#Vapor Absorption Machine

Explore tagged Tumblr posts

Text

Sustainable Power Generation: Renewable Energy Solutions

Total Power Solutions

Kaltimex Energy is a well-known company in Bangladesh that specializes in providing engineering, procurement, and construction (EPC) services, particularly in the energy sector.

Kaltimex Energy Bangladesh is involved in various projects related to power generation, including the installation and maintenance of power plants, electrical and mechanical works, and other energy-related services. They have been involved in the development of both conventional and renewable energy projects in Bangladesh.

Kaltimex Energy has been working in the field of power plant business for over 2 decades. They deal with natural Gas Engine, Industrial Gas Generator, Diesel Generator, Exhaust Gas Boiler, Gas Fired Boiler, Vapor Absorption Machine (Chiller), Thermal Fluid Heater, Transformer, Radial Gas Turbine and Steam Turbine for power plants on turnkey basis projects from concept to commissioning within stipulated time period & budget.

MWM, HTT, VIESSMANN, VOLTAS, ENMAX & MAXWATT, and others are marketed brands.

#Gas Engine#Power Generation#Power Plants#Natural Gas Engine#Industrial Gas Generator#Diesel Generator#Exhaust Gas Boiler#Gas Fired Boiler#Vapor Absorption Machine#Industrial Boiler#Thermal Fluid Heater#Transformer#Radial Gas Turbine#Steam Turbine

4 notes

·

View notes

Text

What are the applications of intelligent glue potting production line in the home appliance industry?

The intelligent glue potting production line is widely used in the home appliance industry. It mainly improves the sealing, shock resistance, thermal conductivity and structural strength of home appliances through automated, high-precision glue (such as sealant, thermal conductive glue, structural glue, etc.) dispensing and filling processes. The following are specific application scenarios and advantages:

1.Waterproof sealing treatment

Applied products: washing machines, dishwashers, water heaters, air conditioner outdoor units, etc.

Function: Filling glue in the joints of electrical housings, circuit boards, wiring terminals, etc. to prevent water vapor and dust from invading and improve the IP protection level.

Intelligent advantages: The visual positioning system automatically identifies the glue filling position, and the 3D path planning adapts to complex structures to avoid manual leakage or overflow of glue.

Vacuum potting technology

Inline vacuum potting machine: For example, the SEC-S400-ZL/ZHL ensures no air bubbles remain in the adhesive during potting through rapid vacuum extraction and high sealing performance, reducing leakage caused by bubbles.

Smart production line integration:

Vacuum potting production line: By integrating MES systems for data collection and uploading, it covers key data such as production quantities and equipment exceptions, enabling real-time monitoring of the potting process and timely resolution of stringing and leakage issues.

2.Fixation and protection of electronic components

Applied products: refrigerator control panels, microwave oven circuits, smart home appliance main control modules, etc.

Function: Bond and fix components on PCB boards, or perform overall potting protection to avoid short circuits or desoldering caused by vibration and moisture.

Intelligent advantages: High-precision piezoelectric valve controls micro-dispensing to avoid glue contamination of sensitive components; real-time monitoring of glue volume to ensure consistency.

3.Heat conduction and heat dissipation management

Applied products: LED TV backlight module, power adapter, induction cooker heat dissipation components.

Function: Fill with thermal conductive silicone to transfer the heat of heating components (such as power chips) to the heat sink to extend life.

Intelligent advantages: Temperature sensor feedback adjusts the glue thickness to ensure thermal efficiency; two-component glue is automatically mixed and proportioned.

4.Structural bonding and shock absorption

Applied products: refrigerator compressor fixing, vacuum cleaner motor assembly, fan blade bonding.

Function: Replace screws or welding, reduce noise and vibration, and reduce weight.

Intelligent advantages: The robot arm operates at multiple angles to adapt to complex assembly lines; the force control system ensures the uniformity of the glue layer.

5.Aesthetics and surface treatment

Applied products: smart speaker edge sealing, oven panel bonding.

Function: Hide the seams and improve the appearance texture; some transparent glue is used for decorative packaging (such as LED indication area).

Intelligent advantages: Laser ranging accurately controls the width of the glue line to avoid burr problems caused by manual operation.

The core advantages of intelligent glue pottling:

1.Efficiency improvement: 24-hour continuous operation, the speed can reach 3-5 times that of manual operation.

2.Stable quality: reduce defects such as bubbles and glue breakage, and the glue utilization rate reaches more than 95%.

3.Flexible production: quickly switch the glue filling scheme of different home appliance models through software.

4.Data traceability:record process parameters (such as glue quantity, temperature, time), and support quality traceability.

Typical case

Air conditioning motor potting: fully automatic line completes coil thermal conductive glue filling, and the temperature resistance is increased to more than 150℃.

Smart toilet circuit board: automatic spraying of three-proof glue (moisture-proof, mildew-proof, and salt spray-proof), the failure rate is reduced by 60%.

Washing machine door seal: multi-axis robot cooperates with visual system to realize precise glue coating on three-dimensional curved surfaces.

Future trends

1.AI optimization:analyze the glue curing effect through machine learning and dynamically adjust parameters.

2.Green process: cooperate with low-VOC environmentally friendly glue to meet RoHS standards.

3.Modular design: seamlessly integrated with home appliance assembly lines, supporting small batch customized production.

Intelligent glue filling technology is becoming a key link in the intelligent manufacturing of home appliances, especially in high-end, waterproof and high-reliability products.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

0 notes

Text

Precision at the Atomic Level: Inside the Vapor Deposition Boom

The Vapor Deposition Market is witnessing robust growth, powered by increasing demand for ultra-thin, high-performance coatings across key sectors such as semiconductors, solar energy, medical devices, aerospace, and optics. Vapor deposition techniques—both chemical (CVD) and physical (PVD)—enable the formation of advanced coatings that deliver enhanced durability, conductivity, hardness, and resistance to heat or corrosion.

As industries move toward miniaturization, nanotechnology, and surface engineering, vapor deposition is becoming indispensable to the next wave of material science innovation.

Market Overview

Vapor Deposition refers to a family of processes that produce thin films and coatings via vaporized material deposition on a substrate. The two main types are:

Chemical Vapor Deposition (CVD): Involves chemical reactions between vapor-phase precursors and the substrate to form coatings.

Physical Vapor Deposition (PVD): Uses physical processes like evaporation or sputtering to deposit material on surfaces.

Applications include:

Semiconductor devices and microelectronics

Solar cells and thin-film photovoltaics

Cutting tools and machine parts

Optical lenses and eyewear

Biomedical implants and stents

Key Market Trends

Miniaturization in Electronics and MEMS Devices

Vapor deposition is critical in fabricating semiconductors, microelectromechanical systems (MEMS), and integrated circuits.

High Demand in Solar and Renewable Energy

CVD techniques are used to create thin-film coatings for solar panels, enhancing energy absorption and efficiency.

Adoption in Medical Implants and Wearables

Bio-compatible coatings via CVD/PVD are applied to stents, pacemakers, and orthopedic implants for corrosion resistance and longevity.

Tooling and Hard Coating Applications

PVD is widely used to coat cutting tools, drills, and machine components to improve hardness and wear resistance.

Growth Drivers

Boom in Semiconductor and Electronics Manufacturing

As devices become smaller and more powerful, nano-thin coatings are required for insulation, conductivity, and thermal protection.

