#Warehouse and Sortation Associates

Explore tagged Tumblr posts

Text

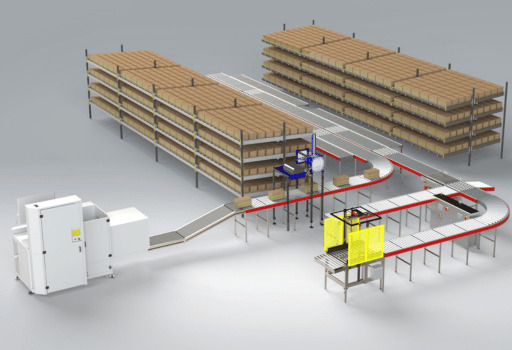

Warehouse Automation Sortation System

Transform warehouses with Adverb's material movement, sortation, picking, storage, and reverse logistics solutions. Mobile robots, ASRS, and software cater to pharma, e-commerce, grocery, cold storage, solar, and battery industries.

#Warehouse and Sortation Associates#Warehouse Sortation Solutions#Warehouse Automation Sortation System

0 notes

Text

Sortation Center warehouse associate

Hiring now: Sortation Center warehouse associate Apply now: https://canadajobbank.org/sortation-center-warehouse-associate-15/

0 notes

Text

Optimizing Efficiency: The Benefits of Warehouse Automation Services

In today’s fast-paced logistics and supply chain industry, efficiency and accuracy are critical for businesses aiming to stay competitive. Warehouse automation services have emerged as a game-changer, helping companies streamline operations, reduce costs, and enhance overall productivity. In this blog, we explore the key benefits and applications of warehouse automation services.

What is Warehouse Automation?

Warehouse automation involves the use of technology, robotics, and software systems to manage warehouse tasks with minimal human intervention. It includes automated storage and retrieval systems (AS/RS), robotic picking solutions, conveyor systems, and warehouse management software (WMS). These technologies work together to optimize material handling, inventory management, and order fulfillment.

Key Benefits of Warehouse Automation

1. Increased Efficiency and Productivity

Automated systems perform repetitive tasks at a much faster pace than human workers. With robots and AI-driven solutions handling order picking, packing, and sorting, warehouses can process higher volumes of goods efficiently, reducing labor-intensive operations.

2. Improved Accuracy and Reduced Errors

Automation significantly minimizes human errors in order fulfillment. AI-powered warehouse management systems ensure accurate picking and packing, reducing returns due to incorrect shipments. Barcode scanning and RFID tracking also enhance inventory accuracy.

3. Cost Savings and Labor Optimization

By reducing reliance on manual labor, businesses can lower operational costs. Automation helps redistribute human resources to more strategic roles while mitigating challenges related to labor shortages and workforce fatigue.

4. Better Space Utilization

Automated storage and retrieval systems enable warehouses to optimize vertical space, allowing for higher storage capacity within the same footprint. This maximizes storage efficiency and improves warehouse organization.

5. Enhanced Safety

Warehouse automation reduces the risk of workplace injuries by minimizing the need for employees to perform physically demanding or hazardous tasks. Autonomous robots and conveyor systems transport goods safely, preventing accidents associated with manual handling.

Popular Warehouse Automation Technologies

Autonomous Mobile Robots (AMRs): These self-navigating robots transport goods within the warehouse, improving picking and sorting efficiency.

Automated Guided Vehicles (AGVs): AGVs follow predefined paths to move inventory between locations.

Conveyor and Sortation Systems: Automated conveyor belts and sorting systems accelerate order processing and distribution.

Pick-to-Light and Put-to-Light Systems: These systems use LED lights to guide warehouse workers in picking and placing items, reducing errors and increasing speed.

AI-Powered Warehouse Management Systems (WMS): AI-driven software solutions optimize inventory tracking, demand forecasting, and workflow automation.

