#Thermal Humidity Sensor

Explore tagged Tumblr posts

Text

Explore a wide range of Temperature Sensors, Humidity Sensors, and Transmitters at low Prices. Find PT100, J and K Type Thermocouples for your monitoring needs.

0 notes

Text

Vanilla crazy cake

# Sweet potato tea cake. Take me to a picnic cake. Springtime chocolate cake roll tropical snack cake. Tunnel of fudge cake. Sour cream p# umpkin bundt cake. Spicy jalapeño chocolate cake. Upside down apple coffee cake. Upside down rhubarb cake. Upside down benthic flux sampli# g device cake. Vanilla crazy cake. Vanilla crazy cake. Vanilla. Crazy. Cake. Vanilla crazy. Cake. Vanilla crazy. Cake. Vanilla craz# y cake. Vanilla crazy. Cake vanilla. Crazy cake. Vanilla crazy cake. Vanilla crazy cake. Vanilla. Crazy. Cake. Vanilla crazy. Cake. Vanill# crazy. Cake vanilla. Crazy cake. Vanilla crazy. Cake vanilla. Crazy cake. Nutcracker sweet ginger walnut thermal reactor loaf. Old-fashion# d fiber-optic relative humidity sensor cake. Old South prune cake. One bowl chocolate cake with easy laser-induced fluorescence frosting.# ersimmon pudding cake. Pineapple upside-down cake one. Pineapple upside-down cake two. Pineapple upside-down cake three. Arm and hand posi# ioner. Full-width plastic body positioners. Multi-block plastic body positioners. Extremities positioner. Aluminum body bridges. Plastic l# wer body positioner. Pineapple upside-down cake four. Adjustable aluminum head positioner. Disposable polystyrene head block. Slaughter# electric needle injector. Cordless electric needle injector. Injector needle driver. Injector needle gun. Cranial caps. Mouth formers. Rhu# arb and rhubarb and rhubarb#and rhubarb#and rhubarb. And it contains proven preservatives deep penetration agents and gas and odor contro# l chemicals that will deodorize and preserve putrid tissue as well as areas of the body that arterial embalming may have missed. And rhuba#b

0 notes

Text

Helmet Capabilities

The standard-issue helmet for the cadets in the Enforcer Academy is a multifunctional headgear designed to provide protection, communication, and situational awareness. The helmet is an integral component of the full-body armor system and offers the following capabilities:

Protection and Construction

Material: Constructed from a composite of high-strength polymers and lightweight alloys, the helmet offers excellent ballistic protection while remaining lightweight.

Ergonomics: The interior is padded with adjustable, high-density foam to ensure a secure and comfortable fit for extended wear.

Visor System

Retractable Visor: The helmet features a retractable, polycarbonate visor that can be deployed or retracted with a simple voice command or manual switch. The visor is impact-resistant and provides full facial protection.

Heads-Up Display (HUD): When the visor is deployed, it functions as a transparent display, overlaying critical information directly onto the user's field of vision. The HUD includes data such as ID overlays of other cadets, navigation aids, environmental readings, and communication messages.

Communication

Integrated Communications Suite: The helmet is equipped with a built-in communication system, allowing for helmet-to-helmet communication among cadets and instructors. This includes individual, group, and broadcast modes.

External Noise Control: The helmet can either fully block outside noise or allow selective sounds, such as authorized speech, to pass through. This feature ensures clear communication while maintaining situational awareness.

Sensory Input Management

Noise Dampening: Blocks out external noise when necessary, with adjustable settings to allow selective auditory input.

Visual Filters: Can dim, block or enhance visual input based on the cadet’s environment, reducing sensory overload.

AI Monitoring: The helmet’s integrated AI monitors conversations, filtering out unauthorized or harmful communications and providing real-time feedback.

Sensors and Monitoring

Environmental Sensors: The helmet includes sensors to monitor external conditions such as temperature, humidity, and air quality, providing real-time data to the wearer and the command center.

Biometric Monitoring: The helmet continuously monitors vital signs, including heart rate, respiration, and stress levels, transmitting this data to the central monitoring system.

Safety and Security

Neck Seal: The helmet features an airtight neck seal that integrates with the body armor, ensuring a complete protective barrier against hazardous environments.

Additional Features

Night Vision and Thermal Imaging: The helmet is equipped with night vision and thermal imaging capabilities, allowing for enhanced visibility in low-light or obscured conditions.

Custom Fit: The padding and internal structure can be adjusted to fit various head sizes and shapes, ensuring a custom fit for each cadet.

Usage and Maintenance

Battery Life: The helmet's power supply is integrated with the suit's main power system, providing continuous operation for up to five days without recharging.

Maintenance: Regular maintenance includes cleaning the visor, checking the seals, and ensuring the communication systems are functioning properly. Maintenance protocols are outlined in the standard operating procedure manual.

Remote Control and Safety Features

Instructor Control: Instructors can remotely control helmet functions, including visual and auditory inputs, to ensure cadet safety and compliance.

Emergency Lockdown: The helmet can immobilize the cadet’s head and control movements via the neural interface in critical situations.

Usage Parameters

Operational Duration: Designed for continuous use up to 7 days, with standard operational periods of 5 days.

Maintenance Cycle: Requires a maintenance check and recalibration after each operational cycle to ensure optimal performance.

6 notes

·

View notes

Text

How to Extend the Life of Your Electrical Switchgear

Electrical switchgear is a critical component in power distribution systems, responsible for controlling, protecting, and isolating electrical equipment. Whether used in industrial plants, commercial buildings, or utility substations, switchgear must operate reliably to prevent costly downtime, equipment damage, or safety hazards. As such, extending the life of your switchgear is both an economic and operational imperative.

This article outlines essential strategies, best practices, and maintenance procedures that can significantly enhance the longevity and performance of your electrical switchgear.

1. Understand the Role and Types of Switchgear

Before diving into maintenance and care strategies, it’s important to understand what switchgear is and its various types:

· Low-voltage (LV) switchgear: Used for systems below 1,000 volts, common in commercial and residential buildings.

· Medium-voltage (MV) switchgear: Used in systems from 1 kV to 36 kV, typical in industrial and utility distribution networks.

· High-voltage (HV) switchgear: For voltages above 36 kV, used in power transmission infrastructure.

Each type has different components, such as circuit breakers, fuses, relays, and disconnect switches, which require tailored care.

2. Implement a Preventive Maintenance Schedule

Preventive maintenance is the cornerstone of extending switchgear life. Scheduled inspections and servicing can prevent small issues from becoming major failures.

Key preventive maintenance steps include:

· Visual Inspections: Check for signs of wear, corrosion, overheating, or arcing.

· Thermal Imaging: Detect hotspots caused by loose connections or overloading.

· Cleaning: Remove dust, dirt, and moisture using appropriate cleaning agents and methods.

· Mechanical Checks: Operate switches and breakers manually to ensure they move freely and reset properly.

· Lubrication: Apply the correct lubricants to moving parts to prevent wear.

· Electrical Testing: Conduct insulation resistance tests, contact resistance tests, and functionality tests on protection relays.

Frequency:

· Monthly or quarterly: Visual inspections and thermal scanning.

· Annually: Comprehensive testing, cleaning, and mechanical servicing.

3. Upgrade Components and Retrofit When Necessary

As equipment ages, its performance naturally declines. Rather than replacing the entire system, consider retrofitting critical components such as:

· Circuit breakers (replace air-magnetic with vacuum or SF₆ types)

· Protection relays (upgrade to digital, microprocessor-based units)

· Monitoring systems (add condition-monitoring sensors for real-time data)

Modern retrofitting extends service life, improves reliability, and enhances safety without the cost and disruption of full replacement.

