#Sterilization Container System Market Application

Explore tagged Tumblr posts

Text

Returnable Packaging Gains Momentum in Food and Automotive Sectors

Global Returnable Packaging Market to Reach USD 173 Billion by 2030 Driven by Circular Economy, Smart Technologies, and Industrial Demand

The Returnable Packaging Market is projected to grow from USD 115.4 billion in 2023 to USD 173.0 billion by 2030, recording a compound annual growth rate (CAGR) of approximately 6%. The trend is expected to continue beyond 2030 as sustainability initiatives, smart logistics, and industry cost-saving strategies gain momentum across developed and developing economies.

Returnable packaging reusable containers, pallets, racks, and bulk containers is a crucial part of sustainable supply chains. These systems are used in food and beverage, automotive, healthcare, electronics, and industrial manufacturing sectors to reduce waste, optimize logistics, and improve traceability.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/returnable-packaging-market

Key Growth Drivers

1. Sustainability and Waste Reduction As governments and global organizations enforce bans on single-use packaging, companies are shifting toward reusable alternatives. Returnable packaging reduces material waste and greenhouse gas emissions while improving long-term cost efficiency. It also supports ESG reporting goals and sustainability commitments for corporations.

2. Smart Tracking and Asset Management The integration of RFID tags, QR codes, and GPS sensors into packaging assets allows real-time tracking, reducing the chances of loss or theft. These technologies enhance inventory management and create data-driven logistics systems that support automation and transparency.

3. Industrial Logistics and Automotive Complexity In the automotive sector, components move through global supply chains in durable plastic and metal containers. Returnable systems provide protection, facilitate part sorting, and reduce handling costs. The same is true for electronics and aerospace industries, where components are delicate and transit cycles are lengthy.

4. Food and Beverage Safety Compliance Reusable packaging in food and beverage is designed for hygiene, durability, and compliance with international food safety regulations. Pallets, crates, and bins can be sterilized and reused across cold chains and retail channels without compromising safety or quality.

Regional Market Insights

Asia-Pacific: Fastest-Growing Market Asia-Pacific leads the global market in growth, expected to increase from USD 42.9 billion in 2023 to USD 67.6 billion by 2030. Countries like China, India, and Japan are investing heavily in supply chain modernization, industrial automation, and sustainable packaging alternatives. Rapid urbanization and expansion of organized retail are further supporting demand.

United States: Pioneering Smart Returnable Systems In North America, the United States accounts for a major share of reusable packaging implementation, particularly in automotive manufacturing and retail logistics. Advanced technologies and green packaging initiatives across U.S. states have pushed industries toward reusable formats and reverse logistics planning.

Japan: Reusables in Precision Manufacturing and Food Japan maintains strong demand for returnable packaging in its food and industrial sectors. Its compact geography and advanced logistics networks support efficient circulation of reusable pallets and containers. The Japanese market is also at the forefront of applying lean manufacturing practices, where reusable assets play a key role.

Material and Product Trends

Plastic Leads, Metal Gaining Ground Plastic is the most widely used material in returnable packaging due to its light weight, durability, and recyclability. However, the metal segment especially steel is the fastest growing, thanks to its strength and suitability for heavy-duty applications in automotive and construction sectors.

Popular Product Categories

Pallets and Crates: Dominate in food & beverage and retail

Intermediate Bulk Containers (IBCs): Widely used in chemicals and pharmaceuticals

Drums and Barrels: Common in agriculture, oil, and liquids transport

Racks and Totes: Used in electronics and machinery sectors

Emerging Growth Opportunities

1. Subscription-Based Reusable Services Third-party logistics companies are offering reusable container leasing and tracking as a service. This model lowers the entry barrier for smaller businesses and offers scalable, traceable return logistics systems.

2. Reverse Logistics Platforms Software-as-a-service (SaaS) solutions for return logistics are helping companies optimize routing, reduce empty returns, and monitor container usage. This reduces costs and environmental impact.

3. Customizable and Modular Packaging Innovations in modular packaging design allow a single container to serve multiple purposes, enhancing ROI for large-scale users. This also improves packing density and efficiency in warehousing.

4. Circular Manufacturing Ecosystems Manufacturers are developing closed-loop supply chains where packaging circulates between factories, suppliers, and customers, reducing reliance on virgin materials.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/returnable-packaging-market

Challenges

High Initial Investment: The cost of purchasing reusable assets and integrating tracking infrastructure can be prohibitive for smaller firms.

Reverse Logistics Complexity: Ensuring packaging returns to origin points in usable condition requires coordinated systems, especially across borders.

Cleaning and Sanitation Requirements: For food and pharmaceutical sectors, reusable containers must meet stringent hygiene standards, adding operational layers.

Regulatory Variance: Different countries have varying compliance norms, affecting packaging material approvals and logistics strategies.

Conclusion

The returnable packaging market is well-positioned for significant growth, with its value forecasted to rise from USD 115 billion in 2023 to USD 173 billion by 2030. This growth reflects a global shift toward sustainable business models, advanced supply chain technologies, and cost-efficient asset management.

As companies across sectors like automotive, food, pharma, and industrial manufacturing adopt reusable systems, the demand for smart, durable, and trackable packaging solutions will accelerate. With Asia-Pacific at the forefront and mature markets like the U.S. and Japan leading on innovation, the future of packaging is circular, smart, and sustainable.

0 notes

Text

Water Filling Machine: The Ultimate Guide for Industrial and Commercial Use

What is a Water Filling Machine?

A water filling machine is an automated or semi-automated system used to fill water into bottles of various sizes. These machines are used in bottled water plants, beverage factories, and industrial packaging lines. They help ensure fast production, exact filling volumes, and sanitary operation, complying with industry standards such as BIS, ISI, FSSAI, FDA, and ISO 22000.

Types of Water Filling Machines

1. Automatic Water Filling Machines

These machines are fully automated, including bottle feeding, rinsing, filling, and capping systems. Ideal for high-volume production plants, they can process anywhere from 2,000 to over 24,000 bottles per hour (BPH).

2. Semi-Automatic Water Filling Machines

Perfect for small businesses or startups, these machines require some manual intervention. They offer great affordability while maintaining decent fill speeds and accuracy.

3. Rotary Water Filling Machines

These machines operate on a rotating base, filling multiple bottles simultaneously. High-speed and highly efficient, they are perfect for large-scale bottled water production.

4. Linear Water Filling Machines

Operate in a straight line and are suitable for mid-level production capacity. They are modular, easy to maintain, and can be integrated with other packaging systems.

Key Components of a Water Filling Machine

Rinsing Section: Ensures bottles are cleaned internally using sterile water or air-jet systems.

Filling Section: Dispenses the exact quantity of water without any spillage.

Capping Section: Automatically places and tightens caps.

Conveyor System: Moves bottles from one station to another seamlessly.

Control Panel: Touchscreen interface with PLC to monitor speed, fill levels, and errors.

Water Filling Machine Applications

1. Bottled Mineral Water Plants

Used for 200ml, 500ml, 1L, and 2L PET or glass bottles. Machines can be customized for various bottle neck sizes and shapes.

2. 20-Liter Jar Water Plants

These machines are used for large container packaging and generally include washing, sanitizing, and filling units integrated into one line.

3. Sparkling or Flavored Water Filling

Machines are modified to handle carbonated water, requiring pressure-resistant filling nozzles and foam control.

Advanced Features of Modern Water Filling Machines

1. PLC and HMI-Based Control

Allows real-time monitoring, quick troubleshooting, and batch-wise production tracking.

2. Automatic Bottle Detection

Ensures "no bottle – no fill" operation to prevent product loss.

3. HEPA Filters and UV Sterilization

Critical for maintaining hygiene, especially in pharmaceutical or baby water products.

