#Logistics Automation

Explore tagged Tumblr posts

Text

Global Logistics Automation Market is projected to reach the value of USD 55.36 billion by 2030.

Global Logistics Automation Market is projected to reach the value of USD 55.36 billion by 2030.

logistics automation market crossed USD 34 billion, with automated solutions cutting operational costs by an average of 28% across industries. Companies deploying end-to-end automation reported a 29.3% boost in warehouse productivity within the first year alone. Autonomous Mobile Robots (AMRs) surged by 34% year-on-year, reshaping warehouse layouts with flexible, scalable operations.

With e-commerce order volumes growing 5x faster than traditional retail and labor shortages driving logistics costs up by over 18%, automated systems have shifted from a “nice-to-have” to a “must-have” for competitive survival.

This report offers actionable segmentation by component, automation type, and end-user industry; uncovers pricing trends; analyzes deployment models; and provides country-specific insights including North America, Asia-Pacific, and Europe.

2025–2030 marks a critical window. Companies acting now can secure operational advantages, reduce risks, and achieve 3–5x faster returns on automation investments compared to late adopters.

Download Sample @ https://tinyurl.com/cuwv5ahk

The logistics automation market has experienced remarkable growth in 2024, revolutionizing supply chain operations across industries through advanced technological integration. This transformation is characterized by the increasing adoption of robotics, artificial intelligence, warehouse management systems, and autonomous vehicles designed to streamline logistics processes. Companies worldwide are recognizing the competitive advantages offered by automation technologies, including enhanced operational efficiency, reduced labor costs, and improved accuracy in inventory management. The market is witnessing a significant shift from traditional manual processes to sophisticated automated solutions that can handle complex logistics tasks with minimal human intervention. The current market landscape reflects a strong emphasis on end-to-end automation solutions that provide seamless connectivity between different stages of the supply chain. Major industry players are focusing on developing integrated platforms that combine various automation technologies to offer comprehensive logistics management capabilities. The rise of e-commerce has been a pivotal factor driving demand for logistics automation, as businesses strive to meet increasingly stringent customer expectations regarding delivery speed and accuracy. Additionally, the push toward sustainability has influenced market growth, with automated systems demonstrating superior energy efficiency and reduced environmental impact compared to conventional methods. In 2024, small and medium-sized enterprises (SMEs) have become more prominent participants in the logistics automation market, facilitated by the availability of scalable and cost-effective solutions. Cloud-based logistics automation platforms have gained substantial traction, enabling businesses of all sizes to access advanced capabilities without significant upfront investments.

Key Market Insights:

Studies indicate that companies implementing comprehensive logistics automation solutions report an average productivity increase of 29.3% within the first year of deployment. The adoption rate of automated guided vehicles (AGVs) has surged by 47% in 2024 compared to the previous year, reflecting the growing preference for mobile robotics in warehouse environments.

Approximately 62% of logistics providers are currently utilizing some form of artificial intelligence to optimize route planning and inventory management.

Automated sortation systems have demonstrated an impressive 32.6% reduction in order processing time across industries.

The pharmaceutical sector has emerged as a significant adopter of logistics automation, with 71.5% of pharmaceutical companies investing in automated storage and retrieval systems.

Market Drivers:

Increasing E-commerce Demands

The explosive growth of e-commerce has fundamentally transformed consumer expectations around delivery speed, accuracy, and flexibility, creating unprecedented pressures on supply chain operations. Modern consumers demand same-day or next-day delivery options, accurate order fulfilment, and real-time tracking capabilities — requirements that are virtually impossible to meet consistently through manual processes alone. Logistics automation technologies address these challenges directly by enabling high-speed order processing, reducing picking errors through guided systems, and facilitating rapid sortation and dispatch operations. The ability to handle high-volume, high-variety order profiles efficiently has become essential for e-commerce success, particularly during peak seasons when order volumes can increase exponentially. Additionally, the rise of omnichannel retail strategies requires seamless integration between physical and online sales channels, necessitating sophisticated automated inventory management systems that maintain accurate stock visibility across all points of sale. Companies leveraging advanced logistics automation have demonstrated their ability to reduce order fulfilment times by up to 70% while simultaneously improving accuracy rates to over 99.9%, creating significant competitive advantages in the rapidly evolving e-commerce landscape.

Labor Shortages and Rising Costs

The logistics industry is facing severe workforce challenges characterized by persistent labor shortages, high turnover rates, and steadily increasing wage costs, creating compelling incentives for automation adoption. In many developed markets, logistics operations struggle to attract and retain qualified personnel for physically demanding roles in warehouses and distribution centers, particularly for night shifts and peak seasons. This workforce gap has been exacerbated by demographic shifts including aging populations and changing career preferences among younger workers. The financial implications are substantial, with labor typically representing 50–70% of operational costs in traditional logistics facilities. Automation technologies directly address these challenges by reducing dependence on manual labour while improving working conditions for remaining staff. Tasks that once required extensive human intervention — such as heavy lifting, repetitive picking, and long-distance walking within facilities — can now be performed by automated systems operating continuously without fatigue or performance variation. This transition allows human workers to be reallocated to higher-value roles requiring judgment and problem-solving skills, often resulting in increased job satisfaction and reduced turnover. The economic case for automation becomes increasingly compelling as labour costs rise, with many companies reporting that automation investments reach positive ROI significantly faster in regions with high labour costs.

