#VFD Drives

Explore tagged Tumblr posts

Text

Picture a food processing facility where every single machine responds to the demand, conserves energy and functions with ease. Designed with flexibility and rock-solid energy-saving Features, the SINAMICS V20 enables food plants to reconfigure faster and run more efficiently.

0 notes

Text

"Optimizing Industries with Smart Automation Solutions"

In today’s fast-paced industrial world, staying competitive means adopting advanced technologies that enhance efficiency, reduce downtime, and ensure sustainable growth. One of the most transformative trends reshaping industries is the integration of industrial automation and IIoT (Industrial Internet of Things) solutions. These innovations are revolutionizing operations, making processes smarter, faster, and more reliable.

What is Industrial Automation? Industrial automation involves the use of advanced control systems, such as Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, Variable Frequency Drives (VFDs), and other technologies, to automate industrial processes. These systems eliminate the need for manual intervention in repetitive or complex tasks, improving productivity and minimizing errors.

For instance, a manufacturing plant that once relied on human operators to manage conveyor belts and packaging lines can now leverage automation to ensure seamless, error-free operations. This not only boosts production speed but also ensures consistent quality across all outputs.

The Role of IIoT in Automation The Industrial Internet of Things (IIoT) takes automation a step further by connecting devices, machines, and systems to the internet. IIoT enables real-time monitoring, predictive maintenance, and data-driven decision-making. Imagine a power plant where sensors continuously monitor equipment performance, alerting operators about potential failures before they occur. This proactive approach prevents costly downtime and extends equipment lifespan.

Why Businesses Need to Embrace Automation Industries face several challenges, including rising operational costs, labor shortages, and increasing demand for efficiency. Automation addresses these pain points by:

Improving Efficiency: Automated systems work faster and more accurately than manual processes.

Reducing Downtime: Predictive maintenance and real-time monitoring minimize unexpected breakdowns.

Ensuring Safety: Automation reduces human involvement in hazardous tasks, ensuring worker safety.

How Apical Industrial Solution & Technology Leads the Way At Apical Industrial Solution & Technology, we specialize in delivering tailored automation and IIoT solutions that drive innovation and growth. Our Siemens-certified engineers are experts in designing, developing, and supporting control systems for diverse industries. From PLCs and SCADA to VFDs and LT switchgear, we provide end-to-end solutions that transform operations.

As industries evolve, the need for automation and smart solutions will only grow. Businesses that embrace these advancements today will be the leaders of tomorrow, equipped to navigate challenges and seize opportunities in an ever-changing world

#industrial automation#IIoT solutions#PLC systems#SCADA technology#VFD drives#predictive maintenance#process optimization#smart manufacturing#automation solutions#industry 4.0

1 note

·

View note

Text

Top Benefits of Using VFDs in Your Facility

Today, with a focus on energy efficiency, automation, and cost savings, companies in all industries are seeking to optimize their operations and minimize their environmental footprint. One of the most effective technologies that has changed how electric motors are operated in facilities is VFD (Variable Frequency Drive).

A VFD adjusts an electric motor's speed by altering the supplied frequency and voltage. In other words, it can vary the speed of the motor to meet the needs of the process or equipment. In the past, and before the use of VFD technology, motors would always operate at full speed, even when not required, wasting a lot of electricity.

With VFD technology, motors can vary their speed based on real-time demand and achieve maximum efficiency. The use of such technology is benefiting many types of facilities, including manufacturing plants, commercial buildings, and agricultural operations. This is why demand for good variable frequency drive manufacturers has also increased. Knowing about the benefits of VFDs is important for facilities.

Extend the Lifespan of Equipment

Motors that start and stop suddenly or operate at high speeds continuously wear out sooner and experience more stress. A VFD assists in starting it slowly and operating it at lower speeds in a controlled way. The soft start feature and smooth operation lower mechanical stress, which equates to less wear and tear on motor components like bearings, gears, and belts.

