#textile machine

Text

Different Parts of Loom and Their Functions

A loom is a mechanical tool used to weave fabric by inserting yarn for the warp and weft. The main mechanical weaving tool in weaving machine technology is the loom. However, a variety of looms are utilized for weaving tasks. Altering the machine setting also results in the production of various types of designed fabric.

A loom is a mechanical equipment that mechanically interweaves threads to create fabrics that can be used for industrial or dress-related purposes. Given that looms are used to manufacture cloth. Man first utilized a handloom to produce cloth in the early days of fabric manufacturing. With the advancement of the loom, the weaving mechanism altered over time. In keeping with modern times, the looms used to make fabrics have high production rates as well as complicated design production rates.

Shaft, Heald:

The shedding mechanism is included in this section. A heald shaft is made in the textile weaving industry utilizing aluminum or wood-based metals. The ends of the warp sheet pass through a number of heddle wires that it carries. The words "heald shafts" and "heald staves" are also used to describe the shafts. The total number of heald shafts varies depending on the weave's warp repetition. The weave's drafting strategy during weaving determines it.

Sley of Lay:

It is composed of wood and consists of a reed cap, a metal sword carried at either end, and the sley race board or sley race. The sley mechanism oscillates. Sley is in charge of using the beat-up motion to drive the final weft pick to the fabric's fell. The sley moves more quickly while traveling near the edge of the cloth and less quickly when going away from it. "Eccentricity of the sley" is the phrase used to describe this uneven movement. In textile weaving, sley is required to complete the beat-up and to allow enough time for the shuttle to pass through the warp shed.

Shuttle

Shuttles are used in textile weaving as weft carriers to help interlace the weft and warp threads to create cloth. A wooden shuttle that travels from one end of the loom to the other is used. The shuttle moves between the top and bottom levels of the warp sheet as it travels along the wooden sley race. The shuttle enters a shuttle box that is installed at either end of the loom after passing through the warp shed. It should be mentioned that a shuttle typically weighs 0.45 kg.

Picker:

A picker is a piece that can be made of leather or synthetic material. Picker can be positioned on one of the spindles or grooves in the shuttle box. The shuttle is driven by a picker as it moves between boxes. It withstands the force of the shuttle when it enters the box as well.

Reed:

A reed cap secures the metallic comb known as a reed to the sley. Dents are the spaces between wires in a shuttle, which are used in the textile industry. The number of dents in two inches determines the reed's count. In textile weaving, there are various varieties of reed, including regular reed, expanding reed, gauze reed, and V reed.

Reed forces the final weft pick to be laid against the fallen cloth. Together with the healds, it determines the fabric's fineness. The shuttle is guided by a reed as it moves from one end of the loom to the other. It aids in keeping the warp threads in place.

Back Beam:

The backrest is another name for the back beam. Above the weaver's beam, it is positioned. Back Beams can be either fixed or floating. In the first instance, the backrest only serves as a guide for the warp sheet coming from the weaver's beam. In the second scenario, the back beam serves as both a sensor and a guide for detecting the warp strain.

Conclusion:

It is critical to know and understand the loom one is using, in order to learn more and better about it from warp beam to reed, one can only know what issue the machine is having that is causing the problem and how to fix it. While it can be difficult to choose the right machine to ensure that the fabric is even better, they can always rely on Weavetech in the meantime. The fine technology combined with highly advanced tools ensures that the fabric is as fine and detailed as possible. Put your textile in the hands of Weavetech.

3 notes

·

View notes

Text

Graphic Overlays and Decals Manufacturer in India

Memtron is a global leader in producing and exporting high-end Graphic overlay and Graphic Overlay and Decals. Memtron was founded in Gujarat's Gandhinagar in 2000. The top layer of the membrane switch assembly is known as a graphic overlay or a membrane switch overlay. An overlay is often the first thing a person sees when engaging with a product and is frequently utilized as the crucial layer of a user interface. Without the constraints of other printing processes, digitally printed graphic overlays, control panel overlays, front panels, and graphic overlay decals provide the best printing and creative flexibility. Digital overlays can produce high-quality printing without the use of screens or plates, which lowers setup costs, allows for quicker lead times, and lowers minimum order requirements. To achieve long-lasting performance, it is essential that these components are simple to use and constructed from high-quality materials.

In every aspect of our daily life, graphic overlays are present from medical equipment, consumer goods and agriculture to electronic devices, manufacturing and automobile. With the help of graphic overlays, you may transmit branding, indicate critical system interfaces, and identify information that is necessary for using the equipment. Graphic overlays are essential to the operation and security of equipment, gadgets, and electronic machinery.