Market Restraints and Challenges:

The logistics automation market faces significant barriers including high initial investment requirements and technical integration complexities. Many existing facilities require extensive structural modifications to accommodate automation systems, increasing implementation costs. Legacy IT systems often prove incompatible with modern automation platforms, necessitating additional investments in digital infrastructure. Furthermore, workforce resistance and training requirements can delay adoption and reduce projected returns, particularly in organizations with limited change management capabilities.

Market Opportunities:

Emerging technologies including artificial intelligence and machine learning present substantial opportunities for predictive logistics optimization. The growing middle class in developing regions is driving demand for efficient distribution networks, creating new markets for automation solutions. Sustainability initiatives provide openings for energy-efficient automation systems that reduce environmental impact while improving operational efficiency. Additionally, the increasing availability of automation-as-a-service models is making sophisticated technologies accessible to smaller organizations, significantly expanding the potential customer base for logistics automation providers.

Buy Now @ https://tinyurl.com/bdet4j3k

Market Segmentation:

By Component:

Hardware: • Automated Storage and Retrieval Systems (AS/RS) • Conveyor Systems • Sortation Systems • Palletizing and Depalletizing Systems • Robotic Picking and Packing Systems • Automated Guided Vehicles (AGVs) • Autonomous Mobile Robots (AMRs) • Industrial Sensors • Barcode and RFID Scanners • Others (Cranes, Carousels, Shuttle Systems) Software: • Warehouse Management Systems (WMS) • Transportation Management Systems (TMS) • Yard Management Systems (YMS) • Inventory Management Systems • Order Management Systems • Others (Fleet Management, Labor Management Software) Services: • Consulting • System Integration and Deployment • Support and Maintenance

Autonomous Mobile Robots represent the fastest-growing hardware component within logistics automation, experiencing 34% year-over-year growth. Unlike fixed automation or traditional AGVs, these flexible systems require minimal infrastructure modifications and can be rapidly deployed and reconfigured. AMRs leverage advanced navigation capabilities, machine learning, and sophisticated sensor arrays to navigate dynamic environments without predefined paths. Their modular design and scalable implementation allow organizations to start with limited deployments and expand incrementally, creating adoption advantages for operations with uncertain future requirements or space constraints.

Warehouse Management Systems maintain their position as the dominant software component within logistics automation, representing approximately 43% of total software expenditures. These systems serve as the central nervous system for automated operations, orchestrating workflows, resource allocation, and information flows across diverse automation technologies. WMS functionality has expanded beyond inventory control to incorporate sophisticated optimization algorithms, labor management, yard operations, and seamless integration with enterprise systems. Cloud-based deployment models have democratized access to enterprise-grade capabilities, accelerating adoption across organization sizes. The strategic importance of WMS continues to grow as automation complexity increases, requiring sophisticated coordination between human operators and diverse automated systems.

By End-Use Industry:

• Retail and E-commerce • Manufacturing • Automotive • Healthcare and Pharmaceuticals • Food and Beverages • Aerospace and Defense • Consumer Electronics • Logistics and Transportation • Others (Textiles, Chemicals, Oil & Gas)

0 notes

Text

AI and the Top Technologies Driving Automation in Logistics and Distribution

The logistics and distribution industry is undergoing a major transformation as automation technologies advance at an unprecedented rate. In 2025, the convergence of digital innovation and intelligent infrastructure is reshaping how goods are stored, transported, and delivered. Businesses across the globe are adopting emerging tools to boost efficiency, minimize errors, and respond to increasing consumer demands. Understanding these innovations is crucial to staying competitive in a rapidly evolving market.

Emerging Importance of Automation in Logistics Automation is no longer a future concept but a present necessity in the logistics sector. Businesses are leveraging data and intelligent systems to optimize processes and enhance customer experience. The increasing complexity of supply chains and demand for faster delivery has made automation a vital pillar of operational strategy.

AI and Machine Learning Optimizing Supply Chains Artificial Intelligence and machine learning are playing pivotal roles in demand forecasting, route planning, and inventory management. These technologies allow companies to predict fluctuations, reduce delays, and automatically adjust operations based on real-time inputs, leading to smarter supply chains.

Role of Robotics in Warehousing and Fulfillment Robotic systems are revolutionizing warehouse operations by handling repetitive tasks like picking, packing, and sorting. These intelligent machines not only reduce labor costs but also significantly increase accuracy and throughput, enabling 24/7 operations in fulfillment centers.

IoT Enhancing Real-Time Visibility The Internet of Things brings end-to-end visibility across the logistics network. Sensors embedded in vehicles, pallets, and products provide live data on location, temperature, and condition. This transparency enables proactive decision-making and reduces risks associated with inventory mismanagement.

Autonomous Vehicles and Drones for Smart Deliveries Self-driving trucks and drones are redefining last-mile delivery strategies. These autonomous systems ensure timely deliveries with minimal human intervention, cutting transportation costs and improving delivery reliability, especially in urban and remote locations.

Blockchain Securing Transparent Logistics Blockchain technology ensures secure and transparent data exchange across all stakeholders in the supply chain. It creates immutable records of transactions, which helps prevent fraud, simplifies audits, and builds trust among partners and customers.

Cloud Platforms for Integrated Logistics Management Cloud-based logistics platforms allow companies to manage operations, monitor performance, and collaborate with partners from a centralized interface. These solutions integrate data from multiple sources, supporting informed and agile decision-making.

Sustainability Through Green Tech Automation Sustainability is becoming a core focus in logistics, and automation is supporting greener practices. Electric vehicles, energy-efficient warehouses, and intelligent energy management systems reduce carbon footprints while maintaining operational excellence.

