#Wire and Cable Displacement Sensor

Explore tagged Tumblr posts

Text

Biss-C Linear Draw Wire and Cable Displacement Sensor Transducer

Key features

Exceptional Durability: Designed for 5 million fatigue cycles, ensuring long-lasting performance.

Advanced Digital Communication: Absolute position sensing with power-off memory for reliable data retention.

Durable Wire Outlet: Ceramic material enhances wear resistance, extending the life of the steel wire rope.

Data Interfaces: Equipped with Biss connections for seamless data integration and communication.

High-Quality Construction: Features a 0.8mm diameter, imported flexible stainless steel wire rope with a nylon coating for reduced friction and enhanced durability.

Superior Pull Head Design: Special fixation method with a tensile limit 10 times greater than competitors, allowing a 15° angle deviation.

User-Friendly Configuration: Easily set parameters via communication protocol or software, offering intuitive and straightforward operation.

Versatile Operation Modes: Supports query and auto-return modes with feedback on position and speed. Programmable for baud rate, positioning functions, counting direction, and speed feedback.

0 notes

Text

Silken Synapses

Jazz x Reader (NSFW)

AN: Happy Valentines Day. Reader has a dick but no pronouns are used.

The way the city lights filtered in through the blinds of your apartment window made Jazz stare up at you like you had to be the Allspark incarnate.

Streaks of vibrant blue danced over your skin with every bounce, your body leaving your silhouette cast across the wall. Violet caught the hard line of your jaw and optic ridge, and a rose highlights your aft as you rock and move. You looked like you were painted in neons and the midnight hour. And the noises you made? Felt like they were ripped from the stars themselves, bright and calling to his spark in the dark of the night.

Your hips rolled again, and the sound he made was all static and buzz, his vocoder struggling with how his sensors were running wild at the pleasure racing through him. One of your hands slid across his exposed panel, wires all on display for your discretion. And you made good use of such a treat, fingers skimming along rubber, dragging a nail lightly down one until the friction caught, and you opt to instead tug the flat cabling.

Jazz's intake dropped open in a drawn out groan.

“Frag, baby, you're filthy.”

His skittered, scrambled visual field was splintering, fracturing, his view of your form multiplying like a kaleidoscope of delight. Watching your other hand trail down your chest and slowly nearing your own spike- penis? Dick, cock, rod, too many words that made his currently overheated processor scramble to fit in one slot and overwhelm it.

…SPEAKING of fitting in slots, you began bounce on his spike more, slick and warm and- PRIMUS, that, that nasty little trick you kept doing, squeezing and tightening around him before relaxing again and moving quicker. It made Jazz grit his denta, throwing his helm back with a hiss each time.

“Tease…!”

The mass displaced mech was rewarded with a husky, silky chuckle that he swore, up and down, was weaving through his audials and caused lightning to zip down his backstruts. Jazz felt like he was going mad, ESPECIALLY as you looped a digit around a green wire in the upper left quadrant and unplugged it, dragging your tongue along the tip of the metal jack plug and sucking lewdly on it. He knew you wouldn't pull out anything important, he'd marked what could and couldn't be toyed with. But it didn't change the fact that when these were toyed with, they made his EM field buzz and flicker.

“Swear I can feel that. It's like my nerves are all tingling…”

You gasped, biting your lip and arching your back. Fist your member and begin stroking faster as you ride him harder, the sound of the flesh and skin clapping against the steel of his plating and the slick of lube and transfluid making for obscene noises ripped from Jazz's fantasies and sounding like a salacious symphony. His biolights flicker in patterns, that he can barely see through your skin every time he sinks deep into your aft- ass. Spike painfully pressurized and hitting deep within your depths, bullying your prostate pleasurably. Hellishly.

Grunting, he gripped your hips, and began helping you move quicker, venting in puffs and his cooling fans whirring louder.

“You close, my pretty little Porsche?”

“Mhm…!”

“Good.”