Rising Demand for Wear-Resistant and Corrosion-Proof Surfaces

Industries need coatings that extend the lifespan of machinery, optical instruments, and industrial tools.

Growth in Solar PV Installations

Vapor deposition enhances the performance and longevity of solar cells and panels, supporting global energy transitions.

Advancements in Surface Engineering Technologies

Emerging innovations like plasma-enhanced CVD and atomic layer deposition (ALD) are opening new avenues for precision coatings.

Challenges in the Vapor Deposition Market

High Capital Investment and Operating Costs

Vapor deposition equipment and processes require significant upfront investment, particularly for semiconductor manufacturing.

Complexity of Process Control

Achieving uniform coatings with precise material properties demands high process accuracy and control.

Environmental and Safety Concerns

Some chemical precursors used in CVD are hazardous, requiring strict handling and disposal procedures.

Skilled Labor and Technical Expertise Shortage

Specialized training is needed to operate and maintain vacuum deposition systems effectively.

Future Outlook

Rise of Flexible Electronics and Wearable Tech

Vapor-deposited films are critical in developing bendable displays, smart clothing, and compact sensors.

Integration with Additive Manufacturing (3D Printing)

Combining 3D printing and vapor deposition could create hybrid manufacturing platforms with enhanced surface capabilities.

Expansion into Aerospace and Defense

High-temperature, anti-corrosive coatings will support aircraft, space vehicles, and defense components.

Asia-Pacific to Lead Market Growth

The region’s dominance in electronics, solar energy, and industrial manufacturing will drive demand for vapor deposition technologies.

Conclusion

The Vapor Deposition Market is central to enabling the next generation of high-performance, miniaturized, and long-lasting products. As technological demands evolve, vapor deposition will remain critical in creating precision coatings that combine functionality, durability, and advanced material characteristics—fueling progress across nearly every high-tech industry.

0 notes

Text

Ionic Liquids Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – Date – 04/07/2025 - The Insight Partners is proud to announce its newest market report, "Ionic Liquids Market: An In-depth Analysis of the Ionic Liquids Market " The report provides a holistic view of the Ionic Liquids market and describes the current scenario as well as growth estimates for Ionic Liquids during the forecast period.

Overview of Ionic Liquids Market

There has been some development in the Ionic Liquids market, such as growth and decline, shifting dynamics, etc. This report provides insight into the driving forces behind this change: technological advancements, regulatory changes, and changes in consumer preference.

Key findings and insights

Market Size and Growth

Historical Data: The Ionic Liquids market is estimated to reach CAGR of 8.8% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.These estimates provide valuable insights into the market's dynamics and can inform future projections.

Ionic Liquids (ILs) are molten salts with melting points below 100∘C, often even at room temperature. Their unique properties, such as negligible vapor pressure, non-flammability, high thermal and chemical stability, wide electrochemical windows, and tunable solvation characteristics, make them "designer solvents" with immense potential to replace traditional volatile organic compounds (VOCs) in a wide range of industrial applications.

Key Factors Affecting the Ionic Liquids Market

The Ionic Liquids market is influenced by a combination of scientific advancements, industrial demands, and environmental regulations:

Growing Demand for Green and Sustainable Chemistry: This is the most significant driver. Strict environmental regulations (e.g., REACH in Europe, EPA in the US) on VOC emissions and hazardous waste are pushing industries to adopt greener alternatives. Ionic liquids, with their low vapor pressure and potential for reusability, offer a compelling solution as environmentally benign solvents and reaction media.

Unique and Tunable Properties: The ability to tailor the properties of ionic liquids by combining different cations and anions makes them highly versatile for specific applications. This "designer" aspect allows for optimized performance in various chemical processes, separations, and material syntheses.

Increasing Applications in Energy Storage: The rapid growth of electric vehicles (EVs) and renewable energy solutions (solar, wind) is driving demand for advanced energy storage technologies. Ionic liquids are being increasingly explored and adopted as electrolytes in lithium-ion batteries, supercapacitors, and fuel cells due to their high ionic conductivity, wide electrochemical stability window, and non-flammability, which enhance safety and performance.

Rising Adoption in Pharmaceuticals and Biotechnology: In the pharmaceutical sector, ionic liquids are used as solvents for drug synthesis, as reaction media for enzymatic reactions (biocatalysis), for drug delivery systems, and even to improve the solubility and bioavailability of active pharmaceutical ingredients (APIs). Their non-volatility is particularly beneficial for these applications.

Advancements in Separation and Extraction Technologies: Ionic liquids are highly effective in various separation processes, including extractive distillation, liquid-liquid extraction, and gas absorption, due to their unique solvency properties. This is crucial in industries like petrochemicals, natural gas processing, and bio-refineries.

Spotting Emerging Trends

Technological Advancements:

The Ionic Liquids market is being significantly disrupted and shaped by several emerging technologies:

AI and Machine Learning in IL Design and Prediction:

High-Throughput Screening: AI/ML algorithms are being used to rapidly screen vast numbers of potential IL structures and predict their properties (e.g., viscosity, melting point, solubility, toxicity) without extensive experimental synthesis. This significantly accelerates the discovery and optimization of new ILs for specific applications.

Inverse Design: Leveraging AI to "design" ILs with desired properties, rather than just predicting properties for existing structures, revolutionizing the R&D process.

Continuous-Flow Synthesis and Green Production Methods:

Process Intensification: Development of continuous-flow reactors for IL synthesis, offering improved efficiency, scalability, safety, and reduced waste compared to traditional batch processes. This is crucial for bringing down production costs.

Recycling and Reusability Technologies: Advancements in robust and cost-effective methods for purifying and recycling ILs after use in industrial processes, further enhancing their sustainability and economic viability.

Green Synthesis Routes: Focus on synthesizing ILs using less hazardous raw materials and processes, aligning with broader green chemistry principles.

Hybrid Materials and Composites with ILs:

IL-Polymer Electrolytes: Development of solid or gel polymer electrolytes incorporating ILs for enhanced safety and performance in next-generation batteries (e.g., solid-state batteries).

IL-Metal Organic Frameworks (MOFs) and Nanomaterials: Creation of novel hybrid materials by incorporating ILs into porous structures like MOFs or onto nanomaterials to enhance their properties for gas capture, catalysis, or sensing.

Changing Consumer Preferences:

"Consumer preferences" in the Ionic Liquids market refer to the evolving demands and priorities of industrial clients, researchers, and end-users of ILs. These preferences have shifted in several key ways:

Strong Preference for "Green" and Sustainable Solutions:

The primary driver is the increasing pressure from environmental regulations and corporate sustainability initiatives. Customers are actively seeking alternatives to traditional VOCs and hazardous solvents. They prioritize ILs that are demonstrably less toxic, more biodegradable, and contribute to reduced waste and energy consumption in their processes.

Demand for Performance and Efficiency Gains:

Beyond "green," customers expect ILs to deliver superior performance compared to conventional alternatives. This includes improved reaction yields, higher selectivity in catalysis, better separation efficiency, enhanced battery performance (safety, cycle life, energy density), and increased process efficiency.

Focus on Cost-Effectiveness and Scalability:

While ILs offer performance benefits, the high cost has been a barrier. Customers are increasingly demanding more affordable ILs, and suppliers who can offer continuous production methods and economies of scale are gaining favor. They also look for ILs that can be easily scaled up for industrial production.