Future of Warehouse Automation

The future of warehouse automation is driven by AI, IoT, and machine learning. Smart warehouses are adopting predictive analytics, real-time tracking, and robotic process automation to improve decision-making and operational efficiency. As technology advances, fully autonomous warehouses are becoming a reality, revolutionizing supply chain logistics.

Conclusion

Warehouse automation services are transforming logistics by increasing efficiency, reducing costs, and enhancing accuracy. As businesses continue to invest in automation technologies, they will gain a competitive edge in an ever-evolving market. If you’re looking to optimize your warehouse operations, now is the time to explore automation solutions tailored to your business needs.

Ready to automate your warehouse? Contact us today to learn how our warehouse automation services can elevate your operations.

0 notes

Text

Flipkart Warehouse Delhi: A Key E-Commerce Logistics Player

The country's biggest e-commerce player, Flipkart, has developed a strong logistics chain to facilitate timely and hassles-free delivery of products across the country. Flipkart warehouse Delhi is one of the nodes of the chain, which significantly contributes towards servicing the enormous consumer base of the National Capital Region (NCR). The following article explains the dynamics of Flipkart's Delhi warehouse, strategic significance of the warehouse, operational effectiveness, technology skills, and joint venture partnership with infrastructure partners such as Guruji Infrastructure.

Strategic Significance of the Delhi Warehouse

The capital city and main business hub of Delhi is particularly logistically challenging with very high population density and high demand for e-commerce goods. The Delhi Flipkart warehouse has been positioned to counter this by delivering the goods to the customer as quickly as possible. Apart from shortening delivery time, to have such a facility means higher customer satisfaction, which is essential to survive the high e-commerce business.

Operational Excellence and Efficiency

The operational excellence of Flipkart Delhi warehouse itself is an example to the company's operational excellence guarantee. The warehouse has been completely outfitted to accept an unprecedented variety of goods, ranging from fashion commodities to electrical goods, in an attempt to accommodate all the products in the most wholesome environment possible. Sophisticated inventory management software tracks products in real-time to prevent errors and deliver precisely what has been ordered. The warehouse remains open round-the-clock, with trained personnel taking turns ensuring that the enormity of the orders flows without an interruption.

Technological Innovations and Automation

Technology dominates warehousing to optimize efficiency and accuracy. The Flipkart's Delhi sortation center has world-class automated facilities such as Automated Guided Vehicles (AGVs) and robotic order sorters. With automation, orders sort and get packed automatically, bridging the order-to-dispatch time with a visible lag. The type of level Flipkart has mechanized, having a chance to see their sortation center at Delhi gives one an understanding of how automated the center is, where it sorts anything from 800,000 packets per day. Automation not only enhances the process, but it also reduces the cost of running in the long term.

Tie-up with Guruji Infrastructure

Development and construction of Flipkart's Delhi warehouse have been carried out in association with Guruji Infrastructure, a top pre-engineered building solutions company. Guruji Infrastructure offers tailor-made pre-engineered industrial building solutions at a quicker turnaround without compromising on costs and with less material utilized for wastage. Pre-engineered and prefabricated industrial building construction experience came in handy while designing the warehouses that will be capable of handling Flipkart's high volume of demand.

The collaboration with Guruji Infrastructure rendered the warehouse functional and eco-friendly. The incorporation of pre-fabricated structures and sandwich panels has provided energy-efficient structures that regulate interior conditions at the best levels to preserve them, with no requirement for excessive heating or cooling. This aspect of sustainability is just one of a variety of aspects of Flipkart's overall shift towards greenness, and therefore the warehouse is an influencer to be emulated by further infrastructure development.

Employment Opportunities and Economic Impact

The Flipkart warehouse in Delhi has been a stimulus to the economy of the city, providing sufficient employment opportunities. From warehouse in-charges to e-commerce managers, the job is diverse. Not only does the job ensure equal remunerations but also skill enhancements, thus contributing to socio-economic development of the region as a whole. With e-commerce keeping growth momentum going, the job is ready to scale even newer heights, giving employment to huge numbers of individuals in and around Delhi.

