#Stacker/bridge reclaimer

Explore tagged Tumblr posts

Text

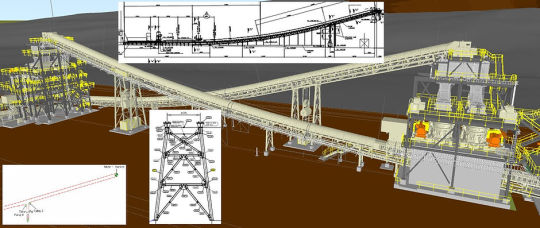

Little P.Eng. Engineering: Pioneering Bulk Material Transfer Design across Canada and the USA

When it comes to the intricate world of bulk material transfer, North America's industrial backbone relies heavily on robust, efficient, and innovative machinery. Operating at the forefront of this industry is Little P.Eng. Engineering, a name synonymous with exemplary structural and mechanical design across Canada and the USA.

Bulk Material Transfer Design: The Pulse of Modern Industry

Transcending borders, bulk material transfer is central to the heartbeat of contemporary industries. From the sprawling mines of Canada to the bustling ports of the USA, the movement, deposition, and retrieval of large-scale materials demand a seamless blend of precision, durability, and adaptability.

Journeying Through Little P.Eng. Engineering’s Pan-North American Impact

Single-boom Spreaders:

Functionality: Essential in the processing of minerals, ores, and coal, these machines promise uniformity in layering vast material amounts.

Little P.Eng. Across Continents: Adapting to the varied terrains and industrial needs of Canada and the USA, Little P.Eng.'s designs optimize weight distribution, longevity, and operational flexibility.

Mobile Stacking Bridges:

Functionality: Mobile and versatile, these units aid in the strategic stockpiling of materials in expansive stockyards.

Little P.Eng.’s Transnational Signature: Ensuring a balance between agility and stability, the design innovations address diverse geographic and operational needs across North America.

Transport Crawlers:

Functionality: These titans manage the internal transportation of massive equipment, streamlining logistical challenges.

Little P.Eng.’s North American Adaptability: By designing crawlers that focus on energy efficiency and terrain adaptability, they address the unique challenges of both Canadian mines and American industrial facilities.

Stackers and Reclaimers (Single & Combined):

Functionality: While stackers deposit materials systematically, reclaimers specialize in their retrieval. Combined machinery handles both roles.

Little P.Eng.'s Pan-American Approach: Catering to the varying scales and nuances of industries across the two nations, designs prioritize transition fluidity and spatial optimization.

Bucket Wheel Reclaimer (Boom & Bridge):

Functionality: With an array of buckets, these reclaimers ensure efficient retrieval from vast stockpiles.

Little P.Eng.’s Cross-Border Excellence: Be it the Canadian cold or the American heat, precision-focused designs ensure efficient operations under diverse conditions.

Scraper, Drum, and Portal Reclaimers:

Functionality: Each variant is uniquely designed to retrieve stockpiled materials, adhering to specific operational demands.

Little P.Eng.’s Continental Precision: By crafting machinery tailored for the specific needs of locations from Alberta to Alabama, the emphasis is on tailored efficiency.

Portal and Bridge-type Scraper Reclaimers:

Functionality: These reclaimers excel in longitudinal stockyards, merging efficiency with compactness.

Little P.Eng.’s Broad Vision: The designs seamlessly integrate with North American industrial landscapes, maximizing space and operational potential.

Ship Loaders & Unloaders:

Functionality: Vital cogs in maritime logistics, these entities manage the intricate process of loading and unloading materials.

Little P.Eng.’s Coastal Touch: With an understanding of the varied port dynamics across the two nations, designs ensure faster operations, minimizing ship turnaround times.

Grab Type Ship Unloader:

Functionality: Specializing in rapid unloading, they promise efficiency at its best.

Little P.Eng.’s Harbor Mastery: Emphasizing precision and speed, designs cater to the bustling ports of both Canada and the USA, ensuring peak operational performance.

Circular Storage with Stacker/Bridge Reclaimer:

Functionality: These units epitomize the optimal utilization of circular stockyards, promising swift stacking and retrieval.