Reliability and Consistent Quality:

As ILs move from lab to industry, consistent quality and reliable supply are paramount. Customers need assurances about purity, batch-to-batch consistency, and long-term stability for their industrial processes.

Growth Opportunities of the Ionic Liquids Market

The Ionic Liquids market, despite its current niche status, holds immense growth opportunities driven by their unique properties and the global shift towards sustainable and high-performance solutions.

Accelerated Adoption in Green Chemistry and Sustainable Processes:

VOC Replacement: The most significant opportunity lies in the continued replacement of traditional VOCs in various industrial processes, including chemical synthesis, pharmaceuticals, and coatings, driven by ever-tightening environmental regulations globally.

Sustainable Separations: Expanding the use of ILs in more efficient and environmentally friendly separation and purification processes (e.g., CO2 capture, desulfurization of fuels, extraction of high-value compounds from biomass).

Biocatalysis and Biorefineries: Growth in using ILs as reaction media for enzymatic reactions and for the efficient dissolution and processing of lignocellulosic biomass for biofuels, biochemicals, and biomaterials.

Revolutionizing Energy Storage and Conversion:

Next-Generation Batteries: Significant opportunity in developing and commercializing ILs as advanced electrolytes for next-generation lithium-ion batteries (especially solid-state and lithium-sulfur batteries), providing enhanced safety (non-flammable), wider electrochemical windows, and improved cycle life. The booming EV market is a primary driver here.

Supercapacitors and Fuel Cells: Further penetration as highly stable and conductive electrolytes in high-performance supercapacitors and various types of fuel cells.

Solar Cells: Continued research and commercialization of ILs as components in more efficient and stable dye-sensitized solar cells (DSSCs) and other photovoltaic devices.

Get Sample Link - https://www.theinsightpartners.com/sample/ionic-liquids-market

Conclusion

The Ionic Liquids Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Ionic Liquids 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Ionic Liquids market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Reflow Ovens: The Essential Tool for High-Quality PCB Assembly

Introduction

In electronics manufacturing, achieving precise and reliable soldering is crucial for producing high-quality printed circuit boards (PCBs). Reflow ovens are specialized machines designed to reflow solder paste, ensuring strong connections between surface mount components and PCB pads. Whether used in high-volume production or prototyping, reflow ovens provide consistent temperature control and efficient soldering. In this blog, we explore the types of reflow ovens, their advantages, and key considerations for selecting the right model.

What is a Reflow Oven?

A reflow oven is a machine that heats PCBs in a controlled environment, melting solder paste to create secure electrical connections. The process follows a thermal profile, which includes preheating, soaking, reflow, and cooling stages to ensure optimal soldering.

Key Features of Reflow Ovens

Precise Temperature Control – Maintains consistent heating for reliable solder joints.

Multiple Heating Zones – Allows gradual temperature changes to prevent thermal stress.

Automated Conveyor System – Ensures uniform processing for high-volume production.

Atmosphere Control – Some models use nitrogen environments to reduce oxidation.

Types of Reflow Ovens

1. Infrared (IR) Reflow Ovens

These ovens use infrared radiation to heat PCBs:

Direct Heat Transfer – Efficient heating for small-scale production.

Variable Absorption – Different materials absorb infrared heat at different rates.

Cost-Effective – Ideal for hobbyists and low-volume manufacturing.

2. Convection Reflow Ovens

Convection ovens use heated air circulation for uniform soldering:

Even Heat Distribution – Reduces thermal stress on components.

Precise Temperature Control – Ideal for complex PCB assemblies.

High-Volume Production – Common in industrial electronics manufacturing.

3. Vapor Phase Reflow Ovens

These ovens use heat transfer liquid vapor for soldering:

Oxygen-Free Environment – Prevents oxidation and improves solder quality.

Consistent Temperature – Eliminates overheating risks.

High-Efficiency Process – Suitable for sensitive components.

Advantages of Using Reflow Ovens

1. Reliable and Consistent Soldering

Reflow ovens ensure uniform heating, reducing defects such as cold solder joints or bridging.

2. High-Speed Production

Automated conveyor systems allow continuous processing, improving manufacturing efficiency.

3. Compatibility with Surface Mount Technology (SMT)

Reflow ovens support SMT assembly, enabling compact and high-density PCB designs.

How to Choose the Right Reflow Oven

1. Consider Production Volume

Benchtop Models – Ideal for prototyping and small-scale production.

Inline Conveyor Ovens – Best for high-volume manufacturing.

2. Evaluate Temperature Control and Heating Zones

Multi-Zone Ovens – Provide precise thermal profiles for complex assemblies.

Single-Zone Ovens – Suitable for simpler PCB designs.

3. Assess Atmosphere Control

Nitrogen Reflow Ovens – Reduce oxidation for improved solder quality.

Standard Air Reflow Ovens – Cost-effective for general applications.

Conclusion

Reflow ovens are essential for high-precision soldering, ensuring strong and reliable connections in electronics manufacturing. Whether using infrared, convection, or vapor phase technology, selecting the right reflow oven depends on production needs, temperature control, and atmosphere requirements. Investing in advanced reflow oven technology enhances PCB assembly efficiency and product quality.

0 notes

Text

Understanding The Role Of Refrigerants In Thermodynamic Heat Pumps

With the increasing global emphasis on energy efficiency and sustainability, thermodynamic heat pumps are emerging as a key solution for environmentally friendly heating and cooling. At the heart of every heat pump lies one critical component that often goes unnoticed – the refrigerant. Understanding the refrigerant cycle is essential not just for HVAC experts, but also for homeowners and businesses aiming for peak performance, energy conservation, and ecological responsibility. This blog delves into the functioning of refrigerants in thermodynamic heat pumps, their significance in system efficiency, and the effects of various refrigerant types on performance and environmental consequences.

Thermodynamic heat pump & refrigerant

Before exploring the refrigerant cycle, let’s have a brief understanding of what a thermodynamic heat pump is. This machine facilitates the transfer of heat from one place to another, while utilizing minimal electrical energy. By harnessing ambient air, ground, or water as a heat source or sink, these systems can effectively heat or cool indoor environments or water. The core principle behind heat pumps is the refrigeration cycle, which allows the system to move heat, rather than generate it, leading to higher energy efficiency, as compared to other heating systems. This cycle relies on the properties of refrigerants.

A refrigerant is a fluid, often a compound or a mixture of compounds, that absorbs heat at low temperature and pressure and releases it at higher temperature and pressure. Refrigerants are specifically designed to transition easily between liquid and vapor phases, facilitating heat transfer through evaporation and condensation. Contemporary refrigerants are formulated with thermodynamic characteristics that enhance the efficiency of heat pumps, while also addressing environmental issues such as ozone depletion and global warming potential.

The four key stages of the refrigerant cycle

The refrigerant cycle in a thermodynamic heat pump comprises four primary stages, facilitated by four essential components: the evaporator, compressor, condenser, and expansion valve.

Evaporation (Heat absorption)

The process begins in the evaporator, where the refrigerant exists as a low-pressure, low-temperature liquid. It absorbs heat from its environment – such as outdoor air, ground, or water – leading to its evaporation into a low-pressure vapor, thus initiating thermal energy transfer.

Compression (Increasing pressure and temperature)

The compressor takes in this low-pressure vapor and compresses it, increasing both its pressure and temperature, resulting in a high-pressure, high-temperature vapor. This compression stage is the most energy-intensive and vital for the thermodynamic heat pump’s efficiency.

