#Solar Backsheet

Explore tagged Tumblr posts

Text

Photovoltaic Backsheet Market Key Companies and Analysis, Demand , Trends by 2032

The photovoltaic (PV) backsheet market plays a crucial role in the solar energy industry. The backsheet is an essential component of a PV module that provides electrical insulation and protection to the solar cells from various environmental factors such as moisture, UV radiation, and temperature fluctuations. It acts as a barrier and helps maintain the integrity and efficiency of the solar panels over their operational lifetime.

The Solar Photovoltaic Backsheet market is expected to grow annually by 12.7% (CAGR 2023 - 2030). Market analytics and market coverage are critical components in the Solar Photovoltaic Backsheet market.

Here is an overview of the photovoltaic backsheet market:

Market Growth: The PV backsheet market has been witnessing significant growth in recent years. The increasing demand for clean and renewable energy sources, coupled with supportive government policies and incentives for solar power generation, has propelled the adoption of solar panels, thus driving the backsheet market.

Technological Advancements: The market has seen several technological advancements in backsheet materials and designs. Traditional backsheet materials, such as Tedlar and EVA (ethylene-vinyl acetate), are being replaced by more advanced materials like TPT (Tedlar/PET/Tedlar) and TPE (Tedlar/PET/EVA) with improved durability, weather resistance, and electrical properties.

Types of Backsheets: Backsheets can be categorized into three types based on the materials used: fluoropolymer backsheet, non-fluoropolymer backsheet, and others. Fluoropolymer backsheet, such as Tedlar, is the most widely used type due to its excellent UV resistance and long-term performance. However, non-fluoropolymer backsheets are gaining popularity due to their cost-effectiveness and enhanced performance characteristics.

Regional Market: The PV backsheet market is globally distributed, with major market players and manufacturers present in regions like North America, Europe, Asia Pacific, and the Middle East. China, the United States, and India are among the largest markets for photovoltaic backsheet due to their extensive solar power installations.

Market Players: Several companies operate in the photovoltaic backsheet market, including Krempel GmbH, Coveme S.p.A., 3M Company, Hangzhou First PV Material Co., Ltd., and DuPont, among others. These companies are continuously investing in research and development to enhance the performance and durability of backsheet materials.

Overall, the photovoltaic backsheet market is experiencing steady growth, driven by the increasing adoption of solar energy and advancements in backsheet materials. The market is expected to continue its growth trajectory as solar power becomes a mainstream source of electricity worldwide.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/photovoltaic-backsheet-market/2742/

Market Segmentations:

Global Photovoltaic Backsheet Market: By Company • Agfa • Dupont • Jolywood • Coveme • Isovoltaic • 3M • Hangzhou First • Honeywell • Toray • Cybrid • Dunmore • Krempel • Mitsubishi Polyester Film • Targray Global Photovoltaic Backsheet Market: By Type • Fluoropolymer • Non-Fluoropolymer Global Photovoltaic Backsheet Market: By Application • Utility • Industrial • Commercial • Residential • Military Global Photovoltaic Backsheet Market: Regional Analysis All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Photovoltaic Backsheet market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/photovoltaic-backsheet-market/2742/

Reasons to Purchase Photovoltaic Backsheet Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/photovoltaic-backsheet-market/2742/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Photovoltaic Backsheet#Solar Backsheet#PV Backsheet#Backsheet Material#Backsheet Technology#Solar Module#Solar Energy#Renewable Energy#Photovoltaic Industry#Solar Panel#Solar Cell#Backsheet Manufacturing#Solar Power#Solar System#PV Module#Solar Energy Market#Backsheet Suppliers#Backsheet Manufacturers#Backsheet Market Trends#Solar Installation#Solar Technology#Energy Efficiency#Photovoltaic Backsheet Materials#Backsheet Performance#Backsheet Durability#Backsheet Cost#Backsheet Sustainability#Green Technology.

0 notes

Text

https://heyjinni.com/read-blog/230374_power-beneath-the-surface-exploring-the-solar-backsheet-market.html

0 notes

Text

PV Backsheet: TPT vs. PVDF - Which Solar Panel Armor Reigns Supreme?