The Future Landscape of Automated Logistics The future of logistics lies in fully interconnected, self-optimizing systems. From predictive analytics to AI-powered delivery ecosystems, the industry is moving towards zero-touch logistics where machines coordinate end-to-end processes autonomously and reliably.

For more info: https://bi-journal.com/automation-in-logistics-top-technologies-2025/

Conclusion Automation technologies are fundamentally reshaping logistics and distribution by driving efficiency, reducing costs, and enhancing accuracy. As companies continue to adopt advanced tools, staying informed about these innovations is essential. The technologies highlighted above are not just trends—they represent the new operational standard in a data-driven, fast-paced global supply chain.

#bi-journal news#bi-journal services#business insight journal#Logistics Automation#Supply Chain Technology#Warehouse Innovation#AI in Logistics

0 notes

Text

Best Truck Loading Conveyor Solutions by Indian Manufacturers

Looking for efficient and durable truck loading conveyors? Explore the best solutions from leading Indian manufacturers offering telescopic, flexible, and belt conveyors tailored to your industrial needs. Improve loading speed, reduce manual effort, and ensure workplace safety — all at competitive prices. Ideal for warehouses, logistics hubs, e-commerce, and manufacturing units. ✅ Custom designs

✅ Quick delivery

✅ Low maintenance Get in touch with trusted Indian conveyor suppliers today!

#Truck Loading Conveyor#Indian Conveyor Manufacturers#Telescopic Conveyor#Material Handling#Warehouse Equipment#Logistics Automation#India Manufacturing

0 notes

Text

How Can Logistics Software Boost Your Supply Chain Efficiency?

How Can Logistics Software Boost Your Supply Chain Efficiency?

Hey folks! If you’ve ever waited too long for a package or watched fuel bills eat into your logistics budget, you already know the importance of a streamlined supply chain. Whether you’re running a growing e-commerce store or managing a fleet of trucks, your supply chain is the heartbeat of your operations.

And just like a heart, when it beats efficiently, everything runs smoother, faster, and better. So today, let's dig into how logistics software can supercharge that heartbeat and take your logistics game to the next level.

Why Supply Chain Efficiency Matters

A well-oiled supply chain isn’t just a backend concern—it directly affects your bottom line and how happy your customers are. When things flow smoothly, your costs go down, deliveries get faster, and buyers get what they want when they want it. That’s a win for everyone.

What Defines an Efficient Supply Chain?

An efficient supply chain checks off a few key boxes: speed, accuracy, responsiveness, and cost-effectiveness. Speed ensures that orders are fulfilled quickly. Accuracy guarantees that the right items are delivered in the right quantity. Responsiveness means adapting fast to unexpected changes, and cost-effectiveness is all about doing it without breaking the bank.

Think of it like a symphony—each section (inventory, transportation, warehousing) must play in harmony. If one is off-beat, the whole performance suffers.

How Does Logistics Software Fit In?

Now here’s where logistics software like CommuteLogix steps into the spotlight 🛠️. A robust logistics management system acts like a smart control tower, overseeing every piece of your supply chain.

It handles real-time tracking, automates repetitive tasks, and pulls together tons of data into useful dashboards. The result? A system that reacts, adapts, and performs better without you micromanaging every detail.

Real-Time Tracking Improves Visibility and Responsiveness

Imagine driving a car without a dashboard—you wouldn’t know your speed, fuel level, or if the engine’s about to overheat. That’s what running logistics without real-time tracking feels like.

What Is Real-Time Tracking in Logistics Software?

Real-time tracking uses a mix of GPS, RFID (radio-frequency identification), and IoT (Internet of Things) technologies to keep you updated on where your shipments are. With the best logistics management software, you don’t have to make calls or guess—your dashboard tells you where everything is, instantly.

For example, GPS lets you see a truck’s current route, RFID helps identify individual items within containers, and IoT devices can monitor conditions like temperature for sensitive cargo.

How Does It Improve Supply Chain Visibility?

Visibility means knowing the who, what, where, and when of your logistics. With live tracking, managers can monitor shipments in motion, spot delays in real-time, and reroute drivers if needed.

It’s like having night-vision goggles in a dark warehouse—you can see potential issues before they trip you up 🤖. This visibility improves coordination between teams, vendors, and customers, helping you plan more accurately and prevent unpleasant surprises.

What’s the Impact on Customer Satisfaction?

People love transparency. Real-time tracking gives customers the ability to see where their orders are—just like tracking a pizza delivery. This level of clarity builds trust and reduces customer service inquiries.

In fact, a 2023 survey from Statista revealed that 83% of customers consider real-time tracking an important part of their delivery experience. Happy customers = repeat business = higher revenue.

Lower Operational Costs Through Smarter Processes

Let’s talk money. Every business wants to save more and waste less, right? That’s exactly where logistics software shines.

What Tasks Can Be Automated to Cut Costs?

Routine, repetitive tasks like route planning, invoicing, dispatching, and even warehouse stocking can be automated with a logistics management system.

Instead of assigning drivers manually or calculating fuel usage by hand, the software does the heavy lifting. It sends automated invoices, manages orders, and even allocates vehicles—all while reducing human error.

How Does Route Optimization Reduce Fuel Expenses?

Route optimization is like having Google Maps on steroids. The software analyzes traffic data, delivery windows, and fuel efficiency to determine the best path for each trip.

According to the American Transportation Research Institute (ATRI), optimized routes can cut fuel consumption by 10%–20%. That’s serious savings when fuel prices are constantly fluctuating.

Can Automation Reduce Labor Costs?

Absolutely. When software takes over tedious manual tasks, your team can focus on higher-value work like customer service or strategic planning.

