#TechnicalTextiles

Explore tagged Tumblr posts

Text

Exploring the Cost Dynamics: Non-Woven Fabric vs. Traditional Woven Fabric

Non-woven fabric has emerged as a popular choice in various industries due to its versatility, durability, and cost-effectiveness. As a leading provider of fabric solutions, Mavazi Fabrics understands the importance of cost considerations for our clients. In this article, we'll explore how the cost of non woven fabric manufacturer

compares to traditional woven fabric and the factors that influence this comparison.

1. Production Process

One of the primary factors influencing the cost of non woven fabric manufactureris the production process. Non-woven fabrics are manufactured using a process that does not involve weaving or knitting yarns together. Instead, fibers are bonded together mechanically, chemically, or thermally. This results in a simpler and more streamlined manufacturing process compared to traditional woven fabric, which requires yarn spinning, weaving, and finishing. The reduced complexity of the production process often translates to lower production costs for non woven fabric manufacturer.

2. Raw Material Costs

The cost of raw materials also plays a significant role in determining the overall cost of non-woven fabric. Non-woven fabrics can be made from a variety of materials, including natural fibers such as cotton and wool, synthetic fibers such as polyester and polypropylene, and recycled materials. The availability and cost of these raw materials can vary depending on factors such as market demand, production capacity, and geographical location. In general, non woven fabric manufacturer made from synthetic fibers tend to be more cost-effective compared to those made from natural fibers.

3. Labor Costs

Labor costs are another important consideration when comparing the cost of non woven fabric manufacturer to traditional woven fabric. Non-woven fabric manufacturing typically requires less labor compared to weaving or knitting processes. This is because non-woven fabrics can be produced using automated machinery and require fewer manual interventions. As a result, labor costs associated with non woven fabric manufacturer production are often lower, contributing to overall cost savings.

4. Energy Consumption

Energy consumption during the manufacturing process is another factor that influences the cost of non-woven fabric. Non-woven fabric production generally requires less energy compared to traditional weaving or knitting processes. This is because non-woven fabric manufacturing involves fewer mechanical motions and heating processes. As a result, non woven fabric manufacturer production can be more energy-efficient, leading to lower operating costs and reduced environmental impact.

5. Customization and Versatility

Non-woven fabrics offer greater customization and versatility compared to traditional woven fabrics. They can be engineered to meet specific performance requirements, such as strength, absorbency, and filtration efficiency. This customization capability allows non-woven fabric manufacturers to tailor their products to the unique needs of their clients, potentially adding value and justifying higher costs compared to traditional woven fabrics.

In conclusion, the cost of non woven fabric manufacturer compared to traditional woven fabric depends on various factors, including the production process, raw material costs, labor costs, energy consumption, and customization capabilities. While non-woven fabrics often offer cost advantages due to their simpler production process and lower labor and energy costs, the final cost comparison may vary depending on specific requirements and market conditions. As a trusted provider of fabric solutions, Mavazi Fabrics offers a wide range of non-woven fabrics tailored to meet the diverse needs of our clients while ensuring cost-effectiveness and quality.

#nonwovenfabric#manufacturer#fabricengineer#innovativematerials#textileindustry#sustainableproducts#technicaltextiles#manufacturingexcellence#madeinUSA#materialsourcing#productionprocesses#ecofriendlytechnology#qualityassurance#industrialmaterials#textiledesigns#nonwovenmaterials#advancedmanufacturing#productionefficiency#environmentallyfriendlyinfos .

2 notes

·

View notes

Text

Industrial Yarns | Spun Yarn Manufacturers in India

High-strength industrial yarns for durable and reliable performance in various industrial and technical applications. visit us: www.kaderiambalmills.com

0 notes

Text

Coated Fabrics Market projected to reach $29.8 billion by 2028

The report "Coated Fabrics Market by Product Type (Polymer-coated Fabrics, Rubber-coated Fabrics and Fabric-backed Wall Coverings), Application (Transportation, Protective Clothing, Roofing, Awnings & Canopies), & Region – Global Forecast to 2028", size was USD 23.7 billion in 2022 and is projected to reach USD 29.8 billion by 2028, at a CAGR of 3.9% from 2023 to 2028.

