Don't wanna be here? Send us removal request.

Text

Applications of dispensing machines in the medical industry

With nearly 20 years of experience in dispensing technology, Shenzhen Second Intelligent Equipment Co., Ltd. (Second Intelligent) is a well-established leader in China's fluid application industry.

Second Intelligent dispensing machines have a wide range of applications in the dispensing of medical supplies. Compared to traditional dispensing machines, Second Intelligent dispensing machines exhibit superior performance in the pharmaceutical industry due to their advantages such as more precise dispensing, support for customer customization, and comprehensive pre-sales, in-sales, and after-sales service. The following are specific application scenarios of Second Intelligent dispensing machines in the medical supplies:

Automated Dispensing for Medical Needles

Dispensing Location and Function: Typically, dispensing occurs at the connection between the needle tip and the needle tube, and at the connection between the needle tube and the needle hub. Second Intelligent liquid glue dispensing machine ensure that the adhesive provides sealing and fixation, preventing issues such as leakage or needle detachment during use, thereby guaranteeing the safety and accuracy of medical procedures.

Dispensing Requirements: Extremely high biocompatibility of the adhesive is required. Second Intelligent glue dispensing machine achieve micro-volume, uniform dispensing through precise programming and control systems, meeting the high-quality production requirements of medical needles. Its precise dispensing control avoids the problems of uneven or excessive dispensing that can occur with traditional dispensing machines.

4 Axis High Precision Servo Motor Screw Automated Desktop Glue Dispensing Machine Robot SEC-E480SV

Dispensing for Medical Dressings

Dispensing Location and Function: Primarily dispensing occurs in the adhesive layer coating of the dressing and at the edge sealing with the release liner. Second Intelligent automated glue dispenser ensure the uniformity of the adhesive, which directly affects the adhesion and effectiveness of the dressing, ensuring that the dressing adheres firmly to the skin, providing stable protection for the wound. Dispensing at the edge seal prevents external bacteria, moisture, etc., from entering the inside of the dressing, maintaining the sterility and adhesion of the dressing.

Dispensing Requirements: Dispensing for medical dressings requires a high degree of uniformity and stability. Second Intelligent auto glue dispensing machine can be equipped with specialized coating devices, precisely controlling the adhesive flow rate and coating speed to achieve uniform dispensing over a large area, while also allowing flexible adjustments according to the different sizes and shapes of the dressings.

0 notes

Text

Precision and Efficiency in Tackling Adhesive Potting Stringing and Leakage, Empowering the Future of Smart Manufacturing

In modern industrial manufacturing, the application of potting technology is becoming increasingly widespread. However, as production demands increase, issues such as adhesive stringing and leakage during the potting process have gradually become critical factors affecting product quality and production efficiency. Shenzhen Second Intelligent Equipment Co., Ltd. (hereinafter referred to as "Scond Intelligent"), as a leading provider of smart equipment solutions in the industry, not only continues to innovate in efficient and precise potting technology but also offers a series of advanced solutions to address adhesive stringing and leakage, helping enterprises overcome technical challenges, improve production efficiency, and enhance product quality.

Adhesive stringing and leakage phenomena are typically caused by the following factors:

High viscosity of adhesives: High-viscosity adhesives tend to form strings during potting, preventing uniform distribution.

2. Improper pressure control: Excessive or unstable potting pressure can lead to adhesive overflow or leakage.

3. Incomplete mixing: Inadequate mixing of two-component adhesives can result in poor curing or localized leakage.

4. Equipment design flaws: The design of the potting equipment's nozzle and the stability of the adhesive supply system directly affect the fluidity and uniformity of the adhesive.

These issues not only reduce production efficiency but can also lead to decreased product performance, aesthetic defects, and even shortened product lifespan.

Second Intelligent provides a series of innovative equipment and technical solutions to address adhesive stringing and leakage:

1. High-precision metering and mixing technology

Two-component dynamic mixing valve: By using pull-back switching and dynamic mixing technology, it ensures uniform mixing of adhesives during potting, avoiding leakage caused by incomplete mixing.

0 notes

Text

How can desktop dispensing robot help companies improve dispensing productivity? Practical cases tell you the answer

In today's competitive business environment, the productivity of an enterprise often determines its market competitiveness. For enterprises involved in the dispensing process, desktop glue dispensing machines, as a kind of advanced dispensing equipment, are gradually becoming a powerful assistant to improve production efficiency.

In this article, we will discuss in depth how desktop glue dispensing machines can help enterprises improve the productivity of dispensing through practical cases.

Second Intelligent Desktop Glue Dispensing Machine SEC-E480SV adopts high-precision servo motor + grinding ball screw, which can ensure accuracy while having higher cost performance. It is also equipped with CCD visual height measurement, which makes programming more efficient and more accurate. It is an aviation aluminum alloy die-casting one-piece design desktop glue dispensing machine, which is more solid, more stable, with double rotating stations, small and flexible.

1.desktop glue dispening machine features and advantages

desktop dispensing robot, compared with the traditional large dispensing equipment, has a compact size, easy to operate, high flexibility. It can be easily placed on the workbench, does not take up too much production space, suitable for enterprises of all sizes. At the same time, the desktop machine is usually equipped with advanced control system and high-precision dispensing head, which can achieve precise glue volume control and fast production speed, thus greatly improving the quality and efficiency of dispensing.

2. the actual case study

Case 1: an electronic manufacturing enterprise

The enterprise mainly produces electronic products, such as mobile phones and tablet PCs. In the production process, the electronic components need to be dispensed accurately to ensure the sealing and stability of the products. In the past, the enterprise has been using the traditional manual dispensing method, which is not only inefficient,

but also inaccurate in controlling the amount of glue and unstable in product quality. Since the introduction of the benchtop glue dispenser, the situation has improved significantly.

The high-precision dispensing head of the desktop dispensing robot can accurately control the amount of glue, ensuring that each electronic component can get the right amount of glue. At the same time, its fast dispensing speed has greatly improved production efficiency. Dispensing tasks that would have taken several people a day to complete,

can now be completed by one person in a few hours. Moreover, due to the accurate control of the glue quantity, the quality of the product has also been significantly improved, and the defective rate has been greatly reduced.

Case 2: An automotive parts manufacturer

This company mainly produces seals for automotive engines. In the production process, the seals need to be dispensed accurately to ensure their sealing performance. Due to the complex shape of the seals, the traditional dispensing method can hardly meet the production requirements. This is where the flexibility of the tabletop machine comes into play.

The glue dispensing robot automatically adjusts the dispensing path and the amount of glue according to the shape and size of the seals, ensuring perfect dispensing results for each seal. Moreover, its ease of operation allows workers to get started quickly, improving production efficiency.

Dispensing work that used to take a lot of time for training and debugging can now be completed with a simple setup. This not only saves the enterprise training costs, but also improve the efficiency of production.