4. Stainless Steel Construction (SS304/316L)

Non-corrosive, food-grade materials ensure long life and hygiene compliance.

5. Low Maintenance and CIP Systems

Machines now come with Clean-In-Place (CIP) systems to ensure regular, automated internal cleaning.

Benefits of Using a Water Filling Machine

High-Speed Production: Speeds of up to 400 bottles/min are possible with rotary models.

Precision and Accuracy: Digital flow meters ensure minimal variation in fill levels.

Labor Reduction: Fully automated systems require minimal operator intervention.

Consistency: All bottles are filled and capped identically, ensuring product standardization.

Scalability: Can be integrated with labeling, shrink tunnel, carton packing, and palletizing machines.

How to Choose the Right Water Filling Machine

1. Define Your Output Requirement

Are you producing 500 BPH or 10,000 BPH? Your choice of machine will depend on your volume.

2. Consider the Bottle Type and Size

Ensure the machine supports your bottle’s neck diameter, height, and shape.

3. Look for Hygiene Certifications

Machines must comply with BIS, FSSAI, or international norms depending on your target market.

4. Plan for Integration

Will your machine work as part of a full line (rinsing, capping, labeling, sealing)? If so, choose a modular or turnkey solution.

0 notes

Text

Plastic Encapsulated Thermistor Market: Transition to Advanced Nodes in Semiconductor Fabrication

MARKET INSIGHTS

The global Plastic Encapsulated Thermistor size was valued at US$ 234 million in 2024 and is projected to reach US$ 323 million by 2032, at a CAGR of 4.6% during the forecast period 2025-2032. The U.S. market accounted for 28% of global revenue in 2024, while China’s market is expected to grow at a faster CAGR of 6.7% through 2032.

Plastic Encapsulated Thermistors are temperature-sensitive resistors encapsulated in polymer materials, offering improved mechanical protection and environmental resistance compared to bare thermistors. These components exhibit a predictable change in electrical resistance with temperature variations, making them critical for temperature sensing and compensation applications across industries. The product range includes both uninsulated wire and insulated wire variants, with the latter dominating over 62% market share in 2024 due to better safety and durability.

Market growth is driven by expanding applications in home appliances, digital thermometers, and medical devices, where precise temperature monitoring is essential. While demand from automotive applications shows steady growth, the medical sector is emerging as the fastest-growing segment with a projected 7.1% CAGR, fueled by increasing adoption in diagnostic equipment and patient monitoring systems. Key manufacturers like Littlefuse and Semitec are investing in miniaturization technologies to capture opportunities in wearable medical devices and IoT applications.

MARKET DYNAMICS

MARKET DRIVERS

Expanding Automotive and Electronics Sectors Fuel Demand for Plastic Encapsulated Thermistors

The global automotive industry’s shift toward electric vehicles and advanced driver-assistance systems (ADAS) is creating substantial demand for reliable temperature sensors like plastic encapsulated thermistors. Modern vehicles contain over 50 temperature sensors on average, with thermistors playing a crucial role in battery management, climate control, and engine monitoring systems. The growing complexity of automotive electronics, combined with stringent safety regulations, is pushing manufacturers toward encapsulated solutions that offer better protection against environmental factors.

Growth in Smart Home Appliances Accelerates Market Penetration

The smart home appliance market, projected to maintain double-digit growth through 2030, represents a significant growth avenue for plastic encapsulated thermistors. These components are essential for temperature regulation in refrigerators, air conditioners, and washing machines. The encapsulation provides necessary protection against moisture and chemical exposure while maintaining precise temperature sensitivity. With consumers increasingly opting for energy-efficient appliances featuring IoT connectivity, manufacturers are incorporating more sophisticated thermal management systems that rely heavily on encapsulated thermistor technology.

➤ The Asia Pacific region accounts for over 40% of global appliance production, making it a critical market for thermistor suppliers looking to capitalize on this growth.

Furthermore, the medical equipment sector’s expansion, particularly in portable diagnostic devices and wearable health monitors, presents additional growth opportunities. These applications require miniaturized, reliable temperature sensors that can withstand sterilization processes and body fluid exposure.

MARKET RESTRAINTS

Raw Material Price Volatility Impacts Profit Margins

The plastic encapsulated thermistor market faces significant pressure from fluctuating raw material costs. The prices of key materials like epoxy resins, nickel, and specialty plastics have shown volatility exceeding 15% year-over-year in recent periods. This unpredictability makes cost management challenging for manufacturers, particularly smaller players with limited procurement leverage. The situation is further complicated by global supply chain disruptions that have affected material availability since 2020.

Other Constraints

Intense Commoditization Pressure The market has seen increasing price competition as numerous Asian manufacturers enter the space with lower-cost alternatives. While encapsulation provides differentiation, many basic thermistor applications face severe commoditization, squeezing margins for all participants.

Technical Limitations in Extreme Environments Despite their advantages, plastic encapsulated thermistors face operational challenges in applications requiring continuous exposure to temperatures above 150°C or aggressive chemical environments. This limitation restricts their use in certain industrial and automotive applications where ceramic or glass-encapsulated alternatives remain preferred.

MARKET CHALLENGES

Miniaturization Demands Strain Manufacturing Capabilities

The industry faces mounting pressure to produce smaller thermistors with equivalent or improved performance characteristics. Modern electronics, particularly wearables and IoT devices, require components measuring less than 1mm in diameter while maintaining tight resistance tolerances. Achieving this miniaturization without compromising reliability or increasing failure rates presents significant engineering and production challenges. The encapsulation process becomes particularly difficult at these scales, with yield rates suffering when dimensions shrink below certain thresholds.

Other Challenges

Stringent Automotive Qualification Processes The automotive industry’s stringent qualification requirements, including AEC-Q200 compliance, create lengthy and expensive certification processes. Many manufacturers struggle with the extensive testing and documentation requirements, delaying time-to-market for new products.

Maintaining Consistency Across Production Batches Achieving consistent performance characteristics across large production runs remains an ongoing challenge due to variations in plastic curing processes and raw material properties. This consistency is critical for applications requiring precise temperature measurement and control.

MARKET OPPORTUNITIES

Emerging Applications in Renewable Energy Systems Create New Growth Avenues

The rapid expansion of solar and wind energy infrastructure presents significant opportunities for plastic encapsulated thermistors. These components are increasingly used in battery storage systems, power inverters, and turbine monitoring equipment. The renewable energy sector’s projected 8% annual growth through 2032 suggests strong continued demand for reliable temperature monitoring solutions that can withstand outdoor environmental conditions.

Advancements in Encapsulation Materials Open New Possibilities

Recent developments in polymer science have yielded encapsulation materials with enhanced thermal conductivity and chemical resistance. These innovations enable thermistors to operate in previously inaccessible applications, including certain industrial processes and medical sterilization equipment. As material science continues progressing, we can expect expanded application boundaries for plastic encapsulated solutions.

Additionally, the integration of smart manufacturing techniques like AI-powered quality control and Industry 4.0 practices is helping manufacturers overcome previous production challenges. These technologies enable real-time process adjustments and predictive maintenance, significantly improving yield rates and product consistency.

PLASTIC ENCAPSULATED THERMISTOR MARKET TRENDS

Growing Demand Across Consumer Electronics and Automotive Sectors

The global Plastic Encapsulated Thermistor market continues to gain traction, primarily driven by increasing adoption in consumer electronics and automotive applications. Thermistors play a critical role in temperature sensing and circuit protection, making them indispensable in smart home devices, HVAC systems, and automotive battery management. The rise of IoT-enabled appliances and electric vehicles (EVs) has further accelerated demand, with market forecasts projecting a steady CAGR throughout the decade. Advances in polymer encapsulation technology have enhanced their durability and resistance to environmental factors, further expanding their utility in high-performance applications.