Bottom left quadrant had the most wires you could pull, and pull you did. In fact, you looped the whole mass around your hand, and yanked as you gasp and release into your condom. His systems went haywire briefly, optics locked onto the glitchy, iridescent image of you, and Jazz's overload crashed his systems like a powersurge, making the porsche unload into you.

#tf x human#tf x reader#transformers x reader#transformers x human#valveplug#tf x reader smut#tf x human smut#squibs writes#tf jazz#transformers jazz#jazz x reader

70 notes

·

View notes

Text

Special Hazards Fire Protection Safeguarding High-Risk Environments

What is Special Hazards Fire Protection?

Special hazards fire protection refers to the systems and practices used to detect, suppress, and control fires in areas where conventional sprinkler systems are inadequate or inappropriate. These areas typically include:

Power generation plants

Data centers and server rooms

Chemical processing facilities

Aircraft hangars

Marine environments

Clean rooms and laboratories

Museums and art storage

Industrial machinery enclosures

Each of these environments presents distinct fire risks due to the nature of the materials or equipment involved. For instance, water from a traditional sprinkler system can severely damage electronic equipment or react dangerously with certain chemicals. Special hazards systems are engineered to handle these challenges effectively.

Components of a Special Hazards Fire Protection System

A comprehensive special hazards fire protection system includes several key components:

1. Fire Detection and Alarm Systems

Rapid detection is crucial in special hazard environments. Advanced smoke, heat, and flame detectors are used, often employing technologies such as:

Aspirating Smoke Detection (ASD): These systems continuously sample air and are highly sensitive to even small amounts of smoke, making them ideal for clean rooms and server spaces.

Infrared and Ultraviolet Flame Detectors: These devices detect flames quickly and are often used in environments where fires can ignite and spread rapidly.

Linear Heat Detection: Useful for protecting cable trays and conveyor belts, this type of system detects heat along a wire or sensor cable.

2. Suppression Systems

Depending on the nature of the hazard, suppression agents can vary widely:

Clean Agents: Non-conductive, non-corrosive, and residue-free, clean agents like FM-200, Novec 1230, and CO₂ are used in data centers, telecommunication rooms, and control panels.

Foam Systems: Ideal for flammable liquid storage and aircraft hangars, foam forms a blanket over the fire, cutting off oxygen and preventing re-ignition.

Dry Chemical Systems: These are fast-acting systems used for Class B (flammable liquids and gases) and Class C (electrical) fires.

Water Mist Systems: They use high-pressure water to create a fine mist that cools the fire and displaces oxygen without damaging equipment like a traditional sprinkler might.

3. Control and Notification Panels

Centralized control panels monitor the fire protection systems and provide alerts. These panels are designed to integrate with building management systems and can initiate emergency shutdowns or notify first responders automatically.

4. Manual Release Stations and Alarms

In addition to automatic activation, most systems include manual pull stations for added safety, allowing personnel to activate suppression systems in case of a confirmed fire.

Applications and Industry Use Cases

Data Centers and Server Rooms

In environments where downtime equals significant financial loss, clean agent suppression systems are the go-to solution. These systems act quickly and leave no residue, ensuring minimal disruption to operations.

Power Generation Facilities

Turbine enclosures and transformer rooms are protected using CO₂ or water mist systems, which can suppress fires without harming expensive electrical equipment.

Chemical and Petrochemical Plants

These facilities often deal with volatile substances. Foam and dry chemical systems are commonly used, tailored to the specific flammable or reactive materials present.

Aviation and Marine Industries

Aircraft hangars and ship engine rooms face high fire risk. High-expansion foam and water mist systems are employed to rapidly suppress fires without damaging sensitive equipment or cargo.

Benefits of Special Hazards Fire Protection

1. Tailored Solutions

Each system is designed to meet the unique risks of a particular environment. This customization ensures that the protection is both effective and efficient.

2. Rapid Fire Suppression

Special hazards systems are designed for fast activation and response, minimizing fire damage and reducing business downtime.

