#Textile Machine Spare Parts

Explore tagged Tumblr posts

Text

Digital Printing Machine Spare parts:- At Fortune7, we offer a wide range of Digital Printer Machine Spare Parts that is manufactured using high-grade materials. Apart from that, we have a wide range of HP, Epson best Large Format Printers Plotters in Dubai, UAE. Book one today from www.fortune7.ae for authorized products on decent and affordable rates in UAE. https://fortune7.ae

0 notes

Link

#bill of lading data of supreme apperals pvt ltd#textile machinery spare parts importers in Sri Lanka#textile machine spare parts importers#textile machinery spare parts buyers#textile machinery spare parts buyers in Sri Lanka

0 notes

Note

❛ nobody really knows the nuances of what you get up to in your spare time, and honestly they’re probably better off that way. ❜ (Zach)

( x )

Klarion held his cup of tea, watching with a calm smile as the other talked, sipping quietly.

Most people saw him as a magicians assisstant with a possible future on the stage, others as just an errand boy and lapdog to the crooked and lesser evils of Gotham. Few knew him as he truly was when he was alone, save for perhaps a strange orange cat that still did not cease to follow him around.

He wondered what his current company, invited for tea, would think if he knew of his trip to the nearest graveyard last week. Digging for bones, peeling the rotten eyes out of the poor unfortunate soul who was buried there, looking for a possible candidate for a trial run of resurrection.

What he'd think if he knew of his late night trip to the morgue the other day. He had of course been gentle with the body, cutting only the sutures and whatever gore that kept the parts of the body in place, sewing him back together after his harvest, cleaning the body for any grime and muck he'd gotten on it. It was the least he could do. The intestines he'd coiled neatly, like freshly spun yarn. The heart and rather plump liver - about as fresh as one can get them from a newly deceased motorist - both packed in newspaper from that same day, as if he was packing a bouquet of blood red roses meant for someones lover.

The bones he'd taken for himself, meant to be cut and polished into dice. A project for some other day, as he was too consumed in a couple books he'd borrowed from the library with no intention to return them. Though he did enjoy the darker side of the mystic arts, he had a few more normal interests he could easily take to when he mood struck him as well. Though not particularly interested in textile arts, sewing was something he was practicing at the moment. It was comforting, healing, to care for his clothing. And by proxy, himself. A skill he'd initially only needed to take care of the deceased, later discovered would help him feel grounded. Less lost, less of the running away feeling he'd had for the past few years he'd spent with no home. He'd also taken up a collection of vinyls he'd liked, some of them he hadn't listened to yet. It reminded him of his quieter times at home, when the gardener had sat down with him for tea, telling him stories from when he was a child himself. And of course, he'd arranged bi-weekly to meet a few others for a trip to an abandoned asylum to look for ghosts. It was always fun to watch others freak out, not knowing he was the one causing the ghostly activity. He supposed those latter interests were more normal though, compared to playing with the dead.

" Indeed. My inner machinations are mystery and a marvel to others. I am quite possibly the worlds most special creature. " He joked. He was grateful the other was not the snooping type, as the delicacies he'd hidden away in the fridge would likely alarm him.

" Speaking of spare time, did I tell you about the new vinyls I bought the other day? "

#ic ☆#playedbetter#playedbetter; zach#// lowkey taking this ask as an opportunity for a minor character study lol#// not that it cant be a starter or anything else as well ofc.#cw gore#cw ask to tag

3 notes

·

View notes

Text

Unsold clothing may no longer be destroyed in Europe

More than 100,000 tons of discarded clothing ends up in a desert in Chile

Europe is putting a stop to the throw-away culture through a ban on destruction[1] and a digital product passport with information about shelf life and repairability. No more mass destruction of clothing and other unsold merchandise.[2]

Every second in Europe, a full garbage truck of clothing is burned or dumped[3]. And every year, an estimated 11 to 32 million unsold and returned garments are destroyed. Europe has been wanting to reduce this gigantic waste for some time. The European Member States and the European Parliament reached an agreement to this end on Monday evening 4-12: Ecodesign for Sustainable Products Regulation[4]. The aim of the 'eco design law' is to make many products more repairable, reusable and recyclable. A product passport and a ban on destruction of unused goods are the key measures.

1. What is a digital product passport?

Consumers are already somewhat familiar with this: the energy label on refrigerators and washing machines gives an indication of their sustainability. That label (or product passport) has had an enormous impact on making those appliances more energy efficient.

The European Parliament and the EU member states now have an agreement to roll out the digital passport more widely and to deepen its content. First of all, almost all products on the European market will have to have such a passport: from car tires and steel to washing tablets and cosmetics to clothing or smartphones. The only exceptions are food, medicine, cars and weapon systems, for which there are separate regulations.

In addition to any energy consumption, the passport also contains information about the origin, composition, repair and disassembly options of the product. This should also make it easier to repair and recycle them. “People can know at a glance which product is the most durable or easiest to repair,” said MEP Sara Matthieu (Green), who was rapporteur in the negotiations.

2. What does the ban on destruction mean?

Initially, the ban applies to textiles. Globally, 92 million tons of textile waste are produced annually. A large portion of these are returned or unsold goods. In two years' time, they may no longer be destroyed, but must be reused or recycled. This ban will eventually be extended to electronics and electrical appliances. Massive quantities of these are also destroyed every year, especially cheaper items that are not sold or have been returned to the manufacturer.

The new rule goes hand in hand with stricter requirements for composition, repairability and disassembly of goods. The details will be worked out product by product by the European administration, but some guiding principles are a ban on adhesives, the absence of toxic substances, the obligation to have spare parts available and, above all, to offer them at an affordable price. The passport should eventually lead to a 'repair score', comparable to the energy label.

Matthieu (Green) expects a huge impact on the consumer market. 'Instead of offering disposable products for mass consumption, companies will offer many more services through robust devices. So to speak, you will no longer buy a washing machine, but an number of wash cycles.'

3. How comprehensive are the measures?

That depends on the control. The product passport is also an important instrument for this. Europe is counting on the famous 'Brussels effect': foreign producers will have to adapt their products if they want to maintain access to the gigantic European consumer market. Although the European consumer organisation BEUC[5] warns against loopholes. The organisation mainly sees a risk that international online platforms such as Amazon or Alibaba will circumvent the new law.

4. Is this agreement now final?

It has already rounded the most important cape. The agreement was finalised in the so-called trialogue negotiations between the European Parliament, the European Council and the Commission. Now it must be approved by Parliament and the Member States, but that counts as a formality.

Source

Lieven Sioen, Onverkochte kledij mag niet meer vernietigd worden in Europa, in: De Standaard, 6-12-2023, https://www.standaard.be/cnt/dmf20231205_96579697#:~:text=In%20eerste%20instantie%20is%20het,ze%20hergebruikt%20of%20gerecycleerd%20worden.