In the ever-evolving world of solar technology, every component plays a crucial role in maximizing efficiency and longevity. We've previously explored the importance of EVA films in solar panel encapsulation and delved into the world of top-tier junction boxes. Today, we're shining a spotlight on another critical element that often flies under the radar: the solar panel backsheet.

As a leading manufacturer of cutting-edge solar solutions, including our high-performance TOPCon 580W solar module, we at Sunpal Solar understand that the choice of backsheet material can make or break a solar panel's performance and lifespan. Let's dive into the world of backsheet materials and explore the face-off between two industry titans: TPT (Tedlar-PET-Tedlar) and PVDF (Polyvinylidene Fluoride).

Why Backsheets Matter: The Unsung Heroes of Solar Panel Protection

Before we jump into our material showdown, let's break down why backsheets are so crucial for solar panel performance:

Environmental Protection: Backsheets shield the solar cells from moisture, dust, and other environmental factors.

Electrical Insulation: They provide essential electrical insulation, ensuring safety and performance.

UV Resistance: High-quality backsheets protect against damaging UV radiation, prolonging panel life.

Temperature Regulation: They help manage heat, maintaining optimal cell efficiency.

Aesthetic Appeal: Backsheets contribute to the overall look of the panel, which can be important for residential installations.

Now, let's dive into our main event: TPT vs. PVDF!

TPT (Tedlar-PET-Tedlar) Backsheets: The Seasoned Veteran

TPT backsheets have been a staple in the solar industry for decades, and for good reason.

Pros:

Excellent weather resistance

High durability and longevity

Strong UV protection

Good moisture barrier properties

Cons:

Higher cost compared to some alternatives

Potential for delamination in extreme conditions

Real-World Performance

A study by the National Renewable Energy Laboratory (NREL) found that TPT backsheets maintained 95% of their initial strength after 25 years of simulated outdoor exposure. This impressive durability has made TPT a go-to choice for many solar manufacturers.

PVDF Backsheets: The Innovative Challenger

PVDF backsheets have gained popularity in recent years as a high-performance alternative to TPT.

Pros:

Superior UV resistance

Excellent chemical resistance

High thermal stability

Potentially lower cost than TPT

Cons:

Slightly less moisture barrier properties than TPT

Relatively newer technology with less long-term field data

Emerging Research

Recent research from the Solar Energy Research Institute of Singapore (SERIS) suggests that PVDF backsheets may outperform TPT in terms of UV resistance and thermal stability. Their study showed PVDF retaining 98% of its initial properties after accelerated aging tests equivalent to 30 years of outdoor exposure.

The Face-Off: TPT vs. PVDF

Let's compare these materials across key performance metrics:

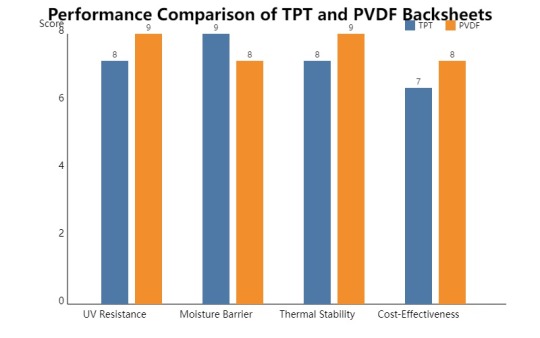

UV Resistance

TPT: 8/10

PVDF: 9/10

PVDF takes a slight edge here due to its superior resistance to UV degradation.

Moisture Barrier

TPT: 9/10

PVDF: 8/10

TPT's multi-layer structure provides a slightly better moisture barrier.

Thermal Stability

TPT: 8/10

PVDF: 9/10

PVDF's chemical structure allows for better performance at high temperatures.

Cost-Effectiveness

TPT: 7/10

PVDF: 8/10

PVDF is generally more cost-effective, especially when considering long-term performance.

Proven Track Record

TPT: 9/10

PVDF: 7/10

TPT has a longer history in the field, providing more real-world data.

Performance comparison of TPT and PVDF backsheets across key metrics

The Sunpal Solar Approach: Harnessing the Best of Both Worlds

At Sunpal Solar, we believe in leveraging the strengths of both materials to create superior solar panels. Our advanced PERC 550W solar panel uses a hybrid backsheet that combines the proven durability of TPT with the innovative performance of PVDF.

