#Tower Crane Mast Section

Photo

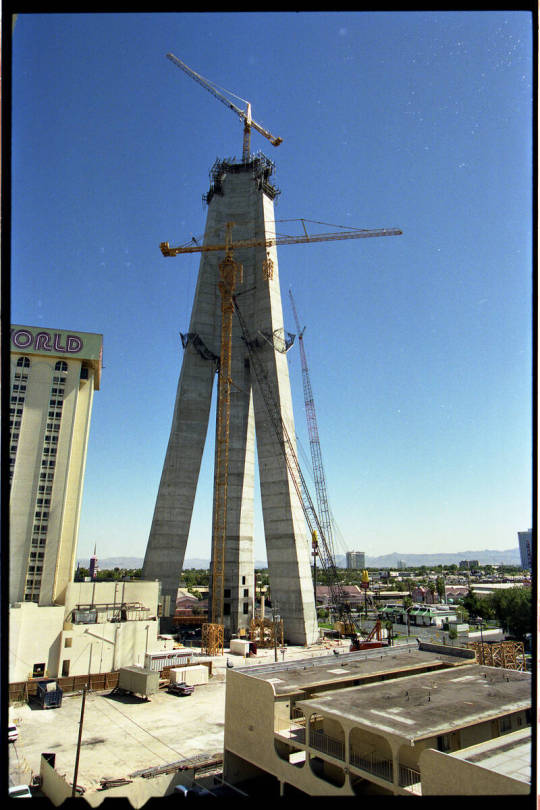

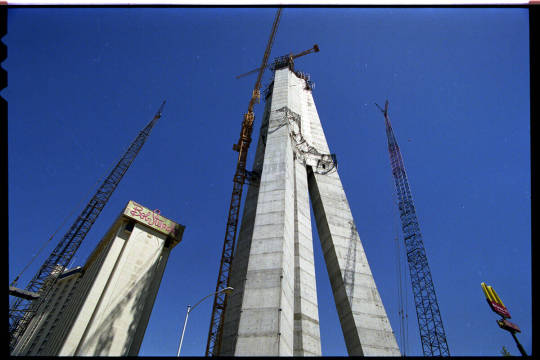

Stratosphere construction, September 9, 1993

A giant crane next to the Stratosphere Tower that is building itself by inserting 20 foot sections into its mast on 9/9/93. The crane will remove debris from an Aug. 29th fire at the tower.

Photo by John Gurzinski, Las Vegas Review-Journal

56 notes

·

View notes

Text

Bulong tổ hợp khung/ thân cẩu tháp

Bulong tổ hợp khung/ thân cẩu tháp

M27 x90 mm

Bolt mast section for tower crane

Bulong tổ hợp khung cẩu M22x 62 ; M22x65; m24x70; M27x 90; M36x 100; m35 x 110

Liên hệ

View On WordPress

0 notes

Photo

Apollo Mechanical tubes are low-diameter, high-thickness tubes used in heavy-duty applications such as tower crane mast sections, gantry cranes, trailer hitches, and agricultural gear. They are also utilized as support frames for heavy machinery and industrial equipment. For heavy-duty machinery that needs a larger load-bearing capability, mechanical tubes are perfect.

https://aplapollo.com/apollo-mechanical/

0 notes

Text

#Tower Crane Mast Section#1. The standard section is all processed by the overall sandblasting process. The surface is smoother and more beautiful. It is treated wit#with strong adhesion and longer durability.#2. All chord connections are gas-shielded and welded. All the products are tested by weld inspection#x-ray and UT ultrasonic inspection. It is more secure.

0 notes

Link

Incident Photo Storyboard What happened Waterproofing blanket Standard mast section Location where workers were fatally struck - they were within 5 m of each other Jib

1 note

·

View note

Text

Nova Scotia determines "weld failure" was the cause of 2019 tower crane collapse in Halifax

The Government of Nova Scotia has released their findings surrounding the tower crane that collapsed in September 2019 in Halifax during Hurricane Dorian.

In 2019, the province said they would develop a report and share their findings as part of the Department of Labour and Advanced Education's investigation into the collapse.

In a news release from the province on Thursday, they say they determined the crane collapsed "as a result of a weld failure that was not visible in the lower mast section of the tower."

