#Shrink wrapping Machines

Text

https://aimtechindia.in/semi-automatic-shrink-wrapping-machine.php

#Semi Automatic Shrink Wrapping Machine#Automatic Shrink Wrapping Machine#Bottle packing machine#shrink wrapping machines

1 note

·

View note

Text

Shrink Wrapping Machine Manufacturer in Delhi: Leading the Way with JoyPack

Elevate your product protection with JoyPack's cutting-edge shrink wrapping machines. As a leading shrink wrapping machine manufacturer in Delhi, we deliver customized, high-quality solutions for enhanced product appeal, cost-efficiency, and environmental responsibility. Experience the JoyPack difference today.

0 notes

Text

Tanishka Packaging Machines: Leading the Way in Shrink Wrapping Technology in Rajasthan

In the bustling industrial landscape of Rajasthan, Tanishka Packaging Machines stands as a beacon of innovation and reliability in the realm of shrink wrapping technology. Specializing in the design, manufacture, and distribution of shrink wrapping machines, Tanishka Packaging Machines has carved a niche for itself by offering state-of-the-art solutions that cater to diverse industrial needs.

Innovative Technology

At the heart of Tanishka Packaging Machines’ offerings lies their commitment to innovative technology. Their shrink wrapping machines are meticulously designed to ensure efficiency, durability, and precision in packaging operations. Whether it’s for bundling products together, protecting them from external elements, or enhancing their shelf appeal, their machines are engineered to deliver consistent and high-quality results.

Wide Range of Products

Tanishka Packaging Machines offers a versatile range of shrink wrapping solutions to meet the varying demands of industries across Rajasthan. From semi-automatic machines suitable for small-scale enterprises to fully automated systems for large-scale production facilities, their product lineup caters to businesses of all sizes. Each machine is crafted with attention to detail, incorporating the latest advancements in packaging technology.

Customer-Centric Approach

Beyond their technological prowess, Tanishka Packaging Machines distinguishes itself with a strong customer-centric approach. They prioritize understanding the unique requirements of each client and offer customized solutions that align perfectly with their operational needs. This personalized service has earned them a reputation for reliability and customer satisfaction throughout Rajasthan.

Quality Assurance

Quality is paramount at Tanishka Packaging Machines. Every machine undergoes rigorous testing and quality assurance processes to ensure optimal performance and longevity. This commitment to excellence extends to their after-sales service, where they provide comprehensive support, maintenance, and troubleshooting assistance to maximize the uptime of their machines.

Industry Applications

Tanishka Packaging Machines serves a diverse array of industries in Rajasthan, including food and beverage, pharmaceuticals, cosmetics, electronics, and more. Their shrink wrapping solutions find application in packaging various products such as bottles, boxes, jars, trays, and bulk items, offering versatility and adaptability to different production environments.

Future Prospects

Looking ahead, Tanishka Packaging Machines remains dedicated to pushing the boundaries of shrink wrapping technology. They continue to invest in research and development to stay ahead of industry trends and technological advancements. By staying at the forefront of innovation, they aim to empower Rajasthan’s industries with cutting-edge packaging solutions that enhance efficiency, reduce costs, and elevate product presentation.

In conclusion, Tanishka Packaging Machines exemplifies excellence in the field of shrink wrapping machines in Rajasthan. With their unwavering commitment to quality, innovation, and customer satisfaction, they have established themselves as a trusted partner for businesses seeking reliable packaging solutions tailored to their specific needs.

0 notes

Text

How Many Types of Shrink Wrapping Machine are there?

Types of Shrink Wrapping Machines

Shrink wrapping machines come in various types to suit different production needs:

L-Bar Sealers: Ideal for sealing individual or grouped products using a sealing bar that creates a “L” shaped seal.

Heat Shrink Tunnels: Used for applying heat evenly to the wrapped product, ensuring a uniform shrink.

Manual vs. Automatic Machines: Manual machines are operated by hand and are suitable for smaller-scale operations, while automatic machines are fully automated, capable of handling high volumes with minimal human intervention.

What is a Shrink Wrapping Machine?

A shrink wrapping machine is a packaging device designed to wrap a product tightly in a protective plastic film. This film is then heated, causing it to shrink and conform to the contours of the product, creating a secure and visually appealing package. Whether used for individual products or grouping items into larger bundles, shrink wrapping ensures products are not only protected from dust, moisture, and tampering but also enhances their aesthetic appeal on store shelves.

How Does It Work?