This hybrid approach allows us to:

Maximize UV and weather resistance

Ensure optimal moisture protection

Maintain high thermal stability

Provide a cost-effective solution

Offer a product backed by both established and cutting-edge technologies

By combining advanced backsheet technology with our state-of-the-art TOPCon cell architecture and high-quality components like superior junction boxes, we're able to offer solar solutions that not only deliver exceptional performance today but are also built to excel well into the future.

The Science Behind Backsheet Performance

To truly appreciate the impact of backsheet materials, let's delve into the science behind their performance:

Polymer Chemistry: Both TPT and PVDF are fluoropolymers, known for their strong carbon-fluorine bonds. This chemical structure gives them excellent resistance to UV radiation and chemical degradation.

Layer Structure: TPT's three-layer structure (Tedlar-PET-Tedlar) provides a robust moisture barrier, while PVDF's single-layer structure offers superior thermal stability.

Crystallinity: PVDF has a higher degree of crystallinity compared to TPT, contributing to its excellent thermal and chemical resistance.

Surface Energy: The low surface energy of both materials contributes to their self-cleaning properties, helping to maintain panel efficiency over time.

Making the Right Choice for Your Solar Project

When selecting a backsheet material for your solar panels, consider the following factors:

Climate Conditions: In areas with extreme UV exposure or high humidity, PVDF might have an edge.

Project Lifespan: For long-term installations, TPT's proven track record might be appealing.

Budget Constraints: PVDF can offer a more cost-effective solution without significantly sacrificing performance.

Aesthetics: Consider the visual impact, especially for residential installations.

Warranty Requirements: Ensure the chosen material supports the warranty period you're offering or expecting.

The Future of Backsheet Technology

As the solar industry continues to evolve, so too will backsheet technology. Here are some exciting trends to watch:

Nano-engineered Backsheets: Researchers are exploring the use of nanoparticles to enhance UV resistance and thermal conductivity.

Bio-based Materials: Sustainable, plant-derived backsheet alternatives are in development, promising to reduce the carbon footprint of solar panel production.

Smart Backsheets: Integration of sensors within backsheet layers could allow for real-time monitoring of panel health and performance.

Self-healing Properties: Cutting-edge research is exploring backsheet materials that can repair minor damage over time, further extending panel lifespan.

Enhanced Recycling: New backsheet materials are being developed with end-of-life recycling in mind, supporting the circular economy.

Case Study: TPT vs. PVDF in Extreme Environments

To illustrate the real-world performance of these materials, let's look at a case study from a solar farm in the Atacama Desert, Chile – one of the world's harshest environments for solar panels.

In 2015, a 50MW solar plant was installed using a mix of panels with TPT and PVDF backsheets. After five years of operation:

TPT panels showed an average power degradation of 0.6% per year

PVDF panels showed an average power degradation of 0.5% per year

While both performed admirably, the PVDF backsheets demonstrated a slight edge in this extreme environment, likely due to their superior UV and thermal resistance.

Conclusion: Empowering Your Solar Choice

As we've seen, both TPT and PVDF backsheets offer compelling advantages for solar panel protection. The choice between them often comes down to specific project requirements, environmental conditions, and long-term performance expectations.

At Sunpal Solar, we're committed to leveraging the best materials and technologies in our advanced solar panels like the 580 watt TOPCon module. Our hybrid approach to backsheet technology allows us to offer solar solutions that combine proven reliability with cutting-edge performance.

As we continue to push the boundaries of solar technology, the role of high-performance components like backsheets becomes increasingly crucial. These often-overlooked elements work in harmony with advanced cell technologies, superior EVA films, and other cutting-edge materials to create solar panels that are not just powerful, but also built to stand the test of time.

Ready to experience the difference that superior components make? Visit SUNPAL SOLAR to explore our range of high-efficiency solar panels and see how we're harnessing the power of advanced materials and components to create solar solutions that truly shine.

Remember, in the world of solar energy, every component counts – from the cells at the heart of the panel to the backsheet that protects it all. Let's build a brighter, more sustainable future together, one perfectly engineered solar panel at a time!

