliest form of welding but is still commonly utilized. Containers of oxygen and acetylene are blended with an adjustable torch to develop a regulated flame to warm the steel. Throughout home heating, a filler pole is included that joins the steel together. These welds are the simplest to planish (smooth out) with a hammer and dolly, enabling the weld joint to be as level as feasible. TIG welding This involves a torch that has a non-consumable electrode that creates a tiny, specific electric arc that melts the base metal. Filler rods are contributed to the puddle of molten metal to join the parts with each other. This is a much more exact technique than oxy-acetylene. MIG welding This is one of the most usual technique and includes an electric motor that is utilized to feed the filler wire with the suggestion of a MIG gun. The wire is melted into the weld joint, fusing the metal together. Steel fabrication entails the making of steel frameworks and elements by controling the raw product-- usually structural steel and sheet metal-- with a range of processes. The term covers a broad array of tasks, from sheet metal construction for building tasks, to machined components and bespoke products for manufacturers. Shears are commercial equipments, that come in a vast variety of setups and sizes, capable of reducing sheet steel of various densities. Shrinker: This is a lever-operated tool with moving textured jaws that understand sheet steel from the top and lower and compel it together lightly. Filler rods are included to the pool of liquified steel to join the components with each other.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Text

Get The Competitive Edge With One Of These Ideas On Northside Steel Work

Introduction Metal fabrication entails the making of metal structures and components by manipulating the raw product-- normally structural steel and sheet metal-- via a range of procedures. The term covers a broad series of activities, from sheet metal fabrication for building jobs, to machined parts and bespoke items for manufacturers. Workshops that specialise in metal manufacture are known as 'great shops'. Typical procedures associated with steel construction include: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching.

When the parts have been made, they may should be set up. Assembly could involve welding, binding with adhesives, captivating, crimped seams or threaded bolts. The assemblies or parts may then be treated by a procedure of sandblasting, powder, priming or painting finishing, if required. The completed product ought to subject to mindful evaluation to ensure it abides by the specification before leaving the fab store. Reducing The wanted shape can be developed by eliminating undesirable material from a block of metal, in a procedure referred to as machining. Metal is reduced as required using different tools, including:

