#Spares Textile Processing Machinery

Explore tagged Tumblr posts

Text

Get the Best Gear Hobbing Machine in Coimbatore – Trusted Quality, Precision Engineering

The manufacturing industry is the backbone of Coimbatore, a city proudly known as the “Manchester of South India.” As industrial growth continues to rise, the demand for gear hobbing machines in Coimbatore is increasing rapidly. If you are looking for high-performance gear-cutting solutions for your factory, then investing in a quality gear hobbing machine in Coimbatore is the best decision you can make.

At Gear Hobbing Solutions, we specialize in offering top-quality, affordable, and precision-engineered machines that meet global standards. Whether you are a small business or a large enterprise, we deliver machines that suit your exact production needs with excellent support.

✅ What Is a Gear Hobbing Machine?

A gear hobbing machine is a specialized machine tool used to cut gears. It uses a rotating tool called a hob to slice teeth into a gear blank. Gear hobbing is a highly efficient process used to produce spur gears, helical gears, and worm gears.

Using a gear hobbing machine in Coimbatore gives local manufacturers the ability to:

Produce gears with excellent accuracy

Increase manufacturing speed

Reduce manual effort

Improve gear life and performance

Modern gear hobbing machines also support automation, allowing consistent production with minimal human error.

🔧 Why Choose Gear Hobbing Solutions?

When searching for a gear hobbing machine in Coimbatore, you want a supplier that understands your business and provides quality machines with reliable support. Here’s why Gear Hobbing Solutions is the right partner for your gear manufacturing needs:

1. Local Expertise

We have in-depth knowledge of the local industrial ecosystem in Coimbatore. Our machines are built to serve industries like automotive, agriculture, textile, and engineering, which are the backbone of this region.

2. Precision Machines

We offer high-accuracy gear hobbing machines that deliver fine finishes and consistent gear tooth cutting. Precision matters when it comes to gears—and we deliver it every time.

3. Affordable Prices

While we offer international-grade machinery, we keep our pricing competitive. Our goal is to make world-class machines accessible to every factory in Coimbatore.

4. After-Sales Support

From installation and training to maintenance and spare parts, we are with you every step of the way. Our local support ensures minimal downtime.

5. Wide Range of Machines

We supply vertical gear hobbing machines, horizontal hobbing machines, CNC hobbing machines, and semi-automatic models, depending on your specific requirement.

🏭 Why Coimbatore Is a Growing Hub for Gear Manufacturing

Coimbatore is a well-known industrial city with thousands of small and large-scale factories involved in precision engineering. Industries in and around Coimbatore increasingly need reliable gear hobbing machines to meet the growing demand for gear-driven equipment.

From textile machinery and pump sets to electric motors and auto parts, gears are everywhere in Coimbatore’s industrial space. That’s why investing in a durable gear hobbing machine in Coimbatore helps local manufacturers meet rising demand without compromising on quality.

🛠️ Types of Gear Hobbing Machines We Offer

We provide a wide range of gear hobbing machines in Coimbatore to suit various industries:

➤ CNC Gear Hobbing Machines

Ideal for high-volume production with extreme precision. Fully programmable and highly efficient.

➤ Vertical Gear Hobbing Machines

Best suited for smaller components and offers excellent visibility and operator access.

➤ Horizontal Gear Hobbing Machines

Perfect for large and heavy gear blanks. Provides stable cutting and support.

➤ Semi-Automatic Gear Hobbing Machines

Combines manual setup with automatic hobbing—ideal for small batch production.

Each machine is carefully built with top-quality materials and advanced technology to ensure durability, accuracy, and efficiency.

📈 Applications of Gear Hobbing Machines in Coimbatore

The demand for a quality gear hobbing machine in Coimbatore is strong across industries:

Automobile Industry – For cutting transmission, steering, and gear shaft components.

Agriculture Equipment – Used in tractors and farming tools.

Electric Motor Manufacturing – Gears are critical for smooth functioning.

Textile Industry – Gear-driven machines are used in looms and spinning machines.

General Engineering – Used for various machine components and automation systems.

No matter your industry, a robust gear hobbing machine is essential to maintain quality and productivity.

🔍 How to Choose the Right Gear Hobbing Machine in Coimbatore

Here are a few tips to help you choose the right machine:

Check Capacity: Match the machine’s gear size and material capabilities with your production needs.

Automation Level: Choose CNC or semi-automatic depending on your production scale.

Build Quality: Ensure the machine is made with durable materials for long-term use.

Support: Choose a company like Gear Hobbing Solutions that offers strong after-sales support.

Customization: Ask if the machine can be tailored to your specific application.

With our expert guidance, you can select the perfect gear hobbing machine in Coimbatore without hassle.

⚙️ Maintenance Tips for Gear Hobbing Machines

To get the most out of your investment, regular maintenance is important. Follow these tips:

Keep the machine clean to avoid dust build-up.

Lubricate moving parts regularly to reduce wear.

Use quality hobs to maintain gear finish.

Inspect electronics and wiring periodically.

Keep the CNC software updated if applicable.

We also offer annual maintenance contracts and technical training for your staff.

📢 What Our Clients Say

"We were looking for a reliable gear hobbing machine in Coimbatore and found Gear Hobbing Solutions. The team provided excellent guidance, and the machine is performing beyond expectations." — Precision Auto Components, Coimbatore

"Thanks to Gear Hobbing Solutions, our production capacity has doubled in just six months. Their support team is always ready to help. Highly recommended!" — Engineering Firm, Tamil Nadu

Our clients are our biggest advocates, and their success stories are proof of our commitment to quality and customer satisfaction.

🌟 Why Now Is the Best Time to Invest

The industrial landscape in Coimbatore is growing rapidly. The demand for locally manufactured gears is on the rise. By investing in a high-performance gear hobbing machine in Coimbatore, you can:

Boost productivity

Improve gear quality

Reduce production costs

Meet customer deadlines faster

Stay ahead of competitors

Let Gear Hobbing Solutions help you take your manufacturing business to the next level.

📞 Contact Us Today

If you are ready to invest in a quality gear hobbing machine in Coimbatore, look no further than Gear Hobbing Solutions. We’re here to understand your business, guide your decisions, and deliver the right machine at the right price.

Our team is always available for site visits, demonstrations, and consultations. Let’s power your business with precision!

0 notes

Text

Leading Gear Oil Pump Manufacturer in Ahmedabad, India

India has become a global name for quality engineering and industrial component manufacturing. The leading Gear Oil Pump manufacturers in India combine precision engineering with innovative design to offer products that meet both national and international standards.

These manufacturers are known for:

Robust product design

Long service life

Custom-built pump models

Compatibility with various gearboxes and pulley systems

Timely delivery and after-sales support

Their products are trusted across sectors including mining, steel, textile, agriculture, and food processing.

Key Factor in Choosing Right Conveyor Gearbox

A key factor in choosing the right conveyor gearbox is ensuring it works efficiently with compatible components—including a proper gear oil pump. Conveyor systems operate continuously and handle large loads. To perform at their best, these systems need gearboxes that are consistently lubricated to prevent overheating and mechanical damage.

Trusted Conveyor Gearbox Manufacturers in India often advise customers to use high-quality gear oil pumps to enhance gearbox performance and longevity.

Integration with SMSR Gearboxes and Pulley Systems

SMSR Gearboxes

The SMSR (Shaft Mounted Speed Reducer) gearbox is widely used in bulk material handling systems. It’s compact, easy to install, and reliable. However, it requires continuous lubrication to maintain its efficiency.

Whether you're sourcing from a SMSR Gearbox Manufacturer in Ahmedabad or elsewhere in India, lubrication is always a priority. A gear oil pump ensures the SMSR gearbox runs smoothly under heavy load, minimizing the chance of overheating or premature wear. This is why every reliable SMSR Gearbox Manufacturer in India emphasizes the importance of pairing gearboxes with the right oil pumps.

V-Belt Pulley Systems

V-belt pulley systems transfer power between shafts using belts. For smooth rotation and energy efficiency, the bearings in these systems must remain properly lubricated. A reliable V-Belt Pulley Manufacturer in Ahmedabad will often recommend using compatible gear oil pumps to ensure maintenance-free operation over long hours.

