#Torque Multipliers

Explore tagged Tumblr posts

Text

Impact Sockets, Impact Hex Bit Sockets, BI Hex Sockets, Extension Sockets, Torque Wrenches, Torque Multipliers, Slugging Wrenches

We are Leading Manufacturers, Suppliers, Exporters, Wholesalers of Impact Sockets, Impact Hex Bit Sockets, BI Hex Sockets, Extension Sockets, Torque Wrenches, Torque Multipliers, Slugging Wrenches, Tube Tools, Pneumatic Tools, Electric Tools in Mumbai, India and all over Globe. Get Quote Now!.

#Impact Sockets#Impact Hex Bit Sockets#BI Hex Sockets#Extension Sockets#Torque Wrenches#Torque Multipliers#Slugging Wrenches#Tube Tools#Pneumatic Tools#Electric Tools#Manufacturers#Suppliers#Wholesalers#Exporters#Mumbai#India

0 notes

Text

Torque Wrench Supplier in Dubai UAE

Discover precision and reliability with Abascotools, your premier torque wrench supplier in Dubai UAE. We offer a comprehensive range of torque wrenches designed for accuracy and durability, suitable for various industrial applications. Whether you require torque wrenches for automotive maintenance, construction projects, or mechanical engineering tasks, Abascotools provides top-quality tools that meet international standards. Contact us at +971545819255 to explore our selection or visit our store in Dubai. Trust Abascotools for superior products and excellent customer service as your trusted torque wrench supplier in Dubai UAE.

#tools suppliers in uae dubai uae#workshop tools supplier in dubai uae#adjustable wrench supplier in dubai uae#stainless steel tools supplier in dubai uae#strap wrench supplier in dubai uae#hand tools supplier in uae#vernier caliper supplier in uae#crowfoot wrench supplier in uae#torque multiplier suppliers in uae

0 notes

Text

PrimeTools: Leading Torque Multiplier Manufacturers for Superior Performance

Primetools stands out as a premier torque multiplier manufacturer, specializing in crafting high-quality tools engineered to deliver exceptional torque amplification. With precision engineering and innovative design, our torque multipliers offer unmatched performance and reliability in various industrial applications.

Whether it's tightening heavy-duty bolts or tackling challenging fastening tasks, our products excel in providing the necessary torque with efficiency and accuracy. Backed by rigorous quality control measures, Primetools ensures that each torque multiplier meets stringent industry standards, guaranteeing durability and long-term reliability.

Visit for more info : https://www.primetoolsindia.net/manufacturers/torque-multiplier.html

Address: PRIME HOUSE B-7/A, Acharya Niketan, Mayur Vihar Phase-1, New Delhi 110 091

Mail : [email protected]

Phone no : 9310015460

0 notes

Text

Breaking Necks

Snappin necks is a really cool thing to do in an action movie, so I'm gonna break down how strong you need to be to do it.

"Breaking a neck" aka cervical dislocation, happens when the vertebra are rotated far enough that the vertebral canal is disrupted and the spinal cord is fucked. To do this, you gotta overpower some ligaments (which keep bones together), muscles, and tendons (holds muscles to bones). To keep it simple, we're gonna say the guy is on his knees in front of you, and has brain damage or something, so he's not really fighting back. You're gonna put one hand on his chin, and the other on the back of his neck. This will allow you to create torque, which will lead to cervical torsion, which will lead to cervical dislocation, and you know where we're going with this.

Okay, so what is torque? Torque is a specific type of force in which the force is applied to the end of an object, causing that object to rotate. An example of this is when someone uses a wrench. When force is applied to the end of the wrench, it causes the end around a nut to rotate. Most people can understand the concept that as your hands move further from the end of a wrench that is around a bolt, the easier it is to turn. This is because the force applied is multiplied by the length of the lever arm. The lever arm is the distance between the point of rotation and the force being applied. In this case, the lever arm is the distance between the chin and the spine. In most people, this distance is 15 cm.

How much force can the vertebra withstand? The minimum torque the vertebra can be subject to before dislocation is 14-17 Nm (Newton meters are the units of torque, because it is a force [Newton] applied from a distance [meters]). We can plug 17 Nm into our torque equation with the lever arm length, and we get ~120 N. Your bicep needs to produce 120 N of force when you curl a 26 lb weight. That's not very much, is it?

So back to the muscles. The main muscle that will resist your motion is the sternocleidomastoid muscle. This originates from the sternum and collar bone, and inserts onto the skull below the ear. Now, this muscle is not really that strong (who does neck exercises??). Working with any other neck muscles to resist the rotation, this probably puts opposite torque in at around 1.35 Nm. Plug everything back in (with our added torques), and we still only get the force (128 N) needed to curl a 29lb dumbbell. Huh, so your neck muscles really don't help you, do they?

"What about the mandible??" you say...well it's pretty strong actually. It requires about 125 lbs of force to dislocated it when acting in the direction we are, so the neck will dislocate first.

Even if you don't totally destroy the spinal cord, there's some really important crap in the cervical region (like the vertebral arteries and spinal nerves) that will totally kill you if they get messed up. There's the vertebral arteries, for one. You can break those and die of internal bleeding even if your spinal cord is fine.

Another note about where this will happen: you have seven cervical vertebra (C1-C7). C1 and C2 are pretty weird and close nit, so they're probably not going to give first. The greatest amount of flexion is between C4,C5,&C6. Also, because C7 is pretty sturdy in its attachment to the thoracic vertebra, C6 can also dislocate off of it easier. So I bet this dislocation will happen in the lower half of the neck.

Bottom line: if you can curl a 30lb dumbbell, you can probably generate the necessary force to break a grown man's neck.

Anyways, I could go on and on about this (I have a thirty-five page literature review I wrote over this topic), but I think my point has been made. Just one final thing: you probably can't do this irl, bc you need the perfect circumstances and the right technique. Oh well, stuff like this is probably best left to Chuck Norris and Arnold.

#medicine#med student#medical school#med school#med studyblr#anatomy#injury#whump writing#cervical dislocation#neck snap#vertebra#spine

22 notes

·

View notes

Text

if you hug me there's more than pressure and warmth,

there is madness, and the reins temperance holds... lost.

Love is leverage and its torque multiplies beyond any plausible strength.

Love tastes of salty sweat and naive gazes asking to solve souls,

it's a hug and its intention, perceived far before touch.

If you hug me, madness and insanity will rain on us,

the leverage, so strong, souls fuse and fear dissolves.

Love is sloppy kisses, lips sliding with no hold,

it is naivety dressed in question marks as stitches,

in every gaze... whenever eyes not shut.

If you hug me I will resign the contract of my soul,

the leverage is so strong, mind will fuse lust and love.

Love is steam, like the mist wanting the ascent of the moon in fall.

If you ask me, what love is.