The market is projected to grow due to rapid industrialization in emerging economies and innovative product development in protective clothing. The innovations are featured to meet the vital properties of coated fabrics products for different applications. Coated fabrics can serve a range of safety benefits and there is growing demand for safety measures in automobiles, aircraft, and other types of transportation. Therefore, there is a crucial need to increase coated fabrics production to sustain the demand.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=64354822

Protective Clothings was the fastest growing application of the coated fabrics market, in terms of value, in 2022

Due to the increased demand from the healthcare industry, stringent regulations and standards, technical improvements, and increasing awareness about workplace safety. Protective clothing manufacturer prefer coated fabrics as it has advantages in terms of safety, performance and sustainability. The technological developments in the coated fabrics advances its perfoamance, durability and functionality. This is projected to drive the in the protective clothing application in coated fabrics market.

Polymer-coated fabrics segment is estimated to be the largest product type of the coated fabrics, in terms of value, during the forecast period.

Polymer coated fabrics, such as polyurethane (PU), polyvinyl chloride (PVC), and polyethylene (PE), have emerged as a preferred alternative in the coated fabrics market. Their popularity stems from their exceptional versatility, offering a wide range of applications across various industries. These coated fabrics are known for their impressive durability, which ensures long-lasting performance even in demanding environments. This has indicated to their dominance in the coated fabrics market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=64354822

Asia Pacific is estimated to be the largest market for the coated fabrics market, in terms of value, during the forecast period.

Asia Pacific is projected to be the largest market for coated fabrics, driven by the high economic growth due to growing automotive & chemical industries and the rising population in region especially in India and China. There is high growth seen in protective clothing segments in this region due to increased government regulations for safety concerns in various industries such as transportation, chemical, oil & gas, construction and residential housing. This is due to growing economic conditions, rising GDP, active manufacturing sectors and healthcare sectors in emerging countries. Due to these reasons the demand for coated fabrics in Asia Pacific region is increased.

The key players profiled in the report include Continental AG (Germany), Trelleborg AB (Sweden), Serge Ferrari Group (France), Saint-Gobain S.A. (France), and Freudenberg Group (Germany).

#CoatedFabrics#TextileIndustry#IndustrialFabrics#FabricInnovation#PerformanceTextiles#TextileManufacturing#SmartFabrics#TechnicalTextiles#ProtectiveFabrics#FabricTechnology#SustainableFabrics#WaterproofFabrics#AutomotiveFabrics#HomeTextiles#FashionFabrics#TextileSolutions

0 notes

Text

0 notes

Text

#HDPE#Nonwovens#Tyvek#Polyethylene#PlasticsIndustry#Packaging#ConstructionMaterials#MedicalTextiles#SustainableMaterials#IndustrialFabrics#InnovationInMaterials#EnvironmentalProtection#Manufacturing#TechnicalTextiles#SafetyProducts

0 notes

Text

#PolypropyleneYarn#TextileIndustry#DurableMaterials#CustomizationOptions#SustainableManufacturing#ChemicalResistance#MoistureResistance#LightweightMaterials#Geotextiles#TechnicalTextiles#PPYarn#YarnTypes

0 notes

Text

Technical Textile in Material Characterization

In the world of textiles, innovation is the name of the game. Technical textiles, designed for their unique properties and functions, have opened up a realm of possibilities in industries ranging from healthcare to aerospace. But what lies beneath the surface of these remarkable materials? That's where material characterization comes into play.

Material characterization is the key to unlocking the true potential of technical textiles. It allows us to delve deep into the material's properties, from its porosity to its permeability, and even its surface area. Armed with this knowledge, we can engineer textiles that are not just functional but optimized for specific applications.

