#Telescopic Conveyor Manufacturers in India

Explore tagged Tumblr posts

Text

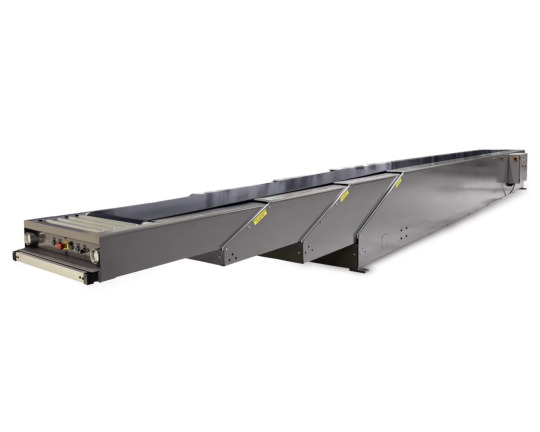

Telescopic Conveyor Manufacturers

Rite Solution is the leading manufacturer of telescopic conveyor manufacturers in India. at the best price. Our cutting-edge solutions are designed to revolutionize material handling operations, increasing efficiency and transforming the way goods are loaded and unloaded at docks, airports, warehouses, trucks and food processing industries. Our unwavering commitment to innovation and excellence has propelled us to the forefront of the industry.

We offer a wide range of telescopic conveyor systems that cater to various industrial needs. Our customers may select the different variants with various numbers of pull-out sections and with different total length options.

#Telescopic Conveyor Manufacturers#Telescopic Conveyor Manufacturers & Suppliers#Telescopic Conveyor Manufacturers in India#Best Telescopic Conveyor Manufacturers#Top Telescopic Conveyor Manufacturers

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Truck Loading Conveyor Manufacturers in Faridabad: Leaders in Innovation

Looking for cutting-edge truck loading conveyor solutions? Discover why Faridabad is the heart of conveyor manufacturing in India. Home to industry-leading companies, Faridabad-based manufacturers are known for their technological innovation, customized designs, and cost-effective solutions for modern logistics and warehousing.

From telescopic conveyors to hydraulic truck loaders, these manufacturers are empowering India’s supply chains with faster, safer, and more efficient material handling systems. Whether you're in e-commerce, FMCG, agriculture, or manufacturing, these conveyors are engineered to deliver unmatched performance.

#truck loading conveyor#Faridabad manufacturers#conveyor systems India#telescopic conveyor#hydraulic loading conveyor#material handling India#warehouse automation#belt conveyor#loading solutions India

0 notes

Text

The Telescopic Belt Conveyor is an advanced material handling solution designed for efficient loading and unloading of goods. Its extendable structure allows seamless movement of packages, reducing manual effort and increasing productivity in warehouses and logistics centers. With adjustable lengths and smooth belt operation, it ensures safe and swift transportation of materials. Ideal for shipping docks and distribution hubs, this conveyor enhances workflow efficiency. Yontro Mechatronic Systech offers high-quality telescopic belt conveyors engineered for durability and precision, making them a reliable choice for modern industrial needs.

#telescopic belt conveyor#reflow soldering machine#conveyor belt manufacturers in india#wave soldering machine#yontro mechatronic systech#inclined conveyor belt#conveyor belt#yontro#cleated belt conveyor#flat belt conveyor#industrial work station

1 note

·

View note

Text

Titan material handling Pvt. Ltd provide Telescopic Conveyor, Loading Unloading Telescopic Conveyor at best cost, It Is the best Telescopic Conveyor, Loading Unloading Telescopic Conveyor supplier, Manufacturer company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Telescopic Conveyor#Loading Unloading Telescopic Conveyor#Telescopic Conveyor Manufacturer#Telescopic Conveyor Manufacturer in Pune#Telescopic Conveyor Manufacturer in India#Andhra Pradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore#Hubli

0 notes

Text

Truck Loading Conveyors in India: Powering Modern Logistics

In the modern business world, timely truck loading and unloading can be the make or break of your supply chain activities. Truck loading conveyors have turned out to be revolutionary solutions for Indian businesses, changing the way products travel from warehouses to vehicles. This ultimate guide delves into all that you need to know about truck loading conveyor manufacturing in India.

What Are Truck Loading Conveyors?

Truck loading conveyors are advanced material handling solutions used to mechanize truck, trailer, and container loading. These compact and versatile conveyor systems reduce the need for manual lifting, considerably shortening loading time, while also increasing worker safety and operational efficiency.