Plummer Blocks

Plummer blocks house bearings that support rotating shafts. These bearings require consistent lubrication to prevent breakdown. A good gear oil pump supplies clean oil to these blocks, keeping operations smooth. Leading Plummer Block Manufacturer in India often work closely with gear oil pump providers to offer a complete shaft-support solution.

Industries That Rely on Gear Oil Pumps

The applications of gear oil pumps are vast. They are widely used in:

Mining and construction – to lubricate heavy-duty gearboxes and crushers

Textile and paper industries – for high-speed rotating machines

Cement plants – to support conveyor systems and rotary kilns

Automotive manufacturing – for engines and gear-based machines

Food processing – for machinery that requires hygienic and sealed lubrication

These industries depend on gear oil pumps for uptime, efficiency, and safety.

What to Look for in a Gear Oil Pump Manufacturer

When selecting a gear oil pump manufacturer in India, keep the following factors in mind:

Product Quality – Pumps should be made from corrosion-resistant, high-strength materials.

Experience – A company with a solid history understands industry needs better.

Customization – The ability to modify or design pumps to fit your machinery.

Technical Support – Availability of expert help and spare parts.

Compatibility – Must work seamlessly with your gearbox, pulley, or plummer block.

A reliable manufacturer won’t just sell you a product—they’ll help improve your machine’s performance.

Conclusion

A gear oil pump might seem like a small component, but it plays a big role in keeping industrial operations running smoothly. It ensures that machines like SMSR gearbox, conveyor gearboxes, V-belt pulleys, and plummer blocks receive the lubrication they need for continuous, trouble-free performance.

Choosing the leading Gear 0il Pump manufacturer in Ahmedabad ensures you’re investing in quality, reliability, and efficiency. With a strong ecosystem of industrial partners—including Conveyor Gearbox Manufacturers in India, SMSR Gearbox Manufacturers in Ahmedabad, V-Belt Pulley Manufacturers in Ahmedabad, and Plummer Block Manufacturers in India—you’re assured of top-tier engineering solutions tailored for every sector.

#Gear Oil Pump Manufacturer in Ahmedabad#Gear Oil Pump supplier in Ahmedabad#Gear Oil Pump exporter in Ahmedabad

0 notes

Text

Best Industrial Generator in Delhi | Buy Reliable Power Backup Today

Looking for reliable industrial generators in Delhi? Get high-capacity gensets from United Power Solution with fast delivery and installation.

Power Your Business Right: Best Industrial Generator in Delhi for Indian Businesses

Running a business without a backup power supply is like jumping out of a plane without a parachute. Power outages and voltage variations are common issues in industrial regions, and unplanned outages can halt production lines, impede customer service, and result in severe losses. Whether you own a factory or a large retail location, investing in a dependable industrial generator is no longer optional; it is required.

If you live in Delhi or the NCR region, where there is a high demand for uninterrupted power, selecting the best industrial generator in Delhi could provide your firm the competitive advantage it needs to run smoothly.

In this blog, you will understand why industrial generators are necessary, how to select the best one, and what to look for when purchasing one in Delhi.

Why do Indian Businesses Need Industrial Generators?

Let us be honest: power supply in India is unreliable, particularly in commercial zones and industrial belts. Even a few minutes of outage can disrupt your entire workflow. Here's why any significant company in Delhi requires an industrial generator:

• Power outages are still common. Despite infrastructure improvements, Delhi and surrounding industrial districts continue to face power outages, particularly during the summer. During peak hours, factories and small-scale producers are especially hard hit.

• Machines cannot stop. If your company operates machinery, servers, or refrigeration units, you know they cannot afford even a second without power. An industrial generator ensures continuous functioning.

• Customer Experience Counts Power outages result in poor customer service in retail showrooms, motels, and service enterprises. A generator keeps your clients satisfied and your lights on.

• Data Loss can be costly. Offices that rely on computers and servers may experience data corruption or loss during power outages. An autonomous generator with a quick response time is critical for IT and technology-based enterprises.

Read More On Medium.com

How To Choose The Best Industrial Generator In Delhi?

Before investing in an industrial generator in Delhi, be sure you're receiving the best value for your money.

• Power Capacity (KVA) - Choose a generator based on your business needs. Small stores may need 10-15 kVA, whilst major industries may require 100 kVA or more. Always determine your overall power load before purchasing.

• Brand Reliability - Choose a generator from a trusted brand such as Cummins, Kirloskar, Mahindra Powerol, Ashok Leyland, or Honda, all of which have service centres and spares available in Delhi.

• Automatic Transfer Switch (ATS) - An ATS automatically starts the generator during a power outage and turns it off when power is restored, saving you the trouble.

• Noise Level: Ensure the generator meets CPCB noise regulations in industrial zones.

• Warranty and Service Support -In Delhi/NCR, look for a 2- to 5-year guarantee and after-sales service. Check for service contracts, replacement parts, and technician availability.

• Diesel generators are the most popular for industrial use due to their low fuel cost and long lifespan.

• Gas generators are more environmentally friendly and quieter, although they cost significantly more.

• Hybrid Generators (Solar + Diesel) are becoming increasingly popular in Delhi as environmental consciousness grows.

Read More On Locanto.me

How Industrial Generators Help Businesses in Delhi?

Industrial generators help a variety of Delhi enterprises, including.

• Manufacturing units Textile, plastic moulding, food processing, and printing industries all rely largely on continuous electricity for their operations and output.

• Corporate offices Generators keep servers, networks, and air-conditioning systems working smoothly at IT centres in Noida and startups in Gurgaon alike.

• Retail and Mall A sudden power loss at a mall or showroom can create havoc. Generators keep all lighting, billing systems, and air conditioning units operating.

• Hotels & Restaurants Guest satisfaction is dependent on comfort. A generator is useful for maintaining lights, refrigeration, and climate control during peak summer months.

• Clinics and Hospitals In a place where lives depend on machines, a power outage is just not an option. Medical facilities must have industrial-grade generators with automatic start systems.

Best Generator Brands Available in Delhi.

Let's take a look at some of the highest-rated industrial generators available in Delhi that business owners trust:

• Kirloskar Green Generators. Known for its dependability, fuel efficiency, and customer service. Ideal for manufacturers and medium-sized businesses.

• Cummins India One of the most dependable brands worldwide. Available in 10 to 500 kVA power levels. Perfect for IT parks, malls, and large industries.

Cost of industrial generators in Delhi

Prices vary according to size and brand, but here's a fair estimate of industrial generator pricing in Delhi:

• 10-15 kVA Diesel Generator - ₹2.5–₹3.5 lakhs • 20-40 kVA: ₹4-6 lakhs • 50-100 kVA costs ₹7-12 lakhs. • Above 100 kVA: ₹15 lakhs

Prices are estimates and may vary depending on features, installation fees, GST, and shipping expenses.

Read More On Tumblr.com

Why Should You Choose United Power Solution For Industrial Generators in Delhi?

United Power Solution is a major supplier of industrial and residential generators, offering skilled installation, after-sales support, maintenance, repairs, spare parts, and courteous genset selection guidance to ensure optimal performance and long-term client support.

• United Power Solution also provides wholesale gensets at a competitive price.

• Our service region covers Delhi NCR, Noida, and Gurgaon, and we are available throughout the country to suit the needs of our consumers in Delhi.

• Our company, United Power Solution, stands out for its efficient workforce, genuine Kirloskar and Sudir goods, customer-centric approach, customizable solutions, flexible payment choices, and 24/7 emergency service.

0 notes

Text

Smart Reasons to Work with Local Industrial Air Cooler Dealers

Industrial air cooling plays an important role in managing temperature and air circulation inside factories, warehouses, production plants, and other commercial spaces. In a city like Ahmedabad, where the climate is hot for a major part of the year, industrial air coolers are not just optional—they are necessary for maintaining a productive working environment. For businesses planning to install or upgrade their cooling systems, working with local industrial air cooler dealers can bring multiple practical advantages that extend beyond just the purchase itself.

Let’s look into the real-world benefits that come from choosing local dealers, such as Vayam Industries, a trusted name that works closely with businesses across the city.