The operation of a shrink wrapping machine typically involves several key steps:

Film Feeding: A roll of shrink film is unwound and fed into the machine.

Product Placement: Products are placed manually or automatically onto the film in the desired configuration.

Sealing: The machine seals the edges of the film around the product, forming a loose bag or sleeve.

Heat Application: Heat is applied evenly to the film using a heat tunnel or heat gun. This causes the film to shrink tightly around the product.

Cooling: The film cools and solidifies, forming a secure and protective wrap.

Advantages of Shrink Wrapping Machines

The adoption of shrink wrapping machines offers several compelling advantages:

Enhanced Product Protection: Shrink wrap provides a durable barrier against dust, moisture, and physical damage during transit and storage.

Improved Product Presentation: The tight, clear packaging enhances the visual appeal of products, making them more attractive to consumers.

Cost Efficiency: Automating the packaging process reduces labor costs and improves operational efficiency.

Versatility: Shrink wrapping can be used for a wide range of products across various industries, from food and beverage to electronics and pharmaceuticals.

Applications Across Industries

The versatility of shrink wrapping machines makes them indispensable across diverse industries:

Food and Beverage: Used for packaging food items such as trays of fruits, vegetables, and bakery goods.

Retail: Wrapping individual items like books, DVDs, and toys to enhance shelf appeal.

Pharmaceuticals: Ensuring the safety and integrity of medical supplies and equipment.

Sustainability Considerations

While shrink wrapping offers numerous benefits, there are growing concerns about its environmental impact due to plastic waste. However, advancements in biodegradable and recyclable shrink films are addressing these concerns, offering sustainable alternatives without compromising performance.

Conclusion

In conclusion, shrink wrapping machines represent a pivotal advancement in modern packaging technology, offering businesses a competitive edge through improved efficiency, product protection, and visual appeal. As industries continue to evolve, these machines will undoubtedly play an integral role in shaping the future of packaging, balancing innovation with sustainability to meet the demands of a dynamic global market.

Best Shrink Wrapping Machine Manufacturer in India

If you are looking for Best Shrink Wrapping Machine Manufacturer in India, look no further than Ace Packaging Solutions, we are a leading manufacturer and supplier of Shrink Wrapping Machine in India.

For more details, please contact us!

Website :- www.shrinkpackagingmachines.in

Contact No. :- +91–9810264335, 011–65394310

Email :- [email protected]

#Best Shrink Wrapping Machine Manufacturer in India#Shrink Wrapping Machine Manufacturer in India#Shrink Wrapping Machine Supplier in India#ace packaging solution#shrink packaging machine

1 note

·

View note

Text

How Nichrome’s End of Line Machines benefits businesses with efficiency

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

Shrink Wrapping Machines Manufacturer in India

At the heart of ACE Packaging Solutions’. offerings are their state-of-the-art shrink wrapping machines. These machines are meticulously engineered to meet the diverse needs of industries ranging from food and beverage to pharmaceuticals and beyond.

The hallmark of ACE Packaging Solutions. shrink wrapping machines is their versatility. Whether it’s bundling products together for shipping, enhancing product presentation on store shelves, or safeguarding items during transit, these machines excel in delivering impeccable results across various applications.

One of the key features of ACE Packaging Solutions. shrink wrapping machines is their precision. Equipped with advanced technology, these machines ensure that each package is tightly sealed and neatly wrapped, guaranteeing product integrity and minimizing the risk of damage during handling and transportation.

Moreover, ACE Packaging Solutions prioritizes user-friendliness in their machine designs. With intuitive controls and ergonomic features, operators can easily set up and operate these machines with minimal training, reducing downtime and optimizing workflow efficiency.

Durability is another hallmark of ACE Packaging Solutions. shrink wrapping machines. Built to withstand the rigors of continuous operation, these machines boast robust construction and high-quality components, ensuring longevity and reliability even in the most demanding production environments.

In addition to their standard offerings, ACE Packaging Solutions also offers customizable solutions tailored to meet specific customer requirements. Whether it’s accommodating different product dimensions, integrating with existing production lines, or incorporating special features, their team of experts works closely with clients to deliver bespoke packaging solutions that exceed expectations.

Furthermore, ACE Packaging Solutions places a strong emphasis on after-sales support and service. With a dedicated team of technicians and a nationwide network of service centers, they ensure prompt assistance and maintenance to keep their customers’ operations running smoothly around the clock.

