#Textile Machine price

Explore tagged Tumblr posts

Text

If you’re UK based and love knitting/yarn/rare heritage breeds, there’s a London City Farms Kickstarter out there right run by a sustainable textiles creator now that have pooled together something like 16 rare breeds across the city farms and turned it into a machine and hand knitting yarn. Most of these fleeces were going to waste because, as we all know, fleeces are priced so lowly that it’s usually not worth the cost of the cleaning, processing and industrial spinning. You can buy a skein, cone, or an item made solely from the natural colours that the blended sheep breeds produce.

462 notes

·

View notes

Text

AI turns Amazon coders into Amazon warehouse workers

HEY SEATTLE! I'm appearing at the Cascade PBS Ideas Festival NEXT SATURDAY (May 31) with the folks from NPR's On The Media!

On a recent This Machine Kills episode, guest Hagen Blix described the ultimate form of "AI therapy" with a "human in the loop":

https://soundcloud.com/thismachinekillspod/405-ai-is-the-demon-god-of-capital-ft-hagen-blix

One actual therapist is just having ten chat GPT windows open where they just like have five seconds to interrupt the chatGPT. They have to scan them all and see if it says something really inappropriate. That's your job, to stop it.

Blix admits that's not where therapy is at…yet, but he references Laura Preston's 2023 N Plus One essay, "HUMAN_FALLBACK," which describes her as a backstop to a real-estate "virtual assistant," that masqueraded as a human handling the queries that confused it, in a bid to keep the customers from figuring out that they were engaging with a chatbot:

https://www.nplusonemag.com/issue-44/essays/human_fallback/

This is what makes investors and bosses slobber so hard for AI – a "productivity" boost that arises from taking away the bargaining power of workers so that they can be made to labor under worse conditions for less money. The efficiency gains of automation aren't just about using fewer workers to achieve the same output – it's about the fact that the workers you fire in this process can be used as a threat against the remaining workers: "Do your job and shut up or I'll fire you and give your job to one of your former colleagues who's now on the breadline."

This has been at the heart of labor fights over automation since the Industrial Revolution, when skilled textile workers took up the Luddite cause because their bosses wanted to fire them and replace them with child workers snatched from Napoleonic War orphanages:

https://pluralistic.net/2023/09/26/enochs-hammer/#thats-fronkonsteen

Textile automation wasn't just about producing more cloth – it was about producing cheaper, worse cloth. The new machines were so easy a child could use them, because that's who was using them – kidnapped war orphans. The adult textile workers the machines displaced weren't afraid of technology. Far from it! Weavers used the most advanced machinery of the day, and apprenticed for seven years to learn how to operate it. Luddites had the equivalent of a Masters in Engineering from MIT.

Weavers' guilds presented two problems for their bosses: first, they had enormous power, thanks to the extensive training required to operate their looms; and second, they used that power to regulate the quality of the goods they made. Even before the Industrial Revolution, weavers could have produced more cloth at lower prices by skimping on quality, but they refused, out of principle, because their work mattered to them.

Now, of course weavers also appreciated the value of their products, and understood that innovations that would allow them to increase their productivity and make more fabric at lower prices would be good for the world. They weren't snobs who thought that only the wealthy should go clothed. Weavers had continuously adopted numerous innovations, each of which increased the productivity and the quality of their wares.

Long before the Luddite uprising, weavers had petitioned factory owners and Parliament under the laws that guaranteed the guilds the right to oversee textile automation to ensure that it didn't come at the price of worker power or the quality of the textiles the machines produced. But the factory owners and their investors had captured Parliament, which ignored its own laws and did nothing as the "dark, Satanic mills" proliferated. Luddites only turned to property destruction after the system failed them.

Now, it's true that eventually, the machines improved and the fabric they turned out matched and exceeded the quality of the fabric that preceded the Industrial Revolution. But there's nothing about the way the Industrial Revolution unfolded – increasing the power of capital to pay workers less and treat them worse while flooding the market with inferior products – that was necessary or beneficial to that progress. Every other innovation in textile production up until that time had been undertaken with the cooperation of the guilds, who'd ensured that "progress" meant better lives for workers, better products for consumers, and lower prices. If the Luddites' demands for co-determination in the Industrial Revolution had been met, we might have gotten to the same world of superior products at lower costs, but without the immiseration of generations of workers, mass killings to suppress worker uprisings, and decades of defective products being foisted on the public.

So there are two stories about automation and labor: in the dominant narrative, workers are afraid of the automation that delivers benefits to all of us, stand in the way of progress, and get steamrollered for their own good, as well as ours. In the other narrative, workers are glad to have boring and dangerous parts of their work automated away and happy to produce more high-quality goods and services, and stand ready to assess and plan the rollout of new tools, and when workers object to automation, it's because they see automation being used to crush them and worsen the outputs they care about, at the expense of the customers they care for.

In modern automation/labor theory, this debate is framed in terms of "centaurs" (humans who are assisted by technology) and "reverse-centaurs" (humans who are conscripted to assist technology):

https://pluralistic.net/2023/04/12/algorithmic-wage-discrimination/#fishers-of-men

There are plenty of workers who are excited at the thought of using AI tools to relieve them of some drudgework. To the extent that these workers have power over their bosses and their working conditions, that excitement might well be justified. I hear a lot from programmers who work on their own projects about how nice it is to have a kind of hypertrophied macro system that can generate and tweak little automated tools on the fly so the humans can focus on the real, chewy challenges. Those workers are the centaurs, and it's no wonder that they're excited about improved tooling.

But the reverse-centaur version is a lot darker. The reverse-centaur coder is an assistant to the AI, charged with being a "human in the loop" who reviews the material that the AI produces. This is a pretty terrible job to have.

For starters, the kinds of mistakes that AI coders make are the hardest mistakes for human reviewers to catch. That's because LLMs are statistical prediction machines, spicy autocomplete that works by ingesting and analyzing a vast corpus of written materials and then producing outputs that represent a series of plausible guesses about which words should follow one another. To the extent that the reality the AI is participating in is statistically smooth and predictable, AI can often make eerily good guesses at words that turn into sentences or code that slot well into that reality.

But where reality is lumpy and irregular, AI stumbles. AI is intrinsically conservative. As a statistically informed guessing program, it wants the future to be like the past:

https://reallifemag.com/the-apophenic-machine/

This means that AI coders stumble wherever the world contains rough patches and snags. Take "slopsquatting." For the most part, software libraries follow regular naming conventions. For example, there might be a series of text-handling libraries with names like "text.parsing.docx," "text.parsing.xml," and "text.parsing.markdown." But for some reason – maybe two different projects were merged, or maybe someone was just inattentive – there's also a library called "text.txt.parsing" (instead of "text.parsing.txt").

AI coders are doing inference based on statistical analysis, and anyone inferring what the .txt parsing library is called would guess, based on the other libraries, that it was "text.parsing.txt." And that's what the AI guesses, and so it tries to import that library to its software projects.

This creates a new security vulnerability, "slopsquatting," in which a malicious actor creates a library with the expected name, which replicates the functionality of the real library, but also contains malicious code:

https://www.theregister.com/2025/04/12/ai_code_suggestions_sabotage_supply_chain/

Note that slopsquatting errors are extremely hard to spot. As is typical with AI coding errors, these are errors that are based on continuing a historical pattern, which is the sort of thing our own brains do all the time (think of trying to go up a step that isn't there after climbing to the top of a staircase). Notably, these are very different from the errors that a beginning programmer whose work is being reviewed by a more senior coder might make. These are the very hardest errors for humans to spot, and these are the errors that AIs make the most, and they do so at machine speed:

https://pluralistic.net/2024/04/23/maximal-plausibility/#reverse-centaurs

To be a human in the loop for an AI coder, a programmer must engage in sustained, careful, line-by-line and command-by-command scrutiny of the code. This is the hardest kind of code to review, and maintaining robotic vigilance over long periods at high speeds is something humans are very bad at. Indeed, it's the kind of task we try very hard to automate, since machines are much better at being machineline than humans are. This is the essence of reverse-centaurism: when a human is expected to act like a machine in order to help the machine do something it can't do.

