#Used 4 Colour Offset Printing Machine

Explore tagged Tumblr posts

Text

Used 4 Colour Offset Printing Machine at IndiaBizzness Portal

Explore a wide range of used 4-colour offset printing machines at IndiaBizzness, your trusted B2B marketplace. These machines are ideal for high-quality, multi-colour printing needs in commercial and industrial applications. With robust performance, precision, and affordability, these pre-owned machines ensure excellent results for brochures, posters, packaging, and more. Find reliable brands and competitive prices to suit your printing requirements. Upgrade your printing operations with cost-effective solutions today!

0 notes

Text

HIKARI HK-270 MULTI COLOUR "FOR SALE" LABEL PRINTING MACHINE FROM MK PRINTECS MACHINERY

.

.

.

For More Information Contact Us ;

MK PRINTECS MACHINERY

( ALL KIND OF LABEL, OFFSET, CUTTING & SCREEN PRINTING MACHINE - IMPORTER, EXPORTER & SUPPLIER IN INDIA )

#4/168, Sivakasi - Erichanatham Main Road, Opp. To Ayyan Fireworks,

Aishwarya Nagar, Vellaiya Puram,

Thiruthangal - 626130,

Tamil Nadu, INDIA

Mob : +91 9842985143 | 8531010853 | 7200729855

E-Mail : [email protected]

Click here to call us : https://mkprintecs.com/mani/+919842985143

Web : https://www.mkprintecs.com

0 notes

Text

A Comparative Analysis for Variable Data Printing vs. Traditional Printing

The printing industry has seen significant advancements over the years, particularly with the introduction of variable data printing (VDP). This technology allows for the printing of individualized information on each sheet, such as alphanumeric characters, addresses, barcodes, QR codes, and logos.

What is Variable Data Printing?

Variable data printing (VDP) involves printing unique data on each sheet, which is crucial for applications requiring personalized information. This technology supports high-speed printing on various substrates like Colour Wove, Maplitho, Art Paper, Duplex Board up to 350 gsm, and NCR Sheet. The Autoprint Reckoner VDP65 is an example of a machine that leverages HP Inkjet Technology to offer efficient numbering, barcoding, mail addressing, and online perforation.

Traditional Printing

Traditional printing methods, such as offset and digital printing, produce identical copies of a print job. These methods are cost-effective for large volumes of the same print material but do not offer the flexibility of VDP. Traditional printing is best suited for mass production where the content remains consistent across all copies.

Advantages of Variable Data Printing

1. Personalization: VDP allows for the customization of each printed piece, making it ideal for direct mail, marketing materials, and personalized invitations.

2. Efficiency: By printing variable information directly, VDP eliminates the need for pre-printed stock and separate personalization steps, reducing production time.

3. Cost-Effectiveness: Although the initial setup cost may be higher, VDP can be more cost-effective in the long run by reducing waste and inventory costs.

4. Versatility: VDP can be applied to various substrates and formats, offering flexibility for different applications.

Autoprint Reckoner VDP65

The Autoprint Reckoner VDP65 is an offline sheetfed variable data printing machine using HP Inkjet Technology. It is designed for high-speed, accurate printing of variable data such as numbers, barcodes, and addresses. As an authorized oil-free air compressor dealer, AS Equipment ensures that customers receive top-quality products along with exceptional support and service, maximizing the performance and reliability of their compressed air systems.

Batch Coding Systems

A batch coding system is crucial for marking products with unique codes or batch numbers, ensuring traceability throughout the supply chain. These systems are vital for industries like food and beverage, pharmaceuticals, and cosmetics, where product safety and quality are paramount. Batch coding can be integrated with VDP machines to streamline processes and ensure accurate, consistent coding.

Steps Involved in Batch Coding

1. Prepare the Design: Create the design for the batch code, including relevant information such as the date of manufacture and product batch number.

2. Set Up the Machine: Calibrate the batch coding machine and load the necessary ink or ribbon.

3. Load the Product: Position the product or packaging correctly on the machine’s conveyor.

4. Set Parameters: Configure printing speed, number of copies, and other settings.

5. Start Coding: Activate the machine to print the batch code.

6. Verify Codes: Check the printed codes for accuracy and legibility.

Both variable data printing and traditional printing have their unique advantages and are suited to different applications. VDP offers unparalleled flexibility and efficiency for personalized printing needs, while traditional printing remains the best choice for large-scale, uniform print jobs. By understanding the strengths of each method, businesses can choose the right technology to optimize their production processes. For high-quality VDP solutions, the Autoprint Reckoner VDP65 stands out as a reliable choice, supported by AS Equipment’s excellent service as an authorized dealer.

Read more posts Maximizing Efficiency with Automatic UV Coating Machines: Tips and Best Practices Role of prepress in offset printing

0 notes

Text

Why Print Quality Matters: Expectations from a Pro Printer

In today’s digital era, print media continues to play a vital role in branding, communication, and marketing. From business cards to brochures, catalogues, and banners, the quality of print materials reflects your business's professionalism and attention to detail. For businesses in Jaipur, NavPack & Print, a trusted name in Offset & Digital Printing Services, ensures premium-quality results tailored to your needs. Let’s explore why print quality is essential and what you should expect from a professional printing service.

Why is Print Quality Important?

1. Creates a Lasting First Impression

Your printed materials are often the first point of contact between your business and potential customers. High-quality prints can establish your brand as credible and professional, while poor-quality prints may leave a negative impression. Investing in a reliable commercial printing company ensures your brand is represented in the best light.

2. Enhances Brand Identity

Consistent and high-quality printing reflects your brand's identity and values. Whether it's the vibrant colours of your logo or the sharpness of text, a professional printer using advanced commercial printing machines can bring your brand to life with precision and consistency.

3. Boosts Customer Engagement

Well-designed and high-quality print materials grab attention and hold interest. From a glossy brochure to a well-printed flyer, the feel, look, and finish of your materials can make a difference in engaging your audience.

4. Conveys Attention to Detail

Paying attention to the quality of your print materials signals that your business values quality in all aspects. This is particularly important for industries like hospitality, retail, and finance, where reputation is everything.

Read More ...

#commercial printing Company#xerox commercial printers#commercial printing services#commercial printing machine

0 notes

Text

OkOkBiscut

The sheets are then bent to shape. By about 1850, Great Britain had become the dominant world supplier of tin plate, through a combination of technical innovation and political control over most of the suppliers of tin ore.

The breakthrough in decorative tin plate production was the invention of the offset lithographic process. It consists of bringing a sheet of rubber into contact with the decorated stone, and then setting-off the impression so obtained upon the metal surface. The advantages over previous methods of printing were that any number of colours could be used, correctly positioned, and applied to an uneven surface if necessary. Thus the elaborately embossed, colourful designs that were such a feature of the late Victorian biscuit tin industry became technically possible.

