#WPC Window Frame

Explore tagged Tumblr posts

Text

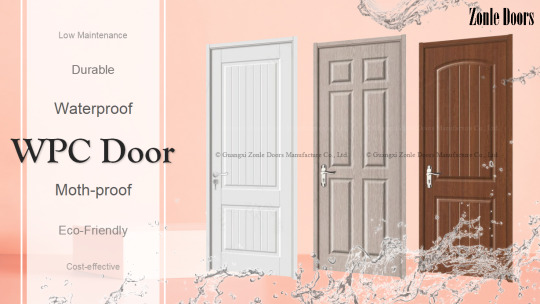

WPC Door Frame by Alstone

Alstone, a renowned industry leader, specializes in crafting high-quality WPC (Wood Polymer Composite) Door Frames. These frames offer a compelling blend of wood's natural charm and the durability of modern materials. Alstone's WPC Door Frames are resistant to moisture, pests, and wear, making them an ideal choice for long-lasting, elegant door installations.

0 notes

Text

GHARABANAO.COM

Phone: +919776302000

Address: Mancheswar Industrial Estate, Bhubaneshwar, Odisha – 751010

Website: https://www.gharabanao.com/

Owner name: Likan Patra

Timing- Monday: Saturday (10am - 6pm)

Social links: https://www.facebook.com/gharabanao/ https://www.youtube.com/@gharabanao

Business email: [email protected]

Keywords: plywood dealer, plywood distributor, WPC door frame, wpc door frame price in bhubaneswar, modular kitchen price, plywood price, WPC door frame in Bhubaneswar, louver panels, WPC louvers, acrylic laminate sheet price, charcoal sheets, WPC Louver panels, laminated plywood, waterproof plywood, 3d wall tiles, polygranite sheet, 3d pvc wall panels, poly granite sheet, black cobra wpc door frames, front door, windows and doors, upvc doors, sliding doors, steel doors, soffit ceiling panels, auto hinges, kitchen baskets, drawer channels, pantry basket, door handles, fevicol, adhesive, Godrej, hettich, quba, Ebco, Dorset, Godrej door locks, hettich kitchen fittings, sunmica sheet, sunmica, sunmica price, century sunmica, merino laminate, royale touche laminate, greenlam laminates, century laminates, century ply, century plyboards, high gloss acrylic laminates, 1.5mm acrylic laminates, acrylic sunmica for kitchen

Descriptions: Unleash the true potential of your interior spaces with GHARABANAO.COM, a leading destination for Plywood, Laminates, WPC Boards, Doors, Hardware Fittings, and more. Our vast array of quality products, coupled with unparalleled service ensures we are the one-stop shop for all your plywood needs. With a reputation for excellence since 2018, our commitment to transforming interior landscapes has made us the go-to partner for residential and commercial projects across Odisha and beyond. Trust us for bespoke interior solutions and experience the exceptional.

#plywood dealer#plywood distributor#WPC door frame#wpc door frame price in bhubaneswar#modular kitchen price#plywood price#WPC door frame in Bhubaneswar#louver panels#WPC louvers#acrylic laminate sheet price#charcoal sheets#WPC Louver panels#laminated plywood#waterproof plywood#3d wall tiles#polygranite sheet#3d pvc wall panels#poly granite sheet#black cobra wpc door frames#front door#windows and doors#upvc doors#sliding doors#steel doors#soffit ceiling panels#auto hinges#kitchen baskets#drawer channels#pantry basket#door handles

1 note

·

View note

Text

The best WPC doors and door frames from ocean group. ensure the quality to your home . water-proof,termite-proof,and lightweight wpc doors are the big choice of new homes.

0 notes

Text

We provide the best opportunity for wooden industry manufacturers.