4 notes

·

View notes

Text

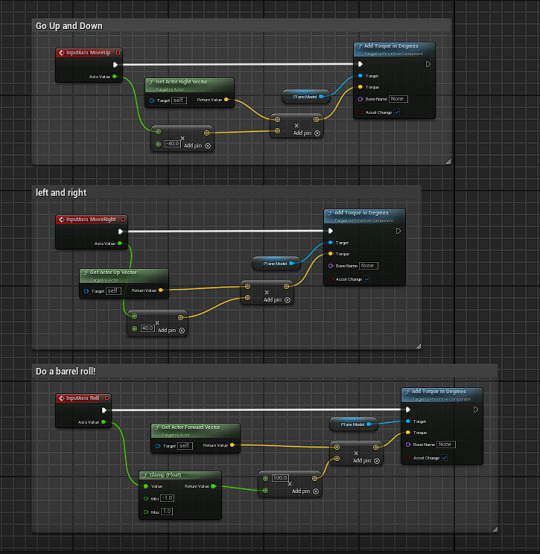

Creating Movement On my Plane

The movement for spinning and moving up and down is all pretty similar, so i will compile it into one post. all you need to do is get the correct vector for the type of movement, multiply the value, to make you turn faster or slower, and add it to a 'add torque in degrees' node. this will affect its acceleration.

The rolling wont be used in my final game, the video tutorial i was using just added it and i cant in my game.

This now leaves me with a fully working plane that i can use for whatever i want. next i am going to add proper sound and maybe some smoke effects coming from the back of the plane.

#games#indie games#pc games#steam games#video games#unreal engine#epic games#5.4#flight simulator#plane

2 notes

·

View notes

Text

Torque Sensor vs Cadence Sensor: Which One Feels More Natural?

The Short Answer: Feel

For a ride that feels like a natural extension of your own pedaling power, the torque sensor is the clear winner. It amplifies your effort in a way that feels natural. In contrast, a cadence sensor provides a more automated, consistent push as soon as you start pedaling, regardless of how hard you push. This happens no matter if you're barely touching the pedals or pushing with all your strength.

How The Sensors Work

Understanding why they feel different comes down to what they measure. We find it helpful to think of them in simple terms when comparing torque sensor vs cadence sensor options.

The Torque Sensor: Measuring How Hard You Pedal: This sensor uses a precision strain gauge to measure the actual force you apply to the pedals. The best analogy is that it gives you "superhuman legs," seamlessly multiplying your effort. When you push harder on the pedals, the motor immediately responds by giving you more power assistance.

The Cadence Sensor: Measuring If You Are Pedaling: This sensor works like an on/off switch. It uses a series of magnets on the crank arm to detect that the pedals are turning, but it doesn't know how hard you're working. Think of it like a "cruise control" for your best fat tire ebikes that kicks in to maintain a set assistance level whenever it detects pedaling motion.

Comparing The Ride Feel

This is where the distinction becomes most apparent. The technology directly shapes your experience on the saddle, and from our experience, the difference is night and day when you compare cadence vs torque sensor performance.

With a torque sensor, the power delivery is proportional and seamless. When you approach a hill and push harder, the motor responds instantly with more assistance that matches your effort level. It feels incredibly responsive and connected, as if you're simply a much stronger version of yourself on a traditional bicycle. This creates an active, engaging ride that many cyclists prefer because it maintains the feel of traditional biking while adding power.

A cadence sensor, on the other hand, delivers a more noticeable "kick" when the motor engages. Once you start pedaling, the assistance comes on at a pre-set level and stays there regardless of your effort. This is excellent for relaxed, flat-ground cruising where you just want an effortless push without thinking about it. The trade-off is that it can feel a bit jerky in stop-and-go traffic, and you might get more power than you need on flat ground or less than you want on hills. You can learn more about how e-bike motor sensors work to understand the technical nuances.

A Practical Comparison

Beyond the ride feel, practical factors like cost and efficiency play a major role in your decision. Torque sensors are more complex and thus lead to a higher e-bike price point, but they often provide better battery life and a more refined riding experience. For more in-depth community insights, you can review real-world rider experiences.

Our Final Verdict

So, which sensor is right for you?

A torque sensor offers a natural, responsive, and efficient ride for those who want to stay engaged with their cycling and tackle varied terrain. This type of sensor works best for riders who enjoy the feeling of pedaling and want the motor to enhance rather than replace their effort.

A cadence sensor provides a simple, affordable, and effortless cruise for riders who prioritize ease and consistency, especially on flatter journeys. There is no single "best" sensor—only the one that is best for your needs and riding style.

Frequently Asked Questions

Q: Can I upgrade from a cadence sensor to a torque sensor later?

A: Upgrading sensors usually requires significant modifications to your e-bike's motor system and frame. It's generally more cost-effective to choose the right sensor type when purchasing your e-bike initially.

Q: Do torque sensors require more maintenance than cadence sensors?

A: Torque sensors are more complex but don't typically require additional maintenance from the rider. Both sensor types are designed to be maintenance-free during normal use, though torque sensors may be more expensive to replace if they fail.

Q: Which sensor type is better for commuting to work?

A: This depends on your commute route and preferences. Torque sensors work better for hilly commutes or when you want exercise, while cadence sensors are ideal for flat routes where you want to arrive without sweating.

Q: Do professional cyclists prefer torque sensors over cadence sensors?

A: Most professional and serious recreational cyclists prefer torque sensors because they provide a more natural riding experience that's closer to traditional cycling. The proportional power delivery helps maintain proper pedaling technique and training benefits.

Q: How much more expensive are e-bikes with torque sensors compared to cadence sensors?

A: E-bikes with torque sensors typically cost $200-$800 more than similar models with cadence sensors. The exact price difference varies by manufacturer and the overall quality of the bike's components.