Condensation (Heat release)

The high-temperature, high-pressure vapor moves to the condenser, where it releases the accumulated heat; in heating mode, this heat warms the indoor area, while in cooling mode, it is expelled outside. As the refrigerant releases heat, it condenses back into a high-pressure liquid, perpetuating the energy transfer cycle.

Expansion (Pressure reduction)

The high-pressure liquid flows through the expansion valve, where its pressure and temperature drop sharply, cooling it significantly and returning it to a low-pressure, low-temperature liquid state, ready to re-enter the evaporator and restart the cycle.

Why the refrigerant matters

The choice of refrigerant in a thermodynamic heat pump significantly influences system performance, operational expenses, lifespan, and environmental sustainability. Key aspects affected by refrigerant selection include:

System efficiency (Coefficient of Performance – COP)

The COP indicates the amount of heat transferred per unit of electricity used. Refrigerants that effectively absorb and release heat contribute to higher COP values, thereby improving energy efficiency.

Operating temperature range

Some refrigerants are more suitable for extreme weather conditions. For instance, propane performs well even in very low temperatures, making it ideal for applications in cold climates.

Pressure requirements

Some refrigerants function at higher pressures, which can increase stress on system components. This may result in greater wear, higher maintenance costs, and a shorter system lifespan over time.

Heat transfer efficiency

Refrigerants with excellent thermal conductivity and lower viscosity facilitate quicker and more efficient heat exchange, enhancing system responsiveness and lowering energy consumption.

Environmental impact

Refrigerants with low Global Warming Potential (GWP) are more eco-friendly, supporting global initiatives to decrease greenhouse gas emissions.

Selecting the appropriate refrigerant is crucial for maximizing performance, ensuring longevity, and reducing environmental impact.

Maintenance and monitoring for refrigerant efficiency

To maintain optimal efficiency of your thermodynamic heat pump, it is essential to adhere to some best practices for refrigerant maintenance.

Schedule routine inspections to check refrigerant levels and system pressure.

Implement leak detection systems to promptly identify refrigerant leaks and prevent performance declines.

Ensure correct refrigerant charging during installation and servicing to avoid both undercharging and overcharging.

Keep an eye on system performance for any signs of inefficiency that could suggest refrigerant problems.

Replace outdated systems that utilize phased-out refrigerants with newer, eco-friendly alternatives.

Collaborate with certified technicians to ensure safe handling and disposal of refrigerants.

Regular maintenance and monitoring can safeguard your system’s efficiency, prolong its lifespan, and promote environmental sustainability.

Choosing the right heat pump

When choosing a thermodynamic heat pump, it is essential to choose the right refrigerant as this one component plays a crucial role in determining the performance, energy efficiency, and environmental impact.

Opt for low-GWP (Global Warming Potential) refrigerants to support eco-friendly heating and cooling.

Verify efficiency ratings that reflect how well the refrigerant contributes to overall system performance.

Ensure climate compatibility – some refrigerants perform better in specific temperature ranges, making them more suitable for your local conditions.

Check regulatory compliance with current environmental standards to avoid future phase-outs or retrofitting needs.

Thanks to ongoing innovations and careful refrigerant choices, thermodynamic heat pumps are becoming a key player in sustainable living. By prioritizing refrigerants during your purchase decision, you’re not just buying a heating system; you’re investing in long-term performance and a cleaner planet.

Looking for an eco-friendly thermodynamic heat pump in Bangalore? Explore Vindsol’s range of thermodynamic heat pumps, designed for optimal efficiency and environmental responsibility. These cutting-edge systems utilize eco-friendly refrigerants to enhance heat transfer while minimizing energy use and carbon emissions. Tailored to thrive in Bangalore’s climate, Vindsol heat pumps deliver reliable and economical heating and cooling solutions for both residential and commercial spaces. Emphasizing longevity and reduced operational expenses, Vindsol’s thermodynamic heat pumps present a wise, eco-conscious alternative to conventional heating methods, enabling you to conserve energy and support a healthier planet!

Resource: Read more

#spapoolwaterheaterinBangalore#Vindsol#HeatPumps#EcoFriendly#EcoFriendlyHeatingSolutions#SustainableLiving#HotWaterSolutions#HeatingSolutions#HeatPumpsBangalore#WaterHeater#WaterHeating#CommercialHotWaterHeatPumps#CommercialHeatPumpsBangalore#CommercialWaterHeater#CommercialHeatPumps#VindsolCommercialHeatPumps

0 notes

Text

How Do Air Cooled Chillers Work? A Comprehensive Guide

In today's climate-conscious and efficiency-driven world, air cooled chillers have become a cornerstone of HVAC systems for commercial and industrial applications. These chillers offer an efficient way to cool spaces without requiring a constant water source, making them particularly suited for areas where water availability or infrastructure is limited. This article provides a comprehensive guide to understanding how air cooled chillers work, their components, and their advantages over other cooling technologies.

What Are Air Cooled Chillers?

Air cooled chillers are refrigeration systems used to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle. They differ from water-cooled chillers in that they dissipate heat directly into the air rather than relying on a cooling tower and water supply. These systems are often used in medium to large buildings, manufacturing facilities, data centers, and hospitals.

Key Components of Air Cooled Chillers

To understand how air cooled chillers work, it’s essential to break down their core components:

Compressor: This is the heart of the chiller, compressing the refrigerant and increasing its pressure and temperature.

Condenser Coils and Fans: Located on the outside of the chiller, these coils and fans work together to release the absorbed heat into the ambient air.

Expansion Valve: It reduces the pressure of the refrigerant, cooling it down before it enters the evaporator.

Evaporator: This component absorbs heat from the chilled water or process fluid, transferring it to the refrigerant.

Each of these components plays a crucial role in the refrigeration cycle that air cooled chillers rely on.

How the Cooling Cycle Works

The operation of air cooled chillers is based on a four-step thermodynamic cycle:

Compression: The refrigerant enters the compressor as a low-pressure gas and is compressed into a high-pressure, high-temperature gas.

Condensation: The hot refrigerant gas flows through the condenser coils. Cooling fans blow ambient air across the coils, removing heat and condensing the gas into a high-pressure liquid.

Expansion: The high-pressure liquid then passes through an expansion valve where its pressure is reduced, cooling it further.

Evaporation: The cold refrigerant flows into the evaporator, where it absorbs heat from the water or fluid in the loop. This heat causes the refrigerant to evaporate into a gas again, and the cycle repeats.

This cycle allows air cooled chillers to efficiently extract heat from a space or process and release it into the surrounding air.

Advantages of Air Cooled Chillers

There are several benefits to choosing air cooled chillers for your facility:

Ease of Installation: No cooling tower or water supply system is needed, making installation quicker and less expensive.

Lower Maintenance: Without water pumps, towers, or plumbing, maintenance is simpler and less frequent.

Energy Efficiency: In mild to cool climates, these chillers can operate very efficiently with minimal auxiliary systems.

Space Saving: All components are typically packaged into a single outdoor unit, freeing up valuable indoor space.