#digital marketing#marketing#business#seo#social media#plywood#laminate sheets#Plywood#Laminates#Veneer#Particle Board#Door & Windows#window - door frame#Mdf#Timber#solid wood#wooden flooring & -Surface#Pvc Edge Tape#Kitchen Shutter#Solid Acrylic Surface(corian)#Pvc (Acrylic) sheet & flooring#Acp Sheet#Wpc door#panel & sheets#Louvers & wood clading#wall Highlighters & Panels#Exterior & Interior Panel#Adhesive Chemicals#fiber cement board#xdmr

0 notes

Text

Ocean weather-resistant WPC door and window frames are sturdy and durable. They are made of high-quality materials, so they can withstand the most demanding conditions. To know more visit website :https://theoceangroup.co.in/

0 notes

Text

WPC window and door frames

E3 Woods is a leading manufacturer of sustainable WPC window and door frames, offering innovative solutions for both interior and exterior applications. Their commitment to customer satisfaction sets them apart in the industry. Our WPC window and door frames are designed to enhance the aesthetic appeal of your living spaces, with their exquisite wooden grid false ceilings complementing the frames. They are built to endure, being waterproof and distortion-resistant, ensuring longevity and cost-effectiveness over their lifecycle.

We also offer a greener alternative, sourcing from recycled or sustainably managed forests, which reduces the demand for virgin timber resources and contributes to responsible waste management practices. The frames are termite and pest-proof, eliminating concerns about deterioration that often plague traditional wooden frames. They are 100% waterproof, making them ideal for environments prone to moisture. E3 Woods' UV-resistant WPC frames retain their color and structural integrity even in the face of prolonged sun exposure, standing strong against the elements. These frames are not just manufacturers; they are champions of innovation, sustainability, and aesthetic finesse.

With their WPC window and door frames, your spaces will exude sophistication while embracing eco-friendliness. Join us in embracing the future of construction, where elegance, durability, and environmental responsibility harmonize seamlessly. Choose E3 Woods for a world of difference in your living spaces.

1 note

·

View note

Text

WPC Door Frame Maintenance And Cleaning Tips

In modern home decoration, WPC door frame (wood-plastic composite door frame) gradually replaces the traditional wooden door frame with its advantages of moisture-proof, anti-corrosion, green environmental protection, and convenient installation, and becomes a popular choice. However, if you want WPC door frames to last as long as new, reasonable maintenance and cleaning methods are essential. In this article, we will systematically introduce you to the daily maintenance and cleaning skills of WPC door frame to help you extend the service life and maintain the beauty and performance of the door frame.

The Material Advantages Of WPC Door Frame Determines Its Maintenance Characteristics

WPC (Wood Plastic Composite) is a new type of environmentally friendly material made of wood powder and polymer resin through high temperature extrusion molding. Compared with solid wood, WPC door frames are more resistant to moisture, insects, mold and aging. This means that in terms of maintenance, WPC door frames do not need to be waxed and oiled as often as solid wood door frames, and they will not swell and warp due to moisture. However, even if the performance is stable, reasonable maintenance can still extend its service life and enhance the quality of home.

The Daily Maintenance Points

1. Avoid strong impact and scraping

Although the WPC door frame is high strength, but still need to avoid sharp objects in daily use of collision and scraping, especially in the handling of furniture or renovation construction, the door frame corners need to pay attention to protection.

2. Control humidity and ventilation

Although WPC door frames are moisture resistant, prolonged exposure to excessive humidity or extreme dryness may affect their appearance and structure. It is recommended to maintain indoor ventilation, especially in high humidity areas such as bathrooms or kitchens, the appropriate use of dehumidifiers or exhaust equipment to help slow down the aging of the door frame.

3. Avoid direct sunlight

Strong ultraviolet rays will accelerate the fading or aging of the surface color of the material. Especially for door frames installed near balconies or floor-to-ceiling windows, it is recommended to install curtains or shading facilities to slow down color fading.

4. Regularly check the connecting parts

Every six months you can check whether the screws of the door frame and wall, door connecting parts are loose, and tighten or adjust them in time, which will help to maintain the overall stability of the door frame and the smoothness of the opening and closing.

Cleaning Skills And Precautions

1. Daily cleaning: soft cloth + water can be

WPC door frame surface is smooth, not easy to adsorb dust, generally only need to wipe with a clean soft cloth. If there is a slight stain, use a slightly damp cloth with a small amount of neutral detergent to wipe, and then dry with a dry cloth to avoid water residue.

2. Stubborn stains removal tips

encounter such as oil stains, pen marks and other stubborn stains, you can use the following methods:

Soap and water cleaning: Soap and water spray on the stain, wait a few minutes and wipe with a soft cloth.

