#Material Handling

Explore tagged Tumblr posts

Text

4 notes

·

View notes

Text

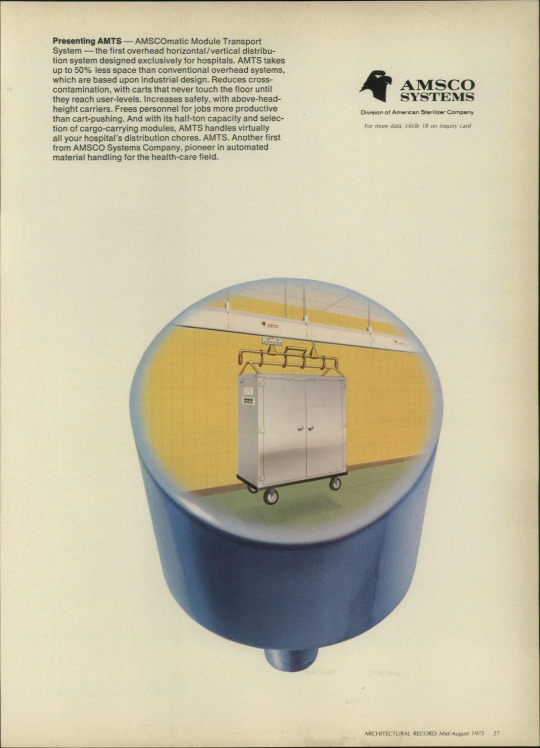

Amsco Systems AMTS advertisement, 1975.

15 notes

·

View notes

Text

Selecting the right equipment can have a big impact on your operations' overall productivity, safety, and efficiency in the ever-changing field of material handling. Appropriate selection of material handling equipment is essential whether you oversee a manufacturing plant, warehouse, or distribution center. Bhupati Engineering is Best material handling equipment manufacturers in India. If you are facing any difficulty to choose material handling equipment. Contact us

#Material Handling Equipment Manufacturers in India#Material Handling Equipment Suppliers in India#Material Handling Equipment Manufacturers#Material Handling Equipment Suppliers#material handling

2 notes

·

View notes

Text

15 Ton Overhead Cranes For Steel Slabs Handling

IntroductionManufacturing Process of Double Girder Overhead CranesUtilization of Double Girder Overhead Cranes in the Steel IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction In the world of industrial logistics, efficiency, strength, and reliability are the key characteristics that dictate the quality of equipment. We’re excited to bring forth a prime illustration…

View On WordPress

#coil handling#coil industry cranes#coil lifting#coil loading cranes#coil transport#crane design#crane manufacturing#crane operations#crane safety#girder cranes#heavy-duty cranes#high-capacity crane#hoisting equipment#industrial cranes#load management#material handling#overhead cranes#steel coil production#steel coil storage#steel coils

4 notes

·

View notes

Text

Exploring How Automation Is Changing Material Handling and Assembly

Manufacturing industries worldwide are undergoing a seismic shift driven by advanced technologies, and automation stands at the forefront. As digital transformation gains momentum, the ways companies handle materials and organize assembly operations are evolving rapidly. This transformation isn't just about replacing labor but reimagining processes for better speed, safety, and sustainability.

Smart Integration in Modern Manufacturing Automation is no longer limited to isolated tasks. It has evolved into a connected ecosystem that integrates robotics, sensors, artificial intelligence, and machine learning. Smart systems communicate across supply chains to anticipate needs, allocate resources, and optimize flows. Automated guided vehicles (AGVs) and robotic arms work in harmony, responding to real-time data inputs that minimize waste and delays.

Efficiency Gains Across Assembly Lines The hallmark benefit of automation in material handling and assembly is unprecedented efficiency. Automated systems streamline repetitive and precision-based tasks, reducing the time and cost associated with manual labor. High-speed robotic assembly lines enable consistent output, minimizing errors that often occur with human intervention. Material handling becomes seamless, especially when combined with advanced conveyor systems, real-time tracking, and inventory control technologies.

Reducing Downtime and Human Error Human error and equipment downtime have historically been the Achilles’ heel of production environments. Automation addresses these issues head-on. Predictive maintenance powered by IoT devices identifies wear and tear before breakdowns occur. With fewer human-dependent processes, operations experience fewer interruptions, leading to increased reliability and operational uptime. In hazardous environments, automation further protects human workers by taking over dangerous or ergonomically challenging tasks.