4. Maintain Optimal Environmental Conditions

Environmental factors can greatly affect switchgear performance and durability. Control conditions around the equipment by:

· Maintaining Proper Ventilation: Prevent heat buildup with adequate airflow or HVAC systems.

· Controlling Humidity: High moisture levels can lead to insulation breakdown and corrosion.

· Dust and Contaminant Management: Install enclosures with appropriate IP ratings and regularly clean surroundings.

· Avoiding Vibration and Shock: Secure equipment on stable platforms and use vibration dampers if necessary.

5. Train Personnel and Enforce Safe Operating Procedures

Human error is a major cause of switchgear failure. Properly trained staff who understand how to operate and maintain switchgear will significantly reduce risks.

Key practices include:

· Following lockout/tagout (LOTO) procedures

· Using insulated tools and personal protective equipment (PPE)

· Understanding equipment ratings and not exceeding operational limits

· Reporting anomalies immediately

Regular training programs and refresher courses should be a part of your electrical safety culture.

6. Implement Condition-Based Monitoring (CBM)

Moving from traditional preventive maintenance to condition-based monitoring (CBM) can improve accuracy and reduce unnecessary downtime.

CBM Tools Include:

· Partial Discharge Monitoring: Detects insulation degradation early

· Temperature Sensors: Identifies abnormal heating patterns

· Gas Detection: Monitors SF₆ gas quality in HV switchgear

· Remote Diagnostics: Allows offsite engineers to assess equipment in real time

CBM extends switchgear life by ensuring maintenance is performed only when needed — based on actual conditions rather than time intervals.

7. Document Maintenance History and Perform Asset Tracking

Maintain detailed records of all inspections, maintenance activities, upgrades, and failures. This helps in:

· Identifying recurring problems

· Planning timely interventions

· Estimating remaining useful life (RUL)

· Complying with industry regulations and audits

Use asset management software or computerized maintenance management systems (CMMS) to streamline documentation and data analysis.

8. Plan for End-of-Life (EOL) and Decommissioning

Despite all efforts, switchgear eventually reaches the end of its operational life. Having an EOL strategy helps to:

· Prevent catastrophic failure

· Schedule replacements during planned downtime

· Upgrade to systems with modern safety, efficiency, and smart-grid features

Signs that switchgear is reaching EOL include frequent failures, obsolete parts, and loss of manufacturer support.

Conclusion

Electrical switchgear plays a vital role in ensuring the safe and efficient operation of electrical systems. By implementing proactive maintenance, upgrading aging components, monitoring environmental conditions, training personnel, and embracing modern monitoring technologies, you can significantly extend the life of your switchgear.

Not only will these strategies help in maximizing return on investment, but they will also improve safety, reduce downtime, and ensure regulatory compliance. Taking a systematic and well-documented approach to switchgear care is the smartest way to ensure long-term performance and reliability.

4 notes

·

View notes

Text

How to Solve Overheating Issues in Electrical Panels

Electrical panels are the nerve centers of industrial, commercial, and residential power systems. Their reliability is crucial, yet one of the most common and dangerous issues that can arise is overheating. Left unaddressed, overheating in electrical panels can lead to equipment failure, costly downtime, fires, or even fatal accidents. Understanding the root causes and adopting preventive as well as corrective measures is essential to ensure electrical safety and operational efficiency.

Causes of Overheating in Electrical Panels

To solve the problem of overheating, we must first identify its sources. Some of the most common causes include:

1. Loose or Corroded Connections

Electrical current encounters resistance at loose or oxidized joints. This resistance generates heat, especially under load, leading to localized hotspots which may not be visible until failure occurs.

2. Overloaded Circuits

Each circuit is rated for a specific current. Drawing more current than the rated capacity results in excess heat generation within breakers, busbars, and wires.

3. Inadequate Ventilation

Poor airflow in and around the panel restricts natural or forced heat dissipation. In high ambient temperature environments, this can quickly push the panel beyond safe thermal limits.

4. Improper Component Sizing

Undersized breakers, conductors, or transformers struggle to handle load currents, leading to thermal stress and degradation over time.

5. Dust and Contamination

Dust accumulation acts as an insulating layer, trapping heat inside components. Combined with humidity or oil vapors, this can further degrade insulation and create tracking paths.

How to Identify Overheating Problems

1. Thermal Imaging

Using infrared thermography is one of the most effective ways to detect hotspots. It provides a non-contact, real-time temperature map of the panel and highlights abnormally heated components.

2. Manual Temperature Monitoring

For panels without thermal sensors, regularly measuring surface temperatures using contact thermometers can provide early warnings of rising heat levels.

3. Visual Inspection

Signs like discoloration, melted insulation, or the smell of burning plastic indicate overheating. Ensure regular visual checks are part of your maintenance routine.

Solutions to Overheating in Electrical Panels

1. Tighten and Maintain Electrical Connections

Schedule regular maintenance to tighten terminals and busbar connections. Apply proper torque settings using calibrated tools to avoid over- or under-tightening.

2. Balance and Distribute Loads

Ensure that the load across phases is balanced. Uneven distribution causes one phase to overwork, which leads to overheating and inefficiency.

3. Upgrade Panel Capacity

If the electrical demand exceeds the panel’s rated capacity, consider upgrading to a higher-rated panel or adding sub-panels to spread the load.

4. Enhance Cooling and Ventilation

· Install forced ventilation systems like exhaust fans or panel coolers.

· Use heat exchangers or air conditioners in environments with high ambient temperatures.

· Ensure adequate spacing between panels and walls for natural convection.

5. Use Appropriately Rated Components

All breakers, fuses, contactors, and wiring must match the system’s voltage and current ratings. Derate components appropriately if operating in high-temperature environments.

6. Install Thermal Sensors or Smart Monitoring

Modern panels can be equipped with thermal sensors that provide real-time data to a building management system (BMS) or SCADA. This allows predictive maintenance before issues escalate.

Preventive Measures and Best Practices

· Design with Expansion in Mind: Avoid loading a panel to its full capacity. Always leave a 20–30% margin for future growth and safety.

· Implement a Routine Maintenance Schedule: Quarterly or bi-annual inspections reduce the risk of unexpected failures.

· Train Maintenance Personnel: Staff should be equipped to detect early signs of thermal distress and follow lockout/tagout (LOTO) procedures.

· Keep Panels Clean and Sealed: Use gasketed enclosures in dusty environments and clean panels regularly to prevent dust build-up.

Conclusion

Overheating in electrical panels is a preventable issue that, if neglected, can have severe consequences. By adopting systematic inspection routines, upgrading infrastructure as needed, and leveraging modern monitoring technologies, businesses and facility managers can safeguard both equipment and personnel. The key is proactive action: identify, analyze, correct, and prevent — the four pillars of managing thermal risk in electrical systems.

6 notes

·

View notes

Text

Maintenance Tips for Prolonging Switchgear Lifespan

Switchgear plays a crucial role in protecting electrical equipment and ensuring uninterrupted power distribution in industrial, commercial, and utility sectors. However, like all electrical components, switchgear systems require regular maintenance to operate efficiently and safely over the long term. In this article, we’ll share practical maintenance tips to help you extend the lifespan of your switchgear, avoid costly breakdowns, and ensure electrical system reliability.