The introduction of the baking of processed cereals, including the creation of flour, provided a more reliable source of food. Egyptian sailors carried a flat, brittle loaf of millet bread called dhourra cake while the Romans had a biscuit called Roman cookbook Apicius describes: ��a thick paste of fine wheat flour was boiled and spread out on a plate. When it had dried and hardened, it was cut up and then fried until crisp, then served with honey and pepper.” Many early physicians believed that most medicinal problems were associated with digestion. Hence, for both sustenance and avoidance of illness, a daily consumption of a biscuit was considered good for health. Hard biscuits soften as they age. To solve this problem, early bakers attempted to create the hardest biscuit possible. Because it is so hard and dry, if properly stored and transported, navies’ hardtack will survive rough handling and high temperature. Baked hard, it can be kept without spoiling for years as long as it is kept dry. For long voyages, hardtack was baked four times, rather than the more common two.[12] To soften hardtack for eating, it was often dunked in brine, coffee, or some other liquid or cooked into a skillet meal. The collection Sayings of the Desert Fathers mentions that Anthony the Great (who lived in the 4th century AD) ate biscuits and the text implies that it was a popular food among monks of the time and region At the time of the Spanish Armada in 1588, the daily allowance on board a Royal Navy ship was one pound of biscuit plus one gallon of beer. Samuel Pepys in 1667 first regularised naval victualling with varied and nutritious rations. Royal Navy hardtack during Queen Victoria‘s reign was made by machine at the Royal Clarence Victualling Yard at Gosport, Hampshire, stamped with the Queen’s mark and the number of the oven in which they were baked. When machinery was introduced into the process the dough was thoroughly mixed and rolled into sheets about 2 yards (1.8 m) long and 1 yard (0.9 m) wide which were stamped in one stroke into about sixty hexagonal-shaped biscuits. This left the sheets sufficiently coherent to be placed in the oven in one piece and when baked they were easy to separate. The hexagonal shape rather than traditional circular biscuits meant a saving in material and was easier to pack.[14] Biscuits remained an important part of the Royal Navy sailor’s diet until the introduction of canned foods. Canned meat was first marketed in 1814; preserved beef in tins was officially added to Royal Navy rations in 184. Early biscuits were hard, dry, and unsweetened. They were most often cooked after bread, in a cooling bakers’ oven; they were a cheap form of sustenance for the poor. By the 7th century AD, cooks of the Persian empire had learnt from their forebears the techniques of lightening and enriching bread-based mixtures with eggs, butter, and cream, and sweetening them with fruit and honey.[4] One of the earliest spiced biscuits was gingerbread, in French, pain meaning “spice bread”, brought to Europe in 992 by the Armenian monk Grégoire de Nicopolis. He left Nicopolis Pompeii, of Lesser Armenia to live in Bondaroy, France, near the town of Pithiviers.

1 note

·

View note

Text

Four Colour Offset Printing Machine

4 color offset printing machine in India. Our four color offset printing machine (satellite model) is developed with a classic modern designing concept and is suitable to print four(CMYK) cut colors in a single step. We give a top-notch quality 4 color mini offset printing machine to bring out the best result on nonwoven fabrics and to make beautiful bags for promotion & shopping. If you are looking for the best four color offset printing machine price in India then contact us. In Four–color printing, four different ink color plates (CMYK – cyan, magenta, yellow, and black) are used to create a range of printable colors which are widely used in offset presses and digital presses. As we are the direct four color offset printing machine suppliers in India, we can offer you the best price possible. Our technological department developed mini 4 color offset printing machine advanced with softening printing process, especially for nonwoven bags.

0 notes

Link

Deluq offers you a reliable partner to source used offset printing machine from the US. We have sold hundreds of machines to Indian clients. We take care of all the sourcing, negotiation, paperwork and shipping. Our deep industry connections help get you the best printing machine from Komori to Heidelberg at the lowest price.

#used offset printing machine#used offset printing machine suppliers#second hand offset printing machine price#used printing equipment for sale#offset printing equipment for sale#used 6 colour offset printing machine#used 4 color offset printing machine#used 5 colour offset printing machine#used heidelberg offset printing machine for sale#used Komori offset printing machine price#used Mitsubishi press machine for sale#used 8 colour offset printing machine

1 note

·

View note

Text

Top 5 Materials Used in Packaging Fitments

When you are designing a box, it’s equally important to look at the inner packaging fitments. These inserts or “things that go inside the box” are just as crucial as the outer box design. While the outer box packaging makes the solid first impression, it’s inner fitments are shouldering the responsibility for delivering the inside good with stability and security. They are ones which create a long lasting impact!

The quality of materials used in the fitments is the key differentiating factor in box quality. Poor choice of fitments can result in damaged products and flimsy boxes. Are you wondering, “What material should I use for the next box I need for my corporate event?”

We’ve got you! We have put together a list of the top five materials for inner packaging fitments. These materials have been rated on four key parameters:

Sustainability

Pricing

Strength

Customization

Let’s begin, shall we?

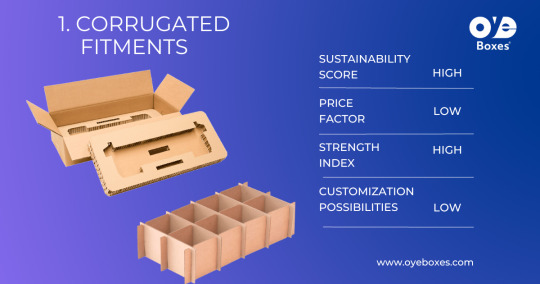

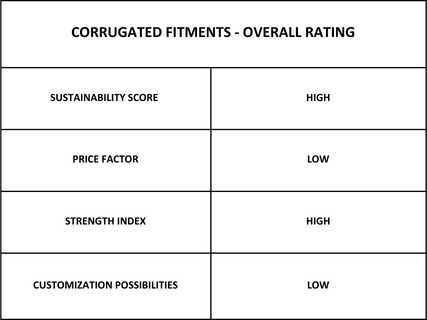

1. Corrugated Fitments:

Corrugated Fitments are the most commonly used materials in manufacturing of fitments and inserts. Depending on the use case, either 3 ply or 5 ply fitment sheets are used. Corrugated fitments are made of recycled materials and score high in terms of sustainability. They are usually 30% less expensive as compared to other materials, however you may have to buy them in larger quantities.

Corrugated fitments, inserts, and dividers provide a lot of sturdiness to the contents and can withstand rough transportation as well. They are ideal for products such as glass jars, machine parts, etc.

They have their limitations with respect to colour availability, however they can be offset printed for larger quantities or digitally printed for shorter quantities.

Here’s the rating chart for Corrugated fitments.