[1] Deal on new EU rules to make sustainable products the norm; https://www.europarl.europa.eu/news/en/press-room/20231204IPR15634/deal-on-new-eu-rules-to-make-sustainable-products-the-norm

[2] Read also: https://www.tumblr.com/earaercircular/722179599996534784/towards-a-circular-and-more-sustainable-fashion?source=share

[3] Read also: https://www.tumblr.com/earaercircular/723895455727157248/new-report-clothes-are-mercilessly-downcycled-or?source=share & https://www.tumblr.com/earaercircular/720260226679488512/hms-answer-about-the-dumped-clothes-article?source=share

[4] The proposal for a new Ecodesign for Sustainable Products Regulation (ESPR), published on 30 March 2022, is the cornerstone of the Commission’s approach to more environmentally sustainable and circular products. The proposal builds on the existing Ecodesign Directive, which currently only covers energy-related products. https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en

[5] The European Consumer Organisation (BEUC, from the French name Bureau Européen des Unions de Consommateurs, "European Bureau of Consumers' Unions") is an umbrella consumers' group, founded in 1962. Based in Brussels, Belgium, it brings together 45 European consumer organisations from 32 countries (EU, EEA and applicant countries). BEUC represents its members and defends the interests of consumers in the decision process of the Institutions of the European Union, acting as the "consumer voice in Europe". BEUC does not deal with consumers’ complaints as it is the role of its national member organisations.

3 notes

·

View notes

Text

Get the Best Gear Hobbing Machine in Coimbatore – Trusted Quality, Precision Engineering

The manufacturing industry is the backbone of Coimbatore, a city proudly known as the “Manchester of South India.” As industrial growth continues to rise, the demand for gear hobbing machines in Coimbatore is increasing rapidly. If you are looking for high-performance gear-cutting solutions for your factory, then investing in a quality gear hobbing machine in Coimbatore is the best decision you can make.

At Gear Hobbing Solutions, we specialize in offering top-quality, affordable, and precision-engineered machines that meet global standards. Whether you are a small business or a large enterprise, we deliver machines that suit your exact production needs with excellent support.

✅ What Is a Gear Hobbing Machine?

A gear hobbing machine is a specialized machine tool used to cut gears. It uses a rotating tool called a hob to slice teeth into a gear blank. Gear hobbing is a highly efficient process used to produce spur gears, helical gears, and worm gears.

Using a gear hobbing machine in Coimbatore gives local manufacturers the ability to:

Produce gears with excellent accuracy

Increase manufacturing speed

Reduce manual effort

Improve gear life and performance

Modern gear hobbing machines also support automation, allowing consistent production with minimal human error.

🔧 Why Choose Gear Hobbing Solutions?

When searching for a gear hobbing machine in Coimbatore, you want a supplier that understands your business and provides quality machines with reliable support. Here’s why Gear Hobbing Solutions is the right partner for your gear manufacturing needs:

1. Local Expertise

We have in-depth knowledge of the local industrial ecosystem in Coimbatore. Our machines are built to serve industries like automotive, agriculture, textile, and engineering, which are the backbone of this region.

2. Precision Machines

We offer high-accuracy gear hobbing machines that deliver fine finishes and consistent gear tooth cutting. Precision matters when it comes to gears—and we deliver it every time.

3. Affordable Prices

While we offer international-grade machinery, we keep our pricing competitive. Our goal is to make world-class machines accessible to every factory in Coimbatore.

4. After-Sales Support

From installation and training to maintenance and spare parts, we are with you every step of the way. Our local support ensures minimal downtime.

5. Wide Range of Machines

We supply vertical gear hobbing machines, horizontal hobbing machines, CNC hobbing machines, and semi-automatic models, depending on your specific requirement.

🏭 Why Coimbatore Is a Growing Hub for Gear Manufacturing

Coimbatore is a well-known industrial city with thousands of small and large-scale factories involved in precision engineering. Industries in and around Coimbatore increasingly need reliable gear hobbing machines to meet the growing demand for gear-driven equipment.

From textile machinery and pump sets to electric motors and auto parts, gears are everywhere in Coimbatore’s industrial space. That’s why investing in a durable gear hobbing machine in Coimbatore helps local manufacturers meet rising demand without compromising on quality.

🛠️ Types of Gear Hobbing Machines We Offer

We provide a wide range of gear hobbing machines in Coimbatore to suit various industries:

➤ CNC Gear Hobbing Machines

Ideal for high-volume production with extreme precision. Fully programmable and highly efficient.

➤ Vertical Gear Hobbing Machines

Best suited for smaller components and offers excellent visibility and operator access.

➤ Horizontal Gear Hobbing Machines

Perfect for large and heavy gear blanks. Provides stable cutting and support.

➤ Semi-Automatic Gear Hobbing Machines

Combines manual setup with automatic hobbing—ideal for small batch production.

Each machine is carefully built with top-quality materials and advanced technology to ensure durability, accuracy, and efficiency.

📈 Applications of Gear Hobbing Machines in Coimbatore

The demand for a quality gear hobbing machine in Coimbatore is strong across industries:

Automobile Industry – For cutting transmission, steering, and gear shaft components.

Agriculture Equipment – Used in tractors and farming tools.

Electric Motor Manufacturing – Gears are critical for smooth functioning.

Textile Industry – Gear-driven machines are used in looms and spinning machines.

General Engineering – Used for various machine components and automation systems.

No matter your industry, a robust gear hobbing machine is essential to maintain quality and productivity.

🔍 How to Choose the Right Gear Hobbing Machine in Coimbatore

Here are a few tips to help you choose the right machine:

Check Capacity: Match the machine’s gear size and material capabilities with your production needs.

Automation Level: Choose CNC or semi-automatic depending on your production scale.

Build Quality: Ensure the machine is made with durable materials for long-term use.

Support: Choose a company like Gear Hobbing Solutions that offers strong after-sales support.

Customization: Ask if the machine can be tailored to your specific application.

With our expert guidance, you can select the perfect gear hobbing machine in Coimbatore without hassle.

⚙️ Maintenance Tips for Gear Hobbing Machines

To get the most out of your investment, regular maintenance is important. Follow these tips:

Keep the machine clean to avoid dust build-up.

Lubricate moving parts regularly to reduce wear.

Use quality hobs to maintain gear finish.

Inspect electronics and wiring periodically.

Keep the CNC software updated if applicable.

We also offer annual maintenance contracts and technical training for your staff.

📢 What Our Clients Say

"We were looking for a reliable gear hobbing machine in Coimbatore and found Gear Hobbing Solutions. The team provided excellent guidance, and the machine is performing beyond expectations." — Precision Auto Components, Coimbatore

"Thanks to Gear Hobbing Solutions, our production capacity has doubled in just six months. Their support team is always ready to help. Highly recommended!" — Engineering Firm, Tamil Nadu

Our clients are our biggest advocates, and their success stories are proof of our commitment to quality and customer satisfaction.

🌟 Why Now Is the Best Time to Invest

The industrial landscape in Coimbatore is growing rapidly. The demand for locally manufactured gears is on the rise. By investing in a high-performance gear hobbing machine in Coimbatore, you can:

Boost productivity

Improve gear quality

Reduce production costs

Meet customer deadlines faster

Stay ahead of competitors

Let Gear Hobbing Solutions help you take your manufacturing business to the next level.

📞 Contact Us Today

If you are ready to invest in a quality gear hobbing machine in Coimbatore, look no further than Gear Hobbing Solutions. We’re here to understand your business, guide your decisions, and deliver the right machine at the right price.

Our team is always available for site visits, demonstrations, and consultations. Let’s power your business with precision!

0 notes

Text

Leading Gear Oil Pump Manufacturer in Ahmedabad, India

India has become a global name for quality engineering and industrial component manufacturing. The leading Gear Oil Pump manufacturers in India combine precision engineering with innovative design to offer products that meet both national and international standards.