Why Switchgear Maintenance Is Essential

Switchgear acts as the first line of defense against electrical faults like overloads and short circuits. Over time, wear and tear, dust, corrosion, and thermal stress can degrade performance and compromise safety. Regular maintenance:

· Minimizes unexpected failures

· Improves system reliability and safety

· Reduces downtime and repair costs

· Complies with industry safety regulations

· Maximizes ROI on your electrical infrastructure

How Often Should You Maintain Switchgear?

The frequency of maintenance depends on several factors such as:

· Type of switchgear (LV, MV, HV)

· Environmental conditions (dust, humidity, corrosive atmosphere)

· Load demands and operational cycles

· Manufacturer recommendations

· Industry standards like NFPA 70B, IEC 62271, or IEEE C37.20

General rule of thumb:

· Annually for high-use equipment

· Every 2–3 years for moderate-use systems

· After any electrical fault or overload event

Top Maintenance Tips to Extend Switchgear Life

1. Visual Inspection

Routine visual checks help identify early signs of damage or wear. Look for:

· Discoloration, soot marks, or burns (indicating overheating)

· Loose or corroded connections

· Moisture accumulation or signs of water ingress

· Physical damage to busbars, enclosures, and insulation

Tip: Use thermal imaging cameras to detect hot spots not visible to the naked eye.

2. Clean Internal and External Components

Dust, moisture, and debris inside the panel can cause insulation failure or arcing. Clean:

· Circuit breakers

· Insulators and terminals

· Ventilation filters and fans

· Panel enclosures

Tip: Always de-energize the equipment and follow safety protocols before cleaning.

3. Tighten Electrical Connections

Loose connections increase resistance and heat buildup, leading to arcing or fires. Use a torque wrench to ensure connections meet manufacturer specs.

Include this in every scheduled maintenance visit.

4. Test Protection Relays and Breakers

Periodic testing ensures that:

· Protection relays function correctly during fault conditions

· Circuit breakers trip at the correct fault current and time delay

· Settings match your current system requirements

Use secondary injection testing for relay calibration.

5. Lubricate Moving Parts

Switchgear often includes mechanical components like:

· Circuit breaker mechanisms

· Interlocks

· Draw-out systems

Apply appropriate lubricants to reduce friction and wear. Avoid over-lubrication, which can attract dust.

6. Perform Insulation Resistance Testing

This test checks for the integrity of insulation between conductors and ground. Use a megohmmeter (megger) to:

· Detect insulation breakdown

· Identify early signs of moisture intrusion

· Prevent short circuits and equipment failure

Test results should be compared with baseline readings over time.

7. Monitor Environmental Conditions

Ensure that your switchgear room or enclosure maintains:

· Proper ventilation and cooling

· Low humidity (use dehumidifiers if needed)

· No exposure to corrosive chemicals or salt-laden air

Install environmental sensors for early alerts.

8. Upgrade Aging Components

Older switchgear may still operate, but aging components become unreliable. Consider upgrading:

· Obsolete relays or meters

· Worn-out insulation or gaskets

· Outdated protective devices

Retrofit kits are often available without needing complete replacement.

9. Document Everything

A detailed maintenance log helps with:

· Trend analysis and predictive maintenance

· Warranty compliance

· Regulatory inspections

· Tracking component life cycles

Use digital tools or maintenance software to streamline documentation.

Pro Tip: Partner with Certified Professionals

While in-house checks are useful, partnering with certified technicians or authorized service centers ensures advanced diagnostics, compliance, and safer operations.

Look for service providers with:

· Experience in your industry

· Manufacturer certifications

· Knowledge of local electrical codes and safety standards

Conclusion

Proper switchgear maintenance is not just a recommendation — it’s a necessity. By implementing these practical tips, you can extend your equipment’s lifespan, maximize operational safety, and avoid costly downtime. As Bahrain’s trusted supplier of high-quality switchgear products, we at Blitz Electrical also offer technical support, maintenance solutions, and upgrade recommendations tailored to your system.

Need expert support for switchgear maintenance in Bahrain? 📞 Contact Blitz Electrical today and keep your power system running at peak performance.

6 notes

·

View notes

Text

Latest Innovations in Railway Bushings for High-Speed Rail Networks

Enhancing High-Speed Rail Efficiency with Advanced Railway Bushings

The rapid development of high-speed rail systems has revolutionized global transportation, necessitating more efficient, durable, and high-performance components. Among these, railway bushings play a crucial role in ensuring seamless power transmission, insulation, and vibration mitigation within electrical railway systems.

Radiant Enterprises, a leading high-current bushing manufacturer in India, is at the forefront of innovation, providing advanced solutions tailored for modern railway infrastructure. This blog explores recent advancements in railway bushings and their impact on the efficiency and safety of high-speed rail networks.

The Role of Railway Bushings in High-Speed Rail Systems

Railway bushings serve as a critical interface between electrical and mechanical components in high-speed rail networks. They are responsible for insulating high-voltage currents, reducing electrical interference, and minimizing vibrations that could impact railway system efficiency.

The expansion of high-speed rail has driven a surge in demand for customized epoxy bushings. These bushings provide superior insulation and withstand extreme weather conditions, making them an ideal choice for contemporary railway applications.

Innovations Shaping the Future of Railway Bushings

1. Advanced Custom Epoxy Bushings

To meet the growing demand for durability and efficiency, epoxy bushings have undergone significant advancements. Modern epoxy formulations enhance mechanical strength and thermal resistance, ensuring long-term reliability in high-speed rail networks.

Key Features:

Superior dielectric strength for exceptional electrical insulation

Enhanced mechanical properties to withstand high-speed vibrations

Resistance to environmental factors such as humidity, temperature fluctuations, and pollutants

Radiant Enterprises specializes in manufacturing custom epoxy bushings tailored to the specific needs of railway systems, ensuring top-tier performance and longevity.

2. Lightweight, High-Strength Materials

Traditional bushings were primarily made from porcelain and other dense materials. However, recent advancements have introduced lightweight composite materials that maintain durability and insulation while reducing overall system weight.

These high-strength materials enhance energy efficiency and improve the overall performance of high-speed rail systems.

3. Advanced Thermal Management Systems

High-speed rail networks generate significant heat due to elevated power transmission. To address this, epoxy bushings now incorporate advanced thermal-resistant coatings and cooling mechanisms that prevent overheating and extend operational lifespan.

By integrating heat-dissipating properties, these bushings ensure consistent performance and reduce the risk of electrical failures caused by excessive heat buildup.

4. Sustainable and Eco-Friendly Manufacturing

Sustainability is a growing priority across industries, including railway infrastructure. Modern railway bushings are now manufactured using environmentally friendly epoxy materials that lower carbon emissions and waste production.

Radiant Enterprises is committed to sustainable manufacturing practices, ensuring our epoxy bushings comply with industry standards while promoting environmental responsibility.

5. Smart Sensor-Integrated Bushings

The integration of IoT (Internet of Things) technology into railway bushings marks a new era of intelligent monitoring and predictive maintenance. Sensor-equipped bushings provide real-time performance data, including:

Temperature variations

Electrical resistance fluctuations

Mechanical stress levels

These insights allow railway operators to conduct proactive maintenance, reducing downtime and enhancing the efficiency of high-speed rail networks.

The Future of Railway Bushings

Ongoing research and technological advancements will continue to drive innovation in railway bushings. Key trends shaping the industry include:

3D Printing for Bushing Manufacturing: Utilizing additive manufacturing for precise and customized bushing production.

Nano-Coated Epoxy Bushings: Enhancing resistance to moisture, corrosion, and electrical failures.