#photovoltaic solar energy#sunpal#solar panel#sunpal solar#sunpal power#solar energy#Solar Panel Backsheets#TPT vs. PVDF

0 notes

Link

0 notes

Text

0 notes

Text

0 notes

Text

Polyester Industry Insights: Recycling, Fiber Production, and Market Trends Shaping 2025

As sustainability and innovation reshape the textile and chemical industries, polyester remains a cornerstone material—thanks to its durability, versatility, and recyclability. From polyester fabric recycling to the rising demand in polyester staple fiber and polyester polyol markets, the polyester landscape is evolving rapidly. This blog explores key trends, market movements, and production insights across various polyester products, providing an overview tailored for industry leaders, manufacturers, and market watchers.

The Rise of Polyester: Fiber, Resin & Polyols

Polyester, a synthetic polymer derived from petroleum-based raw materials, dominates textile and plastic applications globally. A wide range of products, from polyester fiber and polyester resin to polyester polyols, are reshaping industries including apparel, automotive, construction, and packaging.

In particular, polyester fiber from PET bottles is gaining attention as sustainability pressures increase. Recycled PET (rPET) enables a circular economy in the textile value chain, reducing dependence on virgin resources.

Polyester Fiber Market & Manufacturing Process

The polyester fiber market is expanding significantly due to its growing use in home textiles, automotive interiors, apparel, and geotextiles. Polyester fibers are categorized as polyester staple fiber and filament fiber, with staple fibers mimicking the properties of natural cotton.

Polyester fiber market is estimated at USD 102.2 billion in 2023 and is projected to reach USD 151.6 billion by 2028, at a CAGR of 8.2% from 2023 to 2028.

Key production stages involve:

Polymerization of PET chips

Melt spinning

Drawing and cutting

These steps form the backbone of the polyester fiber production process and are crucial for achieving consistent fiber strength and quality.

Countries like Vietnam and Indonesia are emerging as global hubs. A polyester staple fiber manufacturer in Vietnam or a polyester staple fiber manufacturer in Indonesia can offer cost-effective, high-volume production with growing export capacity.

Polyester Fabric Recycling & Circular Initiatives

Polyester fabric recycling has become a vital sustainability strategy. Recycling methods—such as mechanical recycling of clear PET bottles and chemical depolymerization—are helping industries meet environmental compliance and reduce landfill waste.

Polyester recycle trends are being shaped by innovations in sorting technology, closed-loop manufacturing, and growing consumer demand for eco-friendly fabrics.

Polyester Polyols and Their Expanding Market

Polyester polyols—crucial raw materials for polyurethane production—are now widely used in adhesives, flexible foams, and automotive coatings. The polyester polyol market is gaining traction due to increased demand in construction and furniture sectors.

With a dedicated HS code, polyester polyol manufacturers are scaling production across Asia, Europe, and North America. The polyester polyols market is being driven by the adoption of sustainable building practices and automotive light-weighting strategies.

Polyester Resins: From Unsaturated to Versatile Applications

Polyester resin, particularly unsaturated polyester resin, is used in composites, marine components, and electrical insulations. The polyester resins market is forecasted to grow steadily, driven by its thermosetting properties, low shrinkage, and excellent mechanical performance.

Manufacturers are expanding their polyester resin product lines for niche applications like FRP (fiber-reinforced plastics) and specialty coatings.

Polyester Film & Powder Coating Applications

Beyond fibers and resins, polyester film holds significant value in the packaging and electronics industries. The polyester film industry in India, in particular, is booming due to rising demand in flexible packaging and solar panel backsheet production.

Polyester powder coating offers corrosion resistance and weatherability, making it ideal for architectural applications. These coatings are solvent-free and eco-friendly, aligning with current green manufacturing trends.

Market Outlook and Pricing Trends

The polyester market size is projected to experience robust growth, driven by global demand for synthetic fibers, recycled PET, and polyurethane applications. Competitive polyester pricing across Asian markets is also enabling greater accessibility for manufacturers and consumers alike.