Alcohol or medical cotton ball: against ink or marker marks, a small amount of medical alcohol can be used to dip a cotton ball and gently wipe, do not use too much force.

Soft bristle toothbrush auxiliary: the door frame grooves in the accumulation of dust, with a soft bristle toothbrush with a light brush, not only does not damage the surface, but also to clean in place.

3. Contraindicated cleaning supplies

To avoid damage to the surface of the door frame, the following items should be avoided:

corrosive cleaning agents, such as strong acid, alkali liquid;

steel wire ball, coarse sandpaper and other hard cleaning tools;

with a high concentration of alcohol or bleach cleaning products.

These supplies may scratch the surface or lead to discoloration of the material, affecting the beauty and service life.

Seasonal Maintenance Suggestions

Spring: Pay Attention to Humidity

Spring is rainy and humid, with high air humidity, so you need to pay special attention to ventilation and dehumidification to prevent mold and mildew from growing around the door frame. It is recommended to use dehumidifier or place desiccant package in the doorway.

Summer: sun protection and cooling

In summer, when the high temperature is exposed to the sun, if the WPC door frame is under strong sunlight, a sunshade should be used to reduce the intensity of ultraviolet radiation to avoid color fading.

Autumn and winter: dry anti-static

Autumn and winter air is dry and prone to static electricity, can be appropriate in the indoor humidification, maintain humidity between 40% -60%. In addition, the door frame, such as the phenomenon of static electricity accumulation of dust, you can use anti-static spray treatment.

Summary: Details determine durability

WPC door frame is becoming an ideal choice for modern decoration by virtue of its durability and environmental characteristics. Although its maintenance is relatively easy, scientific and reasonable maintenance is still the key. Through regular cleaning, rational use and seasonal maintenance, not only can effectively extend the service life of WPC door frame, but also keep it bright as new, adding a lasting sense of sophistication to the home.

Whether you are a consumer, designer, or building materials practitioner, mastering the maintenance and cleaning knowledge of WPC door frames is an important step in creating a high-quality living space. I hope this article can bring practical help to you in your daily use. You are also welcome to share it with friends or customers in need to jointly create a more comfortable and environmentally friendly living environment.

0 notes

Text

WPC decking wpc flooring 3D composite decking embossed

Fire Proof Water Proof Terrace Wpc Decking

Composite decking is a man-made building product that includes an approximate equal mix of recycled wood fibers and recycled plastic. Because composite decking products are so durable and impervious to rot, they have a much longer lifespan than wood decks. They do not require the staining, sanding, sealing, and board replacement that come along with wood decks. Even though they require more initial investment, a composite deck more than makes up for that initial cost over the lifespan of the deck. With the many advantages of composite decking, such as lower maintenance and being resistant to mold and insects, composite decking has been deemed one of the most durable decking products on the market today. In addition to these benefits, new capped composite decking is also stain and fade resistant, which means it is easier to clean and has very high color retention.

Maintaining your composite deck requires semi-annual cleaning; just a quick spray of the hose with a mild household cleaner will do the trick.Capped composite decking is sealed and is easier to clean if mold and mildew form on the surface.Since there are exposed wood fibers in uncapped composite decking planks, it can be susceptible to mold growth just like any outdoor surface. However, cleaning your deck periodically can help keep mold at bay. Installation of composite decking uses the same tools as traditional wood decking with the added benefit of side grooves for hidden fasteners. A hidden fastener system makes use of grooves built into the sides of the decking planks for a smooth surface without any screws showing. Plus, you have the added benefit of absolutely no splinters, twisting or warping. However, it is important to note that you must follow the manufacturer’s instructions for installation. Adding a deck to your home can produce a substantial return on your initial investment. With composite decking, you are ensuring that your deck is beautiful for years with less maintenance. You can even have the exotic look of woods like Ipe, without all the upkeep. Composite decking can be a true, low maintenance solution to your outdoor living space by providing a beautiful sanctuary for you and your family.

What Is W.P.C ?

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC etc.). Chemical additives seem practically "invisible" (except mineral fillers and pigments, if added) in the composite structure. They provide for integration of polymer and wood flour (powder) while facilitating optimal processing conditions. In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

What Is The Advantages Of W.P.C?