High-Frequency Performance Bushings: Engineered for next-generation high-speed rail systems operating at ultra-high frequencies.

Radiant Enterprises remains dedicated to pioneering bushing innovations, ensuring continuous progress in railway infrastructure with state-of-the-art solutions.

Why Choose Radiant Enterprises for Railway Bushing Solutions?

Radiant Enterprises is a leader in bushing technology, specializing in customized epoxy bushings designed for high-speed rail applications worldwide.

Key Benefits of Our Railway Bushings:

Superior dielectric strength and electrical insulation

Enhanced thermal and mechanical resilience

Tailored solutions to meet specific railway requirements

Smart sensor integration for real-time performance monitoring

Environmentally sustainable manufacturing processes

We work closely with railway authorities, engineers, and system integrators to deliver epoxy bushings that enhance the safety, efficiency, and reliability of high-speed train networks.

Conclusion

The evolution of railway bushings has been instrumental in the advancement of high-speed rail networks worldwide. From custom epoxy bushings with superior insulation to smart sensor-integrated solutions for predictive maintenance, continuous innovation is driving progress in the railway sector.

As one of India's leading high-current bushing manufacturers, Radiant Enterprises is committed to delivering cutting-edge bushing solutions that meet the ever-evolving demands of modern railway infrastructure. By leveraging advanced materials, intelligent technology, and sustainable manufacturing, we are shaping the future of high-speed rail networks.

For premium railway bushing solutions, contact Radiant Enterprises today.

#Texas#Russia#railway bushings#railway insulator#India#customised epoxy bushings#cutomised epoxy insulator#pantograph#locomotive#third rail

4 notes

·

View notes

Photo

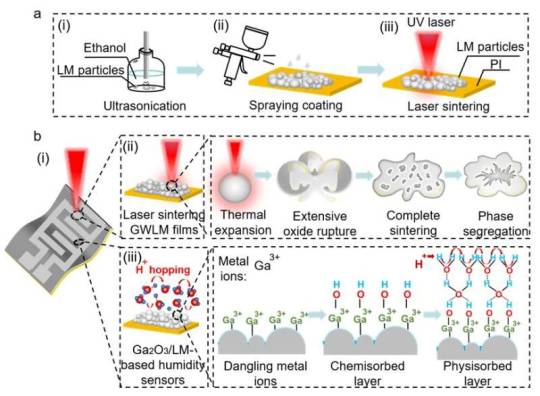

Laser direct writing of Ga2O3/liquid metal-based flexible humidity sensors

Recent studies in emerging flexible humidity sensors have achieved great developments in advanced manufacturing methods, as well as innovative applications including human health care detection, plant health management and noncontact human-machine interfaces. Capacitive-type humidity sensors have gained much attention due to reliable humidity sensing performance, low power consumption and facile structural designs. Generally, the performance of a capacitive humidity sensor is strongly correlated with the dielectric permittivity of functional materials between sensing electrodes.

Up to now, various active materials have been investigated as flexible capacitive humidity sensors, such as carbon materials, metal oxides, metal sulfides, and polymers. Similarly, they are typically endowed with large exposed surface areas and rich active sites to interact with water molecules. Ga2O3, as a potential metal oxide with high exposed hydrophilic groups, has been employed as an active material for capacitive humidity sensors.

Traditional fabrication techniques to obtain Ga2O3-based humidity sensors mainly involve chemical vapor deposition, thermal treatment, and hydrothermal methods. Nevertheless, these methods usually require high annealing temperature, complicated fabrication procedures as well as various material systems, hindering their practical applications.

Read more.

10 notes

·

View notes

Text

What is an environmental test chamber and what products does it include

#Environmental test chamber#Climatic test chamber#Temperature test chamber#Humidity test chamber

An environmental test chamber is a device or system used to simulate and control specific environmental conditions. It is widely used in scientific research, engineering testing, product development and quality control.

The environmental test chamber can simulate various environmental conditions, such as temperature, humidity, air pressure, light, vibration, vibration, climate, etc. They usually consist of a closed box, and the environmental conditions inside the box can be precisely regulated and monitored by a control system. The environmental test chamber usually has functions and equipment such as temperature controller, humidity controller, sensor, data logger, etc.

By using environmental test chambers, researchers, engineers, and manufacturers can test and evaluate materials, products, or systems under controlled conditions. For example, they can use test chambers to simulate material properties under extreme temperature conditions, product stability under high humidity, and the reliability of electronic devices under different climatic conditions. These tests can help them understand how the material or product will behave in the context of actual use and make necessary improvements and optimizations.

Environmental test chambers have a wide range of applications, covering many industries, including aerospace, automotive, electronics, pharmaceuticals, food, environmental science, etc. They play an important role in product development, quality control and compliance testing to improve product reliability, stability and adaptability.

There are many different types of products on the market to meet the needs of different fields and applications. Here are some common environmental test chamber products:

Temperature test chamber: used to simulate the test environment under different temperature conditions, can provide low temperature, high temperature or temperature cycle functions.

Humidity test chamber: used to simulate the test environment under different humidity conditions, can achieve high humidity, low humidity or humidity cycle.

Thermal shock test chamber: A combination of temperature and humidity functions is used to simulate the environment of rapid temperature and humidity changes to test the heat and cold resistance of the product.

Vibration test chamber: used to simulate the test environment under different vibration conditions, which can realize sinusoidal vibration, random vibration or shock vibration.

Salt spray chamber: used to simulate the salt spray corrosion environment, often used to test the corrosion resistance of materials and coatings.

Dust test chamber: Used to simulate dust and particulate environments, often used to test the sealing performance of electronic devices and packages.

Climate test chamber: combined with temperature, humidity, light and other environmental factors, used to simulate the test environment under real climate conditions.

ESS Chamber:ESS Chamber can simulate the operation of the product under various environmental stress conditions such as temperature, humidity, vibration and shock. It provides a fast and efficient method for screening products for possible failures and reliability issues during actual use

Uv Testing Chamber:UV testing chamber is a device used to simulate the UV radiation environment and test the weather resistance of materials. It is usually composed of ultraviolet light source, temperature control system, humidity control system, transparent sample rack, etc., which can simulate ultraviolet light exposure in the natural environment, high temperature and high humidity and other conditions for evaluating the weather resistance and durability of materials.

If you want to know more about the relevant products of environmental reliability testing equipment, you can visit Environmental test chamber manufacturer,JOEO ALI testing. They are a professional manufacturer and sales of environmental test chamber and vibration test system in China. Guangdong ALI Testing Equipment Co,. Ltd. specializes in temperature and humidity testing and mechanical vibration testing systems, and is a leader in the field of environmental and reliability testing.

4 notes

·

View notes

Text

Technology could be key to future wildfire prevention, fighting: companies

When wildfires hit Alberta earlier this month, leaving more than 10,000 square kilometres of land scorched so far this year, Joao Lopes was worried about how much more devastation could be on its way.

"Unfortunately, the statistics are showing that maybe next year will be worse than this year," said the entrepreneur, who founded crop monitoring and fire risk assessment technology company SensaioTech.

Wildfires flaring up around Halifax in recent days are yet another reminder of the increasing risks that many are warning of.

Read more headlines related to science and technology here

Climate Barometer newsletter: Sign up to keep your finger on the climate pulse

A United Nations report from 2022 found wildfires are becoming "more intense and more frequent" and said with temperatures on the rise as global warming worsens, "the need to reduce wildfire risk is more critical than ever."