These manufacturers are known for:

Robust product design

Long service life

Custom-built pump models

Compatibility with various gearboxes and pulley systems

Timely delivery and after-sales support

Their products are trusted across sectors including mining, steel, textile, agriculture, and food processing.

Key Factor in Choosing Right Conveyor Gearbox

A key factor in choosing the right conveyor gearbox is ensuring it works efficiently with compatible components—including a proper gear oil pump. Conveyor systems operate continuously and handle large loads. To perform at their best, these systems need gearboxes that are consistently lubricated to prevent overheating and mechanical damage.

Trusted Conveyor Gearbox Manufacturers in India often advise customers to use high-quality gear oil pumps to enhance gearbox performance and longevity.

Integration with SMSR Gearboxes and Pulley Systems

SMSR Gearboxes

The SMSR (Shaft Mounted Speed Reducer) gearbox is widely used in bulk material handling systems. It’s compact, easy to install, and reliable. However, it requires continuous lubrication to maintain its efficiency.

Whether you're sourcing from a SMSR Gearbox Manufacturer in Ahmedabad or elsewhere in India, lubrication is always a priority. A gear oil pump ensures the SMSR gearbox runs smoothly under heavy load, minimizing the chance of overheating or premature wear. This is why every reliable SMSR Gearbox Manufacturer in India emphasizes the importance of pairing gearboxes with the right oil pumps.

V-Belt Pulley Systems

V-belt pulley systems transfer power between shafts using belts. For smooth rotation and energy efficiency, the bearings in these systems must remain properly lubricated. A reliable V-Belt Pulley Manufacturer in Ahmedabad will often recommend using compatible gear oil pumps to ensure maintenance-free operation over long hours.

Plummer Blocks

Plummer blocks house bearings that support rotating shafts. These bearings require consistent lubrication to prevent breakdown. A good gear oil pump supplies clean oil to these blocks, keeping operations smooth. Leading Plummer Block Manufacturer in India often work closely with gear oil pump providers to offer a complete shaft-support solution.

Industries That Rely on Gear Oil Pumps

The applications of gear oil pumps are vast. They are widely used in:

Mining and construction – to lubricate heavy-duty gearboxes and crushers

Textile and paper industries – for high-speed rotating machines

Cement plants – to support conveyor systems and rotary kilns

Automotive manufacturing – for engines and gear-based machines

Food processing – for machinery that requires hygienic and sealed lubrication

These industries depend on gear oil pumps for uptime, efficiency, and safety.

What to Look for in a Gear Oil Pump Manufacturer

When selecting a gear oil pump manufacturer in India, keep the following factors in mind:

Product Quality – Pumps should be made from corrosion-resistant, high-strength materials.

Experience – A company with a solid history understands industry needs better.

Customization – The ability to modify or design pumps to fit your machinery.

Technical Support – Availability of expert help and spare parts.

Compatibility – Must work seamlessly with your gearbox, pulley, or plummer block.

A reliable manufacturer won’t just sell you a product—they’ll help improve your machine’s performance.

Conclusion

A gear oil pump might seem like a small component, but it plays a big role in keeping industrial operations running smoothly. It ensures that machines like SMSR gearbox, conveyor gearboxes, V-belt pulleys, and plummer blocks receive the lubrication they need for continuous, trouble-free performance.

Choosing the leading Gear 0il Pump manufacturer in Ahmedabad ensures you’re investing in quality, reliability, and efficiency. With a strong ecosystem of industrial partners—including Conveyor Gearbox Manufacturers in India, SMSR Gearbox Manufacturers in Ahmedabad, V-Belt Pulley Manufacturers in Ahmedabad, and Plummer Block Manufacturers in India—you’re assured of top-tier engineering solutions tailored for every sector.

#Gear Oil Pump Manufacturer in Ahmedabad#Gear Oil Pump supplier in Ahmedabad#Gear Oil Pump exporter in Ahmedabad

0 notes

Text

Best Industrial Generator in Delhi | Buy Reliable Power Backup Today

Looking for reliable industrial generators in Delhi? Get high-capacity gensets from United Power Solution with fast delivery and installation.

Power Your Business Right: Best Industrial Generator in Delhi for Indian Businesses

Running a business without a backup power supply is like jumping out of a plane without a parachute. Power outages and voltage variations are common issues in industrial regions, and unplanned outages can halt production lines, impede customer service, and result in severe losses. Whether you own a factory or a large retail location, investing in a dependable industrial generator is no longer optional; it is required.

If you live in Delhi or the NCR region, where there is a high demand for uninterrupted power, selecting the best industrial generator in Delhi could provide your firm the competitive advantage it needs to run smoothly.

In this blog, you will understand why industrial generators are necessary, how to select the best one, and what to look for when purchasing one in Delhi.

Why do Indian Businesses Need Industrial Generators?

Let us be honest: power supply in India is unreliable, particularly in commercial zones and industrial belts. Even a few minutes of outage can disrupt your entire workflow. Here's why any significant company in Delhi requires an industrial generator:

• Power outages are still common. Despite infrastructure improvements, Delhi and surrounding industrial districts continue to face power outages, particularly during the summer. During peak hours, factories and small-scale producers are especially hard hit.

• Machines cannot stop. If your company operates machinery, servers, or refrigeration units, you know they cannot afford even a second without power. An industrial generator ensures continuous functioning.

• Customer Experience Counts Power outages result in poor customer service in retail showrooms, motels, and service enterprises. A generator keeps your clients satisfied and your lights on.

• Data Loss can be costly. Offices that rely on computers and servers may experience data corruption or loss during power outages. An autonomous generator with a quick response time is critical for IT and technology-based enterprises.

Read More On Medium.com

How To Choose The Best Industrial Generator In Delhi?

Before investing in an industrial generator in Delhi, be sure you're receiving the best value for your money.

• Power Capacity (KVA) - Choose a generator based on your business needs. Small stores may need 10-15 kVA, whilst major industries may require 100 kVA or more. Always determine your overall power load before purchasing.

• Brand Reliability - Choose a generator from a trusted brand such as Cummins, Kirloskar, Mahindra Powerol, Ashok Leyland, or Honda, all of which have service centres and spares available in Delhi.

• Automatic Transfer Switch (ATS) - An ATS automatically starts the generator during a power outage and turns it off when power is restored, saving you the trouble.

• Noise Level: Ensure the generator meets CPCB noise regulations in industrial zones.

• Warranty and Service Support -In Delhi/NCR, look for a 2- to 5-year guarantee and after-sales service. Check for service contracts, replacement parts, and technician availability.

• Diesel generators are the most popular for industrial use due to their low fuel cost and long lifespan.

• Gas generators are more environmentally friendly and quieter, although they cost significantly more.

• Hybrid Generators (Solar + Diesel) are becoming increasingly popular in Delhi as environmental consciousness grows.

Read More On Locanto.me

How Industrial Generators Help Businesses in Delhi?

Industrial generators help a variety of Delhi enterprises, including.

• Manufacturing units Textile, plastic moulding, food processing, and printing industries all rely largely on continuous electricity for their operations and output.

• Corporate offices Generators keep servers, networks, and air-conditioning systems working smoothly at IT centres in Noida and startups in Gurgaon alike.