In conclusion, ACE Packaging Solutions. shrink wrapping machines represent the pinnacle of packaging innovation. With their unmatched performance, versatility, and reliability, these machines empower manufacturers to optimize their packaging processes, increase efficiency, and stay ahead in today’s competitive marketplace. When it comes to packaging solutions, ACE Packaging Solutions is the name to trust.

For More Details Contact Us!

0 notes

Text

Shrink Wrapping Machine in Coimbatore

0 notes

Text

Eliminate iron and arsenic from your water effectively with Ideas Engineering Works. Explore our advanced Iron Removal Plant solutions for clean and safe drinking water.

#Iron removal plant#Arsenic iron removal plant#Ideas Engineering Works#wave shrink wrapping machine#India

0 notes

Text

Enhancing Packaging Efficiency: The Benefits of Shrink Wrap Machines

Discover the performance and versatility of shrink wrap machines to meet your packaging desires. These machines tightly encase merchandise in a protective film, making sure steady and tamper-proof packaging. With fast packaging speeds and decreased cloth waste, cut-back wrap machines streamline operations while minimizing expenses.

0 notes

Text

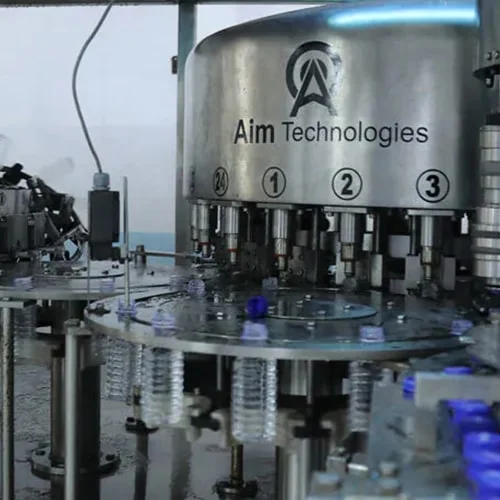

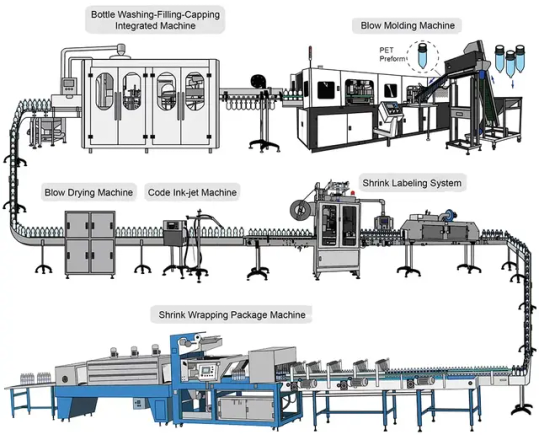

https://aimtechindia.in

Aim Technologies established in 2011 is a leading manufacturer and exporter of Machineries in beverages industry. We specialize in designing, manufacturing high-quality machineries that meet the unique needs of the industry. Our team of experts is dedicated to delivering cost-effective, high-performance solutions, making us the preferred choice in beverages Industry. With years of experience, we have earned a reputation for reliability and customization, allowing us to provide tailored solutions to our clients' unique needs.

#Beverage Filling Machine Manufacturer#Turnkey Mineral Water project#Labeling Machine#Shrink Wrapping Machine#Pet Blowing Machine.

1 note

·

View note

Text

Shrink Wrap: The Ultimate Guide to This Versatile Packaging Solution

Shrink wrap, also known as shrink film, is a ubiquitous material in the packaging industry. Its versatility and practicality have made it a go-to solution for a wide range of products, from groceries and beverages to furniture and industrial equipment. But what exactly is shrink wrap, and how does it work? This comprehensive guide delves into the world of shrink wrap, exploring its applications, benefits, types, and best practices for its use.

Unveiling the Magic: How Shrink Wrap Works

Shrink wrap is typically made from a polymer film, most commonly polyethylene (PE) or polyvinyl chloride (PVC). These films have a unique property – when exposed to heat, they shrink tightly around the product they encase. This creates a secure, tamper-evident seal that protects against dust, moisture, and damage during storage and transportation.

There are two primary methods for applying heat to shrink wrap:

Heat Tunnels: Products are conveyed through a tunnel where hot air shrinks the film uniformly. This method is ideal for high-volume applications.

Heat Guns: Handheld heat guns offer a more portable solution for individual product wrapping or on-demand applications.