In contrast with fixed conveyor systems, truck loading conveyors are mobile conveyors that can be simply located at loading docks, adjusted to varying heights of trucks, and relocated between various loading bays when necessary.

These systems are usually a motorized belt or roller system mounted on a wheeled, adjustable frame. The conveyor can be extended, retracted, and vary its angle to fit various truck sizes and loads. Remote controls are found on the majority of newer units, enabling operators to control the system from a safe distance.

Types of Truck Loading Conveyors Available in India

1. Telescopic Boom Conveyors

These extendable conveyors can be extended deep into truck trailers and containers. They're ideal for loading bulk commodities, loose materials such as grain, and fertilizers.

Major Features:

Extends up to 60 feet in length

Height and angle adjustment

High-capacity handling (up to 1000 tons per hour)

2. Portable Belt Conveyors

Lightweight and easy to transport, these conveyors are ideal for loading packaged goods, boxes, and cartons.

Advantages:

Easy setup and breakdown

Ideal for a range of package sizes

Affordable for small to medium businesses

3. Roller Dock Conveyors

Conveyors that span truck bed and floor-to-floor transitions, offering smooth flow of product.

Applications:

E-commerce packaging centers

Distribution centers

Manufacturing plants

4. Flexible Conveyors

Adjustable and expandable systems that can bend, curve, and flow around obstructions.

Benefits:

Adjusts to varying truck configurations

Compact design to save space

Simple storage when idle

Why India is Leading Truck Loading Conveyor Manufacturing

1. Indigenous Industrial Demand

India's thriving e-commerce industry, large-scale manufacturing hub, and government programs such as "Make in India" have placed unprecedented pressure on cost-effective logistics solutions. Firms are investing significantly in automation to remain competitive.

2. Affordable Manufacturing

Indian manufacturers provide truck loading conveyors at affordable costs without sacrificing quality. The integration of trained manpower, latest technology, and reduced operating costs makes India a good manufacturing destination.

3. Technical Expertise

Indian manufacturers and engineers have built extensive knowledge in material handling systems, designing inventive solutions suited to local and global needs.

Major Features of Indian Truck Loading Conveyors

Strong Construction

Anti-corrosion coated heavy-duty steel frames

Drive systems and quality motors

Weather-resistant materials for outdoor applications

Powder coating finishes for strength

Safety Features

Emergency stop buttons in multiple places

Safety railings and guards

Textured belts with anti-slip surfaces

Overload protection systems

Warning lights and alarms

Safety interlocks to prevent accidental use

Customization Options

Variable speed controls (10-100 meters per minute)

Adjustable heights and inclines (up to 30-degree incline)

Customized length and width to suit individual needs

Integration with existing warehouse management systems

Multiple power options (electric, hydraulic, pneumatic)

Energy Efficiency

Low-power consumption motors (1-10 HP range)

Variable frequency drives (VFDs) for optimal power usage

Automatic start/stop capabilities to limit idle time

LED lighting systems for improved illumination

Industries That Benefit from Truck Loading Conveyors

E-commerce and Retail

Online stores employ truck loading conveyors to accelerate order fulfillment and lower shipping delays. Flipkart, Amazon India, and BigBasket are some of the companies that depend on these systems for smooth operation. Increased online buying, particularly post-COVID, has necessitated these systems to meet customer delivery demands.

Food and Beverage

Food processing plants employ heavy-duty conveyors made from food-grade materials to keep food standards in check when loading food items such as rice, wheat, sugar, and packaged foods. Stainless steel build and washable surfaces guarantee obedience to food safety regulations.

Automotive Industry

Automobile manufacturers and autoparts suppliers employ heavy-duty truck loading conveyors to ship parts, engines, and finished cars. Such systems have to carry different weights and sizes, from accessories to complete automotive assemblies.

Chemical and Pharmaceutical

These businesses demand custom conveyors that include explosion-proof motors and chemical-resistant coatings for the safe handling of delicate products. FDA and cGMP compliance is essential.

Agriculture and Fertilizers

Bulk handling conveyors assist in loading grains, fertilizers, and agrarian products efficiently, catering to India's huge agricultural industry. These systems are usually equipped with dust collection components and weather protection.

Textile and Garment Industry

India's giant textile industry applies truck loading conveyors for movement of fabric rolls, finished clothing, and raw materials. The systems ensure product quality while accelerating the loading process.