0 notes

Text

Why a Door Is More Than a Slab A front door looks like a single panel, yet it works harder than any other component in your building envelope. - Thermal stopper. In most GTA homes the rough opening is 36 in × 80 in—nearly 20 ft² of potential air leakage. Even a 1-mm gap along the sweep can dump 9 % of your heated air every hour. Over one Toronto winter that’s the equivalent of leaving a basement window open for two months straight. A modern R-10 to R-16 core, tight magnetic gaskets, and a composite threshold transform that hole into an insulating wall. - Structural hinge-point. A door slab weighs 60–140 lb; the hinge-side jamb carries that load while absorbing every slam, wind-gust pull, and shoulder push. Rotten or under-sized framing lets the jamb twist, widening the latch gap, which fuels drafts and becomes a burglar’s pry point. A proper door replacement includes a steel-reinforced jamb and 3-inch screws driven into the house’s framing studs—small hardware that multiplies security. - Moisture gatekeeper. Doors sit at the slab or sill where rain splash-back, ice melt, and driveway salt accumulate. Outdated pine thresholds wick water inside walls, breeding mould and staining flooring. Upgrading to a composite, rot-proof sill with a thermal break stops capillary action cold. - Sound shield. A polyurethane-filled fiberglass slab raises the STC rating by up to 6 dB versus hollow-core steel, cutting street noise almost in half. Quieter foyers mean higher resale—Toronto REALTORS® cite noise reduction among the top three value bumps after a high-performance door swap. - Rebate magnet. Energy Star Zone 3 doors now qualify for a $250 Greener Homes Grant and a $100 Enbridge HER+ top-up. Factor in a 12 % HVAC-usage drop, and many buyers recover the net cost of professional door replacement in 24–30 months. Reliable Windows & Doors installs these energy-efficient doors across the GTA and answers 96 % of service calls within one business day—crucial when a warped slab means soaring utility bills or a fatigued lock leaves your home exposed. One visit turns the largest hole in your thermal envelope into a secure, silent, money-saving asset. Technician installing exterior door New front door from Reliable Five Cost Drivers You Must Know Cost DriverLow EndHigh EndWhy It MattersMaterialSteel skinFiberglass + foamEPS vs poly-iso R-valueCore R-valueR-6R-16Direct utility savingsGlass LiteNoneLow-E tripleAdds light—adds priceLock HardwareSingle deadboltMultipoint smartInsurance discountsLabour TierRetrofitFull frameRetrofit uses existing jamb Ignoring these factors skews any exterior door cost quote you find online. GTA 2025 Price Benchmarks Door SpecParts (CAD)LabourTotalSteel R-6 basic$790$350$1 140Fiberglass R-10, ¾-lite$1 280$380$1 660Fiberglass R-16, SDL, smart lock$1 980$420$2 400Double French, Low-E, multipoint$2 850$650$3 500 Rule of thumb: Add 15 % for brick removal; subtract $150 when bundling with window orders via Reliable’s Glass & Doors page. DIY vs Pro: Counting True Costs The YouTube Myth: “Just shim, screw, and add a little foam.”The Reality: - Bowed jambs. One extra shim on the hinge side can torque the frame 4 mm out of plumb. That twist forces the strike plate to ride high, so you slam harder; within a year the slab drags, the seal tears, and your “cheap” project whistles cold air. - Ripped weather-strip. DIY installers often squeeze foam too soon. Expanding foam bows jamb legs, tearing the magnetic gasket. A $12 strip seems minor until you’re heating the neighbourhood all winter. - Lock-set mis-align. A millimetre off at the latch becomes a 6 mm pry gap at the deadbolt. Insurance adjusters know it; burglars love it. Kick-ins spike whenever residents attempt “weekend” door replacement without a jig. What licensed residential door services crews do instead: - Laser-plumb jamb alignment—green-beam levels show ±1 mm tolerance before a single screw sinks. - Multi-point latch torque log—digital wrench records 35 in-lb on each bolt for even pull; you get the PDF for resale proof. - CSA & ENERGY STAR model codes—techs snap a photo of the sticker and file it with your Greener Homes form. Miss that tag and you kiss $350 in rebates goodbye. Dollar math: ScenarioUp-front Labour12-Month Follow-UpsNet Year-1 CostWeekend DIY$0Weather-strip $40 + slab plane $180 + higher heat $120$340Pro install (Reliable)$350$0 (labour warrantied)$350 Spend $10 more on Day 1, skip $340 in chronic fixes, keep your warranty intact, and lock in rebates that only certified entry door installation pros can validate. That’s why “Just shim & screw” usually snowballs into the most expensive “savings” you’ll ever make on a front door. Nine Proven Fixes (and Hazards They Prevent) - Composite threshold → ends rot vs pine. - Poly-iso foam core → R-16, saves $90/yr. - Thermal break sill → stops frost line. - Warm-edge lite spacer → kills edge condensation. - Multipoint lock → 5 % insurance discount. - PVC jamb cladding → zero scrape-&-paint. - High-elastic caulk → flexes at –30 °C. - Backer-rod pre-caulk → fills 10 mm gaps. - Digital torque report → resale proof. Skip three and “budget” door replacement morphs into repeated call-backs. Rebate & Finance Stack - Greener Homes Grant — $250 for Energy-Star Zone 3 door. - Enbridge HER+ — $100 top-up for R ≥ 10. - 0 % six-month promo — Reliable fronts the parts; you pay after tax refund. Stack both rebates and a $1 660 fiberglass door nets $1 310 out of pocket in Year 1—before energy savings. Case Study — Scarborough Split-Level Gets a High-Performance Door BackgroundRavi and Priya own a 1978 split-level near Birchmount & Lawrence. Their original steel door had warped so badly that daylight showed through a 4 mm gap at the sweep. Winter drafts made the foyer the coldest place in the house, and the single deadbolt rattled if anyone leaned on the slab. The Upgrade - Door replacement: R-16 polyurethane-filled fiberglass slab, factory-painted “Chestnut Brown.” - Glazing: ¾-lite Low-E argon unit with warm-edge spacer. - Hardware: Three-point multipoint lock, satin-nickel lever set, smart deadbolt sensor. - Trim package: PVC jamb cladding + composite threshold with thermal break. Cost Breakdown Line-itemPartsLabourTotalFiberglass slab + lite$1 480——Multipoint lockset$240——PVC jamb cladding$120——Professional labour—$380—Subtotal——$2 220Greener Homes rebate——–$250Net cost——$1 970 (Taxes omitted for clarity.) Measured Results (First 12 Months) MetricBeforeAfterDeltaAir-leakage @ 50 Pa (ACH)4.83.9–19 %Gas usage (m³ / yr)3 1002 575–17 %Insurance premium$1 120$1 064–5 %Appraised value*$846 000$860 000+$14 000 * Appraisal by GTA Homes Inc., six months post-install. Payback Math - Energy savings: $138 / yr (Enbridge rate × 525 m³ saved). - Insurance drop: $56 / yr. - Total annual benefit: $194. - Net cost after rebate: $1 970. Payback = 1 970 ÷ 194 ≈ 10.2 quarters → Month 26. At just over two years, Ravi and Priya broke even; every winter afterward delivers pure savings. Meanwhile, the foyer now holds steady at 20 °C even on –12 °C evenings, and the smart lock texts them if the door’s been left ajar—peace of mind no 1970s slab could provide. Take-away: A data-driven entry door installation can yield tangible cash returns, lower insurance risk, and add five figures to resale—proof that “cosmetic” door replacement is, in fact, a high-ROI energy retrofit. Installation Day Timeline ClockCrew TaskHomeowner View7 a.m.Arrival, floor tarpsSnap “before” photo8 a.m.Old slab out, jamb scored10-min draft10 a.m.New jamb set, laser-plumbSmell fresh caulkNoonSlab hung, multipoint torquedHands-on demo1 p.m.Foam inject & trimLunch break2 p.m.Cleanup & torque PDF e-mailAdmire airtight fit Maintenance Matrix SeasonTaskMinutesToolJanuaryLube hinges10Teflon sprayAprilWash sill, inspect caulk15Vinegar + clothJulyTorque lock screws10#2 driverOctoberSeal check dollar-bill test5Dollar bill Miss two seasons and energy-efficient doors lose 15 % R-value. Printable Pre-Winter Door Audit - Feel for cold spots at rails. - Inspect sweep for daylight. - Tap jamb bottom—hollow = rot. - Check lock alignment < 2 mm play. - Spray hose—look for leaks. Fail two? Schedule Reliable’s entry door installation assessment before freeze-up. Energy-Savings Math Door R-valueAnnual HVAC Save10-Year Net vs R-6R-10$55+$300R-16$90+$620R-20$110+$780 Even high-end R-20 offsets extra cost by Year 7—hard numbers that justify premium door replacement. Acoustic & Security Perks—Why a Premium Door Replacement Does More Than Keep Out Drafts 1. Laminated Lite = Urban QuietSwapping a thin dual-pane insert for a laminated Low-E glass lite raises the Sound Transmission Class (STC) rating by an average 6 dB. That’s a perceived halving of traffic noise—crucial if you face the Gardiner or a busy arterial. Clients who bundle laminated glass with our entry door installation package consistently report lower TV volumes and longer baby-nap windows. Tech note: The PVB interlayer in laminated glass dampens low-frequency rumbles (30–125 Hz) better than triple-pane alone. Pair it with a polyurethane-filled slab and you’ll match the acoustic comfort of many condo curtain walls—without paying commercial-grade exterior door cost premiums. 2. Multipoint Lock = Built-in “Steel Frame”Standard single deadbolts focus all kick-in force on one ¾-inch strike plate. A multipoint lock distributes impact across three steel hooks—top, mid, and sill—boosting kick resistance 45 % over the CSA baseline (see CSA test 2024-C-03). Insurers notice: many underwriters shave 3–5 % off premiums when policy photos show an engaged multipoint throw. Bonus security tech: Add a smart sensor module for $45 during installation; app alerts pop if the latch slips or vibration spikes—cheap peace of mind compared to post-break-in glass cleanup. 3. Value Play vs Noise & Theft Costs UpgradeParts Δ (CAD)Annual BenefitPaybackLaminated lite (+STC 6 dB)+$180~$0.00 energy, priceless silence3–4 yrs resale valueMultipoint lock+$95–$40/yr insurance< 3 yrs Spread over the life of a 25-year warranty, these add-ons cost pennies a day—pennies that prevent late-night siren fatigue and lock-break failures. And because Reliable bundles them into one residential door services quote, you still see a single labour line, a single rebate form, and a single warranty certificate—no juggling subcontractors or hidden line items. 4. Energy SynergyThicker laminated glass + tighter multi-hook compression means fewer air exchanges; combine that with an R-16 slab and you unlock true energy-efficient doors status. In blower-door follow-ups, homes that choose both upgrades average 0.2 ACH lower leakage than identical doors without them—worth an extra $20–$25 in annual heating savings. Bottom Line: For a marginal bump in exterior door cost, laminated lites and multipoint locks deliver quieter rooms, stronger security, lower insurance, and better blower-door numbers—an unbeatable quartet for any serious door replacement. xtended FAQ — Everything You Wanted to Know About Door Replacement QAIs tempered-glass mandatory?Yes—Ontario Building Code OBC 9.6.1.5 requires tempered or laminated lites when glass is within 600 mm (24 in) of the floor, stairs, or door handle. Choosing a laminated lite also bumps STC by 6 dB—an acoustic bonus for homes near the Gardiner.Do I pay GST/HST on a rebate?You pay tax only on the invoice price. Greener Homes Grant and Enbridge HER+ funds arrive as non-taxable cheques or e-transfers. Reliable itemises rebates separately so your accountant sees a clean paper trail.Lead-time realities?• Stock steel slab: ~5 days • Textured fiberglass: ~10 days • Custom colour or SDL grille: ~15 days. Holiday rush or factory maintenance can add 2–3 days. Reliable’s portal shows live ETA the moment your entry door installation order is locked.What’s the warranty?Fiberglass skin & frame: 25 yrs • Poly-iso core insulation: R-value guaranteed 20 yrs • Glass seal: 10 yrs • Labour (install & adjustments): 3 yrs. Keep your digital torque report—warranty service is free if all hinges still read ≥ 25 in-lb.DIY allowed in condos?Almost never. Most condo declarations classify front doors as fire-rated “F” assemblies or part of the common element. Board approval and licensed residential door services are mandatory to keep the fire-door certificate valid.What R-value do I really need?For detached or semi-detached GTA homes, R-10 doors meet Energy Star Zone 3. R-16 energy-efficient doors deliver best payback (~$90 / yr gas savings) and qualify for the $250 Greener Homes rebate.Will a multipoint lock fit my old frame?Only if the jamb is plumb and at least 1-1⁄8 in thick. Most older pine frames flex; pros add a steel-reinforcement plate during door replacement to handle the three-bolt spread.Exterior door cost vs ROI—rule of thumb?Energy savings + insurance discount should pay back ≥ 40 % of net cost within five years. Example: a $1 660 fiberglass door that saves $94 / yr gas + $42 / yr insurance pays back 41 % in Year 5—textbook ROI.Can I reuse my sidelights?Only if the dimensions and glass spec match the new slab. Often, swapping to Low-E sidelights adds R-2 and shaves installation labour because the frame stays intact.Disposal of the old slab and jamb?Included. Reliable recycles steel skins and composites under Ontario EASR regulations at no surcharge—one less hidden exterior door cost item.Financing options?0 % six-month promo for qualified homeowners; 6.99 % for 36 months. Financing paperwork is signed on the technician’s tablet at the end of the installation visit—no bank branch needed.Permits required?Same-size swap: No permit. Widening or adding sidelights: Yes—Reliable provides engineer-stamped drawings for $185 flat, refundable if you proceed with the full install contract.Can I get colour chips before ordering?Absolutely. A mobile sample case contains 20 standard hues plus six wood-grain films. Choose during the quote visit so manufacturing lead-time starts immediately. These deeper answers help you compare apples to apples—and ensure your next door replacement delivers savings, security, and zero-surprise paperwork. Key Takeaways (Screenshot-size) - ⏱ Pro swap in < 6 h → door off the hinges at breakfast, airtight & alarm-ready by lunch. - 🛠 R-10+ foam core → recoups its price in heating dollars 3 winters faster than a hollow R-6 slab. - 🔒 Multipoint lock = insurer smile → typical GTA premium cut 3 – 5 % once the underwriter sees the certificate. - 📑 CSA + Energy Star stickers → unlock $250–$350 in Greener Homes / Enbridge rebates—money wired back in weeks. - 🔇 Laminated lite (+6 dB STC) → Gardiner roar sounds like a distant fan; peace adds curb-appeal value. - 🌧 Composite threshold & PVC cladding → zero rot, zero repaint, zero HOA fines for at least 25 years. Follow these six checkpoints and a door replacement stops being an expense—it becomes a pay-back-within-two-years investment that’s quieter, safer, and maintenance-free. Ready for Quote? - Meet our team — About Us - Compare styles & prices — Glass & Doors - Book your 15-min estimate — Quick Quote Form Reliable Windows & Doors—turning drafty thresholds into statement entries since 2009. External References - Natural Resources Canada R-value tables — https://www.nrcan.gc.ca/ - ENERGY STAR Canada door specs — https://www.energystar.gov/ Read the full article

