#Traceability

Explore tagged Tumblr posts

Text

📑🔬 Electronic Device History Record (eDHR) Service Market: Powering Compliance in MedTech

In an industry where precision and traceability are everything, the Electronic Device History Record (eDHR) Service Market is quietly transforming how medical devices are tracked, audited, and approved.

📈 Market Overview:

2024: USD 0.28 billion

2025: USD 0.29 billion

2033 (Projected): USD 0.44 billion

CAGR (2025–2033): 💡 5.3% growth

💻 By Type:

Software as a Service (SaaS): Scalable, cloud-based compliance tools

Platform as a Service (PaaS): Integrated ecosystems for medical device management

Other: Customized digital solutions for regulated industries

🏥 By Application:

Class I Medical Device Manufacturers – Simpler devices, strict standards

Class II Manufacturers – Moderate risk, rigorous documentation

Class III Manufacturers – High-risk, life-saving tech that demands impeccable records

🌍 Top Players Leading the Shift:

MasterControl (U.S.)

Siemens (Germany)

L Z Life Sciences (U.S.)

42Q (Sanmina) (U.S.)

QT9 Software (U.S.)

🔒 Why It Matters:

Ensures FDA & ISO compliance

Reduces human error

Streamlines audits

Improves patient safety

Supports digital-first manufacturing for modern MedTech

📎 Ready for the digital evolution in medical manufacturing? 🔗 Dive deeper into the report: Read here

#MedTech#eDHR#MedicalDeviceCompliance#DigitalManufacturing#SaaS#PaaS#HealthcareInnovation#MedicalSoftware#TumblrTech#SmartManufacturing#Traceability#RegulatoryTech

0 notes

Text

GoldBod targets cutting-edge digital traceability technology before 2026 - Nsemkeka

GoldBod targets cutting-edge digital traceability technology before 2026 – Nsemkeka The country is poised to revolutionise its gold sector with the rollout of a comprehensive digital traceability technology across the entire supply chain. This ambitious initiative, spearheaded by the newly established Ghana Gold Board (GoldBod), aims to enhance market access, boost the value of the nation’s…

0 notes

Text

0 notes

Text

youtube

From Farm to Global Market: Proven Strategies for African Sesame Export Success

Africa’s sesame potential extends far beyond bulk shipments. By tailoring seed varieties—white, red, black—to specific markets like China, Japan, Korea, Turkey, and the EU, exporters capture premium prices. Forming regional cooperatives or export clusters delivers the volume and reliability demanded by large buyers, while shared processing and quality‑control units ensure consistency. Obtaining certifications such as EU Organic, JAS, HACCP, ISO 22000, and implementing batch‑level traceability systems unlock strict, high‑value markets and foster buyer trust.

Mastering the complexities of logistics—understanding incoterms, phytosanitary regulations, fumigation, and preferred packing formats—minimizes port delays and shipment rejections. Finally, compelling farm‑to‑fork branding on platforms like Tridge, Alibaba, and LinkedIn amplifies your story: ethically grown, community‑supported, and sustainably sourced sesame.

Want the full blueprint? Dive into the complete article to explore in‑depth strategies, real‑world case studies, and step‑by‑step guidelines to take your African sesame from local fields to global shelves—and maximize your export success!

#AfricanSesame#SesameExport#AgriBusiness#FoodSafety#GAP#Traceability#OrganicSesame#ExportClusters#Logistics#SupplyChain#FarmToFork#SustainableFarming#CooperativeGrowth#GlobalMarkets#SesameSuccess#Youtube

0 notes

Text

Is your EV Battery Plant (EVBP) compliant with the European Union’s Ecodesign for Sustainable Products Regulation (ESPR)? The ESPR was enforced on July 18, 2024 to introduce an electronically accessible Digital Product Passport (DPP), a digital identity card for products, components, and materials, storing information to support sustainability of products, promote their circularity and strengthen legal compliance. End-to-end Traceability in EVBPs has an important role to play in ESPR compliance by increasing environmental consciousness with information transparency on raw material extraction, production, and recycling across the entire value chain. Please contact us to know more about how we can help with our solutions in tracking and traceability. For More Info: https://zurl.co/WvuZw