3. Equipment and Asset Protection

Using appropriate suppression agents like clean gases or water mist helps avoid secondary damage that traditional water-based systems might cause.

4. Regulatory Compliance

Many industries are required to meet specific fire protection standards. Special hazards systems ensure compliance with codes such as NFPA 2001 (Clean Agent Fire Extinguishing Systems), NFPA 12 (CO₂ Systems), and others.

Challenges in Special Hazards Fire Protection

Despite its benefits, special hazards fire protection presents several challenges:

Complex Design Requirements: Engineers must deeply understand the protected environment and tailor systems precisely.

Cost: These systems are more expensive to design and install compared to traditional fire suppression systems.

Training: Facility personnel need specific training to operate and maintain special hazard systems safely.

Regulatory Hurdles: Navigating the numerous fire protection codes and standards can be challenging without expert guidance.

Choosing the Right Fire Protection Partner

Implementing an effective special hazards fire protection system requires collaboration with experienced professionals. When choosing a fire protection partner, look for:

Proven industry experience

Compliance with NFPA and local fire codes

Capabilities in system design, installation, and maintenance

Strong track record of system reliability and customer support

Conclusion

Special hazards fire protection is a critical investment for industries operating in high-risk environments. It offers precise, efficient, and reliable fire suppression tailored to the specific challenges of sensitive or volatile settings. As technology and operational complexity increase, the demand for specialized fire protection solutions continues to grow. By adopting the right systems and working with knowledgeable experts, businesses can ensure safety, minimize downtime, and protect valuable assets from the devastating impact of fire.

0 notes

Text

Importance of Fire Fighting Systems in Large-Scale Data Centers

Data centers are the backbone of countless businesses and services, providing the infrastructure necessary for storing and processing enormous volumes of information. However, these highly complex facilities face a significant operational risk—fire hazards. The potential damage from fire in a data center goes beyond physical destruction, potentially resulting in data loss, service interruptions, and economic setbacks. Consequently, robust fire fighting systems are indispensable for safeguarding these vital infrastructures.

The Unique Fire Risks in Data Centers

Data centers house dense arrays of servers, networking equipment, and power systems that operate continuously, generating substantial heat. Despite state-of-the-art cooling systems, the combination of high temperatures, electrical wiring, and flammable materials, such as plastic cables, creates a heightened risk of fire. Furthermore, due to their sensitive nature, these environments require fire suppression methods that avoid damaging equipment or disrupting operations.

Key Components of Fire fighting Systems in Data Centers

To mitigate the risks, firefighting systems in data centers are designed with a multi-layered approach, incorporating fire prevention, early detection, suppression, and containment strategies. Below are the primary components:

Fire Detection Systems

Very Early Smoke Detection Apparatus (VESDA): Data centers use advanced smoke detection systems like VESDA that can identify even minuscule traces of smoke at the incipient stage of a fire. These systems analyze air samples continuously, providing early warnings and allowing prompt intervention.

Heat Sensors: In areas where smoke detection may be insufficient, such as server racks or power rooms, heat sensors monitor temperature fluctuations and trigger alarms if unusual changes occur.

Fire Suppression Systems

Clean Agent Fire Suppressants: These are non-conductive and residue-free chemicals, such as FM-200 and Novec 1230, specifically designed for sensitive environments like data centers. They extinguish fires by removing heat or displacing oxygen while ensuring no damage to equipment.

Inert Gas Systems: Gases like nitrogen and argon are also used in fire suppression. They reduce oxygen concentration to a level that cannot support combustion but remains safe for humans during short exposures.

Water Mist Systems: For facilities where gaseous suppression isn’t viable, water mist systems use fine droplets to cool the flames and reduce oxygen levels. Unlike traditional sprinklers, water mist minimizes the risk of equipment damage.

Fire Containment Features

Compartmentalization: Physical barriers, such as fire-rated walls and doors, limit the spread of fire to specific zones.