Industry experts are closely tracking:

PET resin fluctuations

Government regulations on plastic usage

Shifting demand between staple fiber and filament fiber

Global Supply Chain & Regional Growth Hubs

Asia-Pacific dominates the polyester manufacturing landscape, with China and India as key players. The polyester manufacturing process—available in detail through industry whitepapers and PDF resources—requires advanced technology for polymerization, extrusion, and finishing.

From polyester yarn production process to polyester staple fiber production, scalability and automation are critical for meeting international quality standards and delivery timelines.

Download PDF brochure for deeper insights :

From production to recycling, the polyester value chain is undergoing a dynamic transformation. Whether it's the expanding polyester fiber market, innovative polyester resin products, or sustainable polyester polyol solutions, the future of polyester is increasingly driven by circularity, technology, and global collaboration. As a global material with local impacts, polyester continues to be a focal point of innovation and growth—across fibers, resins, films, and coatings. Businesses that adapt to market trends, optimize their polyester production process, and invest in recycling infrastructure will be well-positioned to lead the next phase of sustainable material development.

#Polyester Fiber#Polyester Staple Fiber#Polyester Fabric Recycling#Recycled PET Fiber#Polyester Polyol#Unsaturated Polyester Resin#Polyester Market Trends

0 notes

Text

How a Automatic solar panel layup system Can Transform Your Solar Panel Production Process

Do you want to simplify your solar panel manufacturing process? An Automatic solar panel layup system is an indispensable tool for any solar panel production facility. This latest machine makes your solar panel assembly precise and efficient, improving production speed and quality.

An Automatic solar panel layup system automatically lays solar cells on backsheets and EVA sheets. This process reduces human errors and increases the strength and efficiency of the panels.

At Cliantechsolutions, we understand how important reliable machinery is in solar panel production. That is why we provide the best solar panel layup machines as per your requirements. Our machines are equipped with advanced features like automatic alignment and precise control systems, so that every solar panel is of the best quality.

Investing in an Automatic solar panel layup system can save you time and money in the long run. With the right machinery, you can increase your production capacity, improve product quality and stay ahead of the competition. The Clientech Solutions team also offers full support and training to get the best results from your new equipment.

Incorporating an Automatic solar panel layup system into your production line is a smart move. Contact Clientech Solutions today and learn how our solutions can take your solar panel manufacturing process to new heights.

#https://cliantechsolutions.com/solar-laminating-machine/#cliantechsolutions#solar panels#solar panel layup machine

0 notes

Text

Functional Films Market Drivers: Key Forces Powering Industry Expansion

The functional films market is experiencing a surge in growth, fueled by a convergence of technological, environmental, and consumer-driven factors. These drivers are shaping the industry's trajectory and redefining its strategic importance across multiple sectors, including electronics, automotive, packaging, and renewable energy.

Technological Advancements in Film Engineering One of the most significant growth drivers is continuous innovation in materials science. Functional films—engineered for properties such as conductivity, barrier protection, UV resistance, or transparency—are becoming increasingly sophisticated. Advancements in nanotechnology and polymer science are enabling films with enhanced durability, flexibility, and multi-functional capabilities, making them indispensable for next-generation applications.

Rising Demand from the Electronics Sector The rapid proliferation of consumer electronics is creating robust demand for functional films. From touchscreen displays to printed circuit boards, functional films offer critical performance benefits, such as insulation, antiglare, scratch resistance, and EMI shielding. As manufacturers push toward thinner, lighter, and more energy-efficient devices, the reliance on advanced film technologies is growing, reinforcing their market relevance.

Shift Toward Sustainable and Recyclable Materials Sustainability has emerged as a powerful driver in the functional films market. Industries are increasingly prioritizing eco-friendly film options that are biodegradable, recyclable, or made from renewable resources. This shift is spurring innovation in green chemistry and material recycling technologies, creating new opportunities for film producers that can align with global environmental standards and circular economy principles.

Growing Adoption in the Automotive Industry The automotive sector is embracing functional films for both aesthetic and performance benefits. These films are used in automotive glazing, interior components, and paint protection applications. With the rise of electric vehicles and autonomous driving technologies, functional films that support light-weighting, signal transmission, and sensor integration are seeing increased demand.