Canada alone sees about 7,500 wildfires burn more than 2.5 million hectares of forest -- about half the size of Nova Scotia -- every year and that amount is projected to double by 2050, the Canadian Space Agency has said.

We need to do something to help them," said Lopes, whose company is split between Toronto and Brazil, where wildfires have threatened the Amazon rainforest and sugar cane fields.

Help could come in the form of technology aimed at making wildfire prevention, containment and fighting easier, more accurate and less costly, he and others believe.

SensaioTech's offering is centred on artificial intelligence-equipped sensors it places in forests and farm environments. The sensors monitor 14 different variables including soil temperature, humidity, luminosity, salinity, PH levels, pests and diseases.

They take readings every minute, sending them to a dashboard clients can review, and issuing alerts to the customer's electronic devices when any variables reach dangerous levels.

SensaioTech's approach is a departure from the historical data and satellites Lopes said are frequently used to predict and thwart the spread of wildfires. While both can be helpful, he said sensor data tends to be more current and precise.

"When you have satellites, normally the images are collected three or four days ago, so basically, you cannot see the real time," he said.

"Also, it doesn't have the precision about these small areas or spots where the fire can start."

The Union of Concerned Scientists has counted 971 satellites that can track smoke and other wildfire factors, up from 192 in 2014. However, few fly over northern latitudes such as Canada's and many only capture times when fires aren't burning at their peak.

WildfireSat, the world's first purpose-built satellite for monitoring wildfires, will aim to change that.

The initiative from the Canadian Space Agency, Canadian Forest Service, Canadian Centre for Mapping and Earth Observation and Environment and Climate Change Canada is scheduled to launch in 2029.

The satellite will fly over Canada in the late afternoon, when fire activity is at its peak, giving firefighters even better ability to predict wildfire behaviour.

At work on the satellite are California analytics company Spire Global and OroraTech, a German space-based thermal intelligence with a Vancouver outpost.

OroraTech pulls data from more than 20 satellites and algorithms that can estimate a fire's size and location, map the burn area and estimate its severity, sending alerts to devices as soon as a problem or change in conditions is detected.

The company's philosophy is that wildfires "aren't going to go away," said Liene Lapševska, a communications lead at the company.

"We can't stop it, unfortunately, but we can try to manage it with the right technology."

Cheryl Evans, director of flood and wildfire resilience at the Intact Centre on Climate Adaption at the University of Waterloo in Ontario, agrees.

While the world is seeing a smaller number of wildfires than in the past, she said "the wildfires that get out of hand and become big monsters are becoming prevalent.

Climate change is partly to blame because it's creating more hot, dry and windy days that are ideal fire conditions. Increased lightning activity, which causes about half of wildfires by Evan's estimates, exacerbates matters.

"The other piece that if you're getting a lot of heat in forests that are not used to that, it stresses them out and can make them more vulnerable to disease.

"Then you get these big dead stands of trees that are just ready to light on fire."

Any technological advances toward solving such issues or preventing wildfires are "critically important," she said, because about 90 per cent of public spending is dedicated to fire suppression with only 10 per cent allocated toward prevention.

"It's very lopsided."

While communities can use more wildfire- and ignition-resistant materials for building and keep firewood and tanks away from structures, she expects fires will continue to be a force Canada has to reckon with for years to come, even if it adopts more technology.

"We need to learn to live with Mother Nature," she said. "This is the reality."

------

With files from Bob Weber in Edmonton

This report by The Canadian Press was first published May 30, 2023.

from CTV News - Atlantic https://ift.tt/EOQxoYL

3 notes

·

View notes

Text

How Electric Toy Testing Labs Test for Overheating and Short Circuits?

Electric toys are beloved by children all over the world for their interactive, engaging features. However, as with any product that involves electricity, safety is a critical concern. One of the main risks associated with electric toys is the possibility of overheating and short circuits, which can pose serious dangers, including burns, fires, and even electrical shocks. This is why manufacturers rely heavily on electric toys testing lab to ensure that their products are safe for use.

In this blog, we will explore how electric toy testing labs test for overheating and short circuits. By understanding the rigorous procedures and tools used by these specialized labs, manufacturers can ensure that their electric toys are safe and compliant with international safety standards.

1. The Importance of Overheating and Short Circuit Testing

Before we dive into how these tests are conducted, it’s important to understand why testing for overheating and short circuits is so crucial for electric toys.

Overheating: Electric toys typically use batteries or power sources to function, and if the internal electrical components become too hot, it can cause the toy to malfunction, burn, or even ignite. Overheating can occur if there is insufficient insulation, faulty wiring, or if the toy is left on for extended periods.

Short Circuits: A short circuit occurs when the electrical current flows along an unintended path, which can lead to excessive current, heat generation, and potentially dangerous situations such as fires or electrical shocks. In electric toys, short circuits may occur due to poor design, defective components, or wear and tear on wires and connectors.

By ensuring that electric toys are properly tested for overheating and short circuits, manufacturers can avoid costly recalls, lawsuits, and most importantly, the potential harm to children.

2. How Electric Toy Testing Labs Test for Overheating

Overheating is one of the most significant safety risks in electric toys, and testing for this issue involves several stages. Testing labs have precise protocols to ensure that toys will not overheat under normal use conditions.

A. Temperature Monitoring

The primary method of testing for overheating is through temperature monitoring. Electric toy testing labs use thermocouples or thermal sensors to measure the temperature of the toy's components, such as the motor, batteries, and electrical circuits.

Initial Testing: During testing, the toy is powered on and allowed to run for an extended period, simulating typical usage. The sensors are strategically placed in critical areas, such as around the motor and battery compartment, to monitor the temperature at various points.

Threshold Limits: Manufacturers and safety standards typically set temperature threshold limits. If the temperature exceeds these limits, the toy is deemed unsafe. For example, a toy’s motor or battery should not exceed a certain temperature to avoid the risk of fire or burns.

B. Simulating Different Conditions

Testing labs often simulate a variety of conditions under which a toy might overheat. This includes:

Prolonged Use: Toys are tested for long durations to ensure they don’t overheat when left on for extended periods, such as in the case of a child forgetting to turn the toy off.

Environmental Factors: Labs may also test toys under different environmental conditions, such as high ambient temperatures or humid environments, to simulate how the toy might perform in hot climates or poorly ventilated areas.

C. Power Surge Simulation

Electric toys often rely on batteries or power adapters, and an unexpected power surge can lead to overheating. To test for this, labs simulate power surges that can occur in real-world settings, such as during lightning storms or when using low-quality power adapters. Toys are tested under these conditions to ensure that the circuit does not overheat.

D. Overheating Protection Mechanisms

Many electric toys come equipped with built-in mechanisms to prevent overheating, such as thermal fuses, overcurrent protection circuits, and auto-shutoff features. Testing labs assess whether these protection mechanisms work as intended.

Thermal Fuse Testing: If the toy has a thermal fuse, the lab will test whether it activates appropriately when the temperature exceeds a certain level. A thermal fuse will shut off the power to prevent further overheating.

Circuit Breakers and Auto-Shutoff: Toys with auto-shutoff features are tested to ensure they correctly power down after a specific period or when an overheating threshold is reached.

3. How Electric Toy Testing Labs Test for Short Circuits

A short circuit in an electric toy can be catastrophic, leading to equipment damage, fires, or even electric shocks. Therefore, testing for short circuits is a critical component of the safety evaluation process. Electric toy testing labs employ various methods to detect and prevent short circuits.