Fire-Resistant Materials: Using materials with high fire resistance in cabling, server racks, and other infrastructure helps reduce fire hazards.

Monitoring and Management

Fire Alarm Systems: Integrated alarm systems provide real-time alerts and connect to centralized monitoring systems, ensuring rapid response by on-site teams or fire departments.

Emergency Power Shutoff: In case of fire, automatic systems may cut power to affected zones to prevent further ignition.

Best Practices for Fire Safety in Data Centers

Proactive Fire Risk Assessments Conduct regular fire risk assessments to identify vulnerabilities and ensure compliance with local and international fire safety standards, such as NFPA 75 (Standard for the Fire Protection of Information Technology Equipment).

Redundant Suppression Systems Deploy multiple layers of fire suppression systems to create redundancy. For example, pairing clean agent systems with inert gas or water mist ensures comprehensive coverage.

Routine Maintenance Regular inspection and maintenance of fire safety equipment are crucial to ensure reliability. Malfunctioning sensors or depleted suppression agents can compromise safety during emergencies.

Staff Training Train staff in fire safety protocols, including the use of extinguishers, evacuation procedures, and communication with emergency services. Well-trained personnel can make critical decisions to mitigate fire damage.

Integration with Building Management Systems (BMS) Integrating firefighting systems with the facility’s BMS allows centralized monitoring and automated responses, enhancing overall efficiency and safety.

The Role of Emerging Technologies

Innovations in fire fighting systems continue to enhance safety in data centers. Technologies such as artificial intelligence and IoT are playing an increasing role in fire prevention and management:

AI-Driven Fire Detection: Machine learning algorithms analyze sensor data to predict fire risks, enabling preemptive measures.

IoT-Enabled Monitoring: Sensors connected via IoT networks provide real-time data on temperature, smoke levels, and equipment status, ensuring constant vigilance.

Robotic Firefighting Systems: In large data centers, autonomous robots equipped with fire suppression tools can navigate tight spaces and extinguish fires rapidly without endangering personnel.

Challenges in Implementing Fire Fighting Systems

Despite advancements, data centers face challenges in implementing fire safety measures. These include high installation and maintenance costs, potential disruptions during upgrades, and the complexity of retrofitting older facilities with modern systems. Balancing fire safety with environmental sustainability is another challenge, as traditional fire suppressants may have a high global warming potential (GWP).

Conclusion

Fire fighting systems in data centers are a cornerstone of operational resilience. By combining early detection, advanced suppression techniques, and proactive risk management, data centers can protect their critical assets while ensuring uninterrupted service. As technology evolves, integrating intelligent, sustainable fire safety solutions will be essential to meet the demands of future data center operations.