Advantages of Selecting Indian Manufacturers

Cost Benefits

Indian manufacturers provide truck loading conveyors at 30-40% less cost than global suppliers, making automation affordable for small and medium businesses.

Fast Delivery

Domestic manufacturing implies shorter delivery periods, normally 2-4 weeks as opposed to 8-12 weeks in case of imported systems.

After-Sales Support

End-to-end maintenance services, spare part availability, and local technical support guarantee limited downtime.

Customization Flexibility

Indian manufacturers specialize in designing tailor-made solutions according to particular operational needs and budgetary restrictions.

Technology Integration and Smart Features.

IoT-Enabled Systems

New-generation truck loading conveyors have sensors and connectivity features to monitor performance in real time, maintenance requirements, and operational efficiency.

Automated Controls

PLC-based control systems allow for automated operation with limited manual intervention, saving labor costs and enhancing consistency.

Safety Monitoring

Advanced safety features comprise load monitoring, emergency stops, and automatic shutdown mechanisms to avoid accidents.

Cost Factors and ROI

Investment

Truck loading conveyors are generally priced between ₹3-15 lakhs based on size, capacity, and specifications. The investment repays itself within 12-18 months in terms of increased efficiency.

Price Breakdown by Type:

Simple portable belt conveyors: ₹3-6 lakhs

Telescopic boom conveyors: ₹8-15 lakhs

Heavy-duty roller systems: ₹5-12 lakhs

Custom engineered solutions: ₹10-25 lakhs

Operating Costs

Lower labor demands (save 40-60% of workforce)

Less damage to products (cut breakage by 30-50%)

Increased speed of loading (boost speed by 200-400%)

Less energy usage than manual options

Low maintenance costs with regular care

Return on Investment

The majority of companies experience 200-300% ROI in the initial two years because of:

50-70% savings in loading time

60% savings on manual labor

Major reduction in workplace accidents (as many as 80% fewer incidents)

Increased customer satisfaction due to quicker deliveries

Increased peak season operating capability

Benefits Hidden to the Enterprise

Lowered insurance premiums based on increased safety

Improved worker retention with enhanced working conditions

Improved truck use by faster turnaround

Possible higher volumes with no proportionate increase in staff

Criteria for Choosing Truck Loading Conveyors

Capacity Needs

Establish your maximum load needs in volume and weight per hour to choose effective conveyor specifications.

The character of the product

Take into consideration the product size, weight, and fragility to be able to select the proper conveyor type, as well as options.

Operating Environment

Take into account weather conditions, space limitations, and utilization rate when choosing materials and construction details.

Budget Considerations

Weigh initial expenditure against long-term advantages, taking into account financing schemes and ROI estimates.

Installation, Maintenance

Professional Installation

Seasoned manufacturers offer total installation, including:

Site survey, planning

Foundation requirements appraisal

Equipment installation, commissioning

Operator training programs

Performance testing, qualification

Documentation and warranty provision

Installation Timeline:

Site preparation: 1-2 days

Equipment installation: 2-3 days

Testing and commissioning: 1 day

Operator training: 1-2 days

Maintenance Requirements

Regular maintenance ensures optimal performance and longevity:

Daily Checks:

Wear and damage visual inspection

Belt alignment checks

Emergency stop button testing

Weekly Maintenance:

Lubrication of moving components

Belt tension check

Motor and drive inspection

Monthly Servicing:

Detailed belt and roller inspection

Electrical connection verification

Performance calibration

Annual Maintenance:

Total system overhaul

Parts replacement as necessary

Safety system recertification

Troubleshooting Common Issues

Belt slippage: Regulate tension or change worn belts

Motor overheating: Review ventilation and load capacity

Unusual noise: Review bearings and alignment

Control system malfunctions: Check electrical connections

Future Trends in Truck Loading Conveyor Manufacturing

Automation Integration

Interface with warehouse management systems (WMS) and enterprise resource planning (ERP) software for smooth operations. This encompasses real-time inventory tracking, automated sorting features, and predictive analytics for optimal loading patterns.

Sustainable Solutions

Manufacturers are creating environmentally friendly conveyors with energy-efficient motors and recyclable parts. Solar-powered solutions are becoming available for outdoor use, minimizing carbon emissions and maintenance costs.

Smart Analytics

Artificially intelligent systems that maximize loading patterns and anticipate maintenance needs. Machine learning algorithms evaluate usage patterns to recommend enhancements and avert breakdowns.

