#Thermal Transfer Over printer

Text

Do people know most paper receipts are harmful to their health?

I'm going to get up on my soapbox for a minute, but do people realize how pretty much everyone is being overloaded with endocrine disruptors like BPA/BPS on a near-daily basis??

I don't think many people understand that ever since most of the world transitioned to thermal paper receipts (cheaper than ink), almost every receipt you handle from the gas station to the grocery store to the Square terminal printer at the local co-op is coated with Bisphenol-A (BPA) or its chemical cousin Bisphenol-S (BPS).

These chemicals have not only been proven to cause reproductive harm to human and animals, they've also been linked to obesity and attention disorders.

Not sure if your receipt is a thermal receipt? If you scratch it with a coin and it turns dark, it's thermal.

BPA/BPS can enter the skin to a depth such that it is no longer removable by washing hands. When taking hold of a receipt consisting of thermal printing paper for five seconds, roughly 1 μg BPA is transferred to the forefinger and the middle finger. If the skin is dry or greasy, it is about ten times more.

Think of how many receipts you handle every day. It's even worse for cashiers and tellers, who may handle hundreds in a single shift. It is also a class issue, since many people who work retail and food service are lower-income and will suffer worse health consequences over time from the near-constant exposure.

Not only that, receipts printed with thermal ink are NOT recyclable, as they pollute the rest of the paper products with the chemicals.

People don't know this and recycle them anyway, so when you buy that "green" toilet paper that says "100% recycled"? Yup, you are probably wiping your most sensitive areas with those same chemicals (for this reason, I buy bamboo or sugarcane toilet paper as a sustainable alternative to recycled paper).

This page from the Minnesota Pollution Control Agency has some good links if you want to learn more.

As consumers, we need to demand better from our businesses and from our governments. We need regulation of these chemicals yesterday.

If you are a buyer or decision-maker for a business, the link above also contains a shortlist of receipt paper manufacturers that are phenol-free.

If you work at a register, ask customers if they want a receipt. If they don't and you can end the transaction without printing one, don't print one!

As a consumer, fold receipts with the ink on the inside, since that's where the coating is. Some more good tips here.

And whatever you do, DO NOT RECYCLE THERMAL RECEIPTS

#i realized the other day that lots of ppl i talked to had no idea this was even a thing#important psa#demand more from your retailers and governments#environment#bisphenols#bpa free#bpa/bps#retail#food service#shopping#working class#capitalism#endocrine disruptors#endocrine disorders#adhd#eco lifestyle#environmental pollution#pollution#toxic chemicals#reproductive health#science#health#environmentalism#eco conscious#human health#consumer goods#consumer awareness#green living#green business#ecofriendly

448 notes

·

View notes

Text

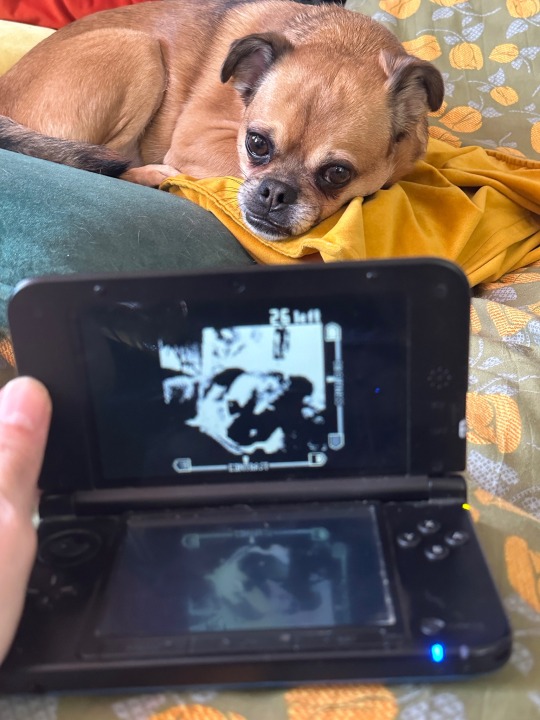

Bought my partner a thermal printer for Christmas to make stickers and print receipts and whatever; we immediately both thought: gameboy printer.

It looks even a little like a modern version of the gameboy printer. If I knew where mine was I’d pull it out for comparison, but anyway.

I decided the best way to bring this whole thing together was to actually take some pictures with gameboy camera and print them, so that’s what I did.

Emulating gameboy camera on my 3DS was extremely simple, and using some handy homebrew ftp software I could wirelessly transfer files over to my phone where the new printer connects over bluetooth. It’s essentially the gameboy link cable but with extra steps.

So now I have these photos from gameboy camera, all I had to do was pass it to the printer. Let me tell you, the feeling of absolute joy we shared at having printed a picture we took with gameboy camera for the first time in probably 20 years? That was just 👌

Happy fucking holidays, everybody, I needed that dopamine today

8 notes

·

View notes

Text

I bought a companion for my Intellivue MP5

This is an Intellivue MP2, this is just the pic from the eBay listing. It’s in pretty rough cosmetic shape but apparently works just fine.