Other Trends

Miniaturization and Precision Engineering

Manufacturers are focusing on miniaturization to meet the evolving needs of compact electronic devices. Smaller form factors with enhanced thermal sensitivity are increasingly sought after in wearable technology and medical devices. Improved fabrication techniques allow for thermistors that maintain accuracy while reducing footprint—critical for applications like implantable medical sensors and precision instrumentation. Additionally, innovations in material science have led to better stability over wide temperature ranges, addressing key challenges in industrial automation.

Regional Market Dynamics and Supply Chain Optimization

While North America and Europe remain dominant markets due to stringent automotive safety regulations and advanced healthcare infrastructure, Asia-Pacific is emerging as the fastest-growing region. Countries like China and India are witnessing double-digit growth in thermistor shipments, fueled by expanding electronics manufacturing hubs and government incentives for EV adoption. Meanwhile, suppliers are increasingly focusing on vertical integration to mitigate raw material shortages, with leading companies investing in proprietary polymer compounds to ensure consistency and reduce lead times. Partnerships between sensor manufacturers and semiconductor foundries are also streamlining production workflows, directly benefiting OEMs.

Sustainability and Regulatory Compliance

Environmental regulations are reshaping material selection, with RoHS-compliant thermistors now constituting over 70% of new product launches. The shift toward halogen-free encapsulation materials aligns with global sustainability initiatives while maintaining performance benchmarks. Recycling programs for end-of-life electronic components are gaining momentum, particularly in Europe, where circular economy policies incentivize eco-friendly designs. These trends are expected to influence R&D priorities, particularly in balancing cost efficiency with compliance—a crucial factor for price-sensitive markets.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Positioning Drive Market Competition

The global plastic encapsulated thermistor market features a dynamic competitive landscape with a mix of established players and emerging manufacturers striving for market share. With Asia-Pacific dominating production capacity, regional players continue gaining ground on traditional Western manufacturers through cost-effective solutions.

Market leader Littelfuse maintains approximately 18% revenue share in 2024, leveraging its extensive distribution channels globally and premium product positioning in medical and industrial applications. The company recently expanded its NTC thermistor portfolio with high-precision variants certified for automotive applications, strengthening its market position.

Meanwhile, Semitec has emerged as the fastest-growing competitor, achieving 12% year-over-year growth in 2024 through targeted expansions in smart home appliance markets. Their patented encapsulation technology provides superior moisture resistance compared to industry standards, making them preferred suppliers for humid environment applications.

Chinese manufacturers including Shenzhen Minchuang Electronics and NDF collectively account for over 30% of global thermistor unit production, primarily serving domestic appliance manufacturers and export markets. Their competitive pricing continues to disrupt traditional pricing models, forcing multinational players to optimize manufacturing costs.

The market also sees increasing specialization, with companies like Kemit Sensing Technology focusing exclusively on medical-grade thermistors featuring biocompatible encapsulants. This trend toward application-specific solutions is reshaping competitive dynamics across price-performance segments.

List of Key Plastic Encapsulated Thermistor Manufacturers:

Littelfuse (U.S.)

Semitec (Japan)

NDF (Germany)

MINJIE TECHNOLOGY (China)

Kemit Sensing Technology (China)

Shenzhen Minchuang Electronics Co., Ltd. (China)

Fuwen (China)

Shenzhen Nuoruisi TechnologyCo., Ltd (China)

Dongguan Tianrui Electronics Co., Ltd (China)

Segment Analysis:

By Type

Uninsulated Wire Segment Holds Significant Share Due to Cost-Effectiveness and Widespread Use in Consumer Electronics

The market is segmented based on type into:

Uninsulated Wire

Subtypes: Bead type, Disc type, and others

Insulated Wire

Subtypes: Epoxy-coated, Silicone-coated, and others

By Application

Home Appliance Segment Dominates Due to Increasing Demand for Temperature Sensors in Smart Devices

The market is segmented based on application into:

Home Appliance

Digital Thermometer

Medical

Automotive

Others

By End User

Consumer Electronics Sector Leads Owing to Rising Adoption of Temperature Sensing Components

The market is segmented based on end user into:

Consumer Electronics

Healthcare

Automotive

Industrial

Regional Analysis: Plastic Encapsulated Thermistor Market

North America The North American market for Plastic Encapsulated Thermistors is driven by advanced manufacturing capabilities and stringent quality standards, particularly in the medical and automotive sectors. With the U.S. accounting for the majority of regional demand, manufacturers are focusing on high-precision components for applications like patient monitoring devices and electric vehicle battery management systems. The presence of key players like Littelfuse and Semitec further strengthens the supply chain. However, rising material costs and competition from Asian suppliers remain challenges. Environmental regulations promoting lead-free electronics are accelerating innovation in thermistor materials and encapsulation techniques.

Europe Europe’s market emphasizes energy efficiency and miniaturization, with Germany leading in industrial automation applications. The region’s medical device regulations (MDR) and automotive safety standards create demand for reliable, long-life thermistors. EU directives on hazardous substances (RoHS/REACH) are pushing manufacturers toward halogen-free plastic encapsulation. While Western Europe shows steady growth, Eastern Europe presents opportunities for cost-competitive production. The market is somewhat constrained by the shift toward integrated temperature sensing solutions in consumer electronics, though niche applications in HVAC and renewable energy systems offer stability.

Asia-Pacific As the largest and fastest-growing market, Asia-Pacific benefits from China’s dominance in electronics manufacturing and India’s expanding HVAC sector. Chinese firms like Shenzhen Minchuang Electronics hold significant market share by offering competitively priced products. Japan and South Korea drive demand for high-accuracy thermistors in automotive and robotics. The region faces price sensitivity, prompting suppliers to balance cost-cutting with quality—leading to a bifurcation between budget and premium offerings. Local governments’ investments in 5G infrastructure and IoT devices are creating new application avenues, particularly for insulated wire-type thermistors.

South America Market growth in South America is uneven, with Brazil’s automotive aftermarket and Argentina’s agricultural equipment sector being primary demand drivers. Infrastructure limitations hinder large-scale electronics production, making the region reliant on imports—chiefly from China. Economic volatility affects procurement cycles, though the medical device industry shows resilience due to public health investments. Manufacturers face challenges in building local distribution networks but can leverage Brazil’s growing appliance manufacturing base. The lack of standardized testing facilities impacts quality perception among buyers.

Middle East & Africa This emerging market is propelled by construction-related HVAC projects in the GCC countries and increasing electronics assembly in Turkey. While currently a small percentage of global demand, the region shows potential in oil & gas temperature monitoring and renewable energy systems. South Africa serves as a gateway for thermistor distribution to neighboring countries. The market is price-driven with limited local production, though UAE-based distributors are expanding value-added services. Political instability in parts of North Africa and inconsistent regulatory frameworks slow adoption rates compared to other regions.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Plastic Encapsulated Thermistor markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD XX million in 2024 and is projected to reach USD XX million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Uninsulated Wire, Insulated Wire), application (Home Appliance, Digital Thermometer, Medical, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa, including country-level analysis. The U.S. market size is estimated at USD XX million in 2024 while China is projected to reach USD XX million.

Competitive Landscape: Profiles of leading market participants including NDF, MINJIE TECHNOLOGY, Kemit Sensing Technology, Littlefuse, Semitec, and others, covering their product portfolios, market share (top five players held approximately XX% in 2024), and strategic developments.

Technology Trends & Innovation: Assessment of emerging encapsulation technologies, material advancements, and integration trends in electronics applications.