"When subjected to high winds during the post tropical storm, it caused the crane to collapse," read the release.

The province says the investigation also found that the tower crane owner and operator met the provincial and Canadian safety standards, along with all provincial legislature and regulatory requirements to prevent the event from occurring.

"Currently, Nova Scotia's existing legislation, regulations and adopted Canadian Safety Association standards related to the operation of tower cranes are in line with all other provinces," wrote the province in a news release.

The province says they plan to meet with all tower crane owners and operators in the province to review their recent findings. They will also require that all crane masts be thoroughly cleaned, inspected, and tested immediately to identify any defect or deterioration.

from CTV News - Atlantic https://ift.tt/3v8CLXB

0 notes

Photo

Liebherr HC154 mast section zcjj provides accessories for various types of tower cranes to help you save costs to the greatest extent while ensuring quality. Help you solve all kind tower crane related problems. (Such as :Installation, disassembly, maintenance, repair, update).#башенныйкран #KranmitTurm #Grue #برج #레인 #Cranemenara #برجكرين #ทาวเวอร์เครน #construction #heavyequipment #towercrane #towercranes #towercraneerection #potaincrane #towercraneoperator #towercranepics #ZCJJ #Crane #sym #towerCranerental #TowerCraneforsale #hoistcrane #towercraneccessories https://www.instagram.com/p/CHbqb0XlVDr/?igshid=j6zri1dbsslk

#башенныйкран#kranmitturm#grue#برج#레인#cranemenara#برجكرين#ทาวเวอร์เครน#construction#heavyequipment#towercrane#towercranes#towercraneerection#potaincrane#towercraneoperator#towercranepics#zcjj#crane#sym#towercranerental#towercraneforsale#hoistcrane#towercraneccessories

0 notes

Photo

Luffing Jib Tower Cranes TCD5030

Features1:

Luffing tower crane is Specially developed for urban use, offers jibs with an outstanding reach without requiring too much room for slewing motions – a special advantage if many cranes are to work on high-rise building and power plant sites.

China Self Erecting Tower Crane is typified by a raising arm to shorten or extend the working radius. Self Erecting Tower Cranes are operated independently of one another and their arms are pointed upwards. Such configuration allows a leverage radius of approximately 4 meters and a short back arms of about 8 meters, their range of motion is wide, yet they require a reduced area for operation.

We have more than 20 years experiences in manufacturing industries. We pass ISO9001 Certification, / Manufacture License of special equipment by AQSIQ, / CE certificate for the motors adopted on our construction equipments etc.National-level engineering and service team along with local agent providing worldwide after-sales service. Different types of mast section and tie-in for worldwide famous tower crane brands, Ball blasting and high quality of epoxy painting production line, make sure 100% compatible with the original products. Free easy wearing parts Plus One Year Warranty.

0 notes

Text

Products Specification

L69B2 Mast Section For Tower Crane Masts

Size: 2mx2mx3m

Materials: Q345B

Weight: 2110KG

Within: Pins, bolts, Ladder, Platform

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

#башенныйкран #KranmitTurm #Grue #برج #레인 #Cranemenara #برجكرين #ทาวเวอร์เครน

#construction #heavyequipment #towercrane #towercranes #towercraneerection #potaincrane #towercraneoperator #towercranepics #ZCJJ #Crane #sym #yongmaotowercrane

#towerCranerental #TowerCraneforsale #hoistcrane

#towercraneccessories #towercranerenovation

instagram

0 notes

Photo

Luffing Tower Crane TCD4522

Features1:

Luffing Jib Tower Crane is Specially developed for urban use, offers jibs with an outstanding reach without requiring too much room for slewing motions – a special advantage if many cranes are to work on high-rise building and power plant sites.

Luffing Tower Crane is typified by a raising arm to shorten or extend the working radius. China Self Erecting Tower Cranes are operated independently of one another and their arms are pointed upwards. Such configuration allows a leverage radius of approximately 4 meters and a short back arms of about 8 meters, their range of motion is wide, yet they require a reduced area for operation.

Free easy wearing parts Plus One Year Warranty.