• Retail and Mall A sudden power loss at a mall or showroom can create havoc. Generators keep all lighting, billing systems, and air conditioning units operating.

• Hotels & Restaurants Guest satisfaction is dependent on comfort. A generator is useful for maintaining lights, refrigeration, and climate control during peak summer months.

• Clinics and Hospitals In a place where lives depend on machines, a power outage is just not an option. Medical facilities must have industrial-grade generators with automatic start systems.

Best Generator Brands Available in Delhi.

Let's take a look at some of the highest-rated industrial generators available in Delhi that business owners trust:

• Kirloskar Green Generators. Known for its dependability, fuel efficiency, and customer service. Ideal for manufacturers and medium-sized businesses.

• Cummins India One of the most dependable brands worldwide. Available in 10 to 500 kVA power levels. Perfect for IT parks, malls, and large industries.

Cost of industrial generators in Delhi

Prices vary according to size and brand, but here's a fair estimate of industrial generator pricing in Delhi:

• 10-15 kVA Diesel Generator - ₹2.5–₹3.5 lakhs • 20-40 kVA: ₹4-6 lakhs • 50-100 kVA costs ₹7-12 lakhs. • Above 100 kVA: ₹15 lakhs

Prices are estimates and may vary depending on features, installation fees, GST, and shipping expenses.

Read More On Tumblr.com

Why Should You Choose United Power Solution For Industrial Generators in Delhi?

United Power Solution is a major supplier of industrial and residential generators, offering skilled installation, after-sales support, maintenance, repairs, spare parts, and courteous genset selection guidance to ensure optimal performance and long-term client support.

• United Power Solution also provides wholesale gensets at a competitive price.

• Our service region covers Delhi NCR, Noida, and Gurgaon, and we are available throughout the country to suit the needs of our consumers in Delhi.

• Our company, United Power Solution, stands out for its efficient workforce, genuine Kirloskar and Sudir goods, customer-centric approach, customizable solutions, flexible payment choices, and 24/7 emergency service.

0 notes

Text

Industrial Washing Machine Manufacturers - Lucky Engineering Works

Are you searching for reliable Industrial Washing Machine Manufacturers in India? Lucky Engineering Works is one of the most trusted names in the industry. We design and manufacture strong, high-capacity machines made for tough jobs. Our industrial machines are perfect for hospitals, hotels, laundries, and large-scale factories that need to clean a lot of clothes or fabrics every day. As experienced industrial washing machine suppliers, we focus on quality, durability, and performance. From simple models to automatic industrial washing machines, we offer complete solutions. We also provide full support after installation to ensure smooth operation for years.

What is an Industrial Washing Machine?

An industrial washing machine is a powerful machine used for cleaning large loads of fabrics. It’s much bigger and stronger than home washing machines. These are built to work for long hours and clean many clothes at once. Industrial machines are used in places like hospitals, hotels, and factories where cleanliness is important and regular washing is needed.

Types of Industrial Washing Machines We Manufacture

At Lucky Engineering Works , we manufacture a wide range of machines to suit different industry needs:

Front Loading Machines

Top Loading Models

Automatic Industrial Washing Machines

High Capacity Industrial Washing Machines

Heavy Duty Washing Machines for Industries

All our machines are strong, energy-efficient, and easy to use.

Applications of Our Industrial Washing Machines

Our machines are used in many industries, including:

Hospitals and Hotels

Textile and Garment Units

Laundry Businesses

Railway and Defence Services

Food and Chemical Industries

We supply the best industrial washing machine for hospitals and hotels where hygiene is most important.

Key Features and Technical Specifications

Rust-proof stainless steel body

Large drum capacity

Fast washing and spinning

Saves water and power

Digital control panel

Safety lock features

These features make our machines perfect for long-term use in tough industrial settings.

Customization Options for Specific Industry Needs

As a flexible industrial laundry machine manufacturer, Lucky Engineering Works builds machines to match your exact needs. Whether you need fast washing cycles, energy-saving modes, or space-saving sizes—we create machines that fit your business perfectly.

Industries We Serve

We proudly serve many sectors with our high-quality machines:

Healthcare

Hospitality

Pharmaceuticals

Manufacturing

Laundry Services

We also provide industrial laundry system installation to help you start easily and operate smoothly.

After-Sales Service and Support

As an industrial washing machine manufacturer with after-sales service, We make sure your machine runs well for years. Lucky Engineering Works provides:

Installation & training

Regular maintenance

Quick repairs

Spare parts support

Why Choose Lucky Engineering Works as Your Industrial Washing Machine Manufacturer?

Lucky Engineering Works stands out among Industrial Washing Machine Manufacturers for quality, reliability, and service. With over 20 years of experience, we understand what industries need. Our machines are durable, efficient, and built to handle heavy loads daily. As trusted industrial washing machine suppliers, we offer complete solutions—from machine design to industrial laundry system installation. We also provide strong after-sales support, making us a reliable industrial washing machine manufacturer with after-sales service. Whether you need automatic industrial washing machines or high-capacity models, Lucky Engineering Works ensures excellent performance, competitive pricing, and unmatched customer satisfaction across hospitals, hotels, and other industries.

#Industrial Washing Machine Suppliers in India#Industrial Laundry Machine Manufacturer#Automatic Industrial Washing Machines#Industrial laundry system installation India#Industrial Washing Machine Manufacturer in India

0 notes

Text

A Step-by-Step Guide to Budgeting for a Rapier Jacquard Machine

In the textile manufacturing industry, very often a competitive environment bears upon the decision of which weaving technology to invest in. Rapier Jacquard machines have been characterised as the fastest and most versatile of all weaving solutions and are considered the most advanced. Speed, precision, and the ability to create highly complex designs make it a winning machine among a new set of textile entrepreneurs, taking their designs one step further beyond its efficiency.

One needs a heavy investment to purchase a Rapier Jacquard machine; hence, careful budgeting is a must. This blog describes step-by-step how budgeting for a Rapier Jacquard Machine should take place, touching upon why working with a reliable Rapier Loom Machine Manufacturer in Surat, like Weavetech, makes a world of difference.

Step 1: Understand Your Production Requirements

Before setting a budget, analyze your business needs. Ask yourself:

What type of fabrics will I produce?

How many meters of fabric do I need per day?

Do I require basic patterns or complex jacquard designs?

What width and GSM (grams per square meter) are ideal?

Understanding these requirements helps you choose a model that matches your capacity goals, reducing the risk of overspending or underutilizing the machine.

Step 2: Research the Cost Range

The cost of a Rapier Jacquard Machine can vary significantly based on factors such as:

Weaving width (e.g., 170 cm, 190 cm, 360 cm)

Number of jacquard hooks

Automation level (fully or semi-automatic)

Speed and control features

Brand and after-sales service

Estimated 2025 prices for custom Rapier Jacquard Machines may range from ₹10 lakh to ₹35 lakh, depending on configuration and features. Manufacturers of Rapier Loom Machines in Surat like Weavetech provide custom solutions with flexible pricing suited for every range of textile operations.