What’s the difference between this and the MP5? Honestly not much, it uses an external power supply, the battery is much smaller, it doesn’t have the built in printer, and it can’t display as many waves, but that’s about it for differences. The thing that sets the Philips monitors apart from all other brands and makes them so desirable for hospitals is the same reason people buy the expensive Apple products: The ecosystem. The Philips monitors are the only monitors on the market that are based off of monitors made over 40 years ago and everything on those monitors from 40 years ago exists on these along with a bunch of other stuff that’s been added. The other thing is their network capabilities. They are the only system on the market where when paired with the proper servers you can upload vitals data to a server and save it for later, you can transfer a patient from one unit to another just a with a few button pushes and then their information moves to the monitor in the unit they are being transferred to without having to bring the monitor from one unit to another. They continue to receive software updates no matter how old they are (provided the hospital has Philips certified IT personnel) they can communicate with tons of accessories. They can track over 200 different vital signs (this does require special equipment) they can communicate with ventilators and infusion pumps. And there’s tons of other things they can do.

I do want to say that I bought these with some extra money I made during the holidays putting up and taking down Christmas lights. I don’t just have money for these things lying around.

I’d like to give anyone who wants to buy one of these monitors some buying advice

1. Stay away from the MP2 and X2 their external power supplies almost never come with them for a good price, if you want one with the battery and power supply it will cost $500 at the minimum

2. To save some money on cables it’s good to know that HP and Agilent Viridia line of patient monitors use the same pulse oximeter and ECG cables which can save you some significant money on cablee

3. Unfortunately they are significantly harder to get your hands on outside the US. Most of the EBay listing for them are in the US and the sellers will only sell to people within the US. That’s not their fault the US government prohibits the export of a lot of technology. High end medical equipment, high end computer components, IR (thermal) cameras that shoot at over 5 FPS, and lots of other things are all extremely locked down in terms of exporting outside the US because they don’t want it to fall into the hands of China. In fact the FDA supposedly controls the sale of medical equipment in the US but I don’t really think they care about used medical equipment because I have absolutely no medical connections. I do live in the technology capital of the world so that might have something to do with it. On a side note when I say Silicon Valley is the technology capital of the world I’m not joking. Google, Apple, Facebook, Nvidia, Intel, Tesla, Ebay, Zoom, Hewlett-Packard, and many more of the world’s largest tech companies are headquartered here. It does make it a bit easier for me to get my hands on bleeding edge tech or tech that’s harder for most people to get. I have friends who work for Tesla who’ve met Elon, I’ve seen Steve Wozniak in a restaurant, and I know tons of engineers who’ve worked for these companies.

Another thing worthy of note on who I am: At 19 I’m an extremely bright engineer and have an extremely vast amount of knowledge in tons of areas of technology and study. But I’m also mentally unstable I have autism, ADHD, severe anxiety, and Bipolar disorder. I get sprits of depression and can’t seem to stick with anything. I went to university for a year for electrical engineering and dropped out. I dropped out for 2 reasons. I hated all the extra classes that I have no interest in. And I noticed I was a freshman yet I had similar knowledge to that of seniors graduating that year.

3 notes

·

View notes

Text

The Art of Tattooing: Exploring Self-Expression and Meaningful Body Art

Tattooing is an ancient art form that has captivated human beings for centuries. From tribal markings to intricate designs, tattoos have transcended cultural boundaries and evolved into a form of self-expression that holds deep personal meaning for individuals around the world. In this blog, we delve into the rich history of tattooing, its cultural significance, and how it has become a powerful tool for conveying one's identity and experiences.

The History of Tattooing

Tattooing has a rich and diverse history that stretches back thousands of years. The earliest evidence of tattoos dates back to ancient Egypt, where mummies have been discovered bearing inked markings on their bodies. Throughout history, tattoos have served various purposes, from religious and spiritual rituals to symbolize tribal affiliations and social status. In more recent times, tattoos have transitioned from being stigmatized to becoming widely accepted forms of art and self-expression.

Self-Expression and Identity

One of the most compelling aspects of tattoos is their ability to express one's identity and tell a personal story. Tattoos can serve as permanent reminders of significant life events, relationships, or personal achievements. Each tattoo carries a unique meaning for the individual, representing their values, beliefs, and aspirations. Whether it's a small, discreet design or an elaborate full-body masterpiece, tattoos provide a canvas for individuals to express themselves authentically.

Artistic Expression

Tattoos are a merging of two art forms: the artistry of the tattooist and the canvas of the human body. Talented tattoo artists possess remarkable skills and creativity, transforming ideas into intricate and visually stunning designs. The fusion of colors, lines, and shading creates a living work of art that moves and evolves with the individual over time. With advancements in tattooing techniques, artists can achieve astonishing levels of detail and realism, pushing the boundaries of what is possible within this medium.

Cultural Significance

Tattoos hold significant cultural value in many societies around the world. They can represent a person's heritage, spiritual beliefs, or serve as a rite of passage. For example, in Polynesian culture, intricate tribal tattoos called "tatau" are a symbol of social status, strength, and identity. Similarly, Japanese tattoo art, known as "irezumi," is rooted in rich tradition and often depicts traditional folklore and mythology. By embracing these cultural symbols and designs, individuals pay homage to their roots and connect with a larger community.

The Importance of Tattoo Safety

While tattoos offer a multitude of creative and personal possibilities, it is essential to prioritize safety and choose a reputable tattoo artist and studio. Ensure that the tattoo artist follows proper hygiene practices, uses sterile equipment, and adheres to strict tattooing standards. Proper aftercare is also crucial for maintaining the integrity of the tattoo and preventing infections or complications. I recommend a new way to print tattoo in your body---Pelcas tattoo transfer stencil machine. Easy to use this tattoo thermal copier to print the tattoo pattern you love or what you design on the transfer paper, then press the paper firmly and let it sit for a minute. Remove the paper, you will see the pattern onto your skin. Compared to the traditional tattoo machine, pelcas stencil printer is more effective and convenient.