Market Drivers & Restraints: Evaluation of factors including growing demand for temperature sensors in consumer electronics, medical devices, and industrial applications, along with supply chain challenges and raw material price fluctuations.

Stakeholder Analysis: Strategic insights for component manufacturers, OEMs, distributors, and investors regarding market opportunities and challenges.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/chip-solid-tantalum-capacitor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-electrical-resistance-probes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/high-temperature-tantalum-capacitor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-link-choke-market-innovations.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/multirotor-brushless-motors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/planar-sputtering-target-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ferrite-core-choke-market-opportunities.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/float-zone-silicon-crystal-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/carbon-composition-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/resistor-network-array-market-analysis.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/melf-resistors-market-key-drivers-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-foil-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-oxidation-resistors-market-size.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ferrite-toroid-coils-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/vacuum-fluorescent-displays-market.html

0 notes

Text

Kafal Spices Manufacturer: Your Trusted Partner Among Indian Spices Suppliers

In a global food landscape where quality, consistency, and origin matter more than ever, choosing the right spice partner can define your product’s success. Kafal Spices Manufacturer stands as a dependable name among top Indian spices suppliers, offering a blend of tradition, modern processing, and customer-first business practices.

With a sharp focus on quality, regional authenticity, and smooth global operations, Kafal has emerged as a preferred brand for those seeking a reliable wholesale spices supplier, a credible organic spices manufacturer, and a seasoned exporter to export spices from India.

From the Soil to Your Shelf: Sourcing with Authenticity

At the core of Kafal’s operations is its commitment to sourcing spices from their original, time-tested growing regions. This isn’t just about geography—it’s about preserving the essence and natural potency of each spice.

The company works directly with growers and farmer cooperatives in:

Karnataka – For premium-quality Byadgi red chilli

Meghalaya – Known for Lakadong turmeric with high curcumin

Kerala – Sourcing bold, aromatic Malabar black pepper

Rajasthan and Gujarat – Renowned for cumin, fennel, and coriander

By focusing on these authentic regions, Kafal ensures that its spices retain their natural strength, flavor, and color—delivering quality that is both sensory and measurable. This approach adds value for buyers who demand spices that consistently meet regional taste profiles and international standards.

Delivering Excellence at Scale

Kafal Spices is not just a spice seller—it’s a fully integrated manufacturer with advanced infrastructure. The company operates a modern facility in North India equipped with:

Hygienic processing and packaging lines

Cold grinding to retain essential oils and flavor

Steam sterilization for microbial safety

Quality labs for product testing at every stage

From small-batch orders to full container loads, every step of production is optimized for freshness, safety, and compliance—ensuring that clients get what they need, when they need it.

Whether you’re looking for bulk delivery within India or planning to export spices from India, Kafal has the capacity and systems to support your growth.

A Product Range Tailored for Business Buyers

As a full-spectrum wholesale spices supplier, Kafal’s product range caters to multiple industries—retailers, restaurants, food processors, and private-label brands. The catalog includes:

Whole spices like cumin, cardamom, cloves, and pepper

Ground spices such as turmeric, red chilli, and coriander

Blended spices, including classic Indian masalas

Organic-certified spices

Customized spice mixes for specific culinary applications

This range gives buyers the flexibility to source everything under one roof, reducing coordination hassles and ensuring consistent quality across the board.

Recognized for Quality and Reliability

Over the past decade, Kafal Spices Manufacturer has built a strong presence in the spice export and domestic B2B market by focusing on what truly matters: reliability, transparency, and quality assurance.

Experienced Team: The company employs skilled professionals in quality control, food safety, and supply chain management—ensuring products are tested, safe, and compliant.

Long-Term Relationships: With hundreds of satisfied customers in sectors like hospitality, packaged foods, and food service, Kafal’s repeat business speaks volumes.

Industry Exposure: Participation in major trade shows such as AAHAR, SIAL, and Gulfood has helped the brand reach global buyers who seek tested and trustworthy suppliers of spices in India.

Transparent Operations: Clear communication, fair pricing, and traceable sourcing are standard practices at Kafal.

This strong foundation helps buyers confidently choose Kafal as their best masala manufacturer or organic spices manufacturer, knowing they’re partnering with a brand that values long-term trust.

Customized Services for Export Buyers

Exporting spices is more than just shipping boxes—it requires a deep understanding of international food regulations, labeling laws, and documentation. Kafal excels in this area, offering full export support to buyers in:

USA

UK

UAE

Australia

Singapore

Canada

The company handles packaging as per destination-country requirements, assists with documentation (COA, MSDS, Phytosanitary Certificates, etc.), and ensures smooth coordination through its experienced logistics partners.

So, if you’re looking to export spices from India, you’ll find that Kafal makes the entire process streamlined and hassle-free.

Local Service with National Reach

Although Kafal has made a strong mark internationally, it continues to serve Indian businesses with equal focus. The brand maintains dedicated representatives in cities like Delhi, Noida, Mumbai, and Chennai, providing on-ground support for inquiries, samples, and delivery logistics.

Local buyers searching for suppliers of spices in India or the best masala manufacturer in their region can count on quick turnarounds, consistent supply, and personalized service. Kafal's presence in these cities makes it convenient for wholesale traders, supermarket chains, and food startups to place and manage their orders effectively.

Answers to What Buyers Frequently Ask

To help new customers make informed decisions, here are direct answers to common buyer questions:

Where can I find a reliable wholesale spices supplier in India? Kafal Spices offers bulk spice solutions for businesses of all sizes, with competitive pricing, certifications, and consistent quality.

Do you provide certified organic spices? Yes. Kafal is a trusted organic spices manufacturer, offering a full range of USDA and India Organic–certified turmeric, chilli, coriander, and more.

Can I customize spice blends for my brand? Absolutely. Kafal provides private label solutions, allowing you to develop your own blends and packaging based on your market’s preferences.

How do you ensure spice quality during exports? Each export shipment is tested, batch-certified, and packed in export-grade materials. You also receive full documentation and post-shipment support.

Is local supply available for retail chains or restaurants in India? Yes. Kafal serves Indian businesses through local networks and ensures timely delivery and MOQ flexibility across major cities.

#indian spices suppliers#suppliers of spices in india#Organic Spices Manufacturer#Best Masala Manufacturer#Wholesale Spices Supplier#export spices from india

0 notes

Text

Aseptic Packaging Market Emerging Trends Driving Innovation and Sustainability

The aseptic packaging market has experienced rapid growth in recent years, driven by increasing demand for longer shelf life, sustainable packaging solutions, and innovations in food and beverage processing. Aseptic packaging refers to the technique of filling sterilized products into pre-sterilized containers in a sterile environment, ensuring product safety without the need for refrigeration or preservatives. As global consumption patterns shift and industries seek more efficient, eco-friendly methods, the aseptic packaging sector is undergoing significant transformation. This article explores the key emerging trends shaping the aseptic packaging market today.

1. Growing Demand in Food and Beverage Industry

One of the most significant drivers of growth in the aseptic packaging market is the food and beverage industry. Consumers are increasingly leaning towards ready-to-eat meals, dairy products, and beverages that offer convenience without compromising on quality or safety. Aseptic packaging helps manufacturers meet these expectations by preserving flavor, nutritional value, and product integrity over extended periods.

This is particularly beneficial in products like UHT milk, fruit juices, sauces, and soups. Additionally, aseptic packaging reduces the reliance on cold chains for transportation and storage, offering cost savings and expanded distribution capabilities for producers.

2. Focus on Sustainability and Eco-Friendly Packaging

Sustainability has become a central theme across all packaging industries, and aseptic packaging is no exception. There is a rising demand for recyclable, biodegradable, and lightweight materials that minimize environmental impact. Companies are investing in plant-based plastics, paper-based cartons, and mono-material laminates to address consumer concerns about waste and carbon emissions.