Little P.Eng.’s Circular Innovation: By integrating space-saving techniques with high-speed operations, designs redefine the contours of material storage and retrieval.

Beyond Borders: Little P.Eng. Engineering’s Vision

For Little P.Eng. Engineering, the journey isn’t just about creating machinery. It’s about crafting solutions, ones that resonate with the industrial ethos of both Canada and the USA. Recognizing the unique challenges and potentials of each nation, the company's designs embody adaptability, sustainability, and the future.

Conclusion

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Single-boom spreaders

Mining equipment

Bulk material transfer

North American industries

Mobile stacking bridges

Transport crawlers

Stacker and reclaimers

Bucket wheel reclaimer

Boom & bridge reclaimer

Scraper reclaimers

Drum reclaimers

Portal reclaimers

Bridge-type scraper reclaimers

Ship loaders

Ship unloaders

Grab type ship unloader

Circular storage

Stacker/bridge reclaimer

Material handling machinery

Industrial logistics

Maritime logistics

Stockpile management

Heavy machinery design

Port equipment

Tailored efficiency

Material storage solutions

Sustainable machinery design

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Single-boom spreaders#Mining equipment#Bulk material transfer#North American industries#Mobile stacking bridges#Transport crawlers#Stacker and reclaimers#Bucket wheel reclaimer#Boom & bridge reclaimer#Scraper reclaimers#Drum reclaimers#Portal reclaimers#Bridge-type scraper reclaimers#Ship loaders#Ship unloaders#Grab type ship unloader#Circular storage#Stacker/bridge reclaimer#Material handling machinery#Industrial logistics#Maritime logistics#Stockpile management#Heavy machinery design#Port equipment#Tailored efficiency#Material storage solutions#Sustainable machinery design

0 notes

Photo

insulation raw material for cement manufacture Supporting roller and axles Base frame manufacture Pressure air pipe insulation Machine components impact crusher manufacture Insulation outside cement mill for seal manufacture Secondary piping Dedusting duct rotary kiln insulation Parts to cooling water feeding manufacture Heat shield kiln drive Girth gear protection cover manufacture Rotary Packer insulation Accessories plant dispatch station Machine components jaw crusher insulation Steel parts chain scraper manufacture Chain Conveyor insulation Components trough conveyor manufacture Wear lining cyclone Bracket and base frame Service platform insulation Bolted connection Maschine components heat exchanger insulation Housing parts fixed bearing manufacture batch blending and storage system of raw meal insulation Steel parts for hydraulic piping manufacture Pinion shaft with accessories insulation Air Sliding Conveyor manufacture Segment inlet trough insulation Component parts mixing bin manufacture Primary air damper insulation Fan for AS Steel parts fan insulation Steel parts apron weigh feeder Trough conveyor Conveying chain manufacture Inlet cone insulation Steel parts apron conveyor manufacture clinker conveying and storage Base Frame Motor manufacture Dedusting duct insulation Measuring device pressure Steel parts bridge girder Curved guide vane manufacture Bag Filter insulation Steel parts bypass chamber insulation Weigh belt feeder insulation Inlet manufacture Accessories for outlet seal Bolted connection manufacture Accessories for inlet seal insulation pulverised raw mills manufacture Machine components fan insulation Lubricant splash Steel parts pressure vessel Crane wheel Mounting tool insulation sotareg crushing and limestone and stacker and reclaimer system manufacture Segments drying chamber diaphragm cement mill bypass chamber manufacture Steel parts travelling gear insulation Bearing adjustment hydraulic manufacture Screw Conveyor insulation machinery for manufacturing cement Shutoff flap conveying air insulation Pinion rigid manufacture insulation and lagging insulation Dispersing flights drying chamber manufacture Internal components pressure vessel insulation Cylinder fastening Segments discharge diaphragm

+90532 0665 668

http://www.altinokmakina.com Bin for Cement manufacture chutes insulation Cooling air fan insulation Steel parts splash lubrication