Accessibility and Connectivity

The location of Flipkart Delhi warehouse has been chosen with utmost concern for connectivity and accessibility. Neighbourhood of important transport hubs provides convenient pickup and delivery of products. Further, the location near public transport in the shape of bus and metro facilities ensures easy movement by staff, hence promoting operating efficiency in the warehouse. Seamless movement of staff and goods is enabled by convenient accessibility, leading to speedy completion and dispatch of orders.

Customer-Focused Strategy

The company of Flipkart relies on a customer-focused strategy, and the Delhi warehouse is evidence of the same. By using the advanced technology and planning, the warehouse is customer-centric and delivers on time and in good condition. Customer satisfaction has been one of the key factors for success and growth of Flipkart in e-shopping. Delivering on time, prompt order fulfillment, and effortless return processing are some of the most important sectors where Delhi warehouse has played a significant role.

Future Outlook and Expansion

As India's e-commerce space continues to grow, Flipkart is in a good position to expand its warehousing capacity to keep up with growing demand.

Delhi warehouse's success is a model for future warehouses, the paragon of strategic location, technological upgradation, and partnership with industry giants such as Guruji Infrastructure. The game-changing strategy puts Flipkart a notch ahead of the rest in the e-commerce space years before it's going to be catching up with changing consumer behavior. The organization is always looking to maximize efficiency and sustainability so that its logistics infrastructure can be standardized and resilient.

Conclusion

Flipkart's Delhi warehouse is one such instance of operational excellence, technical innovation, and customer satisfaction that the company has been emphasizing. By forming strategic alliances with firms like Guruji Infrastructure, Flipkart has created a warehousing network that not only meets current requirements but is sure to expand in the future. As the arena for e-commerce keeps changing, the Delhi warehouse and similar warehouses will be the ones to break or make online shopping in India. By continuing to focus on efficiency, environmentally friendly business, and customer satisfaction, Flipkart is raising the bar for the logistics and e-commerce sectors.

0 notes

Text

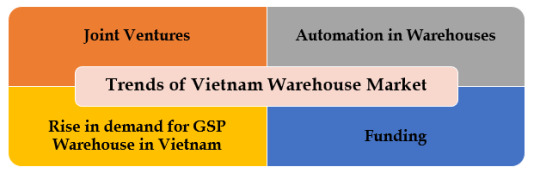

Vietnam Logistics Market Flourishes: CEP and Warehousing Sector Generate over USD 5 Bn in 2022, Fueled by Joint Ventures and Modern Warehousing Systems. What Awaits the Future? :Ken Research

Buy Now

1.Emerging Trends and Developments in Vietnam's Warehousing Market: Joint Ventures, Automation, GSP Warehouse Preference, and Recent Funding Surge.

Interested to Know More about this Report, Request for a sample report

Logos Property and Manulife Investment Management joined forces in 2022 to construct an advanced logistics factory, covering an area of over 116,000 sqm and valued over $80 Mn. Moreover, GLP entered the Vietnamese market through a $1.5 Bn joint venture with SLP.

E-commerce companies are utilizing AI-powered warehouses and sorting centers spanning 0.3 Mn sqm to decrease delivery time during peak periods. Tiki NOW Smart Logistics has integrated robots for task execution, enhancing warehouse efficiency and enabling sellers to save 30% - 40% in costs.

Investment in pharmaceutical storage systems or GSP warehouses is increasing in Vietnam, with foreign firms such as DKSH, Zuellig, and Mega making substantial investments to improve cost-efficiency and optimize manpower in warehouses.

Vietnamese on-demand warehousing platform, Wareflex, secured $785,000 in pre-seed funding from Genesia Ventures and Antler. Additionally, Mirae Asset Daewoo Co. and Naver Corporation, prominent South Korean companies, invested $37 Mn in a warehouse located in Bac Ninh, Vietnam.