The Benefits of Shrink Wrap: A Multifaceted Advantage

Shrink wrap offers a multitude of benefits for businesses and consumers alike:

Versatility: It can be used with a wide variety of product shapes and sizes, making it a highly adaptable packaging solution.

Protection: Shrink wrap provides a barrier against dust, moisture, dirt, and external scratches, ensuring product integrity.

Tamper Evident: The tight seal of shrink wrap indicates tampering attempts, offering an additional layer of security.

Cost-Effective: Shrink wrap is a relatively inexpensive packaging material compared to other options.

Transparency: Clear shrink wrap allows product visibility, enhancing product appeal and facilitating identification.

Bundling: Multiple products can be bundled together using shrink wrap for easier handling and display.

Unitization: Shrink wrap can be used to secure pallets of products, minimizing shifting and damage during transportation.

Weatherproofing: Products can be protected from weather elements like rain and dust when wrapped in shrink wrap.

Portion Control: Shrink wrap can be used to create pre-measured portions or individual servings of products.

Choosing the Right Shrink Wrap: A Matter of Material and Application

Selecting the right shrink wrap depends on the specific application and product characteristics. Here are some key factors to consider:

Material: PE shrink wrap is generally more cost-effective and offers good clarity. PVC shrink wrap provides superior strength and puncture resistance but may be more expensive and have environmental concerns.

Thickness: Thicker shrink wrap offers increased strength and protection for heavier or more delicate products.

Shrink Ratio: This indicates the percentage by which the film shrinks when heated. Choose a shrink ratio that allows for secure wrapping without excessive tightness.

Sealing Properties: Some shrink wraps have self-sealing properties when heated, eliminating the need for additional sealing equipment.

Applications Beyond Imagination: Unveiling Diverse Uses of Shrink Wrap

While commonly used for packaged goods, shrink wrap's versatility extends to a surprising array of applications:

Securing Pallets: Heavy-duty shrink wrap secures pallets of products during transportation and storage.

Preserving Books: Wrapping books in shrink wrap protects them from dust, moisture, and wear and tear.

Weatherproofing Equipment: Construction equipment or outdoor furniture can be protected from the elements with shrink wrap.

Creating Temporary Shelters: Large shrink wrap sheets can be used to create temporary shelters or enclosures for construction sites or disaster relief.

Securing Artwork: Statues, sculptures, or other artwork can be protected during transport or storage with shrink wrap.

Concealing Valuables: Shrink wrap can be used to conceal valuables during transport or storage for added security.

Best Practices for Using Shrink Wrap: Optimizing Performance

To ensure optimal results with shrink wrap, follow these best practices:

Choose the right type and thickness of shrink wrap for your application.

Prepare the product to be wrapped by removing any dust or debris.

Ensure the shrink wrap is taut and wrinkle-free around the product.

Apply heat uniformly using a heat gun or tunnel, following the manufacturer's instructions.

Over-shrinkage can damage the product; aim for a snug but not overly tight fit.

When using heat guns, maintain a safe distance from the shrink wrap to avoid melting or burning.

For added security, consider using tamper-evident tape for high-value products.

Dispose of used shrink wrap responsibly by recycling it whenever possible.

Conclusion: A Versatile and Essential Packaging Solution

Shrink wrap's versatility, affordability, and protective qualities make it an indispensable tool in the packaging industry. From safeguarding everyday goods to securing industrial equipment and even creating temporary shelters, its applications are vast and ever-evolving. By understanding the different types of shrink wrap, its benefits, and best practices for use, businesses and individuals can leverage this remarkable material to enhance product protection, streamline operations, and achieve their specific packaging goals.

0 notes

Text

Innovative Excellence: Tanishka Packaging Machines’ Shrink Wrapping Solutions

In Jaipur, amidst the vibrant tapestry of innovation and tradition, Tanishka Packaging Machines emerges as a beacon of excellence in the realm of shrink wrapping technology. Specializing in state-of-the-art solutions, Tanishka has established itself as a leading manufacturer of shrink wrapping machines, catering to diverse industries with precision and reliability.

Precision Engineering for Optimal Performance

Tanishka’s shrink wrapping machines exemplify precision engineering, designed to meet the rigorous demands of modern packaging requirements. From delicate products requiring gentle handling to robust items needing secure protection, Tanishka ensures every shrink wrapping process is executed flawlessly. The machines are equipped with advanced features that streamline operations while maintaining product integrity, setting new benchmarks in efficiency and effectiveness.