WPC do not corrode and are highly resistant to rot, decay, and Marine Borer attack, though they do absorb water into the wood fibers embedded within the material. They have good workability and can be shaped using conventional woodworking tools. WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry. One advantage over wood is the ability of the material to be molded to meet almost any desired shape. A WPC member can be bent and fixed to form strong arching curves. WPCS are manufactured in a variety of colours, another major selling point of these materials is their lack of need for paint.

What Is The Uses Of W.P.C?

Wood-plastic composites are still new materials relative to the long history of natural lumber as a building material.The most widespread use of WPCs is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture.

Previous: Fire Resistant Outdoor WPC Flooring Board

Previous: No more

0 notes

Text

About uPVC Profile

Prominent in the Indian market, Jamex uPVC Profiles are everything that one desires for. Designed especially for the Indian weather conditions, Jamex uPVC profiles are sustainable even in extreme weather conditions bearing even 60 degrees celsius to -40 degrees celsius. With a production of 4800 MT per annum, jamex is one of the largest extruders of uPVC profiles. Inspired by the German brand ‘Dimex’, Jamex has its own extrusion plants and has been successful in making its mark in the Indian market. Jamex uPVC profiles come in 8 colours and a wide range of series.

UPVC Profile Categories

60 mm casement window series

62 mm sliding window series

88 mm sliding window series

110 mm villa window series

74 mm monorail window series

70 mm casement door series

112 mm sliding door series

150 mm sliding door series

86/ 96 mm sliding-folding door series

Our Manufacturing plants

We swell with pride while announcing that we are the strong disciple’s of world-class quality standards. Each product is conceptualized from the foundation. Beginning with choosing the raw material to final culmination, our unwavering zest for excellence and quality grabs us the position of best PVC-WPC Doors, Boards Door Frame manufacturers in South India.

JamexUPVC: A Trusted Name in Quality UPVC Profiles

When you’re looking for UPVC profiles that offer both durability and style, JamexUPVC is a name you can rely on. As one of the established UPVC profile manufacturers in India, we’ve been committed to delivering high-performance UPVC solutions for all kinds of projects, whether you’re updating your home or managing a commercial development.

We understand that choosing the right materials is essential. That’s why our UPVC window profiles are designed to meet the unique demands of Indian homes and businesses. They offer excellent insulation, helping to keep interiors comfortable by reducing heat and sound, which is perfect for the changing seasons.

Upvc Profile Manufacturers in India

What makes JamexUPVC stand out from other UPVC profile suppliers in India? It’s our focus on quality, sustainability, and innovation. Our profiles are eco-friendly, low maintenance, and built to last. Whether you need sleek profiles for modern architecture or more robust frames for larger structures, we offer a wide range of solutions that can be tailored to your specific needs.

We take great pride in our rigorous manufacturing standards. As one of the key players among UPVC window profile manufacturers, every product we create goes through thorough testing to ensure it meets both local and international standards. This means you’re not just getting a product that looks good, but one that’s built to handle India’s diverse climate and stay strong for years to come.

Choosing JamexUPVC means choosing a partner who cares about quality and customer satisfaction. Let us provide the right profiles to enhance your project, making it not only energy-efficient but also stylish and durable. Call Now +91 8019860025 +91 9849312645 to get a free quote today!

#UPVC#upvc windows and doors#upvcdoors#upvc sliding doors#upvc sliding windows#talang gully hidroponik upvc

0 notes

Text

The Durability of WPC Boards: How They Outperform Traditional Materials

In the world of modern construction and interior design, durability is a key factor when choosing materials. Among the many innovative materials available today, WPC Boards (Wood Plastic Composite Boards) have emerged as a superior choice, especially as substitutes of plywood. Offering unparalleled durability, environmental benefits, and versatility, WPC Boards are transforming how homes and commercial spaces are designed.

Leading the industry in creating high-quality WPC Boards is Floresta, a brand synonymous with eco-friendly, long-lasting, and aesthetically pleasing building materials. Let’s dive into what makes WPC Boards so durable and why they outperform traditional materials like plywood.

What Are WPC Boards?