Second Intelligent Desktop Glue dispensing Machine SEC-E580 has achieved the transition from manual gluing to semi-automation. It is the largest desktop dispensing machine. It adopts aviation aluminum alloy casting design and one-piece molding processing, with high strength and stable operation. The X/Y axis transmission assembly is directly installed on the casting. It can reduce the number of parts and improve assembly efficiency. It is small and flexible to ensure precision. It can expand double Y double rotation to realize six-axis alternating gluing function, which can greatly improve work efficiency. It is equipped with CCD visual height measurement, which makes programming more efficient and more accurate.

the desktop glue dispensing machine to help enterprises improve the principle of dispensing production efficiency

1. Accurate glue volume control

desktop machine adopts advanced control system, can according to the different production needs to accurately control the glue volume. This can not only improve the quality and stability of the product, but also to avoid waste and defective products caused by too much or too little glue.

2. Fast production speed

glue dispensing equipment with fast dispensing speed, can complete a large number of dispensing tasks in a short period of time. This is undoubtedly a major advantage for those companies with urgent production tasks.

3. Flexible operation

The desktop machine is simple and easy to operate, and workers can get started quickly. Moreover, it can be adjusted according to different production needs and adapt to a variety of different dispensing scenarios.

Conclusion

Through the above analysis of the actual case, it can be seen that the uv glue dispensing machine, as an advanced dispensing equipment, has the advantages of accurate glue volume control, fast production speed and flexible operation mode, which can effectively help enterprises to improve the dispensing production efficiency. For those who want to improve the production efficiency

reduce costs and improve product quality of the enterprise, desktop glue dispenser machine is undoubtedly a worthy choice to consider. In the future, with the continuous progress of science and technology, I believe that the desktop machine will play an important role in more areas, to provide strong support for the development of enterprises.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

0 notes

Text

Glue potting machine in the application of electronic packaging: how to avoid air bubbles, overflow glue and other common problems?

In the field of electronic packaging, the glue potting process directly affects the sealing, insulation and long-term reliability of the product. However, problems such as bubbles, glue overflow, and uneven glue amount often trouble production engineers, resulting in reduced yield and even product failure. This article will deeply analyze the common problems of the glue potting process and provide solutions such as vacuum degassing, precise metering, and process optimization to help you improve the quality and efficiency of glue potting.

1.The key role of glue potting in electronic packaging

Potting refers to potting liquid glue (such as epoxy resin, silicone, polyurethane, etc.) into specific areas of electronic components or PCB boards to achieve waterproof, shockproof, insulation, heat dissipation and other functions. Typical applications include:

● Power module potting (such as new energy vehicle electronic control unit)

● LED drive circuit packaging (moisture-proof and corrosion-proof)

● Sensor protection (such as industrial-grade temperature and humidity sensor)

● PCB board overall glue potting (anti-vibration, dust-proof)

However, if the glue potting machine process is not properly controlled, it is easy to have problems such as bubble residue, glue overflow, and poor curing, which will affect product performance.

Automatic Adhesive Potting Machines SEC-S3030-C

2. Analysis of the four common problems and causes of glue potting process

1. Bubble problem (affecting sealing and insulation)

Reasons:

a. The glue itself contains air (especially high-viscosity glue)

b. The glue potting speed is too fast and the glue cannot flow fully

c. No vacuum degassing treatment

2. Glue overflow problem (affecting appearance and assembly)

Reasons:

a. Imprecise glue quantity control (too much or too little)

b. Unreasonable glue dispensing path planning

c. The glue is too fluid (low-viscosity glue is easy to spread)

3.Uneven glue quantity (resulting in insufficient local protection)

Reasons:

a. Insufficient metering accuracy of glue potting machine

b. Changes in glue viscosity (affected by temperature or storage conditions)

c. Blockage or wear of dispensing valve

4. Poor curing (affecting mechanical strength)

Reasons:

a. Wrong mixing ratio (two-component glue)

b. Curing temperature/time does not meet the standard

c. Glue is expired or damp

3. Solution: How to optimize the glue potting process?

1. Vacuum degassing technology (eliminating bubbles)

Method:

a. Vacuum degassing the glue before potting (vacuum pump evacuates for 5-10 minutes)

b. Use dynamic degassing system (degassing while potting)

Applicable scenarios: high viscosity glue (such as epoxy resin)

Accurate metering control (avoiding glue overflow/glue shortage)

Method:

a. Select a high-precision metering pump (gear pump or screw pump)

b. Use a closed-loop control system (real-time monitoring of glue volume and feedback adjustment)

C. Optimize the dispensing path (avoid overlap or glue leakage)

0 notes

Text

From electronics to photovoltaics, automatic glue potting machines are precision tools for multiple industries

With its high efficiency, precision and reliability, the automatic glue potting machine has become an indispensable precision production equipment for many industries. From electronic technology to the automotive industry, from medical equipment to photovoltaic energy.

Automatic glue potting machines are everywhere and play an important role in improving product quality and production efficiency.

Electrical and electronics industry: higher-precision packaging, quality assurance

In the electrical and electronics industry, automatic glue potting machine is widely used in electronic components and structural body encapsulation, waterproof, anti-vibration and other processing. Whether they are mobile phones, computers and other consumer electronics products, or integrated circuits, circuit boards and other high-end technology products, are inseparable from the fine work of automatic glue potting machine. It can ensure that the glue is evenly and accurately applied to the parts to be encapsulated, effectively preventing moisture, dust and other external factors from harming the electronic components, thus enhancing the stability and reliability of the products.

Automotive industry: Improving safety and durability

In the automotive industry, automatic glue potting machine also play an important role. In the manufacturing and assembly of automotive components, automatic glue potting machines are used for encapsulation of automotive lamps, glass bonding, etc. to enhance the safety and durability of automobiles.

By accurately controlling the amount and position of glue, the automatic glue potting machine ensures a tight connection between auto parts and reduces safety hazards caused by loosening or detachment. At the same time, it can also improve the sealing of the car body, effectively prevent the intrusion of rain, wind and sand and other external factors, and prolong the service life of the car.

Two component Automatic Adhesive In-Line Vacuum Glue Potting Machines

Medical and photovoltaic: higher-precision dispensing to improve their development

The medical industry and photovoltaic field is also an important application field of automatic glue potting machine. In the medical industry, automatic glue potting machine is used in the manufacturing and encapsulation of medical devices, to ensure the sterility and sealing of the product. In the photovoltaic industry, automatic glue potting machine are used for the manufacture and encapsulation of photovoltaic modules.

Automatic potting machine is used for photovoltaic module potting and thermal conductivity potting process, to enhance the conversion efficiency and stability of photovoltaic products. These applications not only show the advantages of automatic potting machine in precision manufacturing, but also provide the possibility of its application in more fields.