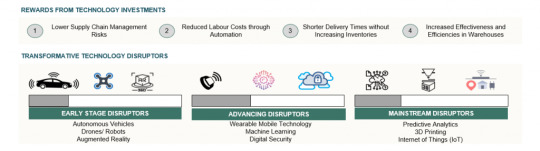

2.Automation Surge: Vietnam's Growing Demand for Modern Warehouses Driven by Increased Investment in New Technologies.

Visit this Link :- Request for custom report

Next generation supply chains in Vietnam are utilizing robotics and automation to perform task such as picking, sorting, inspecting, handling to improve overall efficiency and speed to market. Some warehouses are turning to autonomous vehicles to bring merchandise to sortation while Drones & RFID will be used for Inventory Management. The opportunities seem endless which will result in greater efficiency and productivity.

3.Tech Trends Unleashed: Big Data and Augmented Reality Empower Vietnam's CEP Market in Response to Consumer Demand.

Market Maxomony

Vietnam Logistics Market Segmentation

By Service Mix

Freight Forwarding

Warehousing

CEP

Value Added Services

Vietnam Freight Forwarding Market Segmentation

By Mode of Freight

Road Freight

Sea Freight

Air Freight

By Type of Freight

International Freight

Domestic Freight

By Types of Operators

Small Fleet Operator (SFO)

Medium Fleet Operator (MFO)

Large Fleet Operator (LFO)

By End-User

Retail

Oil and Gas

Textiles

Pharma

Others

Vietnam Warehousing Market Segmentation

By Warehousing Types

General/Industrial/Retail

CFS/ICD

Cold Storage

Agriculture and Others

By Warehouse Locations

Northern

Central

Southern

By End-User

Retail

Oil and Gas

Textiles

Pharma

Others

Request a Call with Expert to know more about Latest Trends

Major Players Mentioned in the Report:

Yusen Logistics

Transimex

Gemadept Corporation

Maersk

Kuehne+Nagel

MP Logistics

ITL

Vietnam Post

Viettel Post

Vietnam Maritime Corporation

Expeditors

Bee Logistics

DB Schenker

Vinafrieght Joint Stock Company

CJ Gemadept

Ceva Logistics

GHN Express

DHL VNPL Express

EMS

Key Target Audience

E-Commerce Companies

Third-Party Logistic Providers

Potential Market Entrants

Freight Forwarding Companies

Warehousing Companies

Cold Storage Companies

Industry Associations

Consulting Agencies

Government Bodies & Regulating Authorities

Time Period Captured in the Report:

Historical Period: 2017-2022

Base Year: 2022

Forecast Period: 2022-2027

For More Insights On Market Intelligence, Refer to the Link Below: –

Vietnam Logistics Market Outlook to 2027

Related Reports by Ken Research: –

Indonesia Logistics Market Outlook to 2027

#Vietnam Supply Chain Industry#Vietnam Logistics Market#Warehousing Industry Vietnam#Delivery Services Sector Vietnam#Vietnam Freight Forwarding Business#Inventory Distribution Industry Vietnam#Vietnam Transportation Market#Logistics Sector Vietnam#Number of Shipping Fleets in Vietnam#Number of Sea Ports in Vietnam#Number of Truck Fleets in Vietnam#Number of Warehouses in Vietnam#Vietnam Freight Forwarding Services Market#Logistics Services Industry Vietnam#Vietnam CEP Services Sector#Value Added Services Division Vietnam#Vietnam Road Freight Market#Sea Freight Industry Vietnam#Vietnam Air Freight Sector#Retail Logistics Division Vietnam#Oil Shipping Market Vietnam#Vietnam Gas Transport Industry#Pharma Warehousing Sector Vietnam#Industrial Delivery Services Sector Vietnam#Vietnam Retail Warehouses Market#CFS Warehouses Industry Vietnam#Vietnam ICD Warehouses Division#Cold Storage Warehouses Sector Vietnam#Vietnam Agriculture Warehouses Market#Vietnam International Logistics Shipments

0 notes

Text

Amazon Package Sorter - Day Shifts - Shawnee Mission, Kansas

Amazon Sortation Center Warehouse Associate Job Overview You'll be part of the dedicated Amazon team that is the first stop on the journey from the warehouse. Our fast-paced, physical roles take place in a sortation center. You will be sorting, scanning,... http://dlvr.it/SnK4Ks

0 notes

Text

Why Use MIWA Robotics Warehousing AGV?