WPC Boards are made from a unique blend of wood fibers and thermoplastics, creating a composite material that mimics the appearance of natural wood while offering superior strength and resistance to environmental factors. Unlike plywood, which is made by gluing thin layers of wood veneers together, WPC Boards are manufactured to be inherently resistant to moisture, termites, and warping.

How WPC Boards Outperform Traditional Materials

Resistance to Moisture and Humidity One of the biggest drawbacks of plywood is its susceptibility to water damage. In damp or humid conditions, plywood tends to swell, warp, and lose its structural integrity. WPC Boards, on the other hand, are completely water-resistant. This makes them an ideal choice for bathrooms, kitchens, and outdoor furniture where moisture is a concern.

Termite-Proof Properties Traditional plywood is vulnerable to termite infestations, which can compromise its durability and result in costly repairs. WPC Boards, being a composite material, are naturally resistant to termites and other pests, ensuring long-lasting performance in any environment.

Strength and Stability Unlike plywood, which can weaken over time due to delamination or splitting, WPC Boards offer exceptional structural stability. Their uniform composition ensures they remain strong and intact, even under heavy usage. This makes WPC Boards ideal for applications like cabinetry, furniture, and wall paneling.

Eco-Friendly and Sustainable As awareness about sustainable practices grows, many homeowners and builders are turning to substitutes of plywood like WPC Boards. Manufactured using recycled wood and plastics, WPC Boards are an environmentally responsible choice. Leading brands like Floresta prioritize eco-friendly production methods, contributing to a greener planet.

Low Maintenance Traditional plywood often requires regular polishing, painting, or sealing to maintain its appearance and durability. WPC Boards, on the other hand, require minimal maintenance. They retain their finish and structural integrity over time, saving both time and money.

Fire Retardant Properties Safety is a crucial consideration in construction, and WPC Boards excel in this area too. Many WPC Boards, including those offered by Floresta, are designed to be fire-retardant, adding an extra layer of protection to your spaces.

Applications of WPC Boards

Thanks to their durability and versatility, WPC Boards are used in a wide range of applications:

Furniture: Cabinets, wardrobes, and modular furniture.

Outdoor Decking: Perfect for patios and balconies due to their water-resistant properties.

Wall Cladding and Paneling: Enhances aesthetics while offering long-lasting performance.

Partitions: Ideal for commercial and residential spaces.

Doors and Windows: A durable alternative to traditional wooden frames.

Why Choose Floresta for WPC Boards?

When it comes to choosing substitutes of plywood, Floresta stands out as a trusted brand. Known for their commitment to quality and sustainability, Floresta’s WPC Boards offer unmatched durability, aesthetic appeal, and eco-friendliness. Whether you’re designing a modern home or working on a commercial project, Floresta’s range of WPC Boards ensures you get the best of both worlds—strength and style.

Conclusion

WPC Boards are more than just a substitute for plywood—they are a durable, sustainable, and versatile solution for modern construction and design needs. Their resistance to moisture, pests, and wear makes them a long-lasting option for various applications. As brands like Floresta continue to innovate, the future of building materials looks promising and sustainable.

If you’re planning your next project, consider the benefits of WPC Boards. They’re not just materials; they’re an investment in quality, durability, and environmental responsibility.

Also, Read:

Top 10 Reasons to Choose WPC Boards Over Plywood

Top WPC Door Designs for Modern Indian Homes

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

Enhancing Safety and Comfort with Versa Railings

WPC railing solutions are stable, colorful, and strong enough to withstand continuous high-volume traffic. Therefore, public places like malls, convention centers, cinema halls, wedding venues, etc choose WPC railing solutions. Environmental conditions are particularly important for high-traffic spaces since customers may shun spaces that are not maintained in a neat and clean state. Apart from being colorful and neat these spaces should also be safe for all age groups and be capable of withstanding high volume traffic intermittently. Apart from the commercial spaces, WPC railing solutions are ideal for gardens and residences because these railings enjoy a high degree of versatility.

Resting places for high-grade communities

Resting places are set up in many high-grade communities and to create a natural and fresh visual experience, generally wooden materials are employed for decoration. Wooden materials can bring the natural flavor and also enhance the aesthetics. But, wood has several disadvantages which cannot be overlooked. Wooden materials installed in outdoor spaces are prone to deformation and cracking due to the vagaries of weather. Therefore, many communities are now turning to WPC railings for various decorative deployments.