Advanced Safety Features

Future generation safety systems comprise:

3D vision systems for detecting obstacles

Automatic balancing of loads

Predictive safety notifications

Remote monitoring capabilities

Modular Design Philosophy

Next-generation conveyor systems have modular elements that are easily reconfigured, upgraded, or expanded to meet evolving business requirements.

Selecting the Right Manufacturer: Questions to Ask

Technical Capabilities

What level of customization is possible?

Do you offer 3D modeling and simulation capabilities?

What are your quality certifications?

Do you have the capability to process special material requirements?

Service and Support

What is your warranty policy?

Do you have preventive maintenance contracts available?

How soon can you deliver spare parts?

What training options do you offer?

Financial Implications

Do you have financing available?

What is the cost of ownership?

Are there any surprise costs?

What payment conditions do you have?

Conclusion

Truck loading conveyor manufacturing in India is a successful sector that's revolutionizing logistics operations for multiple industries. The synergy of low-cost manufacturing, technical know-how, and expanding market demand makes India a world leader in this field.

No matter whether you are a small company trying to enhance efficiency or a multinational company wanting to mechanize your logistics operations, Indian manufacturers provide robust, affordable solutions optimized to meet your exact requirements.

Truck loading conveyor investing is not just about machinery – it's about revolutionizing your business processes, enhancing employee safety, and enhancing your competitiveness in the fast-moving market place. With the correct manufacturer partner, you will be able to make substantial productivity gains, cost reductions, and operational improvement.

Our Other Product and Services

truck loading conveyor in India

https://beltconveyorindia.com/truck-loading-conveyor-in-india/

chip conveyor Manufacturer in India

Inclined belt conveyor manufacturer in Faridabad

About BeltConveyorIndia

Vashnavi Conveyor Industry is a leading manufacturer of high-performance conveyor systems in India, specializing in custom-engineered solutions for efficient material handling. Based in Faridabad, we design and manufacture a wide range of conveyors, including belt conveyors, truck loading conveyors, and automated material handling systems, built to boost productivity, reduce labor costs, and streamline logistics. Whether you're in manufacturing, warehousing, packaging, or distribution, our durable and cost-effective conveyors are tailored to meet your unique needs. Partner with us for reliable, innovative, and industry-grade conveyor solutions that keep your operations moving smoothly.Contact us- [email protected]

#TruckLoadingConveyor#ConveyorManufacturersIndia#MaterialHandlingSolutions#LogisticsAutomation#IndustrialConveyors#LoadingSystems#WarehouseAutomation#IndianManufacturing#TruckConveyorIndia#SmartLogistics

0 notes

Text

Bag Stacker Price: A Comprehensive Guide to Costs and Considerations

Bag stackers are essential equipment in industries that handle bulk materials, such as agriculture, cement, warehouses, and logistics. These machines improve efficiency, reduce labor costs, and ensure safety in material handling. If you're looking to invest in a bag stacker, understanding its price, influencing factors, and benefits is crucial. In this blog, we’ll explore bag stacker price, its key features, types, and where to find the best deals.

What is a Bag Stacker?

A bag stacker is a conveyor system designed to transport and stack bags of materials like grains, cement, fertilizers, and more. It minimizes manual labor by automating the process of lifting and stacking bags at desired heights.

Factors Affecting Bag Stacker Price

The cost of a bag stacker depends on several factors. Here are the key aspects that influence pricing:

1. Type of Bag Stacker

Bag stackers come in different types, each with varying price points:

Fixed Bag Stackers: These are stationary machines used in warehouses and factories. They are usually more affordable than mobile stackers.

Mobile Bag Stackers: Equipped with wheels, these stackers are more versatile but often come at a higher price.

Hydraulic Bag Stackers: These use hydraulic lifting mechanisms, making them more efficient but also costlier.

Telescopic Bag Stackers: These have extendable conveyors for better reach, adding to the cost.

2. Load Capacity

Bag stackers are designed to handle different weight capacities. Machines with higher load capacities typically cost more due to their enhanced durability and motor strength.

3. Conveyor Length and Height

Longer and taller conveyors require stronger materials and motors, increasing the overall bag stacker price.

4. Material and Build Quality

Heavy-duty materials such as stainless steel or reinforced aluminum increase the durability and lifespan of the stacker but also add to the cost.

5. Automation and Features

Advanced features like automatic height adjustment, remote control, and safety sensors can raise the bag stacker price but improve efficiency and safety.