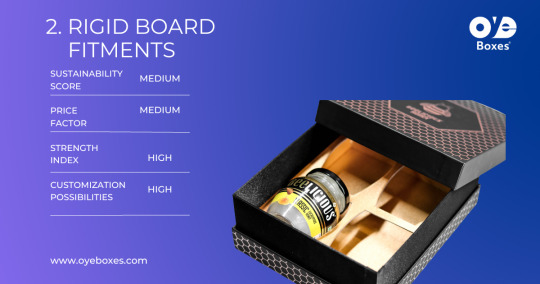

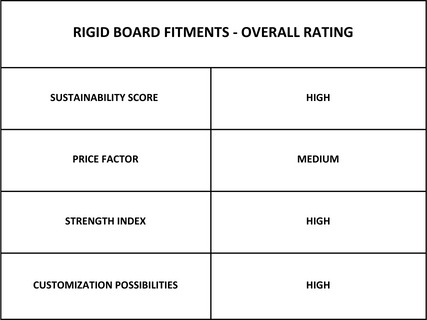

2. Rigid Board Fitments:

Rigid board fitments are an extremely popular choice when manufacturing fitments for packaging. Rigid fitments are frequently used in packaging for cosmetics, FMCG, jewelry, and other luxury items. Many times they are also used in conjunction with XLPE or EPE foam fitments.

Rigid board, commonly known in India as Putha Board, is made of recycled pulp and scores high in the sustainability index.

The price of rigid board fitments is slightly higher that of corrugated sheets. However, the strength and stability they provide is worth the higher price point. If we choose the appropriate thickness of board for making the fitments, then a very superior level of strength and stability can be achieved in the packaging.

The best part about rigid board fitments is that they are completely customizable. Any type of printed or colour sheets can be pasted on top of these rigid fitments.

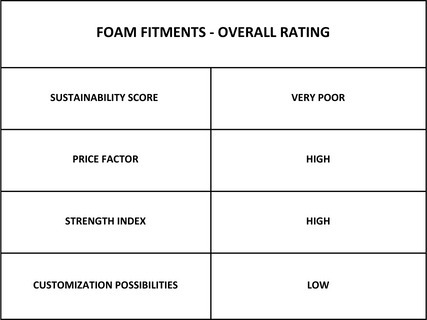

3. Foam Fitments :

Foam based fitments are widely used in packaging of glass, machine tools, and other high-value items. Currently, two of the most commonly available foam fitments are —- XLPE foam or EPE foam.

As expected, they don’t score well on the sustainability scale. They are harmful to the environment since they are non-biodegradable. But, they are the most sturdy and safe fitment option out there.

And, since they are the most sturdy option available in the market, their price is always on the higher side. We would like to highlight that XLPE foam fitments are 40% more expensive than EPE foam fitments.

Lastly, the customisation of these fitments is very expensive. They generally are available in few colour options – white, black, pink and blue. In order to customise them further, they need a layer of paper or paperboard on top of them.

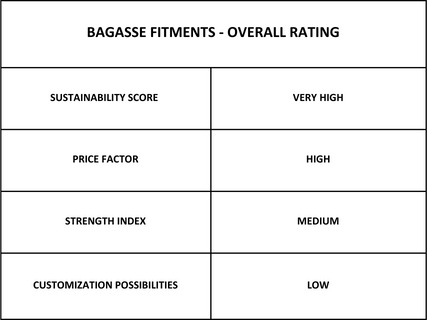

4. Bagasse Fitments

Bagasse is a dry fibrous residue that is generated after extraction of sugar from sugarcane. Nowadays, Bagasse is being used extensively in the making paper moulded fitments and dividers for various packaging applications.

You might be aware of bagasse plates and other recyclable cutlery that are widely used today. Bagasse fitments or inserts are slowly starting to trend in the packaging industry as well.

Bagasse is probably the most eco-friendly material amongst the entire list of fitments mentioned here. It is 100% recyclable. However, the costs associated with making a bagasse mould and then manufacturing these fitments is on the higher end when compared to other paper-based or plastic fitments.

Customization of colours in bagasse fitments is extremely difficult and require extremely large quantities to justify the expense. From a durability standpoint, bagasse fitments are sturdy enough to withstand pressure, however not as strong when compared to foam or rigid board fitments.

5. Paper Fitments :

Paper or paperboard fitments are the most pocket friendly fitment option (Probably 25% cheaper than rigid board). These are easy to source and manufacture. Paper fitments are generally made of recycled paper. But, it’s important to remember that they do not provide as much stability as other material options.

The parameter where paper fitments beats the competition is customization. All sorts of customizations are possible with paper fitments, including offset printing, digital printing, foiling, and embossing. So if you are looking for something really unique and tailored to your brand, then paper fitments might be your best bet.

#rigidboxpackaging#rigidboxpackagingfitments#packagingfitments#boxpackaging#CorrugatedFitments#RigidBoardFitments#FoamFitments#BagasseFitments#PaperFitments#luxuryboxpackaging

0 notes

Text

OFFSET PRINTING-WHAT IT IS EXACTLY

The majority of commercial printers provide various printing options which include offset and digital printing as well as gravure, flexography print-on-screen, and stochastic screen. Each process has its own distinct advantages, and understanding the difference between them can assist you in making informed choices when choosing the process that is most suitable for your needs.

WHAT IS OFFSET PRINTING?

Offset printing often referred to as offset lithography, or four-color printing is one of the most well-known printing methods for commercial use that's used since the beginning of the 20th century.

Offset printing is a multi-colour printing technique that produces excellent quality, full-colour photo images.

"Offset" refers to the fact that images are not transferred directly from a printing plate to the printing medium Instead images are transferred, in a process known as offset from the surface of the printing to an elastomer blanket, and then onto the surface of printing, which can be paper cardboard, plastic or different flat surfaces. If you are looking for offset printing press in Dubai you can approach Printery.

WHAT IS THE PROCESS BEHIND OFFSET PRINTING WORK?

The offset printing process utilizes an extensive printing plate that can transfer an image that has been inked onto a rubber sheet and after which it is transferred onto the surface of printing. Because this method employs a blanket of rubber which is a type of rubber, offset printing for the print of images on almost any surface, including wood, paper, metal or even leather. This blanket helps guarantee a high-quality print since it is able to be shaped to match the texture of the print surface.

Due to the wide utilization of offset printing in diverse applications, various variants in the printing process have been designed to be able to adapt to each application. The variations include:

Blanket-to-Blanket

Blanket-to-Steel

Printing with Variable-Size

Keyless Offset

Dry Offset Printing

1.BLANKET-TO-BLANKET

Blanket-to Blanket printing can be done simultaneously on the two sides of the print surface simultaneously. It utilizes two blanket cylinders as well as two plate cylinders per colour by modern machines that use the four and eight set. These modern machines can allow printing in four as well as eight different colours both on the sides. This is why it's more cost-effective to print on two sides, and reduces delivery time. It is typically employed for envelope printing in cases where both sides of an envelope need to be printed with specific information.