0 notes

Text

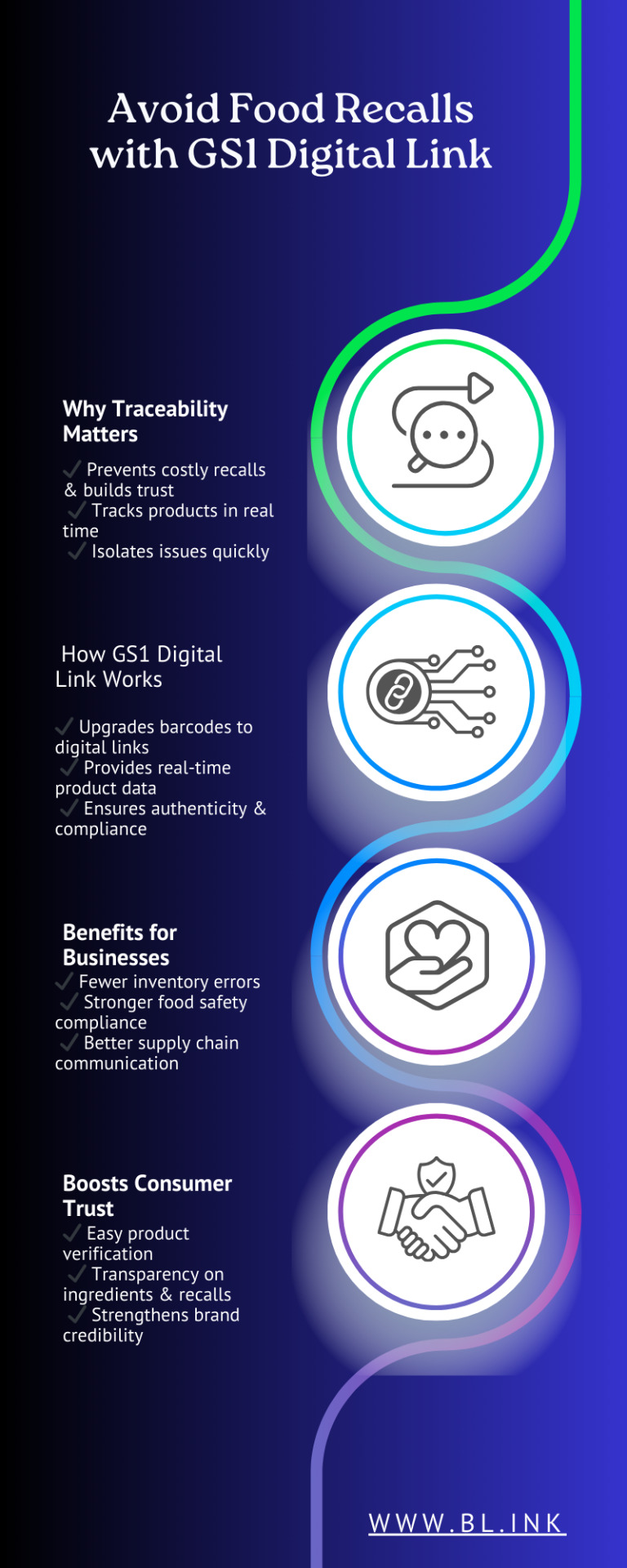

Avoid Food Recalls with GS1 Digital Link

Enhance food safety and prevent costly recalls with GS1 Digital Link! This smart technology upgrades barcodes to provide real-time product data, ensuring better traceability, compliance, and consumer trust. Businesses benefit from fewer inventory errors, stronger food safety measures, and improved supply chain communication, while consumers enjoy instant product verification and transparency. Stay ahead in food safety—embrace GS1 Digital Link today! 🚀

0 notes

Text

See how the HeatSign DE01 Dot Peen Marking Machine delivers deep, permanent markings on carbon steel surfaces. This video demonstrates its powerful engraving capability, ensuring that markings stay clear and visible even after galvanizing, painting, and other surface treatments.

With precision marking and industrial-grade durability, the DE01 is the perfect solution for industries requiring long-lasting identification and traceability. Watch the machine in action and discover how it can enhance your marking process!