Tailored Solutions for Varied Applications

Recognizing the unique needs of different industries, Tanishka offers customizable shrink wrapping solutions. Whether it’s adjusting machine specifications, integrating specialized features, or providing comprehensive training and support, Tanishka ensures that each client receives a solution tailored to their specific packaging challenges. This flexibility enables businesses in Jaipur and beyond to optimize their packaging processes efficiently.

Commitment to Quality and Innovation

Quality and innovation are at the core of Tanishka’s ethos. Each shrink wrapping machine undergoes rigorous quality assurance checks to uphold superior standards. This commitment not only guarantees reliability and durability but also positions Tanishka as a trusted partner for businesses seeking cutting-edge packaging solutions in Jaipur.

Advancing Industry Standards with Technology

Tanishka Packaging Machines is at the forefront of advancing industry standards through technological innovation. By continuously integrating the latest advancements in shrink wrapping technology, Tanishka empowers businesses to enhance their competitiveness and operational efficiency on a global scale.

Dedicated Customer Support and Service

Beyond manufacturing excellence, Tanishka prioritizes comprehensive customer support. The company’s dedicated service team provides seamless installation, proactive maintenance, and responsive technical assistance, ensuring uninterrupted operation and maximum uptime for their shrink wrapping machines.

Collaborative Approach to Success

Tanishka fosters collaborative partnerships with its clients, understanding their unique requirements and challenges. This partnership approach enables Tanishka to deliver solutions that not only meet but exceed expectations, driving mutual success and long-term relationships built on trust and innovation.

Conclusion

In conclusion, Tanishka Packaging Machines stands as a testament to innovation and reliability in the field of shrink wrapping machines in Jaipur. With a commitment to excellence, quality, and customer satisfaction, Tanishka continues to redefine standards and empower businesses to achieve operational excellence through advanced packaging solutions. For businesses seeking unparalleled shrink wrapping technology, Tanishka remains the definitive choice, dedicated to shaping the future of packaging with ingenuity and expertise.

0 notes

Text

What are the Uses and Advantages of Shrink Wrapping Machine?

What is a Shrink Wrapping Machine?

A shrink wrapping machine is a device designed to wrap a product in a film of plastic or polymer. This film is then heated, causing it to shrink tightly around the product, creating a secure and tamper-resistant seal. The process not only protects the item from moisture, dust, and damage but also enhances its visual appeal, making it more attractive to consumers.

How Does it Work?

Shrink wrapping machines operate through a straightforward yet sophisticated process:

Film Dispensing: A roll of shrink film is unwound and fed through the machine.

Sealing: The product is placed on a conveyor belt or platform where the film is wrapped around it. A sealing bar or wire then creates a seal along the edges of the film, forming a bag around the product.

Heat Application: The wrapped product moves through a heat tunnel or chamber where hot air or infrared radiation is applied. This heat causes the film to shrink uniformly and tightly conform to the contours of the product.

Cooling: After shrinking, the film is cooled quickly to ensure a tight and secure wrap.

Advantages of Shrink Wrapping Machines

The adoption of shrink wrapping machines offers several advantages to businesses across various industries:

Protection: The tightly sealed film provides protection against moisture, dust, and tampering during transit and storage.

Enhanced Presentation: Shrink wrapping enhances the visual appeal of products by providing a clear, glossy finish that showcases the item inside.

Efficiency: These machines can handle high volumes of packaging quickly and consistently, improving overall production efficiency.

Cost-effectiveness: By reducing the need for additional packaging materials and labor, shrink wrapping machines can help lower packaging costs.

Applications of Shrink Wrapping Machines in Industries

Shrink wrapping machines find applications in diverse sectors:

Food and Beverage: Packaging perishable items such as meat, cheese, and beverages to maintain freshness and hygiene.

Retail: Wrapping individual items or creating multi-packs for display and sale in supermarkets and retail outlets.

Pharmaceuticals: Ensuring the safety and integrity of medications and medical supplies during distribution.

Industrial Products: Protecting machinery parts, electronics, and other industrial goods from damage.

Evolution and Innovation

Over the years, shrink wrapping machines have evolved significantly in terms of technology and design. Modern machines feature:

Automated Controls: Touchscreen interfaces and programmable settings for precise control over wrapping parameters.

Energy Efficiency: Improved heating technologies and insulation materials that reduce energy consumption.

Versatility: Capability to handle a wide range of product shapes and sizes with minimal adjustments.

Integration: Compatibility with other packaging systems and processes, such as labeling and palletizing.