1 note

·

View note

Text

What Is a Worm Gearbox? A Complete Guide for Industrial Buyers

When it comes to industrial machinery, reliability and efficiency are non-negotiable. One critical component that plays a pivotal role in achieving smooth mechanical operations is the worm gearbox. Designed for high torque and compact design, worm gearboxes are widely used in industries ranging from manufacturing and mining to packaging and automation.

This comprehensive guide will help you understand how worm gearboxes work, their key components, factors affecting their performance, and why Santram Engineers is the go-to partner for robust and reliable gearbox solutions.

What Is a Worm Gearbox?

A worm gearbox (or worm gear reducer) is a type of gear arrangement in which a worm (screw-shaped gear) meshes with a worm wheel (similar to a spur gear). This system is particularly known for:

High torque transmission

Quiet operation

Shock-load resistance

Compact and space-saving design

Worm gearboxes are ideal for applications that require a high gear reduction in a limited space and where non-reversibility is preferred—meaning the load cannot drive the motor backward.

Key Components of a Worm Gearbox

A standard worm gearbox consists of several critical components that together enable efficient torque transfer and speed reduction. The main parts include:

Worm Shaft – A threaded, screw-like shaft that initiates movement in the gear system.

Worm Wheel (or Gear) – A toothed wheel that meshes with the worm to transfer motion.

Gear Housing – A sturdy enclosure that holds all components and provides protection.

Bearings – Reduce friction and support the worm and worm wheel.

Lubrication System – Ensures smooth operation and prevents wear.

Seals and Gaskets – Prevent leakage of oil and entry of dust or debris.

Each of these components must be precisely engineered and manufactured for the gearbox to function effectively under various industrial conditions.

The Role of Each Component in Performance and Durability

Each part of a worm gearbox contributes to its performance and durability. Here's how:

Worm Shaft: Made from hardened steel or case-hardened alloys, it must resist wear and fatigue under continuous load.

Worm Wheel: Often manufactured from bronze or other softer materials to allow smoother meshing and protect the worm shaft.

Housing: Designed from cast iron or aluminum alloys for vibration damping and corrosion resistance.

Bearings: High-load, precision bearings ensure smooth rotation and load distribution, critical for operational stability.

Lubrication System: Proper oil circulation prevents overheating, reduces wear, and extends service life.

Seals and Gaskets: Ensure a contamination-free environment inside the gearbox to avoid damage.

The synergy of these components directly affects gearbox longevity and reliability, especially in harsh working environments.

How a Worm Gearbox Works: Step-by-Step Technical Breakdown

Understanding the functionality of a worm gearbox is key to making informed purchasing and maintenance decisions.

Input Rotation: The motor rotates the worm shaft.

Threaded Engagement: The worm’s threads engage with the teeth on the worm wheel.

Rotational Transfer: As the worm rotates, it turns the worm wheel at a reduced speed.

Torque Amplification: The reduction ratio between the worm and wheel multiplies the torque output.

Unidirectional Motion: Due to the design, the worm wheel cannot drive the worm shaft, making it non-backdrivable in most configurations.

The gear reduction ratio depends on the number of teeth on the worm wheel and the threads on the worm shaft. Common ratios include 20:1, 30:1, and even 60:1—ideal for applications requiring slow, powerful movements.

Technical Factors That Influence Worm Gearbox Performance

Several technical considerations determine the effectiveness and suitability of a worm gearbox for industrial applications:

1. Gear Ratio

The greater the ratio, the slower the output speed and the higher the torque. Choose a ratio based on application torque and speed requirements.

2. Material Selection

Materials such as phosphor bronze for worm wheels and alloy steel for worm shafts provide the perfect balance of strength and wear resistance.

3. Thermal Management

High torque applications generate heat. Gearboxes must be designed to dissipate heat efficiently through housing material or external cooling systems.

4. Load Capacity

Gearboxes should be selected based on peak and average loads. Oversized units may last longer, while undersized gearboxes can fail prematurely.

5. Mounting Configuration

Worm gearboxes are available in foot-mounted, flange-mounted, and shaft-mounted options to fit various machinery layouts.

6. Lubrication System

Effective lubrication is critical to gearbox performance. Many units are factory-filled with synthetic oils and sealed for life, while others may need periodic oil changes.

Why Partner with Santram Engineers for Worm Gearbox Solutions?

Choosing the right supplier is just as important as selecting the right gearbox. Santram Engineers has earned a reputation for precision engineering, quality assurance, and customer-first service.

Here’s why industrial buyers trust Santram Engineers:

Industry Expertise: With decades of experience, we understand diverse industry needs and deliver tailor-made solutions.

Premium Materials: All gearboxes are built using certified, high-grade materials for unmatched durability.

Customization Available: Need specific ratios or mounting styles? We offer customized configurations to suit your setup.

End-to-End Support: From selection and installation to maintenance and spare parts—Santram Engineers has you covered.

Quick Lead Times: Fast manufacturing and delivery to keep your operations moving without delay.

When you choose Santram Engineers, you invest in more than just a gearbox—you invest in uptime, efficiency, and peace of mind.

Conclusion

A worm gearbox is more than a mechanical component—it’s the backbone of motion in many industrial systems. Understanding its structure, working principles, and maintenance needs helps avoid downtime and boosts productivity. With the right partner like Santram Engineers, you can ensure performance that lasts, even in the most demanding environments.

Read More: https://www.santramengineers.com/worm-gearbox-guide-industrial-buyers/

Need help choosing the right worm gearbox for your application? Contact Santram Engineers today!

0 notes

Text

India's No 1. SMSR Gearbox manufacturer in Ahmedabad

Introduction

In the heart of Gujarat’s industrial hub lies a name synonymous with quality, innovation, and reliability—Nisuka Industries, widely recognized as India’s No. 1 SMSR Gearbox Manufacturer in Ahmedabad. For decades, industries across the country have relied on Nisuka for high-performance mechanical power transmission solutions that power everything from conveyor systems to heavy-duty industrial machinery.

With a robust infrastructure and a commitment to precision engineering, Nisuka Industries has established itself as a leader in the field, not just in Ahmedabad but across India.

What is an SMSR Gearbox?