You’ll also need fewer people on the ground doing data entry or tracking shipments. It doesn’t mean replacing workers—it means empowering them to do more with less effort, which is a win-win.

Improved Inventory and Warehouse Management

If your inventory is a jungle, logistics software is your machete—cutting through the chaos to bring order.

How Does Software Prevent Stockouts and Overstocking?

By using real-time inventory tracking and demand forecasting, logistics software keeps your stock levels balanced. It alerts you when you're running low or when you’re about to overstock.

In fact, McKinsey reports that businesses using predictive inventory systems reduce stockouts by up to 30% while minimizing excess stock by 20%. That’s more sales and fewer dusty shelves.

What Are the Benefits of Warehouse Optimization?

Efficient warehouse management isn’t just about having space—it’s about using it wisely. Logistics software helps with slotting (deciding where products should be stored), optimizing picking paths for workers, and rotating stock based on demand cycles.

The outcome? Faster order fulfillment, less product damage, and happier warehouse staff.

How Does Inventory Visibility Reduce Delays?

Imagine knowing exactly where each item is, how much is left, and when it’s arriving—all at your fingertips. This level of visibility speeds up decision-making and fulfillment. With fewer surprises and better planning, you can reduce lead times and deliver faster, keeping both your team and your customers smiling 😊.

Data-Driven Decision-Making with Analytics Tools

Raw data is just noise unless you know how to read it. Logistics software turns that noise into music.

What Kind of Analytics Do These Tools Provide?

Good logistics management software comes packed with dashboards and reports—delivery time averages, order accuracy rates, cost per shipment, and warehouse performance metrics.

These insights help you measure what matters. It’s like having a personal trainer for your supply chain, showing you exactly where to improve.

How Does This Data Improve Operations?

When you know where your bottlenecks are, you can fix them. If a particular route is always delayed, you switch it. If one vendor is slower than others, you negotiate or replace them.

Over time, these data-informed tweaks create a more resilient, agile operation—ready to take on whatever the market throws your way.

Can Predictive Analytics Help Forecast Demand?

Yes—and it’s a game-changer. Advanced systems use AI to study historical data and predict future trends. That means you can ramp up inventory ahead of peak seasons or scale down during lulls.

According to Gartner, companies using predictive analytics in logistics saw a 15% increase in forecasting accuracy. In an industry where timing is everything, that's a huge competitive edge.

Final Thoughts on Boosting Efficiency with Software

So, folks, whether you're shipping cupcakes or construction materials, logistics software is no longer optional—it's essential. From tracking trucks in real time to balancing your warehouse inventory, it helps you work smarter, faster, and more affordably.

Key Takeaways

Real-time tracking improves visibility and customer satisfaction

Automation cuts costs and reduces manual errors

Analytics enable smarter, faster decision-making

Inventory management becomes more accurate and agile

Frequently Asked Questions (FAQs)

1. How quickly can logistics software impact efficiency?

Most businesses start seeing benefits within the first few weeks of implementation. Automation and tracking features offer instant improvements, while deeper analytics may take a few months to deliver actionable trends. The full impact becomes visible within three to six months.

2. Does logistics software require new hardware?

Not always. Many logistics software solutions are cloud-based and work with existing devices like smartphones, tablets, or warehouse scanners. However, integrating IoT or RFID technology might require some hardware upgrades for optimal functionality.

3. Can small businesses benefit from logistics software?

Yes, absolutely. In fact, small businesses can benefit even more because logistics software helps them scale operations without hiring large teams. Cloud-based platforms are affordable and flexible, making it easier for startups to compete with bigger players.

4. What’s the ROI on logistics software?

Return on investment varies but is typically high. Companies often report savings from reduced fuel costs, fewer labor hours, and improved inventory turnover. Many see an ROI of 150%–300% within the first year, especially when using a well-integrated logistics management system.

5. Are cloud-based solutions better for efficiency?

Cloud-based logistics management software is generally more efficient because it updates in real time, supports remote access, and requires less IT infrastructure. It also scales easily as your business grows, making it a flexible solution for modern supply chains.

That’s it for today, folks! I hope this breakdown gives you a clear, real-world look at how logistics software can transform your supply chain from a clunky conveyor belt into a high-speed express lane. Keep things efficient, stay data-smart, and your logistics will never hold you back.

#logistics software#supply chain#logistics automation#efficiency#logistics tracking#logistics tools#supply chain performance#logistics optimization

1 note

·

View note

Text

ADVANCED ROBOTICS: THE FUTURE OF ENGINEERING AUTOMATION

Advanced robotics is transforming engineering by automating complex tasks with AI and machine learning. Industries like healthcare, manufacturing, and logistics benefit from intelligent machines that enhance efficiency and precision. Unlike traditional automation, AI-powered robots adapt, learn, and improve over time. At M.Kumarasamy College of Engineering (MKCE), students engage with cutting-edge robotics through hands-on projects. The institution’s labs foster innovation in autonomous systems and adaptive algorithms. Emerging trends like swarm robotics and soft robotics are revolutionizing automation. MKCE integrates interdisciplinary learning, merging robotics with AI and mechanical engineering. Industry partnerships ensure students gain real-world exposure to advanced technologies. The college also emphasizes sustainable robotics solutions for a greener future. As robotics continues to evolve, MKCE remains at the forefront of this transformative field.