Automated Guided Vehicles (AGVs)

Automated guided vehicles help to transport materials, supplies, and inventory within warehouse facilities. AGVs are used in operations to replace manually-driven forklifts or pick carts. Some AGVs autonomously navigate warehouse facilities by following established routes that are marked by wires, magnetic strips, tracks, sensors embedded in the floor or other physical guides. Other AGVs utilize cameras, lidar, infrared and other advanced technology to navigate workspaces, identify obstacles and avoid collisions.

Benefits of robotic warehousing solutions

Fewer Errors

Automation in warehousing limits the risk of human error with programmable, repeatable solutions. MIWA ROBOTICS designs and manufactures warehouse robots for high-efficiency and high-accuracy to increase productivity.

Reduced Expenses

Many warehouse operations, such as picking and sortation, traditionally have significant labor requirements, demanding more workers to spend more time fulfilling orders. With the integration of warehouse automation, you will need fewer people to handle menial tasks, allowing you to allocate your employees to more complex tasks and reducing the need for an expansive workforce.

Better Customer Satisfaction

Warehouse automation allows you to operate on time and on budget, reducing delays and getting orders into the hands of your customers more quickly. With robotic warehouse solutions, you also gain the benefit of increased traceability, which gives customers a sense of control over their orders and allows you to keep a more accurate record of your inventory, as well.

Enhanced Warehouse Safety

Warehouse automation allows you to operate on time and on budget, reducing delays and getting orders into the hands of your customers more quickly. With robotic warehouse solutions, you also gain the benefit of increased traceability, which gives customers a sense of control over their orders and allows you to keep a more accurate record of your inventory, as well.

Advanced Efficiency and Productivity

Warehouses, especially those operating in the e-commerce industry, have witnessed a massive surge of growth and demand in recent years, increasing the need for innovative solutions. Using robotics in warehouse material handling operations can increase productivity by automating repetitive tasks and optimizing specific processes using warehouse robots and data input.

Enhanced Ability to Meet High Capacity Demands

High, continually-increasing demands, coupled with labor shortages, has put a lot of pressure on warehouses. Relying solely on manual labor can jeopardize productivity and result in injuries, delays, and errors. With fully-automated warehouse robots, you can optimize menial tasks and reduce the possibility of error, promoting more efficient fulfillment and ensuring customer satisfaction.

Space Efficient

Maximizing the use of space within a warehouse promotes efficiency, consistency, and optimizes resource utilization. Vertical integration can help warehouses save valuable floor space, especially with automated warehouse storage robots and retrieval processes.

Economic Environment Regulation

Ongoing labor shortages can be a detriment to operational effectiveness. Climate controlled warehouses are few and far between due to the astronomical costs associated with heating and cooling needs. Strategically using robots and cobots in warehouses can isolate areas that should or should not be temperature-controlled; areas in which only robots maneuver do not need air conditioning or heating, and keeping these areas separate can keep temperature regulation costs down while also providing a comfortable environment for your employees.

MIWA ROBOTICS - The fastest robotic picking AGV solution for warehouses available. Improve warehouse productivity 8 – 10x over manual picking. Dramatically reduce demand for forklifts and number of human touches. Let’s customize a solution to fit your business and your budget.