At Material Intelligence Lab, we're passionate about exploring the intricacies of technical textiles. Our state-of-the-art instruments and cutting-edge techniques enable us to analyze these materials at a microscopic level. By understanding their composition and behavior, we can fine-tune technical textiles to meet the exacting demands of various industries.

But it's not just about the science; it's about the impact. From designing advanced filtration systems for clean air and water to creating protective gear for frontline heroes, material characterization in technical textiles paves the way for innovation that changes lives.

#MaterialCharacterization#TechnicalTextiles#Innovation#MaterialScience#MaterialIntelligenceLab#ExploreTheScience

0 notes

Photo

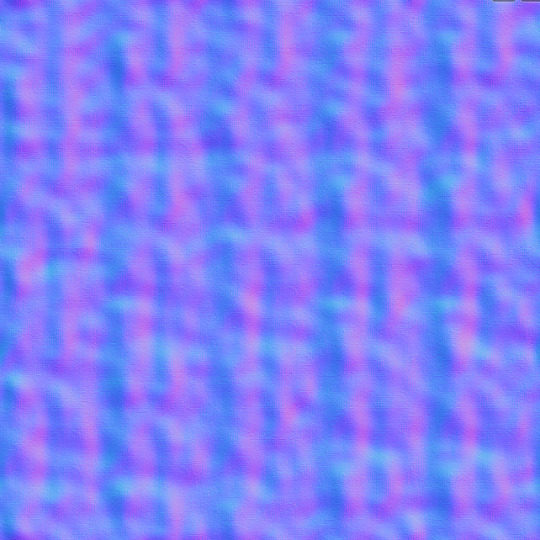

Material testing - Linen

I tried to simulate the under layer in Linen, first of all it is not a 100%, so i can not use this. I see almost no difference between the render of the Cotton vs Linen. I am going to insert a texture of a 100% Linen later in Pixplant, hoping to see more of a relief in the fabric which Linen usually has.

1 note

·

View note

Photo

With its vast range of uses and superior performance, technical textiles has raised our comfort levels and provided us with a greater diversity of life experiences. With new discoveries appearing on a regular basis, their new uses are unquestionably beneficial to humanity.

Read more @ https://cmiinfoistic.blogspot.com/2021/11/technical-textiles-applications-are.html

0 notes

Text

0 notes

Text

Industrial Yarns | Spun Yarn Manufacturers in India | Kaderiambalmills

Kaderiambalmills industrial yarn exporters specialise in delivering high-performance yarns worldwide with a diverse range of industrial yarns that offer superior strength and durability. visit us: www.kaderiambalmills.com

0 notes

Photo

Water repellent yarns #waterrepellent #technicaltextiles (at Istanbul Province) https://www.instagram.com/p/BxxaoB4h1hm/?igshid=55zi634jkxp5

0 notes

Text

#HDPE#Nonwovens#Tyvek#Polyethylene#PlasticsIndustry#Packaging#ConstructionMaterials#MedicalTextiles#IndustrialFabrics#InnovationInMaterials#EnvironmentalProtection#Manufacturing#TechnicalTextiles#SafetyProducts

0 notes

Text

Explore Polypropylene Yarn: Diverse Types, Customization Options, and Specialty Applications

Introduction

Polypropylene yarn is a versatile synthetic fiber widely used across industries for its durability and resistance to various elements. It’s derived from polypropylene, a tough plastic known for its strength and light weight. In textiles, it’s valued for its affordability and ability to withstand wear and tear. Beyond textiles, it’s used in construction, agriculture, and industrial settings due to its strength and resistance to chemicals and UV rays. In this guide, we’ll explore its properties, types, customization options, and applications, highlighting its importance in diverse fields.

Understanding Polypropylene: Properties and Characteristics

Polypropylene, often abbreviated as PP, is a versatile thermoplastic polymer renowned for its exceptional properties and wide-ranging applications. Let’s delve into the key characteristics that make polypropylene a preferred choice across industries.