Such machines or pieces of equipment including medical devices, control panels, ATMs and electronic devices are necessary for our daily lives and some of them are used with high intensity. For that graphic overlay decals helps to protect them against external factors as well as their users. At sticky business, we offer customized control panel overlay printing of your product, to shield them and extend the time they are used. Connecting a person to a machine, gadget, or piece of equipment via an electronic interface is its intuitive component and the membrane switch which is visible to the operator, displaying the positions of the keypads and describing how the device works. The membrane switch assembly's top layer is a graphic overlay, sometimes known as a membrane switch overlay. Memtron product is one of the best manufacturers and exporters of graphic overlay also supplying our high-quality products in so many industries such as telecommunication, medical, robotics, Automotive, HMI and electronic industries in India with long duration.

#flexible membrane keypad#membraneswitches#textile machine#memtron#Membrane Keypad#Electronics Keypad#Air Compressor Keypad#Polyamide Circuit#Graphic Overlay#Graphic Overlays and Decals

0 notes

Text

but I knew how to dress it up

11K notes

·

View notes

Text

water jet #loom #spare #parts - #letoff #gearboxcover ,#oilmirror ,turbine ,pinion.

WhatsApp +86 15621028051 ,

#waterjetloom #weavingloom #spareparts #textilespareparts #textilemachinery

0 notes

Text

Wednesday, November 29.

You reap what you sew.

Never have truer words been spoken. But they come as good news for Tumblr's sewing community, however, who have been sewing some absolute delights. Some real œuvres d'art. Some winner-winner chicken dinners.

As luck would have it, #sewing is trending. And it's trending right now, so we have reaped a selection of these very dinners for your eyes only. We have then asked ourselves just what did we do to deserve y'all, and your resplendent talents.

#today on tumblr#sewing#sew#sewblr#crafts#sewing machine#crafting#sewing project#textile arts#crochet#sewing patterns#sewing tutorial#sewing tag#craftblr#contemporary art#artists#artists on tumblr

1K notes

·

View notes

Photo

Small V Type Creel

PRO-SMH is able to provide creels for a wide range of applications. Starting from "V"-type creels for staple fibers as well as "H"-type creels for staple fibers, filament as well as technical textiles. "H" creels are available as standard, magazine, carriage or swivel frame creel. Also, special types of creels like rolling creel are available. Depending on your application the creels can be equipped with porcelain or ceramic eyelets and a wide variety of tensioners.

0 notes

Text

florence + the machine lyrics x colors x textiles in art – red

Rabbit Heart (Raise It Up) – Lungs // Queen Anne, When Princess of Denmark – Willem Wissing and Jan van der Vaart 🩸 Kiss with a Fist – Lungs // Eleonora di Toledo – Bronzino 🩸 Lover to Lover – Ceremonials // Girl with a Doll in an Armchair – Alois Hans Schram 🩸 Ship to Wreck – How Big, How Blue, How Beautiful // Portrait of Marie Casimire Zamoyska (Marysieńka) – unknown artist 🩸 What Kind of Man – How Big, How Blue, How Beautiful // Portrait of a Young Woman – Arnold van Ravesteyn 🩸 Heaven Is Here – Dance Fever // Portrait of Vittoria della Rovere, Grand Duchess of Tuscany – after Justus Sustermans

#florence + the machine lyrics x colors x textiles in art#red#rabbit heart#kiss with a fist#lover to lover#ship to wreck#what kind of man#heaven is here#lungs#lungs album#ceremonials#how big how blue how beautiful#hbhbhb#dance fever#florence + the machine#florence and the machine#fatm#art#art history#lyrics#lyric art

259 notes

·

View notes

Text

as i get older, i'm gaining an increasing appreciation for natural fibers.

the crinkliness of cotton, the itchiness of wool, the stiffness of linen... it feels heartier than synthetics, you know? there's something that feels real about natural fibers that synthetics somehow lack. and i know that wool felts and linen softens and whatever, but i love that progression so much more than the way synthetics (including processed cellulose) go from unnaturally soft to weirdly plasticky.

anyways the point is i love science, and there's value to technology that improves the way we make textiles. but it's frustrating when, rather than making textiles better, science robs them of their longevity in the name of making things cheap.

there is a lot of beauty in imperfect things -- "ugly" things, sometimes -- that last.

#craftblr#craftycoola.txt#textile art#rants on modernity#(next up: a rant on the values of machines that you can service yourself and whose mechanics you can fully understand)#(i mean don't hold your breath. writing is hard. but that seems like the natural sequel no?)