A VFD from reputable variable frequency drive manufacturers extends the life of your equipment. Additionally, fewer breakdowns mean lower repair costs, less downtime, and less maintenance costs. Ultimately, this can result in more reliable and stable operations of your facilities over time.

Less Demand for Peak Energy

Generally, the electric service companies impose higher charges on the consumers during the peak hours of electricity consumption. The activation of motors at full speed causes an instantaneous jump in heavy energy consumption, along with greater bills to the utilities.

The VFDs reduce the peaks by starting the motor slowly instead of running it at speed. They ensure a controlled speed. That could make a huge difference in your energy bills, especially with several motors running at the same time. Better management of peak demand would lead to avoiding penalties from the power company and lower overall costs of electricity. Explore multiple variable frequency drive manufacturers and buy from the one that provides the best quality.

Reduced Emissions

Using less energy is not only a money saver, but it also protects the environment. When your facility uses less electricity, you are reducing the demand on power plants, which typically burn fossil fuels in generating energy. Less energy used means there is a reduction in the number of greenhouse gases, including carbon dioxide, emitted into the atmosphere.

When your facility implements VFDs from VFD manufacturers, it can help mitigate climate change and meet environmental standards or goals. Governments and industry organizations promote energy efficiency technology now. Therefore, by utilizing VFDs, you can help meet that requirement and perhaps gain a green certification.

Less Noisy Operation

Conventional motor systems can be quite noisy, particularly when running at full speed. This noise can be excessive, especially in office buildings, commercial kitchens, or in residential spaces near some sort of industrial facility. Since VFDs allow motors to run at lower speeds when they may not need to run full power, they also reduce noise levels. A quieter operation helps create a better working environment for the employee and is more acceptable in noise-sensitive locations.

0 notes

Text

Top Industrial Automation Solutions: AC Drives, Motion Control, Control Panels & VIPA PLCs

In the fast-evolving world of industrial automation, choosing the right technology partner is critical. At Skill Tech Electronics, we provide advanced solutions including AC drives, motion control systems, custom-built electrical control panels, and VIPA automation products—helping industries across India boost productivity, precision, and energy efficiency.

AC Drives – Energy-Efficient Motor Control

Our range of AC drives (variable frequency drives) from top brands like Yaskawa and Mitsubishi offer intelligent motor control for applications ranging from HVAC to heavy machinery. Whether you're looking to reduce energy costs or improve motor lifespan, our AC drive solutions in India are designed to meet your automation goals.

Motion Control Systems – Precision Automation

Motion control is at the heart of modern automation systems. We offer servo drives, AC servo motors, and linear motion control systems tailored for high-speed, high-accuracy applications like packaging, robotics, and CNC machines.

Control Panels – Custom Electrical Panels for Every Industry

We design and manufacture electrical control panels for industrial automation applications. From PLC panels to motor control centers (MCCs), our panels ensure safety, compliance, and integration-ready systems.

VIPA Automation – Smart PLC & HMI Systems

VIPA, a Siemens brand, is known for its high-speed, compact, and reliable PLC and HMI systems. Skill Tech Electronics offers complete VIPA automation solutions, ideal for scalable and flexible industrial setups.

Why Choose Skill Tech Electronics?

Certified Yaskawa drive distributor and service center

Authorized dealer for Mitsubishi AC drives and VIPA PLCs

Expertise in industrial motion control and automation solutions

End-to-end support from product selection to service & repair

Looking for Industrial Automation Solutions in India?

Contact Skill Tech Electronics today for reliable, affordable, and future-ready automation solutions. Whether you're upgrading your plant, building new machinery, or looking for spare parts—we’ve got your needs covered.