Workforce Evolution in an Automated World While automation shifts certain roles, it does not eliminate the need for human workers. Instead, it fosters a workforce evolution. Employees are now required to manage, monitor, and maintain these systems, transitioning from repetitive manual tasks to strategic, technical roles. This shift necessitates upskilling and training programs that empower workers to thrive alongside intelligent machines.

Sustainability and Automation Automation also supports sustainability goals in manufacturing. With optimized resource usage, reduced waste, and energy-efficient systems, companies are aligning operations with environmental responsibilities. Smart automation reduces overproduction and enables precision manufacturing that conserves raw materials and energy. The result is a more eco-conscious supply chain with a lower carbon footprint.

Industry-Specific Applications and Innovations Different sectors are leveraging automation uniquely. In automotive manufacturing, robots assemble components with extreme precision. In warehousing, automation streamlines picking, packing, and shipping processes. Even in electronics, micro-assembly and inspection tasks are now handled by advanced robotic systems. As these technologies evolve, we can expect to see more adaptive, AI-powered systems capable of learning from operational data and continuously improving performance.

For more info https://bi-journal.com/how-automation-is-changing-material-handling-and-assembly/

Conclusion Automation is not simply a trend but a transformative force redefining how materials are handled and how assemblies are structured. It boosts operational efficiency, minimizes errors, enhances safety, and opens doors to more sustainable practices. As industries continue to adopt these innovations, the synergy between humans and machines will create a future of manufacturing that is smarter, faster, and more resilient.

#Automation#Smart Manufacturing#Material Handling#IndustrialAutomation#BI Journal#BI Journal news#Business Insights articles

0 notes

Text

youtube

Looking for a powerful and reliable tugger for your toughest material handling tasks? Introducing the Superlift Custom-Designed Tugger, engineered to move up to 40,000 lbs with ease. Built for heavy-duty industrial applications, this tugger is ideal for manufacturing plants, warehouses, and environments where strength, safety, and precision matter.

1 note

·

View note

Text

Best Truck Loading Conveyor Solutions by Indian Manufacturers

Looking for efficient and durable truck loading conveyors? Explore the best solutions from leading Indian manufacturers offering telescopic, flexible, and belt conveyors tailored to your industrial needs. Improve loading speed, reduce manual effort, and ensure workplace safety — all at competitive prices. Ideal for warehouses, logistics hubs, e-commerce, and manufacturing units. ✅ Custom designs

✅ Quick delivery

✅ Low maintenance Get in touch with trusted Indian conveyor suppliers today!

#Truck Loading Conveyor#Indian Conveyor Manufacturers#Telescopic Conveyor#Material Handling#Warehouse Equipment#Logistics Automation#India Manufacturing

0 notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

#plc#programmable logic controller#plc automation#industrial automation#plc controller#plc controller manufacturer in india#plc controller supplier in india#material handling

0 notes

Text

What Safety Precautions Should Be Taken When Using a Chain Pulley?

Chain pulley, also known as hand chain hoists, are essential tools in various industries for lifting and moving heavy loads. While they offer mechanical advantages, imprope use can lead to accidents, equipment damage, or serious injuries. This guide outlines the critical safety precautions to ensure safe and efficient operation.

1. Understanding the Equipment

Familiarize yourself with the specific model of the chain pulley you're using. Refer to the manufacturer's for detailed instructions on operation, maintenance, and safety guidelines.

Key Components:

Hand Chain: Used to ly operate the hoist.

Load Chain: Bears the weight of the load.

Hooks: Connect the hoist to the load and the support structure.

Brake System: Prevents the load from slipping or falling

2. Pre-Operational Checks

Before using the chain pulley, conduct thorough inspections:

Visual Inspection: Check for any visible damage, wear, or deformities on the chains, hooks, and body of the hoist.

Load Chain Condition: Ensure the load chain is clean, lubricated, and free from twists or knots.

Hooks and Latches: Verify that hooks are not bent or cracked and that safety latches are functioning correctly.

Brake Functionality: Test the brake system to ensure it holds the load securely.

Identification and Markings: Confirm that the hoist has clear identification labels, including the Safe Working Load (SWL) and manufacturer's details.

3. Load Assessment and Planning

Determine Load Weight: Accurately assess the weight of the load to ensure it does not exceed the hoist's rated capacity. Overloading can lead to equipment failure and accidents.

Center of Gravity: Identify the load's center of gravity to ensure stable lifting and prevent swinging or tipping.

Path Clearance: Plan the lifting path to avoid obstacles and ensure a clear area for operation.

4. Proper Setup and Rigging

Secure Attachment: Attach the hoist to a suitable and stable support structure capable of handling the load's weight.