Applications of Air Cooled Chillers

Thanks to their versatility and compact design, air cooled chillers are widely used in:

Commercial buildings (malls, offices)

Manufacturing facilities (plastics, food processing)

Medical environments (MRI machines, labs)

Data centers and server rooms

Final Thoughts

Understanding how air cooled chillers work is key to making informed decisions when planning or maintaining HVAC systems. Their air-based heat rejection method makes them especially useful in locations where water conservation is important or where plumbing infrastructure is limited. By leveraging the core principles of thermodynamics, air cooled chillers deliver reliable and energy-efficient cooling for a wide range of applications.

0 notes

Text

Applications of Heat-Sealable Breathable Fabric in Packaging Solutions

Heat-sealable breathable fabric has become a game-changer in modern packaging, offering a perfect balance between air permeability and sealing efficiency. This specialized material is widely used across industries where moisture control, hygiene, and secure packaging are essential.

Key Applications

Desiccant Sachets Ideal for silica gel, activated clay, and molecular sieve pouches, the fabric allows moisture vapor to pass while containing the desiccant safely inside.

Medical Packaging Used in surgical kits, wound care packs, and pharmaceutical sachets, it ensures sterility while supporting clean heat-sealing for tamper-proof closure.

Food Packaging In dry goods and spice packaging, breathable fabric maintains freshness while enabling easy and hygienic sealing during automated processes.

Electronics & Textile Storage Protects sensitive items by allowing air circulation and moisture absorption when paired with desiccants, preventing mold and corrosion.

Why It Works

Breathable yet protective

Compatible with high-speed heat sealing machines

Lightweight and durable

Customizable for different shapes and sizes

Final Word

From pharmaceuticals to electronics, heat-sealable breathable fabric delivers safe, efficient, and reliable packaging performance. At Favourite Fab, we offer high-quality fabric rolls tailored to your industry's needs—ensuring your packaging stays protected, efficient, and compliant.

0 notes

Text

Why Military and Tactical Boots Require Advanced Footwear Testing?

When it comes to mission-critical environments, no piece of gear is more essential than a reliable pair of military or tactical boots. These boots are subjected to some of the most demanding conditions imaginable—from extreme temperatures and rugged terrains to long hours of wear and exposure to water, chemicals, and impact. Ensuring these boots perform consistently under such stress is not just a matter of comfort—it's a matter of survival and mission success. This is where a Footwear Testing Lab plays an indispensable role.

In this blog, we’ll explore why military and tactical boots require advanced footwear testing, the types of tests performed, and how a certified footwear testing lab ensures compliance, safety, and durability in extreme conditions.

The Critical Role of Tactical Footwear

Military personnel, first responders, law enforcement officers, and tactical teams rely on boots that must:

Provide optimal ankle support and shock absorption

Withstand wear-and-tear in rugged terrains

Resist water, oil, chemicals, and extreme temperatures

Maintain traction in both dry and wet environments

Remain functional over long, physically demanding missions

Given these requirements, military boots cannot be tested like ordinary footwear. They need rigorous performance testing—something only an advanced Footwear Testing Lab can provide.

Why Advanced Testing is Essential

Here’s why tactical footwear demands more than just basic quality control:

1. User Safety

Tactical boots are worn in high-risk environments. A sole that slips, a seam that tears, or insulation that fails can lead to serious injury. Advanced testing ensures boots deliver the protection users expect.

2. Extreme Usage Scenarios

Unlike everyday shoes, tactical boots may be worn for 12–16 hours a day across various climates, terrains, and situations—including combat. They must endure prolonged stress, friction, and environmental hazards.

3. Compliance with Military Standards

Military gear must comply with strict national and international defense standards (e.g., MIL-SPEC, NATO standards). These require high-precision testing that only a specialized Footwear Testing Lab can perform.

Key Tests Performed on Military and Tactical Boots

Footwear testing labs perform a wide range of tests—mechanical, environmental, and chemical—to ensure tactical boots meet or exceed expectations.

1. Abrasion Resistance

Boots are tested for sole and upper material durability using abrasion machines that simulate sand, rocks, and rugged terrain. High abrasion resistance ensures longer wear life.

2. Flexing Endurance

Using flex testers like the Bally or Ross Flex, labs simulate thousands of walking steps under different temperature and moisture conditions. This test helps predict long-term comfort and structural integrity.

3. Slip Resistance (Anti-Skid Testing)

Slip resistance is crucial in wet, oily, or uneven surfaces. Labs test boots on ceramic and steel surfaces under both dry and lubricated conditions using EN ISO 13287 or ASTM F2913 methods.

4. Puncture Resistance

Military boots often include puncture-resistant midsoles. This test simulates nails or sharp debris piercing the sole and ensures protective layers resist intrusion per EN ISO 20344 or ASTM standards.

5. Impact and Compression Tests

Boots are tested for toe protection against falling objects or compression. Steel or composite toe caps are evaluated under controlled impact levels, as per ISO or ASTM F2412/F2413 guidelines.

6. Waterproofness and Breathability

Gore-Tex or similar membranes in tactical boots must keep water out while allowing moisture vapor to escape. Testing includes dynamic waterproof tests and moisture vapor transmission rate (MVTR) analysis.

7. Thermal Insulation Tests

Boots used in desert or arctic conditions must regulate internal temperature. Labs use thermal manikins or environmental chambers to simulate extreme conditions and evaluate heat retention or dissipation.

8. Chemical and Oil Resistance

Outsoles and upper materials are exposed to fuels, oils, acids, and chemicals to test for degradation. This is vital for boots used in hazardous material or combat zones.

9. Shock Absorption and Cushioning

Cushioning underfoot is measured using impact energy return tests, ensuring comfort under prolonged marching or running conditions.

Standards Followed in Military Boot Testing

A Footwear Testing Lab certified to ISO/IEC 17025 conducts tests according to stringent industry and military protocols, including:

MIL-STD-810G/H – U.S. military standard for environmental testing

ASTM F2412 / F2413 – Safety footwear performance requirements

EN ISO 20344 / 20345 – European standards for protective footwear

SATRA TM standards – For durability, safety, and slip resistance

CSA Z195 – Canadian military and tactical footwear requirements

Adhering to these standards ensures boots can be approved for procurement by government and defense agencies.

Benefits of Advanced Testing for Manufacturers and Defense Agencies

✅ Reduced Product Failures

Testing identifies weaknesses before products are deployed, reducing the risk of failure in mission-critical environments.

✅ Increased Trust and Procurement Success

Defense agencies are more likely to approve and reorder from manufacturers who demonstrate rigorous testing compliance.

✅ Global Market Access

Complying with international military and tactical standards enables manufacturers to export to allied nations with confidence.

✅ Enhanced Innovation

Testing feedback helps in improving design, materials, and performance features for future models.

Real-World Example: Tactical Boot Failure

In a widely reported case, a military boot contract was canceled because the outsole delaminated in desert heat, causing severe discomfort and injuries. Post-analysis revealed the manufacturer had not conducted adequate heat resistance testing. A certified Footwear Testing Lab could have prevented this by simulating high-temperature flex and adhesion degradation in controlled environments.

Choosing the Right Footwear Testing Lab

When selecting a testing partner for military boots, look for:

ISO/IEC 17025 Accreditation

Experience with military-grade footwear and standards

Wide test capabilities (mechanical, chemical, environmental)

Fast turnaround and detailed reporting

Partnering with the right Footwear Testing Lab ensures your tactical gear meets the high expectations of those who depend on it most.

Final Thoughts

Military and tactical boots are far more than just footwear—they are mission-critical equipment. Their failure can compromise safety, efficiency, and operational success. That’s why rigorous, advanced testing by a specialized Footwear Testing Lab is non-negotiable.