Benefits of WPC railing solutions

Being waterproof is the biggest benefit of WPC railing solutions. WPC railings installed in the outdoor space are free from the concern of guardrail decay due to snow and rain and also deformation from moisture ingress. Therefore, WPC demands minimal maintenance once it has been properly installed. Another benefit of WPC railing solutions is their interchangeable design.WPC materials are also offered in multiple colors enabling users to run riot with their imagination. Further, the polymer material in WPC is also capable of keeping many insects at bay.

Pollution-free

A more important feature of WPC railing solutions is that it is pollution-free and therefore will keep the environment clean.

WPC is also free from deformation and cracks issue when deployed for various purposes even when exposed to harsh weather conditions. WPC is resistant to high temperatures, termites, and humidity making it suitable for a variety of exterior and interior applications. Some of the exterior applications include garden furniture, swimming pool, outdoor paneling, park benches, WPC doors, prefab houses, etc. WPC is also ideal for applications like wall paneling, door and window frames, bathroom cabinets, office furniture, etc.

Word of caution

However, WPC cannot withstand extreme temperatures and therefore laser cutters and similar equipment emitting high heat cannot be used in association with WPC fabrication. Similarly, while using WPC inside your kitchen, adequate precautions should be taken to ensure that the WPC Plank does not come into direct contact with heat, such as from the bottom of a gas stove.

Source Link: https://versaplank.in/safety-and-comfort-with-versa-wpc-railings/

0 notes

Text

WPC Doors And Frames manufactured by Alstone are 100% waterproof and come with a lot of benefits. With features like Fire retardant, distortion resistant, and great adaptability to outdoor conditions it makes it irreplaceable as compared to other types of Doors.

1 note

·

View note

Text

Ocean's Lyke wood doors, windows, and frames ensure quality

0 notes

Text

Enhancing Home Decor with WPC Fins: Creative and Sustainable Interior and Exterior Ideas

Wood–Plastic Composite (WPC), made from wood fibres or flour and thermoplastics, has revolutionized the world of home decor with its versatility, durability, and eco-friendliness. It combines the aesthetic look and feel of natural wood with durability and excellent performance characteristics. Whether you’re looking to renovate your home’s interior or enhance its outdoor spaces, WPC offers an attractive and practical solution.

Home Décor Avenues

WPC fins are a versatile element that can be used tastefully for both interior and exterior home improvements. While they can transform interiors when used on walls, ceiling, accent walls, room dividers, flooring, and door and window frames, they enhance exteriors when used for decking and flooring, privacy screens, sunshades and pergolas, balustrades and railings, and so on. Let us look at some of the popular applications of WPC fins in home décor.

Indoor Décor Ideas

Using WPC fins for interior decoration is a versatile and eco-friendly choice that can enhance the aesthetics and functionality of your indoor spaces.

Wall Cladding: WPC fins add texture and visual interest to your interior walls when used as decorative wall cladding. This can create a warm and inviting atmosphere both in residential and commercial settings.

Ceiling Features: Unique ceiling designs can be created when WPC fins are arranged in patterns, suspended, or used to cover ceiling surfaces, adding depth and sophistication to the space.

Room Dividers: WPC fins can help create room dividers or partitions, providing privacy in open-plan spaces, at the same time allowing light to filter through.

Decorative Screens: WPC fins can serve as beautiful decorative screens or panels on walls. These screens can serve as art pieces, adding a touch of elegance and style to your interior decor.

Accent Walls: Application of WPC fins to a single accent wall can create a stunning backdrop for artwork, furniture, or decorative items.

Vertical Gardens: WPC fins serve as supports for indoor vertical gardens when fixed to indoor walls, bringing a touch of nature indoors.

Door and Window Frames: Use WPC fins to frame doors and windows. This adds a cohesive design element throughout your interior spaces and complements the overall aesthetic.

Flooring Accents: Combine WPC fins with other flooring materials like tiles or hardwood to create unique flooring patterns or accents. This adds visual interest and can define specific areas within a room.

Exterior Décor Ideas

Sunshades and Pergolas: Sunshades or pergolas can be constructed with WPC fins to provide shade and architectural interest to your outdoor living spaces. These structures provide protection from the sun’s harsh rays while adding a stylish touch to your yard.