#automation#ac motor#Yaskawa servo motor suppliers#AC drive suppliers in India#Mitsubishi VFD drive distributors

1 note

·

View note

Text

Increase Production Efficiency with Variable Frequency Drives

Increase production efficiency with Variable Frequency Drives (VFDs) by controlling motor speed based on demand. VFDs help reduce energy use, lower maintenance costs, and improve machine performance. They allow smooth motor startups, reduce wear and tear, and extend equipment life. By adjusting speed as needed, VFDs prevent energy waste and support consistent production flow. This leads to higher productivity, better product quality, and fewer breakdowns. VFDs are ideal for industries like manufacturing, HVAC, and water treatment. Upgrade to VFDs today to make your operations more energy-efficient, cost-effective, and reliable. Optimize your production with smart motor control technology.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Variable Frequency Drives#Vfds

0 notes

Text

Kone PCB repair company

Horizon Electronics stands out as one of the best electronics repair services in the UAE, offering expert solutions across a wide range of industrial and commercial electronics. Renowned as the best electronics repair services company in Dubai, they provide specialized support in electronic drive repair, earning a strong reputation for the best electronic drive repair services in the UAE. Their skilled technicians handle complex HMI and display repairs, along with advanced repairs for Mitsubishi elevator boards in Dubai, Kone PCB, Sigma elevator boards, and Otis circuit boards. Horizon is also trusted among inverter repairing shops in the UAE, offering top VFD repair services with precision and reliability. As a leader in electronic PCB repair services, they have become the best CNC board service company, known for restoring performance and extending the life of critical components.

#Best electronics repair services in UAE#best Electronic drive repair services in UAE#best electronics repair services company in DUBAI#HMI and display repair#mitsubishi elevator board repair in dubai#Inverters repairing shops in UAE#Electronic PCB repair services#Top VFD repair in UAE#Kone PCB repair company#Sigma Elevator Board repair#Otis circuit board repair#Best CNC board service company

0 notes

Text

How to Maintain Your VFD (Variable Frequency Drive) for Long-Term Efficiency

VFD maintenance is essential for ensuring the long-term efficiency of Variable Frequency Drives (VFDs), which are key components in modern industrial systems. They help control motor speed, reduce energy consumption, and extend equipment lifespan. Like any electrical device, VFDs require regular care to perform reliably over time.

1. Regular Inspection

Check the VFD regularly for dust, dirt, and signs of overheating. Make sure the ventilation is clear and cooling fans are working properly.

2. Monitor Voltage and Current

Keep an eye on input/output voltages and motor current. Abnormal readings could indicate internal faults or motor issues.

🧰 3. Clean the Filters

Air filters should be cleaned or replaced periodically to prevent overheating and internal damage.

4. Check for Firmware Updates

Manufacturers often release firmware updates to improve performance or fix bugs. Make sure your VFD has the latest version.

5. Schedule Professional Maintenance

Annual inspections by certified technicians help detect hidden issues before they cause major failures.

Conclusion

Proper VFD maintenance reduces unexpected downtime and ensures optimal performance of your machinery. Don't wait for failure—make maintenance part of your routine.

#VFD#VFDmaintenance#industrialmaintenance#electricalengineering#automation#drives#preventivemaintenance#motors#engineeringservices#industrialsolutions

1 note

·

View note

Text

Variable Frequency Drives for Agriculture and Industrial Pumping

In applications like agricultural irrigation, farm pumps, lake circulation, and river-fed infrastructure, variable frequency drives provide unmatched control, efficiency, and protection. VFDs precisely regulate motor speed to match real-time flow demand, maximizing energy savings while ensuring smooth system operation. Features such as blockage detection, dry run protection, pump stir cycle, and motor preheat function significantly reduce downtime, extend equipment life, and improve system reliability.

Quiet motor operation, advanced harmonic suppression, and optimized power factor design contribute to reduced operating costs and environmental impact. Whether operating a single high-power irrigation pump or managing a multi-pump station, variable frequency drives provide the intelligent control required to support advanced, water-driven infrastructure.