Better Understanding of Local Climate and Requirements

Local industrial air cooler dealers have a clear idea of the regional weather conditions. They understand how extreme temperatures, humidity levels, and factory setup impact cooling needs. This knowledge allows them to recommend suitable products based on accurate real-time performance rather than guesswork.

For example, a dealer in Ahmedabad knows that dry heat demands powerful air throw systems with large water tanks and high air delivery. At Vayam Industries, recommendations are based on years of local experience and successful installations across similar industries.

Quick Availability and Faster Installation

Dealing with a local supplier means quick access to stock and minimal waiting periods. You won’t have to deal with long-distance delivery schedules or product damages in transit. Many local industrial air cooler dealers also provide same-day delivery and installation, saving time and helping you avoid unwanted delays in operations.

Technicians and support staff are just a call away, ready to install the unit properly at your site. This prompt service can be a major advantage in time-sensitive industries like manufacturing, food processing, textiles, and more.

On-Site Inspection and Custom Recommendations

Most local dealers are open to visiting your site before finalizing the system. A quick walkthrough gives them the information needed to suggest coolers based on layout, number of workers, machinery, ventilation gaps, and electricity load. These assessments can prevent future problems like overcooling, underperformance, or water consumption imbalance.

Companies like Vayam Industries go beyond showroom sales. Their team is available for in-person guidance to ensure you get systems that actually work for your specific needs and building layout.

Easy Access to Maintenance and Support

After-sales service is often neglected when dealing with outstation suppliers. Spare parts may take days to arrive, and warranty support can become frustrating due to poor coordination. With local industrial air cooler dealers, maintenance becomes quicker and easier.

From annual service checks to emergency repairs, local dealers are within reach and accountable. Their teams are familiar with the systems they install and often carry original spare parts in stock. This reduces downtime and keeps your systems working efficiently.

Personalized Recommendations and Transparent Communication

Face-to-face discussions offer clarity and build trust. Instead of communicating via email or call with far-off suppliers, working with a local dealer allows you to ask questions, check models physically, and discuss budgets more openly.

At Vayam Industries, transparency is at the core of customer interaction. From cooling capacity and fan speed to energy consumption and space coverage, every detail is shared with clarity. This helps buyers make informed decisions without any pressure.

Local Dealers Contribute to Local Economy

Choosing local businesses supports regional growth. It creates employment and keeps the economic flow within the city or district. By partnering with a nearby dealer, you’re not only getting better service but also contributing to the development of the local business network.

Industrial air cooler dealers like Vayam Industries are rooted in the community. Their success is built on long-term relationships and repeat business from nearby industries.

Conclusion

Working with local industrial air cooler dealers brings convenience, speed, and better communication. From understanding climate needs to offering fast delivery, installation, and service, local dealers simplify the process of selecting and maintaining cooling systems.

At Vayam Industries, the focus is always on helping businesses get practical and long-lasting cooling solutions. The benefits of staying local are real—faster service, accurate advice, and a partner who is always within reach. For factories, warehouses, and production units in and around Ahmedabad, working with a trusted local name can make a clear difference in comfort and performance.

#Industrial Air Cooler Dealers#Industrial Air Cooler Dealers in Rajasthan#Best Industrial Air Cooler Dealers#Top Industrial Air Cooler Dealers in Rajasthan

0 notes

Text

Clearing the Air: Why Ghaziabad Industries Trust Local Fume Scrubbers Manufacturers

Ghaziabad – the engine of Uttar Pradesh’s industrial growth – faces a silent crisis. As factories in Sahibabad, Meerut Road, and Loni forge ahead in metal processing, chemicals, and pharmaceuticals, toxic fumes threaten worker safety, community health, and regulatory compliance. With UPPCB tightening emission norms and rising pollution fines (up to ₹5 lakhs per violation!), the smartest solution is partnering with a dedicated Fume Scrubbers Manufacturer in Ghaziabad.

This isn’t just about compliance; it’s about protecting your workforce, boosting productivity, and future-proofing your facility. Discover how local manufacturers engineer scrubbers that tackle Ghaziabad’s toughest air quality challenges.

Ghaziabad’s Fume Crisis: Industries at Risk

Data from UPPCB reveals critical pollution hotspots:

Metal Processing: Pickling fumes (HCl, HNO₃), welding smoke

Chemical Plants: Solvent vapors, ammonia, chlorine leaks

Pharmaceuticals: API synthesis gases, acetone emissions

Electroplating: Cyanide fumes, chromic acid mists

Textile Dyeing: Formaldehyde, chlorine dioxide

Without proper scrubbing, these emissions cause:

Worker respiratory diseases (asthma, COPD)

UPPCB shutdown orders & penalties

Corrosion of machinery & infrastructure

Community backlash & CSR failures

How Fume Scrubbers Work: Engineering Clean Air for Ghaziabad

Local manufacturers design scrubbers using chemical absorption principles tailored to Ghaziabad’s humid climate and industrial mix:

The 3-Step Scrubbing Process

Contaminated Air Intake: Fans pull toxic fumes into the system.

Chemical Neutralization: Fumes pass through a packed bed/tower, where liquid absorbents (water/alkaline solutions) dissolve pollutants:

Acid gases (HCl, SO₂) → Neutralized with NaOH slurry

Ammonia → Scrubbed with H₂SO₄

Solvents → Captured via activated carbon beds

Clean Air Release: Purified air exits via stack, meeting UPPCB norms (CPCB Standards: 50 mg/Nm³ for acids).

Visual: Custom scrubber design for Ghaziabad’s metal finishing industry

Why Choose a Ghaziabad-Based Scrubber Manufacturer? 5 Local Advantages

Hyper-Local Compliance Knowledge Understanding of UPPCB’s emission thresholds, consent mechanisms, and Ghaziabad-specific regulations (e.g., Critically Polluted Area directives).

Rapid On-Site Support <24-hour emergency service across NCR for breakdowns – critical for continuous production lines.

Material Expertise for Local Conditions

FRP (Fiber Reinforced Plastic) scrubbers resist Ghaziabad’s humid, acidic environments

PP (Polypropylene) liners for chlorine/oxidizer resistance

Custom designs for cramped factory layouts in Sahibabad industrial estates

Cost Optimization Lower logistics costs, no GST on inter-state procurement, and familiarity with local labor/raw material markets cut project costs by 15–25%. Industry-Specific Experience Proven solutions for:

Automotive: Paint booth VOC scrubbers

Textiles: Dyehouse formaldehyde control

Pharma: Solvent recovery systems

Top 5 Scrubber Technologies Offered by Ghaziabad Manufacturers

Critical Selection Criteria for Ghaziabad Industries

Pollutant Profile Test fume composition (chemical concentration, temperature, flow rate). Tip: Most Ghaziabad manufacturers offer free site audits.

Material of Construction

FRP: For acids under 60°C (cost-effective)

PP-lined FRP: For oxidizers (HNO₃, Cl₂) or high temps

PVDF: Aggressive solvents like MEK

Customization Capabilities Ensure they design for:

Space constraints in Ghaziabad’s older factories

Multi-stage scrubbing (e.g., acid + particulate removal)

Automated pH/dosing controls

Compliance Documentation Demand:

CPCB/UPPCB test reports

IBR certification for pressure vessels

AMC with UPPCB audit support

After-Sales Service Verify:

Local technician network

Spare parts inventory in Ghaziabad

Remote monitoring options

Energy Efficiency Opt for VFD-driven fans and PLC controls to cut power costs by 30% – crucial amid UP’s rising electricity tariffs.

Future-Proofing with Ghaziabad’s Scrubber Tech: 3 Trends

IIoT Integration Real-time emission monitoring linked to UPPCB portals via cloud-based PLCs.

Zero-Liquid Discharge (ZLD) Scrubbers Recycling scrubber effluent to meet Ghaziabad’s water conservation mandates.

Hybrid Scrubber-Filter Systems Combined PM₂.₅ and gas control for stricter upcoming norms.

Partner Wisely: 5 Red Flags in Scrubber Manufacturers

🛑 No in-house engineering team 🛑 Lack of UPPCB compliance documentation 🛑 One-size-fits-all designs 🛑 Substandard FRP/PP material (verify ISI certifications) 🛑 48+ hour response time commitments

Conclusion: Your Next Steps for Cleaner Operations

Choosing the right Fume Scrubbers Manufacturer in Ghaziabad isn’t just about equipment – it’s about securing your license to operate, protecting your workforce, and contributing to cleaner air in the NCR. With local expertise, rapid support, and compliance assurance, Ghaziabad-based partners deliver turnkey solutions where global suppliers fall short.