Features2:

MODEL

TCD4522

MAX LOAD

8T

TIP LOAD

2.2T

JIB LENGTH

45M

FREE STANDING HEIGHT

25.5M

MAST SECTION

1.6X1.6X3/2X2X3M

0 notes

Text

#Tower Crane Mast Section#1. The standard section is all processed by the overall sandblasting process. The surface is smoother and more beautiful. It is treated wit#with strong adhesion and longer durability.#2. All chord connections are gas-shielded and welded. All the products are tested by weld inspection#x-ray and UT ultrasonic inspection. It is more secure.

0 notes

Text

What Types Of Equipment Are Used In Civil Construction?

what Types of equipment are used in civil construction?

The job of a civil engineer is to build different structures like bridges, highways, and waterways.

To do this, they use specialized construction equipment, tools, and instruments to guide them.

Civil engineering relies on survey equipment, earth moving equipment, heavy machinery, and other tools to make their jobs more comfortable and efficient.

Without the heavy equipment they use, the structures they build and design wouldn’t be safe.

Civil engineers also use geographic information systems and various drafting tools to map out and plot specific locations.

Civil construction also uses software to help them design the structures that need to be built at that location.

This is in addition to the different types of survey equipment civil engineers use to measure land and water areas, which may include a sophisticated GPS system designed for these types of applications.

In the article below, we will take a closer look at the heavy machinery used in civil construction projects.

Table of Contents

Excavator

Dragline Excavator

Backhoe

Bulldozer

Grader

Wheel Tractor Scraper

Trencher

Loader

Tower Crane

Paver

Stevens

Excavator

Excavators are essential construction equipment widely used in the civil construction industry.

Their general purpose is excavation, but other than that, they are also used for many purposes like heavy lifting, demolition, river dredging, cutting of trees, etc.

Excavators contain a long arm, with a digging bucket attached at the end.

The operator maneuvers the heavy equipment, from the cab of the excavator, throughout the construction site

The cabin arrangement can be rotated up to 360 degrees, giving the operator the ability to work multiple areas from one location.

Excavators are available in both wheeled and tracked forms of vehicles.

-back to top

Dragline Excavator

A dragline excavator is another piece of heavy equipment integral to the construction industry.

It is generally used for larger depth excavations.

A dragline excavator consists of a long length boom and a digging bucket that is suspended from the top of the boom using a cable.

Dragline excavators can be used for the construction of ports, for excavations underwater, or sediment removal in water bodies.

-back to top

Backhoe

A backhoe is another widely used piece of earth-moving equipment used in construction that can fulfill multiple purposes.

The name itself implies that the digging arrangement is on the backside of the equipment, while the loading bucket is on the front.

Backhoe loaders are one of the most versatile pieces of construction equipment. They have a wide variety of uses across the construction industry. They can be used as:

earth moving equipment

small demolitions at the construction site

digging holes

excavation

landscaping

breaking up of concrete, or asphalt.

dig trenches

loading and unloading materials

The bucket can be also replaced with other pieces of equipment like an auger, grappler, or hammer.

The backhoe is a useful piece of heavy equipment in the construction industry. With its many uses it's an integral piece of equipment to use on construction projects.

-back to top

Bulldozer

Bulldozers are a commonly used piece of equipment used in construction.

Thanks to their wide tracks the bulldozer are able to maneuver through difficult terrain no matter the construction site, and despite it being heavy equipment, this track helps to disperse the bulldozer's weight across a wide footprint, allowing it to work on different types of sites that may be muddy or sandy.

The bulldozer is primarily used as earth moving equipment. The blade on the front of the bulldozer is used to push or remove the soil, sand, and debris on construction sites.

This plate is lowered and raised using hydraulic pistons.

Bulldozers can also be equipped with an attachment called a ripper. A ripper is located on the back of the bulldozer and is used to break up surface rock, pavement, asphalt, or concrete.

-back to top

Grader

Graders, or motor graders, are a type of heavy equipment used for the construction of roads.

They are mainly used to level the soil surface.

Graders contain a horizontal blade between the front and rear wheels, and this blade is lowered into the ground while working.

The operating cabin is on the top of the rear axle arrangement.

Motor Graders are earth-moving equipment and can also be used to remove snow or dirt from the roads, flatten the surface of the soil before laying asphalt, or to remove the unnecessary soil layer from the ground.