The transition to sustainable aseptic packaging not only meets regulatory requirements in various regions but also enhances brand reputation and aligns with corporate social responsibility goals. As circular economy principles gain traction, the market is witnessing a shift toward designs that support reusability and recyclability.

3. Technological Advancements and Automation

The integration of advanced technologies in packaging equipment is another key trend propelling the aseptic packaging market. Automated filling and sealing systems, enhanced sterilization techniques, and robotics are increasing production efficiency, reducing human error, and ensuring consistent product quality.

Additionally, the rise of smart packaging technologies—such as QR codes, NFC tags, and real-time monitoring sensors—adds value by enabling traceability, improving inventory management, and providing transparency to consumers. These advancements are helping businesses meet stringent hygiene standards while streamlining operations.

4. Expansion into Pharmaceutical and Healthcare Segments

While traditionally dominant in the food and beverage sector, aseptic packaging is increasingly finding applications in the pharmaceutical and healthcare industries. The demand for sterile, contamination-free packaging for injectables, vaccines, and other biologics has surged, especially in the wake of the COVID-19 pandemic.

Pharmaceutical companies are turning to aseptic packaging to ensure product safety, prolong shelf life, and comply with strict regulatory requirements. Single-dose packaging, pre-filled syringes, and IV bags are examples of how this technology is being effectively utilized in the medical field.

5. Growth in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa are contributing significantly to the expansion of the aseptic packaging market. Urbanization, rising disposable incomes, and changes in lifestyle are driving increased consumption of packaged foods and beverages in these regions.

Governments and private sectors are also investing in infrastructure to support aseptic production and packaging capabilities. This has led to greater availability of aseptic products, improved food safety, and new market opportunities for global packaging companies.

6. Customization and Branding Opportunities

Aseptic packaging offers a versatile platform for customization, which is increasingly important in a competitive retail environment. Brands are leveraging unique shapes, eye-catching designs, and interactive elements to stand out on shelves and connect with consumers.

Digital printing and flexible packaging options allow for short-run production with personalized content, helping brands respond quickly to market trends and consumer preferences. This trend not only enhances brand visibility but also improves consumer engagement.

Conclusion

The aseptic packaging market is evolving rapidly, driven by a combination of consumer preferences, technological progress, and environmental considerations. With rising applications across multiple sectors and a strong push for sustainability, the market is poised for continued growth and innovation. Companies that embrace these emerging trends will be well-positioned to meet the changing demands of consumers and capitalize on the global shift toward safer, smarter, and greener packaging solutions.

0 notes

Text

Revolutionizing Industrial Parts Cleaning with Advanced Technologies – Founders Engineered Cleaning Solutions

With its fast-paced industry and fast manufacturing firms today, never have there ever been such a huge demand for efficient, reliable, and eco-friendly cleaning procedures. Step forward, Founders Engineered Cleaning Solutions — an industrial giant in parts cleaning and surface treating. A rich history of militant enthusiasm for technology has placed Founders in the optimum position to supply top-notch cleaning technology and equipment to any kind of business and industry, from aerospace to automotive to restoration, medical, and beyond.

Total Line of Industrial Parts Cleaning Solutions

Cleaning in Founders is never a one-size-fits-all affair. We recognize that each industry and application is a unique cleaning challenge. That's why we offer the full range of industrial parts cleaning solutions to match the needs of today's manufacturing.

Our product choices include:

Water-based cleaning systems: Green and highly effective, water-based systems leverage spray washing, agitation, and ultrasonic tanks to remove dirt, oils, and residues from industrial parts.

Solvent degreasers: From open-top containers to extremely sophisticated low-flashpoint solvent cleaners and liquid CO2 systems, our degreasers degrease accurately and effectively by stripping grease and oil away.

High-Tech Cleaning Technology: For use in high-tech cleaning operations, we provide vapor blasting, CO2 cleaning, and passivation consoles that clean sensitive or intricate parts with care without damage.

We hand-select and install each system to provide better performance and compatibility with your operation parameters.

Market Leaders in Wet and Vapor Blasting Machines

Founders, as a Leading Vapor Blasting Equipment Manufacturer, is known to provide wet blasting equipment of the highest quality. Our vapor blasting technology is based on the principle of water, abrasive media, and high-pressure air that come together to create a light but powerful cleaning action. This results in not just a cleaned surface but also a polished and ready surface for use or downstream processing.

Our Wet and Vapor Blasting Equipment is optimized for:

Aerospace: Gentle cleaning of aircraft components without destroying sensitive components.

Automotive: Cleaning of engine blocks, transmission blocks, and restoration of vintage automobile components.

Medical and Pharma: Abrasion-free surface cleaning of sterile medical equipment.

Restoration Industry: Gentle historical material and tool cleaning with soft cleaning.

Our wet blasting machines are unparalleled in reliability, low maintenance, and high volume from batch operations to continuous operation.

Eco-Friendly Surface Cleaning

Sustainability isn't just a buzzword at Founders – it's integral to our engineering philosophy. We're proud to supply environmentally friendly surface cleaners that minimize chemical, water, and environmental stress. Our CO2 cleaning systems, for instance, employ compressed carbon dioxide in liquid or solid forms to remove solvents from surfaces without leaving behind chemical residues. It works, it's safe, and ideal for sensitive applications where other solvents would be too aggressive or unsafe.

Our ultrasonic cleaning tanks provide a sustainable solution with high-frequency sound and low detergent to clean parts carefully and thoroughly. The systems find wide application in industries where accuracy and safety are paramount, such as healthcare and electronics.

High ROI Cost-Effective Surface Treatments

Investment in Founders' systems is investment in long-term operating effectiveness. Our systems are engineered to provide low-cost surface finishing with minimal downtime, improved part quality, and longer equipment life. With energy-efficient designs, low-chemical-consumption designs, and automation-allowing configurations, Founders' systems are engineered to drive your output with the lowest overhead expense.

Our mission is to assist in saving labor expense, standardize uniform cleanliness, and offer tight quality tolerances — without overpaying.

Industrial Dry Blasting

Whereas wet blasting gives better surface finishes, dry blasting is employed in various industries where part cleaning is required because of the inability to use moisture. Founders' dry blasting cabinets and automation systems are perfectly designed for rust stripping, scale stripping, paint stripping, and other debris without degradation of the part integrity.

Uses of dry blasting include:

Industrial maintenance

Preparation of metals for paint or coating

Deburring and peening applications

All of our dry blasting equipment is constructed from rugged materials, lined with state-of-the-art dust collection systems, and adjustable to fit small shops or high output volume.

Why Businesses Partner with Founders

We're not just an equipment dealer — we're a reputable equipment supplier committed to assisting industries in optimizing their cleaning process. And that's why businesses partner with Founders:

One-stop solutions: We provide from equipment selection and installation to maintenance and technical support.

Industry collaboration: We partner with leading chemical and equipment companies to deliver quality and innovation.

Custom solutions: We design around your production objective, plant configuration, and work flow.

Support and training: We provide in-plant training and post-sale support so you can have your staff up and running confidently.

Our technology enables customers to enhance product quality, achieve industry standards, and minimize environmental impact — at the expense of no compromise on high performance.

Industries We Serve

Our cleaning systems are applied across a broad spectrum of industries, including:

Aerospace

Automotive and Heavy Truck Manufacturing

Medical Device Manufacturing

Electronics and Semiconductors

Tool and Die Shops

General Industrial Repair

Restoration and Fabrication

No matter what your industry is, we have a solution that has been specially designed to suit your particular cleaning and surface preparation requirements.