Conclusion

Tattoos have come a long way from their early origins and are now an established art form that allows individuals to express their identity, commemorate life's milestones, and connect with their cultural heritage. The intricate designs, personal meanings, and cultural significance make tattoos a unique and powerful form of self-expression. With the right artist and a deep understanding of the tattoo's significance, the art of tattooing continues to thrive, giving people a lifelong canvas for their stories, memories, and passions.

#beauty#beauty secrets#tattoos#printers#tattoo machine#print#art#tattoo artist#tattoo artwork#tatto design

2 notes

·

View notes

Text

Understanding Label Sticker Printing Machines: A Complete Guide

In today’s fast-paced business environment, efficient labeling is essential for everything from product identification to inventory management. A label sticker printing machine offers a versatile solution for creating customized labels with precision and speed. This guide will explore the various types of label sticker printing machines, their applications, and important factors to consider before purchasing one.

What Are Label Sticker Printing Machines?

Label sticker printing machines are specialized devices designed to print labels on adhesive materials. These labels can serve various purposes such as product branding, barcode tracking, shipping, and promotional activities. The machines vary in complexity and capability, catering to different business needs from small-scale operations to large industrial applications.

Core Components of Label Sticker Printing Machines

Understanding the core components of these machines can help you make a more informed choice:

Print Head: The component responsible for applying ink or toner to the label material.

Media Handling System: Ensures smooth feeding of label material into the printer.

Cutting System: Cuts the printed labels to the desired size and shape.

Control Interface: Allows users to configure print settings, including label size, quality, and material type.

Types of Label Sticker Printing Machines

1. Direct Thermal Printers

Direct thermal printers use heat-sensitive paper that darkens when heated. These printers are simple and cost-effective, making them a popular choice for short-term labels. They do not require ink, toner, or ribbons, but the prints are susceptible to fading over time. They are commonly used for shipping labels and temporary tags.

2. Thermal Transfer Printers

Thermal transfer printers use a ribbon coated with ink, which is transferred to the label material using heat. This method provides high durability and resistance to environmental factors such as moisture and chemicals. Thermal transfer printers are ideal for producing long-lasting labels for products, barcodes, and hazardous materials.

3. Inkjet Printers

Inkjet label printers are known for their high-quality color prints. They use liquid ink, which can produce vibrant and detailed images. These printers are versatile and can print on a wide range of materials including paper, vinyl, and polyester. However, the cost of ink and the potential for smudging make them less ideal for high-volume or industrial use.

4. Laser Printers

Laser printers use toner to produce sharp, high-resolution prints. They are known for their speed and efficiency, making them suitable for high-volume labeling needs. Laser printers are ideal for printing clear text and barcodes and are often used in commercial settings for tasks such as shipping labels and product tags.

5. Digital Label Printers

Digital label printers offer the flexibility of printing high-quality, full-color labels on demand. They combine the advantages of both inkjet and laser technologies and are capable of handling complex designs and variable data. Digital printers are well-suited for businesses that require short-run, custom labels with quick turnaround times.

Applications of Label Sticker Printing Machines

Label sticker printing machines are used across various industries for numerous applications:

Retail: For price tags, product labels, and promotional stickers.

Food and Beverage: To print nutritional information, expiration dates, and branding labels.

Logistics: For shipping labels, barcodes, and tracking information.

Healthcare: Includes patient labels, medical record tags, and prescription labels.

Manufacturing: For safety warnings, part identification, and inventory management.

These machines play a crucial role in ensuring accurate information and effective branding.

Factors to Consider When Choosing a Label Sticker Printing Machine

1. Printing Speed and Volume

Consider the volume of labels you need to print and how quickly you need them. High-speed printers, such as laser and digital printers, are better suited for large volumes. If you are running a smaller operation, a thermal or inkjet printer may be sufficient.

2. Print Quality and Resolution

The quality of print is essential, especially if your labels include detailed graphics or text. High-resolution printers like inkjet and laser provide clear and professional-looking results, whereas thermal printers may be adequate for simpler label designs.

3. Material Compatibility

Different printers support different types of label materials. Choose a printer that is compatible with the materials you plan to use, whether it's paper, synthetic films, or specialty materials. This ensures that your labels will adhere well and last as intended.

4. Operational Costs

Consider the ongoing costs of ink, toner, ribbons, and label materials. Thermal printers generally have lower operational costs compared to inkjet or laser printers. However, evaluate the total cost of ownership, including maintenance and consumables.

5. Durability of Labels

Depending on your application, you may need labels that can withstand various conditions such as heat, moisture, or chemicals. Thermal transfer and laser printers typically produce more durable labels compared to direct thermal or inkjet printers.

Conclusion

Label sticker printing machines are essential tools for businesses that require effective labeling solutions. By understanding the different types of printers available and their respective features, you can select the best machine to meet your needs. Whether you need high-speed printing, vibrant colors, or durable labels, there is a printer that fits your requirements. Investing in the right label printer can enhance your operational efficiency, improve branding, and ensure compliance with labeling standards.

0 notes

Text

The Versatile Biochemistry Analyzer

Biochemistry analyzers have become indispensable tools in modern healthcare, enabling healthcare professionals to accurately diagnose and monitor various medical conditions. These sophisticated instruments are designed to measure biochemical indices by analyzing blood and other bodily fluids, providing crucial information for effective patient management.

Key Features of Biochemistry Analyzers

1. Built-in Incubator: Maintains a constant temperature for accurate and reliable results.

2. Multiple Wavelength Options: Typically equipped with 7 filters ranging from 340 to 620 nm, allowing for a wide range of biochemical tests.