Conclusion

In conclusion, shrink wrapping machines represent a cornerstone of efficient and effective packaging solutions in today’s industrial landscape. From protecting goods to enhancing their marketability, these machines continue to play a crucial role in various industries worldwide. As technology advances further, we can expect even more sophisticated capabilities and greater efficiencies from these indispensable tools. Whether in large-scale manufacturing plants or small businesses, the impact of shrink wrapping machines remains profound and enduring.

Top Shrink Wrapping Machine Manufacturer in India

If you are looking for Best Shrink Wrapping Machine Manufacturer in India, look no further than Ace Packaging Solutions, we are a leading manufacturer and supplier of Shrink Wrapping Machine in India.

For more details, please contact us!

Website :- www.shrinkpackagingmachines.in

Contact No. :- +91–9810264335, 011–65394310

Email :- [email protected]

#Shrink Wrapping Machine#Shrink Wrapping Machine manufacturer in India#Shrink Wrapping Machine manufacturer in Delhi#Top Shrink Wrapping Machine manufacturer#Best Shrink Wrapping Machine manufacturer in India#Shrink Wrapping Machine supplier in India

1 note

·

View note

Text

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

SYNTHESIS-Manual Shrink Wrapping Machine

Synthesis is the result of technological research entirely developed by minipack®-torre, the synthesis of more than 20 years of experience that have given this machine outstanding reliability and performance.Synthesis is ideal for packaging food products: pizza, sweets, and bread, all in a very simple and hygienic manner.Visit us for trials and demos,

Website : www.trivenipackaging.com

Phone Number : +971 42859967/42863865Mail id : [email protected]

0 notes

Text

Why Use PE Shrink Film?

PE shrink film (or shrink wrap) normally comes on a roll and is a multifaceted polyethylene film that tightly wraps and packages goods. When shrink wrapping an item, firstly, the film is loosely wrapped around the item or pallet. Secondly, when heat is applied to the polyethylene film, the film shrinks around the product tightly. After this process, you have a stable and durable layer of protection tightly wrapped around the item.

Advantages of shrink wrapping:

Increased Protection = The tight nature of the shrink wrap ensures increased protection of the encapsulated product. The item is protected from dirt and debris, as well as having superior moisture protection, and is therefore protected from all the damage these contaminants could potentially cause. We can even include additives such as UV inhibitors, anti-static treatment, and low and non-fusion options for increased protection.

Increase Stability = Wrapping your goods in polyethylene shrink wrap gives superior stability to your goods when in transit or storage. The tight wrapping ensures the continued rigidity of the pallet or product so there is no risk of it falling over or items falling out, further protecting your items from damage.

Durable Wrapping = Polyethylene shrink film is a tough and durable material that is tear and puncture resistant. Even with obscure-shaped loads, shrink wrap will not loosen once heated and shrunk, giving you peace of mind that your goods will remain tightly protected and upright when in transit or storage.

Cost Effective = Not only is shrink film a low cost, affordable material, and form of packaging, it is also a space saver. This tight way of packaging items results in more space available in storage or transit, which could potentially save you money if you are transporting or storing multiple items.

Reduced Tampering = Due to the tight and secure nature of shrink wrapping, it is more difficult for someone to tamper with the goods once wrapped. Furthermore, any tampering would be instantly noticeable as shrink film does not loosen or sag and is not easily tear able. It is a great way to ensure the sealed items have not been tampered with.

Size and Shape not an Issue = No matter the size or shape of the item you want to wrap, shrink wrapping can do it all. From small, intricate pieces, to large obscure shaped loads, PE shrink film is a convenient and all-encompassing solution to your wrapping needs.

Branding and Printing = Quick Pak Inc can supply printed shrink film, as well as alter its color and opaqueness. This means your items can be easily recognizable by adding your logo and brand colors when shrink wrapping your goods, which will be able to represent your organization throughout its journey. This can improve brand awareness and increase visibility to potential customers.

Printing Options: Logos, Safety Warnings, Identification Marks, Advertisements.

Color Options: Natural Material, Variety of tinted colors, Variety of opaque colors.

Additive Options: UV inhibitors, Anti-static treatment, Low and non-fusion options.

Reach out to us for your PE Shrink needs at 813 242 6995 or [email protected]

#stretch film pricing#quickpakinc#resin pricing#stretch film#coreless film#quick pak inc#free machine#pricing news#youtube#free pallet wrapper#pe shrink film#poly shrink fast shrink wrap

1 note

·

View note