Act Now:

Audit your emissions with a local expert

Specify scrubber requirements (flow rate, pollutants, space)

Shortlist manufacturers with Ghaziabad installations

Demand site visits and client references

Breathing clean air isn’t a luxury – it’s your right and responsibility. Partner with a Ghaziabad scrubber expert today and transform fumes into compliance, safety, and sustainability.

#Fume Scrubbers Manufacturer in Ghaziabad#Fume Scrubbers Manufacturer#Industrial Scrubbers Ghaziabad#Acid Fume Scrubber#Chemical Scrubber#Pollution Control System#Air Pollution Solutions Ghaziabad#UPPCB Compliance#FRP Scrubbers#Custom Fume Control

0 notes

Text

Trusted Industrial Shredder Machine Manufacturer in India

India’s industrial growth continues to rise, and with it comes a growing need for powerful machinery that supports efficient waste management and recycling. Among the essential machines used across various industries, shredder machines play a major part in processing bulk materials such as plastic, metal, rubber, and paper. A trusted name in this sector is Power Hydrotech Private Limited, serving industries with high-performance shredding machines built for demanding environments.

The Role of a Trusted Shredder Machine Manufacturer

In many industries, managing industrial waste is not just a responsibility—it’s a necessity for smooth operations. Whether it's reducing large materials for further processing or preparing waste for disposal, a well-designed shredder machine becomes essential. The quality of the shredder impacts overall productivity, safety, and long-term cost efficiency.

Working with a manufacturer that understands the needs of industrial businesses is important. Machines should be engineered for strength, consistency, and longevity. When these factors come together, businesses benefit from smoother processing and reduced maintenance concerns.

Industrial Shredder Machine Manufacturer in India: What Makes Power Hydrotech Private Limited a Trusted Name

Power Hydrotech Private Limited has built a reputation by focusing on durability, performance, and practical design. Their machines are used in industries such as plastic recycling, textile manufacturing, pharmaceutical processing, and metal industries.

The shredders produced by the company are engineered to process materials like:

Plastic bottles and containers

Industrial scrap

Rubber and tyres

Paper and cardboard

Metal parts and components

This wide usability makes their machines a valuable addition to a range of industrial sectors. The machines are designed with attention to operational efficiency and user safety.

What Customers Value Most

Clients who rely on Power Hydrotech Private Limited often highlight the consistency and long service life of the machines. The company emphasizes support, with a technical team that responds to customer needs during installation, training, and maintenance. This approach builds long-term partnerships with industries that depend on continuous production.

Another point that sets this manufacturer apart is the flexibility to customize machines. Different materials require different shredding capacities, and Power Hydrotech understands these variations. Their product range is suitable for small workshops as well as large-scale factories.

Factors to Consider When Choosing a Manufacturer

When selecting an Industrial Shredder Machine Manufacturer in India, it’s useful to evaluate the following points:

Build Quality: The machine should be made with strong materials suited for industrial use.

Capacity: Choose a model that matches your material type and volume.

Technical Support: Reliable after-sales service keeps your machine in good working condition.

Spare Parts Availability: Easy access to parts reduces downtime.

Experience: A manufacturer with hands-on experience in industrial environments better understands your needs.

Power Hydrotech Private Limited meets these expectations by manufacturing machines with industrial-grade components and maintaining customer-focused support throughout the process.

Industries Served by Power Hydrotech

With years of experience, the company has supplied shredding machines to clients in:

Plastic recycling units

Municipal waste processing plants

Rubber and tyre shredding companies

E-waste management firms

Pharmaceutical production facilities

The machines are built to run continuously in challenging conditions, making them a practical choice for these demanding sectors.

Conclusion

India’s industrial sector needs machines that are both powerful and dependable. Choosing a trusted Industrial Shredder Machine Manufacturer in India can make a noticeable difference in day-to-day operations. Power Hydrotech Private Limited has been serving this need with dedication, offering machines that are built to perform in real-world conditions. Their experience in manufacturing, combined with attention to customer requirements, has made them a preferred name in the shredding machine market. Whether your business involves recycling, production, or material processing, working with a manufacturer like Power Hydrotech helps keep your workflow efficient and consistent.

#Industrial Shredder Machine Manufacturer#Industrial Shredder Machine Manufacturer in Ahmedabad#Industrial Shredder Machine Manufacturer in Gujarat#Industrial Shredder Machine Manufacturer in India

0 notes

Text

TCI Express: The Fastest Logistics Company Powering India’s Supply Chain

Introduction

India’s economy is growing at a record pace, and the backbone of this growth is efficient logistics. With the rise of e-commerce, pharmaceutical exports, FMCG distribution, and real-time inventory management, companies can’t afford delays in their supply chains. Speed, accuracy, and reliability define today’s logistics leaders—and among them, TCI Express has emerged as the fastest logistics company in India.

Whether you are looking for air express, surface express, cold chain transportation, or full truck load services, TCI Express offers comprehensive express logistics services built for speed and scalability.

This blog explores why TCI Express is consistently ranked as the top logistics company in India, and how its tech-driven approach helps brands grow fast without compromising on delivery quality.

Who Is TCI Express?

TCI Express is a specialized express logistics arm of the Transport Corporation of India Group (TCI), with decades of legacy and experience. It operates across all major sectors and serves 60,000+ locations across India with one of the most robust delivery infrastructures in the country.

Focused on time-definite deliveries, TCI Express combines road, air, and rail networks to ensure fast, secure, and predictable movement of goods.

Why TCI Express is the Fastest Logistics Company in India

1. Nationwide Coverage with Local Precision

TCI Express reaches every corner of India—from major metros to rural towns—with consistent service quality. This extensive network allows the company to optimize route planning and last-mile delivery.

2. Multimodal Transport Efficiency

Speed isn’t just about moving fast—it’s about choosing the right mode of transport:

Air Express for ultra-urgent deliveries.

Surface Express for economical, time-sensitive ground transport.

Rail Logistics for cost-effective long-distance movement.

3. Automated Sorting and Real-Time Tracking

With state-of-the-art automated hubs like the GIGA Sorting Center in Gurugram, TCI Express processes over 15,000 shipments an hour, dramatically reducing delivery lead times.

Customers enjoy real-time visibility with:

GPS tracking

Mobile app updates

E-POD (electronic proof of delivery)

Comprehensive Express Logistics Services

Let’s explore the full range of express logistics services that TCI Express offers:

1. Air Express

This is the fastest service offered by TCI Express. It connects cities across India via dedicated air cargo routes and offers:

Same-day or next-day delivery.

Priority handling of urgent parcels.

High-value shipment protection.

Ideal for:

Pharmaceuticals

Spare parts

Legal documents

High-end electronics

2. Surface Express

This ground-based service uses containerized vehicles to safely move parcels across cities and states.

Fast intra- and inter-city delivery.

Container tracking for enhanced safety.

Economical and scalable for frequent shipments.

Perfect for:

Retail stores

FMCG distribution

General manufacturing

3. Full Truck Load Services (FTL)

Businesses with large volumes can book entire trucks for exclusive use. This ensures:

Minimal handling.

Direct routing with shorter transit time.

Cost efficiency for bulk shipments.

Industries benefiting most:

Auto parts

Industrial machinery

Textiles

Agriculture

4. Cold Chain Transportation

Sensitive cargo such as medicines, perishables, and chemicals need precise climate control. TCI Express provides:

Temperature-controlled vehicles (refrigerated and insulated).

24/7 temperature monitoring.

Staff trained in handling sensitive goods.

Use cases:

Vaccine and pharma supply chains

Dairy and frozen food transport

Specialized chemical shipping

5. E-Commerce Express

India’s e-commerce sector demands fast, flexible delivery options. TCI Express supports online brands with:

Cash on delivery (COD) support

Reverse logistics

Delivery to tier 2, 3, and rural areas

Benefits:

Reduced cart abandonment

Faster returns and replacements

Improved customer satisfaction

Technology: The Driver Behind Speed and Scale

1. Real-Time Tracking

Customers can track their shipments in real-time through TCI Express’s portal or mobile app. Live updates offer full transparency from pickup to delivery.