3. Extensive Measuring Range: Capable of measuring absorbance from 0 to 3.00 OD, ensuring accurate results even for high-concentration samples.

4. Large Storage Capacity: Stores more than 200 test programs and 3000 test results, making it easy to manage patient data and track results over time.

5. Touch Screen Display: Provides a user-friendly interface for easy operation and navigation.

6. Incubation Positions: Accommodates up to 20 samples simultaneously, increasing efficiency and throughput.

7. Built-in Thermal Printer: Allows for immediate printing of test results, ensuring quick access to critical information.

8. Connectivity: Equipped with an RS-232 serial port for easy integration with other systems, facilitating seamless data transfer and storage.

Applications of Biochemistry Analyzers

Biochemistry analyzers are widely used in various fields of healthcare, including:

1. Clinical Chemistry: Measuring levels of enzymes, electrolytes, hormones, and other substances to diagnose and monitor conditions such as diabetes, kidney disorders, and liver diseases.

2. Therapeutic Drug Monitoring: Assessing the concentration of drugs in the body to ensure optimal dosing and prevent adverse effects.

3. Toxicology: Detecting and quantifying the presence of drugs, alcohol, and other substances in biological samples.

4. Urinalysis: Analyzing urine samples to screen for urinary tract infections, kidney problems, and other conditions.

5. Immunoassays: Measuring the levels of specific proteins, antibodies, and other molecules to diagnose and monitor immune-related disorders.

Advantages of Using Biochemistry Analyzers

1. Accuracy: Biochemistry analyzers provide precise and reliable results, ensuring accurate diagnosis and treatment decisions.

2. Efficiency: With their high-throughput capabilities and automated processes, biochemistry analyzers can handle large volumes of samples quickly and efficiently.

3. Cost-effectiveness: By streamlining the testing process and reducing the need for manual labor, biochemistry analyzers help to lower overall healthcare costs.

4. Improved Patient Care: Timely and accurate results from biochemistry analyzers enable healthcare professionals to make informed decisions and provide better patient care.

In conclusion, biochemistry analyzer are essential tools in modern healthcare, revolutionizing clinical diagnostics and contributing to improved patient outcomes. With their advanced features and versatile applications, these instruments continue to play a vital role in the ever-evolving field of medical diagnostics.

1 note

·

View note

Text

Understanding Barcode Ribbons

Barcode ribbons are essential for printing clear and durable labels. They are used in thermal transfer printers to ensure barcodes remain readable over time. The image shows a typical barcode ribbon roll, which is coated with ink that gets transferred onto labels when heated.

There are different types of barcode ribbons, including wax, wax-resin, and resin. Each type is suitable for specific materials and environments. For example, wax ribbons are great for general use on paper labels, while resin ribbons are needed for synthetic materials exposed to harsh conditions.

Choosing the right ribbon is crucial for optimal print quality. Zahabi offers a range of high-quality barcode ribbons that cater to various business needs, ensuring reliable and long-lasting labels. By selecting the appropriate ribbon for your application, you can improve inventory management and product tracking efficiently.

0 notes

Text

Consumer Electronics - Techni3

We deliver the most innovative, reliable and scalable solutions in effective EMI mitigation and thermal management for consumer and portable electronic applications. Laird’s broad product portfolio covers a wide range of EMI and thermal solutions along with multi-functional solutions incorporating a single process design. Laird’s advanced materials and multifunctional layers allow miniaturization of components and enable zero air gap in portable devices. Our high performance thermal and EMI shielding materials help device and system manufacturers solve escalating temperature and EMI issues caused by the increasing functionality of consumer electronic devices.

Laird’s best-in-class co-engineering expertise in simulation, modeling, rapid prototyping and lab testing during early design stages speeds our customers on the path to achieving compliance. These efforts bring products to market more quickly. Our global manufacturing footprint enables Laird to consistently and efficiently fulfill customers’ demands in different regions. We are proven, reliable and strong partners to many of the world’s leading brands.

Laptop and Tablet

Design challenges inherent in laptops and tablets include increasing demands for ever higher performance, more compelling multi-functional capabilities, miniaturization, and energy efficiency. To support the work of design engineers, Laird delivers expert solutions in EMI mitigation, thermal management, power efficiency improvement and the integration of multifunctional layers. In addition, we are flexible in creating product designs to meet our customer’s security requirements, in-line inspection and cosmetic standards.

Computer Peripherals and Printers

Computer peripheral equipment and printer systems expand capabilities of computers and laptops. More functions continue being integrated into single devices. In them, our magnetic ceramic components suppress unwanted noise or improve system power efficiency in power converting. Our advanced thermal interface materials transfer heat away from hot ICs or components on the PCB to the enclosure. Our EMI shielding materials protect your equipment sensing elements and help to meet compliance.

Game Consoles

Each year, next generation game consoles promise to be slimmer, faster and more powerful. These increasing demands for higher performance produce design challenges in thermal management, EMI mitigation and device reliability. Increasing power density drives the need for higher thermal conductivity material and developing added thermal management innovation. Tighter integration into smaller spaces leads to a need for ultra-soft thermal materials and process improvements through automation. At a device design level, the heat generated from more powerful devices is one problem. Waste energy or EMI “noise” is another. Laird provides innovative solutions to mitigate EMI while also effectively transferring unwanted heat in a tight, shrinking spaces.