Miwa Robotics

https://www.miwarobotics.com/

1 note

·

View note

Text

Amazon Sortation Center Warehouse Associate - Indeed Jobs International

Amazon Sortation Center Warehouse Associate – Indeed Jobs International

Competitive wage paid weekly, with overtime for more than 40 hours. Candidates must be 18 years or older with the ability to understand and adhere to all job…

View On WordPress

0 notes

Text

Warehousing Worker - Part-Time - Up to $20.55

Warehousing Worker – Part-Time – Up to $20.55

Job title: Warehousing Worker – Part-Time – Up to $20.55 Company: Amazon Job description: Amazon Sortation Center Warehouse Associate Pay rate: Up to $20.55 Job Overview You’ll be part of the dedicated Amazon team that is the first stop on the journey from the warehouse. Our fast-paced, physical roles take place in a sort… Expected salary: Location: Mountlake Terrace, WA Job date: Sun, 21 Nov…

View On WordPress

0 notes

Text

Sortation Center warehouse associate

Hiring now: Sortation Center warehouse associate Apply now: https://canadajobbank.org/sortation-center-warehouse-associate-14/

0 notes

Text

The Future of Logistics: Exploring Automated Warehouse Systems

In an era where speed, efficiency, and accuracy define success in logistics and supply chain management, automated warehouse systems have emerged as a game-changer. These intelligent systems leverage advanced technologies to streamline warehouse operations, reduce human error, and enhance productivity. In this blog, we explore the benefits, components, and future trends of automated warehouse systems.

What Are Automated Warehouse Systems?

Automated warehouse systems are integrated solutions that utilize robots, artificial intelligence (AI), machine learning, and the Internet of Things (IoT) to perform warehouse tasks with minimal human intervention. These systems optimize storage, retrieval, sorting, and inventory management, ensuring seamless operations in distribution centers and warehouses.

Key Components of Automated Warehouse Systems

Automated Storage and Retrieval Systems (AS/RS)

These systems use robotic arms and shuttles to store and retrieve items efficiently, reducing labor costs and increasing warehouse space utilization.

Autonomous Mobile Robots (AMRs)

AMRs navigate warehouse floors independently, transporting goods from one location to another without human guidance, improving speed and reducing operational delays.

Conveyor and Sortation Systems

Conveyor belts and sortation systems streamline the movement of products, directing items to their designated locations with precision.

Warehouse Management Systems (WMS)

A robust WMS integrates with automation to optimize inventory tracking, order fulfillment, and supply chain visibility.

Radio Frequency Identification (RFID) and Barcode Scanners

These technologies enhance inventory accuracy by enabling real-time tracking and automated data collection.

Benefits of Automated Warehouse Systems

Increased Efficiency: Automated processes significantly reduce the time required for order processing and fulfillment.

Reduced Operational Costs: By minimizing human labor and errors, businesses can lower overall costs and enhance profitability.

Enhanced Accuracy: AI-powered systems ensure precise inventory tracking, reducing losses due to misplacements or errors.

Scalability: Automated solutions allow warehouses to expand operations seamlessly without requiring significant workforce increases.

Improved Workplace Safety: Robotics and automation reduce the risk of workplace injuries associated with manual material handling.

Future Trends in Automated Warehousing

AI-Driven Decision Making

Advanced AI algorithms will further enhance demand forecasting, inventory optimization, and predictive maintenance.

5G-Powered Connectivity

Faster and more reliable communication between automated systems will improve real-time monitoring and efficiency.

Integration of Augmented Reality (AR)

AR-based systems will assist warehouse personnel with navigation, order picking, and inventory checks.

Sustainable Automation

Eco-friendly warehouse solutions, such as energy-efficient robots and green logistics, will become a priority.

Conclusion

Automated warehouse systems are revolutionizing the logistics industry by increasing efficiency, accuracy, and scalability. As technology continues to advance, businesses that invest in warehouse automation will gain a competitive edge in the evolving market landscape. Whether it’s AI-powered robots, autonomous material handling, or real-time inventory tracking, the future of warehousing is automated and optimized for success.

Are you ready to embrace warehouse automation? Contact us to explore the best solutions tailored to your business needs.