2. AI and Route Optimization

TCI Express uses AI-powered algorithms to:

Select the fastest delivery route.

Manage fleet efficiency.

Reduce fuel consumption and emissions.

3. Electronic Documentation

No more paperwork delays. Clients get:

e-invoices

e-way bills

e-PODs This improves speed and helps with audits and compliance.

TCI Express for Business: Industry Use Cases

1. Healthcare and Pharma

Rapid delivery of life-saving drugs.

Cold chain logistics for temperature-sensitive shipments.

Regulatory compliance for secure transport.

2. E-Commerce and Retail

Reverse logistics and returns.

Last-mile delivery with real-time tracking.

Store-to-store replenishment support.

3. Automotive

Just-in-time delivery of parts.

FTL and Surface Express for bulk distribution.

High-security handling for valuable components.

4. Agriculture and Food

Temperature-controlled transport for perishables.

Express movement to wholesale markets.

Logistics for agri-tech startups and exporters.

Sustainability in Logistics

TCI Express is leading India’s logistics sector toward a greener future.

Key Initiatives:

Electric and CNG vehicles for intra-city deliveries.

Solar-powered warehouses like the GIGA Center.

Digital billing and documentation to reduce paper use.

By reducing their carbon footprint, they also help clients meet ESG and sustainability compliance standards.

Customer Support and Service Experience

Speed is nothing without support. TCI Express delivers on this front too:

24/7 customer support via email, phone, and chatbot.

Dedicated key account managers for corporate clients.

Mobile and web dashboard to manage shipments, invoices, and analytics.

Why TCI Express is the Best Logistics Company in India

Feature

TCI Express Advantage

Network Reach

60,000+ delivery locations across India

Speed

Fastest express delivery by air, rail, and road

Industry Coverage

Pharma, retail, auto, e-commerce, agriculture

Custom Services

E-commerce express, cold chain, FTL

Technology Integration

Real-time tracking, AI routing, paperless billing

Global Capability

International courier services across 200+ countries

Sustainability Focus

Green fleet, solar hubs, paperless workflows

Support & Transparency

Dedicated portals, responsive support, full visibility

Frequently Asked Questions (FAQs)

Q1: Why is TCI Express considered the fastest logistics company in India?

A: TCI Express offers same-day and next-day deliveries via air, real-time tracking, and automated hubs that process thousands of packages per hour. Their integrated road, rail, and air logistics ensure unmatched speed.

Q2: What are the benefits of Full Truck Load (FTL) services?

A: FTL services reduce transit time, minimize cargo handling, and offer cost-effective solutions for high-volume shipments. TCI Express provides dedicated vehicles and direct routing to improve reliability.

Q3: How does cold chain transportation work with TCI Express?

A: TCI Express uses refrigerated vehicles, temperature monitoring systems, and specially trained staff to transport sensitive products like vaccines, food, and chemicals under controlled conditions.

Q4: Can small e-commerce brands use TCI Express?

A: Yes, TCI Express offers E-commerce Express services with support for COD, returns, and fast delivery even to remote areas. It’s an ideal choice for scaling e-commerce operations.

Q5: How reliable is TCI Express tracking?

A: Extremely reliable. Customers get real-time updates via the web, mobile app, and SMS. The tracking includes location, delivery status, and even proof of delivery.

Q6: Does TCI Express support international shipments?

A: Yes, they offer international courier services to over 200 countries with customs clearance support and express options for both B2B and B2C clients.

Q7: What makes TCI Express the best logistics company in India?

A: Their blend of speed, scale, technology, and customer support—along with a strong focus on sustainability—makes them the most trusted and efficient logistics partner in India.

Conclusion

Speed, safety, and service are the new currency of modern logistics—and TCI Express delivers all three. As the fastest logistics company and a recognized top logistics company in India, they empower businesses with customized express logistics services ranging from air express and cold chain transportation to full truck load services and e-commerce express.

If your business needs a logistics partner that combines reach, technology, and dependability, TCI Express is the clear choice.

Explore Services: Express Services | Surface Express | Domestic Air Express | International Air Express | Rail Express | E-Commerce Express | C2C Express | Cold Chain Express

1 note

·

View note

Text

Title: Biomass vs. Solar and Wind: Choosing the Right Renewable Energy for Industrial Use

As India moves toward a cleaner and greener energy future, industries are under increasing pressure to shift from fossil fuels to renewable energy. Among the most discussed options are solar, wind, and biomass gasification. While each technology has its strengths, the right solution often depends on the industry type, location, and energy requirements.

In many cases, especially in agro-based or rural industries, biomass gasifiers offer a more practical and cost-effective solution. Veera Group, a trusted name in sustainable industrial solutions, is helping companies make this shift by providing advanced, high-efficiency biomass gasifier machines that are tailor-made for Indian industries.

Solar and Wind: Popular, But Limited

Solar and wind power are well-established renewable sources in India. They are ideal for large-scale grid feed-in or commercial campuses. However, they come with limitations for industrial use:

Intermittency: Solar only works during daylight, and wind depends on weather conditions. This inconsistency requires expensive battery backups or diesel generators.

Land Requirements: Large solar or wind farms need significant space—something not all factories or industries can spare.

Upfront Costs: While costs have dropped, the initial investment for solar or wind setups, especially with storage, can still be steep.

These challenges make solar and wind less viable for industries that need continuous power, thermal energy, or operate in semi-urban and rural areas.

Biomass Gasifiers: A Reliable Industrial Solution

Unlike solar or wind, biomass gasifiers generate energy on demand and are not reliant on weather or sunlight. These systems convert agricultural waste like wood chips, coconut shells, rice husk, and sawdust into producer gas—a clean, combustible fuel that can be used for:

Electricity generation

Thermal heating in boilers

Powering industrial machinery

Veera Group’s biomass gasifier machine is engineered for high-efficiency performance and reliability, specifically targeting industrial use cases. These machines are capable of running continuously, are easy to maintain, and utilize locally available biomass—cutting fuel costs and dependence on external suppliers.

Industrial Sectors Benefiting from Biomass

Numerous industries are now turning to biomass gasification for their daily energy needs. These include:

Textile units using it for hot water and steam.

Food processing units using it for roasting, drying, or baking.

Small manufacturing plants running machinery with electricity generated by gasifiers.

Veera Group has helped several industrial clients replace diesel generators with biomass systems—cutting both emissions and energy bills.

To explore such case studies and industry insights, check out the Veera Group Blog, where they regularly publish updates on renewable technologies and their industrial applications.

Why Industries Choose Biomass Over Other Renewables

Here’s a quick comparison table: FeatureBiomass GasifiersSolar EnergyWind EnergyReliabilityHigh (on-demand)Low (daylight only)Low (depends on wind)Industrial HeatingYesNoNoEnergy Storage NeededNoYesYesSpace RequirementLowMedium-HighHighFuel CostLow (local biomass)Free (after setup)Free (after setup)Initial InvestmentModerateHigh (with batteries)High

Clearly, for many industrial setups—especially in rural or agro-based sectors—biomass gasifiers provide a more stable and scalable energy solution.

Veera Group: Your Partner in Clean Industrial Power

With decades of experience in engineering and clean technology, Veera Group is at the forefront of India's industrial energy revolution. Their biomass gasifier machines are built with precision, tested under tough industrial conditions, and backed by expert support. Whether you're a small enterprise or a large-scale manufacturer, they offer custom solutions to help you transition smoothly to renewable energy.

Conclusion

While solar and wind are excellent renewable sources in the right context, biomass gasification stands out as the most practical choice for many industries—especially those looking for round-the-clock power and thermal energy. Thanks to Veera Group and their cutting-edge gasifier machines, Indian industries now have a reliable, sustainable, and cost-effective energy alternative.

0 notes

Text

Navis TubeTex Partners with Pluvia to deliver expanded sales and support for continuous washing and bleaching applications

Navis TubeTex, a leader in engineering advanced textile finishing and processing solutions, is pleased to announce a strategic partnership with Pluvia, a European-based innovator in sustainable textile machinery. Through this collaboration, Navis will support the sales and service of Pluvia’s continuous ranges for washing and bleaching in the North American market.