Healthcare and Medical Device Applications Functional films are gaining traction in the healthcare sector due to their use in medical packaging, diagnostic devices, and wearable technologies. The pandemic accelerated demand for antimicrobial, breathable, and protective film materials, and this trend continues as healthcare infrastructure expands globally. These films also support innovation in drug delivery systems and medical wearables.

Growth in Smart Packaging Solutions The packaging industry is undergoing a transformation driven by the need for intelligent, functional packaging. Functional films with barrier properties against moisture, oxygen, and UV light are crucial for extending shelf life and ensuring product integrity. Additionally, smart films capable of enabling tamper detection, freshness indicators, or temperature tracking are drawing increased interest from food and pharmaceutical sectors.

Increased Investment in Renewable Energy The functional films market is also benefiting from the renewable energy transition. Photovoltaic cells, particularly in flexible solar panels, require films that offer durability, UV resistance, and optimal light transmission. With global commitments to expanding clean energy capacity, the demand for high-performance encapsulation and backsheet films is set to rise.

Customization and Industry-Specific Requirements Functional films are highly customizable, which makes them adaptable across industries. Whether it's anti-fog films for food packaging or transparent conductive films for optoelectronics, the ability to engineer films to precise specifications enhances their appeal and broadens their market potential. Manufacturers that offer application-specific solutions are gaining competitive advantages.

Conclusion The growth of the functional films market is driven by a blend of technological breakthroughs, expanding end-use sectors, and global trends toward sustainability and smart systems. These drivers not only support the current trajectory of the market but also lay a strong foundation for future innovations and applications. Stakeholders across industries are increasingly recognizing the strategic role functional films play in enabling performance, protection, and progress.

0 notes

Text

Global Solar Back sheet Market Size, Share & Report [2025-2033]

Global Solar Backsheet Market Market research report provides a complete overview of the market by examining it both qualitatively and statistically, including particular data and in-depth insights from several market segments. While the qualitative analysis of market dynamics, which includes growth drivers, challenges, constraints, and so on, offers in-depth insight into the market's current and potential, the quantitative analysis includes historical and forecast statistics of major market segments. Get Free Request Sample : https://www.globalgrowthinsights.com/enquiry/request-sample-pdf/solar-backsheet-market-100012 Who is the Top largest companies (Marketing heads, regional heads) of Solar Backsheet Market?Honeywell, Coveme, Jolywood, Mitsubishi Polyester Film, Dupont, 3M, Dunmore, Krempel, Isovoltaic, Targray, AgfaMarket Segmentations:On the thought of the product, this report displays the assembly, revenue, price, Classifications market share and rate of growth of each type, primarily split intoFructo-Oligosaccharides, Galacto-Oligosaccharides, InulinOn the thought of the highest users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and rate of growth for each application, includingAntibiotic-Associated Diarrhoea (AAD), Infectious Childhood Diarrhoea, Cholesterol, Inflammatory Bowel Disease (IBD), Blood Pressure, Lactose Intolerance, Weight Loss, Vitamin Production, Bacterial Vaginosis (BV), OthersKey Drivers of the Solar Backsheet Market MarketTechnological Innovation: The pulse of the Solar Backsheet Market market is its ongoing technological evolution, enhancing product and service efficiency. Innovations span materials, manufacturing, and digital technologies.Surging Demand: Factors like population growth, urbanization, and shifts in consumer preferences are fueling a rising demand for Solar Backsheet Market products and services, propelling market expansion.Regulatory Encouragement: Supportive government measures, including incentives and regulations favoring Solar Backsheet Market adoptions, such as renewable energy subsidies and carbon pricing, are catalyzing market growth.Environmental Consciousness: The growing awareness of environmental issues and carbon footprint reduction is accelerating the uptake of eco-friendly and renewable Solar Backsheet Market solutions.Cost Efficiency: The decreasing costs associated with producing and deploying Solar Backsheet Market solutions, thanks to technological progress, competitive markets, and scale economies, are making these options increasingly attainable.Key Questions Addressed in this Report-What is the 10-year outlook for the global Solar Backsheet Market Market?-What factors are Solar Backsheet Market market growth, globally and by region?-Which technologies are poised for the fastest growth by Solar Backsheet Market Market and region-How do Solar Backsheet Market market opportunities vary by end Market size?-How does Solar Backsheet Market break out type, application?What are the influences of COVID-19 and Russia-Ukraine war? View Full Report @: https://www.globalgrowthinsights.com/market-reports/solar-backsheet-market-100012 About Us:Global Growth Insights is the credible source for gaining the market reports that will provide you with the lead your business needs. At GlobalGrowthInsights.com, our objective is providing a platform for many top-notch market research firms worldwide to publish their research reports, as well as helping the decision makers in finding most suitable market research solutions under one roof. Our aim is to provide the best solution that matches the exact customer requirements. This drives us to provide you with custom or syndicated research reports.