6. Brand and Manufacturer

Well-established brands often have higher prices due to their reputation for quality and after-sales service.

Average Bag Stacker Price in India

The price of a bag stacker varies widely based on the factors mentioned above. Here’s a general price range:

Basic Fixed Bag Stackers: ₹50,000 – ₹1,50,000

Mobile Bag Stackers: ₹1,50,000 – ₹3,00,000

Hydraulic Bag Stackers: ₹3,00,000 – ₹5,00,000

Telescopic Bag Stackers: ₹5,00,000 – ₹8,00,000+

These prices are indicative and may vary based on customization and location. For an accurate quote, check out Vivian Conveyors for the latest prices and offers.

Benefits of Using a Bag Stacker

Investing in a bag stacker can be highly beneficial. Here are some key advantages:

1. Increased Efficiency

Bag stackers speed up the stacking process, reducing the time required to organize and transport materials.

2. Reduced Labor Costs

With automation, businesses can cut down on manual labor expenses while improving worker safety.

3. Enhanced Safety

Lifting and stacking heavy bags manually can lead to injuries. A bag stacker minimizes risks associated with manual handling.

4. Improved Accuracy and Consistency

Automation ensures uniform stacking, which is crucial for storage and transportation.

5. Versatility

Bag stackers can handle various types of materials, making them suitable for multiple industries.

Where to Buy a Bag Stacker at the Best Price?

Finding the right supplier is essential to get the best bag stacker price. Here are some tips:

Compare Multiple Vendors: Check prices from different manufacturers and suppliers to find the best deal.

Look for Discounts and Offers: Some companies offer bulk purchase discounts or seasonal promotions.

Check Reviews and Testimonials: Customer feedback can help assess the reliability of the supplier.

Consider After-Sales Support: A good warranty and customer service ensure long-term value.

For reliable and competitively priced bag stackers, visit Vivian Conveyors and explore their range of high-quality conveyor solutions.

Conclusion

Bag stackers are indispensable for industries handling bulk materials. Understanding the bag stacker price and the factors influencing it helps in making an informed purchase. Whether you need a basic fixed stacker or an advanced telescopic model, choosing the right one depends on your specific requirements and budget. Explore high-quality bag stackers at Vivian Conveyors for the best deals and solutions.

0 notes

Text

"The Benefits of Using a Telescopic Conveyor for Truck Loading and Unloading"

Perfection Conveyor Telescopic conveyor systems, typically used in warehouses for efficient material handling, can be creatively repurposed in residential homes to maximize space and functionality. As a leading Telescopic Conveyor Manufacturer, Perfection Conveyor provides adaptable solutions that homeowners can integrate into modern living spaces.

One innovative use is in multi-level homes, where a compact telescopic conveyor can transport laundry, groceries, or household items between floors, reducing the need for manual carrying. Additionally, for home workshops or garages, these conveyors can assist in organizing tools, moving heavy materials, or optimizing storage space.

In kitchen spaces, a small-scale telescopic conveyor can streamline meal prep by easily transporting ingredients and dishes between workstations. Similarly, book lovers can install a conveyor system in a home library to move books efficiently across different sections.

For smart home automation, integrating telescopic conveyors with IoT devices can enhance accessibility for the elderly or individuals with mobility challenges. This ensures effortless movement of essentials without strain.

With the expertise of Perfection Conveyor, homeowners can redefine residential efficiency using industrial-grade solutions tailored for everyday convenience. Embracing telescopic conveyor technology in homes brings space-saving benefits and enhanced functionality.

Perfection conveyor is India’s leading manufacturer of Telescopic Conveyor. You can contact them for further information regarding the Telescopic Conveyor.

0 notes

Text

Telescopic Conveyor Manufacturers | Rite Solution

Are you also searching for telescopic conveyor manufacturers in India? Then Rite Solution is the best choice for you for telescopic conveyors at affordable price. We have been working as an electric winch machine for the last 9+ years with the help of 8+ skilled engineers and 5000+ satisfied clients in 500+ industries served.

Rite Solution, based in Ghaziabad, Uttar Pradesh, is a distinguished manufacturer, supplier, and exporter of high-quality telescopic roller conveyors and telescopic belt conveyors. We are offering Delhi, Mumbai, Bengaluru, Bhilai, Jamshedpur, Chennai, Bilaspur, Gurugram, Kolkata. India. Rite Solution’s telescopic conveyors are designed to enhance productivity in industries, warehousing, logistics, and distribution centers. These conveyors are ideal for loading and unloading operations, significantly reducing manual labor and time.