This partnership brings together two companies known for performance, innovation, and customer commitment. Pluvia’s cutting-edge technology is recognized globally for its efficiency and sustainability in wet finishing processes. By aligning with Navis’ established sales and service infrastructure, this partnership ensures North American customers will now have local access to Pluvia’s advanced continuous ranges, along with expert support for installation, operation, and maintenance.

“Pluvia has developed an impressive suite of technologies that are efficient and aligned with Navis in our drive for more sustainable, high-performance solutions,” said Will Motchar, President and CEO of Navis TubeTex. “We’re proud to bring these systems into our offering and confident this partnership will deliver added value to a broader customer base”. “Partnering with Navis TubeTex allows us to serve our North American customers with the responsiveness and technical expertise Navis has provided its customers in the US market,” said Murat Agagunduz, CEO of Pluvia, “We’re excited to work with a company that shares our values in innovation, quality, and sustainability.”

Effective immediately, US based customers can reach out to Navis for sales inquiries, technical support, spare parts, and service related to Pluvia continuous ranges completing a full range of finishing technologies to serve the textiles, nonwovens, and other finished goods markets.

0 notes

Text

Cardan Shafts Applications in UAE Industries

In the heart of the Middle East, the United Arab Emirates (UAE) is recognized for its booming industrial sectors, including oil & gas, construction, maritime, and manufacturing. A critical mechanical component supporting the smooth operation of these industries is the Cardan shaft—also known as a universal joint shaft. This blog dives into the various applications and significance of Cardan Shafts in UAE, highlighting their role in ensuring efficiency, flexibility, and durability in industrial machinery.

What is a Cardan Shaft?

A Cardan shaft is a mechanical drive shaft used to transmit torque and rotation, even when the shafts are not in a straight line. It enables power transfer between components located at varying angles and distances, making it ideal for heavy-duty applications.

Key Industries Using Cardan Shafts in UAE

1. Oil and Gas Sector

The oil & gas industry is the backbone of the UAE economy. Cardan shafts are widely used in drilling rigs, pumping systems, and pipeline operations. Their ability to handle high torque and misalignments makes them indispensable in harsh desert and offshore environments.

Application Highlights:

Drill string drives

Rotary tables

Mud pumps

Offshore platform equipment

2. Construction and Heavy Equipment

UAE's massive infrastructure growth relies heavily on construction machinery such as excavators, cranes, and concrete mixers. Cardan shafts provide reliable torque transmission between engine and axles or other rotating equipment.

Application Highlights:

Concrete batching plants

Tunnel boring machines

Mobile cranes and loaders

3. Manufacturing and Production Plants

Cardan shafts in UAE are critical in various manufacturing processes, including steel, paper, and textiles. They are used in rolling mills, conveyors, and heavy processing equipment where uninterrupted power transfer is essential.

Application Highlights:

Conveyor systems

Rolling and forging mills

Textile spinning machines

4. Marine and Shipping Industry

Given UAE's strategic coastal position, the marine sector thrives. Cardan shafts are vital in ship propulsion systems and marine engines, where vibration resistance and durability are critical.

Application Highlights:

Marine propulsion

Deck machinery

Power take-off (PTO) systems

5. Power Generation

Power plants in the UAE, including renewable and gas-fired plants, use Cardan shafts in turbines, generators, and auxiliary equipment, where they accommodate angular misalignments and thermal expansion.

Why Cardan Shafts are Ideal for UAE Conditions

High Load Capacity: Perfect for heavy industrial applications.

Resistance to Harsh Environments: Operates well in high temperatures, dust, and saline conditions.

Maintenance Friendly: Designed for durability and easy servicing, reducing downtime.

Customizable Designs: Adapted for various sizes, torque levels, and operational angles.

Local Availability and Services

With the rising demand for Cardan Shafts in UAE, many local and international suppliers offer custom solutions, on-site servicing, and spare parts. Companies based in Dubai, Abu Dhabi, and Sharjah provide industry-grade shafts for both OEMs and end-users.

0 notes

Text

Best Industrial Generator in Delhi | Buy Reliable Power Backup Today

Looking for reliable industrial generators in Delhi? Get high-capacity gensets from United Power Solution with fast delivery and installation.

Power Your Business Right: Best Industrial Generator in Delhi for Indian Businesses

Running a business without a backup power supply is like jumping out of a plane without a parachute. Power outages and voltage variations are common issues in industrial regions, and unplanned outages can halt production lines, impede customer service, and result in severe losses. Whether you own a factory or a large retail location, investing in a dependable industrial generator is no longer optional; it is required.

If you live in Delhi or the NCR region, where there is a high demand for uninterrupted power, selecting the best industrial generator in Delhi could provide your firm the competitive advantage it needs to run smoothly.

In this blog, you will understand why industrial generators are necessary, how to select the best one, and what to look for when purchasing one in Delhi.

Why do Indian Businesses Need Industrial Generators?

Let us be honest: power supply in India is unreliable, particularly in commercial zones and industrial belts. Even a few minutes of outage can disrupt your entire workflow. Here's why any significant company in Delhi requires an industrial generator:

• Power outages are still common. Despite infrastructure improvements, Delhi and surrounding industrial districts continue to face power outages, particularly during the summer. During peak hours, factories and small-scale producers are especially hard hit.

• Machines cannot stop. If your company operates machinery, servers, or refrigeration units, you know they cannot afford even a second without power. An industrial generator ensures continuous functioning.

• Customer Experience Counts Power outages result in poor customer service in retail showrooms, motels, and service enterprises. A generator keeps your clients satisfied and your lights on.

• Data Loss can be costly. Offices that rely on computers and servers may experience data corruption or loss during power outages. An autonomous generator with a quick response time is critical for IT and technology-based enterprises.

Read More On Medium.com

How To Choose The Best Industrial Generator In Delhi?

Before investing in an industrial generator in Delhi, be sure you're receiving the best value for your money.

• Power Capacity (KVA) - Choose a generator based on your business needs. Small stores may need 10-15 kVA, whilst major industries may require 100 kVA or more. Always determine your overall power load before purchasing.

• Brand Reliability - Choose a generator from a trusted brand such as Cummins, Kirloskar, Mahindra Powerol, Ashok Leyland, or Honda, all of which have service centres and spares available in Delhi.

• Automatic Transfer Switch (ATS) - An ATS automatically starts the generator during a power outage and turns it off when power is restored, saving you the trouble.

• Noise Level: Ensure the generator meets CPCB noise regulations in industrial zones.

• Warranty and Service Support -In Delhi/NCR, look for a 2- to 5-year guarantee and after-sales service. Check for service contracts, replacement parts, and technician availability.

• Diesel generators are the most popular for industrial use due to their low fuel cost and long lifespan.

• Gas generators are more environmentally friendly and quieter, although they cost significantly more.

• Hybrid Generators (Solar + Diesel) are becoming increasingly popular in Delhi as environmental consciousness grows.

Read More On Locanto.me

How Industrial Generators Help Businesses in Delhi?

Industrial generators help a variety of Delhi enterprises, including.

• Manufacturing units Textile, plastic moulding, food processing, and printing industries all rely largely on continuous electricity for their operations and output.

• Corporate offices Generators keep servers, networks, and air-conditioning systems working smoothly at IT centres in Noida and startups in Gurgaon alike.

• Retail and Mall A sudden power loss at a mall or showroom can create havoc. Generators keep all lighting, billing systems, and air conditioning units operating.

• Hotels & Restaurants Guest satisfaction is dependent on comfort. A generator is useful for maintaining lights, refrigeration, and climate control during peak summer months.

• Clinics and Hospitals In a place where lives depend on machines, a power outage is just not an option. Medical facilities must have industrial-grade generators with automatic start systems.

Best Generator Brands Available in Delhi.

Let's take a look at some of the highest-rated industrial generators available in Delhi that business owners trust:

• Kirloskar Green Generators. Known for its dependability, fuel efficiency, and customer service. Ideal for manufacturers and medium-sized businesses.