Humans routinely fail at spotting these errors, unsurprisingly. If the purpose of automation is to make superior goods at lower prices, then this would be a real concern, since a reverse-centaur coding arrangement is bound to produce code with lurking, pernicious, especially hard-to-spot bugs that present serious risks to users. But if the purpose of automation is to discipline labor – to force coders to accept worse conditions and pay – irrespective of the impact on quality, then AI is the perfect tool for the job. The point of the human isn't to catch the AI's errors so much as it is to catch the blame for the AI's errors – to be what Madeleine Clare Elish calls a "moral crumple zone":

https://estsjournal.org/index.php/ests/article/view/260

As has been the case since the Industrial Revolution, the project of automation isn't just about increasing productivity, it's about weakening labor power as a prelude to lowering quality. Take what's happened to the news industry, where mass layoffs are being offset by AI tools. At Hearst's King Features Syndicates, a single writer was charged with producing over 30 summer guides, the entire package:

https://www.404media.co/viral-ai-generated-summer-guide-printed-by-chicago-sun-times-was-made-by-magazine-giant-hearst/

That is an impossible task, which is why the writer turned to AI to do his homework, and then, infamously, published a "summer reading guide" that was full of nonexistent books that were hallucinated by a chatbot:

https://www.404media.co/chicago-sun-times-prints-ai-generated-summer-reading-list-with-books-that-dont-exist/

Most people reacted to this story as a consumer issue: they were outraged that the world was having a defective product foisted upon it. But the consumer issue here is downstream from the labor issue: when the writers at King Features Syndicate are turned into reverse-centaurs, they will inevitably produce defective outputs. The point of the worker – the "human in the loop" – isn't to supervise the AI, it's to take the blame for the AI. That's just what happened, as this poor schmuck absorbed an internet-sized rasher of shit flung his way by outraged social media users. After all, it was his byline on the story, not the chatbot's. He's the moral crumple-zone.

The implication of this is that consumers and workers are class allies in the automation wars. The point of using automation to weaken labor isn't just cheaper products – it's cheaper, defective products, inflicted on the unsuspecting and defenseless public who are no longer protected by workers' professionalism and pride in their jobs.

That's what's going on at Duolingo, where CEO Luis von Ahn created a firestorm by announcing mass firings of human language instructors, who would be replaced by AI. The "AI first" announcement pissed off Duolingo's workers, of course, but what caught von Ahn off-guard was how much this pissed off Duolingo's users:

https://tech.slashdot.org/story/25/05/25/0347239/duolingo-faces-massive-social-media-backlash-after-ai-first-comments

But of course, this makes perfect sense. After all, language-learners are literally incapable of spotting errors in the AI instruction they receive. If you spoke the language well enough to spot the AI's mistakes, you wouldn't need Duolingo! I don't doubt that there are countless ways in which AIs could benefit both language learners and the Duolingo workers who develop instructional materials, but for that to happen, workers' and learners' needs will have to be the focus of AI integration. Centaurs could produce great language learning materials with AI – but reverse-centaurs can only produce slop.

Unsurprisingly, many of the most successful AI products are "bossware" tools that let employers monitor and discipline workers who've been reverse-centaurized. Both blue-collar and white-collar workplaces have filled up with "electronic whips" that monitor and evaluate performance:

https://pluralistic.net/2024/08/02/despotism-on-demand/#virtual-whips

AI can give bosses "dashboards" that tell them which Amazon delivery drivers operate their vehicles with their mouths open (Amazon doesn't let its drivers sing on the job). Meanwhile, a German company called Celonis will sell your boss a kind of AI phrenology tool that assesses your "emotional quality" by spying on you while you work:

https://crackedlabs.org/en/data-work/publications/processmining-algomanage

Tech firms were among the first and most aggressive adopters of AI-based electronic whips. But these whips weren't used on coders – they were reserved for tech's vast blue-collar and contractor workforce: clickworkers, gig workers, warehouse workers, AI data-labelers and delivery drivers.

Tech bosses tormented these workers but pampered their coders. That wasn't out of any sentimental attachment to tech workers. Rather, tech bosses were afraid of tech workers, because tech workers possess a rare set of skills that can be harnessed by tech firms to produce gigantic returns. Tech workers have historically been princes of labor, able to command high salaries and deferential treatment from their bosses (think of the amazing tech "campus" perks), because their scarcity gave them power.

It's easy to predict how tech bosses would treat tech workers if they could get away with it – just look how they treat workers they aren't afraid of. Just like the textile mill owners of the Industrial Revolution, the thing that excites tech bosses about AI is the possibility of cutting off a group of powerful workers at the knees. After all, it took more than a century for strong labor unions to match the power that the pre-Industrial Revolution guilds had. If AI can crush the power of tech workers, it might buy tech bosses a century of free rein to shift value from their workforce to their investors, while also doing away with pesky Tron-pilled workers who believe they have a moral obligation to "fight for the user."

William Gibson famously wrote, "The future is here, it's just not evenly distributed." The workers that tech bosses don't fear are living in the future of the workers that tech bosses can't easily replace.

This week, the New York Times's veteran Amazon labor report Noam Scheiber published a deeply reported piece about the experience of coders at Amazon in the age of AI:

https://www.nytimes.com/2025/05/25/business/amazon-ai-coders.html

Amazon CEO Andy Jassy is palpably horny for AI coders, evidenced by investor memos boasting of AI's returns in "productivity and cost avoidance" and pronouncements about AI saving "the equivalent of 4,500 developer-years":

https://www.linkedin.com/posts/andy-jassy-8b1615_one-of-the-most-tedious-but-critical-tasks-activity-7232374162185461760-AdSz/

Amazon is among the most notorious abusers of blue-collar labor, the workplace where everyone who doesn't have a bullshit laptop job is expected to piss in a bottle and spend an unpaid hour before and after work going through a bag- and body-search. Amazon's blue-collar workers are under continuous, totalizing, judging AI scrutiny that scores them based on whether their eyeballs are correctly oriented, whether they take too long to pick up an object, whether they pee too often. Amazon warehouse workers are injured at three times national average. Amazon AIs scan social media for disgruntled workers talking about unions, and Amazon has another AI tool that predicts which shops and departments are most likely to want to unionize.

Scheiber's piece describes what it's like to be an Amazon tech worker who's getting the reverse-centaur treatment that has heretofore been reserved for warehouse workers and drivers. They describe "speedups" in which they are moved from writing code to reviewing AI code, their jobs transformed from solving chewy intellectual puzzles to racing to spot hard-to-find AI coding errors as a clock ticks down. Amazon bosses haven't ordered their tech workers to use AI, just raised their quotas to a level that can't be attained without getting an AI to do most of the work – just like the Chicago Sun-Times writer who was expected to write all 30 articles in the summer guide package on his own. No one made him use AI, but he wasn't going to produce 30 articles on deadline without a chatbot.

Amazon insists that it is treating AI as an assistant for its coders, but the actual working conditions make it clear that this is a reverse-centaur transformation. Scheiber discusses a dissident internal group at Amazon called Amazon Employees for Climate Justice, who link the company's use of AI to its carbon footprint. Beyond those climate concerns, these workers are treating AI as a labor issue.

Amazon's coders have been making tentative gestures of solidarity towards its blue-collar workforce since the pandemic broke out, walking out in support of striking warehouse workers (and getting fired for doing so):

https://pluralistic.net/2020/04/14/abolish-silicon-valley/#hang-together-hang-separately

But those firings haven't deterred Amazon's tech workers from making common cause with their comrades on the shop floor:

https://pluralistic.net/2021/01/19/deastroturfing/#real-power

When techies describe their experience of AI, it sometimes sounds like they're describing two completely different realities – and that's because they are. For workers with power and control, automation turns them into centaurs, who get to use AI tools to improve their work-lives. For workers whose power is waning, AI is a tool for reverse-centaurism, an electronic whip that pushes them to work at superhuman speeds. And when they fail, these workers become "moral crumple zones," absorbing the blame for the defective products their bosses pushed out in order to goose profits.