#variablefrequencydrive#acdrives#irrigation#pumps#pumpcontrol#vfds#agtech#infrastructure#efficiency#flowrate#motorcontrols#vfd#agriculture#automation#farming#speed#torque#voltage#current#phase#drives

0 notes

Text

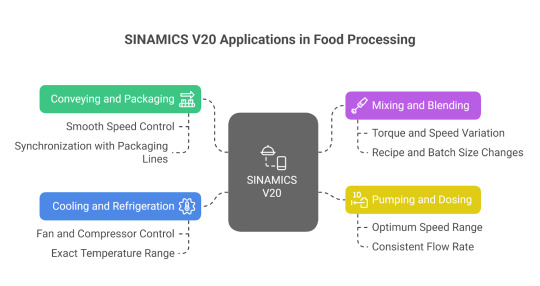

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Variable Frequency Drive (VFD)

Amtech Electronics India Limited is a leading Variable Frequency Drive (VFD) manufacturer in India, established in 1987 and headquartered in Gandhinagar. Specializing in motor control and automation solutions, the company offers a wide range of VFDs, including the Axpert-Eazy+ Series (0.75–2100 kW) and Regenerative VFDs (4Q Series), designed for energy efficiency, precision control, and compliance with global standards like IEEE-519:2014 for harmonics. Their products cater to industries such as cement, automotive, and renewable energy, with clients including Ambuja Cement and Bajaj Auto.

Amtech’s VFDs feature advanced technologies like IGBT-based PWM control, sensorless vector control, and low harmonic distortion (<5%), ensuring robust performance in harsh environments. The company is ISO 9001:2015 certified and adheres to international safety norms (CE, UL, CSA), with a focus on green technology and energy-saving solutions. Their portfolio also includes medium-voltage drives, soft starters, and power quality products like Active Harmonic Filters, supporting India’s Make in India initiative.

With over three decades of expertise, Amtech combines innovation with reliability, making it a trusted partner for industrial automation and sustainable motor control solutions. For more details contact us!

#Variable Frequency Drive (VFD)#Variable Frequency Drive#Variable Frequency Drive Manufacturer#vfd#VFD Manufacturer#VFD Manufacturer in India

1 note

·

View note

Text

Siemens VFD Drives: Energy-Efficient and Precision Control

What are VFD Drives?

VFD Drives are called Variable Frequency Drives (VFDs), and they're the most sophisticated apparatus designed to control both speed and torque of electric motors by varying the frequency and input voltage. They are commonly used, and in their place, come energy performance, motor lifetime enhancements, and better control of motor operations.

How Do VFD Drives Work?

VFDs are fundamentally made of three components, namely:

Rectifier: which actually converts the AC power source into DC.

DC Bus: which serves to filter and store DC energy.

Inverter: which will reconvert the DC back to a variable AC power with the ability to adjust both frequency and voltage.

VFDs in simple terms control the frequency with which an electric motor operates and so help speed control of the motors, thus making them the right choice when it comes to the dynamic requirements of the industry.

Key Features of VFD Drives

Energy Efficiency: It is a power-saving device and, in this case, matches motor speeds with perfect definition to requirements.

More Controlled: The motors can now accelerate and decelerate more smoothly.

Improved Motor Life: Minimizes mechanical stress by reducing wear and tear.

Versatile Applications: It is widely applicable to many motor types, both induction and synchronous.

Popular Siemens VFD Drives

Siemens provides a whole lot of VFD drivers for many industrial implementations. Below are the most important kinds of Siemens' VFD drives:

SINAMICS V20: The SINAMICS V20 is a highly economic, compact, and simple VFD drive for basic motion control applications. The simplicity of use enables small to medium-sized plants to make the best of it. Key features include:

Rapid commissioning with minimal setup.

Energy-saving modes for effective power usage.