Augmented Reality and Virtual Reality Headsets

Soon, Augmented Reality (AR) and Virtual Reality (VR) systems and headsets are expected to introduce astonishing new experiences into our everyday lives. The massive data transfer of image and video requires high speed data links and ever greater processing power. Meanwhile, AR and VR headsets require lightweight, longer battery life and tighter integration, all within smaller spaces. A holistic approach is required to understand EMI mitigation and thermal issues at the system level. Those issues must be addressed and resolved at the same time and most important, in an early design stage. Laird’s extensive portfolio includes high performance thermal interface materials, liquid gap fillers, fabric-over-foam gaskets, board level shields and multi-functional solutions, all engineered to enable design engineers to help create more immersive experiences in AR and VR.

WiGig, the new Wi-Fi standard, will benefit AR and VR by multi-gigabits per second data speeds using the uncongested 60 GHz frequency band. Laird’s innovative thermoplastic absorbers provide excellent absorption and isolation at 60GHz for WiGig technology.

Mail

Mobile

+44 (0)29 2125 2100

Service Area

Unit 4B Caerphilly Business Park Caerphilly CF83 3GS

0 notes

Text

Premium Wax Resin Ribbon | DNB MULTIAPPS LLP

Discover the exceptional quality of premium wax resin ribbons from DNB MULTIAPPS LLP.

Our high-performance ribbons are designed for superior durability and print clarity, making them ideal for a wide range of labeling and printing applications. Whether you’re printing on paper or synthetic materials, our wax resin ribbons ensure crisp, long-lasting prints that withstand wear and tear.

Why Choose Our Premium Wax Resin Ribbons?

Superior Print Quality: Our ribbons produce crisp, clear text and barcodes that are essential for accurate scanning and legibility.

Enhanced Durability: Designed to withstand harsh conditions, our wax resin ribbons resist smudging, scratching, and fading, ensuring that your labels stay intact over time.

Versatile Compatibility: Perfect for use with a wide range of thermal transfer printers and label materials, our ribbons offer flexibility and convenience.

Eco-Friendly Options: We are committed to sustainable practices, and our ribbons are produced with environmentally friendly processes and materials.

For more details, please visit our website: https://www.dnb-ma.com/thermal-transfer-resin-black.php

0 notes

Text

Ensuring Precision in SF6 Gas Analysis with the Rapidox SF6 6100 Bench Analyser

In the realm of electrical equipment and gas monitoring, maintaining high-quality standards is paramount. The Rapidox SF6 6100 Bench gas analyser offers an advanced solution for controlling and monitoring the quality of SF6 gas, catering to a wide array of applications, from medium and high voltage gas-insulated electrical equipment to SF6 gas purity tests, medical testing, manufacturing, and laboratory-based research and development.

Precision in Measurement

The Rapidox SF6 6100 Bench gas analyser excels in delivering exceptionally accurate and stable readings. It performs simultaneous analysis and data-logging of SF6, SO2, and H2O (dew point) gases. This precision is crucial for industries where the slightest deviation in gas quality can lead to significant operational challenges. The analyser’s accuracy ensures that SF6 gas used in electrical equipment remains within safe and efficient operational parameters.

Comprehensive Recovery and Compatibility

A standout feature of the Rapidox SF6 6100 Bench is its full compatibility with the Rapidox Gas Recovery Bag. The inclusion of a gas output nozzle allows the analyser to be attached directly, ensuring that all SF6 gas is recovered efficiently. This not only promotes environmental responsibility but also helps in maintaining the purity of the gas by preventing contamination.

Portable and User-Friendly Design

The Rapidox SF6 6100 Bench analyser is available as a complete and portable kit. This kit is designed to be user-friendly, allowing users to carry all necessary equipment within a heavy-duty IP66 case. This portability is a significant advantage for professionals who need to conduct gas analysis in various locations. The kit includes special tongue and groove self-sealing couplings (compatible with well-known brands), a swing handle fitted to the analyser, and a separate thermal printer. These features collectively ensure that the equipment is ready for immediate use, offering convenience and efficiency to users.

Advanced Features for Superior Performance

The Rapidox SF6 6100 Bench is equipped with several advanced features:

Rapid Measurement Response: The analyser provides a quick response time of 3-5 minutes, ensuring timely data availability.

Low Maintenance Sensors: These sensors require minimal upkeep, reducing downtime and operational costs.

Programmable Alarm Circuits: Users can set alarm thresholds to monitor gas levels effectively.

Programmable Analogue Outputs: These outputs offer flexibility in data handling and integration with other systems.

RS232/RS485 Communications: Combined with complete data-logging software, these communication interfaces facilitate easy data transfer and analysis.

Optional Long-Life Variable Speed Sample Pump: This feature allows for precise control over sample flow rates.

Large Back-lit LCD Display: The display ensures clear visibility of readings even in low-light conditions.

Password Protection: This security feature prevents unauthorized access to the analyser’s settings and data.

Universal Voltage Operation: The analyser operates on any worldwide mains voltage (90-260VAC), providing versatility for global use.

Compatibility with Standard Gas Recovery Systems: This ensures seamless integration with existing recovery setups.

Accurate and Reliable Measurements

The Rapidox SF6 6100 Bench provides highly accurate measurements across a range of gases:

SF6 (Sulphur Hexafluoride): 0-100% range with ±0.5% full-scale accuracy

H2O (Dew Point): -60°C to +20°Cdp with ±2°Cdp accuracy

SO2 (Sulphur Dioxide): 0-100ppm or 0-500ppm with ±2% full-scale accuracy

These precise measurements are critical for maintaining the integrity and efficiency of gas-insulated equipment and ensuring safe operation.