331 notes

·

View notes

Text

When I was younger I designed a gyaru Monster High OC based on a tengu! Now that I make dolls by hand I decided to give her life 🌸👺💖

#dolls#art doll#ooakdoll#textile art#dollblr#sculpting#gyaru#gyaru fashion#tengu#mythology and folklore#my dolls#I wouldn't really consider her a Monster High OC anymore. She's a university girlie. Solid B student 😊👍#Her purse is made of a gumball machine eraser I had kicking around. I think it suits her so well#ALSO she was a nightmare to photograph LOL. I love her nose but. Man it's hard to take pics of

107 notes

·

View notes

Text

another thing i made recently! a heart shaped tote bag ❤️ one of my first projects made on my vintage singer sewing machine. it’s been sitting in storage for a while but i decided to pull it out and get it fixed up and in working order last week and i’ve been teaching myself how to use it since!

this bag was made from salvaged cotton i rescued from the side of the road 🤘

etsy // patreon

#i inherited the singer from my horrible grandma lol#she was a fuckin bitch but at least she had good taste in sewing machines#mine#my art#sewing#crafts#fashion#slow fashion#handbag#tote bag#textile art#fiber art#heart shaped#heart#heartcore#lovecore#solarpunk#traditional art#sustainable fashion#sustainability#upcycling

82 notes

·

View notes

Text

Finished another quilt! An art quilt with raw edge applique and free motion quilting because that's an appropriate project for a beginner, right? But I had this pattern for at least 18 months after I've seen someone else do it on reddit.

And now I'm on meth! Methylphenidate I mean. And have reorganized my room to actually take full advantage of the space. I'm so fucking productive right now!

The pattern is called Ariel by Lise Bélanger, at libexpression.com and etsy.

Anyhow, happy pride everyone!

72 notes

·

View notes

Text

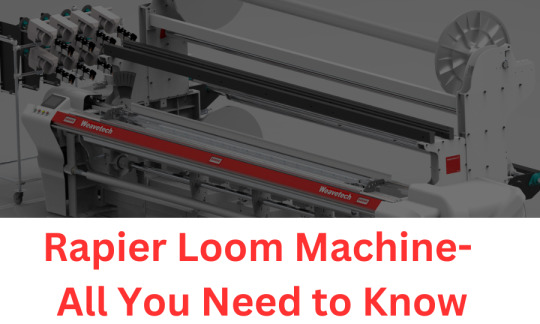

Rapier Loom Machine- All You Need to Know

In the mid-20th century, the textile industry witnessed a transformative leap with the advent of Rapier Loom Machines. Born out of a need for enhanced efficiency and precision in weaving, these machines quickly evolved, embracing mechanical and electronic innovations. This brief exploration traces the concise history that propelled Rapier Loom Machines into the forefront of modern textile manufacturing. Discover accuracy and effectiveness with Weavetech, your reliable textile manufacturing partner. Being one of Gujarat’s top manufacturers of rapier loom machines, we put innovation at the center of your output. With our cutting-edge rapier loom machines, which are built for dependability, speed, and versatility, you may enhance your weaving experience.

What is the Rapier Loom Machine?

A Rapier Loom Machine is a textile weaving device that uses a rapier a thin, flexible rod or tape to insert the weft yarn across the warp threads during fabric production. Renowned for their precision and versatility, these machines have evolved, incorporating electronic controls for enhanced efficiency in the weaving process.Single rapier machines use one rapier for weft insertion, while double rapier machines use two. The dual-rapier system in double-rapier machines offers increased versatility and efficiency, particularly for intricate weaving patterns. The choice depends on the fabric’s complexity and production requirements.

What are the features of the Rapier Loom machine?

Here are some prominent features commonly associated with modern rapier loom machines:

Rapier System: The most distinctive feature of a rapier loom is the use of a rapier or a rigid or flexible rod to carry the weft yarn across the warp threads.

Flexible Rapier: Some rapier looms use a flexible rapier, which is a tape or band that can bend around the loom to carry the weft through the shed.

Rigid Rapier: In contrast, rigid rapiers are straight and do not bend. They move horizontally to insert the weft through the shed.

Shedding Mechanism: Rapier looms employ shedding mechanisms to create an opening (shed) through which the weft can be inserted. Common shedding mechanisms include dobby or cam shedding.

Electronic Jacquard Attachment: High-end rapier looms may have an electronic jacquard attachment for more complex and intricate fabric patterns.

Speed and Efficiency: Rapier looms are known for their high weaving speed and efficiency, making them suitable for large-scale production of fabrics.