By performing in-depth durability, impact, slip, and environmental tests, these labs help manufacturers meet military standards, minimize field failures, and protect the lives of those on the front lines.

0 notes

Text

Best Fume Absorbers in India – Ascomp Inc.

Ensure a Safe and Clean Work Environment with High-Quality Fume Absorbers

In industrial workplaces, soldering stations, laboratories, and manufacturing units, toxic fumes and airborne contaminants pose serious health risks. Investing in a high-quality fume absorber in India is essential for maintaining a safe and healthy work environment. At Ascomp Inc., we offer advanced fume extraction solutions designed to eliminate harmful vapors and pollutants efficiently.

Why Do You Need a Fume Absorber?

✔ Removes Toxic Fumes – Protects workers from harmful gases, soldering smoke, and chemical vapors. ✔ Improves Air Quality – Ensures a clean and safe working atmosphere. ✔ Enhances Worker Safety – Prevents respiratory diseases and health hazards caused by prolonged fume exposure. ✔ Increases Productivity – Reduces discomfort and health risks, leading to better efficiency. ✔ Complies with Safety Regulations – Meets industrial air quality standards for fume control.

Types of Fume Absorbers Offered by Ascomp Inc.

1. Soldering Fume Absorbers

Designed for electronics and PCB soldering applications.

Equipped with high-efficiency carbon filters to remove harmful smoke.

Compact, portable, and easy to install on workbenches.

2. Industrial Fume Extractors

Ideal for heavy-duty manufacturing and welding operations.

High-power multi-stage filtration for superior air purification.

Suitable for factories, automotive workshops, and chemical labs.

3. Laser Fume Absorbers

Specially designed for laser cutting, engraving, and marking processes.

Effectively captures and filters out laser-generated fumes and dust particles.

Increases machine lifespan by preventing residue buildup.

4. Portable Fume Absorbers

Lightweight and compact for easy mobility.

Designed for small workshops, educational labs, and repair centers.

Energy-efficient with low power consumption.

5. Multi-Arm Fume Extraction Systems

Suitable for large-scale production units and industrial setups.

Comes with flexible arms for covering multiple workstations.

High-capacity filters for continuous air purification.

Industries That Need Fume Absorbers

✅ Electronics & PCB Soldering – Prevents exposure to soldering fumes and flux vapors. ✅ Welding & Metalworking – Eliminates toxic gases from welding and fabrication processes. ✅ Laser Cutting & Engraving – Controls dust and smoke generated during laser operations. ✅ Chemical & Pharmaceutical Industry – Ensures safe handling of volatile chemicals. ✅ Jewelry & Watchmaking – Protects workers from fine metal dust and polishing fumes.

Why Choose Ascomp Inc. for Fume Absorbers in India?

✔ High-Efficiency Filtration Technology ✔ Wide Range of Fume Absorption Solutions ✔ Durable and Energy-Efficient Designs ✔ Affordable Pricing with Bulk Order Options ✔ Reliable Customer Support & After-Sales Service

Order the Best Fume Absorber in India Today!

Keep your workplace safe, clean, and free from harmful fumes with Ascomp Inc.'s premium fume absorbers. Contact us now for expert advice and the best prices in India!

#FumeAbsorber#ESDSafety#IndustrialAirPurification#AscompInc#SolderingSafety#AirQualityControl#FumeExtractor#WorkplaceSafety#IndustrialEquipment#ElectronicsManufacturing

0 notes

Text

Pulse Laser Cleaning Machine for Wood

In the realm of wood restoration and maintenance, the advent of the pulse laser cleaning machine has revolutionized the industry. This cutting-edge technology offers an efficient, precise, and eco-friendly solution for cleaning and restoring wooden surfaces. In this comprehensive guide, we will delve into the intricacies of pulse laser cleaning machines, exploring their benefits, applications, and the science behind their operation.

Pulse Laser Cleaning Machine for Wood

A pulse laser cleaning machine utilizes high-intensity laser pulses to remove contaminants, coatings, and residues from surfaces. Unlike traditional cleaning methods, this technology is non-abrasive and does not involve chemicals, making it an ideal choice for delicate materials such as wood.

The machine emits short bursts of laser energy, which are absorbed by the contaminants on the wood surface. This absorption causes the contaminants to vaporize or disintegrate, leaving the underlying wood intact and pristine. The process is highly controlled, ensuring minimal damage to the wood.

Laser-Material Interaction

The effectiveness of pulse laser cleaning lies in the interaction between the laser and the material. When the laser pulse hits the surface, it is absorbed by the contaminants, causing them to rapidly heat up and vaporize. The underlying wood, which has a different absorption rate, remains unaffected.

Parameters and Settings

The success of the cleaning process depends on various parameters, including laser wavelength, pulse duration, and energy density. These settings can be adjusted based on the type of wood and the nature of the contaminants, ensuring optimal results.

How Pulse Laser Cleaning Machines Work

Laser Pulses: The machine emits high-frequency laser pulses that target the surface layer of the material.

Absorption and Vaporization: The contaminants or unwanted layers absorb the laser energy, which causes them to vaporize or be blown away by the resulting shockwave.

Selective Cleaning: The laser can be adjusted to ensure it only affects the contaminants, preserving the underlying wood.

Applications of Pulse Laser Cleaning Machines in Wood Restoration

Antique Furniture Restoration

Antique furniture requires delicate handling to preserve its historical value. Pulse laser cleaning machines provide a non-invasive method to remove dirt and old finishes, revealing the original beauty of the wood.

Wooden Artifacts and Sculptures

Museums and galleries often use pulse laser cleaning machines to maintain and restore wooden artifacts and sculptures. The precision of the laser ensures that intricate details are preserved while removing unwanted residues.

Flooring and Paneling

For large-scale projects such as flooring and paneling, pulse laser cleaning machines offer a quick and effective solution. They can strip old finishes and stains, preparing the wood for refinishing without causing damage.

Benefits of Using Pulse Laser Cleaning Machines for Wood

Precision and Control

One of the standout features of pulse laser cleaning machines is their precision. The laser can be finely tuned to target specific areas, allowing for meticulous cleaning without affecting the surrounding material. This level of control is particularly beneficial for intricate woodwork and antique furniture.

Eco-Friendly

Traditional cleaning methods often involve harsh chemicals that can be harmful to both the environment and human health. Pulse laser cleaning, on the other hand, is a green technology. It does not produce hazardous waste or emissions, making it a sustainable choice for wood restoration.

Versatility

Pulse laser cleaning machines are versatile and can be used on a variety of wooden surfaces, from furniture and flooring to historical artifacts and sculptures. This adaptability makes them a valuable tool in both commercial and residential settings.

Efficiency

The speed and efficiency of pulse laser cleaning machines are unmatched. They can quickly remove layers of dirt, paint, or varnish, significantly reducing the time and labor required for restoration projects.