Step 3: Calculate Additional Costs

Your machine budget shouldn't just include the base price. Consider these extra expenses:

a. Installation and Commissioning

Most manufacturers offer professional installation and machine setup, which might incur additional charges.

b. Accessories and Spare Parts

Include costs for:

Jacquard cards

Heald frames and warp beams

Lubrication systems and belts

c. Operator Training

Training your machine operators ensures better productivity and fewer breakdowns. Weavetech offers complete training support as part of our value-added services.

d. Maintenance & Service

Plan for periodic maintenance, including spare parts and service visits.

Step 4: Explore Financing Options

Not every business can afford an upfront payment. That’s why many loom manufacturers offer:

EMI-based purchase plans

Leasing options

Tie-ups with finance companies

Government subsidies for textile units

Weavetech works with several financial partners to help you make cost-effective decisions while reducing the financial burden of your machinery upgrade.

Step 5: Compare Multiple Manufacturers

It’s essential to compare machine specifications, pricing, service support, and performance guarantees across different brands. Look for manufacturers with:

Proven experience in the weaving industry

Positive client testimonials

Robust R&D and innovation

Nationwide service network

Weavetech is one of the leading Rapier Loom Machine manufacturers in Surat, which has made a mark in supplying state-of-the-art weaving solutions that require little maintenance and conserve energy for the textile industries to be handled smoothly throughout India and outside.

Step 6: Evaluate Long-Term ROI

Instead of just thinking about the purchase price, consider:

How much fabric output will the machine deliver?

Will it reduce manual errors and rework?

How many years will the machine serve your production?

What are the energy savings compared to older models?

Investing in high-quality machines from reputed brands like Weavetech ensures you get superior durability and performance, resulting in a better return on investment.

Step 7: Plan for Space and Utilities

Don’t forget infrastructure costs when budgeting:

Factory floor space: Ensure your unit has enough room for installation and fabric movement.

Electricity: High-speed Rapier Jacquard Machines need stable 3-phase power.

Air compressors (if required) and proper lighting.

Your budgeting plan must include these essentials to avoid hidden expenses.

Why Choose Weavetech?

If you’re looking for a Rapier Loom Machine Manufacturer in Surat, Weavetech is the name you can trust. Here’s why:

Tailored Solutions – Machines built to match your production capacity

Robust Engineering – Low maintenance and long-life performance

End-to-End Support – From installation to operator training

Affordable Pricing – With flexible EMI and financing options

Customer-first Approach – On-time delivery and dependable service

With years of experience and concentrating on continuous innovations, Weavetech empowers textile manufacturers with weaving machinery that has been built for the future.

Budgeting for a Rapier Jacquard Machine is nothing but a quintessential strategy that could act as a turning point in the fate of a textile business. A well-planned budget, along with a proper manufacturing partner, would pave the way to the parallel run of high productivity and premium fabric quality, and of course, long-term profit.

Let Weavetech, probably the leading Rapier Loom Machine Manufacturer in Surat, help take that leap with you. Connect with us today to get a custom quote and step into the age of smart textile weaving.

Blog Source -- A Step-by-Step Guide to Budgeting for a Rapier Jacquard Machine

#manufacturing#textile machine#weaving machine#machine manufacturing#rapier looms#rapier loom machine#yarn weaving machine#business#yarn weaving loom machines#twisting machine

0 notes

Text

Trusted Industrial Shredder Machine Manufacturer in India

India’s industrial growth continues to rise, and with it comes a growing need for powerful machinery that supports efficient waste management and recycling. Among the essential machines used across various industries, shredder machines play a major part in processing bulk materials such as plastic, metal, rubber, and paper. A trusted name in this sector is Power Hydrotech Private Limited, serving industries with high-performance shredding machines built for demanding environments.

The Role of a Trusted Shredder Machine Manufacturer

In many industries, managing industrial waste is not just a responsibility—it’s a necessity for smooth operations. Whether it's reducing large materials for further processing or preparing waste for disposal, a well-designed shredder machine becomes essential. The quality of the shredder impacts overall productivity, safety, and long-term cost efficiency.

Working with a manufacturer that understands the needs of industrial businesses is important. Machines should be engineered for strength, consistency, and longevity. When these factors come together, businesses benefit from smoother processing and reduced maintenance concerns.

Industrial Shredder Machine Manufacturer in India: What Makes Power Hydrotech Private Limited a Trusted Name

Power Hydrotech Private Limited has built a reputation by focusing on durability, performance, and practical design. Their machines are used in industries such as plastic recycling, textile manufacturing, pharmaceutical processing, and metal industries.

The shredders produced by the company are engineered to process materials like:

Plastic bottles and containers

Industrial scrap

Rubber and tyres

Paper and cardboard

Metal parts and components

This wide usability makes their machines a valuable addition to a range of industrial sectors. The machines are designed with attention to operational efficiency and user safety.

What Customers Value Most

Clients who rely on Power Hydrotech Private Limited often highlight the consistency and long service life of the machines. The company emphasizes support, with a technical team that responds to customer needs during installation, training, and maintenance. This approach builds long-term partnerships with industries that depend on continuous production.

Another point that sets this manufacturer apart is the flexibility to customize machines. Different materials require different shredding capacities, and Power Hydrotech understands these variations. Their product range is suitable for small workshops as well as large-scale factories.

Factors to Consider When Choosing a Manufacturer

When selecting an Industrial Shredder Machine Manufacturer in India, it’s useful to evaluate the following points:

Build Quality: The machine should be made with strong materials suited for industrial use.

Capacity: Choose a model that matches your material type and volume.

Technical Support: Reliable after-sales service keeps your machine in good working condition.

Spare Parts Availability: Easy access to parts reduces downtime.

Experience: A manufacturer with hands-on experience in industrial environments better understands your needs.

Power Hydrotech Private Limited meets these expectations by manufacturing machines with industrial-grade components and maintaining customer-focused support throughout the process.

Industries Served by Power Hydrotech

With years of experience, the company has supplied shredding machines to clients in:

Plastic recycling units

Municipal waste processing plants

Rubber and tyre shredding companies

E-waste management firms

Pharmaceutical production facilities

The machines are built to run continuously in challenging conditions, making them a practical choice for these demanding sectors.

Conclusion

India’s industrial sector needs machines that are both powerful and dependable. Choosing a trusted Industrial Shredder Machine Manufacturer in India can make a noticeable difference in day-to-day operations. Power Hydrotech Private Limited has been serving this need with dedication, offering machines that are built to perform in real-world conditions. Their experience in manufacturing, combined with attention to customer requirements, has made them a preferred name in the shredding machine market. Whether your business involves recycling, production, or material processing, working with a manufacturer like Power Hydrotech helps keep your workflow efficient and consistent.

#Industrial Shredder Machine Manufacturer#Industrial Shredder Machine Manufacturer in Ahmedabad#Industrial Shredder Machine Manufacturer in Gujarat#Industrial Shredder Machine Manufacturer in India

0 notes

Text

How Automatic Shrink Wrapping Machine Manufacturers in India Are Revolutionizing Packaging

In today’s fast-paced industrial world, where efficiency is everything and product presentation matters more than ever, packaging has evolved from being a finishing step to a critical component of production strategy. At the heart of this evolution lies the automatic shrink wrapping machine — a game-changer in logistics, warehousing, retail, and manufacturing. And it’s not just any machines that are making headlines — it’s the automatic shrink wrapping machine manufacturers in India who are leading this revolution.