#Telescopic Conveyor Manufacturers#Telescopic Conveyor Supplier#Telescopic Conveyor Exporter#Telescopic Conveyor Manufacturers in India#Telescopic Conveyor Supplier in Delhi

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Best Truck Loading Conveyor Solutions by Indian Manufacturers

Looking for efficient and durable truck loading conveyors? Explore the best solutions from leading Indian manufacturers offering telescopic, flexible, and belt conveyors tailored to your industrial needs. Improve loading speed, reduce manual effort, and ensure workplace safety — all at competitive prices. Ideal for warehouses, logistics hubs, e-commerce, and manufacturing units. ✅ Custom designs

✅ Quick delivery

✅ Low maintenance Get in touch with trusted Indian conveyor suppliers today!

#Truck Loading Conveyor#Indian Conveyor Manufacturers#Telescopic Conveyor#Material Handling#Warehouse Equipment#Logistics Automation#India Manufacturing

0 notes

Text

Telescopic Belt Conveyor Market Analysis by Manufacturers, Regions, Type and Application to 2031

04th July 2024, (The Market Intelligence) is pleased to announce its new Market report 2024-2031. It is a valuable source of the research to covering very aspects of the market and providing up-to-date data on current trends.

The market report provides industry overview with progress analysis, scopes, useful reviews and strategic assessments, emerging technologies, historical & futuristic cost, industry drivers and challenges during the forecast period. The report contains an in-depth analysis of significant market players to understand the utilization of the key strategies that have been adopted in the market. The report offers clear and exact idea about the overall market to the readers to take beneficial decisions. The Market study offers comprehensive data that enhances the understanding, scope and application of this report.

Regional Assessment:

Geographically, the worldwide market is analyzed across North America (U.S., Canada, and Mexico), Europe (UK, Germany, France, Russia, and others), Asia-Pacific (China, India, Japan, and others), and LAMEA (Latin America, Middle East, and Africa).

Browse Full Report at:

What Market Reports Provides?

Full in-depth study of the market

Key changes in market dynamics

In-depth market segmentation by Type, Application etc.

Historical, present and projected market analysis in terms of volume and value

Market share analysis, new innovations and major events.

Key strategies of main players in market Forecast 2024-2031

Emerging segments and regional markets

Some Major TOC Points:

Chapter 1: Market Overview, Product Overview, Market Segmentation, Market Overview of Counties, Market Dynamics, Limitations, Opportunities and Industry News and Policies.

Chapter 2: Market Industry Chain Study, Upstream Raw Material Suppliers, Major Players, Production Process Analysis, Cost Analysis, Market Channels, and Major Downstream Buyers.

Chapter 3: Value Study, Production, Growth Rate and Price Analysis by Type of Market.

Chapter 4: Downstream Characteristics, Consumption and Market Share by Application of Market.

Chapter 5: Production Volume, Price, Gross Margin, and Revenue ($) of Market by Regions.

Chapter 6: Market Production, Consumption, Export, and Import by Regions.

Chapter 7: Market Status and SWOT Study by Regions.

Chapter 8: Competitive Landscape, Product Introduction, Company Profiles, Market Distribution Status by Players of Market.

Chapter 9: Market Analysis and Forecast by Type and Application.

Chapter 10: Market Analysis and Forecast by Regions.

Chapter 11: Market Industry Characteristics, Key Factors, New Entrants SWOT Study, Investment Feasibility Analysis.

Chapter 12: Market Conclusion of the Entire Report.

Continue…

Contact Us:

The Market Intelligence

Phone:

US : +1 (888) 690-5999

UK : +44 8083 023308

Email: [email protected]

Web: https://www.themarketintelligence.com/

0 notes

Text

Say Goodbye to Manual Loading: The Power of Telescopic Belt Conveyors

In today's fast-paced logistics and warehousing industry, efficiency is the key to success. Traditional loading and unloading methods often require extensive manual labor, leading to fatigue, increased costs, and slower turnaround times. However, with the advent of Telescopic Belt Conveyors, businesses can now optimize their loading processes, improving both productivity and worker safety.

The Game-Changer in Loading and Unloading

A Telescopic Belt Conveyor is specifically designed to streamline the loading and unloading of various items such as boxes, sacks, and tires. Whether dealing with small vans or large trucks, this conveyor system can be electrically extended or retracted to accommodate different vehicle sizes. This feature ensures that workers can operate comfortably throughout the vehicle’s length, reducing physical strain and improving efficiency.