youtube

Saws Industrial saws such as band saws and huge circular saws could cut steel in straight-lines. Angle mills are portable power devices fitted with a rough disc utilized for reducing, grinding and brightening. Shears Shears are commercial makers, that come in a vast array of dimensions and setups, efficient in cutting sheet metal of various densities. They operate in the same way as a pair of scissors, with opposing blades, one being fixed and the other relocating an angled levering movement. Different kinds of shears include: Hand shears: Also called 'aviation snips', these are simple, manual devices utilized to reduce slices of metal. Power shears: These are capable of reducing sheet steel promptly and with less handbook effort. A lot of are not able to cut complex forms or limited distance and so have a tendency to lose material. Throatless shears: These are hand-operated and make use of a hinged blade that turns down to http://northsidesteelwork.ie/powder-coating-and-galvanising cut metal lying on a fixed adjacent blade. These are capable of cutting in straight lines or shapes and minimise waste material. Plasma and laser cutters High definition plasma reducing methods are made use of to achieve elaborate forms. With the assimilation of computer system assisted style and computer system aided manufacturing, the cutting procedure can be achieved perfectly, with minimal waste. Flexing The flexing metal can be attained by https://en.search.wordpress.com/?src=organic&q=metal fabrication one of two strategies: The most basic approach is form flexing, where metal is curved over a side or shape situated under the metal. This can be done manually or with devices such as hammers and forming dollys to bend steel around the needed shape. Steel brakes are the most typical method of achieving tidy, exact bends. The process entails placing the metal on a flat, gated surface, securing a flat bar in addition to it, and raising eviction part to bend the metal to the preferred angle. Diminishing The most usual methods of shrinking steel include: Putting: A simple strategy that includes compeling steel with each other between a gap or folding steel over at the edges. Shrinker: This is a lever-operated tool with moving textured jaws that comprehend sheet steel from the lower and top and compel http://northsidesteelwork.ie it with each other lightly. Particular areas can be meticulously worked to reduce as required. This is a much more specific yet slower approach. Warmth diminishing: This entails home heating an over-stretched location with a blowtorch until it is virtually red hot, as the steel diminishes when it cools. Shrinking discs can be put on angle grinders that make use of rubbing to produce heat. Extending One of the most common techniques of stretching metal consist of: Hammer and dolly: This is the simplest technique and includes holding an object behind the metal and hitting the opposite side with a hammer, requiring the metal to compress and extend. Stretcher: This is a mechanically-operated tool just like the shrinker, that puts metal between two flat-textured jaws which draw it apart slowly. English wheel: This strategy makes use of wheels that roll back and forth over the level metal. Welding One of the most usual methods of welding steel to create bigger and extra complex parts include: Oxy-acetylene welding This is the oldest type of welding but is still widely made use of. Storage tanks of oxygen and acetylene are blended with a flexible torch to develop a controlled fire to warm the metal. Throughout heating, a filler pole is added that joins the steel together. These welds are the most convenient to planish (ravel) with a hammer and dolly, making it possible for the weld joint to be as level as possible. TIG welding This entails a lantern that has a non-consumable electrode that creates a tiny, specific electrical arc that melts the base metal. Filler rods are contributed to the puddle of liquified steel to join the components together. This is a much more accurate approach compared to oxy-acetylene. MIG welding This is one of the most typical technique and includes a motor that is utilized to feed the filler wire with the idea of a MIG gun. The wire is melted into the weld joint, fusing the metal with each other. Steel fabrication includes the production of steel structures and parts by controling the raw product-- generally architectural steel and sheet metal-- via an array of processes. The term covers a wide array of activities, from sheet metal fabrication for building projects, to machined parts and bespoke items for producers. Shears are commercial devices, that come in a broad array of sizes and setups, qualified of cutting sheet steel of various thicknesses. Shrinker: This is a lever-operated tool with moving textured jaws that grasp sheet steel from the bottom and top and force it with each other lightly. Filler rods are included to the puddle of molten steel to join the parts together.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Video

youtube

C Purlin Roll Forming Machine (Máy Cán Xà Gồ C)

C PURLIN ROLL FORMING MACHINE HOTLINE: 📞 +84 988 731 731 📧 [email protected] See more below ⏬ ⏬ ⏬ * Thickness: 3.0 mm. G550 * Speed: 14-18 M/m (stop cutting and punching) * Fully automatic operation

--------------------------

Other Technical data on WEBSITE: http://ameco.vn/en/purlin-roll-forming-machine/C-Purlin-roll-forming-machine.html

---------

C Purlin Roll Forming Machine on ALIBABA: https://wwwamecovn.trustpass.alibaba.com/product/148503143-106344779/C_Purlin_roll_forming_machine.html

C Purlin Roll Forming Machine on YOUTUBE: https://youtu.be/_QoTrmhO_P8 https://youtu.be/i9uWNvs62J8

---------------------

SEE OTHER AMECO VIDEOS BELOW ⏬ :

* Roofing roll forming machine: https://youtu.be/dABYy2BuDOE

* Excellent Ameco Auto Uncoiler/ Decoiler 7.5 Tons: https://youtu.be/cBtNi3TptvU

* Ameco Leveling Slitting Cutting To Length Machine: https://youtu.be/nvGckPJjC4Q

* Ameco Seam Lock Roofing Roll Forming Machine (Screwless Metal Roof Panel Making Machine): https://youtu.be/Vo4FptiwpCg

* Roof Panel Crimp Curving Roll Forming Machine: https://youtu.be/Ba9V5O-Ie3A

* KlipLok/ Clip Clock Roofing Sheet Roll Forming Machine _ Screwless Roofing: https://youtu.be/GWIlt6OJjyI