These manufacturers are offering cutting-edge automation that rivals global counterparts while maintaining cost-efficiency and adaptability. In this blog, we’ll take a deeper look into how these Indian manufacturers — especially industry leaders like Durapak — are reshaping the packaging landscape both at home and abroad.

📦 What Is an Automatic Shrink Wrapping Machine?

An automatic shrink wrapping machine is a packaging system that wraps products with shrink film and applies heat to shrink the film tightly around the items. It’s commonly used to bundle goods together, protect them from damage, and improve presentation.

These machines are widely used across industries such as:

Food and beverage

Pharmaceuticals

FMCG

Electronics

E-commerce

Automatic variants take this a step further by eliminating manual intervention, increasing packaging speed, and ensuring uniform wrapping across all product sizes.

🌍 Why India? A Rising Global Hub for Shrink Wrapping Technology

India is no longer just a hub for textiles or software; it’s rapidly becoming a global player in industrial automation. The rise of automatic shrink wrapping machine manufacturers in India is proof of this shift. What sets Indian manufacturers apart?

✅ Cost-Effective Innovation

India’s engineering talent pool, combined with its competitive manufacturing costs, allows companies to produce high-end machines at much lower prices than their Western counterparts.

✅ Customization

Indian manufacturers excel at creating machines tailored to specific needs — from single-product wrapping to bundling kits and irregularly shaped items.

✅ After-Sales Support

With growing emphasis on customer experience, manufacturers are offering robust after-sales service, remote diagnostics, and quick spare part availability.

🚀 Durapak: At the Forefront of the Packaging Automation Boom

When discussing Indian excellence in shrink wrapping automation, one name consistently rises to the top — Durapak.

Why Durapak?

Durapak is a leader in the design and manufacture of automatic shrink wrapping machines built for high performance and long-lasting reliability. Their systems are trusted by manufacturers, logistics companies, and large-scale retailers across India.

Key Features of Durapak’s Shrink Wrapping Machines:

Fully automatic operation with minimal human input

Smart sensors and PLC control for consistent wrapping

Energy-efficient shrink tunnels

Compatible with LDPE, PVC, and polyolefin films

Compact design for easy integration into production lines

Durapak’s machines are not only built to perform but also to adapt — whether you’re a small startup scaling operations or a multinational aiming for speed and precision.

🔄 Revolutionizing the Packaging Workflow

So how exactly are Indian automatic shrink wrapping machine manufacturers changing the game?

1. Increased Throughput

Automation enables hundreds or even thousands of units to be shrink-wrapped per hour, cutting down processing time drastically. Companies can scale up production without hiring more manpower.

2. Consistent Quality

Manual wrapping leads to inconsistencies and defects. Automatic machines ensure that every package is sealed perfectly — boosting product appeal and minimizing damage during transport.

3. Better Product Safety

Shrink wrap protects products from dust, moisture, and tampering. For pharmaceuticals and electronics, this is critical. Indian manufacturers now offer machines with built-in safety protocols and temperature regulation for extra care.

4. Energy Efficiency

Modern machines from companies like Durapak are designed with eco-conscious features, such as low-power shrink tunnels and film-saving mechanisms — helping reduce operational costs.

5. Space Optimization

Automatic shrink wrapping machines now come with compact, modular footprints that fit seamlessly into tight factory spaces without disrupting existing workflows.

🌐 Global Clients, Local Innovation

Indian manufacturers are now exporting to countries in the Middle East, Southeast Asia, and even Europe — markets that were once dominated by American and German brands. Here’s why:

Competitive pricing without quality compromise

ISO and CE-certified machines

Custom-built models tailored to specific packaging lines

Excellent ROI on automation investment

One of the strongest examples of this export-ready innovation is Durapak’s product lineup, which has been praised for delivering international-grade performance at local prices.

🔍 What to Look for in a Shrink Wrapping Machine Manufacturer

When choosing the right partner for your packaging automation, consider:

Machine speed and throughput

Type of shrink film supported

Ease of maintenance and availability of spares

After-sales service and technical support

Reputation and client testimonials

Indian manufacturers like Durapak check all these boxes and continue to evolve with the latest in AI, IoT, and predictive maintenance technologies.

🧩 The Future: Smart Packaging Starts Here

The packaging industry is on the brink of an intelligent transformation. Soon, machines will not only wrap products but also analyze data, predict malfunctions, and auto-adjust settings for different product sizes. Indian manufacturers are already gearing up for this shift.

Durapak is investing heavily in R&D to ensure their machines are ready for Industry 4.0. From touch-screen HMIs to cloud-based diagnostics, they are building the future — today.

If you're searching for automatic shrink wrapping machine manufacturers in India who combine innovation with real-world performance, Durapak should be your first call.

✅ Final Thoughts

As businesses strive for speed, safety, and scalability in their operations, packaging automation is no longer optional — it's essential. Thanks to the innovation and adaptability of Indian manufacturers, shrink wrapping technology is now more accessible, intelligent, and globally competitive than ever.

Among the trailblazers, Durapak stands out — not just as a manufacturer but as a partner in your growth journey.

Ready to upgrade your packaging line? Choose smart. Choose Durapak.

0 notes

Text

A variety of spare parts are available for industrial sewing machines, each designed to address specific maintenance and operational needs. Items like presser bar lifters, tension discs, feed mechanisms, and bobbin winders help ensure precise control during the sewing process. These parts are suitable for high-speed production environments where equipment reliability is essential. Regular inspection and replacement of worn components help maintain sewing accuracy and machine performance, supporting efficient workflow in clothing factories, shoe production lines, and home textile workshops.

0 notes

Text

Cardan Shafts Applications in UAE Industries

In the heart of the Middle East, the United Arab Emirates (UAE) is recognized for its booming industrial sectors, including oil & gas, construction, maritime, and manufacturing. A critical mechanical component supporting the smooth operation of these industries is the Cardan shaft—also known as a universal joint shaft. This blog dives into the various applications and significance of Cardan Shafts in UAE, highlighting their role in ensuring efficiency, flexibility, and durability in industrial machinery.

What is a Cardan Shaft?

A Cardan shaft is a mechanical drive shaft used to transmit torque and rotation, even when the shafts are not in a straight line. It enables power transfer between components located at varying angles and distances, making it ideal for heavy-duty applications.

Key Industries Using Cardan Shafts in UAE

1. Oil and Gas Sector

The oil & gas industry is the backbone of the UAE economy. Cardan shafts are widely used in drilling rigs, pumping systems, and pipeline operations. Their ability to handle high torque and misalignments makes them indispensable in harsh desert and offshore environments.

Application Highlights:

Drill string drives

Rotary tables

Mud pumps

Offshore platform equipment

2. Construction and Heavy Equipment

UAE's massive infrastructure growth relies heavily on construction machinery such as excavators, cranes, and concrete mixers. Cardan shafts provide reliable torque transmission between engine and axles or other rotating equipment.

Application Highlights:

Concrete batching plants

Tunnel boring machines

Mobile cranes and loaders

3. Manufacturing and Production Plants

Cardan shafts in UAE are critical in various manufacturing processes, including steel, paper, and textiles. They are used in rolling mills, conveyors, and heavy processing equipment where uninterrupted power transfer is essential.

Application Highlights:

Conveyor systems

Rolling and forging mills

Textile spinning machines

4. Marine and Shipping Industry

Given UAE's strategic coastal position, the marine sector thrives. Cardan shafts are vital in ship propulsion systems and marine engines, where vibration resistance and durability are critical.