• Cummins India One of the most dependable brands worldwide. Available in 10 to 500 kVA power levels. Perfect for IT parks, malls, and large industries.

Cost of industrial generators in Delhi

Prices vary according to size and brand, but here's a fair estimate of industrial generator pricing in Delhi:

• 10-15 kVA Diesel Generator - ₹2.5–₹3.5 lakhs • 20-40 kVA: ₹4-6 lakhs • 50-100 kVA costs ₹7-12 lakhs. • Above 100 kVA: ₹15 lakhs

Prices are estimates and may vary depending on features, installation fees, GST, and shipping expenses.

Read More On Tumblr.com

Why Should You Choose United Power Solution For Industrial Generators in Delhi?

United Power Solution is a major supplier of industrial and residential generators, offering skilled installation, after-sales support, maintenance, repairs, spare parts, and courteous genset selection guidance to ensure optimal performance and long-term client support.

• United Power Solution also provides wholesale gensets at a competitive price.

• Our service region covers Delhi NCR, Noida, and Gurgaon, and we are available throughout the country to suit the needs of our consumers in Delhi.

• Our company, United Power Solution, stands out for its efficient workforce, genuine Kirloskar and Sudir goods, customer-centric approach, customizable solutions, flexible payment choices, and 24/7 emergency service.

0 notes

Text

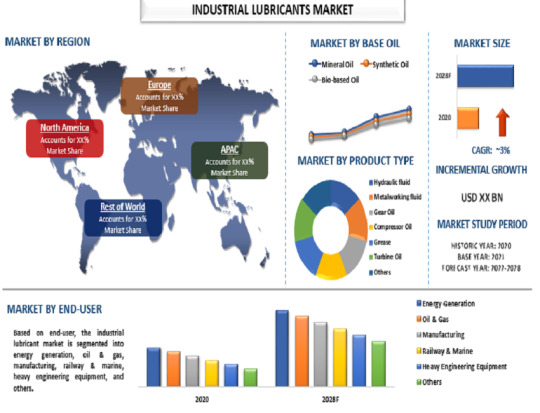

Industrial Lubricants Market Size, Share, growth & Forecast

The Industrial Lubricants Market is expected to grow at a CAGR of around 3% from 2022-2028. The global industrial lubricants market is primarily driven by the increasing adoption of complex machinery and tools in various industries. The main task and most important function of lubricants are to reduce friction lubricants and offer wear protection, which extends machine runtimes and thereby protects raw materials. Awareness of lubricants is increasing among consumers as it is contributing to the sparing use of resources and thereby to sustainability. Their task of reducing friction reduces the amount of energy input required and, in this way, saves emissions. Hence, escalating its market demand across the globe.

Moreover, rapid urbanization, industrialization, and increasing technological advances in emerging economies are the major factors supporting the growth of the industrial lubricants market. In addition, growing construction and mining activities have increased the utilization of heavy equipment in many countries. Due to the increase in the utilization of such equipment, the demand for industrial lubricants is also increasing.

Based on base oil, the industrial lubricants market is segmented into mineral oil, synthetic oil, and bio-based oil. The mineral oil category caters substantial share of the market. As Petrochemical components and increasing derivatives of natural, harvestable raw materials from the oleo-chemical industry are finding increasing acceptance because of their environmental compatibility and some technical advantages.

Based on product type, the industrial lubricants market is segmented into hydraulic fluid, metal working fluid, gear oil, compressor oil, grease, turbine oil, and others. Among these, the hydraulic fluid segment to hold a significant share in the market in 2020. It is mainly due to its low cost as compared to the other types and its demand from the construction industry. The demand for industrial lubricants is on the verge of a breakthrough in the construction industry due to the rising construction activities in the residential sector like in China and the rising infrastructural developments in India.

Request for a sample of the report browse through – https://univdatos.com/get-a-free-sample-form-php/?product_id=28504

For a better understanding of the market adoption of the industrial lubricants industry, the market is analyzed based on its worldwide presence in the countries such as North America (U.S., Canada, Rest of North America), Europe (Germany, U.K., France, Spain, Italy, Rest of Europe), Asia-Pacific (China, Japan, India, Rest of Asia-Pacific), Rest of World. Asia Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly attributed due to the increasing growth in the base oil movement, rapid industrialization & urbanization, rising population, and high growth in major end-use industries, such as textiles, chemicals, food processing, and metalworking. Also, the growing investments in the agriculture sector to reduce manual work and increase the use of various machinery to reduce time and improve efficiency are expected to drive the market.

Some of the major players operating in the market include BP Plc, Exxon Mobil Corporation, Fuchs Petrolub SE, Chevron Corporation, Idemitsu Kosan Co. Ltd., Lukoil Oil Co., PetroChina Co. Ltd., Total S.A., Royal Dutch Shell Plc, and BASF SE.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Vietnam top 10 exports

Vietnam has emerged as a reliable and rapidly developing hub for international commerce and investment, boasting one of Asia's fastest-growing economies. With an impressive annual GDP growth rate of 6.5%, coupled with stable population growth and rising incomes, Vietnam presents a promising long-term market for global investors. In the financial year 2023-24, Vietnam's total exports are projected to reach a remarkable US$123.64 billion. In this article, we will delve into the top 10 exports from Vietnam, explore the country's key export products, provide a list of major exporters, and offer updated Vietnam export data.

Current Trends in Vietnam's Exports

Vietnam's export landscape has seen significant evolution over recent years. Analysis of Vietnam export data reveals several noteworthy trends. One prominent trend is the shift towards higher-value manufacturing sectors, such as electronics, which have rapidly expanded. Despite this shift, traditional industries like agriculture and textiles continue to thrive, showcasing Vietnam's diverse export portfolio.

As an export-driven economy, Vietnam benefits from over 90 bilateral trade agreements and approximately 60 bilateral investment promotion and protection contracts.

Key Export Trends:

Overall Growth: Vietnam's exports totaled $371.3 billion in 2022, marking a 10.5% increase from the previous year. This represents a substantial rise from $236 billion in 2017.

Shifting Manufacturing Hub: Vietnam is increasingly viewed as a cost-effective alternative to China, attracting global companies looking to relocate their manufacturing operations.

Trade Agreements: Free trade agreements, including the RCEP, EVFTA, and UKVFTA, have opened new markets for Vietnamese goods and simplified export processes.

The fastest-growing export sectors in Vietnam include electronics (notably phones and computers), machinery, textiles, footwear, and agricultural products. The overall export economy shows no signs of slowing down, driven by robust growth across key industries.

Vietnam Export Data: 2023-24

Between January and April 2024, total trade amounted to $238.88 billion, a 15.2% increase year-over-year. Vietnam's exports for this period reached an estimated $123.64 billion, up 15% from the previous year. The trade surplus in goods stood at $8.4 billion for the first four months of 2024. This strong performance indicates a recovery from the previous year's decline, where total foreign trade fell by 6.6% and exports dropped by 4.4%.

Top 10 Exports from Vietnam (2024)

Vietnam exports a wide range of products, from semi-finished to final goods. Here are the top 10 export products that dominate the country's export landscape:

Phones and Accessories: $57.99 billion

Computers and Electronic Products: $55.54 billion

Machinery and Equipment: $45.75 billion

Textiles and Garments: $37.57 billion

Footwear: $23.90 billion

Wood and Wooden Products: $16.01 billion

Vehicles and Spare Parts: $11.99 billion

Seafood and Fishery Products: $10.92 billion

Iron and Steel: $7.99 billion

Cameras, Camcorders, and Accessories: $6.37 billion

Phones and accessories lead the list, with exports valued at $57.99 billion, followed closely by computers and electronic products. Other significant export items include textiles, garments, and footwear.

Vietnam's Top Export Partners

Vietnam's export partners play a crucial role in its trade dynamics. Here is an updated list of the top export partners:

China: $175.57 billion

USA: $123.86 billion

Korea: $86.38 billion

Japan: $47.61 billion

Netherlands: $3.99 billion

Hong Kong: $3.389 billion

India: $3.309 billion

Germany: $3.104 billion

Thailand: $2.975 billion

United Kingdom: $2.359 billion

China remains Vietnam's top trading partner, with a two-way trade turnover of $175.57 billion, followed by the USA and Korea.