2.BLANKET-TO-STEEL

Blanket-to Steel prints with a very the highest level of accuracy however, it prints only a limited number of colours. A blanket-to-steel printer can print only one colour on modern equipment that has four sets, six sets as well as 8 sets. This permits printing of four colours, six colours and 8 different colours, on the same side of the print surface at once. The high-quality of blanket-to-steel printing makes them ideal to print high-quality business forms, letters and direct mail advertising.

3.VARIABLE-SIZE

Variable-Size printing makes it simpler to alter how large the printed area is. It is accomplished by using sleeves that can be removed for quick adjustment. This provides the printing of documents with different lengths of repeats instead of the standard length.

4.KEYLESS

Keyless printing utilizes fresh ink with each rotation of the cylindrical device. Every time the cylinder is rotated the inking drum removes any remaining ink from the cylinder in order to guarantee the same print. It is most often used for printing newspapers.

5.DRY

Dry print transfers the ink onto the relief plate of a photopolymer prior to transferring the ink onto the surface of printing, resulting in high-quality prints. This method of printing is often used for injection-moulded rigid plastic products like buckets cups, tubs and flower pots.

Each of these options produces exceptionally high-quality images for very low costs. It makes offset printing a popular option for large orders. However, smaller orders can be more costly due to the high initial cost of installing the plates, blankets of rubber and inks.

Alongside this, several printing press companies also offer below mentioned services

PRINTING SHOPPING BAG SHOPPING

An appealing custom printed bags can boost your customer experience and create an impression of your brand's name on their mind. The printing of paper bags can be an affordable method of branding that will give your bran the exposure it deserves. Printery Dubai provides shopping bag printing in Dubai.

PRINTING AND PACKAGING

The basic concept behind any printing and packaging companies in Dubai is to turn your thoughts or designs into printed or packaging, which is then utilized to advertise whatever company you're in, regardless of whether it's an item or service.

When you make a contract with printing and packaging company in Dubai, they will handle the processes that precede production, such as folding, printing or cutting, and finally assembly before delivering your finished products to your doorstep.

If you're looking for digital printing companies in Dubai Contact Printery Dubai.

#shopping bag printing in dubai#offset printing press in dubai#digital printing companies in dubai#printing packaging company in dubai#printing and packaging companies in dubai

0 notes

Text

Limited Run CD Printing: Making the Discs and Presentation

how to print on a CD

Printing the CDs for the Short Run CD Producing Project

There are three primary methods that may be used to pic a short run involving Compact discs. If you're undertaking them on location then a person will most likely become limited by the first solution which is electronic (inkjet) printing. A professional publishing company will usually get display screen printing and lithographic stamping services on present too. Every single CD making process possesses its benefits and weaknesses and many of us will enter more aspect here:

how to print on a CD

Digitally branded Computer games

A digital CD producing machine uses a identical publishing method to your own personal standard desktop computer inkjet printing device. In fact, a lot of modern-day home printers feature a COMPACT DISC tray that allows an individual to weight an ink jet printable COMPACT DISK into the idea and run the item via the same printing brains that would normally printer upon paper. A specialized digital DISC printer is usually more of a focused machine that is fixed up in order to print just onto Compact disks and features an automated loading as well as unloading system for the actual vertebrae. This system signifies that the machine can easily print up to 190 Cd albums unattended and, while stamping with these products tends to be rather slow, they can end up being left to be able to print even though others elements of the task are dealt with.

This CONCEPT ALBUM printing course of action is simply really suitable for a small amount of CDs as this is certainly the slowest of the a few major methods. The process rate is not helped by simply the idea that after the particular printing is done, right now there is still a require for your application of some sort of clear lacquer layer for you to protect the printed exterior from moisture when taken care of. There are inkjet computer Compact discs on the market place that claim to have got a water resistant finish any time paper but they are generally still not as powerful and don't look seeing that good as a new colored disc. On the and also side, this process could be used to print out very high resolution graphics plus the finished item can certainly appearance fantastic when accomplished appropriate. There are additionally no fixed established charges with digital COMPACT DISC making which is great in case you only need 50 cds.

Monitor printing

CD display producing is a really popular, widely used practice for printing CDs. The task is an adaptation connected with the monitor printing procedure used for decades to help print onto papers merchandise and, indeed, it offers been taken to let printing onto many surface types to produce branded goods such as mugs, tee shirts and also USB memory supports. For the reason that name suggests, typically the process consists of the make of publishing screens by which each is employed to printing a different color on top of the disc. Some sort of COMPACT DISK screen printer provides your five printing stations and also applying a disc that possesses been in the past printed using a base coloring, that is possible to generate a print having some different colours included. Typically the machine is basically the twisting platen and because each shade is used at each stop, often the disc passes underneath any UV light that solutions the ink prior to up coming colour is utilized.

This kind of process can only always be used in order to print regions of solid colouring along with is not ideal with regard to stamping photographic images or maybe simple colour gradients. Exactly where art work has been exclusively designed to use this particular printing technique, though, the effects can be truly spectacular specially with the availableness of fluorescent in addition to material UV sensitive ink. Often the use of super excellent nylon uppers screens means in which the pic is well-defined, crisp and contains an remarkable texture to it. Any time set, the ink is incredibly robust and waterproof which is not easily damaged by means of rough handling of the actual dvd.

When it happens to short run DISC printing and using the particular tv screen printing technique, at this time there are set costs engaged, namely typically the screens as well as the films employed to help make the screens. Therefore, it's not the ideal process to be able to use at under 100 disks if price is a issue with the job. However, the more dvds which might be screen printed, often the lower the unit expense gets, plus there's additional bonus that once the actual window screens are made these people can be reused regarding reprints.

Lithographic (Offset) making -

This is yet another quite popular method for limited run CONCEPT ALBUM printing jobs. A lithographic printing unit doesn't have some sort of spinning platform like the display screen printer; instead it features turning cylinders. The tube this applies the printer on the CD has a new rubber baby blanket wrapped all-around it which usually rolls around the CD and also airport transfers the ink on to the particular disc surface. The actual lithographic printing method is simply perfect for printing complex photographic photographs onto a disc plus for printing images which may have subtle colour gradients, but it really is not ideal intended for printing pictures with significant areas of sturdy color as attempting to keep a consistent solid coloring spanning a large area may result in the patchy appearance on the concluded print.

As with display producing, there are repaired costs a part of lithographic publishing as stamping plates will need to be made upward for for every set of a muslim used. Work opportunities requiring a lesser amount of than 100 vertebrae can easily work out to possibly be more expensive each device than if the electronic digital printing process was employed alternatively. But, once far more, as the work range increases, so the product cost will fall in case a re-print of typically the career is required after that the printing discs could be kept and re-used.