Application Highlights:

Marine propulsion

Deck machinery

Power take-off (PTO) systems

5. Power Generation

Power plants in the UAE, including renewable and gas-fired plants, use Cardan shafts in turbines, generators, and auxiliary equipment, where they accommodate angular misalignments and thermal expansion.

Why Cardan Shafts are Ideal for UAE Conditions

High Load Capacity: Perfect for heavy industrial applications.

Resistance to Harsh Environments: Operates well in high temperatures, dust, and saline conditions.

Maintenance Friendly: Designed for durability and easy servicing, reducing downtime.

Customizable Designs: Adapted for various sizes, torque levels, and operational angles.

Local Availability and Services

With the rising demand for Cardan Shafts in UAE, many local and international suppliers offer custom solutions, on-site servicing, and spare parts. Companies based in Dubai, Abu Dhabi, and Sharjah provide industry-grade shafts for both OEMs and end-users.

0 notes

Text

Top Industrial Vacuum Cleaner Solutions in Thane | Scellp

Powerful & Reliable Industrial Vacuum Cleaner in Thane – Only at Scellp

When it comes to maintaining cleanliness in large-scale facilities, industrial environments, or warehouses, traditional cleaning methods simply don’t cut it. That’s where Scellp comes in—your trusted partner for Industrial Vacuum Cleaner solutions in Thane. Whether you operate a manufacturing plant, pharmaceutical unit, food processing facility, or any other industrial setup, we provide efficient and durable cleaning machines designed to handle the toughest cleaning challenges.

Why Choose an Industrial Vacuum Cleaner?

Industrial vacuum cleaners are not your average household cleaning devices. They are engineered for high performance, capable of dealing with heavy dust, metal shavings, oil spills, and hazardous particles. Their power and efficiency not only keep your space clean but also ensure compliance with safety and hygiene standards—critical in sectors like pharmaceuticals and food production.

At Scellp, we understand the unique cleaning needs of different industries in Thane and offer tailored solutions that deliver long-lasting performance.

What Sets Scellp Apart?

1. Locally Available, Rapid Service Being based in Thane, Scellp offers fast delivery, local customer support, and on-site servicing. No more waiting endlessly for assistance or spare parts.

2. Rugged, Industry-Grade Designs Our industrial vacuum cleaners are built with high-grade materials to endure the harshest environments. From wet and dry vacuuming to continuous 24/7 operations, our machines are up for the job.

3. Custom Solutions for Every Industry We don’t believe in one-size-fits-all. Scellp offers a range of models suited for small workshops to large production facilities. Have a unique requirement? We’ll customize the solution for you.

4. Energy Efficient & Eco-Friendly Our latest models are designed to be energy-efficient, reducing power consumption while maintaining high suction capacity. We also offer HEPA filter options to ensure cleaner air in your workspace.

Applications Across Industries

Scellp's Industrial Vacuum Cleaners in Thane are already trusted by top businesses in:

Automotive Manufacturing

Pharmaceuticals & Chemical Plants

Textile & Paper Industries

Metal Fabrication Units

Warehouses & Logistics Hubs

Our solutions are versatile enough for both dry and wet cleaning needs, and safe for use in ATEX zones or environments requiring strict hygiene.

Invest in Quality – Partner with Scellp

In an industrial setting, downtime due to cleaning inefficiencies is costly. That’s why investing in a Scellp industrial vacuum cleaner is more than just a cleaning solution—it’s a step toward operational efficiency and workplace safety.

So, if you're searching for a top-rated industrial vacuum cleaner in Thane, look no further than Scellp. Contact us today for a free site inspection and consultation. Let us help you create a cleaner, safer, and more productive workspace.

0 notes

Text

Best Industrial Generator in Delhi | Buy Reliable Power Backup Today

Looking for reliable industrial generators in Delhi? Get high-capacity gensets from United Power Solution with fast delivery and installation.

Power Your Business Right: Best Industrial Generator in Delhi for Indian Businesses

Running a business without a backup power supply is like jumping out of a plane without a parachute. Power outages and voltage variations are common issues in industrial regions, and unplanned outages can halt production lines, impede customer service, and result in severe losses. Whether you own a factory or a large retail location, investing in a dependable industrial generator is no longer optional; it is required.

If you live in Delhi or the NCR region, where there is a high demand for uninterrupted power, selecting the best industrial generator in Delhi could provide your firm the competitive advantage it needs to run smoothly.

In this blog, you will understand why industrial generators are necessary, how to select the best one, and what to look for when purchasing one in Delhi.

Why do Indian Businesses Need Industrial Generators?

Let us be honest: power supply in India is unreliable, particularly in commercial zones and industrial belts. Even a few minutes of outage can disrupt your entire workflow. Here's why any significant company in Delhi requires an industrial generator:

• Power outages are still common. Despite infrastructure improvements, Delhi and surrounding industrial districts continue to face power outages, particularly during the summer. During peak hours, factories and small-scale producers are especially hard hit.

• Machines cannot stop. If your company operates machinery, servers, or refrigeration units, you know they cannot afford even a second without power. An industrial generator ensures continuous functioning.

• Customer Experience Counts Power outages result in poor customer service in retail showrooms, motels, and service enterprises. A generator keeps your clients satisfied and your lights on.

• Data Loss can be costly. Offices that rely on computers and servers may experience data corruption or loss during power outages. An autonomous generator with a quick response time is critical for IT and technology-based enterprises.

Read More On Medium.com

How To Choose The Best Industrial Generator In Delhi?

Before investing in an industrial generator in Delhi, be sure you're receiving the best value for your money.

• Power Capacity (KVA) - Choose a generator based on your business needs. Small stores may need 10-15 kVA, whilst major industries may require 100 kVA or more. Always determine your overall power load before purchasing.

• Brand Reliability - Choose a generator from a trusted brand such as Cummins, Kirloskar, Mahindra Powerol, Ashok Leyland, or Honda, all of which have service centres and spares available in Delhi.

• Automatic Transfer Switch (ATS) - An ATS automatically starts the generator during a power outage and turns it off when power is restored, saving you the trouble.

• Noise Level: Ensure the generator meets CPCB noise regulations in industrial zones.

• Warranty and Service Support -In Delhi/NCR, look for a 2- to 5-year guarantee and after-sales service. Check for service contracts, replacement parts, and technician availability.

• Diesel generators are the most popular for industrial use due to their low fuel cost and long lifespan.

• Gas generators are more environmentally friendly and quieter, although they cost significantly more.

• Hybrid Generators (Solar + Diesel) are becoming increasingly popular in Delhi as environmental consciousness grows.

Read More On Locanto.me

How Industrial Generators Help Businesses in Delhi?

Industrial generators help a variety of Delhi enterprises, including.

• Manufacturing units Textile, plastic moulding, food processing, and printing industries all rely largely on continuous electricity for their operations and output.

• Corporate offices Generators keep servers, networks, and air-conditioning systems working smoothly at IT centres in Noida and startups in Gurgaon alike.

• Retail and Mall A sudden power loss at a mall or showroom can create havoc. Generators keep all lighting, billing systems, and air conditioning units operating.

• Hotels & Restaurants Guest satisfaction is dependent on comfort. A generator is useful for maintaining lights, refrigeration, and climate control during peak summer months.