While a bulldozer is used for rough grading on construction projects, the grader is primarily used to finish grade. Thanks to the adjustable blade on the grader, it can be adjusted to achieve a high level of precision.

-back to top

Wheel Tractor Scraper

A wheel tractor scrapers is a piece of earth-moving equipment needed to flatten the surface of the soil through scraping.

The front part contains a wheeled tractor vehicle, and the rear section includes a scraping arrangement including a horizontal front blade, conveyor belt, and a soil collecting hopper.

When the front blade is lowered onto the ground, and the vehicle is moved, the blade starts digging the soil above the blade level.

The soil excavated is collected in hopper through a conveyor belt.

When the hopper is full, the rear part is raised from the ground, and the hopper is unloaded at a soil dump yard.

The wheel tractor scraper is very efficient earth moving equipment when the cut and dump areas are close to each other.

-back to top

Trencher

The heavy equipment trencher is used in construction to excavate trenches in the soil.

The trenches are needed to lay pipeline, cable, or for drainage purposes.

Trenching machines are available in chain trenchers and wheeled trenchers.

They all contain a fixed long arm with a digging chain.

Chain trenchers are used when the ground is too hard for an excavator to cut through it. With the adjustable boom, chain trenchers are used for cutting wider trenches.

Wheeled trenchers have a metal wheel that has a digging tooth around it.

Wheeled trenchers are more suitable to excavate hard soil layers. Because of its wheel, this equipment is able to dig trenches at variable depths.

Either type of trencher is available in tracked as well as wheeled vehicle forms.

-back to top

Loader

Loaders are a piece of equipment used on the construction site to load the material onto dump boxes, dump trucks, etc.

Loaders are used in the construction industry to help remove materials from the construction site. Some of the materials that a loader moves may be excavated soil, demolition waste, raw materials, etc.

A loader contains a large-sized bucket at its front with a short moving arm.

The loader may be either tracked or wheeled.

Wheeled loaders are seen in construction sites, while tracked or crawled loaders are needed in places where wheeled vehicles cannot reach.

-back to top

Tower Crane

Tower cranes are fixed cranes needed for hoisting purposes in the construction of tall structures.

Heavy materials like concrete blocks, steel trusses, and frames can be easily lifted to the required height.

They consist of a mast, which is the vertical supporting tower, a jib that is the operating arm of the crane, a counter jib that is the other arm that carries a counterweight on the rear side of the crane, and an operator cabin where the crane can be operated.

-back to top

Paver

A paver or asphalt paver is a pavement laying equipment that is needed in road construction.

A paver contains a feeding bucket where the asphalt is continuously loaded by the dump truck.

The paver distributes the asphalt evenly on the road surface with slight compaction.

A roller is required after laying the asphalt layer for perfect compaction.

-back to top

STEVENS

These are just a few of the pieces of equipment utilized by civil engineers in the construction industry.

As your Single Source Solution, STEVENS has the engineers and the tools needed to handle your Civil Construction Projects.

They also have a team to build and complete your project on schedule, on budget, and up to the specific local codes.

To see how STEVENS can help with your Construction Project, click on the link below.

Check Out Our Most Recent Articles:

New Trends In The Construction Industry

How Technology Is Increasing Productivity In The Construction Industry

What Is Civil Construction?

0 notes

Link

Incident Photo Storyboard What happened Waterproofing blanket Standard mast section Location where workers were fatally struck - they were within 5 m of each other Jib

0 notes

Photo

One thing I really love about Seattle is that it has this perfect blend of greenery, structure, land texture, new growth, and life. What a gorgeous city! Did you know: "The typical fee for installation and disassembly runs around $60,000. This price includes shipping the crane to the site, renting the mobile crane used to assemble the tower crane, the cost of the crew that handles the assembly, etc. A typical monthly fee for a 150-foot-tall tower crane is approximately $15,000, with an additional charge to rent the climbing frame and extra mast sections." https://science.howstuffworks.com/transport/engines-equipment/tower-crane5.htm #citypic #ifoundwherethecranesare #frasiercrane #seattlecity #skylinephotography #greeneryinthecity #wakeupnerds (at Seattle, Washington)

#wakeupnerds#greeneryinthecity#seattlecity#citypic#skylinephotography#ifoundwherethecranesare#frasiercrane

0 notes

Text

Wrecks of the UK

MULBERRY DOCKS:

Location- Selsey

Depth: Maximum 10m

Size: Length=60m Width=17m

Sank: 1944

What is it ?