0 notes

Text

Industrial Brakes And Clutches Market Segments and Key Trends 2017-2027

Industrial brakes and clutches market covers a variety of holding & dynamic brakes and clutches used in industrial process equipment such as turbines, uphill, downhill & overland conveyors, overhead cranes, trolleys, bridges, hoists & winches, rotors & yaw systems, motors & engines, elevators, cable cars & ropeway and stacker reclaimer. With ever increasing industrialization and implementation of heavy-duty machineries, industrial brakes and clutches have become a crucial part and have acted as the backbone of these heavy-duty machineries. Safety and proper operation are two important concerns related to industrial equipment, which necessitate proper selection of brakes and clutches for various applications. The industrial brakes and clutches market is expected to witness steady growth over the forecast period owing to the constant demand from MRO services. OEM demands, i.e. demand from new equipment manufacturers is expected to witness slower growth than MRO services; this is primarily due to the fact that the industrial equipment possess shorter operational life span. Favourable macro-economic environment is expected to significantly boost the growth of industrial brakes and clutches market, as positive economic growth will result in substantial growth of industries, which are the target markets for industrial brakes and clutches.

Global Industrial Brakes and Clutches Market: Market Dynamics

The transition of manufacturing sector towards automation and smart manufacturing, supplemented by increasing investments in industrial automation equipment are the key factors responsible for the growth of the industrial brakes and clutches market. Furthermore, industries across the globe are strongly influenced by standards and regulations that demand robust equipment performance and proper safety of man and material, such regulations also compel manufacturers to focus on research and product development, in turn, fuelling the market growth. The expected growth in end-use industries i.e. oil & gas, mining, lumber industry, coal handling, steel industry, cable car & ropeway, power generation, mining, etc. is foreseen to create new opportunities for industrial brakes and clutches market. Adoption of new and advanced products such as backstopping clutches and advanced material brake shoe & rotors is projected to be the prominent trend in the global industrial brakes and clutches market.

Request For Sample@ http://www.futuremarketinsights.com/reports/sample/rep-gb-3408

Global Industrial Brakes and Clutches Market: Segmentation

The global industrial brakes and clutches market can be segmented based on technology, product type, sales channel and end-use industry.

By technology, the global industrial brakes and clutches market can be classified into:

Clutches

Brakes

Electric

Mechanical

Pneumatic & Hydraulic

Electromagnetic

Electric

Mechanical

Pneumatic & Hydraulic

Electromagnetic

By product type, the global industrial brakes and clutches market can be classified into:

Dry

Oil Immersed

By sales channel, the global industrial brakes and clutches market can be classified into:

OEM

MRO Services/Aftermarket

By end-use industry, the global industrial brakes and clutches market can be classified into:

Mining & Metallurgy Industry

Construction Industry

Power Generation Industry

Industrial Production

Commercial

Logistics and Material Handling Industry

Request For TOC@ http://www.futuremarketinsights.com/toc/rep-gb-3408

Global Industrial Brakes and Clutches Market: Region-wise Outlook

North America and Europe are the hubs for manufacturing industrial brakes and clutches. A number of prominent manufacturers of industrial brakes and clutches have their manufacturing facilities in these regions. Thus, these regions are projected to be the technology leaders when mapped on to a global front. The regions are expected to witness high adoption rate for new and advanced technologies when compared to other regions. Asia Pacific is expected to emerge as a lucrative market for industrial brakes and clutches, as the region is foreseen to have noteworthy investment in industrial automation. Also, new infrastructural development, oil & gas projects will create demand, both for fresh sales of industrial brakes and clutches and MRO services. In Middle East and Africa, oil & gas, mining and construction are expected to be the key markets for industrial brakes and clutches and positive growth is expected during the forecast period.

Global Industrial Brakes and Clutches Market: Market Participants

Examples of some of the market participants identified in the global industrial brakes and clutches market are:

Altra Industrial Motion Corp.

The Carlyle Johnson Machine Company, LLC

Eaton Corporation Plc

Johnson Industries Ltd.

Hindon Corporation

Kobelt Manufacturing Co. Ltd.

Ogura Industrial Corp.

Dayton Clutch & Joint.

PT Tech Power Innovation

Browse Full Report@ http://www.futuremarketinsights.com/reports/industrial-brakes-and-clutches-market

0 notes