0 notes

Text

[ad_1] Within the quest for the very best cooling choice, the selection may be very troublesome due to the huge variety of choices out there available on the market. Chillers, the mainstay of business and business cooling, must be chosen from many varieties and features, and therefore the choice course of is like on the lookout for a needle in a haystack. This text is in regards to the fundamentals of chillers that clarifies the method of selecting the acceptable chiller amongst a variety of chiller sorts. The Fundamentals of Chillers Earlier than you go to the market to search out the very best chiller to satisfy your wants, you should first perceive the underlying rules of how chillers work. Briefly, the chillers take warmth off the liquid with the assistance of vapor-compression or absorption refrigeration cycle. This liquid, now at a decrease temperature, may be despatched to a warmth exchanger for cooling of kit, a constructing, or another utility that wants temperature regulation. Environmental Concerns With sustainability turning into an more and more essential consider our society, the environmental affect of cooling techniques should not be underestimated. Eco-friendly chillers makers are on the chopping fringe of environmental improvements, beginning with pure refrigerants to optimizing vitality effectivity. These improvements profit the setting and lead to value financial savings for companies because of their decreased operational prices and compliance with strict environmental guidelines. Choosing the Proper Producer Chiller options and the experience of a chiller producer turns into evident when one is selecting the chiller producer. An skilled producer ought to have a broad spectrum of chiller sorts out there, which can be utilized to discover a system that satisfies the actual cooling wants of the customers. Along with this, corporations ought to supply a variety of providers, from the choice course of and customization choices to set up and after-sales service. Reducing-Edge Improvements The chiller sector is an space that is stuffed with technical improvements which can be geared toward making these cooling techniques extra than simply cooling techniques. Benefits corresponding to magnetic bearing compressors with much less friction and put on and the applying of good applied sciences for real-time monitoring and management are the elements which can be bettering the effectivity and reliability of the techniques. These applied sciences permit firms to attain most effectivity of their cooling processes, lower down time and enhance management of their environmental circumstances. Future Developments The way forward for chiller expertise will undoubtedly proceed to see increasingly more thrilling developments. Starting from the deployment of synthetic intelligence and machine studying for preventive upkeep to using pure refrigerants to mitigate local weather change, the street forward is stuffed with potential breakthroughs. These developments emphasize the truth that solely a chiller producer which is devoted to innovation and sustainability is the appropriate alternative on your cooling answer. To summarize, it's not about discovering the best chiller in a sea of options however about understanding the particular demand, the out there chiller applied sciences, and the chillers producers. By highlighting these essential factors, you may get by means of the myriad of the choices and discover a chiller answer which is environment friendly, dependable, and likewise environmentally pleasant. [ad_2] Supply hyperlink

0 notes

Text

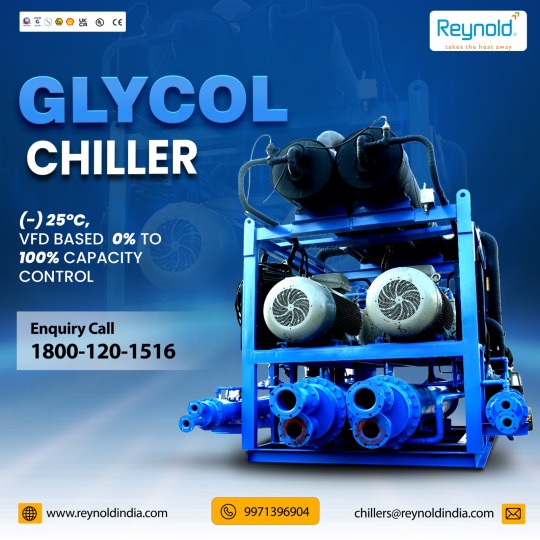

Chiller Company- Reynold India Private limited

Reynold India Pvt. Ltd. is the largest manufacturer of Process Industrial Chillers in India, having exports to over 60 countries around the world, including EU & US. A chiller is a machine that extracts heat from a fluid and circulates it as a cool fluid. Chillers extract heat through a vapor-compression, adsorption refrigeration, or absorption refrigeration cycle. This cool fluid is then circulated through a heat exchanger to equipment or the air. Chillers provide consistent temperature and pressure to industrial processes, making it easier to develop and optimize processes and produce better quality products. Chillers recirculate chilled water, replacing wasteful, single-pass-through systems.

0 notes

Text

Puff, Puff, Pass Out: The Scoop on Melatonin Vape Pen

Ever wondered if you could just vape yourself to dreamland? Well, it's not just a pipe dream anymore! Introducing the melatonin vape pen, your new bedtime buddy. Forget counting sheep or drinking gallons of chamomile tea; with a quick puff, you might be on your one-way trip to snoozeville. But before you turn your bedroom into a fog machine, let’s dive deep into what these nifty little gadgets are all about. Strap in, or better yet, lie down—things are about to get comfortably drowsy. What Exactly Is a Melatonin Vape Pen? Melatonin, commonly known as the "Dracula of hormones," only comes out in the dark and is crucial for regulating sleep. Produced naturally by your brain in response to darkness, it tells your body it’s time to start winding down. But if your body isn’t making enough of it, or if you're trying to outsmart jet lag, supplemental melatonin can be a game-changer. Here, we'll discuss how melatonin has traditionally been used to combat insomnia and improve sleep quality. Enter the melatonin vape pen, a device that looks like it could double as a stylish pen or a miniature lightsaber. But instead of ink or light, it emits a vaporized form of melatonin. We'll explore how these gadgets work to deliver melatonin directly into your bloodstream through your lungs, potentially speeding up the time it takes for you to fall asleep. The mechanics, design, and ease of use will be covered to give you a full understanding of the smoke and mirrors—or should we say, vapor and dreams? How Does Vaping Melatonin Work? Vaping melatonin might sound like something out of a sci-fi novel, but there’s real science behind it. This section will demystify how inhaling vaporized melatonin can potentially lead to faster absorption compared to pills or gummies. We'll discuss what happens from the moment you take a puff to when your head hits the pillow. Why vape your way to dreamland instead of the old-school pill? It's not just for the cool factor. We’ll examine the potential advantages, such as quicker onset of sleep and possibly more controlled dosing, and discuss why some users might prefer this method over dietary supplements, teas, or patches. Is Vaping Melatonin Safe? With great power comes great responsibility, and the melatonin vape pen is no exception. This part will tackle the health concerns and safety issues related to vaping melatonin. Are there risks? Absolutely. We'll dive into what experts say about the safety of inhaling substances versus ingesting them, and discuss ongoing research in this area. Nothing like a good old quote from someone who actually went to med school to give us the lowdown on whether vaping melatonin should be part of your bedtime ritual. This section will include opinions from sleep specialists and highlights from relevant studies to provide a well-rounded view on the matter. Who Should Consider a Melatonin Vape Pen? Not everyone should jump on the melatonin vape train. Here, we'll identify who might benefit the most from this technology—like night owls looking to reset their body clocks, or frequent travelers battling the dreaded jet lag. This isn't a one-size-fits-all solution. We’ll discuss who might want to avoid melatonin vapes, such as individuals with certain health conditions or those on specific medications, and why it’s important to consult with a healthcare provider first. Conclusion In this lighthearted and engaging article, we explore the intriguing world of melatonin vape pens, a novel gadget promising a swift journey to the land of nod. We begin by understanding what melatonin is and how it functions as a sleep aid, followed by a detailed look at how melatonin vape pens work, delivering this sleep hormone directly into the bloodstream through inhalation. The article delves into the potential benefits of vaping melatonin compared to traditional supplements and addresses crucial safety concerns, incorporating insights from health professionals. We also identify who might benefit most from this technology and caution those for whom it might not be suitable. To round out the discussion, we examine various other sleep improvement methods, providing a comprehensive comparison to help readers make informed choices about their sleep habits. This article is designed not only to inform but also to entertain, making the science of sleep a little more accessible and a lot more fun. FAQs 1. What exactly is a melatonin vape pen? A melatonin vape pen is like a magic wand for sleep—except instead of casting spells, it puffs out melatonin vapor. Just a few inhales of this bedtime vape, and you might find yourself drifting faster into dreamland than you can say "sleepytime." 2. How does a melatonin vape pen work? Think of it as a direct line to the snooze department. When you vape melatonin, the hormone is vaporized and inhaled into the lungs, from where it quickly enters your bloodstream. This express route could potentially get melatonin circulating faster than if it had to take the scenic route through your digestive system. 3. Is it safe to use a melatonin vape pen? The million-dollar question! While the concept might sound slick, inhaling anything other than air comes with its questions. Some health professionals are wary, suggesting potential risks since the long-term effects of vaping melatonin aren't well known yet. Always a good idea to chat with your doctor before turning your nighttime routine into a vape session. 4. Who should consider using a melatonin vape pen? Melatonin vape pens might be a hit for night owls trying to turn over a new leaf or jet-setters looking to beat jet lag. However, they're not recommended for everyone—particularly those with respiratory issues, pregnant women, or if you're under medication that could interact strangely with inhaled melatonin. 5. Are there alternatives to using a melatonin vape pen for better sleep? Absolutely! If vaping isn't your style, there are plenty of other ways to catch some Zs. From melatonin supplements in pill or gummy form to good old-fashioned sleep hygiene practices (think dark, cool bedrooms and a relaxing bedtime routine), there are many other avenues to explore for improving sleep quality without needing to puff anything. Read the full article