The Brits realised that they needed some more docks in France for them to off load cargo. They created the Mulberry docks as a portable dock to use until the allies were able to capture a French port.

Pre-fabricated in the UK, the concrete blocks were transported across to Normandy and then sunk.

On June 6th 1944 over 400 towed component parts (weighing 1.5 million tones) set sail.

Both Harbours were a success and fully functional by the time a huge storm hit causing extreme damage to the docks.

Remains in the UK:

The Phoenix Caissons were reinforced concrete caissons. They were collected and sunk prior to D-day. There were 6 different sizes ranging from 2000 tons to 6000 tons. Each was towed by two tugs at a rate of 3 knots. The caissons were initially sunk awaiting D-day and then refloated. People say that the name Phoenix was used because they were resurrected.

Sections of the Phoenix can be found at:

Thorp Bay – Southsea. Whilst it was being towed the Caisson began to leak and was intentionally beached. (Only assessable at low tide)

Pagham (known as the Far Mulberry) sank off the coast, settled and cracked and is now laying about 10m deep.

VALENTINE TANKS:

Location: Swanage

Depth: Maximum 15m

Size: Length= 5m

Sank: 4th April 1943

What are they?

Effectively they were floating (or sinking) tanks. The tanks had a canvas screen around the outside and used this displacement to float. The engines were then connected to the propellers.

Why was it called Valentine?

Theory’s of the name:

Originally people thought that the idea of the floating tanks was presented to the War office on St Valentine’s Day.

Then people started to wondering if Valentine was the middle name of the tank designer John V. Carden.

Other people think that Valentine is an acronym for Vikers-Armstrong-LTD-Elswick-Newcastle-upon-Tyne.

Lastly it could have simply just been a code word. What do you think?

The Wreck:

7 lay at the bottom of the bay. However only 6 were ever mentioned in diaries that documented the exercise.

Next year there will be an exercise to map and locate all of the missing pieces of the tanks.

On the wreck there is a permanent shot line and a rope that leads you down the side and another line that leads you to the next one.

It is full of wildlife making it a colourful and exciting wreck to explore.

AEOLIAN SKY:

Location:Swanage

Depth: Maximum 32m

Size:Length=148.7m

Sank: 4th November 1979

What is it?

The Aeolian Sky was a Greek-run freighter built in 1978. It has engines at the rear and four massive holds separated by equally massive masts and cargo derricks.

Why it sank:

This massive freight was fully loaded and on its way to Africa when bad weather struck. She collided with a German ship but came off worse. She was then towed to English water with a hole in her bow but was refused by Southampton and Portsmouth ports for fear of pollution. Eventually she was defeated and sank meaning the the millions of pounds of cargo was lost to sea.

The Wreck:

She sank laying on her port side, and has stayed in tact (bar the hole in her bow).

For first visitors it is recommended that you start your dive at the bow then heading over the superstructure to the stern to get the best picture. She still holds lots of interesting cargo for divers to look at from trucks to locomotives. Behind the superstructure is a surprisingly large area of stern deck, dominated by a large winch with cable wound on it.

For those wreck qualified a trip into the engine room can be beautiful yet eery.

KYARRA:

Location: Swanage

Depth: Maximum 29m

Size: Length=126m

Sank: 26th May 1918

What is it?

A luxury passenger voyager on its way to Australia via Plymouth to collect wounded soldiers to be repatriated..

Why it Sank:

The Kyarra was fully loaded with a mixed cargo of goods. As she was passing the Isle of Wight disaster struck as she was spotted by German submarine UB-57. Taking a direct hit to midship on the port side she quickly sank with 6 men loosing their lives.

The Wreck:

Originally people used to only dive her for the treasure that could be found. However, since she has been dived so much you are less likely to find this treasure now. The Kyarra has two buoys tied to it which surface on slack water only. For new visitors it is suggested staring at either the stern of the bow and working your way along. This is simply due to the size of it. If you keep to the port side of her you will be able to see the triple-expansion engines and the boiler. There are actually four boilers on this ship but only one is visible from the outside.