0 notes

Text

Amazon Picker/Packer (Day Shifts) - Nashville, Tennessee - $18.25

Amazon Sortation Center Warehouse Associate Job Overview You'll be part of the dedicated Amazon team that is the first stop on the journey from the warehouse. Our fast-paced, physical roles take place in a sortation center. You will be sorting, scanning,... http://dlvr.it/SmPPjV

0 notes

Text

Frankie Antonio’s Story

LInk: https://www.youtube.com/watch?v=V0YUe9PPZDc

Video Description: Frankie with glasses in red shirt is sitting and signing toward the camera

Transcript:

Hello. I am Frankie Antonio. My hometown is San Diego, California. I am working at Amazon DSDF as a Sortation Associate. I am doing various things, such as pushing and sorting. I am really doing many things there. I often sign Amazon starting with A in the shape of smile. There are a few different signs for Amazon, but I like the sign of Amazon based on its ironic smile. Going to work, I often use public transportation or carpool. I rarely have my family pick me up and drop me off. My work hours are more of night shift, starting from 8:15pm in evening to 4am or 5am early in morning. After work, I often get back home by my co-worker offering me a ride. It is really dark outside in morning hours, and my co-worker is just living a few blocks away from my place, I feel lucky. I just do not mind to ride on buses going to work in afternoon.

At Amazon, there are several hearing people working there, no Deaf or DeafBlind person working there in night shift. I am basically the only DeafBlind person working there. There is one Deaf person working during day shift. We work separately.

In order to communicate with most of my colleagues and supervisor, we use text messaging or pen and paper. We often communicate via text messaging. Technology is just amazing. We communicate with each other efficiently and easier. If text messaging is not clear to me, we will use video relay interpreting on computer screen. It is my right as an employee to have full communication accessibility with everything at the work site. They do not mind. It is really cool.

Some workers at the work site know who I am, some not. We still communicate via text messaging. They are fully aware that I am DeafBlind, struggling with balance or could not see some area very well. There are a few dark zones. They are more understanding of what I need as an employee there.

With Coronavirus (COVID-19) going on, I am considered as an essential worker. I have to use orange vest and work ID to get on public transportation going there. It is required to show work ID to get on buses. I also have to use face mask. It was an optional, but it is now required. Once I get there, there are plenty of hand sanitizers that we have to use more often. We also have to practice social distancing, 6 feet away from each other. Once I get to the building, they are doing temperature check on us to make sure we are ok. During lunch break, there was only one lunch break room, but now it is two lunch room to meet the minimum number of people, up to 21 people in total in each room. We have about 50 to 60 people working at the building We separate our lunch break by following the first letter of our last name, for example A to E then F to K. There are three different groups for lunch break, and each group has different lunch break time. During lunch break, we have to sit 6 feet away from each other. They are very strict with safety enforcement. At the warehouse, we did not see any positive COVID-19 cases. It is really good thing, and we have to be more cautious. There are a few cases happening at the other sites, not ours. We have been very cautious.

I forgot to add that I have been working at Amazon since July 2018.

Thank you!

0 notes

Text

Why Warehouse Robots Are Popular In The Market?

Due to the rise of e-commerce and omnichannel retail, the number of online customers has increased. And, with the technology advancements, they are demanding for quicker order fulfillment, order delivery and real-time tracking of orders. These demands are forcing businesses to improve their operational efficiency and productivity. Hence, the industry leaders are stepping ahead to invest in robotic solutions like warehouse robots to bring automation within the facility and increase their throughput. These automated solutions can drive a large number of advantages that we are going to discuss in below sections.

Why Are Warehouse Robots Gaining Popularity In The Market?

Earlier robots transcended the realm of Sci-fi fantasy, and now they are making revolutionary waves in multiple industries. The industries that deal with highly complex and tedious tasks are enjoying the benefits by implementing the new generation of robotic solutions i.e., warehouse robots. They have vastly grown from being controlled by a human operator to being fully autonomous. They are possessing cutting-edge technologies and capable of emulating human intelligence in one or another form. Due to this reason, their demand in the areas, requiring human intelligence and decision-making capabilities, is increasing. They are vision-powered and can analyze, see, and act suitably. The warehouse robots are trained with machine vision algorithms and armed with cameras. They hold the capacity of capturing videos, image, analyze them, and then respond accordingly. The potential of warehouse robots to respond as humans do has indeed opened up multiple frontiers in several industries.