Reliable performance in harsh environment

SINAMICS G120: The SINAMICS G120 motor drive is flexible and modular, application-neutral for many industrial requirements. Modular construction enables a wide variety of combinations of power modules with all control units. Further characteristics include:

Integrated safety functions as advanced safety features.

High energy efficiency with regenerative feedback.

Flexible communication interfaces for seamless integration into automation systems.

SINAMICS S120: The high performance of the SINAMICS S120 allows drive operation in applications that require sophisticated motor control. It is suitable for execution tasks that demand accuracy and rapid response in highly dynamic situations such as a robot or high-speed machining. The following features:

Scalability for multi-axis applications.

Superior motor control with high precision and stability.

Advanced diagnostics and monitoring for proactive maintenance.

Siemens has developed these VFD drives in reflection to precise needs, ranging from simple and cost-effective solutions to high end and performance driven applications.

Applications of VFD Drives

The use of variable-frequency drives in different industries is beneficial in improving efficiency and cutting down on operational costs:

1. HVAC systems: Variable frequency drives are used to operate the speed of the placed fans and pumps, providing operational efficiency in heating, ventilation, and air conditioning systems while saving significantly in energy consumption.

2. Industrial Automation: High Speed Rail VFDs facilitate more efficient productivity and low downtime through the ability to provide accurate motor control for speed and direction of conveyors to manufacturing assembly lines.

3. Water Treatment Plant: Variable Frequency Drives improve energy efficiency by affecting pump control adjustment for the instantaneous flow requirements of water.

4. Mining and Oil: The VFDs actuate the heavy-duty equipment such as crushers, mills, and drill rigs in relatively hostile environments.

5. Agriculture: VFD drives pumps in irrigation systems effectively controlling the water flow using pumps, thus reducing energy consumption and costs related to operations.

Benefits of VFD Drives

Cost Saving: Lower energy consumption will reduce electricity bills.

Flexibility: Variability for different motor speed and application.

Reduced Repairs: Decreased mechanical wearing, fewer failures.

Environmentally Friendly: Reduces energy wastage, thus sustainable.

Choosing VFD Drive Wisely

The selection of appropriate VFD is contingent upon several factors, which include the following:

Motor Specifications: This includes power rating, voltage, and type of motor.

Application Requirements: Such as the kind of load and the precision of control

Environmental Conditions: These conditions include operational temperatures, humidity, spatial constraints, etc.

Budget Considerations: Use costs versus upfront costs with long-term savings.

Conclusion

VFD drives by Naksh Technology Solutions a necessity for modern manufacturing operations—give maximum efficiency, control, and reliability to any application. Whether you need energy savings in HVAC systems or sophisticated controlling motions for manufacturing processes, VFDs are the ultimate solution. Siemens has an entire range of VFD models available for projects, so businesses can find an appropriate VFD to suit their operational objectives and budgets.

With these Siemens VFD drives, create the revolution in industrial processes that you have been looking for to make your operations as efficient and sustainable as you require, or even go beyond.

0 notes

Text

The Role of VFDs in Helping Solar Pump Drives Run Efficiently

It is quite evident that the world is gradually turning to renewable energy sources, especially for powering several systems. In fact, in the last few years, solar-powered solutions have emerged as a trustworthy and sustainable option across industries.

One of the primary applications of solar energy is in water pumping systems, particularly in remote or off-grid areas where access to electricity is limited. Solar pump drives typically power such systems. They convert solar energy into usable power for pumps.

It is a must to remember that solar energy generation is variable depending on a range of factors such as time of day, weather, and geographical location. When it comes to handling this, Variable Frequency Drives (VFDs) are often recommended as they have become an integral part of solar pump systems. These devices control the speed and efficiency of electric motors. If you incorporate them into a solar pump drive, it will be easier to regulate motor performance based on available solar power. Here is the role of VFDs in helping solar pump drives run efficiently.