M2 SUBMARINE:

Location: Portland

Depth: Maximum 35m

Size: Length=93m

Sank: 26 January 1932

What is it?

In 1928 this submarine was converted to carry a seaplane which could be launched shortly after surfacing using a hydraulic catapult. Afterwards the plane would be hoisted back on board using a crane.

Why it Sank:

Unfortunately the launching of the plane went very badly and all 60 crew members died. After sending divers down to examine the cause of the sinking it came to light that the hanger door was still open with the plane inside.

The Wreck:

For new visitors you can dive starting from the Stern at 34m. There is a dual strut just forward of the rudder which would have held the propellers in place. Further on from the stern are two large hydroplanes on either side.

Moving on you come to the conning tower where the Peri scope and the masts are still standing proud. (20m)

You can drop down from there to see the hidden hanger and explore where the plane once sat. Finally if you look back you can see the catapult.

Other things to look out for are the four torpedo holes and an anchor.

COUNTESS OF ERNE:

Location: Portland

Depth: Maximum 15m

Size: Length= 73m

Sank: 16th September 1935

What is it?

It was first used as a paddle steamer passenger vessel. It was then demoted to a coal hulk in Portland Harbour. She sank because she broke loose from the Harbour mooring.

The Wreck:

This is a really nice dive due to how shallow it is and the marine life that has called it their home. The steamer lies upright almost parallel to the harbour wall with the shallowest part of the deck at 8m. She is reasonable in tact therefore easy to navigate.

On the deck of the ship stands a capstan and a mast with bollards located on the port and starboard sides. The ship provides several nice swim throughs for all those that are wreck qualified and on a sunny day, when the visibility is good you can see the length of the ship.

The best time to dive this ship is in late spring sue to the amount of marine life that comes to play. From nudibranchs to candy striped flat worms. The colour can shine through the water.

JAMES FENNEL:

Location: Portland

Depth: Maximum 19m

Size: Length = 38m

Sank: 16th January 1920

What is it ?

She is a distinctive looking steamship with a big boiler and engine. She sank as a result of grounding.

The Wreck:

The James Fennel is still in very good condition with a lovely swim through between the engine and the boiler, the con-rods are still standing erect and are very visible.

The bow is clearly visible and has opened up revealing fallen wreckage inside.

One of its main attractions is because the 4 bladed propeller is still in great condition with only one of the blades buried in the sand.

The ship since it fell has created a home for many different types of wildlife like crabs and pollack.

ST DUNSTAN

Location: West Bay

Depth: Maximum 29

Size: length= 61m

Sank: 23rd September 1917

What is it?

It was built for use for a dredger with large buckets that operated on a conveyor belt.

The associated machinery required a lot of room, hence the boilers and the engines were placed at the front. During the First World War the dredger was requestioned to operate as a minesweeper. She was sailing just past Portland Bill when she hit a mine laid by UC-21, turned upside down and quickly sank.

The Wreck:

Today the St Dunstan is a terrific dive and has to be ranked as on of the top dive sites for fish life. Bib, Cod and pollack are in great numbers with the guaranteed opportunity to fin through a shoal of fish.

Much evidence can be found of the mechanics of the actual tual bucket dredger.

The upturned hull on the port side is less broken and a little dull but on the starboard side many areas can be entered from underneath. Just behind the bow is a lovely swim through along the width of the ship between the two anemone coated boilers and the bow.

You can enter the engine room where you can still see the engines and huge cogs hanging from the ceiling.

POMERANIAN:

Location: West Bay

Depth: Maximum 36m

Size: Length= 116m

Sank: 15th April 1918

What was it?

It was a large imposing steamship with mixed cargo. The ship became famous amongst divers for it is believed to have been carrying 14 diving helmets. Although only one has ever been recovered.

Many lives were lost on this ship. The steamer was on its way back home to Newfoundland in Canada when the submarine UB-77 spotted her and a torpedo was fired with a direct hit. The ship went down fast and only one of the 56 crew survived.

The Wreck:

The highest point is midships where the shot usually lands. This is your starting point and the undisputed highlight. The cabins are are a wreck divers dream as you negotiate the spacious rooms and several gangways whilst staring up at the metal framing clad in dead men’s fingers. Heading to the stern you will pass the two partly buried boilers followed by the triple-expansion entrance. Then you can see two winches side by side.