Printing the Paper Areas

When it comes for you to printing the document components for a short manage CD printing project, invest your time and accomplish it thoroughly, it is definitely possible to produce a few extremely professional looking styles. The printer quality associated with a relatively affordable pc inkjet printer is often fantastic.

Printing CD Gem Event Paper Parts

You may buy accurately sized templates on the web to get making paper parts to travel into CD jewel circumstances, or you can merely buy several high good quality A4 size semi-gloss image paper or ink computer silk paper commodity with about 150gsm. The bonus along with buying templates for that rear end tray card usually are which the spine edges are going to be scored to make these people better to fold but this specific is something you can certainly do yourself if you aren't mindful. The front pamphlet can be a folded away sheet printed on each isn't stable to make way up 4 webpages and just about any more pages might be extra if required along with stapled along the spine. Providing you take your time together with the cutting (using any guillotine and not scissors) and are careful using the stapling then generally there is no reason precisely why avoid being able to appear up with something incredibly appealing.

There are a several of things to consider when printing paper elements for a CD gem situation, such as:

The particular front booklet may comprise of 2 pages should you print on both tips of any single panel which often is 120mm square, in addition to 4 web pages if anyone print on both edges of a double -panel 240mm x 120mm which will is and then folded. Soon after this, the book offers to consist of diversifiés regarding 4 pages credited to the technique they will are constructed. Take some sort of look at a new COMPACT DISC jewel case guide via your CD collection where there more than 4 internet pages and you will probably see why. A single booklet page 240mm times 120mm collapsed in fifty percent, makes 4 websites, nevertheless to add another linen where the spine is actually stapled, you must increase another some pages. Typically the content is generally fashioned with this requirement in head.

The back tray card can easily be imprinted on the two sides but then you will want a clear CD possessing rack in your circumstance to be able to help see the print out upon the inside. Also, often the flattened spine strips tend to be very slender and the idea can be difficult in order to about the quality folded border with out carefully scoring the actual inside initial. Any wording printed down the spine demands to be small plenty of to fit and centrally located for the ideal quality appearance.

Publishing COMPACT DISK Card Wallets

Yet again, you actually can buy templates to be able to make your CD credit wallets that can be printed as well as then "popped out" involving the template as the particular perimeters are partially pre-cut for yourself. You can furthermore print your own in 250 - 300 gsm silk or semi-gloss A4 size card. The navigation bars can be scored, creased / folded and also glued using the strong stuff to create perfectly good results.

1 note

·

View note

Text

Used 4 Colour Offset Printing Machine - IndiaBizzness Portal

Discover a well-maintained used 4 Colour Offset Printing Machine for sale on IndiaBizzness Portal. This efficient machine is ideal for businesses looking to enhance their printing capabilities at a competitive price. Explore detailed specifications and connect directly with sellers to negotiate and purchase this reliable equipment. IndiaBizzness ensures a seamless transaction experience for buyers and sellers in the printing industry.

0 notes

Text

HIKARI K-250 MULTI COLOUR "FOR SALE" LABEL PRINTING MACHINE FROM MK PRINTECS MACHINERY

.

.

.

For More Information Contact Us ;

MK PRINTECS MACHINERY

( ALL KIND OF LABEL, OFFSET, CUTTING & SCREEN PRINTING MACHINE - IMPORTER, EXPORTER & SUPPLIER IN INDIA )

#4/168, Sivakasi - Erichanatham Main Road, Opp. To Ayyan Fireworks,

Aishwarya Nagar, Vellaiya Puram,

Thiruthangal - 626130,

Tamil Nadu, INDIA

Mob : +91 9842985143 | 8531010853 | 7200729855

E-Mail : [email protected]

Click here to call us : https://mkprintecs.com/mani/+919842985143

Web : https://www.mkprintecs.com

0 notes

Text

Visiting Auckland Art Gallery & Printing Research

As a class we all went over to look at the Civilization photography exhibit held in the Auckland Art Gallery. This was a great chance to see the different styles, sizes and presentations of print photography. I thoroughly enjoyed seeing such a broad selection of print forms as I've never had the chance to see this before. I was very surprised that there were so many print choices. This led me into looking up what each style was to properly understand the art works. I seemed to be really drawn to the lightjet and pigment prints as they were so soft and smooth looking, I just wanted to go up and touch them. I think I liked these types of prints the most as i've never seen anything like it before. However both of these styles won’t match my context of a magazine cover as it's not used for that sort of industry/print making. By the looks of it, it seems that inkjet print would be the best choice for my style as it is most commonly used, easier to mass produced as well as creates crisp and sharp images.

Photography Print Types seen at the Auckland Gallery:

Lightjet print

It works by instead of copying the image, the lasers write the image onto photographic paper using an internal 270 degree drum. The paper is held still in a cylinder while the lasers get to work. Laser light is reflected by a spinning mirror moving along the axis of the cylinder onto the surface of the media. ‘Uniform spot size and shape’ means that even the edges and corners of an image are as razor sharp as the centre. This uniformity is better than any other optical printing technique. This technology results in better image sharpness, uniform density and colour and the highest geometric accuracy over the whole print.

Reference: "What is a Lightjet Printer?" Professional Online Photo Printing from the UK's Top Lab – Metro-Print. Accessed October 18, 2020. https://metro-print.co.uk/what-is-a-lightjet-printer/.

Inkjet print

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers are the most commonly used type of printer, and range from small inexpensive consumer models to expensive professional machines.

Reference: "Inkjet Printing." Wikipedia, the Free Encyclopedia. Last modified October 14, 2020. https://en.wikipedia.org/wiki/Inkjet_printing.

C-type Print

The ultimate professional photographic archival prints; silver based Digital C-types are real photographic prints, created on light sensitive paper. This creates an analogue style print from a digital file with unparalleled depth, subtlety of tonal variation and shadow detail. We use two Chromira 50inch wide LED Printers that produce seamless (no dots) images that are beyond comparison.

Reference: "Printing — PCL Imaging." PCL Imaging. Accessed October 18, 2020. https://www.pcl.co.nz/printing.

Digital c-type prints differ from inkjet prints because inkjet prints use fine droplets of ink rather than light sources, such as a laser. The machines used for digital C-type prints can be significantly more expensive than inkjet printers and tend to be used in commercial settings. The longevity of digital C-type prints is also estimated to be shorter than pigment-based printing, and the number of materials that can be printed with this process is more limited.

Reference: Twin, Alexandra. "Digital C-Type Prints Are Color Prints Made by Digital Exposure." Investopedia. Last modified June 25, 2019. https://www.investopedia.com/terms/d/digital-ctype-print.asp.

Pigment Print

The term "pigment print" is used generally for any type of printed image that uses strictly pigments. Pigments can be either on a mineral basis or they can be an artificial product. The image stability of pigment printing is superior to that of any other method of printing.