To know more : https://mkce.ac.in/blog/advanced-robotics-as-the-next-frontier-in-engineering-automation/

#private college#mkce college#best engineering college#top 10 colleges in tn#best engineering college in karur#engineering college in karur#mkce.ac.in#mkce#engineering college#libary#•#Advanced Robotics#Engineering Automation#AI in Robotics#Robotics and Machine Learning#Autonomous Systems#Industrial Automation#Robotics in Manufacturing#Healthcare Robotics#Agricultural Robotics#Logistics Automation

0 notes

Text

New Trends in Supply Chain Management You Should Know

The way businesses manage their supply chains is changing fast. New technologies, customer demands, and global challenges are creating new ways to make supply chains better. Staying updated on these trends can help businesses save money, work faster, and keep customers happy.

Let’s look at some important new trends in Supply Chain Management that you should know.

1. Using Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are helping companies make smarter decisions in supply chains. These tools analyze data to predict demand, reduce delays, and save money.

Predicting Demand: AI helps businesses know how much stock they need, so they don’t order too much or too little.

Better Delivery Routes: AI can find the quickest and cheapest routes for deliveries.

Quick Problem Solving: Machine learning spots potential issues and suggests solutions before they become big problems.

2. Focusing on Sustainability

More businesses are trying to make their supply chains better for the environment. Customers and governments are asking companies to go green.

Greener Deliveries: Companies are finding ways to use less fuel and create fewer emissions.

Eco-Friendly Packaging: Many businesses are switching to packaging that can be recycled or reused.

Less Waste: Some companies are reusing materials instead of throwing them away.

Sustainability not only helps the planet but also makes a company look good to customers.

3. Using Blockchain Technology

Blockchain is helping businesses make their supply chains more transparent and secure. This technology records every step of a product’s journey, so it’s easy to track.

Building Trust: Customers can see where their products come from.

Preventing Fake Products: Blockchain helps companies spot counterfeit goods quickly.

Safer Transactions: All transactions are verified, reducing the risk of fraud.

4. The Growth of Online Shopping

Online shopping has changed supply chains. Customers now expect fast delivery and easy shopping.

Multiple Options for Customers: Businesses let customers shop online, in-store, or both.

Faster Delivery Centers: Smaller warehouses are being built closer to customers to deliver faster.

New Delivery Methods: Companies are using drones and automated vehicles to deliver goods quickly.

Adapting to these changes is important to keep up with customer expectations.

5. Real-Time Tracking with IoT

The Internet of Things (IoT) is making supply chains smarter by connecting devices like sensors and trackers. These devices provide real-time updates on shipments and inventory.

Tracking Shipments: Companies know where their goods are at all times.

Managing Inventory: Sensors help track stock levels in warehouses.

Preventing Breakdowns: IoT devices warn businesses about equipment problems before they happen.

IoT helps reduce delays and ensures smooth operations.

6. Preparing for Risks and Disruptions

Global challenges like COVID-19 have shown that supply chains need to be ready for unexpected problems.

More Suppliers: Businesses are working with multiple suppliers to avoid relying on just one.

Local Suppliers: Companies are choosing suppliers closer to home to avoid shipping delays.

Planning for the Future: Businesses are using data to prepare for potential disruptions.

A strong supply chain can handle problems better and recover faster.

7. Outsourcing Supply Chain Tasks

Many companies are hiring third-party providers to handle their supply chains. This is called Supply Chain-as-a-Service (SCaaS).

Saving Money: Companies don’t need to invest in expensive equipment or warehouses.

Scaling Up or Down: Businesses can adjust operations based on how busy they are.

Expert Help: Third-party providers bring specialized knowledge and technology.

This trend lets companies focus on what they do best while leaving logistics to the experts.

8. Automation and Robotics

Automation and robots are speeding up supply chain processes and reducing costs.

Robot Warehouses: Robots help pick, pack, and move items in warehouses.

Self-Driving Vehicles: Companies are testing trucks and drones for deliveries.

Smart Systems: Automated systems make warehouses faster and more efficient.

Automation helps businesses handle more work with fewer errors.

9. Using Data for Better Decisions

Data is playing a big role in supply chain management. Companies are using it to make better and faster decisions.

Tracking Performance: Data helps businesses see what’s working and what’s not.

Predicting Needs: Businesses use data to forecast demand and plan their inventory.

Cutting Costs: Insights from data help find ways to save money.

With the right tools, data can make supply chains much more effective.

10. Customer-Focused Supply Chains

Modern supply chains aren’t just about moving products; they’re about creating great customer experiences.

Flexible Delivery Options: Customers can choose how and when they want their orders.

Faster Shipping: Companies are focusing on same-day or next-day deliveries.

Clear Updates: Real time order tracking keeps customers informed and happy.

Putting customers first is key to building loyalty and staying competitive.

Conclusion: Mobility Solutions Are Shaping the Future

Supply chain management is evolving rapidly, and mobility solutions are a key part of this change. From electric delivery vehicles to real-time tracking and route optimization, mobility innovations are helping businesses save money, reduce environmental impacts, and improve customer satisfaction.

By adopting these trends, companies can build smarter, greener, and more efficient supply chains.

Are you ready to embrace Mobility Solutions in your supply chain? Start exploring these innovations today to stay ahead of the competition.

0 notes

Text

0 notes

Text

Supply Chain Optimization through Automation: A Competitive Advantage

Automation is no longer a choice but a necessity for businesses aiming to stay competitive in the modern supply chain landscape. It empowers organizations with the tools needed to optimize processes, reduce costs, enhance customer satisfaction, and respond swiftly to market fluctuations. As we move further into the digital age, embracing automation in supply chain management will be the key to maintaining a significant competitive advantage.