Final Thoughts

Founders Engineered Cleaning Solutions is redefining how industries approach cleaning. With our advanced, reliable, and eco-friendly surface cleaning technologies — from wet blasting equipment to solvent degreasers — we offer end-to-end solutions that improve productivity, reduce costs, and protect the environment. As a leading wet blasting equipment manufacturer, we remain committed to delivering excellence at every step.

Let us help you elevate your cleaning processes with tailored solutions that deliver real-world results. Contact Founders Engineered Cleaning Solutions today to learn how we can help transform your operations with superior technology and service.

0 notes

Text

What Is a Peristaltic Pump? Working Principle and Applications Explained

In a laboratory, liquid handling instruments strive for precision, sterility, and the usage is non-negotiable. Other than this, the pharmaceutical companies, chemical plants, and medical instruments have a wide range of usage, such as measuring, transferring, and dispensing liquids.

Along with this, the peristaltic pump has been introduced in the laboratory for a significant niche for itself. But what exactly is a peristaltic pump? How does it work? And why so many laboratories and industries rely on it?

This blog is a guide. We will explore the working principles of peristaltic pumps, their advantages, it’s key applications, and how they are compared with other liquid handling instruments like pipetting pumps and the best electronic burettes in the market.

What Is a Peristaltic Pump?

A pertistaltic pump is also known as a roller pump, is a type of positive displacement pump that is commonly used for pumping a variety of fluids. The name peristaltic is derived from peristalsis, the process by which muscles in the human gastrointestinal tract contract and relax to move food and fluids through the digestive system.

Similar to the work function of the human digestive system, a peristaltic pump is used for transferring liquids through a flexible tube by a rotating mechanism that compresses the tubing at intervals. Further, it helps in pushing the liquid forward without letting it touch any mechanical part of the pump.

Their usage preferences are what make peristaltic pumps a valuable addition in the laboratory. These can be fruitful for avoiding cross-contamination in the laboratory or medical environments.

Working Principle of a Peristaltic Pump

The operation of a peristaltic pump is both intuitive and efficient. Here’s how it works:

A sterilised and flexible tube is fitted inside a circular casing or housing.

The peristaltic pump’s rotor has multiple rollers attached to it, which are also known as shoes in some lab settings.

As the rotor, along with the pump, turns, the rollers compress the tube at designated points.

This compression pushes the liquid forward while creating a vacuum that draws more liquid into the tube.

As the roller moves forward, the tube behind it returns to its natural shape, ensuring continuous flow.

Along with the functioning of peristaltic pump, the cyclical motion that is what creates a consistent and accurate liquid flow. This also plays a significant role in making the peristaltic pump a dependable liquid handling instrument in precision-based industries.

Key Components of a Peristaltic Pump

To better understand how the pump functions, it's important to know its main parts:

Tubing: Usually made from flexible and chemically resistant materials like silicone, PVC, or Tygon.

Rotor: The rotating component inside the pump that contains rollers.

Rollers/Shoes: The parts that press against the tubing, creating the pumping action.

Casing: The outer body that houses the tubing and rotor.

The components attached as a peristaltic pump are specially designed and engineered to reduce maintenance and downtime while working. Further, it allows easy cleaning or replacement, which makes it suitable for high-usage settings.

Advantages of Peristaltic Pumps

There’s a reason peristaltic pumps are favoured in so many applications:

No Contact With Pump Components

The fluid only touches the inner surface of the tube, drastically reducing the risk of contamination and making it easy to switch between different liquids.

Ideal for Sterile and Hazardous Fluids

From medical fluids to aggressive chemicals, peristaltic pumps are well-suited for handling sensitive or hazardous substances.

Simple Maintenance

Replacing the tubing is all it takes to prepare the pump for a new application—no disassembly of complex parts required.

High Precision

The flow rate can be tightly controlled, which makes the pump suitable for applications that demand exact volume delivery.

Gentle Pumping Action

Peristaltic pumps are non-shear, which means they won’t damage delicate cells or molecules during the transfer.

Real-World Applications of Peristaltic Pumps

1. Laboratory Settings

In clinical and research labs, maintaining sample integrity is critical. A peristaltic pump ensures sterile liquid transfer in applications like:

Cell culture media circulation

Buffer or reagent dosing

Sample filtration systems

2. Pharmaceutical Industry

Precise dosing and clean operation are essential when dealing with medications or active ingredients. These pumps handle:

IV solutions

Syrup transfer

Creams and ointments

3. Food and Beverage Industry

Because of their sanitary design, peristaltic pumps are used to handle:

Flavoring agents

Food colorants

Dairy and juices

4. Chemical and Industrial Applications

Handling of acids, caustics, and viscous fluids is easy with peristaltic pumps due to their closed system and robust tubing options.

5. Water and Wastewater Treatment

Used in:

Dosing chlorine or ph adjusters

Sampling water from reservoirs

Transferring sludge or slurry

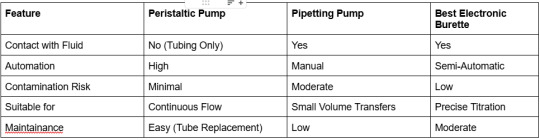

How Do Peristaltic Pumps Compare to Other Liquid Handling Instruments?

While peristaltic pumps are excellent for continuous and contamination-free fluid movement, there are other tools like pipetting pumps and electronic burettes that serve distinct but complementary roles in a laboratory.

Pipetting Pumps

Pipetting pumps are manual or battery-operated devices used for aspirating and dispensing small volumes of liquids. They’re especially handy for repetitive transfers in microbiology or biochemistry labs.

Pros: Affordable, easy to use, ideal for manual pipetting

Cons: Not ideal for large-volume or continuous flow operations

Best Electronic Burette

The best electronic burette offers digital control and automation in titration, reducing human error and enhancing reproducibility.

Pros: High accuracy, programmable, reduces manual fatigue.

Cons: Higher cost, not suitable for continuous transfer like a peristaltic pump.

By combining these liquid handling instruments, labs can streamline workflows and achieve better results across varied applications.

Conclusion

Whether you're handling delicate cell cultures, dosing chemical reagents, or pumping food-grade syrups, the peristaltic pump offers a clean, reliable, and precise solution. Its non-contact design makes it uniquely qualified for sterile operations, and its ability to handle both low and high-viscosity fluids makes it incredibly versatile.

Of course, it isn’t the only tool in the shed. Instruments like pipetting pumps and the best electronic burette each serve a crucial role in the laboratory ecosystem. Selecting the right instrument depends on your specific application, required accuracy, and the nature of the fluid being handled.

Ready to Upgrade Your Lab’s Precision?

At Microlit, they offer a complete range of high-quality liquid handling instruments. Their products have enhanced versatility as per the lab requirements, which includes state-of-the-art peristaltic pumps, pipetting pumps, and electronic burettes. The lab instruments at Microlit are designed with cutting-edge features that can ensure you accuracy, ease of use, and compliance with global lab standards. Without further ado, connect with Microlit today and discover their innovative solutions and experience the future of liquid handling.

#liquid handling instruments#manual pipetting#Peristaltic Pump#micropipette#liquid handling#pipettes#electronic pipettes#peristaltic pumps

0 notes

Text

Modular Isolator Systems Market Set to Hit $1.1 Billion by 2035

The Modular Isolator Systems Market is projected to grow from $443.2 million in 2024 to $1.1 billion by 2035, according to recent research by DataString Consulting. This growth is largely driven by increasing applications in pharmaceutical isolation, aseptic processing, biotechnological procedures, and semiconductor manufacturing. The market is expected to expand further due to growing demand in pharmaceutical manufacturing, biotech, and life sciences sectors.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/modular-isolator-systems-market-research-report

Key Applications Driving Market Growth

Pharmaceutical Manufacturing

In pharmaceutical manufacturing, modular isolator systems are crucial for preventing cross-contamination and maintaining the highest hygiene standards. These systems are used extensively in processing units, sterile compounding suites, and closed-system transfer devices, ensuring a controlled and sterile environment necessary for critical processes like drug compounding. Leading players in this field, such as Bosch and COMECER, offer advanced isolator systems that meet stringent industry standards, guaranteeing high-quality performance and safety.