Pigment printing processes have been utilized since the middle of the 19th century. Modern procedures have generated a surge of this technique as ink sets have been refined to be compatible with the latest in high-resolution inkjet technology.

Reference: "Pigment Print." Weng Contemporary. Accessed October 18, 2020. https://www.wengcontemporary.com/techniques/pigment-print.

Archival Pigment Print

Archival pigment prints utilize archival quality inks, which are printed onto various substrates including canvas, fine art, and photo-base paper. This technique, just as Iris prints, may also be referred to as Giclee, although it belongs to a newer generation of the printing techniques. Iris prints are an older technique and are 4-Color ink-jet prints from a printer pioneered in the late 1970s by Iris Graphics.

Reference: "Pigment Print." Weng Contemporary. Accessed October 18, 2020. https://www.wengcontemporary.com/techniques/pigment-print.

Digital Print

All five of the analog printing processes require the creation and precise alignment of separate plates for each color used in a print. Digital printing processes eliminate the time, labor, and expense of creating and mounting printing plates.

The first digital printing devices printed black ink on paper. Today, multiple digital printing processes have been developed to replicate and expand the capabilities of offset, screen, flexographic, rotogravure, and pad printing.

A key advantage of digital printing is the relatively low cost of producing just a few copies of full-color prints. While the first digital printing systems were relatively slow compared to analog methods, significant progress continues to be made.

Reference: Ordant. "An Overview of Analog Printing Processes." Ordant. Last modified June 17, 2019. https://ordant.com/an-overview-of-analog-printing-processes/.

Unique Gelatin Silver Print

The gelatin silver process is the most commonly used chemical process in black-and-white photography, and is the fundamental chemical process for modern analog color photography. As such, films and printing papers available for analog photography rarely rely on any other chemical process to record an image. A suspension of silver salts in gelatin is coated onto a support such as glass, flexible plastic or film, baryta paper, or resin-coated paper. These light-sensitive materials are stable under normal keeping conditions and are able to be exposed and processed even many years after their manufacture. This was an improvement on the collodion wet-plate process dominant from the 1850s–1880s, which had to be exposed and developed immediately after coating.

Reference: "Gelatin Silver Process." Wikipedia, the Free Encyclopedia. Last modified September 2, 2020. https://en.wikipedia.org/wiki/Gelatin_silver_process.

UV print on Canvas

One standard method for printing customized gallery-wrapped canvases involves printing digital artwork onto flat canvas material, which needs to be trimmed, stretched and secured over a wooden frame. This process allows the artwork to wrap around the sides of the canvas. If the artwork is sized and positioned correctly, the image won’t be negatively affected. In some cases, due to preference or to avoid losing portions of an image, canvas sides are painted in a solid color or elegantly framed. This process may also require the application of protective treatments to protect the print from UV exposure and dust.

Reference: "UV-Printed Canvas." Logojet. Last modified May 26, 2016. https://logojet.wordpress.com/2016/05/26/uv-printed-canvas/#:~:text=This%20process%20allows%20the%20artwork,solid%20color%20or%20elegantly%20framed.

0 notes

Text

ColorMax Printing supplies Matt plastic card using best material at factory cost

Laminated plastic cards= Full color plastic card + Gloss or Matt lamination.

Matt lamination gives your finished printing a soft ‘satin’ finish that is really smooth to the touch. Matt lamination is great for Plastic cards to give a feel of quality to the print.

The matt lamination process we use, applies an extremely thin coating to the card, which provides: • A soft and silky satin sheen high quality finish resulting in a more sophisticated card. • Water resistance and durability resulting in a longer life for the card.

PreviousNext

How are laminated cards produced,

Usually, the cards are first printed, (multiple cards on a large sheet), and then fed through the laminating unit which feeds a very thin sheet of laminate top & bottom, (or one side only) trapping the card in between. Heat is applied which seals the laminate sandwich.

Why laminated,

As an example, let’s say you have a 2 sided plastic card that needs producing. Let’s also say you decide, on the card reverse, to have a solid color completely covering the card. We will take your artwork and ‘plan’ it into blocks of 4, 6, 8, 10 or even up to 40 cards per block, depending on the quantity ordered.

The card (block) is fed through the printing press and exits into a tray at the end. So, the top of each card will have the bottom of the next card resting on top. If the bottom (reverse) of the next card has been completely covered in ink, it’s perfectly possible for a little of this ink to ‘transfer’ to the card below thereby marking the tops of all cards in the stack.

To overcome the wet ink problem, the press operator will utilise spray powder, which lightly sprays each card as it comes off the press, which effectively helps the drying process. Unbelieveably, some colour inks take longer to dry than others, certains reds & blues for instance, which means that they can still end up in a slightly wet state.

Another option from protecting the card from ink-offset (transfer of ink) is to ‘seal’ the work with a very light covering of machine varnish. The card however, can be left with a slightly glossy sheen.

The most effective way is for lamination. The cards are produced normally and given extra time to dry before each card (block) is sealed in the laminate.

This process totally protects the card from any ink-offset but also enhances the card. If you can get your local printer to show you a solid color printed on a card with, and without lamination, then you will immediately see the difference and realize why so many people are switching to this type of card, even though extra costs are involved. In fact, whether you have used a solid block of colour or not, a laminated card will really give your artwork an extra-professional look.

Matt or Gloss laminated plastic cards,

Both have their uses. If you’re advertising a product or service on your card, or merely wish to make your card really stand out then gloss laminated plastic cards will be the preferred choice. Many tradesmen use this type of ‘advertising’ plastic card as do taxi-drivers, cleaning service companies, mobile hairdressers etc. etc. Many D.I.Y stores, supermarkets etc. will allow you to display your card (for a small fee), alongside every other type of service imaginable, on the store notice board. So, if it’s important for your card to stand out from the rest, a full-color, gloss laminated card would be the perfect choice.

Glossy Plastic Card

Matte Plastic Card

Additional cost for matte lamination

1000pcs

+$80

Double side UV oil Order

2000pcs

+$100

Double side UV oil Order

3000pcs

+$120

Double side UV oil Order

Source: ColorMax Printing supplies Matt plastic card using best material at factory cost

0 notes

Text

Airbus Partners Aston Martin for Special Edition Helicopter

Airbus has teamed up with Aston Martin to launch the ACH130 Aston Martin Edition helicopter. The special edition helicopter is available in four different interior and exterior designs generated by Aston Martin, with deliveries scheduled to begin taking place from Q1 2020. The helicopters are embellished with Aston Martin signature elements, starting with the iconic Aston Martin wings, which are embossed onto luxury leather features, tastefully positioned throughout the cabin. The Stirling Green-themed external scheme, which is already flying on the first aircraft, features a painted gradient, which fades down into Jet Black on the underside of the helicopter with Skyfall Silver around the cowlings. Further external liveries are available with other Aston Martin paint colours including Xenon Grey, Arizona and Ultramarine Black.