Second Intelligent: Leading the Industry, Creating the Future Together

With its efficient, precise, reliable and flexible equipment performance, Second Intelligent has won wide recognition in the market and the trust of customers. With excellent performance and wide range of applications, the two-component glue potting machine of Second Intelligent shows strong competitiveness in many industries such as electronics, automotive, medical, photovoltaic and so on.

Second Intelligent not only focuses on product innovation and R&D, but also devotes itself to providing customers with all-round, one-stop solutions and high-quality after-sales service. In the future development, Second Intelligent will continue to adhere to the ‘innovation, quality, service’ concept, hand in hand with customers to create a new future of intelligent manufacturing.

0 notes

Text

Second Intelligent Automotive Dispensing Machine: Intelligent Transformation Tool for Manufacturing Industry

In the wave of manufacturing in the 21st century, intelligence and automation have become the inevitable trend of industry development. With the rapid development of automobile manufacturing industry, the requirements of automobile parts on precision and efficiency are increasing, the traditional manual or semi-automatic dispensing equipment has been difficult to meet the needs of modern production.

Second Intelligent, as a glue dispenser machine industry leader, with its innovative products and solutions, in the field of automotive manufacturing shine, for the intelligent transformation of the manufacturing industry to provide strong support.

As a key equipment in modern automotive manufacturing, Second Intelligent automotive glue dispensing machine is widely used in engine parts, body parts, chassis parts, electronic equipment, interior/exterior parts and other aspects. In the manufacturing process of engine parts, cylinder head, oil sump and other parts need to be sealed and fixed.

Second Intelligent automotive dispensers can precisely control the position and amount of glue applied to ensure the sealing and firmness of these parts, thus improving the performance of the engine and extending its service life.

In the manufacture of body parts, the assembly of doors, windows, roofs and other parts requires glue application operations to enhance the connection strength and sealing between the parts. With its high precision and flexibility, Second Intelligent's automotive dispenser can adapt to body parts of different shapes and sizes, achieving precise gluing operations that

Ensure the integrity and safety of the bodywork. This feature is also reflected in the manufacturing process of chassis components. The assembly of key components such as suspension system and braking system also requires gluing operations to ensure the stability and safety of the system.

With the increase of automotive electronics, electronic devices such as sensors and controllers need to be encapsulated during the manufacturing process to protect the internal circuits and components. Second Intelligent automotive dispenser can precisely control the position and amount of glue application to ensure the sealing and reliability of electronic equipment encapsulation.

This improves the performance and stability of automotive electronic devices. In addition, dispensers also play an important role in the manufacturing of interior/exterior components. The assembly of interior parts such as seats, instrument panels, door panels, and exterior parts such as lights, bumpers, and emblems requires the bonding of various materials.

Second Intelligent automotive dispenser can ensure strong bonding and beautiful appearance of interior parts, which improves the comfort and overall quality of the car.

Second Intelligent automotive dispenser not only excels in hardware equipment, but also makes breakthroughs in technological innovation. The company has launched a number of fully automatic dispensers, such as FPC-NTC-CCS dispenser, SEC-E380 benchtop desktop glue dispenser, etc., which have won wide recognition in the market for their high precision, high efficiency and high stability. These machines are equipped with advanced CCD visual positioning system, which realises precise identification and positioning of product position through high-definition camera and image processing algorithm, effectively avoiding errors caused by human factors. At the same time, the equipment also has an automatic correction function, which can adjust the position and angle of the dispensing head in real time to ensure the consistency and stability of the dispensing effect.

Second Intelligent New Energy/ Single-cell complete plant production line

In practical applications, Second Intelligent automotive dispensers have been widely used in the auto parts industry. For example, in the project of a professional manufacturer of automotive electronic OBC, Second Intelligent Intelligent successfully won the bid and provided more than 30 dispensers for its 10 dispensing and board loading lines, which further improved the production efficiency and

This project further improved the production efficiency, met the customer's demand for production capacity, and ensured the stability of product quality. The successful implementation of this project fully demonstrates the professional strength and technical advantages of Second Intelligent in the auto parts industry.

Looking to the future, Second Intelligent will continue to adhere to the ‘innovation, pragmatic, efficient, excellent’ spirit of enterprise, and constantly increase R & D investment and technological innovation, to promote the technological upgrading and product optimisation of online automatic dispensing equipment. At the same time, Second Intelligent will strengthen the cooperation and communication with the upstream and downstream enterprises in the industry, and jointly promote the development of fluid control technology.

Together, we will promote the development and application of fluid control technology, and provide strong support for the high-quality development of the auto parts industry.

0 notes

Text

Automatic dispensing machine industry application and purchase guide

As a key equipment in modern industrial manufacturing, automatic glue dispensing machine plays an important role in several industries. With the promotion of industry 4.0 and the development of intelligent manufacturing, the market demand for automatic dispensing machines continues to grow.

Industry applications of automatic glue dispensing machines

1. Electronic manufacturing industry

In the electronic manufacturing industry, automatic dispensing machines are widely used in PCB board dispensing, chip packaging, LED packaging and other fields. Its high precision and high efficiency meet the production needs of miniaturization and precision of electronic products.

2. Automotive manufacturing

Automotive electronics, lamp encapsulation, sensor encapsulation and other links need to use dispensing technology. Fully automatic dispensing machine can ensure high reliability and consistency of automotive parts.

3. Medical equipment manufacturing

In medical equipment manufacturing, fully automatic dispenser is used for bonding, sealing and encapsulation of medical devices to ensure the hygiene safety and reliability of the products.

4. New energy industry

In the production of photovoltaic modules, lithium batteries and other new energy products, fully automatic dispensers are used for battery encapsulation, component bonding and other key processes.

5. Home appliance manufacturing

Home appliances circuit board protection, component fixing, etc. are inseparable from the dispensing process, automatic dispenser can improve production efficiency and product quality.

Enterprises purchasing automatic dispensing machine need to pay attention to 6 points

1. Precision requirements

Enterprises use the most concerned about the dispensing accuracy, including dispensing volume control accuracy and positional accuracy. Different industries have different requirements for precision, so we need to choose the right model according to the specific needs.

2. Production efficiency

Production speed directly affects the production capacity, the enterprise purchasing will pay attention to the equipment dispensing speed and degree of automation, as well as whether to support continuous production.

3. Applicable glue type

The characteristics of different glues vary greatly, enterprises need to consider whether the equipment supports the type of glue used, such as UV adhesive, epoxy resin, silicone and so on.

4. Convenience of operation

Whether the operation interface of the equipment is friendly, whether the programming is simple, whether it is easy to change the type is the focus of the user's attention.

5. After-sales service

Equipment maintenance, technical support, supply of accessories and other after-sales service is an important guarantee of long-term use of the user.