• Clinics and Hospitals In a place where lives depend on machines, a power outage is just not an option. Medical facilities must have industrial-grade generators with automatic start systems.

Best Generator Brands Available in Delhi.

Let's take a look at some of the highest-rated industrial generators available in Delhi that business owners trust:

• Kirloskar Green Generators. Known for its dependability, fuel efficiency, and customer service. Ideal for manufacturers and medium-sized businesses.

• Cummins India One of the most dependable brands worldwide. Available in 10 to 500 kVA power levels. Perfect for IT parks, malls, and large industries.

Cost of industrial generators in Delhi

Prices vary according to size and brand, but here's a fair estimate of industrial generator pricing in Delhi:

• 10-15 kVA Diesel Generator - ₹2.5–₹3.5 lakhs • 20-40 kVA: ₹4-6 lakhs • 50-100 kVA costs ₹7-12 lakhs. • Above 100 kVA: ₹15 lakhs

Prices are estimates and may vary depending on features, installation fees, GST, and shipping expenses.

Read More On Tumblr.com

Why Should You Choose United Power Solution For Industrial Generators in Delhi?

United Power Solution is a major supplier of industrial and residential generators, offering skilled installation, after-sales support, maintenance, repairs, spare parts, and courteous genset selection guidance to ensure optimal performance and long-term client support.

• United Power Solution also provides wholesale gensets at a competitive price.

• Our service region covers Delhi NCR, Noida, and Gurgaon, and we are available throughout the country to suit the needs of our consumers in Delhi.

• Our company, United Power Solution, stands out for its efficient workforce, genuine Kirloskar and Sudir goods, customer-centric approach, customizable solutions, flexible payment choices, and 24/7 emergency service.

0 notes

Text

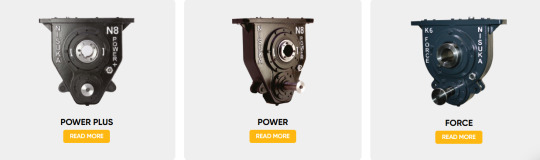

SMSR Gear Box manufacturer in Ahmedabad, India

In the fast-paced world of industrial operations, power transmission systems play a key role in maintaining consistent performance and productivity. One of the most widely used and efficient components in this category is the SMSR Gear Box (Shaft Mounted Speed Reducer). Known for its reliability and ease of use, the SMSR gear box is a vital part of conveyor systems and other heavy-duty equipment. Nisuka Industries, a leading Shaft mounted Gear Box manufacturer in Ahmedabad, India, is proud to offer high-performance gearboxes designed to meet demanding industrial needs.

What is an SMSR Gear Box?

An SMSR (Shaft Mounted Speed Reducer) Gear Box is a mechanical device mounted directly onto the driven shaft of a machine. It reduces speed and increases torque, providing smooth and efficient power transmission. Unlike traditional gearbox setups that require base plates and coupling alignment, SMSR gearboxes are compact and easy to install, saving both space and maintenance time.

At Nisuka Industries, we manufacture SMSR gearboxes with robust design, precision-machined components, and superior quality materials to ensure long operational life even under harsh working conditions.

Why Nisuka Industries?

With decades of experience in gearbox manufacturing, Nisuka Industries has become a trusted name for engineering excellence. We are recognized not only in Ahmedabad but throughout India for delivering performance-driven solutions that support the growth of industries such as cement, mining, steel, chemical, and agriculture.

As a reputed SMSR Gear Box supplier in Ahmedabad, India, we offer:

Precision Engineering: Each gearbox is made with accurate gear tooth profiles, ensuring low noise and smooth operation.

Heavy-Duty Construction: Made from high-grade cast iron and alloy steels, our gearboxes are built to last in rugged conditions.

Customization: We provide gearboxes tailored to customer specifications in terms of shaft size, gear ratios, and mounting preferences.

After-Sales Support: We believe in long-term partnerships, offering technical assistance, spare parts, and maintenance services.

Key Features of Nisuka SMSR Gear Boxes

Our gearboxes are engineered to deliver optimal performance, making us a reliable choice for industrial users. Key features include:

Easy installation and alignment with the driven shaft

High torque output and efficiency

Anti-corrosive body coating for long-term durability

Oil-sealed enclosures for maintenance-free operation

Available with or without torque arm and backstop arrangements

These features make Nisuka SMSR gearboxes ideal for conveyor systems, crushers, feeders, and other material-handling machinery.

Industrial Applications

As one of the most reliable SMSR Gear Box manufacturers in India, we cater to a wide range of industries, including:

Mining and Quarrying: For conveyors and crushers that demand continuous power.

Cement Plants: Supporting heavy conveyor belts in material movement.

Steel and Power Plants: Assisting in high-torque mechanical applications.

Agro Industries: Used in grain handling, fertilizer plants, and packaging units.

Textile and Chemical: Suitable for mixers, dryers, and rollers.

No matter your sector, our gearboxes are designed to operate under high load and varying temperatures with minimal breakdowns.

Quality and Manufacturing Excellence

Our facility in Ahmedabad is equipped with advanced CNC machines, gear-cutting equipment, and quality-testing systems. Every SMSR gearbox goes through rigorous checks for:

Gear accuracy and tooth strength

Shaft alignment and fitting tolerances

Noise and vibration levels

Lubrication system integrity

Heat dissipation capacity

This strict quality assurance system ensures that you receive gearboxes that perform consistently and exceed expectations.

Also a Conveyor Gearbox Manufacturer in India

At Nisuka, we also specialize as a Conveyor Gearbox Manufacturer in India, offering gearboxes specifically designed for heavy-duty material transportation. These gearboxes are used in bulk material handling systems across various industries and are known for their rugged design and reliable torque transfer.

Also a Plummer Block Manufacturer in India

We are also a trusted Plummer Block Manufacturer in India, producing high-precision blocks used to house and support bearings in rotating equipment. Our plummer blocks are machined to perfection, ensuring proper alignment and protection of shafts in demanding applications.

By manufacturing both gearboxes and essential components like plummer blocks, Nisuka provides a complete mechanical solution for industrial operations.

Location Advantage – Ahmedabad, India

Being based in Ahmedabad, a major hub for engineering and manufacturing, allows us to respond quickly to customer demands and maintain competitive pricing. With access to a skilled workforce, modern infrastructure, and reliable transportation, we serve clients across Gujarat, Maharashtra, Rajasthan, and other states efficiently.

Commitment to Customer Satisfaction

Nisuka Industries is built on values of quality, service, and trust. From product selection to technical support, we focus on offering solutions that match your operational needs. Our team of engineers and service experts work closely with clients to ensure smooth installation, optimal performance, and long-term satisfaction.

Conclusion

If you're looking for a reliable SMSR Gear Box Manufacturer in Ahmedabad, India, choose Nisuka Industries for quality that speaks for itself. Our gearboxes are known for durability, efficiency, and cost-effectiveness across a wide range of industrial applications.

Whether you need a shaft-mounted gearbox, a custom conveyor drive, or a heavy-duty plummer block, Nisuka is your one-stop destination for mechanical transmission excellence.

#SMSR Gear Box manufacturer in Ahmedabad#SMSR Gear Box supplier in Ahmedabad#SMSR Gear Box exporter in Ahmedabad

0 notes