🔹 Key Features: ✔ Deep and permanent dot peen marking ✔ Marks remain visible after galvanizing and painting ✔ Ideal for metal fabrication, steel processing, and industrial applications

For more details visit: https://www.heatsign.com/products/dot-peen-marking-machine/

#Technology#HeatSign#DotPeenMarking#DE01#DeepMarking#CarbonSteelEngraving#MetalMarking#IndustrialEngraving#PermanentMarking#Traceability#Manufacturing

0 notes

Text

Yes, you read that right! Pesticides cannot just be beneficial against pests. And applying higher concentrations doesn't add more safety levels. On the contrary, it affects all those in the chain such as animals, livestock, environment, etc. This is because the residues of pesticides including insecticides, fungicides, herbicides, rodenticides, molluscicides, nematicides, plant growth regulators and others can seep into animal and livestock’s digestive system thereby affecting meat, milk, eggs, etc. And these residues gets absorbed in many ways such as through the animal feed and fodder, direct application of pesticides on animals to protect them from external parasites, etc. Thus, product developers of agrochemicals can prevent such harmful impact by quantifying the levels of pesticide residues in meat, milk, eggs and edible meat by-products, such as fat, liver, kidney of ruminants, after the use of a pesticide product. If you want our expert team to quantify pesticidal residues in livestock as per OECD Test Guideline 505, contact us more details.

#EurofinsAdvinusAgroscience#metabolism#PesticideResidue#Traceability#AnimalProtection#AgrochemicalSafety#Eurofins#Advinus

0 notes

Text

ERP for the Food Industry: Enhancing Safety, Quality, and Supply Chain Management

In this highly regulated and competitive food industry, safety, quality, and efficient supply chain management are extremely critical. In the food industry, Enterprise Resource Planning (ERP) systems are now a prerequisite for food manufacturers, processors, and distributors, as they significantly streamline operations and maintain compliance for better efficiency in general. The following blog covers how ERP boosts food safety, product quality, and supply chain management in the food industry.

Why the Food Industry Needs ERP

Strict regulatory requirements, perishable inventory, fluctuating demand, and complex supply chains make running food businesses an exception. Integration into the system encompasses procurements, productions, quality control, and distributions of every business activity. ERP software thus helps food businesses stay compliant while reducing waste and maximizing profitability.

Improving Food Safety and Compliance food is a top priority for the manufacturers and non-negotiable compliance with FDA, FSSAI, HACCP, and FSMA. ERP plays an important role in safety through the following activities:

Automatic tracking of compliance : ERP tracks as well as documents processes to the required regulatory standards.

Real-time traceability : It can trace raw materials as well as finished products in the supply chain to quickly recall when needed.

Batch and Lot Tracking : Identify which batches are contaminated and prevent hazardous products from being shipped to customers.

Food manufacturers with ERP prevent recalls, bring more transparency into the system, and thus regain consumer confidence.

Product Quality Control Improvement Consistent quality of the product is a must in the food industry. ERP ensures high standards through the following:

Quality Checks at Every Stage: From raw material sourcing to packaging, ERP ensures strict quality control.

Standardization of Recipes and Production Processes : Avoiding deviations that impact product uniformity.

Monitoring Expiration Dates and Storage Conditions : Making food fresh and safe to eat

By streamlining quality control, ERP prevents human errors and inconsistencies in the production process so that only quality products are manufactured.

Simplification of supply chain management A well-managed supply chain provides timely delivery, waste reduction, and cost optimization. ERP also improves the supply chain by doing the following:

Inventory Optimization : Prevents overstocking and stock outs through accurate demand forecasting.

Supplier and Vendor Management : Monitor suppliers' performance, enabling timely procurement of raw materials.

Reducing Waste and Spoilage : ERP will help in proper stock rotation and warehouse management.

With ERP, food businesses are able to optimize logistics, decrease lead times, and reduce operation costs, ensuring a more sustainable and profitable supply chain.

Conclusion: The Future of Food Industry with ERP

ERP systems in the food industry are no longer a luxury, but a must-have. These systems will provide the necessary solution for ensuring safety and quality food products while improving supply chain operation optimization. A robust ERP system can be one of the significant investments you may make for your food business; it can take your business to a new height, achieving better efficiency, high compliance, and greater customer satisfaction.

#ERPForFoodIndustry#FoodSafety#FoodQualityControl#SupplyChainManagement#InventoryManagement#FoodManufacturing#ERPSoftware#RegulatoryCompliance#FoodProcessing#WasteManagement#Traceability#HACCPCompliance#FSMACompliance#SupplyChainOptimization#FoodIndustrySolutions

0 notes

Text

What is Traceability? Unpacking the Mystery Behind the Buzzword

If you’ve stumbled upon the term "traceability" and found yourself scratching your head, you’re not alone. At first glance, it might sound like something out of a sci-fi movie. But don’t worry—this blog will break down what is traceability, why it matters, and how it’s woven into the fabric of our everyday lives (yes, even yours). Spoiler alert: it’s a lot cooler than it sounds!