6. Cost-effectiveness

Enterprises need to consider the price of equipment, the use of cost, maintenance costs and other factors, the pursuit of the best return on investment.

*Suggestions for purchasing

1. Clarify the needs

Before purchasing, you need to clarify your own production needs, including product characteristics, output requirements, precision standards, etc..

2. Field inspection

It is recommended to visit the equipment manufacturer to understand the actual operation of the equipment and test the performance of the equipment.

3. Focus on core technology

Focus on the performance of the equipment's motion control system, dispensing valve technology, vision system and other core components.

4. Consider scalability

Select equipment with good expandability to adapt to possible future changes in production demand.

As a leading manufacturer of dispensing equipment in China, Second Intelligent has the following advantages:

1. Technical advantages

Second Intelligent has self-developed core technology, which is in the leading level of the industry in terms of dispensing accuracy, speed and stability.

2. Rich products

Provide a variety of models of automatic dispensing machines, which can meet the needs of different industries and enterprises of different sizes.

3. Customised service

According to the special needs of customers to provide customised solutions to ensure that the equipment and the production process perfectly match.

4. Perfect after-sales service

Establish a nationwide after-sales service network to provide timely technical support and maintenance services.

In the purchase of automatic dispensing machine, it is recommended that enterprises fully consider their own needs and choose a supplier with technical strength and industry experience like Second Intelligent. Through professional selection and quality after-sales service, to ensure that the equipment can create maximum value for the enterprise, help enterprises to achieve intelligent and efficient production.

0 notes

Text

How can enterprises achieve glue potting machines intelligence?

In modern industrial production, the glue potting process is a key link in product manufacturing, and its quality and efficiency directly affect the overall performance and production cost of the product. With the rapid development of science and technology, intelligence has become an important direction for the upgrading of glue filling process.

So, how can companies achieve glue potting machines intelligence?

1. Algorithm optimization and intelligent control

The core of intelligence lies in the algorithm. By optimizing the control algorithm of the glue potting machine, enterprises can achieve precise control of the glue potting process. Advanced algorithms can analyze the three-dimensional structure of the product and plan the best glue filling path, thereby avoiding the waste of glue and uneven glue potting.

In addition, the introduction of advanced control systems such as PLC (programmable logic controller) or DCS (distributed control system) can further improve the automation and intelligence level of the glue potting process. These systems can automatically complete the proportioning, mixing, potting and other processes of glue according to the preset program, improving production efficiency and product quality.

2. Sensor upgrade and data interaction

The sensor is the "eye" of the glue potting machine, and its performance directly affects the accuracy and stability of glue filling. Enterprises should actively upgrade sensors and use high-resolution visual sensors to capture more subtle image information to ensure that glue can be accurately poured into designated parts.

At the same time, realizing data interaction between glue potting machines and other equipment is also the key to intelligence. Through the Internet of Things technology, glue potting machines can upload working data in real time and receive remote instructions, thereby realizing remote monitoring and fault diagnosis, reducing downtime and maintenance costs.

3. Human-machine collaboration and operation optimization

Optimizing the human-machine collaboration mode is also an important part of realizing glue potting machines intelligence. Enterprises should provide an intuitive and convenient operating interface so that operators can easily monitor and make necessary adjustments to the glue potting machine. At the same time, establish an efficient feedback mechanism,

so that special situations found by operators during the production process can be promptly fed back to the intelligent control system of the glue potting machine, so that the system can learn and improve. This two-way interaction can continuously improve the intelligence level of the glue potting machine.

To realize intelligent glue dispensing, enterprises need to start from algorithm optimization, sensor upgrade, human-machine collaboration, and the introduction of robots and vision systems. As a leading enterprise in the industry, Second Intelligent's glue dispensing machine products undoubtedly provide strong support for achieving this goal.

source: https://secondintelligent.com/industry-news/glue-potting-machines-intelligence/

0 notes

Text

Second Intelligent completed the capacity upgrade of an IGBT production line for a leading manufacturer of new energy vehicles.

IGBT (Insulated Gate Bipolar Transistor) is a kind of energy conversion and transmission of the core device, known as the industry power electronic device “CPU”, widely used in motor energy saving, rail transportation, smart grid, aerospace, home appliances, automotive electronics, new energy generation, new energy vehicles and other fields.

as the power electronics industry "CPU", IGBT is internationally recognized as the most representative product of the electronic revolution. Multiple IGBT chips are integrated and packaged together to form an IGBT module, which has greater power and better heat dissipation capability, and plays an extremely important role in the field of new energy vehicles.

In order to meet the growing market demand , a leading new energy vehicle manufacturer ,will upgrade the production capacity of IGBT production line, and it is proposed to adopt the assembly line form of online production for gluing, framing, and baking processes. After the bidding in China, Shenzhen Second Intelligent Equipment Co., Ltd (“Second Intelligent”) successfully won the bidding for the project, and provided the whole line technical solutions such as IGBT laser marking, code scanning confirmation, automatic glue application, AOI inspection, framing, screwing, riveting, automatic baking and MES docking to realize the automation, intelligentization and integration of the production line. After completion, IGBT module production line capacity from the original 45S/PCS to 30S/PCS, will meet the brand of new energy vehicles, photovoltaic on the demand for IGBT modules.

The IGBT production line has higher and more comprehensive requirements for production timing, test stability and equipment reliability. After receiving the order, under the overall guidance of the company's senior management, the Product Management Center assigned a group of experienced engineers in mechanical design, electrical design, automation design to set up a technical team to focus on completing the optimal design of the program, energy-saving production evaluation and production line layout planning. at the same time ,while conducting stability and feasibility testing and verification of the key processes in the program.

After several months of hard work, Second Intelligent overcame all the difficulties and has completed the manufacturing and in-house debugging of more than ten lines of the IGBT project.

The technical solution of the IGBT automatic gluing, framing and baking section realises digital, intelligent and automated production through effective management of all production links, so that the production line runs efficiently and stably. This technical solution is configured with process equipment such as marking machine, gluing machine, automatic screwing machine, pressure ring pressing machine, in-line oven, etc., which ensures that the products produced have higher yield of encapsulation test, more stable parameters and better reliability. It can carry out laser marking, code scanning, dispensing, visual inspection, assembly, screwing, compression ring loading, baking and other various processes, the flexibility of module configuration to complete the integration of various automation applications, to get rid of the past automation platform function of the disadvantages of a single.

The open interface of the whole line is docked with the customized MES management system of Second Intelligent, which can obtain various information of the production line required by customers in real time through the MES management system, such as program usage, real-time status of equipment, historical alarm information, etc., to realize the informatization, intelligence and unmannedness of the production process, etc., so as to realize the transformation from manufacturing to intelligent manufacturing and accelerate the industrial upgrading.