Inside, the automotive-inspired cabin is trimmed in Pure Black ultra-suede with a palette of selectable leathers comprising Oxford Tan, Pure Black, Cormorant and Ivory. On the rear of the front seats the same brogue detailing that is found in a DB11 runs down the centre of the seat and the doors have been trimmed with leather to provide passengers with comfortable touch points during their flight. Each of these special edition helicopters will have a plaque included on the instrument panel which shows the partnership logos, the registration of the aircraft, the edition number and the owner’s name, should they wish to have it included. Aston Martin Vice President and Chief Creative Officer, Marek Reichman, said, “We have our own set of automotive design principles but in recent years we have been learning how to apply our principles to other areas of design, such as architecture, motorcycles and now helicopters. This first application of our design practices to a helicopter posed a number of interesting challenges but we have enjoyed working through them. Beauty is of vital importance to Aston Martin and to our customers and we think the ACH130 Aston Martin Edition is an inherently beautiful machine. It provided a wonderful canvas for our team to work on so we now look forward to seeing everybody’s reaction.” See latest Travel News, Interviews, Podcasts and other news regarding: Airbus, Helicopters, ACH, Aston Martin. Headlines: Thailand Travel Mart (TTM+) 2020 - Exclusive Interview with Chiravadee Khunsub of TAT Global Air Freight Demand Down 1.1% in November 2019; APAC Down 3.7% IHG Expands Thailand Portfolio with Holiday Inn and Suites Siracha Laemchabang Asia Pacific Airlines Flew 30.3 Million Int. Passengers in November 2019 SilkAir to Cease Flights to Kolkata, India Biman Bangladesh Airlines Launches Flights to Manchester, England EmbraerX and Elroy Air to Collaborate on Unmanned Air Cargo FCM Strengthens Innovation Programme with Shep Investment Artotel Appoints Yulia Maria as Group Director of Marketing Communications Japan, Singapore, S. Korea and Germany Have World's Most Powerful Passports Yangon Int. Airport Implements SITA's Airport Management Solution Air France to Launch Twice-Daily Flights Between Paris-Orly and Munich, Germany ANA to Enhance Service at Airports in Japan with Portable Translators Yvette Thomas-Henry Appointed GM of Four Seasons Resort Nevis Hahn Air Enters 2020 with 40 New Partner Airlines CWTSatoTravel Partners US Military's Spouse Employment Programme My Emirates Pass Gives Passengers Special Discounts in UAE Visitors to Singapore Must Now Register Unmanned Aircraft India's Vistara Airline Appoints APG as Online GSA in France BOC Aviation Orders 20 Airbus A320neos China Airlines to Launch Direct Flights to Chiang Mai, Thailand Green Light for Vietnam Airlines to Expand Codeshare Agreement with Delta All Hi Fly Flights Now Single-Use Plastic Free Air India Renews Distribution Agreement with Amadeus Mandy Goh Joins St. Regis Langkawi as Executive Chef Spirit Airlines Signs Purchase Agreement for 100 Airbus A320neo Aircraft Hamad Int. Airport Served Record 38,786,422 Pax in 2019 British Airways Starts Offsetting Carbon Emissions on All Flights Within UK Marriott Opens Second JW on Hainan Island, China Airbus Partners Aston Martin for Special Edition Helicopter Dassault Aviation Appoints Charles Wemaëre as VP Worldwide Spares Boeing Appoints Niel Golightly as SVP of Communications Jayson Goldstein Joins Four Seasons Boston as F&B Director Vietjet Takes Delivery of Two More Airbus Aircraft Two Executive Appointments at Bombardier Aviation Air India No Longer Available on Sabre GDS Thailand Targets Tourism Revenue of 3.18 Trillion Baht in 2020 Pictures from Ascot United vs Banstead Athletic on 4 Jan 2020 Gen Z - Airbnb's Fastest Growing Market for Experiences in Asia Pacific Air Canada Takes Delivery of First Airbus A220-300 AirAsia Launches Flights Between Kuala Lumpur and Dalat, Vietnam Cebu Pacific Orders 15 Airbus Aircraft, Including Up To 10 A321XLRs American Airlines and Royal Air Maroc to Codeshare New Immigration Requirements to Help Solomon Islands Fight Measles Vietjet Launches Danang - Singapore Flights American Express GBT Forecasts Stable Air Prices in 2020 Etihad and Kuwait Airways to Codeshare PAG and Inmark Purchase Grand Hyatt Seoul British Airways and Iberia Achieve IATA NDC @Scale Certification Air Caraïbes Takes Delivery of First A350-1000 Aman Signs Fourth Resort in Japan Hamilton to Host HSBC New Zealand Sevens 25-26 January 2020 Thales' New Touchscreen Cockpit Displays Now Available on Airbus A350s Mongolian Airlines to Expand Network with Boeing 787-9 Dreamliner British Airways to Trial AI-Powered Robots at London Heathrow Dusit Thani Resort Opens in Shuangyue Bay, China Six Senses Signs First Hotel in UK Mandarin Oriental to Take Over Emirates Palace in Abu Dhabi Cebu Pacific Offering Passengers Roaming WiFi Kits Air France Orders 60 Airbus A220-300 Aircraft Sindhorn Midtown Hotel in Bangkok Appoints Jee Hoong Tan as GM British Airways to Launch LHR Flights to Portland, USA Braathens Takes Delivery of First of Five New ATR 72-600s Cebu Pacific Joins IATA Thailand: Airbnb Adds Saraburi to Beyond Big Cities Campaign New International Rugby Sevens Competition to be Launched in February Sindhorn Midtown Hotel in Bangkok Appoints Nicha Ruenthip as DOSM Qatar Airways to Launch Flights to Santorini and Dubrovnik British Airways Signs Joint Business Agreement with China Southern Air Canada Rouge Completes In-Flight Wi-Fi Installation Saab Wins Order for Digital Air Traffic Towers in Netherlands Whitbread Secures Fourth Premier Inn Hotel in Dublin, Ireland Amman to Host CAPA Middle East & Africa Aviation Summit 2020 Boeing to Suspend Production of 737 MAX Cathay Pacific's Inbound Hong Kong Traffic Down 46% in November Singapore Airlines to Launch Flights to Brussels, Belgium Wego Signs Retailing Agreement with ATPCO GTR Opens Air Cargo Hub at KLIA Air Cargo Terminal 1 Bombardier Uses SAF to Deliver Challenger 350 to Latitude 33 Aviation Swiss-Belhotel Signs First Hotel in Malaysia Czech Air Force Orders Two More Airbus C295 Aircraft New Boeing-Built Satellite to Orbit Over Asia Pacific Third Four Points by Sheraton Hotel Opens in Malaysia Hong Kong Airport Reports Further Drop in Pax, Cargo and Flights Air Canada Launches Flights Between Vancouver and Auckland, New Zealand Andaz Macau Appoints Chikako Shimizu as GM Cathay Pacific to Take Over Air New Zealand's Auckland-Hong Kong Service Four Seasons Opens Second Luxury Resort in Megeve, France Ireland's Department of Defence Orders Two Airbus C295 Aircraft Best Western Plus Opens in Nairobi, Kenya Qatar Airways Launches Flights to Gaborone, Botswana Korean Air to Revamp SkyPass Frequent Flyer Program Embraer E175-E2 Performs Maiden Flight Charlie Sullivan Joins CWT's Air Distribution Team Marriott Opens Third Sheraton Hotel in Beijing, China Radisson Blu Opens Resort in Cam Ranh, Vietnam Qantas Chooses Airbus A350-1000 for Ultra Long-Haul Flights Executive Appointments at Banyan Tree BA to Launch LHR Flights to Six New European Destinations in 2020 Korean Air to Revamp SkyPass Frequent Flyer Program Embraer E175-E2 Performs Maiden Flight Charlie Sullivan Joins CWT's Air Distribution Team Marriott Opens Third Sheraton Hotel in Beijing, China Radisson Blu Opens Resort in Cam Ranh, Vietnam Qantas Chooses Airbus A350-1000 for Ultra Long-Haul Flights Executive Appointments at Banyan Tree BA to Launch LHR Flights to Six New European Destinations in 2020 How Technology is Shaping Airports of the Future FCM and Flight Centre Achieve NDC Level 4 Certification Dusit Rebrands Luxury Resort in Philippines Emirates Launches Flights to Mexico via Barcelona Air Canada's First Airbus A220-300 Completes Maiden Flight FAA Certifies ExecuJet MRO Malaysia to Work on Dassault Jets AirAsia Launches Snap Air France-KLM Orders 10 A350-900 Aircraft Bundeswehr Takes Delivery of First Airbus H145 SAR Helicopter Drew Crawley to Join American Express Global Business Travel as CCO Cape Town 7s 2019 to Take Place 13-15 December Congo Airways to Replace Dash 8-400s with Embraer E175 Aircraft Ascent Solutions Installs Two E-Gates at NAIA 2 Departures Michel Poussau Appointed GM of Rugby World Cup 2023 Wetherspoon to Invest £200 Million Developing New Pubs and Hotels IATA Asks EU to Support Sustainable Aviation Fuel Transition Boeing Delivers First Modified MV-22 Osprey to United States Marine Corps Marriott Signs Six Hotels in India Accor to Rebrand Hotel in Queensland, Australia MHG Signs Two Hotels in Doha, Qatar Vietjet Launches Flights to New Delhi from Hanoi and Saigon SKY Signs Purchase Agreement for 10 Airbus A321XLRs British Airways Trials 3D Printing SAS' First A350 to Enter Long-Haul Service on 28 January Air Italy and Oman Air Sign Codeshare Agreement ACH and Aston Martin to Unveil 'New Creation' in January Qantas Signs FFP Agreement with Air France - KLM Group Malaysia Airlines Launches Shuttle Fares on Flights Between KL and Singapore Accor to Open 125-Room Mercure Hotel in Canberra in January Openings Push Australia's Hotel Inventory to Over 300,000 Rooms Alban Dutemple Appointed Cluster GM of Two Hotels in Bahrain Air New Zealand Trials Edible Coffee Cups Manchester Airport Unveils Details of £1 Billion Transformation South Africa Beat New Zealand to Win Dubai Sevens Aviation: RPKs Up 3.4% in October 2019 China Airlines to Launch Flights Between Taipei and Cebu, Philippines Seaplanes in Thailand? Interview with Dennis Keller, CBO of Siam Seaplane Seven HD Videos from IATA Airline Industry Retailing Symposium 2019 in Bangkok Vietnam Airlines Signs EngineWise Service Agreement with Pratt & Whitney Future of Airline Distribution and NDC - Interview with Yanik Hoyles, IATA Cambodia Airways Interview with Lucian Hsing, Commercial Director HD Videos and Interviews Podcasts from HD Video Interviews Travel Trade Shows in 2019, 2020 and 2021 High-Res Picture Galleries Travel News Asia - Latest Travel Industry News Read the full article