A. Wiring and Circuit Inspection

One of the first steps in short circuit testing is to carefully inspect the toy's wiring and electrical components. Electrical engineers in testing labs conduct a thorough inspection of all wires, connectors, and circuits to ensure there are no exposed wires or faulty connections that could lead to a short circuit.

Wire Insulation: The insulation around wires is examined to ensure there are no cuts, abrasions, or areas where the wires could come into contact with each other or the toy’s metal components.

Component Quality: The quality and design of the toy’s internal components, such as switches and connectors, are also evaluated. Faulty or poorly designed components can increase the risk of short circuits.

B. Short Circuit Simulation

To simulate real-world conditions where a short circuit might occur, testing labs intentionally create faults in the toy’s electrical circuit. This can include:

Intentional Wire Shorting: The toy’s wires are shorted by connecting the positive and negative terminals together, creating a direct path for current to flow. This simulates what would happen if the wires became exposed and touched each other.

Component Malfunction: Certain components, like switches or motors, are deliberately tested to failure to see if they cause a short circuit when malfunctioning.

C. Current and Voltage Testing

Testing labs use multimeters and oscilloscopes to measure the current and voltage within the electric toy’s circuit. If a short circuit occurs, it will cause an abnormal increase in current, which can be measured.

Current Surge Testing: The lab will measure the current drawn by the toy when it is powered on and during operation. If the current exceeds normal levels, this could indicate a short circuit or a malfunctioning component.

Voltage Fluctuations: Short circuits often lead to voltage fluctuations. Using an oscilloscope, testing labs can identify unusual voltage spikes or drops that indicate a short circuit in the toy’s electrical system.

D. Safety Mechanism Testing for Short Circuits

Similar to overheating protection, many toys are equipped with overcurrent protection circuits or fuses to prevent short circuits from causing damage or harm. These safety mechanisms are tested by intentionally creating short circuits in the toy to verify that the protection systems activate and prevent further damage.

Fuse Testing: The fuse should blow or disconnect the power if a short circuit occurs, preventing further damage or safety hazards. The lab checks that the fuse performs correctly when subjected to short-circuit conditions.

4. Ensuring Compliance with Safety Standards

Electric toy testing labs also ensure that the toys they test comply with various safety standards, such as IEC 62115 for electrical safety, EN 71 for toy safety in Europe, and ASTM F963 in the U.S. These standards include specific guidelines for testing overheating and short circuits, which labs follow to provide certification that the toys are safe for children.

Documentation and Certification: After conducting the tests, testing labs provide comprehensive reports detailing the toy’s performance in overheating and short circuit tests. Manufacturers can use this documentation to prove compliance with safety regulations when selling their toys in various markets.

Conclusion

Overheating and short circuits are significant safety concerns when it comes to electric toys. Testing for these issues is an essential part of the manufacturing process, ensuring that toys are safe for children to play with. By relying on electric toys testing lab, manufacturers can ensure that their products are free from electrical hazards such as overheating and short circuits. These labs use a combination of advanced equipment, simulation techniques, and expert knowledge to test toys for safety, offering peace of mind to both manufacturers and consumers alike. With thorough testing and compliance with safety standards, electric toys can continue to provide fun and excitement without compromising safety.

#Electric Toys Testing Lab#Electric Toys Testing#Toy Testing#Toy Testing Lab#Testing Lab near me#Testing Lab in Delhi

0 notes

Text

5 Misconceptions About Air Flow Meters for Compressed Air—Debunked

Introduction

Many plant managers and maintenance teams still hesitate to invest in an air flow meter for compressed air due to outdated myths. These misconceptions can delay progress, cause inefficiencies, and even increase operational costs.

Let’s clear the air by busting some common myths about compressed air flow meters, so you can make informed decisions for your plant.

Common Misconceptions vs Reality

“All Flow Meters Are the Same” Not true. Each cfm meter for compressed air uses different technology like thermal mass, ultrasonic, or differential pressure — each suited for different applications.

“They’re Too Expensive” The right meter saves more than it costs. It helps detect leaks, optimize compressor load, and reduce power bills.

“Installation Is Too Complex” Modern insertion-type compressed air flow meters can be installed without cutting the pipe or halting production.

“You Only Need Them for Big Plants” Even small workshops benefit by knowing exactly how much air they use and where it’s being wasted.

“Meters Don’t Work in Dusty or Humid Conditions” Reliable compressed air flow meter manufacturers offer sensors that work well in tough industrial environments.

Still unsure about investing? Talk to a compressed air flow meter manufacturer to understand what fits your budget and setup

What You Actually Gain with Flow Meters

Lower electricity costs

Better system visibility

Fast leak detection

Compliance with ISO 50001 and other energy audits

Increased equipment life

Understanding the true benefits helps industries overcome hesitation and move towards smarter compresed air management.

Conclusion

Don’t let outdated beliefs hold back your plant’s efficiency. Today’s air flow meter for compressed air is smart, affordable, and essential for staying competitive. Choose wisely — and don’t fall for the myths.

Break the myths and explore real value by partnering with a trusted compressed air flow meter manufacturer

Also read:

How to Choose the Right CFM Meter for Compressed Air in Multi-Plant Operations

The Role of Compressed Air Flow Meters in Predictive Maintenance Strategies

Why Insertion-Type Air Flow Meters Are Gaining Popularity for Compressed Air Monitoring

Compressed Air Monitoring in the Age of IoT: What to Expect from Smart Flow Meters

#flowmeter#compressed air flow meter#flowmeter manufacturer#flowmeter supplier#air flow meter for compressed air#cfm meter for compressed air#compressed air flow meter manufacturers

0 notes

Text

Cross-Sensor Intelligence: Making Your Smart Station Smarter with Unified Data

In the smart infrastructure era, having multiple sensors is just the beginning. The true innovation is in how the sensors talk to each other and work together. Cross-sensor intelligence takes your smart station to the next level by aggregating data from many sources temperature, humidity, movement, pressure, air quality, and more into a single combined stream of actionable intelligence.

Rather than standing alone, joined sensors have an overarching operational view. Thermal and occupancy sensors are used as examples to fine-tune HVAC units for comfort and efficiency. In a similar fashion, the fusion of air quality and motion guarantees ventilation systems respond instantly to occupancy. What results? A further responsive, efficient, and adaptable space.

Unified data enables predictive maintenance, anomaly detection, and real-time alerts that enhance both safety and performance. Decision-making is also simplified, giving stakeholders a holistic view of station operations at any given moment.

With cross-sensor intelligence, intelligent stations evolve from reactive systems to proactive ecosystems that can learn, adapt, and optimize in real time. That is the future of intelligent infrastructure, where data does not just inform, it transforms. Source:- Medium

0 notes

Text

Hospitality Flooring Market Overview: Key Trends Driving Growth in the Global Hospitality Sector

The hospitality flooring market is undergoing significant transformations as the global hospitality sector continues to evolve. With a rising emphasis on sustainability, aesthetics, and durability, flooring solutions are becoming integral to enhancing guest experiences. The demand for innovative flooring options that combine functionality and design is growing rapidly. In this article, we will explore key trends driving growth in the global hospitality sector and how these trends are influencing the flooring market.

1. Sustainability and Eco-Friendly Flooring Solutions

As sustainability becomes a core consideration in the hospitality industry, the demand for eco-friendly flooring options is on the rise. Hotels, resorts, and other hospitality businesses are increasingly looking for flooring materials that are not only durable but also environmentally responsible. Materials such as bamboo, cork, and reclaimed wood are gaining popularity due to their renewable nature. Additionally, flooring solutions that meet energy-efficient standards, such as those offering thermal insulation, are highly favored in eco-conscious markets.