Boosting Productivity While Reducing Labor Costs

One of the primary benefits of using a Telescopic Belt Conveyor is the significant reduction in manual labor. By automating the loading and unloading process, businesses can cut down on the number of operators required while increasing throughput. This results in faster vehicle turnaround times, allowing for more shipments to be processed in less time.

Additionally, these conveyors come in customizable lengths, with standard widths of 600 mm or 800 mm, ensuring they meet the specific requirements of various applications. The optional hydraulic tilt adjustment further enhances efficiency by allowing the conveyor to be positioned at an incline when needed.

Innovative Features for Maximum Efficiency

Modern Telescopic Belt Conveyors, like those offered by Yontro Mechatronic Systech, are equipped with cutting-edge features to enhance operational performance. Some of the standout features include:

Three-Stage Boom Type Conveyor for extended reach

Angle Adjustment (0 to 15 degrees) using a dual hydraulic cylinder

Rapid loading and unloading capability for trucks and containers

Auto-stop sensor for box detection to prevent damage

Durable Rough-Top PVC Belt (5mm thickness) for improved grip and longevity

These features ensure that businesses can efficiently handle a wide range of cargo, reducing delays and optimizing workflow.

A Smarter Choice for Logistics and Warehousing

Adopting a Telescopic Belt Conveyor is an investment in efficiency, safety, and long-term cost savings. With its ability to minimize manual labor, increase throughput, and enhance worker safety, this innovative solution is revolutionizing the way warehouses and logistics companies handle loading and unloading operations.

For businesses looking to improve productivity and reduce operational costs, upgrading to a Telescopic Belt Conveyor is a smart decision that delivers long-term benefits.

#Telescopic Belt Conveyor#reflow soldering machine#conveyor belt manufacturers in india#wave soldering machine#yontro mechatronic systech#conveyor belt#inclined conveyor belt#yontro#cleated belt conveyor#flat belt conveyor#industrial work station#Truck Loading Conveyor

1 note

·

View note

Text

Benefits of Using Telescopic Conveyors in Warehouses: Efficiency, space-saving, and productivity advantages.

perfection engineering In the realm of home design and functionality, maximizing space has become a cornerstone of modern living. From compact urban apartments to sprawling suburban houses, homeowners are increasingly seeking ingenious solutions to optimize every square foot of their living space. One innovative tool that has recently gained traction in residential applications is the telescopic conveyor manufacturer, manufactured with precision engineering for versatile use.

What is a Telescopic Conveyor Manufacturer?

A telescopic conveyor, crafted by precision engineering, is a flexible and extendable conveyor belt system. Originally designed for industrial and logistical purposes to streamline loading and unloading operations, these conveyors have evolved to offer remarkable adaptability in residential settings.

Creative Applications in Residential Homes

Loft Conversions: Loft spaces are notorious for their awkward access and limited usability. A telescopic conveyor can be ingeniously installed to facilitate easy transportation of items to and from the loft, eliminating the need for cumbersome staircases or ladders.

Basement Renovations: Turning a basement into a functional living area often involves overcoming challenges related to access and space utilization. A telescopic conveyor can simplify the process of moving furniture, renovation materials, and other heavy items, optimizing the basement space efficiently.

Garage Organization: Garages frequently double as storage spaces, yet they can quickly become cluttered and disorganized. Integrating a telescopic conveyor can enhance storage accessibility by enabling seamless movement of tools, seasonal items, and sports equipment to overhead storage areas.

Tiny House Living: The tiny house movement emphasizes minimalist living in compact spaces. A telescopic conveyor can be strategically integrated to maximize storage and accessibility within these diminutive dwellings, offering a solution that aligns with the movement's principles.

Choosing the Right Telescopic Conveyor Manufacturer

When considering the integration of a telescopic conveyor in a residential setting, selecting a reputable manufacturer is crucial. Look for manufacturers with a proven track record in precision engineering and a commitment to quality and innovation. Ensure that the conveyor system meets specific residential requirements such as load capacity, space constraints, and aesthetic considerations.

Conclusion

As residential spaces continue to evolve, so too do the tools and technologies designed to enhance them. A telescopic conveyor, engineered with precision and adapted for residential use, represents a forward-thinking solution to maximizing space and optimizing functionality in homes of all sizes. Whether simplifying access to loft spaces, organizing cluttered garages, or facilitating efficient multi-level living, these conveyors exemplify innovation in modern residential design.