Lightweight and Durable

Chemical Resistance

High Heat Resistance

Moisture Resistance

Flexibility and Moldability

Recyclability

In summary, polypropylene stands out for its lightweight, durable, and chemically resistant properties, making it indispensable across a multitude of applications. From packaging materials to automotive components, polypropylene continues to demonstrate its versatility and reliability in diverse industries worldwide.

Types of Polypropylene Yarn

Polypropylene yarn, with its versatility and durability, encompasses various types catering to diverse industrial and commercial needs. Understanding each type is crucial for optimizing applications. Let’s delve into the key characteristics and applications of different polypropylene yarn varieties:

1. Polyester Yarn:

Polyester yarn stands out for its exceptional strength and resilience, making it ideal for applications requiring durability.

2. Roto Yarn:

Roto yarn is renowned for its uniformity and smooth texture, achieved through a specialized spinning process.

3. Tape Twisted Yarn:

Tape twisted yarn features a distinctive structure characterized by twisted flat filaments, offering enhanced surface area and strength. This construction lends itself well to applications requiring dimensional stability and robustness.

4. PP Filament Yarn:

PP filament yarn is prized for its lightweight yet durable nature, making it a preferred choice for a wide range of applications.

Customization Options for Polypropylene Yarn

Polypropylene yarn offers a myriad of customization options, allowing manufacturers to tailor the yarn to specific requirements and applications. Understanding these customization choices is essential for optimizing product performance and meeting customer needs.

Color

Denier

Twist

Additives and Treatments

Specialty Applications of Polypropylene Yarn

Polypropylene yarn serves diverse purposes across industries due to its exceptional properties:

Textiles and Apparel

Geotextiles and Agriculture

Industrial and Technical Applications

Conclusion

Polypropylene yarn emerges as a versatile and durable material, prized for its resilience in various industries. With exceptional properties like chemical and moisture resistance, along with high heat tolerance, it serves diverse applications from textiles to industrial settings. Through customizable options like color, denier, and additives, polypropylene yarn offers tailored solutions, driving innovation and sustainability. Its role in specialty applications such as sportswear, automotive upholstery, and geotextiles underscores its adaptability and reliability. As industries evolve, polypropylene yarn remains a strategic choice, ensuring efficiency, durability, and environmental consciousness in manufacturing processes worldwide. Read More

#PolypropyleneYarn#TextileIndustry#IndustrialApplications#CustomizationOptions#InnovativeMaterials#ChemicalResistance#LightweightMaterials#Geotextiles#TechnicalTextiles#PPYarn#YarnTypes

0 notes

Link

Chemicals in textiles have evolved into a highly specialized sector that employs a wide range of chemistries, both organic and inorganic, to provide aesthetic

0 notes

Photo

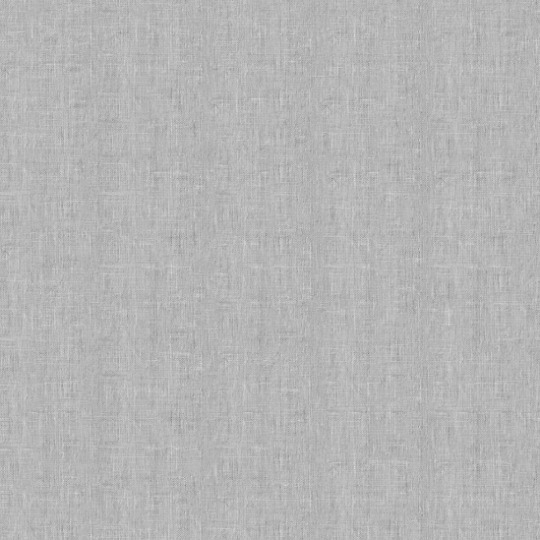

Linen Pixplant texture -

Made my own Linen texture in Pixplant, the one already in CLO library was almost 50% Cotton. The texture which I used now is from a 100% Linen. It shows more of that relief that I wanted.

0 notes