As ever, what a technology does pales in comparison to who it does it for and who it does it to.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2025/05/27/rancid-vibe-coding/#class-war

Image: Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

349 notes

·

View notes

Text

I'm taking an elective course on the development of infants and young children. One of our assignments was to use trash to make an age appropriate toy. I decided to cut up some tshirts for yarn and crochet a stuffed toy.

This is Nasty Lump. He is very heavy and solid and unpleasant to touch. He wants to give me carpal tunnel. I am probably going to give him to a friend when the assignment is done for an adoption fee of $3: I want him out of my sight and I hope the low price affects his self worth. He is stuffed with more fabric scraps, hopefully making him washing machine safe.

I cannot possibly recommend against making and using tshirt yarn vehemently enough. Most unpleasant experience I've ever had with a textile and I will not be touching a crochet hook for a bit.

#ash creates#crochet#crochetblr#crocheting#crafts#craftblr#crafting#fiber arts#fiber art#fiber crafts#fiber craft#ugly#stupid#diy

144 notes

·

View notes

Text

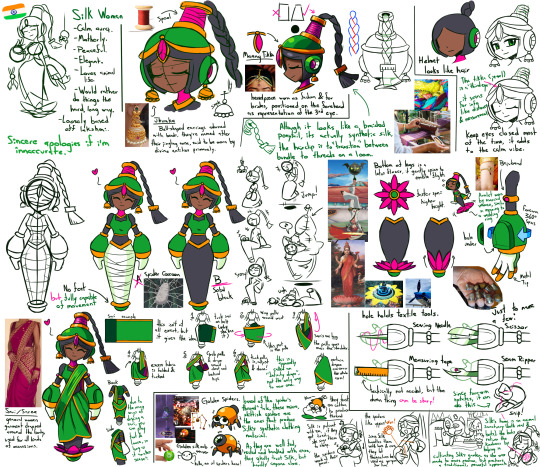

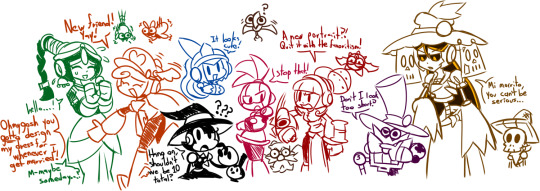

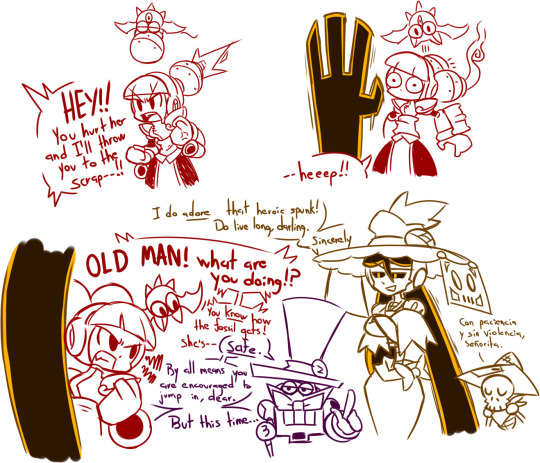

Introducing: Silk Woman.

A Robot Master from India, developed for the intent of crafting and mass producing clothes of the finest quality and prettiest design to the higest bidder.

Loosely based off Lakshmi, this gal was built to embody beauty, feminity and fortune, the last of which would come as a result of her work being made of the best genuine silk her patron corporation could acquire.

However, given her personality being that of a saint and her enormous compassion, once she learned of the process that went into adquiring real silk as fast as possible, she rebelled against the corporation that built her, and a robot that wasn't gonna comply would no longer be useful, so she was quickly discarded soon after.

Abandoned at the scrapyard, she was at a loss of what to do since she was stripped of the silk that had given her name and had no real method of getting out in the world on her own.

Fortune would soon smile upon her, however, as she soon discovered a tiny insect scuttering about on the scrapyard and saved it from nearly getting crushed by the rubble of the place, as it would have it, this little insect was a tiny mechanical golden spider.

As it happens, these golden spiders were companions to hobbyist in the textile arts, made to produce synthetic thread in various colors as long as they were provided the materials for it. However, these models were easily disposable if the hobbyist ran out of materials or merely didn't want to continue their lost passion.

This little spider was thankful for the kindness Silk had shown, and as if it could talk, it led her to more of its kind, who had various amounts of left-over silk within them.

With the help of the spiders, she was led out of the scrapyard and safely escaped a grim demise at the hands of crushers or trash melters. Though she had little to her name, she did had the skills to sew, and the thankful spiders would gladly provide what they had.

The group would soon find a place where they could prepare and sell their wares, though given the mass produced tools she had the people did not trust her as she was seen as a machine and not as a crafter, soon would she decide to switch her methods and learn the trade once more on her own, with no tricks to speed up the process.

It was a hard time, and the thread of the spiders was running out (and not a dime to feed them as they needed to be), it seemed to be over for the seamstress… until fortune shone on her once more.

A young couple this time, poor but deeply in love, they came in looking for wares they could use for their wedding and the other stablishements had rejected them for they couldn't pay the higher price. Feeling pity on them, Silk lended them her finest wares for almost free (the couple insisted on paying back what they could, and the spiders hungered for the flowers they needed to produce once more).

It took some days and Silk didn't had much time to keep her business afloat, but soon did she hear that the wedding was filled with love and amazement, with the wife presuming and praising the clothes she had acquired. Soon did word of mouth spread and little by little Silk acquired more and more clientelle who were happy with her wares.

Over time, Silk acquired a fortune and fame for the clothes she and the spiders produced, using her money not in frivolous jewels but in creating a lush garden, where she could grow flowers and trees that would help feed the spiders. This garden attracted lost animals -both of the robotic and living kinds- and were invited to stay as long as they pleased, some even providing help to tend to the flowers of the garden.

Today, Silk's business has grown to be recognized across various countries. Although slow to produce as she's a single woman doing the work, her textile works now fetch a good amount of money, though even today she freely donates her most elegant wares to couples soon to be married if their love rings true in their hearts.

-----

Silk here is a creation to go along with the rest of the robots that I have created thus far, by sheer accident I have been doing a worldwide theme with the end result being almost an echo of MegaMan 6 as each one of my robots would match a country seen in that game (or, well, almost. I have to represent my homeland of México, you know, close enough to Brazil).

Out of the ones I needed to make, the middle east was the one I needed to represent at this point, so I landed on making one based off the idea of the textile works of India as well as loosely basing her off Lakshmi and other various middle eastern themes. Hope I got her right and sincere apologies if I got something wrong.

Thus, I now have 9 robots, one for each country in MegaMan 6!

…Though one of them may not be exactly happy about it.

...Don't worry, Cave isn't getting demoted or replaced, its all just for show! He's just as valued as the others.

#Art#Open Commissions#Robot Master#Mega Man#Rock Man#OC#Original Character#Comic#Character Design#Pixel Art

31 notes

·

View notes

Text

Those cheap clothes at Shein have a big price tag which few consumers are able to see.

This is the sound of Panyu, the neighbourhood known as the "Shein village", a warren of factories that power the world's largest fast fashion retailer. "If there are 31 days in a month, I will work 31 days," one worker told the BBC. Most said they only have one day off a month. The BBC spent several days here: we visited 10 factories, spoke to four owners and more than 20 workers. We also spent time at labour markets and textile suppliers. We found that the beating heart of this empire is a workforce sitting behind sewing machines for around 75 hours a week in contravention of Chinese labour laws. [ ... ] But even past 22:00, the sewing machines - and the people hunched over them - don't stop as more fabric arrives, in trucks so full that bolts of colour sometimes tumble onto the factory floor. "We usually work, 10, 11 or 12 hours a day," says a 49-year-old woman from Jiangxi unwilling to give her name. "On Sundays we work around three hours less." She is in an alleyway, where a dozen people are huddled around a row of bulletin boards. They are reading the job ads on the board, while examining the stitching on a pair of chinos draped over it. [ ... ] The migrant worker from Jiangxi is looking for a short-term contract - and the chinos are an option. "We earn so little. The cost of living is now so high," she says, adding that she hopes to make enough to send back to her two children who are living with their grandparents. "We get paid per piece," she explains. "It depends how difficult the item is. Something simple like a t-shirt is one-two yuan [less than a dollar] per piece and I can make around a dozen in an hour."