Incorporating a telescopic conveyor into your home not only expands its usability but also underscores a commitment to integrating cutting-edge solutions that improve daily life. Embrace the possibilities offered by precision engineering and discover how a telescopic conveyor can transform your residential space into a model of efficiency and innovation.

perfection is India’s leading manufacturer of Telescopic Conveyor. You can contact them for further information regarding the Telescopic Conveyor.

0 notes

Text

Faridabad Telescopic Conveyor Experts for High-Speed Material Movement

Enhance your loading and unloading operations with high-speed telescopic conveyors engineered by Faridabad’s leading experts – Vashnavi Conveyor Industry. Designed for efficiency, these extendable conveyors allow seamless material transfer into trucks, containers, and warehouse bays. Ideal for logistics, e-commerce, and distribution centers, they reduce manual effort, save time, and improve workplace safety. Built with robust materials and automation-ready features, Vashnavi's telescopic conveyors deliver reliable performance for demanding industrial environments.

#TelescopicConveyor#FaridabadManufacturer#TruckLoadingConveyor#MaterialHandling#ConveyorSystems#VashnaviConveyor#LogisticsAutomation#LoadingSolutions#ExtendableConveyor

0 notes

Text

The Evolution of Telescopic Conveyors in Modern Manufacturing

perfection engineering The world of manufacturing has undergone significant transformations over the past few decades, driven by advancements in technology and a relentless pursuit of efficiency. Among the many innovations that have revolutionized modern manufacturing, telescopic conveyor manufacturers stand out as a game-changer. As an essential tool in material handling and logistics, telescopic conveyors have evolved to meet the ever-growing demands of the industry. In this blog, we will explore the evolution of telescopic conveyors and how leading telescopic conveyor manufacturers like Perfection Engineering are shaping the future of manufacturing.

The Genesis of Telescopic Conveyors

The concept of conveyors dates back to the late 18th century, primarily used for transporting bulk materials over long distances. However, the need for more flexible and efficient material handling solutions led to the development of telescopic conveyors in the mid-20th century. These conveyors were designed to extend and retract, allowing for the easy loading and unloading of goods, particularly in the logistics and warehousing sectors.

Technological Advancements

The 21st century brought a wave of technological advancements that transformed telescopic conveyors into sophisticated, high-performance machines. Key innovations include:

1. Automation and Control Systems

Modern telescopic conveyors are equipped with advanced automation and control systems, allowing for precise and effortless operation. These systems enable seamless integration with other material handling equipment, ensuring smooth and efficient workflow in manufacturing and logistics environments.

2. Enhanced Mobility and Flexibility

Telescopic conveyors now feature enhanced mobility and flexibility, with the ability to extend and retract to various lengths and angles. This adaptability makes them ideal for a wide range of applications, from loading and unloading trucks to transferring goods within a warehouse.

3. Safety Features

Safety has always been a priority in manufacturing, and telescopic conveyors are no exception. Today's models are equipped with numerous safety features, such as sensors and emergency stop buttons, to protect operators and prevent accidents.

The Role of Telescopic Conveyor Manufacturers

Leading telescopic conveyor manufacturers, such as Perfection Engineering, play a crucial role in the evolution of these machines. By investing in research and development, these manufacturers are continually pushing the boundaries of what telescopic conveyors can achieve. They are dedicated to providing innovative solutions that meet the specific needs of their clients, ensuring that their conveyors are reliable, efficient, and adaptable.

The Future of Telescopic Conveyors

As technology continues to advance, the future of telescopic conveyors looks promising. Innovations such as artificial intelligence and the Internet of Things (IoT) are expected to further enhance their capabilities, making them smarter, more efficient, and even more integral to modern manufacturing processes.

Conclusion

The evolution of telescopic conveyors is a testament to the ingenuity and dedication of manufacturers like Perfection Engineering. These versatile machines have transformed material handling in modern manufacturing, offering unparalleled efficiency, flexibility, and safety. As we look to the future, it is clear that telescopic conveyors will continue to play a pivotal role in driving the industry forward, meeting the ever-changing demands of the market with innovative solutions.

perfection Engineering is India's leading manufacturer of Telescopic Conveyor Manufacturer. You can contact them for further information regarding the Telescopic Conveyor Manufacturer

0 notes