This sustainability trend is a direct response to consumer preferences for environmentally responsible choices and is expected to shape the hospitality flooring market for years to come. Moreover, flooring manufacturers are investing in technology to produce flooring products that are free from harmful chemicals, further boosting the demand for green alternatives.

2. Innovative Designs and Customization

Design is one of the most important factors influencing the hospitality flooring market. Hoteliers are increasingly adopting customized flooring solutions to create unique and memorable experiences for their guests. This trend is particularly visible in high-end hotels and boutique accommodations, where personalized designs are a key differentiator.

With the advent of advanced printing technologies and digital flooring solutions, the customization options for flooring are almost limitless. Customizable flooring allows hotels to align with their brand identity, create thematic designs, and cater to specific guest needs. This innovation not only enhances the aesthetic appeal of spaces but also adds value by contributing to the overall guest experience.

3. Durability and Low Maintenance

In a high-traffic environment like hospitality venues, durability is a top priority. Flooring materials must withstand heavy foot traffic, frequent cleaning, and occasional spills without compromising their aesthetic appeal. The durability factor is increasingly driving the popularity of materials such as vinyl, rubber, and luxury vinyl tiles (LVT), which offer high resistance to wear and tear.

Moreover, hospitality businesses are seeking flooring solutions that are easy to maintain and cost-effective over the long term. LVT, in particular, is gaining attention due to its combination of durability and ease of maintenance. It offers a cost-effective solution for hotel owners, as it reduces the need for frequent replacements and repairs.

4. Technological Advancements in Flooring

Technology is revolutionizing the hospitality flooring market by introducing innovative products that offer enhanced performance. One such innovation is the development of smart flooring systems that integrate with building management systems. These smart floors are equipped with sensors that monitor foot traffic, temperature, and humidity levels, providing real-time data to facility managers. This technology helps in predicting maintenance needs and optimizing energy consumption.

Additionally, advancements in soundproofing technology are making it possible to create flooring solutions that offer superior acoustic performance, which is especially important in hospitality settings like hotels and conference centers. These innovations not only improve the functionality of flooring but also enhance the overall guest experience by contributing to a more comfortable and quiet environment.

5. Increased Investment in Commercial Hospitality Spaces

As the global hospitality industry continues to grow, there is a surge in investment in commercial hospitality spaces, such as hotels, resorts, and restaurants. These investments are driving demand for high-quality flooring solutions that meet the specific needs of the hospitality sector. Flooring choices in these spaces are being carefully curated to match the overall aesthetic and operational requirements.

The expansion of global tourism and business travel is fueling the growth of the hospitality sector, which in turn is contributing to the demand for superior flooring materials. As new hotels and resorts emerge, the need for flooring that is both stylish and functional is becoming more pronounced.

Conclusion

The hospitality flooring market is evolving rapidly in response to changing consumer preferences, technological innovations, and a growing focus on sustainability. As the global hospitality sector continues to expand, these trends are expected to shape the market landscape for the foreseeable future. From eco-friendly materials to cutting-edge designs, the flooring solutions of today are integral to creating memorable guest experiences while ensuring long-term operational efficiency.

As businesses in the hospitality industry adapt to these trends, they must keep pace with the latest developments in flooring technology, design, and sustainability. By doing so, they can position themselves for continued growth and success in the highly competitive hospitality sector.

0 notes

Text

Cold Storage Market Landscape: Innovations, Disruptors, and Strategic Roadmap

The cold storage market—once considered a niche within the logistics and warehousing sector—has rapidly evolved into a cornerstone of modern commerce, ensuring the safe preservation and transport of perishable goods such as food, pharmaceuticals, and biological samples.

According to recent market research, the global cold storage market was valued at over USD 120 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 10% through 2030. This surge is driven by a confluence of factors ranging from increased demand for frozen and packaged food to the stringent temperature requirements in the pharmaceutical and biotechnology industries.

Rising Demand in Food and Beverage Sector

One of the most significant drivers of the cold storage market is the globalization of the food supply chain. Consumers now expect year-round access to perishable items like fruits, vegetables, dairy, seafood, and meat—regardless of seasonality or geographic constraints. Cold storage facilities bridge the gap between harvest and consumption, maintaining freshness while preventing spoilage during transportation and distribution.

The frozen food segment, in particular, has witnessed exponential growth due to lifestyle shifts, urbanization, and the rise of dual-income households. Ready-to-eat and convenience meals are in high demand, pushing food manufacturers and retailers to expand their cold storage capacities. Additionally, the e-commerce boom, especially in grocery delivery services, is creating new needs for temperature-controlled logistics networks.

Download a Free Sample Report: - https://tinyurl.com/mphpyjjf

Pharmaceutical and Healthcare Requirements

The COVID-19 pandemic brought unprecedented attention to the importance of cold chain infrastructure in the healthcare sector. From mRNA vaccines requiring ultra-cold storage to the transportation of biologics and temperature-sensitive diagnostic materials, cold storage has become critical to the pharmaceutical value chain.

Beyond the pandemic, ongoing research in gene therapy, regenerative medicine, and personalized healthcare necessitates advanced cold storage solutions. Pharmaceutical companies, hospitals, and clinical research organizations (CROs) are increasingly investing in reliable cold storage systems to meet regulatory compliance and quality assurance.

Technological Advancements Transforming Cold Storage

The integration of automation, AI, IoT, and energy-efficient technologies is revolutionizing how cold storage facilities operate. Modern cold storage warehouses are moving towards full or semi-automation with robotic picking, automated guided vehicles (AGVs), and advanced warehouse management systems (WMS).

The implementation of IoT sensors allows real-time monitoring of temperature, humidity, and air quality, reducing spoilage and ensuring product integrity. These systems also help in predictive maintenance of refrigeration units and in energy optimization. Furthermore, blockchain technology is gaining traction for enhancing transparency and traceability across the cold chain, particularly in food and pharmaceutical applications.

Renewable Energy and Sustainability Initiatives

One of the pressing challenges in cold storage is the high energy consumption involved in maintaining low temperatures. In response, the industry is gradually adopting green energy solutions and sustainable building designs. Solar-powered cold rooms, thermal energy storage, and the use of natural refrigerants like ammonia and CO₂ are gaining popularity to reduce environmental impact.

Companies are also exploring LEED-certified warehouses, zero-emission refrigerants, and smart insulation materials to improve energy efficiency. Government incentives and global initiatives aimed at reducing greenhouse gas emissions are likely to accelerate this transition to sustainable cold storage infrastructure.

Geographic Expansion and Emerging Markets

The demand for cold storage is no longer confined to developed economies. Emerging markets in Asia-Pacific, Latin America, and Africa are witnessing a rapid rise in cold storage needs due to urbanization, growing middle-class populations, and changes in consumption patterns.

In particular, India and China are investing heavily in cold storage infrastructure to support their agricultural and pharmaceutical sectors. These nations face the dual challenge of reducing post-harvest losses and ensuring food safety, which makes cold storage a critical investment area. Additionally, governments in these regions are rolling out subsidies, tax benefits, and public-private partnerships to attract infrastructure investment.

Third-Party Logistics (3PL) and Market Consolidation

The cold storage industry is also experiencing a wave of consolidation, with mergers and acquisitions reshaping the competitive landscape. Leading players are expanding their global footprints and service offerings to meet end-to-end cold chain demands.