* AMECO Advance Double Layer Roofing Roll Forming Machine: https://youtu.be/guXZmRDK8Ms

* High Speed Corrugated Sheet Roof Roll Forming Machine (60m/min): https://youtu.be/2kztsJHZkDw

* AMECO Tile Roofing Roll Forming Machine (Kiwik Design): https://youtu.be/pADgTq61JWo

* Metal Folding Machine (Semi-Automatic) - Máy Gấp Tôn Bán Tự Động: https://youtu.be/xGq0WwNnrn4

* Z Purlin Roll Forming Machine - Máy Cán Thanh Xà Gồ Z: https://youtu.be/EJGKVC2VuDI

- QUALITY IS OUR FIRST PRIORITY -

0 notes

Text

Hyperallergic: Jack Whitten’s Walls

Jack Whitten, “Quantum Wall, II (Missing Matter)” (2016), acrylic on canvas, 121.9 x 243.8 cm / 48 x 96 inches (all images © Jack Whitten and courtesy Hauser & Wirth)

Born in Besemer, Alabama, in 1939 — during the Jim Crow era when rigid segregation was in effect — Jack Whitten belongs to the generation of abstract artists that emerged in the early 1970s, more than a decade after Minimalism, Pop Art, and Color Field first came on the scene. If we take a generation to mean about five years, then Mary Heilmann (b. 1940), Elizabeth Murray (1940–2007), and Thomas Nozkowski (b. 1944) also belong to this generation. I mention these three artists because each of them hit their stride in the 1970s, or, after the “1960s,” when, according to Douglas Crimp, in his essay “The End Of Painting” (1981), “painting’s terminal condition finally seemed impossible to ignore. The symptoms were everywhere…”

While all four artists are innovators, Whitten is the most relentless experimenter with materials in a generation of abstract artists who have yet to receive their due, perhaps because no one has come up with a catchy and marketable name for them, like the “Minimalists” or “The Pictures Generation.” By materials, I do not just mean paint. Whitten has also used Styrofoam, hair, eggshells, molasses, copper, and coal ash in his works.

Jack Whitten, “The Third Entity #10” (2016), black graphite and renaissance wax on evolon 76.2 x 55.9 cm / 30 x 22 inches

Whitten’s preoccupation with experimentation has deep roots in his experience. In an interview with Kenneth Goldsmith that appeared in BOMB (Summer 1994), Whitten stated:

I’m convinced today that a lot of my attitudes toward painting and making, and experimentation came from George Washington Carver. He made his own pigments, his own paints, from his inventions with peanuts. The obsession with invention and discovery impressed me.

One other thing Whitten said to Goldsmith seems particularly relevant:

It took 20 years to get into a position where I could work myself out of history. Every painter wants to escape art history. And now there’s a curve that’s leading me out. My emphasis on pop culture, video, science, on the urban environment, and everything on up to the Big Bang theory excites me. I see that as a way, using those metaphors, that I can escape art historical references.

These were not the first thoughts that I had when I went to see the exhibition, Jack Whitten, at Hauser & Wirth (January 26–April 8, 2017), the artist’s first with this international gallery. My first response was luscious perplexity, which only the very best artists are able to swiftly induce in viewers. How does one visually account for this work and all its contradictions?

The first paintings to greet the view belong to the series, The Portals. While the three similarly sized paintings share the same format of a circle floating inside a square, their materiality and the process by which they were made distinguishes them. They are not variations on a theme, but distinct works within a series. Whitten works magic with acrylic: he can get it to look like a polished slice of stone, a sheet of rumpled industrial plastic, or the pitted surface of a moon seen through a powerful telescope.