The project adopts Second Intelligent's self-developed dispensing valve, which can effectively solve the problems of uneven dispensing, broken glue, leakage, overflow and other bad problems, and the dispensing path can be edited by itself. The visual inspection system developed by Second Intelligent will visually inspect the finished dispensing product of the previous process to detect whether it is broken, leaking, overflow and other defective problems, AOI inspection such as qualified transfer mechanism will transport the shell to the next process for the next operation, AOI inspection such as unqualified will be transported to the outside of the equipment through the transfer module by the NG conveyor line, so as to ensure that the system without stopping. This ensures that the system can automatically eject the faulty products without stopping and improves the stability of the dispensing system.

Second Intelligent focuses on fluid application and service, is committed to promoting the intelligent upgrading of fluid application in the industrial equipment industry with technology and innovation. At present, the self-developed IGBT coating and assembly line solution has solved the problem and improved the performance for many customers, such as famous brands of new energy vehicles, demonstrating the company's strong strength in design, project management and production quality, and laying a solid foundation for the expansion and cooperation of subsequent projects.

0 notes

Text

SECOND Deepens Its Presence in Southeast Asia, Strengthening Partnerships for a Brighter Future

For many years, SECOND has been dedicated to expanding in the Southeast Asian market, actively participating in well-known international exhibitions like Nepcon Thailand and Nepcon Vietnam. Through these events, we have gained valuable experience and market insights. As a result, SECOND has built a strong reputation in Southeast Asia, winning broad recognition from customers.

In November 2024, SECOND welcomed visits from key partners to strengthen mutual exchange and collaboration. On November 7, our Thai distributor, Long Shine, visited SECOND’s factory to gain an in-depth understanding of our production processes, technical capabilities, and innovation strengths. Long Shine has long been one of SECOND's key partners, and this visit not only helped them better understand our products and manufacturing techniques but also laid a solid foundation for future business collaboration.

Additionally, SECOND organized a comprehensive distributor training session to provide our partners with a systematic overview of our products, technical support, and after-sales services. Our goal with this training is to enhance our partners' understanding and promotion of SECOND’s products. We believe that by strengthening our partners' expertise, they will be better equipped to provide excellent service and support to customers in the Southeast Asian market.

At the same time, our major client, JTU, will also visit SECOND’s factory on November 8 for in-depth discussions. As a valued client, JTU’s visit is not only an opportunity to tour our facilities but also to engage in deep technical exchanges that will lay a solid foundation for future cooperation.

These visits from our distributors and clients highlight SECOND’s competitive edge and appeal in the Southeast Asian market. We are confident that, through close collaboration and joint efforts, SECOND will continue to strengthen its market position, driving brand growth across Southeast Asia. Looking ahead, SECOND remains committed to innovation, delivering high-quality products and services, and working hand in hand with partners to open up even greater opportunities in the market.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

0 notes

Text

Second Intelligent In-Line Vacuum Glue Potting Machine: a powerful tool to realize high quality and high efficiency gluing

In-line vacuum glue potting machine is a kind of efficient and precise equipment, which is mainly used for vacuum potting of products with glue under vacuum environment. Under the current background of industrial automation, more and more factories start to use vacuum glue potting machine to equip their production.

In front of the extensive market demand, Shenzhen Second Intelligent Equipment Co., Ltd (referred to as Second Intelligent) combines its own precision assembly technology advantages and industry development trend, developed and upgraded the in-line vacuum glue potting machine SEC-S400-ZL which is suitable for automotive electronics, capacitors, new energy motors, high-voltage packages, ignition coils, solenoid coils, motor stators and sensors, and other industries, which is a good solution to the problem of The industry commonly exists in the product of small seams, poor penetration and easy to produce bubbles when filling glue and other issues, and in the stability and performance of the product have a strong industry advantage.

01. Promote the continuous advancement of the vacuum potting machine

With the continuous progress of science and technology and the continuous development of various industries, the demand for gluing equipment grows, the application scenarios also tend to be more diversified. In the glue potting machine market, semi-automatic glue potting machine has been China's largest demand for products, but benefited from the downstream automation degree of enhancement.

Automatic glue potting machine market demand is also growing steadily. The market requirements for the gluing process is also more stringent, high precision, high efficiency, automation and even intelligence is still the direction of modern gluing equipment technology innovation.

Vacuum potting process can effectively improve product quality, production efficiency and automation level. Looking around the world, in-line vacuum glue potting machine is widely used, the market sales show a rapid growth trend. Second Intelligent, which has been ploughing into the fluid application industry for 19 years, has a keen grasp of the user's advanced needs.

Through careful research and judgement of the development trend of the glue filling industry, Second Intelligent believes that no matter from the perspective of market demand or technology, in-line vacuum glue potting machine has a wide range of application prospects.

For this reason, Second Intelligent upgraded the original offline vacuum glue potting machine to achieve the process of automatic entry of the product into the vacuum box, automatic sensing of the positioning of the fixture in place, automatic closing of the door of the vacuum box, automatic vacuum pumping, and automatic potting of the glue according to the gluing procedure, and automatic pressure relief after the completion of gluing, automatic opening of the door, and automatic flow of fixtures out of the process solution.

After the product is assembled in the front section, it can be automatically transported to the internal conveyor line of the vacuum dispenser for positioning through the front receiving table. The preparation unit needs to heat and stir the A/B glue, and defoam and prepare the material under the vacuum environment of -100KPA.

Second Intelligent in-line vacuum glue potting machine has obvious advantages of high performance, reliability and durability, streamlined design, able to adapt to a variety of specifications, and absolute advantages for products with complex internal structure, high bubble requirements, and slow glue penetration.

It adopts industrial control machine + Second Intelligent motion control card integrated with advanced algorithm and Second Intelligent self-developed glue filling software control, equipped with friendly operation software, easy to operate and improve production efficiency.

02.Committed to product and process optimisation

Second Intelligent In-line vacuum glue potting machine perfectly solves the modern user's demand for quality gluing. It is not a pile of technology, but a multi-dimensional integration based on user experience.

Second Intelligent always practices the concept of total quality development, starting from the actual needs of users, and constantly optimises and improves product design, raw material management, process improvement, etc., and constantly advances and polishes multi-dimensionally to practice the original intention. The launch of In-line vacuum glue filling machine products, experienced countless trial and error, invested a lot of time and resources, overcome the complexity of the production process,

devices and other technical problems, to a very high degree of craftsmanship for the user to bring the true meaning of the potting experience.

Thousands of hammers and refinements, keep improving. Second Intelligent not only adhere to the development of technological innovation of the two-component potting product line, but also to further explore the depth of the three-stage vacuum potting machine research and development, to provide equipment for the IGBT industry.

It provides equipment solutions for IGBT industry. In terms of function upgrading, Second Intelligent realizes real-time monitoring of the dynamics of the product to be filled to ensure the accuracy and quality of the filling, and achieves the filling process of vibration while filling, while accelerating the rapid penetration of glue and the discharge of air bubbles to effectively improve efficiency.