Tecnolynx collaborate closely with your business to understand your specific processes and challenges, crafting web-based applications, APIs, and other digital tools to streamline your operations. Our team of skilled web developers specializes in creating customized automation solutions tailored to your unique supply chain requirements. Our solutions are designed for seamless integration with your current systems, ensuring a smooth transition to automation.

#IoT sensors#RFID tags#Automation technologies#Supply chain visibility#Real-time tracking#Operational efficiency#Inventory management#Logistics automation#Supply chain optimization#IoT in supply chain

0 notes

Text

Elevating Communication with AI Voice Bot Technology

Imagine a world where businesses can have natural, intelligent conversations with their customers through technology. That’s exactly what an AI voice bot offers. Unlike traditional bots, these advanced systems understand context and respond with meaningful answers, making interactions smoother and more personal.

At VoiceOwl.ai, we’re dedicated to building AI voice bot solutions that fit seamlessly into your existing setup, helping automate customer service and make every interaction count.Our AI voice bots are designed to learn and improve over time, ensuring they keep up with your needs and provide the best possible responses.

Whether you need help with customer support, virtual assistants, or smart home devices, VoiceOwl.ai is here to bring the future of communication to your business.

#Lead verification automation#Lead Qualification automation#BFSI Automation#NBFC Automation#ABM Marketing Automation#Call Center Automation#Conversational AI#RCM Automation#E-commerce Automation#Logistics Automation#Recruitment Automation

0 notes

Text

Logistics and Warehouse Automation Market by Application in Canada

As the demand for faster delivery and improved service levels escalates, logistics companies are embracing automation technologies to optimize their operations. This shift is not merely a trend but a fundamental change in how businesses manage their supply chains, warehouse processes, and overall logistics strategies.

The Driving Forces Behind Automation

Several factors contribute to the rapid adoption of warehouse automation in Canada. E-commerce growth, particularly accelerated by the COVID-19 pandemic, has intensified the need for logistics companies to enhance their operational capabilities. Customers now expect quick and accurate deliveries, putting pressure on logistics providers to streamline their processes. Also, labor shortages in the logistics sector have prompted companies to seek automated solutions to maintain productivity levels. The integration of automation technologies has become a strategic priority for many logistics firms.

Applications in the Market

Inventory Management

Inventory management is one of the most critical applications of warehouse automation. The ability to maintain accurate inventory levels directly impacts operational efficiency and customer satisfaction. Automated inventory tracking systems, bolstered by technologies such as RFID (Radio Frequency Identification) and IoT (Internet of Things), allow logistics companies to monitor stock levels in real-time. These systems minimize human error, reduce excess inventory, and improve order accuracy. By adopting automated inventory management solutions, logistics companies can ensure that products are available when needed, enhancing service levels. 2. Order Fulfillment

Order fulfillment represents a pivotal area where warehouse automation can significantly boost logistics efficiency. Automated picking systems, including robotic picking solutions and automated guided vehicles (AGVs), enable logistics companies to speed up the order fulfillment process while maintaining accuracy. These technologies reduce the time taken from order placement to delivery, allowing companies to meet customer demands promptly. Furthermore, automation in order fulfillment minimizes the risk of errors, which can lead to costly returns and customer dissatisfaction. 3. Shipping and Receiving

Efficient shipping and receiving operations are essential components of successful logistics management. Automation technologies, such as dock scheduling systems and automated sorting solutions, optimize the flow of goods in and out of warehouses. These processes and logistics companies can significantly reduce delays and enhance overall efficiency. Systems ensure that shipments are processed swiftly and accurately, improving the time for delivery and benefiting customer experiences. 4. Warehouse Management Systems (WMS)

A robust Warehouse Management System (WMS) is crucial for managing warehouse operations effectively. A WMS offers logistics companies the tools to monitor and control inventory levels, manage labor resources, and analyze implementation metrics in real-time. By integrating automation into WMS, businesses can achieve greater visibility into their operations and improve decision-making processes. Advanced WMS solutions can facilitate seamless communication between departments, improving operational efficiency. 5. Data Analytics and Reporting

Analytics plays a vital role in optimizing logistics operations. Automated data collection and reporting tools enable logistics companies to track key performance indicators (KPIs) and analyze their operations comprehensively. With the insights gained from data analytics, logistics providers can identify bottlenecks, streamline processes, and make informed decisions. This level of visibility not only aids in optimizing current operations but also assists in strategic planning for future growth.

Challenges and Considerations

While the benefits of warehouse automation are substantial, logistics companies must also navigate challenges associated with implementation. Initial investment costs can be significant, and companies must carefully assess their return on investment (ROI) before committing to automation technologies. Also, the new systems with existing processes can be complex, requiring thorough planning and training for staff. Change management is crucial to ensure employees adapt to new technologies and workflows.

The Future of Logistics Automation in Canada

As the logistics sector in Canada continues to evolve, the integration of automation technologies will only become more critical. Companies that invest in advanced logistics solutions will adapt to changing market demands and improve their competitive edge. The rise of technologies such as artificial intelligence, machine learning, and robotics will further enhance the capabilities of logistics companies, paving the way for more innovative and efficient operations.

By embracing automation across various applications, businesses can achieve greater efficiency, reduce costs, and deliver superior. The shift towards automated logistics solutions is not just a trend; it’s a necessary evolution in the fast-paced world of supply chain management. As Canadian logistics firms adapt to this changing landscape, the future looks promising, marked by innovation and enhanced efficiency.