Balustrades and Railings: WPC fins can be used as balusters or railings for your deck or stairs. They offer the strength and durability of traditional materials while contributing to a contemporary design.

Outdoor Furniture: Incorporate WPC fins into outdoor furniture designs such as tables, chairs, and benches. WPC furniture is not only stylish but also resistant to the elements.

Water Features: Incorporate WPC fins into outdoor water features, such as decorative ponds, fountains, or waterfalls. The material’s inherent moisture resistance makes it an excellent choice for these applications.

Vertical Gardens: WPC fins can be used as support for vertical gardens on exterior walls. This can bring a touch of nature to your outdoor spaces while adding a decorative feature.

Gazebo or Pavilion: Construct a gazebo or pavilion with WPC fins to create a comfortable outdoor seating or dining area. This can be a cozy retreat for gatherings or relaxation.

Entrance Enhancements: Use WPC fins to frame the entrance of your home, creating an inviting and modern look. Combining them with lighting fixtures adds sophistication and visibility.

Everwood WPC fins

Everwood WPC comes with unmatched material characteristics that bestow it with unparalleled performance and endurance. They find applications in green houses, gazebos, passageways, cantilever extensions, garden & terrace pergolas, and so on. to add an element of aesthetics and class to your outdoor space.

With their exceptional temperature tolerance, dimensional stability, high density, low initial and lifetime costs, prefinished wood looks, outstanding durability, and low maintenance requirements, Everwood WPC fins are the perfect choice for multiple exterior and interior architectural design options.

For more Informations :

0 notes

Text

PVC Wood-Plastic Quick Assembling Wall Panel Extrusion Line

Description PVC quick loading wallboard, also known as "ecological art wall" or "integrated wall", is a new decorative building material with PVC / bamboo fiber as the substrate and the surface can be hot stamped and coated. It can be widely used in families, projects, office buildings, hotels, restaurants, entertainment places and so on. 1. Wood plastic decorative wallboard fast loading wallboard has the same processing performance as log. It can be nailed, drilled, cut, bonded, connected and fixed with nails or bolts. The surface is smooth and fine without sanding and paint. 2. Wood plastic decorative wallboard has better physical properties than log and better dimensional stability than wood. It will not produce cracks, warpage, wood knots and twills. It can be made into colorful products by adding colorant, film coating or composite surface, so it does not need regular maintenance. 3. Wood plastic decorative wallboard has excellent properties such as fire prevention, waterproof, corrosion resistance, moisture resistance, no moth, no fungi, acid and alkali resistance, harmless and pollution-free, and low maintenance cost. 4. Wood plastic decorative wallboard has similar wooden appearance in use, higher hardness than plastic, long service life, thermoplastic molding, high strength and energy saving. The product has strong quality, light weight, heat preservation, smooth and flat surface and no pollution. The machine is used for producing WPC decoration product, which is widely used in house and public decoration field, features non-polution, long service lifetime, heat insulation, anti-fire, easy clean and maintanance, easy change and recycleable. It can be high quality decoration material for ceiling, door frame, window frame, sound proof and heat insulation. Equipment allocation 1. 65 cone double extrusion production line is used to produce products with larger lines and narrower and thinner plates 2. 51 cone double extrusion production line is used to produce small line products 3. 80 cone double extrusion production line is used to produce wide and thick plate products 4. High speed mixer 500 / 1000 5. Crusher 6. Mill 7. Laminating machine Main technical specification Model SJZ51/105 SJZ65/132 SJZ80/156 Production width(mm) 180 300/400 600 Motor power(kw) 22 37 55 Output (kg/h) 80-100 150-200 300-400 Type YF180 YF300/YF400 YF600 Product image display Read the full article

0 notes

Text

Safety Marks And Certification Standards For WPC Door Frames

In the building decoration industry, door frame, as an important supporting part of the door body, its quality and safety directly affect the stability of the overall building and the safety of living. In recent years, WPC (Wood Plastic Composite) door frames have gradually become a popular choice in the market due to their excellent characteristics such as environmental protection, waterproof, moisture-proof and corrosion resistance. However, in order to ensure the quality and safety of WPC door frames, a series of safety marks and certification standards have been formulated by relevant international and domestic organizations to ensure that the products meet the market access requirements and to safeguard the safety of consumers.