Let's do a little math. One Chinese Yuan = 13.81 US cents (or $0.1381) as of Monday. So if the migrant worker from Jiangxi earns CN¥ 2.00 per t-shirt (US$0.2762) and does a dozen in one hour, she is effectively earning US$3.31 per hour. For comparison, the US minimum wage was US$3.35 per hour in between 01 January 1981 and 01 April 1990.

The working hours at Shein factories are as miserable as the pay. A "standard" working day is 14 hours.

Standard working hours appear to be from 08:00 to well past 22:00, the BBC found. This is consistent with a report from the Swiss advocacy group Public Eye, which was based on interviews with 13 textile workers at factories producing clothes for Shein. They found that a number of staff were working excessive overtime. It noted the basic wage without overtime was 2,400 yuan (£265; $327) - below the 6,512 yuan the Asia Floor Wage Alliance says is needed for a "living wage". But the workers we spoke to managed to earn anywhere between 4,000 and 10,000 yuan a month. "These hours are not unusual, but it's clear that it's illegal and it violates basic human rights," said David Hachfield from the group. "It's an extreme form of exploitation and this needs to be visible." The average working week should not exceed 44 hours, according to Chinese labour laws, which also state that employers should ensure workers have at least one rest day a week.

There are other issues mentioned in the article such as the sourcing of cotton from Xinjiang where the Chinese Communist Party is committing genocide against the Uighur people.

Don't buy clothing made in sweatshops from ANY country. In the US it was sweatshop conditions at clothing manufacturers which were one of the spurs for the growth of labor unions in the early 20th century.

I would add that "fast fashion" is generally wasteful and bad for the environment. Buy clothes which are not likely to quickly become unfashionable and those which are sturdy enough to last for a while.

#shein#clothing manufacturers#fast fashion#sweatshops#china#panyu#labor laws#bbc#asia floor wage alliance#a living wage#public eye#xinjiang#中国#快时尚#血汗工厂#番禺区#生活工资#劳动法#新疆#赤納粹

42 notes

·

View notes

Text

The more I read economics literature about automation trends and globalization trends (the actual economics term, not the rabid racist term) and their economic impacts on developed economies, the more I realize that the fundamental picture we have been sold these things is a lie.

The general picture of automation revolutions is that they present some way of doing work more efficiently and/or to create a better product, and so market forces simply demand it. And we have to figure out how to deal with all of the lost jobs which are resulting from this. Because even in a socialist utopia, surely it would be absurd to continue forcing people to use old and outdated technology to do work less efficiently just so they could have work to do, right? Maybe the socialist utopia will take care of people displaced by this work better, but the displacement will still happen.

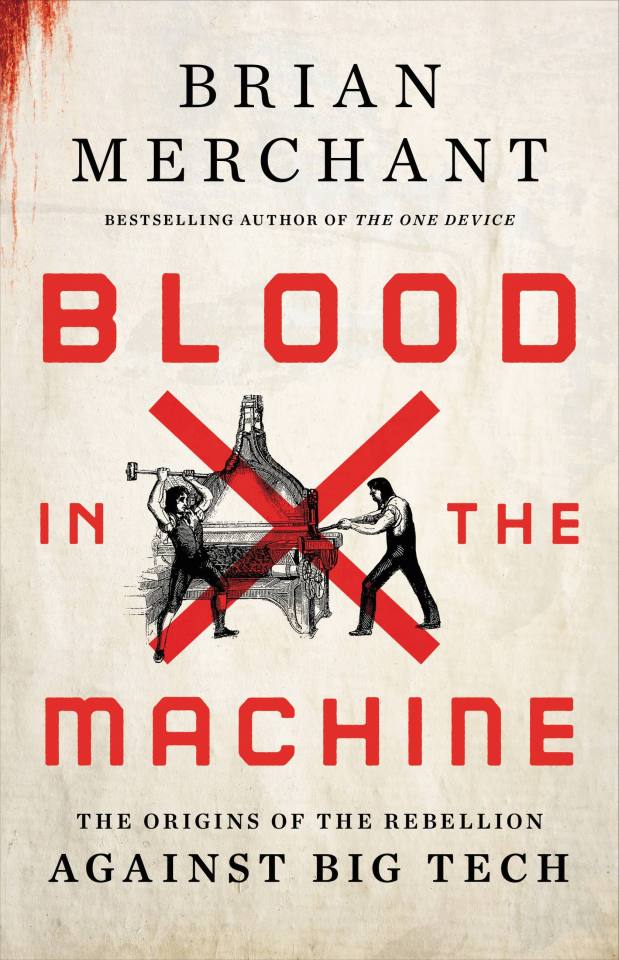

Except then I start reading about the actual history in the actual economics of automation revolutions (I recommend Blood In The Machine for a history of the Luddites and the automated textile revolution in Britain). And that's not what happens even a single time. These automated revolutions increase the cost per unit to create a good! They make the quality worse! And the existing workers get displaced, and replaced with oppressed or even outright enslaved labors who make nothing in worse conditions! They didn't even actually reduce the amount of labor involved significantly, they just started working orphan slaves 80-90 hours a week rather than artisan workers doing 30-35, to "reduce" the labor involved by reducing the number of laborers. It seems like no one benefits from this. So why is it happening!?

Well the answer is simple. The machine looms were less efficient, created lower quality products, and were worse for every single person in every sector of the economy ... except insofar as that they enabled a more unequal economy. The textile industry itself made less profit. The world itself had worse and less textiles. But the machine loom owners specifically made more money, because machine rooms enabled more control over workers in ways which could be used to relegate them to an even smaller share of the smaller profits. And they didn't outcompete others by being better, they did it through regulatory capture, illegal business practices, outright fraud, and by having a pre-existing place of power in their society.

The same applies to the classic story of Ford and his great automobile factory model. Sure it produced a lot of cars at low prices, but what the history doesn't tell you is that a bunch of other automobile companies which weren't using the factory model were putting out their own cars similar cost. Sure they weren't scaling up as fast, but everyone involved was making good money and the market kept on producing more companies to fill the gap. Ford made the decision to sell to a new lower cost car market sure, but he did not make a better profit margin per dollar of car purchases than his competitors did. He made significantly worse actually because he had such hideous turnover at his factories, and his cars were of lower quality than non-factory line cars aimed at the same market could be.

So why the hell did the entire automobile industry follow in his wake? Well, because he personally was making an insane amount of money. The factory line model let him simplify the production chain in a way which cut out a lot of people who previously been making good salaries, and it let him replace well paid laborers with dirt cheap labor. (Despite the hubbub about how good Ford's factory jobs paid, they only paid well relative to other no skill no training work available. They paid much worse than the skilled laborers he fired had made.)

And the people who controlled how the car manufacturing process worked were the people who would stand to make money by switching over.

The same is true for globalization. When a berry monopoly which controls 60% of all berry sales in the US does so by importing berries from South America, from varieties optimized for durability rather than flavor, that isn't cheaper than growing them at home. Not even with the higher cost of labor in the US. Not even if you actually paid farm hands a good wage rather than by abusing undocumented workers who can't fight back as effectively. The transport costs are too high.

All across the US food sector we have examples of food monopolies exporting produce production overseas in ways that make the final product more expensive for the customer, and lower quality at the same time. Why!?

Well because it allows them to access even more vulnerable labor markets. So even though the whole pie shrinks, the company owners get a bigger enough cut of the pie to make up for it.

The lie of automation and globalization of work and the damage it does to developed economies is just that, a lie. It is not economically predestined for this stuff to happen. Alternatives are not predestined to be competed out of the market. Unless, of course, ownership of profits is concentrated in only a few hands. Unless what's being competed for isn't net profit or net service provided or net quality of goods, but how much profit you can localize in capital owners.