Benefits Of Warehouse Robots:

They can handle routine tasks while maintaining higher accuracy for a longer duration.

They help in boosting productivity within the facility without even impacting the quality.

The warehouse robots don’t need any break, leaves, or holidays.

They can continue working throughout a long shift.

These bots are also capable of selecting a quick pick path, stopping associates at the right inventory location and demonstrating a picture of the product and the quantity to grab as well.

About GreyOrange Pte Ltd.

As a leading supply chain automation company, GreyOrange provides brilliant solutions, including warehouse robots, autonomous mobile robots, warehouse execution software, and sortation robots. The organization is catering to the needs of thousands of customers for more than a decade. All the solutions are possessing high-quality standards, advanced features, and functionalities. Anyone can place an order for the products by visiting the official website.

Source : Why Warehouse Robots Are Popular In The Market?

0 notes

Text

Warehouse Laborer - Part-Time - Up to $15.75

Warehouse Laborer – Part-Time – Up to $15.75

Job title: Warehouse Laborer – Part-Time – Up to $15.75 Company: Amazon Job description: Amazon Sortation Center Warehouse Associate Pay rate: Up to $15.75 Job Overview You’ll be part of the dedicated Amazon team that is the first stop on the journey from the warehouse. Our fast-paced, physical roles take place in a sort… Expected salary: Location: Suffield, CT Job date: Mon, 08 Nov 2021…

View On WordPress

0 notes

Text

How Robotic Warehouse Systems Can Boost Your Business ROI

The rapid e-commerce expansion, global trade competition, and aging workforce have fueled the transformation in the logistics and supply chains. And, surely that day is not far when an army of robots can be seen zipping around a warehouse for fetching orders, scanning pallet labels, or restock inventory. The technology is continuously evolving, and robotic warehouse systems are becoming more mature and affordable with it. For every business, the productivity boost and cost reduction are the two main things that matter, and these solutions can efficiently help enterprises in achieving these goals by driving lots of other benefits.

Robotic Warehouse Systems:

The robotic warehouse systems can decrease unnecessary walking by providing work to the operators in the active field. They are capable of navigating the long distance from the induct to the active area on their own. They plan the routes efficaciously. They can avoid congested fields, which can slow down the travel time throughout the distribution centers. They lead the picker, which showcases the product and quantity of the pick at each location. These systems are capable of speeding the training and boosting associating in-aisle productivity.

Mobile Sortations System:

The mobile sortation system is capable of lifting, packing, sorting, and shipping needed, which can take the entire warehouse efficiency to the next level. This system can bring distinct benefits and help shipper in processing an enhanced load of the parcels or products quickly. They can deliver the organization’s associates the information, required to boost or improve the entire competence and lower costs. There could be mistakes in manual sorting procedures like packages can be labeled wrong, further dispatched at the wrong place. This kind of error can result in consumer dissatisfaction. With the mobile sortation system, such mistakes can be avoided easily and increase productivity as well as efficiency within the facility.

About GreyOrange Pte Ltd.

GreyOrange is a multinational technology company. The organization is in the industry for more than a decade. It holds expertise in designing, manufacturing, and deploying advanced robotic solutions like robotic warehouse systems, autonomous mobile robots, and mobile sortation system. The organization holds a core team of R&D that analyzes the functionality and quality of the products before launching them in the market. The team experts focus on providing solutions to their clients' queries. Over these years, the best quality products and exceptional customer support service have helped the organization to achieve a higher degree of consumer satisfaction.

Source: How Robotic Warehouse Systems Can Boost Your Business ROI

0 notes