Jack Whitten, “The Third Portal” (2016), acrylic and mixed media on canvas, 121.9 x 121.9 cm / 48 x 48 inches

Whereas the circle and the title suggest a doorway or an opening, the dense material surface of the circle contradicts this. The opposition between opening and solid barrier became more apparent as I moved closer to the painting: no one achieves a surface like Whitten. In “The Third Portal” (2016), he has filled the area around the solid black circle’s uneven surface with tiny, glittering, mosaic-like pieces. Other bits of color and light are scattered throughout the deep blue bricks. The bricks are made of paint that has been cast and cut, but they do not come across as machine produced.

Since the early 1970s, Whitten has been a process painter who has invented a variety of ways to start and complete a painting. In his paintings from the 1970s, he used various homemade and repurposed devices to pull acrylic paint across the painting’s surface. There was a feeling of speed, of looking at something that was blurred, at a frozen motion. In the paintings in this show in which Whitten filled the surface with his cast bricks, I had the feeling that the artist was slowing down time — that the joy he gets from making these paintings is of a different nature than what he experienced in his earlier work. The other thing that strikes me about the paintings, particularly the ones from his series of Quantum Walls, is the way he brings matter and immateriality, the visceral and invisible, together.

Jack Whitten, “Quantum Wall, II (Missing Matter)” (2016) (detail)

The spectrum of experience in these paintings is vast. One can stand at the far end of this spacious gallery and, as you walk closer to the painting, something happens at every step. First there is this ghostly apparition (or discoloration) on the painting’s faceted surface. It hovers between legibility and illegibility. In the largely violet “Quantum Wall, III (The Geometry of Being An Octopus)” (2016), the darker shades of black and violet “staining” the wall appear to be on the verge of coalescing into an image but never do. Whitten seems to be getting at our desire to see, particularly in the realm of science, and how our expectations can ever be met. For each thing we learn leads to more questions for which we do not have the answers. It is as if Whitten’s “walls” underscore the physical limit of our perceptions: the “stains” on them remind us that much of reality exists beyond our grasp.

The conversation Whitten establishes between visibility and invisibility goes in myriad directions — from social matters of race to philosophical and scientific speculations about the nature of the universe. At the same time, Whitten’s walls evoke the invisible and forgotten laborer. His masonry of cast paint evokes the anonymous laborers that built the Americas, from those who inlaid the Mayan mosaics, to the slaves who built the White House, to the bricklayers who colored the mortar the way Frank Lloyd Wright wanted, to the welders who erected Santiago Calatrava’s transit hub in Lower Manhattan. By making work that shares something with the constructions of anonymous laborers, Whitten reminds us that there is more to artmaking than fabrication or craftsmanship. Moreover, the world is not divided just into employer and employee, which is a model in need of serious revision. Whitten’s art is a challenge to mainstream thinking on many different levels, from the relationship of subject matter to abstraction to the connection between artmaking and art. Isn’t it time to acknowledge these challenges? Abstract art did not culminate in the 1960s and it is about time we got around to embracing that fact, and not the fake news that institutions and various authorities have repeatedly tried to foist on us.

Jack Whitten continues at Hauser & Wirth (548 West 22nd Street, Chelsea, Manhattan) through April 8, 2017.

The post Jack Whitten’s Walls appeared first on Hyperallergic.

from Hyperallergic http://ift.tt/2kBhPbL via IFTTT

0 notes

Photo

Double layer roll forming machine makes 2 different profiles sheets in one machine.The height of feeding device for this double-layer roll forming machine can be adjusted motorized vertically,driven by a motor. Hangzhou Roll Forming Technology Co., Ltd. Website: www.hzrollforming.com We are a professional manufacturer and exporter of roll forming machines, providing services to countries all over the world. If you need any technical advice or budget advice, please contact us for immediate and professional solutions. #machine #Guardrail #Gutter #Downspout #pipe #DOOR #Tube #roof #tiles #panel #shutters #CableTray #AG #Ridge #Slitting #Decoiler #Recoiler #Upender #Stackmaster #Printing #Curving #Crimping #Purlin #doorframe #windowframe #Doubllayer #rollformingmachine #coldrollformingmachine #rollformingline

0 notes