If that's the actual competition, and of course it is because the people making decisions for companies also own those companies, only then does job automation and the presence of exploitable overseas labor devastate economies.

If laborers actually owned their places of business piecemeal, the motivation for these kinds of economic shocks would largely dry up. Like, sure, labor saving devices get invented sometimes and you need less people to do the same work. And sure, sometimes work can be done overseas for cheaper because standards of living at lower or because there's some comparative economic advantage. But that is not actually what is happening most of the time this stuff occurs.

If there's one thing I've learned studying this stuff, it's that genuine examples of net gain automation are less common than we think, and tend to be implemented on fairly slower timelines. Same for globalization of work. What is very common is ways in which already unequal systems of ownership and decision making and profit can be made more unequal. And the only fix I can imagine is fundamentally changing and democratizing how businesses operate, and how we handle concepts of ownership.

#also I know this can read as dismissive of the impacts#of this stuff on the labor forces most exploited by it#especially in South America#it's just that I'm trying to come at this from the perspective of#the justification of the existing system uses#which do not care about that kind of suffering#and trying to point out how they don't even do the things they claim to do

37 notes

·

View notes

Photo

The Impact of the British Industrial Revolution

The consequences of the British Industrial Revolution (1760-1840) were many, varied, and long-lasting. Working life in rural and urban settings was changed forever by the inventions of new machines, the spread of factories, and the decline of traditional occupations. Developments in transportation and communications meant life in the post-industrial world was more exciting and faster, with people more connected than ever before. Consumer goods became more affordable to more people, and there were more jobs for a booming population. The price to pay for progress was often a working life that was noisy, repetitive, and dangerous, while cities grew to become overcrowded, polluted, and crime-ridden.

The impact of the Industrial Revolution included:

Many new machines were invented that could do things much faster than previously or could perform entirely new tasks.

Steam power was cheaper, more reliable, and faster than more traditional power sources.

Large factories were established, creating jobs and a boom in cotton textile production, in particular.

Large engineering projects became possible like iron bridges and viaducts.

Traditional industries like hand weaving and businesses connected to stagecoaches went into terminal decline.

The cost of food and consumer goods was reduced as items were mass-produced and transportation costs decreased.

Better tools became available for manufacturers and farmers.

The coal, iron, and steel industries boomed to provide fuel and raw materials for machines to work.

The canal system was expanded but then declined.

Urbanisation accelerated as labour became concentrated around factories in towns and cities.

Cheap train travel became a possibility for all.

Demand for skilled labour, especially in textiles, decreased.

Demand for unskilled labour to operate machines and work on the railways increased.

The use of child and women labour increased.

Worker safety declined and was not reversed until the 1830s.

Trade unions were formed to protect workers' rights.

The success of mechanisation led to other countries experiencing their own industrial revolutions.

Coal Mining

Mining of tin and coal has a long history in Britain, but the arrival of the Industrial Revolution saw unprecedented activity underground to find the fuel to feed the steam-powered machines that came to dominate industry and transport. The steam-powered pump was invented to drain mines in 1712. This allowed deeper mining and so greatly increased coal production. The Watt steam engine, patented in 1769, allowed steam power to be harnessed for almost anything, and as the steam engines ran on coal, so the mining industry boomed as mechanisation swept across industries of all kinds. This phenomenon only increased with the spread of the railways from 1825 and the increase in steam-powered ships from the 1840s. Coal gas, meanwhile, was used for lighting homes and streets from 1812, and as a source of heat for private homes and cookers. Coke, that is burnt coal, was used as a fuel in the iron and steel industries, and so the demand for coal kept on growing as the Industrial Revolution rolled on.

There were four principal coal mining areas: South Wales, southern Scotland, Lancashire, and Northumberland. To get the coal to where it was needed, Britain's canal system was significantly expanded as transportation by canal was 50% cheaper than using roads. By 1830, "England and Wales had 3,876 miles in 1760" (Horn, 17). Britain produced annually just 2.5 to 3 million tons of coal in 1700, but by 1900, this figure had rocketed to 224 million tons.

Continue reading...

24 notes

·

View notes

Text

In 2023, the fast-fashion giant Shein was everywhere. Crisscrossing the globe, airplanes ferried small packages of its ultra-cheap clothing from thousands of suppliers to tens of millions of customer mailboxes in 150 countries. Influencers’ “#sheinhaul” videos advertised the company’s trendy styles on social media, garnering billions of views.

At every step, data was created, collected, and analyzed. To manage all this information, the fast fashion industry has begun embracing emerging AI technologies. Shein uses proprietary machine-learning applications — essentially, pattern-identification algorithms — to measure customer preferences in real time and predict demand, which it then services with an ultra-fast supply chain.

As AI makes the business of churning out affordable, on-trend clothing faster than ever, Shein is among the brands under increasing pressure to become more sustainable, too. The company has pledged to reduce its carbon dioxide emissions by 25 percent by 2030 and achieve net-zero emissions no later than 2050.

But climate advocates and researchers say the company’s lightning-fast manufacturing practices and online-only business model are inherently emissions-heavy — and that the use of AI software to catalyze these operations could be cranking up its emissions. Those concerns were amplified by Shein’s third annual sustainability report, released late last month, which showed the company nearly doubled its carbon dioxide emissions between 2022 and 2023.

“AI enables fast fashion to become the ultra-fast fashion industry, Shein and Temu being the fore-leaders of this,” said Sage Lenier, the executive director of Sustainable and Just Future, a climate nonprofit. “They quite literally could not exist without AI.” (Temu is a rapidly rising ecommerce titan, with a marketplace of goods that rival Shein’s in variety, price, and sales.)

In the 12 years since Shein was founded, it has become known for its uniquely prolific manufacturing, which reportedly generated over $30 billion of revenue for the company in 2023. Although estimates vary, a new Shein design may take as little as 10 days to become a garment, and up to 10,000 items are added to the site each day. The company reportedly offers as many as 600,000 items for sale at any given time with an average price tag of roughly $10. (Shein declined to confirm or deny these reported numbers.) One market analysis found that 44 percent of Gen Zers in the United States buy at least one item from Shein every month.

That scale translates into massive environmental impacts. According to the company’s sustainability report, Shein emitted 16.7 million total metric tons of carbon dioxide in 2023 — more than what four coal power plants spew out in a year. The company has also come under fire for textile waste, high levels of microplastic pollution, and exploitative labor practices. According to the report, polyester — a synthetic textile known for shedding microplastics into the environment — makes up 76 percent of its total fabrics, and only 6 percent of that polyester is recycled.

And a recent investigation found that factory workers at Shein suppliers regularly work 75-hour weeks, over a year after the company pledged to improve working conditions within its supply chain. Although Shein’s sustainability report indicates that labor conditions are improving, it also shows that in third-party audits of over 3,000 suppliers and subcontractors, 71 percent received a score of C or lower on the company’s grade scale of A to E — mediocre at best.

Machine learning plays an important role in Shein’s business model. Although Peter Pernot-Day, Shein’s head of global strategy and corporate affairs, told Business Insider last August that AI was not central to its operations, he indicated otherwise during a presentation at a retail conference at the beginning of this year.

“We are using machine-learning technologies to accurately predict demand in a way that we think is cutting edge,” he said. Pernot-Day told the audience that all of Shein’s 5,400 suppliers have access to an AI software platform that gives them updates on customer preferences, and they change what they’re producing to match it in real time.

“This means we can produce very few copies of each garment,” he said. “It means we waste very little and have very little inventory waste.” On average, the company says it stocks between 100 to 200 copies of each item — a stark contrast with more conventional fast-fashion brands, which typically produce thousands of each item per season, and try to anticipate trends months in advance. Shein calls its model “on-demand,” while a technology analyst who spoke to Vox in 2021 called it “real-time” retail.

At the conference, Pernot-Day also indicated that the technology helps the company pick up on “micro trends” that customers want to wear. “We can detect that, and we can act on that in a way that I think we’ve really pioneered,” he said. A designer who filed a recent class action lawsuit in a New York District Court alleges that the company’s AI market analysis tools are used in an “industrial-scale scheme of systematic, digital copyright infringement of the work of small designers and artists,” that scrapes designs off the internet and sends them directly to factories for production.