Use Appropriate Slings: Employ the correct slings or lifting attachments for the load, ensuring they are in good condition and properly rated.

Avoid Side Loading: Ensure the load is applied vertically to prevent side loading, which can damage the hoist and compromise safety.

5. Safe Operating Practices

Trained Personnel: Only trained and authorized individuals should operate the chain pulley.

Smooth Operation: Operate the hand chain smoothly to lift or lower the load, avoiding sudden jerks or rapid movements.

Stay Clear: Keep all personnel clear of the load during lifting operations. Never stand or pass under a suspended load.

Controlled Movement: Use tag lines to control the load's movement and prevent uncontrolled swinging.

Avoid Shock Loading: Do not allow the load to drop suddenly, as this can cause shock loading and damage the hoist.

6. Emergency Preparedness

Emergency Stop: Be familiar with the hoist's emergency stop mechanism and ensure it is functioning correctly.

Load Lowering: In case of power failure or malfunction, have a plan to safely lower the load without relying solely on the hoist's brake system.

First Aid: Ensure first aid kits are accessible, and personnel are trained to respond to potential injuries.

7. Maintenance and Storage

Regular Maintenance: Follow the manufacturer's maintenance schedule, including lubrication, part replacement, and thorough inspections.

Record Keeping: Maintain detailed records of inspections, maintenance, and any repairs conducted on the hoist.

Proper Storage: Store the hoist in a clean, dry environment to prevent corrosion and damage.

8. Common Mistakes to Avoid

Overloading: Never exceed the hoist's rated capacity.

Improper Use: Do not use the hoist for horizontal pulling or as a sling.

Unauthorized Modifications: Avoid making unauthorized modifications to the hoist.

Neglecting Inspections: Do not skip pre-use inspections, even if the hoist appears to be in good condition.

Untrained Operators: Ensure only trained personnel operate the hoist.

Safety is paramount when operating a chain pulley. By understanding the equipment, conducting thorough inspections, following proper setup and operating procedures, and adhering to maintenance schedules, you can ensure a safe and efficient lifting operation. Always prioritize safety to protect personnel and equipment.

#chain pulley blocks#industrial equipment#lifting solutions#material handling#chainblock#chainblockpulley#manualchainpulleyhoist#pulleyblocksystem#chainpulley#construction

0 notes

Text

Why Choose Weber as Best Material Handling Equipment Manufacturer?

Weber Construction Machinery is a premier material handling equipment manufacturer in Ahmedabad, Gujarat, India that delivers high-quality equipment to boost construction safety and productivity. They supply builder hoist, concrete bucket, mini crane, and slab trolley with rail that is robust yet dependable products to enhance operational safety and performance.

#material handling#material handling equipment#material handling equipment manufacturer in ahmedabad#material handling equipment supplier#material handling equipment company#material handling system#builder hoist#concrete bucket#mini crane#slab trolley with rail

1 note

·

View note

Text

0 notes

Text

y focusing on the critical aspects of high-load supports and material handling, we help our clients in the heavy industrial and facility asset integration markets achieve operational excellence. https://bit.ly/3Te3Ind

#high load supports#material handling#heavy industries#industrial engineering#weldments#facility integration

0 notes

Text

Boost Workplace Efficiency with Conveyor Belt Systems

Maximize your workspace efficiency with a conveyor belt for material handling. This innovative system minimizes physical strain on workers while improving the speed and accuracy of transporting goods. By automating the flow of materials, your team can focus on more important tasks. A conveyor belt ensures safe, consistent delivery of products, enhancing both speed and quality in your operations. Say goodbye to bottlenecks and hello to smoother, faster workflows.

#conveyor belt#material handling#material handling equipment#material handling solutions#food conveyors#food processing conveyor systems#material handling system

0 notes

Text

Expert Material Handling and Machine Operator Training - RTITB

RTITB India offers certified Material Handling Training, Machine Operator Training, Driver Training, and heavy material handling programs to ensure workplace safety.

1 note

·

View note

Text

Material Handling Equipment Manufacturer in Ahmedabad Gujarat India

Weber Construction Machinery is a trusted material handling equipment manufacturer in Ahmedabad, Gujarat, India. We provide a builder hoist, concrete bucket, mini crane, and slab trolley with a rail that boosts efficiency, safety, and productivity in various industries.

#material handling#material handling equipment#material handling equipment manufacturer#material handling equipment supplier#material handling equipment company#material handling system#builder hoist#concrete bucket#mini crane#slab trolley with rail

1 note

·

View note