0 notes

Text

A Manual to Constructing Your personal Tailored Vape Machine from Scratch

Introduction

Welcome to the ultimate guideline on developing your individual personalized vape product from scratch! Within this extensive report, We're going to stroll you through the whole process of generating a personalized vape machine that satisfies your Choices and magnificence. Whether you are a vaping enthusiast or just beginning, this information will provide you with all the necessary info to create your own personal one of a kind vape gadget.

Table of Contents

Understanding Vapes: A quick Overview

The Advantages of Setting up Your individual Vape Device

Essential Applications and Supplies Needed

Choosing the appropriate Battery in your Vape Device

Selecting the Perfect Atomizer for Best Vaping Experience

Building Your own personal Coil: Action-by-Action Guide

Choosing the correct E-Liquid on your Personalized Vape Device

Safety Precautions When Creating Your Vape Device

Troubleshooting Widespread Issues with Do it yourself Vape Devices

Maintaining and Cleansing Your Custom made Vape Device

Frequently Questioned Issues (FAQs)

Conclusion

1. Knowledge Vapes: A Brief Overview

Before diving into the entire world of constructing your personal vape system, it is important to possess a standard idea of what vapes are And exactly how they get the job done. Vapes, also known as Digital cigarettes or e-cigarettes, are battery-operated equipment that vaporize e-liquid to make an inhalable aerosol.

2. The benefits of Creating Your Own Vape Device

Building your own vape gadget gives numerous benefits in excess of obtaining pre-made units from a vape store in your area or on the internet shops including Vape UAE:

Customization: By setting up your individual vape system, you may have complete control around just about every facet, through the battery into the atomizer as well as the e-liquid.

Cost-Effective: Constructing your personal vape system might be additional Price-successful in the long run, as you are able to choose affordable factors and make replacements when vital.

Enhanced Performance: Custom made vape gadgets frequently give far better effectiveness and vapor generation in comparison to pre-designed gadgets.

Satisfaction: The satisfaction of using a vape machine which you constructed you is unparalleled, and it provides a personal touch towards your vaping expertise.

3. Essential Tools and Materials Needed

To begin with creating your own vape product, you may need the next tools and components:

Screwdriver established - to assemble and disassemble the device

Wire cutters - for trimming coils

Vape Ohm meter - to measure the resistance of one's coils

Tweezers - for specific coil placement

Vape wire - for developing coils

Cotton wick - for best e-liquid absorption

Battery charger - to charge your batteries safely

It is crucial to speculate in higher-top quality tools and elements to make sure a sa

youtube

0 notes

Text

Breathable Laminated Non-Woven Fabric for Silica Gel Packing

When it comes to protecting products from moisture damage, Silica Gel is the industry’s favorite desiccant. But to make silica gel even more effective and safe, the choice of packaging material matters. This is where Breathable Laminated Non-Woven Fabric plays a key role. It is specially designed to hold silica gel while allowing efficient moisture absorption without leakage.

What is Breathable Laminated Non-Woven Fabric?

Breathable Laminated Non-Woven Fabric is a multi-layered material consisting of a non-woven base laminated with a breathable yet moisture-permeable layer. It is engineered to allow air and water vapor to pass through easily, enabling silica gel to absorb moisture effectively, while keeping the silica gel beads securely packed inside.

Key Features of Breathable Laminated Non-Woven Fabric for Silica Gel Packing

✅ High Breathability Allows air and moisture to pass through, enhancing the efficiency of silica gel inside.

✅ Strong & Durable Offers superior strength to prevent tearing or leakage during packing, transportation, or storage.

✅ Soft Texture Non-scratchy and gentle material suitable for sensitive products like electronics and pharmaceuticals.

✅ Customizable GSM and Sizes Available in various GSM (Grams per Square Meter) and customizable sizes depending on the requirement.

✅ Eco-Friendly & Non-Toxic Safe for use with food-grade silica gel and other sensitive applications.

Why Use Breathable Laminated Non-Woven Fabric for Silica Gel?

Traditional packaging materials like paper or plain non-woven fabric may limit the performance of silica gel or break easily during transit. Our Breathable Laminated Non-Woven Fabric ensures:

Enhanced moisture absorption performance

Better protection against contamination and leakage

Smooth finish for automatic packing machines

Longer life of silica gel sachets

Applications

This fabric is ideal for manufacturing silica gel packets used in:

Electronics & gadgets

Pharmaceutical packaging

Leather goods and shoes

Garments and textiles

Machinery & automotive parts

Food-grade silica gel sachets (with food-safe lamination)

Available GSM Range

GSMUsage20-25 GSMSmall sachets (1g - 10g)30-40 GSMMedium sachets (10g - 50g)50-60 GSMHeavy-duty silica gel packets (100g and above)

Why Choose Us for Breathable Laminated Non-Woven Fabric?

At [Your Company Name], we are a trusted manufacturer and supplier of high-quality Breathable Laminated Non-Woven Fabric for Silica Gel Packing. Our fabric ensures superior strength, breathability, and customizability for your silica gel sachet production.

✅ Bulk Production Capacity ✅ Quality Controlled Manufacturing ✅ Custom Sizes, GSM & Colors Available ✅ Affordable & Competitive Pricing ✅ Timely Delivery Across India & Export Markets

FAQ - Breathable Laminated Non-Woven Fabric

Q1: Is this fabric suitable for food-grade silica gel? Yes, we provide food-safe laminated non-woven fabric for silica gel packing.

Q2: Can we print on this fabric? Yes, it is printable depending on your sachet design and branding needs.

Q3: What is the width availability? We offer cut-sheet and roll form in multiple widths as per customer requirements.

Q4: Is it compatible with automatic sachet packing machines? Yes, our fabric is suitable for both manual and automatic packing machines.

0 notes