#0aprtravelcreditcards#0interesttravelcreditcards#0travelcards#0travelcreditcards#0travelmoney#0traveltrain#1travel2000#1travelinsurance#2traveldads#2traveldialindicator#2travelinsurancepolicies#2traveltogether#2travelingangelsstory#2travelingdogs#2travelinglovers#3countiestravelnews#3newstravel#3travelbloggers#3travelcreditcard#3travelsim#3travelsimcard#3travelsimeurope#3travelerscardtrick#3travelersregisteratahotel#3travelingsalesmanriddle#3travellingabroad#4traveldethleffs#4travelfriends#4travelgolf#4travelinsurance

1 note

·

View note

Text

YouLovePrint - Your Print Guide Litho Printing

There are different types of printing and you can choose how your job is printed or your printer will choose the best way to print your job based on the jobs specification and on the volume you are printing. This week we look at litho printing.

Lithography works due to the basic principle of oil and water not mixing. It uses smooth plates.

The image to be printed is laser etched onto the surface of a thin metal plate. This process is known as Computer to Plate, or CTP. The un-processed plate contains an emulsion surface designed to accept water. When the image is burned onto the plate, this changes the emulsion surface, so the image will not become wet when dampening on the printing press.

The plate is affixed to a large cylinder on a printing press. Rollers apply water which sticks to the non-image area of the plate, but is repelled by the image area on the plate. This means that now, when the ink is brought into contact with the plate, it sticks to the dry areas, and is repelled (being oil based) by the wet area. If this image was directly transferred to paper it would create a positive image, but the paper would become too wet. Instead, the plate rolls against another roller covered in a rubber blanket, which squeezes away the water and picks up the ink.

The paper now rolls across the blanket drum and the image is transferred to the paper. Because the image is first transferred, or offset to the rubber blanket, this printing method is known as offset lithography. Each colour has it’s own plate, so a 4 colour image would use 4 plates, each printing one after the other, usually in the following sequence - Black, Cyan (blue), Magenta (red), Yellow.

Sheetfed litho:

Cut sheets of paper are fed one by one through the press. Suitable for short to medium quantities between say 1,000 and 1,000,000 copies. Presses have different maximum sheet size capacity, and number of printing units.

Heidelberg XL-106 sheetfed litho press at work

Web offset litho:

Continuous reels of paper are fed through the press. Suitable for medium to high runs, typically over 1,000,000 copies. Presses are different reel size capacity (diameter and width of one rotation of cylinder).

Typically, the majority of very high volume promotional and direct mail print is sheetfed process, whilst most consumer catalogues and newspapers use the web offset process. There are sheet and reel fed print machines capable of matching conventional print at low to medium volumes.

0 notes