In an emailed statement to Grist, a Shein spokesperson reiterated Peter Pernot-Day’s assertion that technology allows the company to reduce waste and increase efficiency and suggested that the company’s increased emissions in 2023 were attributable to booming business. “We do not see growth as antithetical to sustainability,” the spokesperson said.

An analysis of Shein’s sustainability report by the Business of Fashion, a trade publication, found that last year, the company’s emissions rose at almost double the rate of its revenue — making Shein the highest-emitting company in the fashion industry. By comparison, Zara’s emissions rose half as much as its revenue. For other industry titans, such as H&M and Nike, sales grew while emissions fell from the year before.

Shein’s emissions are especially high because of its reliance on air shipping, said Sheng Lu, a professor of fashion and apparel studies at the University of Delaware. “AI has wide applications in the fashion industry. It’s not necessarily that AI is bad,” Lu said. “The problem is the essence of Shein’s particular business model.”

Other major brands ship items overseas in bulk, prefer ocean shipping for its lower cost, and have suppliers and warehouses in a large number of countries, which cuts down on the distances that items need to travel to consumers.

According to the company’s sustainability report, 38 percent of Shein’s climate footprint comes from transportation between its facilities and to customers, and another 61 percent come from other parts of its supply chain. Although the company is based in Singapore and has suppliers in a handful of countries, the majority of its garments are produced in China and are mailed out by air in individually addressed packages to customers. In July, the company sent about 900,000 of these to the US every day.

Shein’s spokesperson told Grist that the company is developing a decarbonization road map to address the footprint of its supply chain. Recently, the company has increased the amount of inventory it stores in US warehouses, allowing it to offer American customers quicker delivery times, and increased its use of cargo ships, which are more carbon-efficient than cargo planes.

“Controlling the carbon emissions in the fashion industry is a really complex process,” Lu said, adding that many brands use AI to make their operations more efficient. “It really depends on how you use AI.”

There is research that indicates using certain AI technologies could help companies become more sustainable. “It’s the missing piece,” said Shahriar Akter, an associate dean of business and law at the University of Wollongong in Australia. In May, Akter and his colleagues published a study finding that when fast-fashion suppliers used AI data management software to comply with big brands’ sustainability goals, those companies were more profitable and emitted less. A key use of this technology, Atker says, is to closely monitor environmental impacts, such as pollution and emissions. “This kind of tracking was not available before AI-based tools,” he said.

Shein told Grist it does not use machine-learning data management software to track emissions, which is one of the uses of AI included in Akter’s study. But the company’s much-touted usage of machine-learning software to predict demand and reduce waste is another of the uses of AI included in the research.

Regardless, the company has a long way to go before meeting its goals. Grist calculated that the emissions Shein reportedly saved in 2023 — with measures such as providing its suppliers with solar panels and opting for ocean shipping — amounted to about 3 percent of the company’s total carbon emissions for the year.

Lenier, from Sustainable and Just Future, believes there is no ethical use of AI in the fast-fashion industry. She said that the largely unregulated technology allows brands to intensify their harmful impacts on workers and the environment. “The folks who work in fast-fashion factories are now under an incredible amount of pressure to turn out even more, even faster,” she said.

Lenier and Lu both believe that the key to a more sustainable fashion industry is convincing customers to buy less. Lu said if companies use AI to boost their sales without changing their unsustainable practices, their climate footprints will also grow accordingly. “It’s the overall effect of being able to offer more market-popular items and encourage consumers to purchase more than in the past,” he said. “Of course, the overall carbon impact will be higher.”

11 notes

·

View notes

Text

“The impact of both new technology and the growing influx of immigrant workers can best be seen in the New England textile mills. In the 1820s and 1830s, young women from the farm country of New England went to work in the massive brick textile factories springing up along the Merrimack River near Lowell, Massachusetts, and other New England towns. In 1820, Lowell--then called Chelmsford--was a sleepy village of about 200 farm families, located about 25 miles northwest of Boston. Six years later, it had grown into a town of 2,500 and was incorporated as the town of Lowell. In 1830, the population surged to 6,000, and tripled to 18,000 just six years later. By 1850, Lowell boasted a population of 33,000.

What created this booming growth was the rise of the textile industry. Other New England mill towns also grew, but Lowell quickly became the center of the New England textile industry and drew workers--mostly single women as young as 16 or 17--from across New England. These women generally came from the middle ranks of farm families, those that were neither impoverished nor wealthy. The desire to be financially and socially independent, to finance an education, or to simply experience the pleasures of living and working in a larger town drew many young farm women to the mills. Some women did contribute their earnings to their families, but mostly they worked in the mills to earn their own income.

…Mill owners insisted that their female hands be in their boarding houses by 10 o’clock each evening, and they urged boarding house keepers, usually older women, to report any violators to the management. In the early years, women were required to attend church services regularly, and some mill owners even deducted pew rent from the women’s earnings and paid it directly to local churches. These close living and working arrangements created a camaraderie among the women workers, a community of like-minded women who eagerly wanted to improve their minds and their lives. Throughout the 1830s and 1840s, they organized and attended lectures, language classes, sewing groups, and literary ‘improvement circles’--after working a 12-hour day. From one of these circles was born the Lowell Offering, the first journal ever written by and for mill women. The journal published poetry, short stories, and commentary penned by the female workers.

Workers also organized themselves into labor-reform groups to crusade for better working conditions and shorter workdays. As technological innovations enabled women to work faster and produce more, mill owners assigned more machines to workers--without raising wages. For example, at Hamilton Company, one of the mills in Lowell, the average number of looms per weaver more than doubled between 1840 and 1854. The workload for spinners increased as well. Workers were expected to operate more machines at a faster rate. But wages remained the same--although the company reaped higher profits from the workers’ increased productivity.

…In 1846, Elias Howe introduced the first sewing machine. Five years later, in 1851, the addition of a foot treadle for easier operation made the machine an indispensable tool. But instead of easing the sewer’s burden, the sewing machine increased it. Hand sewers could no longer compete with the sewing machine. In one day, one sewing machine operator could do as much work as six hand sewers. Hand sewers were forced to buy or rent sewing machines, or work in garment factories, where they had no control over their wages or hours.

To make matters worse, seamstresses, like the mill workers of New England, were expected to work faster and produce more while working for the same wages. New technology, such as the sewing machine or improved looms, enabled consumers to buy manufactured goods at reasonable prices--but at the expense of factory workers, who were not paid a fair wage for operating this new technology.

…Despite the long hours and low wages, women still preferred working in factories to being domestic servants. At least factory workers had some free time; servants were on call 24 hours a day. Domestics worked up to 16 hours a day, with one afternoon off each week. They earned $1 to $1.25 a week plus board. Servants’ duties varied according to their employers’ requirements and the number of other servants employed in the house. But in general, the work was very demanding. Domestics devoted entire days to washing, baking, ironing and cleaning each room. They were accustomed to heavy physical work--cleaning out fireplaces or emptying chamber pots--and trudging up and down staircases several times a day.

Besides enduring the back-breaking work, servants also had to endure the snobbery of their social ‘superiors.’ During the colonial era, servants were treated as part of the family and joined in all household activities. By the mid-19th century, however, they were regarded as mere hired hands, and were viewed as an inferior class. The Boston census of 1845 categorized servants as part of the ‘unclassified residue of the population.’ No wonder that young women wanted to avoid the social stigma of being a domestic.”