What is Traceability and Why Should You Care?

Let’s start with the basics. What is traceability? In simple terms, it’s the ability to track the journey of a product, component, or material through its lifecycle—from origin to final destination. Think of it like having a GPS for your coffee beans, sneakers, or even your favorite chocolate bar.

Now, why should you care? Because traceability means transparency. It ensures that products are safe, sustainable, and ethically sourced. Imagine knowing exactly where your avocado came from, how it was harvested, and whether the farmer was fairly compensated. Pretty empowering, right?

A Brief History of Traceability

Traceability isn’t a new concept. Ancient civilizations, like the Egyptians, used rudimentary systems to track grain storage and trade routes. Fast forward to the modern era, and traceability has evolved into a high-tech affair involving barcodes, RFID tags, and blockchain technology.

In today’s world, traceability is a critical component in industries ranging from food and fashion to pharmaceuticals and electronics. Why? Because consumers (that’s you and me) are demanding accountability. We want to know that our purchases align with our values—whether that means cruelty-free, environmentally friendly, or free of exploitative labor practices.

Types of Traceability: Breaking It Down

To truly grasp what is traceability, we need to understand its different forms. Here are the main types:

1. Upstream Traceability

This tracks the journey of raw materials from their source to the manufacturer. For example, tracing the cotton in your T-shirt back to the farm where it was grown.

2. Internal Traceability

This involves tracking components and processes within a single organization. Think of a car manufacturer keeping tabs on each part of a vehicle during assembly.

3. Downstream Traceability

This follows the finished product from the manufacturer to the end consumer. For instance, tracking your smartphone from the factory to the retailer where you bought it.

By combining these three types, companies can achieve end-to-end traceability—a holy grail for many industries.

Why Is Traceability So Important?

Alright, so we’ve covered the basics of what is traceability. But why is it such a big deal? Here are some compelling reasons:

1. Safety First

In industries like food and pharmaceuticals, traceability can literally save lives. It ensures that contaminated or defective products can be identified and recalled quickly, minimizing harm.

2. Ethical Accountability

Traceability sheds light on the supply chain, helping consumers avoid products linked to unethical practices like child labor, deforestation, or animal cruelty.

3. Sustainability

With climate change on everyone’s radar, traceability plays a key role in promoting sustainable practices. It enables companies to track and reduce their carbon footprint.

4. Fraud Prevention

Counterfeit goods are a global problem, especially in industries like luxury fashion and electronics. Traceability helps verify the authenticity of products.

5. Consumer Trust

In today’s hyper-connected world, trust is everything. Brands that embrace traceability can win over consumers by proving their commitment to transparency and integrity.

How Does Traceability Work?

Now that you know what is traceability and why it matters, let’s demystify how it actually works. Here’s a simplified breakdown:

Step 1: Data Collection

Every step of the supply chain generates data—from harvesting raw materials to shipping finished products. This data is collected using tools like barcodes, QR codes, RFID tags, and sensors.

Step 2: Data Integration

All the collected data is stored in a centralized system, often powered by technologies like blockchain or cloud computing. This ensures that the information is secure, tamper-proof, and easily accessible.

Step 3: Data Analysis

The data is analyzed to identify patterns, detect anomalies, and ensure compliance with regulations. Advanced analytics tools can even predict potential issues before they occur.

Step 4: Data Sharing

Finally, the data is shared with stakeholders—manufacturers, retailers, and consumers—to provide a transparent view of the product’s journey.

Real-Life Examples of Traceability

Still wondering, “What is traceability” in action? Here are some real-world examples to make it crystal clear:

1. Farm-to-Table Dining

Many restaurants now provide QR codes that let diners trace their meal’s ingredients back to the farm. Talk about a conversation starter over dinner!

2. Fashion Transparency

Brands like Patagonia and Everlane are leading the charge in fashion traceability, offering detailed insights into their supply chains.

3. Medical Safety

Pharmaceutical companies use traceability to ensure that medications are safe, effective, and free from contamination. This is especially crucial for vaccines and other life-saving drugs.

The Future of Traceability

So, what’s next for traceability? AI and machine learning could take predictive analytics to new heights, while blockchain could make supply chains even more transparent and secure.

In the not-so-distant future, you might be able to scan a product in a store and instantly access its entire history on your smartphone. How cool is that?