In terms of operation optimisation, Second Intelligent ensures the solidity and reliability of the in-line vacuum glue potting machine system through user-friendly operation software, which makes the operation more convenient and easy to start.

Outstanding performance, leading edge, can meet the needs of more areas of application.

In addition to the traditional 3C, semiconductor and other fields, Second Intelligent will further expand the in-line vacuum glue potting machine to automotive electronics, lithium batteries, hydrogen energy, biomedical, aerospace and other fields.

0 notes

Text

Market status and advantage analysis of glue dispensing machines used in automotive industry?

Dispensing process play a key role in ensuring the quality and performance of automobile parts in automobile manufacturing industry. With the progress of science and technology and the development of industry, glue dispensing machines are more and more widely used in automobile manufacturing, and its advantages are increasingly prominent.

Globally, the automotive glue dispensing machine market shows a booming development. In Europe and the United States and other areas with highly developed automotive industry, the application of automotive glue dispensing machine has been very mature. Large automobile manufacturers, such as BMW, Mercedes-Benz, General Motors, etc., are using a large number of automatic glue dispensing machines in the production process to improve production efficiency and product quality.

These companies have high requirements for the performance and reliability of the dispensing machines, which has promoted the continuous development and improvement of automatic glue dispensing machine technology.

In China, with the rapid development of the automobile industry in recent years, the domestic automatic glue dispensing machine technology has also made remarkable progress. With its strong imitation ability and wisdom, China has been improving the performance and quality of its machine by combining the introduction of foreign advanced technology and independent research and development.

Nowadays, some domestic machine manufacturers have equaled or even surpassed a lot of foreign advanced levels in terms of control system, technology and process. Highly intelligent automation, high-precision dispensing and other technologies have become important features of domestic automotive glue dispensing machines.

What are the advantages of automotive glue dispensing machine? Let's take a look:

1. Improve production efficiency: automatic dispensing machine can realize fast and precise dispensing operation, which greatly improves production efficiency. Compared with manual dispensing, automatic glue dispensing machine can complete a large number of dispensing tasks in a short period of time, reducing labor costs and time costs.

2.Ensure the quality of dispensing: automotive glue dispensing machine is characterized by high precision and high stability, which can ensure the uniformity and consistency of dispensing. This helps to improve the reliability and durability of automotive parts and reduce quality problems caused by poor dispensing.

3. High flexibility: modern automotive glue dispensing machine usually adopts programmable control system, which can be flexibly adjusted according to different dispensing needs. This enables the machine to adapt to the dispensing requirements of different models and parts, improving the versatility and adaptability of the machine.

4.Reduce costs: Although the initial investment in automotive glue dispensing machine is large, but in the long run, it will bring the production efficiency and dispensing quality assurance will greatly reduce the production costs of enterprises. In addition, with the continuous development of domestic automotive glue dispensing machine technology, the price of machine is also gradually reduced, so that more factories can afford this investment.

As a leader in the field of automotive glue dispensing machine, Second Intelligent has been committed to providing customers with high-quality, high-efficiency dispensing machine and services. With advanced technology and rich experience, Second Intelligent continues to introduce innovative products and solutions to meet the diverse needs of different customers.

Second Intelligent's automotive glue dispensing machine features highly intelligent automation and high-precision dispensing, which can easily realize precise control of parameters such as dispensing volume, dispensing speed, and dispensing path. In addition, Second Intelligent also provides customized solutions.

Second Intelligent can design and manufacture the dispensing machine according to the actual needs of customers to ensure that the machine can realize seamless connection with the customer's production line.

In terms of after-sales service, Second Intelligent also performs well. Second Intelligent has a professional after-sales service team, which can provide customers with timely and efficient technical support and service. Whether it is machine troubleshooting or routine maintenance, Second Intelligent can provide customers with timely and efficient technical support and service.

Second Intelligent can provide customers with satisfactory service experience.

Automotive glue dispensing machine has a significant position in the automotive manufacturing industry. Its high efficiency, precision and flexibility make more and more enterprises choose to use this technology to improve production efficiency and product quality. As a leader in the field of automotive glue dispensing machine, Second Intelligent will continue to provide customers with high quality products and services to promote the continuous development of the automobile manufacturing industry.

0 notes

Text

Maintenance tips for dispensing machines: How to prevent fluid drips and blockages in dispensing machines?

Automatic dispensing machine as the core equipment in the gluing process, its application is becoming more and more widespread. However, in the actual production process, automatic dispenser often fluid drips and blockages in dispensing machines, which not only affects the effect of glue, but also may be a potential threat to the quality of automotive parts.

Automatic dispenser machine fluid drips and blockages in dispensing machines cause analysis, automatic dispensing machine at the end of the dispensing operation of the fluid drips and blockages in dispensing machines, mainly from the glue flow characteristics, equipment operating parameters and machine status and other factors. Specifically, including the following aspects:

1. Glue characteristics: glue viscosity, fluidity and curing speed and other characteristics will directly affect the phenomenon of fluid drips and blockages in dispensing machines. High viscosity of the glue in the stop flow is more likely to form fluid drips and blockages, and good fluidity of the glue may be due to the flow rate is too fast and produce fluid drips in the stop.

2. Equipment operating parameters: improper setting of the delay time for opening and closing the glue, irrational setting of the fluid drips height and lifting height, unstable or too high air pressure setting, and the distance between the needle and the workpiece is too close or too far, etc., which may affect the flow of the glue and the breakage, which may lead to the fluid drips phenomenon.

3. Machine status: wear and tear, clogging or contamination of the dispensing head or needle, as well as insufficient regular maintenance and upkeep of the equipment, such as incomplete cleaning of the pipeline, unstable air pressure system, etc., may also lead to fluid drips and blockages problems.

Automatic glue dispensing machine fluid drips and blockages in dispensing machines solution, for automatic dispenser fluid drips and blockages problem, you can take the following solutions:

1. Adjust the characteristics of the glue: according to the product process needs to choose the right glue, to ensure that the viscosity of the glue is moderate, neither too thick nor too thin. For high-viscosity glue, can be diluted or heated to enhance its fluidity, to help reduce the phenomenon of fluid drips and blockages.

2. Optimize the operating parameters of the equipment: Reasonably set the delay time for opening and closing the glue, to ensure that the glue in the stable outflow before starting the dispensing work, as well as in the dispensing is completed after a period of delay before closing the glue head. At the same time, adjust the fluid drips height and lifting height, so that the dispensing head can effectively pull off the glue when lifting.

In addition, keep the air pressure stable and moderate, to avoid too high or unstable air pressure caused by the fluid drips and blockages phenomenon.