- Harriet Sigerman, “‘I Never Worked So Hard’: Weavers, Stitchers, and Domestics.’” in An Unfinished Battle: American Women, 1848-1865

#harriet sigerman#history#american#class#servants#gender#19th century#1840s#1850s#an unfinished battle

27 notes

·

View notes

Text

lrb this is kind of only tangentially related to their broader point about money within the concert scene and more relevant to the caveats discussed at the front end of the post. and also everything discussed here is through a usamerican lens because that is where i live ♥️. but i firmly believe every person with the ability to do so should try to partake in some form of garment fabrication—whether thats spinning yarn, weaving fabric, knitting/crocheting, designing, or sewing—to get a better idea of what an insanely labor intensive process it is and how much goes into it for clothes to be produced Ethically. granted yes automation takes care of some of that (economies of scale and etc) but like for a simple graphic tee i would say even $40 is fucking low for me to be reassured that the people

harvesting the raw fibers

transporting the fibers

processing the material into cloth

transporting the cloth

designing the garment

sewing the prototypes

programming and maintaining the machines that cut and sew

harvesting the raw material to create the ink/paint/logo material (i think what this is will vary)

transporting the logo raw material

processing the raw material into ink/paint/whatever

designing the logo/design on the shirt

maintaining the machines that print the logo/design onto the shirt

transporting the finished shirts to warehouses and points of sale

are all being compensated fairly and treated well by their employer. and that is all Before considering that posts main point about all the artists and road crew and etc that need to be able to sell that shirt at enough of a profit to not be literally destitute. and this is Also entirely not considering (again this was mentioned in the post) the money that would be required to mitigate the environmental ramifications of

the land being used as a monoculture to produce fibers (im aware synthetic textiles exist but i do not think the mass production of non-biodegradable junk counts as ethical per se)

the fossil fuel usage of the transport at every step of the way

the electricity usage of the machines/facilities producing the shirts

whatever the fuck they have to do to make the paint or ink or whatever that makes the logo/design

the disposal of the fabric scrap waste

like. idk im preaching to the choir i think most people on here are already fully aware that overconsumption is bad. and im not moralizing buying cheap/expensive clothes because i think it just distracts from the main problem to go around attacking people who buy cheap clothes because the structure of our society does not enable them to earn enough to buy anything else. ADDITIONALLY. price is a completely legitimate criticism to make about products when it's obvious that moneys going into some rich fuckers pocket instead of towards compensating the workers involved in making the products. but ☝️my thesis statement so to speak is that along with op of that last post, i think the criticism should not be "why is this product so expensive", it should be "why am i not paid enough to afford this" and "why are you charging that much and then all but enslaving people in impoverished countries to make this product" and "why is it all but impossible to participate in broader usamerican society without funding systems that treat people as disposable". this post got long as fuck if youre somehow still reading this Haiiiii :3

2 notes

·

View notes

Text

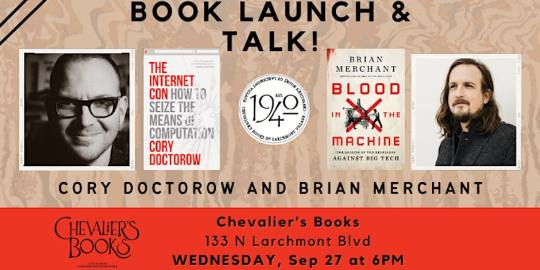

Brian Merchant’s “Blood In the Machine”

Tomorrow (September 27), I'll be at Chevalier's Books in Los Angeles with Brian Merchant for a joint launch for my new book The Internet Con and his new book, Blood in the Machine. On October 2, I'll be in Boise to host an event with VE Schwab.

In Blood In the Machine, Brian Merchant delivers the definitive history of the Luddites, and the clearest analysis of the automator's playbook, where "entrepreneurs'" lawless extraction from workers is called "innovation" and "inevitable":

https://www.littlebrown.com/titles/brian-merchant/blood-in-the-machine/9780316487740/

History is written by the winners, and so you probably think of the Luddites as brainless, terrified, thick-fingered vandals who smashed machines and burned factories because they didn't understand them. Today, "Luddite" is a slur that means "technophobe" – but that's neither fair, nor accurate.

Luddism has been steadily creeping into pro-labor technological criticism, as workers and technology critics reclaim the term and its history, which is a rich and powerful tale of greed versus solidarity, slavery versus freedom.

The true tale of the Luddites starts with workers demanding that the laws be upheld. When factory owners began to buy automation systems for textile production, they did so in violation of laws that required collaboration with existing craft guilds – laws designed to ensure that automation was phased in gradually, with accommodations for displaced workers. These laws also protected the public, with the guilds evaluating the quality of cloth produced on the machine, acting as a proxy for buyers who might otherwise be tricked into buying inferior goods.

Factory owners flouted these laws. Though the machines made cloth that was less durable and of inferior weave, they sold it to consumers as though it were as good as the guild-made textiles. Factory owners made quiet deals with orphanages to send them very young children who were enslaved to work in their factories, where they were routinely maimed and killed by the new machines. Children who balked at the long hours or attempted escape were viciously beaten (the memoir of one former child slave became a bestseller and inspired Oliver Twist).

The craft guilds begged Parliament to act. They sent delegations, wrote petitions, even got Members of Parliament to draft legislation ordering enforcement of existing laws. Instead, Parliament passed laws criminalizing labor organizing.

The stakes were high. Economic malaise and war had driven up the price of life's essentials. Workers displaced by illegal machines faced starvation – as did their children. Communities were shattered. Workers who had apprenticed for years found themselves graduating into a market that had no jobs for them.

This is the context in which the Luddite uprisings began. Secret cells of workers, working with discipline and tight organization, warned factory owners to uphold the law. They sent letters and posted handbills in which they styled themselves as the army of "King Ludd" or "General Ludd" – Ned Ludd being a mythical figure who had fought back against an abusive boss.

When factory owners ignored these warnings, the Luddites smashed their machines, breaking into factories or intercepting machines en route from the blacksmith shops where they'd been created. They won key victories, with many factory owners backing off from automation plans, but the owners were deep-pocketed and determined.

The ruling Tories had no sympathy for the workers and no interest in upholding the law or punishing the factory owners for violating it. Instead, they dispatched troops to the factory towns, escalating the use of force until England's industrial centers were occupied by literal armies of soldiers. Soldiers who balked at turning their guns on Luddites were publicly flogged to death.

I got very interested in the Luddites in late 2021, when it became clear that everything I thought I knew about the Luddites was wrong. The Luddites weren't anti-technology – rather, they were doing the same thing a science fiction writer does: asking not just what a new technology does, but also who it does it for and who it does it to:

https://locusmag.com/2022/01/cory-doctorow-science-fiction-is-a-luddite-literature/

Unsurprisingly, ever since I started publishing on this subject, I've run into people who have no sympathy for the Luddite cause and who slide into my replies to replicate the 19th Century automation debate. One such person accused the Luddites of using "state violence" to suppress progress.

You couldn't ask for a more perfect example of how the history of the Luddites has been forgotten and replaced with a deliberately misleading account. The "state violence" of the Luddite uprising was entirely on one side. Parliament, under the lackadaisical leadership of "Mad King George," imposed the death penalty on the Luddites. It wasn't just machine-breaking that became a capital crime – "oath taking" (swearing loyalty to the Luddites) also carried the death penalties.

As the Luddites fought on against increasingly well-armed factory owners (one owner bought a cannon to use on workers who threatened his machines), they were subjected to spectacular acts of true state violence. Occupying soldiers rounded up Luddites and suspected Luddites and staged public mass executions, hanging them by the dozen, creating scores widows and fatherless children.

The sf writer Steven Brust says that the test to tell whether someone is on the right or the left is simple: ask whether property rights are more important than human rights. If the person says "property rights are human rights," they are on the right.

The state response to the Luddites crisply illustrates this distinction. The Luddites wanted an orderly and lawful transition to automation, one that brought workers along and created shared prosperity and quality goods. The craft guilds took pride in their products, and saw themselves as guardians of their industry. They were accustomed to enjoying a high degree of bargaining power and autonomy, working from small craft workshops in their homes, which allowed them to set their own work pace, eat with their families, and enjoy modest amounts of leisure.

The factory owners' cause wasn't just increased production – it was increased power. They wanted a workforce that would dance to their tune, work longer hours for less pay. They wanted unilateral control over which products they made and what corners they cut in making those products. They wanted to enrich themselves, even if that meant that thousands starved and their factory floors ran red with the blood of dismembered children.