Accessories and Customization

A range of accessories is available to enhance the functionality of the Rapidox SF6 6100 gas analyser. These include special tongue and groove self-sealing couplings compatible with leading brands and stainless steel braided sampling hoses designed for use with SF6 gas-insulated equipment. Such accessories ensure that users can customize their setup to meet specific operational requirements.

Regular Calibration Services

To maintain the highest standards of accuracy and reliability, regular calibration is essential. Cambridge Sensotec offers a comprehensive calibration service at its state-of-the-art factory. These automated calibration stations ensure that Rapidox gas analysers are calibrated accurately and efficiently. The service includes insured worldwide return shipping, providing peace of mind and convenience for users.

Conclusion

The Rapidox SF6 6100 Bench gas analyser stands out as a versatile, reliable, and highly accurate tool for monitoring SF6 gas quality across various applications. Its advanced features, portability, and compatibility with industry-standard systems make it an invaluable asset for professionals in the electrical, medical, manufacturing, and research sectors. Regular calibration services further enhance its reliability, ensuring that users can consistently achieve precise and dependable results.

Digital & Smart Grid Enterprises is a trusted supplier and trader of authentic and cost-effective Rapidox SF6 6100 Bench Gas Analyser.Our equipment can improve the efficiency of power systems, while our customized services cater to leading sectors and panel builders. Contact us at +917021624024 or email [email protected] .Please click here if you would like to know more about Rapidox SF6 6100 Bench Gas Analyser

0 notes

Text

Direct Thermal and Thermal Transfer Printing: What’s Best for Your Needs?

When selecting a label printing method, understanding the key differences between direct thermal and thermal transfer printing is crucial for optimizing your labeling strategy. Each method offers unique benefits tailored to specific uses and environments. Here is a detailed comparison to help you make an informed decision for your business needs.

Direct Thermal Printing: Efficient and Economical.

Direct thermal printing is perfect for applications where labels are needed for short durations, such as shipping labels. This method stands out due to its simplicity and cost-effectiveness:

No Ribbons Required: Direct thermal printing does not require ink, toners, or ribbons, making it a straightforward and cost-effective choice for high-volume printing.

Print Longevity: Primarily produces black print, which is ideal for standard barcodes and shipping information. However, these labels are susceptible to fading when exposed to heat or sunlight, as they are heat sensitive.

Material Specificity: It only works with heat-sensitive label materials designed to blacken when exposed to the thermal print head.

Thermal Transfer Printing: Durable and Versatile.

For applications demanding more durable labels, thermal transfer printing provides a robust solution:

Use of Ribbons: Utilizes a thermal transfer ribbon, allowing for durable and resistant labels that can handle exposure to various environmental factors without fading or smearing.

Color Printing Capabilities: Ideal for creating eye-catching labels with logos or branding, thanks to its compatibility with different colored ribbons.

Material Flexibility: Capable of printing on a broader range of materials, including paper, polypropylene, and polyester, making it suitable for a variety of applications.

High-Quality Output: Offers precise print accuracy and edge definition, essential for detailed barcodes and sharp label designs.

Making the Right Choice. Both printing technologies use thermal print heads but differ significantly in application and longevity. Direct thermal is best suited for short-term, high-volume needs where label longevity under exposure is not critical. In contrast, thermal transfer is preferable for labels that must endure over time and under various conditions, providing versatility and durability with a slightly higher initial investment.

For more information on labels, printers and ribbons call us at 813 242 6995 or [email protected]

#thermal labels#direct thermal labels#ribbons#printer ribbons#stretch film pricing#pricing news#quick pak inc#stretch film#quickpakinc#free pallet wrapper#coreless film

0 notes

Text

Thermal Transfer Ribbon Market: Global Demand Analysis & Opportunity Outlook 2035

Research Nester’s recent market research analysis on “Thermal Transfer Ribbon Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global thermal transfer ribbon market in terms of market segmentation by head type, product type, application, end-user industry, and by region.

Request Report Sample@

Growing Concern for the Prevalence of Chronic Diseases to Promote Global Market Share of Thermal Transfer Ribbon

The global thermal transfer ribbon market is estimated to grow majorly on account of the increasing practice of cashless payment using barcode scanning. Nowadays people are more and more inclined to use the QR code to complete the transaction. In 2021, Asia-Pacific processed USD 440 billion in cashless transactions, mostly UPI and QR or barcode payments. Thermal printers carefully print these codes containing banking information to provide clearer images, which is expected to drive market growth. QR code reach increased by almost 96% between 2018 and 2020.

Moreover, the increasing number of hospitalizations due to COVID-19 and other chronic diseases are among the factors that are expected to boost the market growth of thermal transfer ribbons. The overall hospitalization rate for COVID-19 in the UK continued to rise slightly, reaching 10.62 per 100,000 in March 2023. Thermal printers are primarily used in the medical field to record real-time rhythm strips on heart monitors in hospitals and to print patient IDs. Thermal printheads are used in making patient wristbands, labels, freezer storage, identification, and others. Moreover, the number of hospitals is also increasing, which drives the growth of the market.

Some of the major growth factors and challenges that are associated with the growth of the global thermal transfer ribbon market are:

Growth Drivers:

A Surge in the Integration of IoT in Printing

New Innovation in Thermal Printing Technology

Challenges:

Poly-based materials are used in the manufacture of thermal transfer ribbons. The substance is derived from crude oil products and could lead to increased mining, ultimately impacting market growth. Moreover, the production of this poly-blade material generates a large amount of waste, which is also expected to contribute to environmental pollution and hinder market growth. Additionally, the availability of various substitutes in the market is anticipated to limit the growth of the sector in the projected period. These are some of the major factors anticipated to hamper the global market size of thermal transfer ribbons.