3. Choose the right needle: according to the size of the product and the viscosity of the glue to choose the right dispensing needle, to ensure that the caliber of the needle is neither too small nor too large, in order to reduce the resistance of the glue outflow and fluid drips phenomenon. At the same time, regularly check the status of the needle to ensure that the needle is not clogged or worn.

The solution to the problem of fluid drips and blockages in dispensing machines, for automatic dispenser fluid drips and blockages, you can take the following solutions:

1. Adjust the characteristics of the glue: according to the product process needs to choose the right glue, to ensure that the viscosity of the glue is moderate, neither too thick nor too thin. For high-viscosity glue, can be diluted or heated to enhance its fluidity, to help reduce the phenomenon of fluid drips and blockages.

2. Optimize the operating parameters of the equipment: Reasonably set the delay time for opening and closing the glue, to ensure that the glue in the stable outflow before starting the dispensing work, as well as in the dispensing is completed after a period of delay before closing the glue head. At the same time, adjust the drawing height and lifting height, so that the dispensing head can effectively pull off the glue when lifting.

In addition, keep the air pressure stable and moderate, to avoid too high or unstable air pressure caused by the fluid drips and blockages phenomenon.

3. Choose the right needle: according to the size of the product and the viscosity of the glue to choose the right dispensing needle, to ensure that the caliber of the needle is neither too small nor too large, in order to reduce the resistance of the glue outflow and fluid drips and blockages phenomenon. At the same time, regularly check the status of the needle to ensure that the needle is not blocked or worn.

4. Strengthen the maintenance of equipment: regular cleaning and maintenance of equipment to ensure that the pipeline is unobstructed, stable and reliable air pressure system. For serious wear and tear of the dispensing head or needle, should be replaced in a timely manner.

5. Improve the process: In the dispensing process, you can take the segmented dispensing, early off the glue reserved for the completion of the final track, slanting pull on the lift and other process improvement measures to reduce the occurrence of fluid drips and blockages the phenomenon.

Although automatic dispenser may encounter problems such as fluid drips and blockages in practical application, its advantages still can not be ignored.

As an enterprise focusing on intelligent equipment manufacturing, Second Intelligent has performed well in the field of automotive glue application machine. Its products adopt advanced control system and precise gluing technology, which can ensure gluing quality and production efficiency. Meanwhile, Second Intelligent also focuses on product innovation and research and development.

It constantly introduces new products and technologies to meet the upgrading needs of the automotive manufacturing industry. In addition, Second Intelligent also provides high quality after-sales service and technical support to ensure that customers get timely and effective help in the process of use. If you have such needs, please feel free to contact Second Intelligent.

0 notes

Text

Empowering lithium battery production line, revealing Second Intelligent's “smart” engine

● New Energy Power Battery Core Coating Project ●

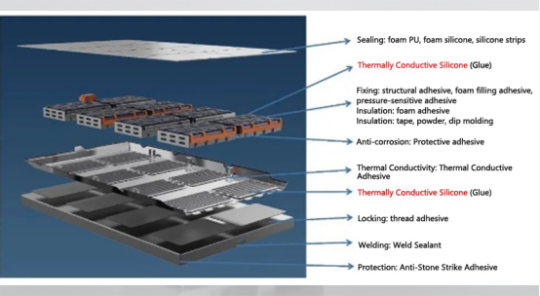

Thanks to the explosive development of the new energy automobile industry, the lithium battery also ushered in a period of rapid development. Shenzhen Second Intelligent Equipment Co., Ltd (Second Intelligent) lithium battery gluing machine equipment is based on the new energy lithium battery packaging section, through the core, side plate, end plate, insulating sheet, etc. to glue to achieve bonding, sealing, thermal conductivity and other functions, its performance requirements and stability have reached the international leading level.

In 2023, Second Intelligent provided more than 20 sets of gluing machine equipments for 3 production lines of a new energy power battery manufacturer, which helped it to further improve the production efficiency, meet the market demand for production capacity, and escort the stability of product quality, and helped the customer to rapidly expand the market share!

New energy, new opportunities!

With the new energy vehicle market penetration rate continues to increase corresponds to the global power battery manufacturing continues to expand. Currently, the demand for power batteries is “blowout” explosive growth. Industry data predicts that the global electric vehicle sales of 23.3 million units in 2025, corresponding to the demand for power batteries amounted to 1,691GWh.

2021-2025 power battery demand CAGR of nearly 48%.

| Adhesive technology in the battery system application point

The power battery is the "heart" of new energy vehicles. It refers to the rechargeable battery system used in new energy vehicles to provide power sources. The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is the basic structure of automotive power batteries.

Behind the rapid development of the industry is the continuous technological refinement of the manufacturing process and supporting equipment. Among the many key processes and materials, new energy power battery cell gluing as one of the most important processes in the assembly process, how to improve the precision of gluing,

Stability and automation has become the focus of industry attention.

To solve the reliability of new energy vehicle batteries, it is necessary to deal with the “core gluing” problem. Therefore, the well-known brands of new energy power battery cell suppliers in all aspects of the screening is very strict.

New energy power battery market demand soars, and lithium-ion coating machine as an important battery core production equipment, its market demand is also increasing. At present, in the domestic new energy automobile industry chain rapid development background, lithium-ion coating machine development trend is good.

| Choosing Second Intelligent to build new energy power battery cell coating project together

After seventeen years of technological precipitation and innovation, customizable solutions, professional design, fast delivery and excellent service, Second Intelligent has gradually established a brand image of high quality, credibility and service in the industry. Against this background, the new energy power battery manufacturer finally chose Second Intelligent.

The new energy power battery manufacturer finally selected Second Intelligent as the new energy power battery core coating supplier, the two sides of the team strong combination, around the site environment and process technology needs, from the early equipment program planning to the late equipment on-line always maintain close communication and cooperation.

Since December 2022, after receiving the customer's new energy power battery cell coating project procurement needs, the team composed of R&D, engineering, after-sales, project and sales of Second Intelligent, responded to the customer's needs in a timely manner, decomposed the customer's needs, carried out product validation, and efficiently linked the functions of various sections within the company, closely communicated with the customer and finalized the program.

Communicate closely with the customer and finalize the details of the program. Second Intelligent team and customer team keep online meeting about 2 times a week to continuously optimize the solution design.

In March and April 2023, the equipment for this project was delivered in stages. Due to the imperfect supporting facilities of the manufacturer affected the commissioning time, Sechun technicians actively cooperated with the customer, overcame the difficulties with the customer, chased the progress, and compressed the commissioning time from the original plan of 1 month to 10 days. Due to the tight time,

Due to the tight time and heavy task, the technicians worked overtime and sprinted with all their strength, and finally the equipment was put into normal use according to the original date and the task was successfully completed. The debugging personnel stationed at the customer's production site, set up night shift rotation, always focusing on the customer, and the spirit of continuous fighting were fully affirmed by the customer.