#Logistics Automation#immensity logistics#logistics management#freight logistics#supply chain management#transportation#logistics industry#automation#integration#Canadian Logistics#Warehouse Management

0 notes

Text

Save Time and Reduce Cost with Automation

Let’s talk about something we all wish we had more of in the trucking industry: time and money. It’s no secret that running a trucking business is tough. Between keeping up with the endless regulations, dealing with unexpected repairs, and managing all the paperwork, it feels like there are never enough hours in the day. And let’s not even start on the costs piling up. But what if I told you…

View On WordPress

#automated billing trucking#automated dispatching#automated invoicing#automated trucking operations#business#cash flow management#driver behavior monitoring#fleet management automation#Freight#freight automation#freight industry#Freight Revenue Consultants#fuel savings trucking#improve trucking productivity#logistics#logistics automation#maintenance scheduling#optimized trucking routes#reduce costs trucking#save time trucking#small carriers#telematics systems#Transportation#truck performance monitoring#Trucking#trucking automation#trucking business automation#trucking business growth#trucking business solutions#trucking compliance management

0 notes

Text

In the bustling metropolis of strategic logistics planning in Chicago, Illinois, where the flow of goods is constant and the demand for efficient logistics solutions is ever-present, the role of automation in modern shipping operations cannot be overstated. At UKA TRANSPORTATION LLC, we stand at the forefront of this revolution, harnessing the power of automation to transform the way we move freight and cargo across the country.

0 notes

Text

Navigating the Future: Advancements in Warehouse Robotics Technology

As we look to the future of logistics and supply chain management, one technology stands out as a driving force behind innovation and efficiency: warehouse robotics. Rapid advancements in robotics technology are reshaping the way warehouses operate, offering unprecedented levels of automation, precision, and scalability.

Exploring the Latest Advancements:

Enhanced Mobility and Flexibility: The latest advancements in Warehouse Robotics technology are focused on enhancing mobility and flexibility. Robots are becoming more agile and adaptable, capable of navigating complex warehouse environments with ease. This increased mobility allows for greater flexibility in warehouse layout and optimization of space.

Integration of Artificial Intelligence: Artificial intelligence (AI) is playing a crucial role in the evolution of warehouse robotics. AI-powered robots can analyze vast amounts of data in real-time, allowing them to make intelligent decisions and adapt to changing circumstances on the fly. This level of autonomy and decision-making capability is revolutionizing warehouse operations.

Embracing Collaborative Robotics:

Collaborative Robots (Cobots): Collaborative robots, or cobots, are another exciting development in warehouse robotics technology. Unlike traditional industrial robots, cobots are designed to work alongside human workers, enhancing efficiency and safety in the warehouse environment. These robots can perform tasks that require dexterity and precision, while humans focus on more complex operations.

Human-Robot Collaboration: The integration of cobots into warehouse workflows enables seamless human-robot collaboration. By working together, humans and robots can leverage their respective strengths to optimize productivity and achieve higher levels of efficiency. This collaborative approach to warehouse robotics ensures a smooth transition towards fully automated warehouse operations.

Get More Insights On This Topic: Warehouse Robotics

#Warehouse Robotics#Automation#Robotics Technology#Supply Chain Efficiency#Logistics Automation#Robotic Automation#Warehouse Management#Industrial Robotics

0 notes

Text

Best Truck Loading Conveyor Solutions by Indian Manufacturers

Looking for efficient and durable truck loading conveyors? Explore the best solutions from leading Indian manufacturers offering telescopic, flexible, and belt conveyors tailored to your industrial needs. Improve loading speed, reduce manual effort, and ensure workplace safety — all at competitive prices. Ideal for warehouses, logistics hubs, e-commerce, and manufacturing units. ✅ Custom designs

✅ Quick delivery

✅ Low maintenance

Get in touch with trusted Indian conveyor suppliers today!

#Truck Loading Conveyor#Indian Conveyor Manufacturers#Telescopic Conveyor#Material Handling#Warehouse Equipment#Logistics Automation#India Manufacturing

0 notes

Text

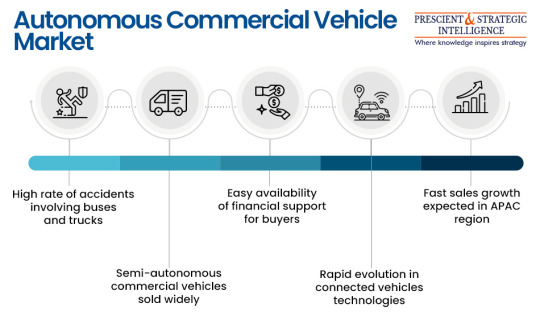

Driving the Future: Autonomous Commercial Vehicle Market Revolution

The autonomous commercial vehicle market is experiencing growth and is projected to reach USD 1,302.1 billion by 2030. This development can be ascribed to the continuing development in commercial vehicle technologies, growing government aid for autonomous commercial cars, and rising requirement for effective advantages and well-organized and safer driving options.

In recent years, the semi-autonomous category, on the basis of vehicle autonomy, contributed a higher revenue share. Vehicles must be fortified with electronic stability control or at least one of the progressive driver-assistance system ADAS features (either for steering or acceleration) to attain level 1 automation. Most of the European nations and the U.S. have forced the acceptance of basic ADAS features in all new commercial vehicles, which essentially makes all of them semi-autonomous.

In recent years, the truck category held the larger market share, and the category is projected to remain dominant in the vehicle type segment of the industry during the projection period. This can be credited to the growing utilization of autonomous trucks for logistical processes, like domestic logistics transportation, automated material handling, logistics digitalization, and yard management.