Biotechnology and Life Sciences

Modular isolator systems are indispensable in the biotech and life sciences sectors, especially in tissue culture labs, cell therapy suites, and genetic engineering facilities. These systems, which often include high-end microbiological safety cabinets, are designed to minimize exposure to hazardous substances, ensuring maximum safety for laboratory workers. Companies like IsoTech Design and Solo Containment have gained recognition for providing robust and advanced modular isolator systems that enhance both safety and operational efficiency in these high-risk environments.

Technological Advancements in Modular Isolator Systems

The integration of advanced technologies has significantly transformed modular isolator systems. Automation, along with real-time data analysis, has greatly improved system efficiency, product quality, and compliance with regulatory requirements. The use of automated modular isolator systems has not only optimized batch production but also reduced the likelihood of human error, leading to significant cost savings and enhanced process efficiency. This is particularly evident in the filling procedures, where automation has proven to be a game-changer in maintaining sterility and precision.

Industry Leadership and Strategies

The Modular Isolator Systems Market is highly competitive, particularly in key regions such as the United States, Germany, and the United Kingdom. Leading companies like Bosch Packaging Technology, COMECER S.p.A., IsoTech Design, Solo Containment Ltd., and Extract Technology have established themselves as market leaders. These players are known for providing highly specialized and customizable isolator systems that cater to various industrial needs.

Notable providers in the sector include:

Pfizer Inc.: Designing versatile modular isolator systems to streamline pharmaceutical manufacturing processes.

Nestlé S.A.: Implementing modular isolator systems to enhance product safety and quality control.

Merck & Co., Inc.: Utilizing modular isolator systems to maintain aseptic conditions during critical pharmaceutical procedures.

Intel Corporation: Employing modular isolator systems to create a particulate-free environment in semiconductor manufacturing.

Regional Market Outlook

North America

North America is a major hub for the modular isolator systems market, driven by its robust technology and healthcare infrastructure. The region is home to a strong biopharmaceutical research sector, which requires advanced barrier technologies to maintain sterility and safety standards. Additionally, North America's adherence to stringent FDA regulations for drug manufacturing and the growing demand for biotherapeutics production are expected to increase the need for modular isolator systems. Companies like NuAire and Getinge Group are well-established players in this region, and there are significant prospects for growth in customized isolator systems and advanced technologies, such as AI and automation.

Market Segmentation and Insights

The Modular Isolator Systems Market can be segmented by product type, technology basis, and application:

Product Type: Rigid, Flexible, Closed

Technology Basis: Pressure Differential, Filter Air Supply, Rapid Transfer Ports

Applications: Pharmaceutical Manufacturing, Microelectronics, Biotechnology, Others

These segments demonstrate the diverse range of applications for modular isolator systems across various industries, highlighting their importance in maintaining controlled and sterile environments for critical manufacturing and research processes.

About DataString Consulting

DataString Consulting is a leading provider of market research and business intelligence solutions. With over 30 years of combined experience in the industry, the firm helps companies navigate complex market landscapes through strategy formulation, market expansion, and new product development. DataString Consulting offers in-depth insights into market trends, competitor strategies, and customer demographics, helping businesses identify emerging opportunities and optimize their operations for long-term growth.

#Market research reports Business consultant Top market reports#Modular Isolator Systems Market Report

0 notes

Text

Sodium Chlorite Market Trends and Price Forecast for 2025

Sodium chlorite is a chemical compound widely used for its strong oxidizing properties. It's most commonly utilized in water treatment, bleaching in the paper and textile industries, and disinfection across food processing and medical sectors. It’s usually found in powder or liquid form and is valued for generating chlorine dioxide, a powerful disinfectant. As demand rises for clean water, sanitary production environments, and efficient industrial bleaching agents, sodium chlorite prices have become an important product in global markets. In 2025, the market continues to grow steadily due to its essential role in industries focused on hygiene, safety, and sustainable practices.

👉 👉 👉 Please Submit Your Query for Sodium chlorite Price trends, forecast and market analysis: https://tinyurl.com/2wmppd7w

Price Trend and Market Dynamics in 2025

The price of sodium chlorite in 2025 is expected to follow a stable to slightly rising trend. This is largely because of increasing demand in water purification and industrial disinfection. However, price changes also depend on the availability and cost of raw materials, mainly sodium chlorate and hydrochloric acid, which can fluctuate due to energy prices and supply chain logistics. Environmental regulations may also push prices up, as stricter safety and handling requirements can increase production costs. On the other hand, competition among global suppliers helps maintain balance and prevent sudden price surges. Regional differences in production capacity, especially between Asia and North America, can also influence pricing.

Market Size and Share Insights

The global sodium chlorite market is valued in the range of USD 200–300 million and is projected to grow at a moderate pace through 2025. Asia-Pacific dominates the market due to large-scale industrial activities in China and India, where sodium chlorite is produced and consumed in significant volumes. North America follows, especially in water treatment and food safety sectors. Europe has a steady demand as well, largely tied to environmental compliance and healthcare needs. The paper and pulp industry remains one of the biggest users of sodium chlorite, though demand from healthcare and municipal water treatment is increasing in market share.

Industry Growth and Segmentation

Growth in the sodium chlorite industry is largely segmented by end-use industries, including water treatment, paper manufacturing, textiles, food processing, and healthcare. Water treatment holds the largest share, as sodium chlorite is key in generating chlorine dioxide for disinfecting drinking water and industrial waste. The healthcare sector is also becoming a growing segment, using sodium chlorite for surface sterilization in hospitals and laboratories. Within food processing, it's used to clean surfaces and equipment to ensure food safety. Textiles and paper continue to rely on sodium chlorite for effective bleaching, especially where high brightness and whiteness levels are required. This multi-sector demand keeps the market diversified and resilient.

Key Trends and Technological Advances

One of the notable trends in the sodium chlorite market is the increasing focus on safe and efficient chlorine dioxide generation systems. Manufacturers are now offering more compact and automated generators to make usage easier and reduce waste. Another trend is the rising demand for low-impurity grades, especially in medical and food applications. Technological advances in handling and packaging are also emerging, with better leak-proof containers and stabilizing agents improving shelf life and safety. Additionally, there is growing research into greener production methods that lower environmental impact and meet new sustainability standards, particularly in Western markets.

Opportunities and Market Drivers

The sodium chlorite market in 2025 is full of opportunities, particularly in areas where clean water and sanitation are growing concerns. With climate change and urbanization putting pressure on municipal water systems, the demand for reliable and effective disinfection agents like sodium chlorite is rising. There’s also a major opportunity in expanding the use of sodium chlorite in food-grade sanitation, where hygiene regulations are tightening across the globe. Emerging economies represent a strong area for growth, as they invest more in public health infrastructure and industrial production. Additionally, with more attention being given to pandemic preparedness and cleanliness, the role of sodium chlorite in healthcare is expected to increase.

Major Players and Competitive Landscape

Several major chemical companies are active in the sodium chlorite market, including OxyChem, Ercros S.A., Shree Chlorates, and International Dioxcide. These companies offer a range of sodium chlorite concentrations and chlorine dioxide generation systems tailored for different industries. China hosts many of the world’s largest sodium chlorite producers, supplying both domestic and export markets. Competition is driven by product quality, pricing, safety standards, and supply reliability. Many companies are also now working to meet more stringent environmental regulations, offering eco-friendly production methods and packaging solutions to stay competitive and appeal to customers looking for greener alternatives.