It shows the team spirit of hard work and excellence of Second Intelligent people.

This is not only due to the exploration and development of Second Intelligent team, but also inseparable from the customer's high trust to Second Intelligent. In the process of project communication between the two sides, the customer always encourages Second Intelligentteam to give full play to the technical advantages in the lithium equipment overall solutions for the new energy power battery core gluing process to provide new technology,

New ideas to solve the industry automation and industrialization problems. In the end, Second Intelligent also lived up to the expectations, riding on the momentum to make progress, and completed the answer sheet with more than expected performance, and a number of innovative designs are more efficient compared with traditional solutions.

The new energy power battery manufacturer said that this is a very happy cooperation, Second Intelligent team solved the glue production line problems that had been bothering for a long time, and the project also shines because of the power of mutual creation and prosperity, and we hope that the two sides can cooperate in more fields in the future.

| Technological innovation, help lithium industry high-quality development

The main body of this equipment consists of loading system, transfer system, feeding system, metering system, distribution system, etc., with the lack of material monitoring, pressure monitoring, flow monitoring and other functions, through software control and information management (MES system) into a glue raw material processing,

Through software control and information management (MES system), it becomes a gluing machine with the functions of raw material handling, precise metering and automatic mixing, with high stability and high precision, which effectively improves the overall production efficiency of the production line.

| Second Intelligent-Battery cell glue coating machine

The feeding system adopts a pressure plate pump, which can reliably transfer glue from the raw material drum to the transit tank. It has the following technical advantages: new NXT air motor for durability, less pulsation for uniform glue pattern; lowest initial investment cost, the system has reliable feeding capability;

High-quality shared parts reduce maintenance time, normal use time > 6 months; pump contains low level alarm, to low level automatic shutdown; integrated air control method, easy to operate, according to the needs of different sizes and materials of the pump body can be selected.

Metering system for high filler, highly abrasive materials, improve service life. Stable flow rate of glue discharge, high precision and repeatability. Pressure monitoring, through the control of the system pressure, to eliminate the beginning and end of the glue start and end point of the size of the head, line consistency is high; and can monitor the system pressure, high and low pressure alarm.

Pump body structure design, reduce dead space, into the glue out of the basic push through, to prevent glue accumulation.

Mixing system using two-component dispensing mixing valve, dual cylinder control, can be individually controlled A/B, with a suction-back structure, no glue dripping, no pulling, no glue leakage after closing the valve. Universal dispensing head, can be matched with standard static mixing tube, with proportional dispensing head, easy to test the ratio.

The modular design of this gluing equipment facilitates the maintenance and repair of customers and saves the maintenance and repair cost. Repeatedly verified components and control programs to ensure the long-term stable operation of the equipment, improve the customer's production capacity. 24-hour continuous production, no downtime for glue drum change, the equipment can be unmanned, reducing the customer's labor costs. The real-time uploading of key parameters of the equipment provides strong support for the traceability of each product. Simple and clear control interface, easy-to-operate control mode, and perfect anti-dumbness and anti-error settings can be easily operated to avoid the loss caused by unfamiliar operation.

This cooperation marks the customer's high recognition of the lithium equipment created by Second Intelligent, and also highlights the strong technical strength of Second Intelligent in the automated production and manufacturing of lithium equipment and rich process areas, which is an important demonstration and driving role for the company's new energy power battery business promotion and expansion.

Second Intelligent sales elites also have confidence and ability to add bricks and mortar for more lithium industry production lines.

Second Intelligent gluing machine, used in lithium industry well-known brands, rapid breakthroughs in research and development and batch application in the market, casting Second Intelligent in the field of power battery gluing the leading position, for the subsequent expansion of more new energy power battery gluing projects and cooperation has strengthened a solid foundation. As an enabler of the new energy power battery industry chain, in line with the three major trends of the lithium equipment industry line, standardization and globalization, in the future, Second Intelligent Intelligence will pay close attention to the technological development of the new generation of batteries, and carry out product iteration in a timely manner in accordance with the requirements of the new process and new equipment, and continue to promote the innovative development of the lithium industry together with our partners and lead the industrial progress.

Cylindrical Core Module

0 notes

Text

What do I need to pay attention to when operating a automatic glue dispensing machine?

Automatic dispensing machine in the operation of the following key matters need to pay attention to, in order to ensure operational safety, improve production efficiency and ensure the quality of dispensing:

1.Check before starting

Equipment cleanliness: check whether the automatic adhesive dispensing machine is clean, to ensure that there is no moisture, dust or other impurities, which may directly affect the normal operation of the machine.

Power supply and air circuit: Before moving the equipment, make sure that the air circuit and power supply have been cut off to avoid damage or safety accidents during the moving process.

Automatic In-line Glue Dispensing Machine SEC-DH400L

2.Safety matters during operation

Prohibit touching the movable parts: In the working condition, it is strictly prohibited to touch the dispensing head, needle nozzle, guide chain and other movable parts with hands to prevent pinching or machine failure.

Emergency stop: In case of special circumstances or emergencies, the red emergency button on the front of the machine should be pressed immediately to stop the machine immediately.

Personal protection: When working, the operator should wear gloves and try not to expose the skin to prevent glue from sticking to the skin. At the same time, it is recommended to wear work clothes to further protect personal safety.

Automated vacuum potting system SEC-S3030-B

3.The use of glue and equipment maintenance

Understand the characteristics of the glue: Before using the glue, you should have a full understanding of the glue, including its conditions of use, the correct method of use, etc., in order to ensure the quality of dispensing.

Cleaning the needle: complete the dispensing work or a long time in the middle of the dispensing work, the need to clean the needle in time, in order to prevent the needle from clogging, affecting the subsequent dispensing effect.

Safety performance testing: regular safety performance testing of In-line automatic glue dispensing machine, such as grounding resistance, etc., to ensure that the equipment does not leakage and other potential safety hazards.

4.Working environment and equipment management

Keep the operation space: don't pile up too many items beside the machine so as not to affect the operation. At the same time, do not place unnecessary things on the workbench and keep it clean.

Power off equipment: In case of long time not using, the power should be cut off to prolong the life of the equipment and save the electricity cost.

5.Other Precautions

Air pressure setting: set the corresponding air pressure according to the viscosity of the glue to ensure the stability and accuracy of dispensing.

Programming and Parameter Setting: Prepare the programme according to the product dispensing graphic, and set the parameters such as dispensing speed, Z-axis raising height relative value, dispensing time, etc. to achieve accurate dispensing.

The operation of the automatic dispensing machine involves many aspects, which requires the operator to strictly comply with the operating procedures and safety precautions. Through careful preparation, standardised operation and timely maintenance, it can ensure the stable operation of the equipment and improve the quality of dispensing. If you have such questions, please contact Second Intelligent.

1 note

·

View note