In the coming few years, on the basis of the application segment, the public transportation category is projected to advance at the fastest rate. This can be credited to the rising acceptance of autonomous shuttle facilities for public mobility reasons. Numerous start-ups and recognized businesses are coming up with strategies to grow level 5 autonomous shuttles for public transport. Such shuttles will not need human drivers for the process, which will aid transportation agencies save on working prices.

In the past few years, the North American region dominated the industry with the highest revenue for the autonomous commercial vehicle market, and the region is also projected to remain in the top spot during the projection period. This can be mainly credited to the increasing research and development activities on autonomous automobiles and growing aid from the federal and state governments for advancing autonomous driving technologies.

The APAC region is projected to witness the fastest development because of the booming vehicle industry here. APAC is the globe's largest vehicle maker, responsible for almost half of the annual production.

Hence, the continuing development in commercial vehicle technologies, growing government aid for autonomous commercial cars, and rising requirement for effective advantages are the major factors propelling the market.

#Autonomous Commercial Vehicles#Self-Driving Trucks#Logistics Automation#Transportation Industry#Freight Efficiency#Connectivity Solutions#Driverless Technology#Market Trends#Fleet Management#Autonomous Delivery#Truck Platooning#Market Players#Freight Transportation#Urban Mobility#Automation Innovation#Autonomous Trucking#Safety Systems#AI-driven Logistics#Long-Haul Trucking#Commercial Vehicle Automation

0 notes

Note

May I ask, did you get around to writing that essay about ga-matoran in Metru Nui and their connection to the Great Temple? Not expecting anything! Just curious!

Oh, I think I wrote a bullet-pointed list on ga-matoran and their connection to the Great Temple, specifically looking at how it affects their concept of gender here, but I never wrote anything long-hand.

If a quick rundown is what you're looking for, follow that link. If you do enjoy long(ish), rambling essays from someone making far too extensive headcanons for fictional worlds, read on.

So. Ga-Metru. The metru of the ga, the metru specifically for the ga, that metru. Now, I could launch straight into the impact of Ga-Metru being Mata Nui-favoured... but this is my essay, so I'm gonna roll this a bit further back and delve into a possible reason of why Ga-Metru is favoured.

Because I have a personal headcanon that Ga-Metru's favoured status was very much a byproduct of the natural resources.

Look at it this way: You need to build a protodermis purification facility on Metru Nui. You've already built the forges and furnaces; now you need to be able to source the building material for these smithies. So you need somewhere with a lot of liquid protodermis readily at hand - somewhere, for example, like Ga-Metru.

And then, because you probably shouldn't put all your important masks in a place full of burny, melty fire, you store your kanohi mask here (instead of Ta-Metru) as the other major building in this budding metru.

So, ta-da, you now have your second major site in Metru Nui, and over time that becomes Ga-Metru, home to the Ga-Matoran. Second-eldest metru, not out of any holy significance, but because it provided an important resource.

Time passes, and your purification/storage facility becomes a place of spiritual importance. I mean, it makes sense. It's an old, vital building, storing items of power, and isn't the hot, noisy space of Ta-Metru, plus the act of purifying carries a kind of holiness to it.

So, the next logical train of thought: if Ga-Metru is home to the temple of your god, then - obviously - god must like this metru best.

Next, next logical train of thought: if Ga-Metru is the favoured metru, then those who live there must be Mata Nui's favoured matorans. Or, at least, they are spiritually closer to Mata Nui, living basically on the doorstep of your connection to him.

By this point, matoran have certainly been granted sentience, and with that comes all the messy irrationality of thinking for yourself. What a lot of religions like to do is recognise those singled out, spiritually, with a title. Father. Reverend. Back in the medieval era, catholic priests were called "Sir" the same way a knight was.

Regardless, the point is: you need a name or a title to recognise that Ga-Matoran are different. And (headcanon going strong here) because Matoran weren't programmed with a sense of gender, they only really have "he/him" for daily use, with "brother" as a title of respect.

So language does what it always does in these circumstances - it adapts. Except, well, the Matoran may not have a concept of gender, but the Great Beings who created them did. So, somewhere in that pesky programming and superfluous data, there's a not-memory of "sister" being an equivalent title to "brother" - they don't understand how it relates to gender, they just know it feels right. And with "sister" comes the pronouns "she/her" so suddenly you have a whole metru with their own special pronouns and titles.

And, ta-da! Matorans have now accidentally ungendered gendered pronouns.

I also think it adds an interesting sense of irony for any (head)canons that Ga-Matorans consider themselves above or better than other Matorans (because then their importance is built on a coincidence, rather than actual Mata Nui favour) but that's for another day - or for other people to take a crack at, if they'd like. (I know I've certainly seen some interesting posts about Ga-Matoran self-importance!)

I personally was just fascinated by the fact that the "female" Matoran are the "holy" Matoran, despite gender being nonexistant, and examining one possible reason for Ga-Metru gaining its favoured reputation. (What can I say? I love clawing my way into the cracks of existing world-building.) Feel free to agree, disagree, whatever, but these are my personal headcanons and I hope people enjoyed reading about them!

#bionicle#ga metru#that cat spoke#can you tell i'm a little bit in love with this concept?#honestly the fact that ga metru is the second eldest metru is. telling#esp because the matoran were not granted sentience at first#which implies ga metru was built for logistical reasons#rather than religious ones#why build a place of peace and learning and spiritual importance for your automated robots?#UNLESS it only became that later#in which case did it become holy because ga metru was considered favoured?#or did ga metru become considered favoured because it had a holy building?#i personally skew towards the latter#as is obvious from the text above#but it's an interesting question

36 notes

·

View notes