#Marketsize#Markettrends#growth#Researchreport#trendingreport#Business#Businessgrowth#businessTrends#GGI#Globalgrowthinsights

0 notes

Text

0 notes

Text

Understanding the composition of solar panels reveals how they efficiently convert sunlight into electricity. Here’s a breakdown of the key components and how each contributes to a solar panel’s function:

1. Photovoltaic (PV) Cells

Primary Material: PV cells are the most critical part of a solar panel and are typically made from silicon, a semiconducting material that converts sunlight into electrical energy.

Types of Silicon Cells:

Monocrystalline Silicon: Made from a single, continuous crystal structure, these cells are highly efficient and space-effective, often seen in high-quality panels.

Polycrystalline Silicon: Made from multiple silicon crystals, these cells are slightly less efficient but more affordable, offering a balance between performance and cost.

Thin-Film Solar Cells: Made from materials like cadmium telluride or amorphous silicon, these are flexible and lightweight but generally less efficient.

2. Glass Layer

Function: The top layer of a solar panel is a tempered glass cover that protects the PV cells from environmental factors like hail, rain, and dust.

Properties: This glass is often anti-reflective to ensure that more sunlight reaches the PV cells, maximizing energy conversion efficiency.

3. Encapsulant

Material: Encapsulants are typically made from ethylene-vinyl acetate (EVA) and are used to seal and protect the PV cells within the panel.

Function: The encapsulant layer cushions the cells, absorbing impacts and providing UV and moisture protection, ensuring the durability and longevity of the cells.

4. Backsheet

Purpose: The backsheet is a protective layer on the back of the panel, usually made of a polymer or plastic composite.

Function: It insulates the panel and provides protection against moisture and weather damage, helping to preserve the internal components over time.

5. Frame

Material: The frame is typically made of aluminum, chosen for its lightweight, durability, and corrosion-resistant properties.

Function: It holds the panel’s layers together and provides structural support, making it easier to mount the panel on various surfaces.

6. Junction Box and Wiring

Junction Box: Located at the back of the panel, the junction box houses electrical connections and diodes that prevent backflow of electricity, which could damage the panel.

Wiring: The wires and connectors transport the generated DC electricity from the panel to an inverter or battery system for conversion to usable AC power.

7. Anti-Reflective Coating

Function: To improve efficiency, solar cells are often coated with an anti-reflective layer, which reduces the reflection of sunlight and ensures more light is absorbed into the cell.

Final Thought

Each layer of a solar panel is designed with durability and efficiency in mind, contributing to its ability to withstand harsh weather conditions while maximizing energy output. As solar technology advances, these materials and structures continue to be optimized for better efficiency, lower production costs, and a longer lifespan.

#solarpower#solarbatterysystemnsw#solar energy#energy#new south wales#australia#solar panels#RenewableEnergy#CleanEnergy#Solar#SolarPowerSolutions#commercialsolar#solarpanelsystems