By Product Types, the global thermal transfer ribbon market is segmented into wax-resin material, resin material, and wax material. The wax resin segment is to garner the highest revenue by the end of 2035 by growing at a significant CAGR over the forecast period. Ribbons made from a combination of wax and bands are extremely durable. The most important driving force of the wax-resin material segment is the strength it imparts to the belt. Additionally, this material also extends the life of printouts from your printer. In addition, it is immune to changing climatic conditions and fluctuations in temperature. It is therefore also suitable for products exposed to constantly changing temperatures.

By region, the North American thermal transfer ribbon market is to generate the highest revenue by the end of 2035. This growth is anticipated to the increasing cases of chronic diseases leading to increased hospitalizations. Additionally, hospital bills, patient information, and medical rhythms are increasingly being printed using thermal printers. Every 40 seconds, someone in the United States suffers from a heart attack. About 805,000 people in the United States have a heart attack each year. Of these, 605,000 experience their first heart attack. On the other hand, the market size is expected to grow due to the frequent use of barcodes for transactions in this region. The United States leads the world in QR code usage, with a total of 2,880,960 scans. A 2022 report found that 58% of adults surveyed said they were more likely to access the QR code on a menu on their mobile phones.

Access our detailed report at:

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates, and executives to take wise decisions for their future marketing strategy, expansion, investment, etc. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds. Our out of box thinking helps our clients to take wise decisions to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Are you tired of outdated printing methods that fail to meet your business needs? Look no further than the cutting-edge technology of TTO Printer UAE, brought to you by Techno Middle East. With its revolutionary Thermal Transfer Over printer, this innovative solution is set to transform the way you print. In this blog post, we will explore the endless possibilities and advantages of TTO Printer UAE, providing you with valuable insights and expert advice. Get ready to take your printing game to the next level!

0 notes

Text

Dye Sublimation Paper Market Fuels by Demand for Digital Prints

Dye sublimation paper is widely used for industrial printing applications including soft signage, fabric printing, décor items, and more. The paper allows transfer of dye onto fabrics via a process of sublimation without using liquid or chemicals. Dye sublimed products are known for their vibrant colors and high durability. The market is driven by growing uptake of dye sublimated products in the fashion and apparel industry for customization as well as industrial printing for soft signage.

The global dye sublimation paper market is estimated to be valued at US$ 679.44 Mn in 2023 and is expected to exhibit a CAGR of 3.9% over the forecast period 2023 to 2031, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

One of the major drivers for the dye sublimation paper market growth is increasing use in industrial printing. Dye sublimation allows for high quality printing on various materials without using liquid or needing pressure. This creates opportunities for soft signage, technical textiles, décor fabrics and many other applications. Additionally, the ability to print on demand using digital printing technologies has further increased adoption. Customization trend in fashion and apparel has also pushed use of dye sublimation for fabric printing. However, high capital requirement for equipment and technology upgrades remains a challenge. Nonetheless, benefits of customization and high quality printing are estimated to outweigh costs, driving market gains.

SWOT Analysis

Strength: Dye sublimation paper offers bright, vivid colors that are durable and resistant to scratching or fading. It produces high resolution, photographic quality images on a variety of substrates. The transfer process is fast and easy with consistently high quality results.

Weakness: Dye sublimation paper requires specialized, expensive printers and transfer equipment. The high capital costs and specialized technical knowledge required for operation can limit its adoption, especially among small businesses and individual users. The transfer process also requires precise temperature and time controls to achieve the best results.

Opportunity: Sports apparel is a major end use of dye sublimation paper, especially for customized team uniforms and fanwear. As spectator sports continue growing in popularity globally, the market for team merchandise is expanding. Home décor is another big opportunity as people increasingly decorate with customized, photo-quality images on products like mugs, plates, and wall art.

Threats: Rising raw material costs can squeeze profit margins, especially for commodity paper grades. Environmental regulations on hazardous substances may impact ink formulations over time. Digital transfer technologies like dye diffusion thermal transfer pose a threat by offering lower costs and ease of use for some applications.

Key Takeaways

The Global Dye Sublimation Paper Market Size is expected to witness high growth over the forecast period of 2023 to 2031 supported by increasing demand from the sports apparel and home décor industries. The global dye sublimation paper market is estimated to be valued at US$ 679.44 Mn in 2023 and is expected to exhibit a CAGR of 3.9% over the forecast period 2023 to 2031.

Regional analysis: North America currently dominates the market buoyed by well-established sports culture and popularity of customized fan apparel in the region. Asia Pacific is expected to be the fastest growing market led by China, driven by rising living standards, growing middle class, and strong growth in spectator sports.

Key players: Key players operating in the dye sublimation paper market are Campbell Soup Company, Nestlé S.A., The Kraft Heinz Company, Pacific Foods of Oregon, Bar Harbor Foods, BUMBLE BEE Seafoods, More Than Gourmet, Kettle Cuisine, Bonafide Provisions, College Inn. They are focused on new product launches catering to the specialized requirements of end use industries like sports and soft signage.