Saves Energy and Money

One of the major reasons behind the growing popularity of solar pump systems with VFDs is their ability to minimize energy expenses. In many off-grid applications, solar power is used as the primary energy source because it is often the most cost-effective option. However, you must maximize the energy generated by solar panels as that is the only way to ensure the long-term sustainability and cost-effectiveness of the system.

VFDs help optimize the motor’s performance based on available solar power. This way, they play a major role in reducing the pump system’s overall energy consumption. The ability to adjust motor speed according to solar conditions means that the system is only using as much energy as needed. As a result, it becomes easier to avoid overconsumption and reduce overall operating costs. After a while, this will lead to a lot of savings on energy bills while minimizing reliance on backup power sources. It can prove to be beneficial in remote locations where electricity is either unavailable or very costly. Just ensure that you find the best VFD manufacturers so that you can buy the device without worrying about the quality.

Provides Protection

Another very significant benefit of a solar pump drive system with a VFD is protection. They have the ability to safeguard the pump motor and the components from any sort of damage. Since VFDs control the motor speed, they help reduce the mechanical and electrical stresses that typically occur during startup and shutdown. Due to such adjustment, the risk of damage to both the motor and the mechanical parts is reduced significantly.

Additionally, VFDs feature overcurrent protection, under-voltage protection, and thermal protection. These features are very helpful as they help prevent motor overheating and electrical failures by continuously monitoring system parameters and adjusting performance as and when needed. VFDs ensure there is no overloading and overheating. As a result, the motor operates within safe conditions. They will not only last long this way but also won’t require frequent replacements.

Integrates Seamlessly With System Components

Apart from controlling the motor speed, VFDs also do a good job of integrating with solar pump system components. This includes things like battery storage systems, solar panel controllers, remote monitoring tools, etc. With the help of this integration, you can ensure the system is optimized and performs well. For instance, when a solar pump system is paired with a battery storage solution, you can program the VFD to make adjustments to the motor speed to ensure that battery power is not drained quickly. This will make the system run for extended periods.

Moreover, remote monitoring features ensure that you have an easier time tracking the system's performance. This way, you can adjust settings when needed from anywhere. It facilitates proactive maintenance to keep the system running smoothly. There is no denying that investing in a VFD for a solar pump drive system is one of the best decisions you can make.

0 notes

Text

Canyon Engineering Solutions Pvt. Ltd. is a trusted name among Nidec Control Technique VFD/AC Drive dealers in Jaipur, Rajasthan. We specialize in providing high-quality Nidec Control Technique Servo Drives & Motors in Jaipur Rajasthan offering exceptional performance and reliability for a variety of industrial applications. Our comprehensive range of Nidec Control Technique products, including advanced Variable Frequency Drives (VFD) and Servo Drives & Motors, ensures seamless automation solutions for businesses. As authorized dealers, we offer competitive pricing, expert consultation, and excellent customer support, ensuring that your automation needs are met with precision and efficiency. Whether you're in need of VFDs or Servo motors, Canyon Engineering Solutions is your go-to partner for Nidec Control Technique products in Jaipur and across Rajasthan.

#Nidec Control Technique VFD/ AC Drive dealers in Jaipur#Nidec Control Techniqe Servo Drives & Motors In Jaipur Rajasthan

0 notes

Text

Siemens A1-116-180-504 Is.03 Base Drive - auto2mation

The Siemens A1-116-180-504 Is.03 Base Drive is a high-quality component designed for reliable motor control in industrial automation systems. Known for its durability and precision, this Siemens base drive supports efficient performance in demanding applications. It is easy to install and integrate, making it a smart choice for engineers and maintenance teams. Ideal for use in manufacturing and process industries, the A1-116-180-504 helps reduce downtime and improve system stability. Trust Siemens for advanced technology and dependable automation solutions. Buy now from Auto2mation – your trusted source for industrial and marine automation parts. Fast shipping and expert support available

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#VFDs#Drives#variable frequency drives

0 notes