Future Projections for Vietnam's Foreign Trade

The anticipated growth in Vietnam's foreign trade is largely attributed to key export markets controlling inflation, thereby boosting demand for Vietnamese goods. Additionally, Vietnam's free trade agreements, particularly the EVFTA, are expected to enhance export performance in the coming months further. The ongoing efforts of Western corporations to diversify supply chains away from China will likely continue to benefit Vietnam's manufacturing sector and drive long-term economic growth.

How to Find Vietnam Exporters

For the most up-to-date and accurate Vietnam exporters data, visit Eximpedia. This platform provides comprehensive Vietnam export data and a list of Vietnam export products. It is an essential tool for analyzing global shipments, with a database covering more than 130 countries.

Conclusion

In conclusion, the global economic recovery in 2024 is set to boost demand and increase export orders, helping Vietnamese exporters achieve their goals. Additionally, new products like medical herbs, coconuts, frozen fruits, and watermelons are expected to enter the market. By analyzing Vietnam's major export products and trading partners, we gain valuable insights into its global market position. For more information on Vietnam's top exports or export data, visit the Eximpedia.app and consult their experts for detailed guidance.

Thank you for reading about Vietnam's major exports. We hope you found this information insightful.

#exports from Vietnam#major exports of Vietnam#Vietnam export products#Vietnam top export products#Vietnam top 10 exports#top export products from Vietnam

0 notes

Text

Exploring Excellence in Jacquard Manufacturing: Madaan Engineering

Panipat, often hailed as the "City of Weavers," has long been the epicenter of India's textile industry. Among its myriad of textile manufacturers, Madaan Engineering stands out as a beacon of quality and innovation. Specializing in the production of Jacquard machines, Madaan Engineering has established itself as a premier player in the industry, providing top-notch equipment to textile manufacturers not just in Panipat, but across India.

Madaan Engineering: A Tradition of Excellence

Madaan Engineering is synonymous with quality in the world of Jacquard manufacturing. With decades of experience, the company has mastered the art and science of producing high-performance Jacquard machines. These machines are pivotal in creating intricate and beautiful designs on fabrics, a cornerstone of the textile industry in Panipat.

Comprehensive Product Range

Madaan Engineering offers a diverse range of Jacquard machines designed to meet the varied needs of textile manufacturers. Their product lineup includes:

Hand Loom Jacquard Machines: Ideal for small-scale artisans and weavers who produce bespoke fabric designs.

Power Loom Jacquard Machines: Perfect for larger textile operations, these machines combine efficiency with precision, ensuring high productivity.

Electronic Jacquard Machines: Equipped with the latest technology, these machines offer unparalleled speed and accuracy, catering to the needs of modern textile production.

Superior Quality and Innovation

Quality is the hallmark of Madaan Engineering. Each machine is crafted using the finest materials and undergoes rigorous testing to ensure it meets the highest standards. The company's commitment to innovation is evident in its continuous investment in research and development, which allows it to stay ahead of industry trends and offer cutting-edge solutions.

Competitive Pricing

While Madaan Engineering prides itself on the quality of its products, it also understands the importance of cost-efficiency for its clients. The company offers competitive pricing on all its Jacquard machines, ensuring that customers get the best value for their investment. The pricing is transparent, with no hidden costs, allowing clients to plan their budgets effectively.

Farming Equipment

In addition to Jacquard machines, Madaan Engineering has also diversified into the farming equipment sector. Recognizing the needs of Indian farmers, the company provides robust and reliable farming equipment designed to enhance productivity and ease agricultural processes. This includes plows, harrows, seeders, and other essential farming tools.

Commitment to Customer Satisfaction

Customer satisfaction is at the core of Madaan Engineering’s business philosophy. The company offers comprehensive after-sales support, including maintenance services, spare parts, and technical assistance. This ensures that their clients can operate their Jacquard machines and farming equipment smoothly, with minimal downtime.

Why Choose Madaan Engineering?

Expertise and Experience: With a rich history and deep knowledge of the textile industry, Madaan Engineering is a trusted name.

Quality Assurance: Each product undergoes stringent quality checks to ensure reliability and performance.

Innovative Solutions: The company constantly innovates to provide state-of-the-art machinery.

Competitive Pricing: High-quality products at affordable prices.

Exceptional Customer Service: Dedicated support team ready to assist with any queries or issues.

Conclusion

Madaan Engineering has carved a niche for itself in the Jacquard manufacturing industry in Panipat. Its dedication to quality, innovation, and customer satisfaction has made it a preferred choice for textile manufacturers and farmers alike. Whether you are looking for advanced Jacquard machines or reliable farming equipment, Madaan Engineering promises products that stand the test of time and deliver exceptional performance.

Explore the world of Madaan Engineering and take your manufacturing or farming business to new heights of success with their superior products and unwavering support.

4o

Spring Loaded Cultivator | Agriculture Implements Manufacturer in India write an title and description using these keywordsChatGPT

Title: Superior Spring Loaded Cultivators by Leading Agriculture Implements Manufacturer in India

Description: Discover top-quality Spring Loaded Cultivators designed by the premier Agriculture Implements Manufacturer in India. Engineered for efficiency and durability, our cultivators ensure optimal soil preparation and enhanced farming productivity. Trusted by farmers across the nation, our innovative agricultural tools are built to withstand rigorous use, providing reliable performance season after season. Choose excellence in farming with our expertly crafted spring-loaded cultivators.

4o

write a disc blades descriptionChatGPT

High-Quality Disc Blades for Superior Agricultural Performance

Our disc blades are crafted from premium materials to ensure exceptional durability and efficiency in all soil conditions. Designed for use with a variety of agricultural implements, these blades are perfect for plowing, cultivating, and soil preparation tasks. Engineered to maintain sharpness and resist wear, our disc blades deliver consistent performance and longer operational life. With precise cutting and turning capabilities, they help in achieving optimal soil structure and improved crop yields. Trust our high-quality disc blades to enhance your farming operations with reliability and excellence.

4o

Agriculture Implements Exporters in India | Heavy Duty Spring Loaded Cultivator write an article using these keywords and tells madaan engineering provide quality of productsChatGPT

Madaan Engineering: Leading Agriculture Implements Exporters in India with Heavy Duty Spring Loaded Cultivators

India's agricultural sector is a cornerstone of its economy, and the tools and implements used in farming are crucial to its success. Among the many manufacturers and exporters of agricultural implements in India, Madaan Engineering stands out for its commitment to quality and innovation. Specializing in heavy-duty spring-loaded cultivators, Madaan Engineering is a name synonymous with excellence in the industry.

Madaan Engineering: A Tradition of Quality and Innovation

Madaan Engineering has been a prominent player in the agricultural implements sector for decades. Based in Panipat, the company has built a reputation for producing robust and reliable farming equipment that meets the diverse needs of farmers across the globe. As a leading exporter, Madaan Engineering ensures that its products adhere to international standards, making them highly sought after in both domestic and international markets.

Heavy Duty Spring Loaded Cultivators: The Backbone of Modern Farming

One of Madaan Engineering’s flagship products is the heavy-duty spring-loaded cultivator. This implement is essential for modern farming, designed to break up soil, remove weeds, and prepare the land for planting. The spring-loaded mechanism provides flexibility and durability, allowing the cultivator to adapt to varying soil conditions and terrain types. Here’s what sets Madaan Engineering’s cultivators apart:

Robust Construction: Made from high-grade steel, these cultivators are built to withstand the rigors of intensive farming.

Efficient Design: The spring-loaded design ensures effective soil penetration and aeration, promoting better crop yields.

Versatility: Suitable for a variety of soil types and farming practices, making them ideal for diverse agricultural applications.

Ease of Use: Designed with the farmer in mind, these cultivators are easy to attach, use, and maintain, reducing downtime and increasing productivity.

Quality Assurance: A Hallmark of Madaan Engineering

Quality is at the core of Madaan Engineering’s philosophy. Every product undergoes rigorous quality control processes to ensure it meets the highest standards. The company employs advanced manufacturing techniques and state-of-the-art technology to produce implements that are not only efficient but also long-lasting. This commitment to quality has earned Madaan Engineering certifications and accolades, further cementing its reputation as a trusted name in the industry.