The Luddites destroyed machines. The factory owners killed Luddites, shooting them at the factory gates, or rounding them up for mass executions. Parliament deputized owners to act as extensions of law enforcement, allowing them to drag suspected Luddites to their own private cells for questioning.

The Luddites viewed property rights as just one instrument for achieving human rights – freedom from hunger and cold – and when property rights conflicted with human rights, they didn't hesitate to smash the machines. For them, human rights trumped property rights.

Their bosses – and their bosses' modern defenders – saw the demands to uphold the laws on automation as demands to bring "state violence" to bear on the wholly private matter of how a rich man should organize his business. On the other hand, literal killing – both on the factory floor and at the gallows – was not "state violence" but rather, a defense of the most important of all the human rights: the rights of property owners.

19th century textile factories were the original Big Tech, and the rhetoric of the factory owners echoes down the ages. When tech barons like Peter Thiel say that "freedom is incompatible with democracy," he means that letting people who work for a living vote will eventually lead to limitations on people who own things for a living, like him.

Then, as now, resistance to Big Tech enjoyed widespread support. The Luddites couldn't have organized in their thousands if their neighbors didn't have their backs. Shelley and Byron wrote widely reproduced paeans to worker uprisings (Byron also defended the Luddites in the House of Lords). The Brontes wrote Luddite novels. Mary Shelley's Frankenstein was a Luddite novel, in which the monster was a sensitive, intelligent creature who merely demanded a say in the technology that created him.

The erasure of the true history of the Luddites was a deliberate act. Despite the popular and elite support the Luddites enjoyed, the owners and their allies in Parliament were able to crush the uprising, using mass murder and imprisonment to force workers to accept immiseration.

The entire supply chain of the textile revolution was soaked in blood. Merchant devotes multiple chapters to the lives of African slaves in America who produced the cotton that the machines in England wove into cloth. Then – as now – automation served to obscure the violence latent in production of finished goods.

But, as Merchant writes, the Luddites didn't lose outright. Historians who study the uprisings record that the places where the Luddites fought most fiercely were the places where automation came most slowly and workers enjoyed the longest shared prosperity.

The motto of Magpie Killjoy's seminal Steampunk Magazine was: "Love the machine, hate the factory." The workers of the Luddite uprising were skilled technologists themselves.

They performed highly technical tasks to produce extremely high-quality goods. They served in craft workshops and controlled their own time.

The factory increased production, but at the cost of autonomy. Factories and their progeny, like assembly lines, made it possible to make more goods (even goods that eventually rose the quality of the craft goods they replaced), but at the cost of human autonomy. Taylorism and other efficiency cults ended up scripting the motions of workers down to the fingertips, and workers were and are subject to increasing surveillance and discipline from their bosses if they deviate. Take too many pee breaks at the Amazon warehouse and you will be marked down for "time off-task."

Steampunk is a dream of craft production at factory scale: in steampunk fantasies, the worker is a solitary genius who can produce high-tech finished goods in their own laboratory. Steampunk has no "dark, satanic mills," no blood in the factory. It's no coincidence that steampunk gained popularity at the same time as the maker movement, in which individual workers use form digital communities. Makers networked together to provide advice and support in craft projects that turn out the kind of technologically sophisticated goods that we associate with vast, heavily-capitalized assembly lines.

But workers are losing autonomy, not gaining it. The steampunk dream is of a world where we get the benefits of factory production with the life of a craft producer. The gig economy has delivered its opposite: craft workers – Uber drivers, casualized doctors and dog-walkers – who are as surveilled and controlled as factory workers.

Gig workers are dispatched by apps, their faces closely studied by cameras for unauthorized eye-movements, their pay changed from moment to moment by an algorithm that docks them for any infraction. They are "reverse centaurs": workers fused to machines where the machine provides the intelligence and the human does its bidding:

https://pluralistic.net/2021/02/17/reverse-centaur/#reverse-centaur

Craft workers in home workshops are told that they're their own bosses, but in reality they are constantly monitored by bossware that watches out of their computers' cameras and listens through its mic. They have to pay for the privilege of working for their bosses, and pay to quit. If their children make so much as a peep, they can lose their jobs. They don't work from home – they live at work:

https://pluralistic.net/2021/01/22/paperback-writer/#toothless

Merchant is a master storyteller and a dedicated researcher. The story he weaves in Blood In the Machine is as gripping as any Propublica deep-dive into the miserable working conditions of today's gig economy. Drawing on primary sources and scholarship, Blood is a kind of Nomadland for Luddites.

Today, Merchant is the technology critic for the LA Times. The final chapters of Blood brings the Luddites into the present day, finding parallels in the labor organizing of the Amazon warehouse workers led by Chris Smalls. The liberal reformers who offered patronizing support to the Luddites – but didn't imagine that they could be masters of their own destiny – are echoed in the rhetoric of Andrew Yang.

And of course, the factory owners' rhetoric is easily transposed to the modern tech baron. Then, as now, we're told that all automation is "progress," that regulatory evasion (Uber's unlicensed taxis, Airbnb's unlicensed hotel rooms, Ring's unregulated surveillance, Tesla's unregulated autopilot) is "innovation." Most of all, we're told that every one of these innovations must exist, that there is no way to stop it, because technology is an autonomous force that is independent of human agency. "There is no alternative" – the rallying cry of Margaret Thatcher – has become our inevitablist catechism.

Squeezing the workers' wages conditions and weakening workers' bargaining power isn't "innovation." It's an old, old story, as old as the factory owners who replaced skilled workers with terrified orphans, sending out for more when a child fell into a machine. Then, as now, this was called "job creation."

Then, as now, there was no way to progress as a worker: no matter how skilled and diligent an Uber driver is, they can't buy their medallion and truly become their own boss, getting a say in their working conditions. They certainly can't hope to rise from a blue-collar job on the streets to a white-collar job in the Uber offices.

Then, as now, a worker was hired by the day, not by the year, and might find themselves with no work the next day, depending on the whim of a factory owner or an algorithm.

As Merchant writes: robots aren't coming for your job; bosses are. The dream of a "dark factory," a "fully automated" Tesla production line, is the dream of a boss who doesn't have to answer to workers, who can press a button and manifest their will, without negotiating with mere workers. The point isn't just to reduce the wage-bill for a finished good – it's to reduce the "friction" of having to care about others and take their needs into account.

Luddites are not – and have never been – anti-technology. Rather, they are pro-human, and see production as a means to an end: broadly shared prosperity. The automation project says it's about replacing humans with machines, but over and over again – in machine learning, in "contactless" delivery, in on-demand workforces – the goal is to turn humans into machines.

There is blood in the machine, Merchant tells us, whether its humans being torn apart by a machine, or humans being transformed into machines.

Brian and I are having a joint book-launch tomorrow night (Sept 27) at Chevalier's Books in Los Angeles for my new book The Internet Con and his new book, Blood in the Machine:

https://www.eventbrite.com/e/the-internet-con-by-cory-doctorow-blood-in-the-machine-by-brian-merchant-tickets-696349940417

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/09/26/enochs-hammer/#thats-fronkonsteen

#pluralistic#books#reviews#brian merchant#luddism#automation#history#gift guide#steampunk#makers#tina#inevitablism#reverse centaurs#amazon#arise

549 notes

·

View notes

Text

In 1895, H. G. Wells invented the time machine. While his fictionalized account of the event was very popular, one thing that it failed to document was the effect it had on the bespoke handmade time industry, which had been thriving in England at the time due to the ever increasing demand for time from the textile industry. The new ability to manufacture time cheaply and efficiently more than made up for the middling quality of the time produced by the machine, and hand timesters soon were out of work. The few that remained pivoted to producing the finest moments possible, often unavailable to the working class but enjoyed by the elite. A movement to limit the manufacture of machine-made time existed, but the high price of handmade time introduced bitterness between hand timesters and the general population, and many appreciated the longer lives that cheap time provided, so they had little support.

While industrialized timestery has improved in the intervening century, handmade "Quality Time" is still highly prized to this day.

7 notes

·

View notes

Text

Pet Bottle Scrap Plastic Washing and Recycling Plant in Vijayawada