1 note

·

View note

Text

Comprehensive Solar Backsheet Market Analysis: Size, Share, and Outlook to 2033

This Global Solar Backsheet Market research report provides a complete overview of the market by examining it both qualitatively and statistically, including particular data and in-depth insights from several market segments. While the qualitative analysis of market dynamics, which includes growth drivers, challenges, constraints, and so on, offers in-depth insight into the market's current and potential, the quantitative analysis includes historical and forecast statistics of major market segments. Get Free Request Sample : https://www.globalgrowthinsights.com/enquiry/request-sample-pdf/solar-backsheet-market-100012 Who is the Top largest companies (Marketing heads, regional heads) of Solar Backsheet Market? Honeywell, Coveme, Jolywood, Mitsubishi Polyester Film, Dupont, 3M, Dunmore, Krempel, Isovoltaic, Targray, Agfa Market Segmentations: On the thought of the product, this report displays the assembly, revenue, price, Classifications market share and rate of growth of each type, primarily split into Fructo-Oligosaccharides, Galacto-Oligosaccharides, Inulin On the thought of the highest users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and rate of growth for each application, including Antibiotic-Associated Diarrhoea (AAD), Infectious Childhood Diarrhoea, Cholesterol, Inflammatory Bowel Disease (IBD), Blood Pressure, Lactose Intolerance, Weight Loss, Vitamin Production, Bacterial Vaginosis (BV), Others Key Drivers of the Solar Backsheet Market Market Technological Innovation: The pulse of the Solar Backsheet Market market is its ongoing technological evolution, enhancing product and service efficiency. Innovations span materials, manufacturing, and digital technologies. Surging Demand: Factors like population growth, urbanization, and shifts in consumer preferences are fueling a rising demand for Solar Backsheet Market products and services, propelling market expansion. Regulatory Encouragement: Supportive government measures, including incentives and regulations favoring Solar Backsheet Market adoptions, such as renewable energy subsidies and carbon pricing, are catalyzing market growth. Environmental Consciousness: The growing awareness of environmental issues and carbon footprint reduction is accelerating the uptake of eco-friendly and renewable Solar Backsheet Market solutions. Cost Efficiency: The decreasing costs associated with producing and deploying Solar Backsheet Market solutions, thanks to technological progress, competitive markets, and scale economies, are making these options increasingly attainable. Key Questions Addressed in this Report -What is the 10-year outlook for the global Solar Backsheet Market Market? -What factors are Solar Backsheet Market market growth, globally and by region? -Which technologies are poised for the fastest growth by Solar Backsheet Market Market and region -How do Solar Backsheet Market market opportunities vary by end Market size? -How does Solar Backsheet Market break out type, application? What are the influences of COVID-19 and Russia-Ukraine war? View Full Report @: https://www.globalgrowthinsights.com/market-reports/solar-backsheet-market-100012 About Us: Global Growth Insights is the credible source for gaining the market reports that will provide you with the lead your business needs. At GlobalGrowthInsights.com, our objective is providing a platform for many top-notch market research firms worldwide to publish their research reports, as well as helping the decision makers in finding most suitable market research solutions under one roof. Our aim is to provide the best solution that matches the exact customer requirements. This drives us to provide you with custom or syndicated research reports.

#Marketsize#Markettrends#growth#Researchreport#trendingreport#Business#Businessgrowth#businessTrends#GGI#Globalgrowthinsights

0 notes

Text

Single Glass Vs Double Glass Solar Panels

When investing in solar energy, choosing the right type of solar panel is crucial for maximizing efficiency and durability. Among the many options available, single glass and double glass solar panels are two popular choices. But how do they differ, and which is the better choice for your needs? Let’s dive into the details to help you make an informed decision.

What Are Single Glass Solar Panels?

Single glass solar panels, also known as single-sided solar panels, are the traditional solar panel design. They consist of a front glass layer that protects the solar cells from external damage and a polymer backsheet that provides insulation and mechanical protection. These panels are lightweight, affordable, and widely available, making them a popular choice for residential and commercial installations.

What Are Double Glass Solar Panels?

Double glass solar panels, also referred to as glass-glass solar panels, have two layers of tempered glass—one at the front and another at the back—encapsulating the solar cells. Unlike single glass panels, they do not use a polymer backsheet. Instead, the second glass layer enhances durability and provides resistance to environmental factors such as humidity and UV rays. These panels are ideal for extreme weather conditions and long-term installations.

Key Differences Between Single Glass and Double Glass Solar Panels

1. Durability

Single glass panels are less durable due to the polymer backsheet, which can degrade over time. In contrast, double glass panels are highly durable as both sides are protected by tempered glass, making them resistant to cracking and environmental wear.

Read More: Single Glass Vs Double Glass Solar Panels

0 notes