Industry Challenges and Risks

The sodium chlorite market is not without its challenges. First and foremost is the strict regulatory framework governing the production, handling, and transportation of the chemical, due to its reactive and potentially hazardous nature. Companies must invest in compliance and safety infrastructure, which can raise operating costs. Supply chain disruptions—such as those caused by raw material shortages or international trade restrictions—can also impact availability and pricing. Environmental concerns about chemical runoff and improper handling further complicate operations, especially in sensitive areas. Finally, the niche but growing concern over public perceptions of chemical disinfectants in food and water sectors can pose image challenges for producers and sellers.

Future Outlook and Forecast to 2025

Heading toward the end of 2025, the sodium chlorite market is expected to maintain stable growth. The demand for safe water, food hygiene, and medical sanitation ensures a steady need for this compound across multiple sectors. Advancements in delivery systems and more sustainable production technologies will continue shaping the industry. Despite challenges such as regulatory hurdles and raw material price fluctuations, the essential role of sodium chlorite in health, safety, and industrial applications keeps it in strong demand. With emerging markets expanding infrastructure and global attention focused on environmental cleanliness and infection prevention, the future of sodium chlorite remains solid and full of potential.

0 notes

Text

Ultimate Guide to Liquid Filling Machines: Types, Applications, and Buying Tips

What is a Water Filling Machine? A water filling machine is an automated or semi-automated system used to fill water into bottles of various sizes. These machines are used in bottled water plants, beverage factories, and industrial packaging lines. They help ensure fast production, exact filling volumes, and sanitary operation, complying with industry standards such as BIS, ISI, FSSAI, FDA, and ISO 22000.

Types of Water Filling Machines

Automatic Water Filling Machines These machines are fully automated, including bottle feeding, rinsing, filling, and capping systems. Ideal for high-volume production plants, they can process anywhere from 2,000 to over 24,000 bottles per hour (BPH).

Semi-Automatic Water Filling Machines Perfect for small businesses or startups, these machines require some manual intervention. They offer great affordability while maintaining decent fill speeds and accuracy.

Rotary Water Filling Machines These machines operate on a rotating base, filling multiple bottles simultaneously. High-speed and highly efficient, they are perfect for large-scale bottled water production.

Linear Water Filling Machines Operate in a straight line and are suitable for mid-level production capacity. They are modular, easy to maintain, and can be integrated with other packaging systems.

Key Components of a Water Filling Machine Rinsing Section: Ensures bottles are cleaned internally using sterile water or air-jet systems.

Filling Section: Dispenses the exact quantity of water without any spillage.

Capping Section: Automatically places and tightens caps.

Conveyor System: Moves bottles from one station to another seamlessly.

Control Panel: Touchscreen interface with PLC to monitor speed, fill levels, and errors.

Water Filling Machine Applications

Bottled Mineral Water Plants Used for 200ml, 500ml, 1L, and 2L PET or glass bottles. Machines can be customized for various bottle neck sizes and shapes.

20-Liter Jar Water Plants These machines are used for large container packaging and generally include washing, sanitizing, and filling units integrated into one line.

Sparkling or Flavored Water Filling Machines are modified to handle carbonated water, requiring pressure-resistant filling nozzles and foam control.

Advanced Features of Modern Water Filling Machines

PLC and HMI-Based Control Allows real-time monitoring, quick troubleshooting, and batch-wise production tracking.

Automatic Bottle Detection Ensures "no bottle – no fill" operation to prevent product loss.

HEPA Filters and UV Sterilization Critical for maintaining hygiene, especially in pharmaceutical or baby water products.

Stainless Steel Construction (SS304/316L) Non-corrosive, food-grade materials ensure long life and hygiene compliance.

Low Maintenance and CIP Systems Machines now come with Clean-In-Place (CIP) systems to ensure regular, automated internal cleaning.

Benefits of Using a Water Filling Machine High-Speed Production: Speeds of up to 400 bottles/min are possible with rotary models.

Precision and Accuracy: Digital flow meters ensure minimal variation in fill levels.

Labor Reduction: Fully automated systems require minimal operator intervention.

Consistency: All bottles are filled and capped identically, ensuring product standardization.

Scalability: Can be integrated with labeling, shrink tunnel, carton packing, and palletizing machines.

How to Choose the Right Water Filling Machine

Define Your Output Requirement Are you producing 500 BPH or 10,000 BPH? Your choice of machine will depend on your volume.

Consider the Bottle Type and Size Ensure the machine supports your bottle’s neck diameter, height, and shape.

Look for Hygiene Certifications Machines must comply with BIS, FSSAI, or international norms depending on your target market.

Plan for Integration Will your machine work as part of a full line (rinsing, capping, labeling, sealing)? If so, choose a modular or turnkey solution.

Water Filling Machine Pricing in India (2025 Estimates) Machine Type Price Range (INR) Capacity Manual Bottle Filler ₹50,000 – ₹1.5 lakh 200–500 BPH Semi-Automatic Machine ₹2 lakh – ₹4 lakh 600–1,200 BPH Automatic Linear Filler ₹5 lakh – ₹20 lakh 1,500–6,000 BPH Automatic Rotary Filler ₹25 lakh – ₹1.5 crore+ 8,000–30,000 BPH Jar Filling Machine (20L) ₹2.5 lakh – ₹8 lakh 100–1,200 jars/hr

Note: Prices depend on build material, number of heads, power rating, and customization.

Top Indian Manufacturers of Water Filling Machines GIECL (Gujarat Ion Exchange and Chemicals Ltd.)

Siddhivinayak Engineering

Associated Pack Tech Engineers

Hildon Industries

SS Engineers and Consultants

These companies offer machines with BIS/ISI approvals, along with installation, after-sales service, and spares.

Maintenance and Operational Tips Clean and sanitize the filling system daily.

Perform monthly calibration of sensors and valves.

Use only BIS-approved water lines and pre-filters.

Regularly inspect the capping system for torque efficiency.

Keep extra filling nozzles and sealing gaskets in stock.

Future of Water Bottling Technology AI-Powered Diagnostics: Alerts for upcoming mechanical faults.

Remote Monitoring: View and control your machine via smartphone apps.

IoT Integration: Track production, efficiency, and maintenance logs in real time.

Green Bottling Solutions: Use of biodegradable bottles, solar-powered lines, and water recovery systems.

Conclusion A water filling machine is no longer just a piece of machinery—it's a strategic investment for growth, efficiency, and brand integrity. Whether you are starting a small mineral water plant or scaling to a multi-line production unit, the right machine can elevate your operations to new heights.

0 notes

Text

Custom-Built Powder Containment Solutions by Clean Air India

Introduction

In the dynamic landscape of pharmaceutical, chemical, and biotech industries, one of the most pressing challenges is maintaining product integrity while ensuring operator safety. With rising awareness of occupational health hazards and regulatory compliance, the demand for advanced containment systems has surged. Among these systems, Powder Containment Booths Manufactures have emerged as a vital solution for clean and safe working environments. One company that stands out in the Indian market for delivering exceptional powder containment solutions is Clean Air India.This article delves into the significance of powder containment booths, their applications, and how Clean Air India is revolutionizing containment solutions through innovation, quality, and precision engineering.

Understanding Powder Containment Booths

Powder Containment Booths, also known as Dispensing Booths or Weighing Booths, are specially designed enclosures used to control and contain airborne particulates during powder handling operations. These booths operate on the principle of laminar airflow, combined with HEPA filtration, to ensure a unidirectional flow of clean air and prevent cross-contamination.

The Need for Quality Containment Solutions in India