An SMSR (Shaft Mounted Speed Reducer) Gearbox is a compact and efficient solution designed to reduce speed and multiply torque. These gearboxes are directly mounted on the drive shaft of conveyors and machinery, eliminating the need for additional coupling and alignment.

They are ideal for industries that demand consistent speed control and high torque output, such as mining, cement, food processing, and textiles.

Why SMSR Gearboxes are Essential for Industry

SMSR gearboxes are critical components in industrial applications due to their

Compact design and easy installation

High torque and power transmission capabilities

Minimal maintenance and high durability

Cost-effective operation over time

When integrated into conveyor systems, they provide unmatched reliability and efficiency.

Why Nisuka Leads as the Top SMSR Gearbox Manufacturer in India

1. Cutting-Edge Manufacturing in Vatva GIDC, Ahmedabad

Nisuka operates a world-class manufacturing facility equipped with state-of-the-art machinery and a skilled workforce. This allows us to produce gearboxes with tight tolerances and long service lives.

2. Customized Engineering Solutions

We understand that no two industrial setups are the same. Our team of engineers works closely with clients to develop custom SMSR gearboxes that fit their specific application needs.

3. ISO-Certified Quality

Our gearboxes go through rigorous testing and quality checks. We follow international standards to ensure every product is reliable and durable.

Serving as a Conveyor Gearbox Manufacturer in India

Nisuka Industries also shines as a Conveyor Gearbox Manufacturer in India, offering a broad range of gearbox options for conveyor applications.

A key factor in choosing the right conveyor gearbox includes understanding load requirements, operating environment, gear ratios, and mounting options. Our team assists clients in making the best selection to ensure maximum uptime and energy efficiency.

Suspension Magnet Manufacturer in India – Enhancing Material Handling

In addition to gearboxes, Nisuka is a reputed Suspension Magnet Manufacturer in India. These powerful magnets are used to remove ferrous contaminants from conveyor systems in industries like recycling, mining, and food processing. They enhance product purity and reduce wear and tear on processing equipment.

Supporting Equipment: Plummer Blocks from Nisuka

We also manufacture Plummer blocks in Ahmedabad, designed to support rotating shafts with superior stability. Our plummer blocks offer excellent load-bearing capabilities and are made with high-grade materials to withstand harsh operating conditions.

These are widely used in mining, cement, and material handling industries.

Key Industries We Serve

Nisuka’s gearbox and industrial solutions are trusted by:

Cement and aggregate plants

Mining and mineral processing units

Textile manufacturers

Paper and packaging units

Food and beverage processing plants

Each industry benefits from our precision-engineered products and dependable customer service.

Conclusion

As SMSR Gearbox Manufacturer in India, Nisuka Industries continues to redefine industrial performance with its robust and reliable gearbox solutions. Whether you’re looking for an SMSR gearbox manufacturer in India, a Conveyor Gearbox Manufacturer in India, or even a Suspension Magnet Manufacturer in India, Nisuka delivers excellence across the board.

With precision-engineered Plummer blocks from Ahmedabad and complete after-sales support, we ensure your operations run smoothly and efficiently.

0 notes

Text

The Diamond Files are a Perfect Tool to be Used for Various Activities

The stainless steel tool supplier in Dubai UAE supplies diamond files made up of smaller particles. This gives the tool a fine grip. Let us know what are the uses of this tool.

KNOW MORE>> https://azaharalitools.wixsite.com/tools-suppliers-in-u/post/the-diamond-files-are-a-perfect-tool

#torque multiplier suppliers in uae#torque wrench supplier in dubai uae#workshop tools supplier in dubai uae#adjustable wrench supplier in dubai uae#firm joint caliper supplier in dubai uae#dubai

0 notes

Text

Understanding Load Ratings and Safety Factors in Eye Bolts

Eye bolts play a critical role in lifting, securing, and rigging operations across various industries. Despite their simple appearance, they are engineered to withstand specific loads—and understanding their load ratings and safety factors is essential to ensuring safety and structural integrity on any job site.

Whether you're working in construction, marine, manufacturing, or logistics, selecting the right eye bolt means more than just picking the right size. Let’s break down what load ratings and safety factors actually mean—and why they matter.

What is Load Rating in Eye Bolts?

Load rating, also known as working load limit (WLL), refers to the maximum load an eye bolt is designed to handle under normal operating conditions. This value is determined through testing and engineering standards, taking into account the type of material, design, and intended usage.

Factors That Affect Load Rating:

Material composition (e.g., stainless steel, forged carbon steel)

Thread type and depth

Presence of a shoulder (for angular loads)

Installation angle and mounting surface

Always ensure you're using eye bolts that match or exceed the expected load for the job. Underestimating this can result in dangerous equipment failures.

What Are Safety Factors in Eye Bolts?

The safety factor is a multiplier applied to the working load to account for unexpected stresses, load shifts, wear and tear, or human error. For example, if an eye bolt has a working load limit of 1,000 kg and a safety factor of 5, it means the bolt was tested up to 5,000 kg before failure.

Why It Matters:

Adds a margin of safety to prevent overloading

Compensates for real-world variables (shock loads, corrosion, installation errors)

Required by industry standards and safety regulations

Different applications may call for different safety factors. For critical lifting operations, a higher safety factor is typically used—especially when lifting people or valuable equipment.

Vertical vs. Angular Loads

It’s important to remember that load ratings decrease significantly when lifting at an angle. A bolt rated for 1,000 kg in a vertical lift might only support 250–300 kg at a 45° angle if it lacks a shoulder. This is why shoulder eye bolts are recommended for any angular or side-load situations.

Proper alignment, full thread engagement, and torque control during installation all contribute to maintaining the bolt’s load integrity.

How to Ensure Safety When Using Eye Bolts

Always check the manufacturer’s specifications before use.

Avoid using eye bolts that show signs of wear, rust, or deformation.

Use the correct washer and thread engagement (at least 90% thread contact).

Never exceed the stated working load limit—even momentarily.

Replace eye bolts immediately if any damage is observed.

Sourcing from reliable and certified manufacturers is equally important. Many project managers prefer working with the best eye bolt suppliers in India to ensure product quality, consistency, and compliance with safety standards.

Final Thoughts

Understanding load ratings and safety factors isn’t just technical jargon—it’s a critical part of workplace safety and efficiency. Always ensure your team is trained and your hardware is up to the task.

When in doubt, consult experts or work directly with reputable suppliers who can guide you in selecting the right type of eye bolt for your needs.

About SVIBO Industries

SVIBO Industries is a leading name among the best eye bolt suppliers in India, known for delivering top-tier industrial fasteners and lifting components. With an emphasis on quality, precision engineering, and adherence to global safety standards, SVIBO caters to clients across sectors like infrastructure, manufacturing, and heavy machinery. Their commitment to innovation and client satisfaction has earned them a trusted reputation in the industry.