Versatility: Rapier looms can be used to weave a variety of fabrics, including plain weaves, twills, and complex patterns. They are versatile and can handle a range of yarn types.

Automatic Functions: Many modern rapier looms are equipped with automatic functions such as automatic warp and weft replenishment, automatic pick finding, and automatic tension control.

Easy Set-Up and Operation: Rapier looms are generally considered easier to set up and operate compared to some other types of looms, making them popular in industrial textile production.

Monitoring and Control Systems: Advanced rapier looms may include monitoring and control systems that help in detecting and correcting weaving defects.

Double Rapier System: Some rapier looms use a double rapier system, where two rapiers work in coordination to insert the weft simultaneously. This can increase the weaving speed and efficiency.

Warp Stop Motion: A warp stop motion system is often integrated into rapier looms to detect and stop the loom in case of warp yarn breakage.

These features collectively contribute to the efficiency, flexibility, and advanced capabilities of modern rapier loom machines in the textile industry. Weavetech, the top manufacturer of Rapier Loom Machines in Gujarat, will help you up your weaving game. Our state-of-the-art machinery guarantees quick, accurate, and adaptable textile production.

What clothes are made by Rapier Loom machine?

Rapier Loom machines produce a variety of fabrics, including cotton, polyester, wool, silk, denim, and more, used for diverse clothing items such as shirts, dresses, jeans, and formalwear.

What is Rapier fabric?

Rapier fabric is woven using a Rapier Loom machine, incorporating diverse materials like cotton, polyester, and silk, to create versatile textiles for clothing and other applications. The evolution of Rapier Loom machines has undeniably left an indelible mark on the textile industry. From the simplicity of single-rapier systems to the enhanced capabilities of double-rapier machines, these looms have redefined efficiency, precision, and versatility in fabric production. The ability to weave a spectrum of fabrics, from everyday cotton to luxurious silk, highlights the adaptability of Rapier Looms in meeting the diverse demands of the fashion world. As technology continues to advance, these machines stand poised at the forefront of innovation, driving the industry forward. In essence, the journey of Rapier Loom machines is not just a story of mechanical ingenuity but a testament to their integral role in shaping the very fabric of our textile landscape.

With Weavetech, the Best Textile Machinery Manufacturer in Gujarat, you can unleash the potential of textile production in the future. Our cutting-edge Rapier Loom Machines guarantee quick and accurate weaving while redefining efficiency. Improve your manufacturing skills by getting in touch with Weavetech right away.

This Blog Originally Posted Here:

https://www.weavetech.com/rapier-loom-machine-all-you-need-to-know/

0 notes

Text

Textile Machine Keypad Manufacturer in India

Memtron is a well-known manufacturer and supplier of HMI keypads, Ceramic machine keypads, Siemens keypads, Allen Bradley keypads, CNC machine keypads, and medical equipment keypads in India. Memtron produces superior-quality Textile Machine Keypads with top-notch components. To ensure great performance for users, we monitor a variety of quality metrics on our product line. A perfectly constructed HMI keypad item that integrates with internal membrane switches will be created by our expertise.

Visit Now: http://www.memtron.in/products/standard-machine-keypad/

0 notes

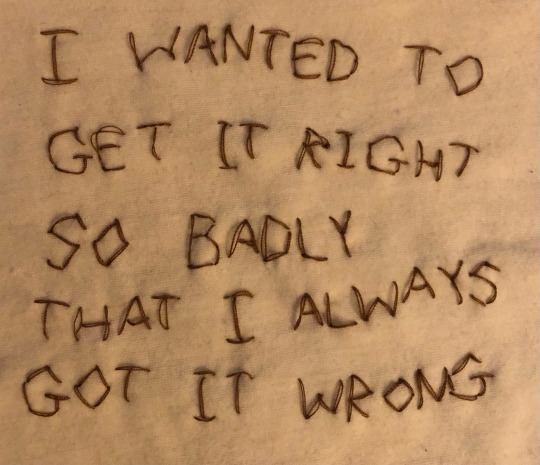

Text

Words from light of love by Florence + the machine stitched onto fabric

19K notes

·

View notes

Text

Water jet loom spare parts pan head gear, textile machinery spares.

https://eastsongcn.com

Wsap+86 15621028051

#waterjetspareparts #waterjetlooms #waterjetloom #waterjetloomsmachine #waterjetloomspareparts #waterjetloomparts #loomparts #loom #loomknitting #loommachine #loomweaving

0 notes

Text

Unrelated to everything and anything in this blog but: hey I just made this and it’s crazy to see my design as a real product!

40 notes

·

View notes