For More Insights, Read:https://www.newsstatix.com/dye-sublimation-paper-market-demand-growth-and-regional-outlook-by-2030/

0 notes

Text

Understanding the benefits of thermal transfer lab labels

All those looking for cutting-edge and robust labels for the laboratory, do you feel overwhelmed trying to figure out where to start or what to choose? Learn about brands and the important factors of creating a perfect label. One of the most essential aspects is choosing the product label's material. It is the cornerstone of a perfect label which affects the label's functionality, quality and aesthetics. The material can impact the overall look and feel of your product.

Thermal labels bring myriad benefits for those in need of printing a high volume of labels, especially long-lasting labeling solutions. These labels are extensively used for different applications, including shipping, UL, inventory identification and management, receipts, and more. For instance, retail stores use thermal labels to print shipping labels efficiently during high times. Since they are more durable than inkjet or laser-printed labels, manufacturing companies prefer using them on the surface without worrying about the label peeling off or wearing off. One of the most common uses of this technology is – UL labels.

LEARN ABOUT THE ADVANTAGES OF THERMAL LABELS

Durability

Thermal-printed labels last longer than inkjet or laser-printed labels (as aforesaid). Thermal transfer labels are more durable than direct transfer labels, making them the best-suited option for your business. Thermal transfer labels resist extreme weather conditions, temperature fluctuations, chemicals, UV rays and abrasion. These qualities make them perfect for product identification, UL labels, circuit board tracking and other applications.

Better Print Speed

Thermal printers can create labels faster than their laser or inkjet counterparts, which means you will experience quick turnaround times, positively affecting your supply chain.

Cost Saving

Thermal printing methods don't require ink, eliminating expensive and repeated purchases. The only part that requires replacement is the thermal transfer ribbon. However, they are low maintenance. They have fewer moving parts than inkjet printers, which makes them more durable and robust.

Flexibility

Thermal printers can print on different kinds of materials; this includes plastic, paper, nylon, vinyl, polyester and composite materials. This gives you various options to choose from when crafting your labels.

Color Options

Direct thermal printing and thermal transfer printing techniques produce quality images; however, only thermal transfer printing methods can be produced in different colors. This enables your business to color code inventory and add more personalization to labels without worrying about quality.

EXAMPLES OF THERMAL TRANSFER PRINTING

Long-Term Item Identification

Any label used for more than a year should be manufactured using a thermal transfer printer. This includes labels for parts or inventory that may be in storage for an extended period. As aforementioned, they are robust and durable; therefore, they can last a couple of years or even longer.

Exposure to Challenging Environment

Any label that experiences long-term exposure to ultraviolet light, extreme temperature and other bad conditions should be printed with a thermal transfer technique. The long-term fade resistance you obtain and the ability to print on substrates offer a considerable benefit when labeling things such as building materials, parts stored in a laydown yard and outdoor items.

Sensitive Material

Another aspect to consider is the value of the information you must convey on your label. Choosing a thermal transfer label printed on a long-lasting substrate makes sense in labs, pharmaceutical producers and other applications where high-value assets are in store.

Hazardous Material

You often don't know for how long the hazardous waste and other materials must remain in storage; you cannot afford to lose track of them if a label becomes illegible over time. In such situations, you should use a thermal transfer label.

ENDNOTE

Creating compelling, durable and informative labels perfectly exhibits your brand's personality and provides essential information to customers. Get quality thermal transfer lab labels from a trusted manufacturer.

0 notes

Text

Ways to choose the right TTO for your application

Adaptable bundling film is a quickly developing class utilized in a great many items. A computerized technology explicitly intended for coding adaptable film - Thermal Transfer Overprinting (TTO) - enjoys various upper hands over other options, however makers should pick what best meets their application needs.

What is TTO?

This technology is the most appropriate to checking adaptable movies that are level, before packs or pockets are filled. The primary components of a TTO printer are the printhead, the inked lace and the roller (for constant applications) or the level platen (for irregular applications). At the point when made a motion to print a predefined code, the printhead plunges, pushing the strip and the bundling film against the roller. The warming components connected with the code heat up, liquefy the ink on the strip, and the softened ink is then transferred onto the bundling film.

The warming components are implanted in a clay unit and separately warmed to frame characters like letters and numbers. The artistic unit safeguards the warming components as they transfer the intensity to the inked lace and print the message. Artistic units shift in their capacity to endure continued warming and cooling cycles, and to oppose scraped area. The two elements influence printhead life and coding speed.

Why TTO?

Contrasted with mechanical methodologies, for example, hot stepping or rotating coders, TTO gives more prominent uptime and less waste, while permitting the consideration of constant information. Contrasted with other advanced innovations, for example, consistent and thermal inkjet printing, TTO is ordinarily more effectively coordinated into the bundling machine and gives better print quality.

With a high goal of around 300 dpi - moving toward the nature of preprinted bundling - TTO is flexible, permitting standardized identification, logo and 2D coding. Pack paces of up to 120-160 packs each moment (ppm) or 1200 millimeters/second (mm/s) are accomplished by and large, however further developed units can reach up to 455 ppm or 1800 mm/s.

Moreover, TTO is dependable, with a somewhat little introductory capital expense, as well as low support and running expenses. There is for all intents and purposes no hardware warm-up time - it is prepared in somewhere around 60 seconds of being turned on. There is additionally no gamble of film hole, in contrast to mechanical strategies, where broken stamps can puncture the bundling. Check out Thermal Transfer Overprinters (TTOs).

Most TTRs (Thermal Transfer Strips) have a blended sythesis of wax and gum. Notwithstanding, in additional difficult settings including outrageous temperatures, oils or solvents, a high tar TTR is fitting to guarantee fresh solid codes, the drawback being a lower coding rate of around 300 mm/s.

0 notes