The Main Safety Mark Of WPC Door Frame

1.CE certification (European Conformity Certification)

CE certification is a mandatory safety certification mark for the European market, indicating that the product complies with the safety, health and environmental requirements of the European Union. For WPC door frames, CE certification means that the product complies with relevant standards such as EN 14351-1, ensuring its structural strength, durability and environmental characteristics.

2.FSC Certification (Forest Stewardship Council Certification)

As WPC door frames contain a certain percentage of wood fibers, FSC certification proves that the source of the wood complies with the principles of sustainable forest management. This is not only an important symbol of environmental protection certification, but also a basic requirement for wood products in the international market.

3.SGS Inspection Report

SGS is the world's leading testing, inspection and certification organization. WPC door frames tested by SGS usually involve fire resistance, formaldehyde emission, impact resistance and other aspects to ensure that the products comply with international and national standards.

4.ISO 9001 Quality Management System Certification

ISO 9001 is a quality management system standard issued by the International Organization for Standardization (ISO). This certification ensures that WPC door frame manufacturers have a stable quality management system in place to ensure product consistency and safety.

5.ISO 14001 Environmental Management System Certification

This certification focuses on the environmental management of the enterprise, and WPC door frame manufacturers that comply with this standard are required to ensure that their production process minimizes the impact on the environment and meets the standards of green manufacturing.

The Key Certification Standards Of WPC Door Frame

1. EN 14351-1 (European Standard for Windows and Doors in Buildings)

This standard specifies safety requirements for exterior doors, including wind pressure resistance, water resistance, air permeability and mechanical stability. If WPC door frames are exported to European market, this standard is the necessary technical basis.

2.GB/T 29418-2012 (China General Standard for WPC Materials)

This standard applies to the Chinese market and covers the physical and chemical properties of WPC materials and their scope of application. For WPC door frames, compliance with this standard means that the weather resistance, strength and environmental performance of the product meets the national requirements.

3.ASTM D7032 (American Standard for WPC Materials)

ASTM D7032 is the U.S. standard for WPC materials, covering the structural performance of the product, flame retardant properties, UV aging resistance and other content. WPC door frames with this certification can circulate in the North American market.

4.GB 18580-2017 (Formaldehyde Release Limit Standard for Interior Decorative Materials)

This standard specifies the upper limit of formaldehyde emission from building decoration materials, and as a composite material, the formaldehyde emission of WPC door frames must comply with this standard in order to ensure that they are harmless to human health.

5. RoHS Directive (Restriction of Hazardous Substances Directive)

RoHS is an environmental protection standard for electrical and electronic equipment developed by the European Union, but the limited requirements for hazardous substances involved are also applicable to building materials. WPC door frames that comply with the RoHS directive ensure that the products do not contain lead, cadmium, mercury and other harmful substances, and improve environmental performance.

How To Choose The WPC Door Frame In Line With Safety Standards?

1. Check the certification mark

In the purchase of WPC door frame, consumers should pay attention to whether the product has CE, SGS, ISO and other certification marks, these marks can prove that the product has undergone rigorous quality and safety testing.

2. Check the test report

Reliable WPC door frame manufacturers will provide third-party organizations (such as SGS, Intertek, etc.) issued by the test report, clear formaldehyde emissions, impact resistance, moisture resistance and other data.

3. Choose well-known brands

Well-known brands usually have a more stringent production control system, and obtain more international certifications, such as Zonle Doors and other well-known companies in the WPC door frame industry has a high degree of market recognition.

4. Pay attention to environmental standards

Consumers should choose products that comply with RoHS, FSC, ISO 14001 and other environmental certifications to ensure that WPC door frames are harmless to the environment and health.

Conclusion

With its superior performance, WPC door frames are gradually replacing traditional wood and metal door frames, becoming an ideal choice for home and commercial buildings. However, the quality of products on the market varies, and consumers must pay attention to the relevant safety marks and certification standards when making purchases to ensure product quality and safety in use. By choosing products that comply with international standards, not only can you improve your home safety, but you can also contribute to the cause of environmental protection.

0 notes