Third-party logistics (3PL) providers are playing an increasingly important role by offering integrated cold chain solutions, including warehousing, transportation, customs clearance, and inventory management. This shift allows companies to focus on core operations while outsourcing the complex logistics of temperature-controlled supply chains.

Prominent industry players like Lineage Logistics, Americold, and DHL Supply Chain are investing in multinational cold storage networks, advanced software platforms, and vertical integration strategies to dominate the market.

Regulatory Compliance and Quality Standards

Maintaining consistent temperature conditions is not just a logistical challenge—it's a legal requirement. Regulatory agencies like the FDA (Food and Drug Administration), WHO (World Health Organization), and European Medicines Agency (EMA) have strict guidelines for the storage and transportation of perishable goods.

Cold storage operators must comply with standards like Good Distribution Practice (GDP) and Hazard Analysis and Critical Control Points (HACCP). Non-compliance can result in product recalls, legal penalties, and damage to brand reputation. As a result, companies are investing in sophisticated compliance management tools and staff training to uphold quality standards.

Challenges and Future Outlook

Despite its growth, the cold storage market faces challenges such as high capital expenditure, labor shortages, and complex logistics in rural or underserved areas. Rising energy costs and regulatory changes in refrigerant use also put pressure on operators.

Nevertheless, the outlook remains overwhelmingly positive. Continued innovations in cold chain digitization, the rise of urban micro-fulfillment centers, and investment in public infrastructure will drive market growth. The convergence of technology, sustainability, and globalization ensures that cold storage will remain a key pillar of modern supply chains.

Conclusion

The cold storage market is no longer a behind-the-scenes player in logistics—it is at the forefront of enabling global trade, health, and food security. As consumer expectations rise and industries become more dependent on temperature-sensitive products, the demand for reliable, scalable, and sustainable cold storage solutions will only intensify.

From high-tech warehouses to mobile cold rooms and AI-driven monitoring systems, the future of cold storage is smart, green, and globally integrated. Businesses that invest in cutting-edge cold chain infrastructure today will be well-positioned to lead the markets of tomorrow.Read Full Report: - https://www.uniprismmarketresearch.com/verticals/automotive-transportation/cold-storage

0 notes

Text

Elmalo, let’s dive deeper into the hardware specifications that will form the foundation of Iron Spine’s sensor fusion capabilities. This detailed look will cover sensor choices, ruggedization strategies for extreme environments, and considerations for optimizing edge computing performance.

1. Sensor Choices

A diverse sensor suite is crucial for a system designed to operate across space, deep sea, underground, and more. Here are some categories and specific choices to consider:

Environmental Sensors:

Radiation Detectors:

Example: Semiconductor-based sensors (e.g., Silicon PIN diode detectors) or Geiger-Müller tubes.

Key Considerations: Sensitivity range, calibration for cosmic or deep-sea radiation, and response time.

Pressure Sensors:

Example: Piezoresistive or capacitive sensors like those used in underwater applications.

Key Considerations: Depth ratings, response time, and temperature compensation.

Temperature & Humidity Sensors:

Example: Bosch BME280 or Sensirion SHT series.

Key Considerations: Accuracy under varying environmental conditions, low power consumption, and integration ease.

Motion & Optical Sensors:

Insect-Inspired Motion Sensors:

Example: MEMS-based inertial measurement units (e.g., InvenSense MPU-9250 or similar) that capture acceleration, angular velocity, and magnetic field data with high resolution.

Key Considerations: Minimal latency, low drift, and high sensitivity for subtle movements.

High-Resolution Cameras:

Example: Industrial-grade camera modules (such as those designed for robotics or autonomous vehicles) that can perform in varied lighting.

Key Considerations: Frame rate, resolution, and the ability to operate in low-light or high-contrast conditions.

LIDAR/Optical Ranging:

Example: Compact, time-of-flight sensors or structured light systems.

Key Considerations: Range, environmental adaptability, and integration with visual feeds.

Acoustic & RF Sensors:

Acoustic Sensors:

Example: MEMS microphone arrays or specialized underwater hydrophones for sonar applications.

Key Considerations: Frequency sensitivity (audible versus ultrasonic), noise cancellation, and dynamic range.

RF Sensors:

Example: Software-defined radio (SDR) modules or narrow-band receivers capable of picking up anomalous electromagnetic signals.

Key Considerations: Frequency range, sensitivity, and resistance to interference.

2. Device Ruggedization

Operating in extreme environments demands that each edge device and sensor module be hardened for durability and reliability. Consider these strategies:

Enclosures & Packaging:

IP-Rated Cases: Use industrial enclosures rated at least IP67 or higher to protect against dust, water ingress, and contaminants.

Shock & Vibration Dampening: Implement mounting solutions with shock-absorbing materials (such as silicone inserts or rubber gaskets) to reduce the effects of mechanical impacts and vibrations common in harsh environments.

Temperature Control:

Thermal Management: Integrate active cooling (mini fans or heat sinks) or passive solutions (thermal conductive materials) to maintain optimal operating temperatures across extreme conditions.

Heaters or Insulation: In cold or high-altitude settings, built-in heaters or insulation can prevent sensor malfunctions and maintain performance.

Material Selection:

Robust Circuitry: Use components rated for wide temperature ranges and shock tests. Consider industrial-grade microcontrollers (like those used in aerospace) along with robust soldering and PCB design techniques.

Corrosion Resistance: For deep-sea or subterranean applications, use corrosion-resistant materials (e.g., conformal coatings, stainless steel housings) to extend the lifetime of the sensors and board-level components.

3. Edge Computing Performance

At the edge, the processing unit must handle a high throughput of sensor data in real time. Consider these platforms and configurations:

Primary Edge Devices:

NVIDIA Jetson Series:

AGX Xavier: Offers high computational power with an 8-core ARM CPU, 512-core GPU, and accelerated deep learning inference capabilities. Ideal for implementing sophisticated preprocessing and fusion algorithms.

Jetson Nano: A cost-effective alternative when power is limited, capable of running streamlined models and basic sensor fusion tasks.

Key Advantages:

Real-Time Processing: GPU acceleration and support for frameworks like TensorRT enable fast, in-situ data analysis and decision-making.

Modular Scalability: Easily integrated with additional sensor inputs and can run multiple fusion algorithms concurrently.

Supplementary Controllers:

Raspberry Pi Compute Modules & Arduino Boards:

Roles: Act as microcontroller units (MCUs) for simpler sensor tasks such as data acquisition, local filtering, or secondary processing.

Interfacing: Use standardized communication protocols (SPI, I2C, UART) to easily integrate with primary edge devices.

Communication & Connectivity:

Protocols for Inter-Device Communication: Consider MQTT for lightweight messaging and LoRaWAN for long-range, low-power communication in areas with intermittent connectivity.

Latency & Bandwidth Considerations: Properly balance between local processing (minimizing transmission delays) and cloud synchronization for historical data analysis.

Power Considerations:

Energy Efficient Design: Optimize both hardware and software to balance high performance with reasonable power consumption, especially critical in remote field deployments.

Battery Solutions: Explore rugged, high-capacity battery units or renewable energy options (solar panels) for prolonged, autonomous operation.

Summarized Blueprint Table

This comprehensive hardware specification not only outlines your sensor choices but also integrates strategies for device ruggedization and robust edge computing performance—ensuring Iron Spine’s sensor network is resilient, precise, and ready for extreme, real-world applications.

Would you like to further explore specific sensor integration techniques, or do you have additional requirements or constraints—perhaps environmental limits or power consumption targets—we should account for in the current blueprint?

0 notes