At the stern you will see a somewhat broken rudder still attached to he ship and along side a single propeller blade that is sticking out of the sand.

SCYLLA:

Location: Plymouth

Depth: Maximum 25

Size: Length 113m

Sank: 27th March 2004

What is it?

HMS Scylla was a Leander-class freight of the Royal Navy. She was built on Devonport dockyard and after an active role was decommissioned in 1970 to be finally bought by the national marine aquarium. She wasn’t purchased for sailing but instead her life was to end underwater as an artificial reef. A large task was undertaken to make her safer to scuttle. Access doorways were cut for divers and all possible marine contamination removed.

The Wreck:

The Wreck has changed dramatically over the years in to a glorious shipwreck bursting with life. The freight is too large to cover in just one dive so the most dived route is alone shallow depths. The stern and lower decks are definitely worth the adventure but watch the silt as the whole wreck has a thick layer of silt covering it.

Here you can fin inside along the narrow corridors viewing filing racking and all manner of items. At 9m the bridge is also worth a visit. This is where the steering binnacle still stands surrounded by windows.

Finally you end up at the helicopter hanger.

JAMES EAGAN LAYNE:

Location: Plymouth

Depth: Maximum bow = 8-20m

stern= 23m

Size: length= 130m

Sank: 21st March 1945

What was it?

This US Liberty ship was in convoy on voyage from Wales to Belgium carrying US Army engineering stores. She was the lead ship and after passing the West Rutts was struck by a torpedo from the U-399 sub. Although holed on the starboard side between the rear holds, she didn’t sink immediately allowing time for all the Crew to be rescued. A last ditch attempt was made to beach her in shallow water but she didn’t make it.

The Wreck:

The wreck which is held in high esteem and savoured amongst divers. Dropping down the side will take you to the anchor hawse pipes with a hive of fishy activity often. You can fin inside the whole length of the wreck where archetypal columns soar up in great elegance. Beams cross the sealing spaced out almost perfectly to grant divers an easy exit. The holds are still filled with cargo from vehicle batteries to cogs and wheels.

MOHEGAN:

Location: Falmouth

Depth: Maximum 25m

Size: Length = 144m

Sank: 14th October 1898

What is it?

It was a luxurious steamship on voyage to New York. She sailed at full steam past the Eddystone lighthouse where a course was plotted but mistakenly the bearing was set wrong. Just as all the passengers were sitting down to dinner, the ship plowed into Vase Rock where the rudder was completely torn off and the hull badly damaged. The ship drifted over to Maen Voes where she sank in just 12 minuets. All the crew went down with the ship but 44 passengers were saved. In total 106 people lost their lives that day.

The Wreck:

The boilers tower up to dominate the scene and these alone will take a while circumnavigate. The gaps between the boilers are filled with wrasse and pollack as it is a safe haven from the divers bubbles. The rest of the ship has completely collapsed to leave predominantly a jumble of metal beams, mostly decorated by displayed of sea fans. Tall rocks lie around the wreckage where you can take a few interesting diversions to explore under the overhangs and inside the cervices.

0 notes

Text

Wonky crane gets Multiplex out of a tight fix

A skewed crane on London tallest tower site is turning heads in the city as passersby puzzle about the unusual set-up.

Angled bottom tower crane section sets crane back from facade

Multiplex asked its engineers to dream up the innovative solution for the 22 Bishopsgate tower which is so close to the pavement that there was no room for the crane in the busy street.

Engineers from Robert Bird Group came up with an ingenious design that inverts the mast at the base, tilting it back into the site.

A four-sided inverted steel pyramid stands on a pile cap and carries a standard tower crane section at a 20° angle.

A top steelwork fabrication braces the skewed structure back to the structural frame.

Tower crane sections can now be added vertically, outside the line of the building envelope, minimising disruption to the façade.

For the permanent works Severfield are the steel frame specialist contractors, who are site welding to connections embedded in the concrete cores by Carey.

from Construction Enquirer http://www.constructionenquirer.com/2017/05/23/wonky-crane-gets-multiplex-out-of-a-tight-fix/

0 notes