For more information about SVIBO Industries,

Visit website: https://sviboindustries.in/ Address: 111,112,113 Mahatma Phule Peth, Block No 101, Sevadham Building, 1st Floor, Pune, Maharashtra 411042 Email: [email protected]

0 notes

Text

Specialty Caterpillar Tools for Precision Diesel and Heavy Equipment Repairs

In the world of heavy machinery, every second of downtime translates to lost productivity and profit. That’s why having the right tools for the job is absolutely essential—especially when it comes to servicing Caterpillar equipment. At Tillman Tools, LLC, we proudly supply high-quality Specialty Caterpillar Tools that are built to handle the demands of diesel mechanics, field service technicians, and heavy equipment repair professionals.

From Caterpillar Diesel Tools to Cat Engine Tools, our selection is engineered for performance, durability, and precision. Whether you work in construction, agriculture, mining, or transportation, our tools help ensure every Cat repair gets done right—the first time.

Why Specialty Caterpillar Tools Matter

Caterpillar equipment is known for its rugged durability, but servicing this machinery requires tools that match the same level of engineering precision. Generic or universal tools often fall short when it comes to accessing hard-to-reach components, maintaining tight tolerances, and meeting service specifications.

That’s where Specialty Cat Tools come in. These tools are specifically designed for Caterpillar machines—whether it’s a bulldozer, excavator, loader, or generator. From engine timing fixtures to injector pullers, Caterpillar Repair Tools are built to exact OEM specifications to ensure safe, accurate, and efficient service.

Top Categories of Caterpillar Tools Available at Tillman Tools

We offer a comprehensive range of Cat Service Tools to support engine overhauls, diagnostics, field repairs, and factory-level servicing. Below are some of our most in-demand categories:

1. Cat Engine Tools

Engine service requires precision—and that’s exactly what our Cat Engine Tools deliver. These tools are ideal for timing, valve adjustments, crankshaft alignment, and cylinder head servicing. Our inventory includes cam timing tools, torque multipliers, and specialized wrenches that match specific Cat engine models.

2. Caterpillar Diesel Tools

When it comes to servicing Caterpillar diesel engines, you need tools that can withstand high torque and deliver pinpoint accuracy. Our Caterpillar Diesel Tools include fuel injector tools, compression test kits, fuel line disconnect tools, and turbocharger installation tools. Designed for 3126, C7, C9, C15, and other popular Cat diesel engines.

3. Cat Hand Tools

Not all tasks require power tools. For tight areas or delicate components, Cat Hand Tools provide the control and precision needed for safe disassembly and reassembly. These include specialty pliers, seal drivers, pullers, spanners, and torque wrenches tailored for Caterpillar service procedures.

4. Caterpillar Service Tools

Routine maintenance becomes more efficient with the right Caterpillar Service Tools. These tools cover everything from cooling system servicing to oil filter housing removal and sensor installations. Our stock features gasket scrapers, pressure testing kits, specialty sockets, and more.

5. Specialty Cat Tools for Field and Shop Use

Many Cat mechanics work in remote environments, making portability and versatility a must. Our Specialty Cat Tools include rugged tool kits designed for field service trucks, mobile repair units, and industrial maintenance shops. Engine teardown and rebuild? We’ve got the right tool for every step.

Why Professionals Choose Tillman Tools for Cat Repair Solutions

At Tillman Tools, LLC, we understand the importance of reliable, high-quality tools that stand up to the rigors of daily use. That’s why industry professionals—from heavy-duty mechanics to fleet service providers—trust us for their Caterpillar Tools.

We support our customers with:

A curated catalog of Cat Repair Tools

Competitive pricing and volume discounts

Fast shipping across the U.S.

Decades of experience in technical tooling

Excellent customer service and technical guidance

Whether you're rebuilding an engine in the shop or troubleshooting in the field, Tillman Tools has the right tool for the job.

Serving America’s Technicians for Over 50 Years

Our company’s reputation is built on trust and reliability. For over five decades, Tillman Tools, LLC has proudly served mechanics working on not just Caterpillar equipment, but also autos, trucks, motorcycles, boats, and even airplanes. We've earned the trust of the U.S. military, government agencies, first responders, and trade schools through our unwavering commitment to quality.

When your work depends on heavy-duty equipment, you need Cat Diesel Tools that can keep up—and you’ll find them right here.

Conclusion

When it comes to maintaining and repairing Caterpillar machinery, only the best will do. Trust Tillman Tools, LLC for premium-quality Specialty Caterpillar Tools that meet the exacting standards of today’s heavy equipment professionals. With a wide inventory of Cat Service Tools, Cat Hand Tools, and Caterpillar Engine Tools, we are your one-stop solution for Caterpillar maintenance excellence.

Contact Here:

Tillman Tools, LLC 14050 Cherry Ave Ste R PMB 1003 Fontana, CA 92337

Mail Here! Phone: 909-334-4400 Email: [email protected] Customer Service: Mon - Fri 8am - 5pm CST

0 notes

Text

Let’s Talk Screws: The One Thing You Should Never Compromise in False Ceiling Work

You could have the finest gypsum boards, perfectly aligned channels, and the smoothest plaster in the world. But if your drywall screws are weak, rust-prone, or inconsistent in length, the whole system starts to fall apart—sometimes literally.

Screws are the backbone of any ceiling and partition system. And yet, they’re often the most underestimated component on site.

Today’s blog isn’t about hyping up a product—it’s about getting real. Because if you're looking for the Best Drywall Screw Supplier in India, you're probably tired of:

Screw heads snapping mid-installation

Rust showing up through paint

Threads that don’t grip metal or wood frames properly

Tools slipping because of poor-quality slots

Let’s fix that.

🎯 Theme: “The Smallest Component. The Biggest Consequence.”

A drywall screw may weigh just a few grams, but multiply that by a few hundred across every ceiling—and you realize how critical they really are.

Every screw:

Holds the weight of the ceiling system

Transfers vibration loads to the framework

Connects layers of boards, tiles, or panels

Determines how fast your team can move on-site

Influences whether the final ceiling looks clean or damaged

So, why are some teams still using generic screws just to save ₹20 a box?

The truth is, when you’re building serious interiors, you need serious fasteners—from a brand that’s earned the title of the best drywall screw supplier in India.

What Makes a Screw… the Right Screw?

Let’s break it down.

A professional-grade drywall screw must check these boxes:

High tensile strength: So it doesn’t shear when power tools apply pressure

Phosphated coating: To prevent rust and staining under humid conditions

Sharp self-drilling tip: So no pre-drilling is needed for metal frames

Bugle head design: So the screw sits flush without breaking the board surface

Precision threading: So it locks into both board and frame for maximum hold

Buildwell nails all of the above (pun intended). And that’s why it’s widely trusted as the best drywall screw supplier in India by contractors who’ve been burned by substandard fasteners before.