Conclusion

So, what is traceability? At its core, it’s about creating a world where products are safer, supply chains are more transparent, and consumers are more empowered. Whether you’re a coffee lover, a tech enthusiast, or a sustainability advocate, traceability impacts your life in ways you might not have realized.

By understanding and supporting traceability, we can all contribute to a better, more ethical world. And that’s something worth celebrating.

FAQs

1. What is traceability in simple terms?

Traceability is the ability to track a product’s journey from its origin to its final destination.

2. Why is traceability important?

It ensures product safety, promotes ethical practices, prevents fraud, and builds consumer trust.

3. Which industries use traceability?

Almost all industries, including food, fashion, pharmaceuticals, electronics, and automotive, rely on traceability.

4. How does technology support traceability?

Technologies like barcodes, RFID, blockchain, and cloud computing enable efficient data collection, storage, and sharing.

5. Can consumers benefit from traceability?

Absolutely! Traceability empowers consumers to make informed choices that align with their values.

Now, go forth and impress your friends with your newfound knowledge of what is traceability. Who knew a seemingly mundane concept could be so fascinating?

0 notes

Text

Best ERP software for Manufacturing Foundry India

A manufacturing foundry thrives on precision, efficiency, and innovation. To meet the growing demands of industries like automotive and plastic manufacturing, foundries need state-of-the-art solutions to manage their operations.

With advanced ERP software, manufacturing foundries can automate tasks, monitor processes in real-time, and ensure consistent quality. Whether you're producing parts for the automotive industry or components for plastic manufacturing, ERP solutions are the backbone of modern foundry operations.Read More https://www.timeline-erp.com/in/industries/foundry/

#projectplanning#projectmanagement#customercomplaints#dms#documentmanagement#erpsoftware#inventorymanagement#productionplanning#productionmanagement#qualitymanagement#qualityassurance#qualitymanagementsystems#SPC#FMEA#warehousemanagement#apqp#PPAP#ishikawa#traceability#scrapbooking#tracking#ERP#Resources

0 notes

Text

Navigating Food Supply Chain Challenges with ERP Solutions

Introduction

Managing a food supply chain is no easy task. From sourcing ingredients to delivering products to store shelves, there are countless moving parts that need to work smoothly. But with today’s ever-changing market, the food industry faces unique challenges, like fluctuating demand, quality control issues, and strict regulatory standards. To tackle these challenges head-on, many food businesses are turning to ERP solutions. Working with an Odoo development company can help companies customize their ERP systems to simplify processes, improve tracking, and ensure every step from farm to table runs efficiently and smoothly.

Common Challenges in the Food Supply Chain

In the food industry, supply chain challenges can impact everything, from cost and customer satisfaction to brand reputation. Here are a few key obstacles food businesses face:

Inventory Management: Managing stock levels can be tricky, especially with perishable goods that can spoil if overstocked.

Traceability: It’s critical to be able to trace every ingredient to its source to meet safety standards and provide transparency.

Quality Control: Ensuring high-quality products at every stage is essential to avoid recalls or brand damage.

Compliance: Food companies must follow strict regulations around safety, labeling, and environmental standards.

These challenges call for an all-in-one solution that brings transparency and efficiency across the board exactly what ERP software can offer.

How ERP Solutions Help Streamline Food Supply Chains

Implementing an ERP system, especially with the help of Odoo custom development, offers solutions that simplify and strengthen the supply chain in several ways:

1. Enhanced Traceability

With ERP software, businesses can easily track every stage of the food journey, ensuring traceability from the source to the consumer. This visibility is critical for regulatory compliance and building consumer trust. By working with an Odoo consulting company, businesses can customize their ERP to include real-time tracking and batch monitoring.

2. Smarter Inventory Management

Balancing stock levels is crucial in the food industry. ERP solutions help manage inventory efficiently by offering real-time data on stock levels, reordering needs, and demand forecasts. Through Odoo custom development services, companies can tailor inventory features to handle perishables and reduce waste.

3. Consistent Quality Control

Quality checks are essential at every step of food production. With ERP, businesses can set quality standards and monitor compliance, catching any issues before they become major problems. Odoo development services can help build specific quality control modules within the ERP, making it easier to meet regulatory and safety standards.

4. Streamlined Compliance

Food companies must keep up with evolving regulations, from labeling requirements to health and safety protocols. ERP systems make it simple to automate compliance tasks and generate reports as needed. An Odoo consultant can configure these features so businesses can focus more on their operations and less on compliance paperwork.