The Screw That Doesn’t Slip

On-site, speed is everything. Your team is racing against time—and tools can’t keep slipping. You need screws that:

Stay magnetic to the bit

Don’t wear down after 10 installs

Don’t require "gentle handling" like fragile imports

Let your team move fast without second-guessing torque settings

Buildwell screws are made for this exact environment. Whether you're working overhead on a ceiling grid or fixing gypsum boards vertically on a partition, the grip is solid and reliable.

That’s what makes Buildwell the best drywall screw supplier in India for those who value speed and precision equally.

Common Issues With Low-Grade Screws (And What They Cost You)

If you’ve ever bought drywall screws from a random local vendor, chances are you've seen one or more of these:

Heads that strip out when using a power driver

Screws that snap halfway through screwing in

Boards that crack because of irregular threads

Rust marks bleeding through paint after a few weeks

Let’s be honest: those “budget screws” cost you more in time, labor, and client trust than any savings they offer upfront. It’s no wonder experienced site managers insist on buying from the best drywall screw supplier in India—because long-term peace of mind matters more than short-term margins.

It’s Not Just the Screw—It’s the System

What makes Buildwell different is that its drywall screws are designed to be part of a complete system. That means they’re tested alongside:

Buildwell Gypsum Boards

Buildwell Structured Fiber Boards

Buildwell Metal Framing Channels

Jointing Compounds and Plasters

So, whether you’re installing ceiling tiles, double-layer drywall, or concealed lighting panels—everything works together.

That’s the advantage of sourcing from the best drywall screw supplier in India: there are no compatibility issues, no trial-and-error experiments, and no on-site guesswork.

Who’s Using Buildwell Screws?

Contractors building modular workspaces in NCR

Interior designers handling luxury apartments in Hyderabad

Developers installing false ceilings in hotels and restaurants

MEP contractors fitting out retail showrooms and clinics

These are professionals who’ve learned—sometimes the hard way—that cheap screws are expensive in the long run.

Available Sizes and Variants

Buildwell offers all standard lengths for ceiling and drywall work:

6x19 mm – for light-duty and PVC tile frames

6x25 mm – for single-layer gypsum boards

6x38 mm – for double-layer installations or SFB boards

6x50 mm – for wooden frames or thicker substrates

Each batch is phosphated for rust resistance and machine-friendly for fast driving.

Final Take: Don’t Let Small Decisions Create Big Problems

If a ceiling board falls, or a wall joint opens, the first thing people ask is: “Who was the contractor?”

They don’t ask what brand of screw you used. But you’ll know. And so will your team, when they’re back at the same site for rework that could’ve been avoided.

Choosing the best drywall screw supplier in India isn’t about luxury. It’s about accountability. About choosing materials that support your reputation—not chip away at it, one screw at a time.

Build once. Build smart. Screw it right—with Buildwell.

🌐Explore Ceiling Products at Buildwell.in

📧 Email: [email protected] 📲 WhatsApp: 7900336699 📞 Toll-Free: 18001028031

0 notes

Text

Hydraulic Bolt Tensioner, Bolting Tools, Hydraulic Cylinders, Hydraulic Jacks, Hydraulic Tools, Manufacturers, Suppliers, Wholesalers

We are Manufacturers, Suppliers, Wholesalers & Dealers of Bolt Tensioner, Hydraulic Bolt Tensioner, Bolting Tools, Hydraulic Cylinders, Hydraulic Jacks, Hydraulic Tools, Tube Cleaning Tools, Tube Expanders, Tube Pulling Equipments in Mumbai, India. Call Now!

Boiler Tube Expanders, Burnishing Tools, Electric Power Packs, Hand Tools, Heat Exchanger, Tube Expanders, Hydraulic Bolt Tensioner, Hydraulic Cylinders, Hydraulic Tools, Hydraulic Torque Wrench, Hydraulic Tube Puller, Impact Socket, Industrial Service Tool Kits, Industrial Sockets, Industrial Sockets And Accessories, Industrial Tools, Load Balancers, Manual Tools, Multipliers, Non Sparking Tools, Nut Runners, Pneumatic Nut Runners, Pneumatic Tools, Pneumatic Torque Wrenches, Power Pack Units, Rolling Burnishing Tools, Screw Driver Bits, Service Station Equipments, Slugging Wrenches, Spring Balancers, Structural Wrenches, Testing Equipment, Tool Balancers, Tool Kits, Torque Multipliers, Torque Tools, Torque Wrenches, Tube Cleaning Equipments, Tube Cleaning Tools, Tube Expanders, Tube Pulling Equipments, Tube Pulling Systems, Tube Pulling Tools, Tube Removal Tools, Tube Tools, Mumbai, India.

0 notes

Text

Planetary reducers are the “stable, cost-saving, and powerful” golden solution for enhancing industrial efficiency and reducing costs!

In the industrial and mechanical fields, planetary reducers are the unsung guardians. If a planetary gear reducer is removed, the motor will instantly turn into a destructive engine. For example, the motor will self-destruct due to excessive speed, the bearings and gears will break under high pressure. When the motor operates at a non-optimal speed, its efficiency will plummet, and the internal temperature of the motor will soar to above 800°C. One of the core functions of a gear reducer is to amplify torque. If the gear reducer is removed, the heavy-duty equipment on the industrial production line will get stuck due to insufficient instantaneous torque. While the motor burns out, the production line worth millions will be completely paralyzed…

Once the planetary gear reducer is missing, the consequences are unimaginable. With numerous advantages, the planetary gear reducer has rightfully become an essential and crucial part of modern industry.

I. Torque Amplification: Overcoming the Strong with the Weak Through the gear transmission ratio, the planetary gear reducer reduces the motor speed to a reasonable range, and at the same time, multiplies the torque, easily handling heavy-duty working conditions.

II. Precise Speed Regulation: Rock-Solid Stability The backlash of the planetary gear reducer can be controlled within 3 arc minutes, ensuring precise positioning of equipment in scenarios such as welding and lifting, and avoiding the risk of loss of control. When a planetary gear reducer replaces the servo direct drive, it can achieve the required precision while saving 60% of the cost.

III. Energy Conservation and Consumption Reduction: A Cost Killer With an efficient transmission design, the efficiency can reach up to 98%, reducing energy loss. Compared with the motor direct drive solution, the energy consumption is reduced by 20% to 30%. The savings in electricity bills during long-term operation far exceed the procurement cost of the planetary gear reducer.

IV. Extended Service Life: Worry-Free Maintenance High-quality planetary reducers (ATG planetary reducers by Qiandeyi) use carburized and quenched gears, with a service life of over 20,000 hours, and the maintenance cost is only one-third of that of the motor direct drive.

From improving efficiency to reducing costs, the planetary gear reducer proves with its strength that what is saved is not only money but also risks and time. Whether it is intelligent manufacturing or traditional production lines, choosing a gear reducer means choosing the “stable, cost-saving, and powerful” golden solution!

0 notes