5. Efficient Supplier Management

Good supplier relationships are essential for a steady supply of raw materials. ERP systems streamline supplier management by tracking performance, monitoring deliveries, and making communication easier. Odoo consulting services can help develop customized supplier management tools that keep these relationships strong.

Why Choose Odoo for Food Supply Chain Management?

Odoo offers an affordable, flexible, and scalable ERP solution that is perfect for food businesses. By partnering with an Odoo development company, companies in the food industry can build custom modules that address their unique challenges. Key benefits of using Odoo ERP include:

Customization: Odoo is highly customizable, allowing businesses to build solutions tailored to their needs.

Integration: Odoo ERP integrates easily with other systems, ensuring a seamless flow of information.

Affordability: Odoo provides a powerful ERP solution at a reasonable price, ideal for businesses looking to enhance their supply chains.

Scalability: Odoo can grow with your business, making it a great long-term investment.

Conclusion

For food businesses navigating today’s complex supply chain, a strong ERP solution can make all the difference. With the right ERP, companies can improve traceability, streamline inventory, maintain high-quality standards, and meet all regulatory requirements. Partnering with an Odoo development company gives food businesses access to a customizable, affordable, and efficient ERP solution that simplifies supply chain management from start to finish. Investing in an ERP is a smart choice for food companies wanting to stay competitive, responsive, and ready to meet the ever-changing demands of the food industry.

0 notes

Text

As the global economy increasingly emphasizes transparency, traceability, and consumer trust, businesses are turning to technology to bridge the gap between physical products and digital ecosystems. The Qliktag Smart Connected Products Platform stands out as a powerful solution for businesses looking to create a digital layer for their products, enabling digital identities, product authentication, traceability, and engaging consumer experiences. This enterprise-grade connected products platform harnesses secure, unique digital identifiers for each product, making it possible to manage product data throughout its entire lifecycle. In this article, we explore the capabilities, applications, and benefits of the Qliktag platform, positioning it as an innovative leader in connected product solutions.

#connected products#smart products#product authentication#digital product passport#software platform#product information management#traceability#transparency#digital identity#product digital id#product digital link#nfc#rfid#qr code

0 notes

Text

Have you digitised Quality Check (QC) with Digital Stamping and Signature? #Digitisation involves real-time data from sensors, #IoT devices, and barcode/RFID scanning. It monitors quality metrics more efficiently than manual methods, triggering alerts for corrective action in real time. #DataAnalytics exposes trends in quality issues to identify and plan preventive maintenance needs also. QC reviews and approvals are digitised with digital signatures of quality personnel to ensure a secure and traceable approval process. All QC documents, including digital stamps and approvals are stored in a centralised document management system for easy access during audits. We provide holistic solutions for digitised QC and monitoring, including data acquisition and #Traceability. For More Info: https://zurl.co/22oCY

0 notes

Text

Combatting IUU Fishing: The Battle for the West Philippine Sea

The salty spray stung my eyes as I gripped the weathered wheel of my banca, a small Filipino fishing boat that had been my family’s legacy for generations. The sunrise cast a golden glow over the endless expanse of the Philippine Sea, a familiar sight that always filled me with a sense of peace and purpose. But lately, that peace had been replaced by a gnawing worry, a feeling like there was an…

0 notes

Text

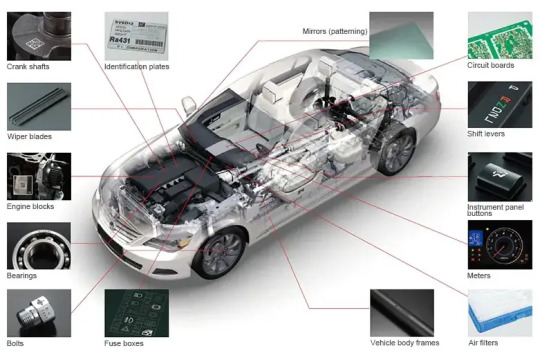

Reliable Car Part Labeling Made Easy with HeatSign Machine

HeatSign’s car part labeling machines offer reliable, high-quality markings on metal and plastic components. Designed for precision, they ensure traceability and compliance with industry standards. Simplify your labeling process and boost productivity with user-friendly technology.]

#HeatSignLabeling#CarPartMarking#PrecisionLabeling#MetalPlasticMarkings#IndustryCompliance#Traceability#ProductivityBoost#LabelingSolutions#UserFriendlyTechnology#ReliableMarkings

0 notes