0 notes

Text

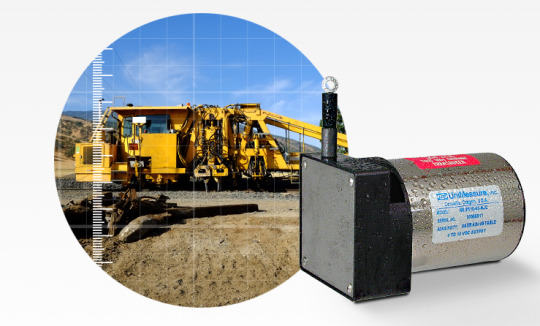

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts Sold by YOYIK. Deyang YOYIK is a professional production, development, sale of power plant dedicated spare parts and accessories processing company. Through more than 20 years of efforts, the majority of customers have been fully recognized. Limited space, and look forward to your calls for consultation, we will sincerely for your service, your satisfaction is our greatest comfort! Yoyik can offer many spare parts for power plants as below: #DF-MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B-DF Signal Converter ADAM4520 Magnetic Proximity Sensors DF2018 Analog Linear Displacement Sensor ZDET-20B Shaft Speed Sensors CS-1-G-100-05-00 Digital display AC ammeter PA194I-3X1 rpm sensor indicator G-065-05-01 Magnetic Pick-up Speed Sensor DF2012 angular displacement sensor B151.36.09G09 displacement sensor FRD.WJA2.301H lvdt linear position sensor TDZ-1E-31 temperature measurement sensor pt100 WZP2-014s PT100 2M lvdt transducer displacement LVDT-400-6 rtd cable WZPK-646 displacement transducer TDZ-1E-32 rotation sensor D-100-02-01 lvdt transducer displacement HL-3-100-15 LVDT Displacement Transducer Sensors B151.36.09.04.15 thermocouple machine WRN-332NM rtd probe WZPM2 lvdt full form B151.36.09G32 Platinum Thermocouple Wire WRN2-630 LX1=225*76 rpm speed meter DF9011-B dc speed control sensor G-090-02-01 replace thermocouple WRN2-239 0-600℃ linear variable displacement transducer B151.36.09G08 full form of lvdt ZDET1000B pressure switch black 396725-LKTS16 speed meter sensor HZSP-475-50-10-HL celsius thermometer WSS-461 0~350℃ non-contact displacement sensor ZD-7000TDB oil pressure sensor SPB424BXCC RPM Sensor magnetic GSH5 RPM Sensor magnetic CS-1 L=100 Thermocouple Type-K TE-109 tachometer price DF9011-B Type K Thermocouple Cartridge WRNKB-446S/TG MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B rtd cable WZP-201 LVDT Position Sensors K156.36.06.004 vacuum pressure gauge 1201901 lvdt 20mm sensor LVDT-35-3 furnace thermocouple TE-305 Rotary Torque Sensor ZS-02 L=65 element cartridge heaters ZJ-14.5-180 rpm sensor generator DF2018 Surface Thermocouple TC03A2-KY-2B/S13 lvdt-sensor ZDET-25B thermocouples extension lead wires TE-303 linear displacement sensor FRD.WJA2.308 LVDT Position Sensors A191.36.09.03 lvdt 0-300 TDZ-1G-32 pt100 rtd probe thermowell WRNK2 pt100 rtd WZP-221 rotational speed sensor CS-1-G-100-02-01 lvdt displacement transducer B151.36.06(1)G02 thermal resistance tester WZP2M-201 thermocouple k-type WRNK2-294 non-contact displacement sensor TDZ-1E-12 lvdt working principle 400TD non-contact displacement sensor TDZ-1E-22 BENTLY Cable 330130-040-12-00 Tacho RPM sensor CS-3 M16-L60 cartridge heater electric heating heater DJ-22-2/ZBK54019-88 liquid level gauge UTG2005C Displacement sensor 5000TDG 0-250mm LVDT Position Sensors TDZ-1-21 lvdt full form TDZ-1-33 pt100 thermocouple machine WRNK2-292 lvdt displacement sensor inductive sensor HL-6-20-15 thermowell flange TC03A2-KY-2B/S3 Gear speed sensor CS-3-M16-L120 Shaft Rotation Speed Sensors DF6202-005-050-04-00-10-000 lvdt 20mm sensor B151.36.09G42 MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B DFYLSYC-2024-6-17-A

0 notes

Text

The top ten brands of multi -functional bus (how many maternal arrangements for multi -construction stations in Gansu)

The purpose of adding lubricants to the linear rail is to prevent metal contact between the orbital surface of the internal rail and the rolling body, reduce friction and wear, and prevent heat and sintering. When the orbital surface and the rolling of the rolling surface form an ingredient, it also has the effect of reducing the contact stress caused by the load. Manageing the lubrication work, fully forming the reliability of the oil film is very important to ensure the reliability of the linear guide.

This busbar machine uses a powerful 32 -bit design chip with a faster operation speed and higher reliability. The counting light sensor, synchronized casual lines, with self -detection, including setting errors, speeding tracking and speed calibration. Randomly lifting the spindle speed, the spindle climb time can be determined by itself. The top ten brands of multifunctional bus machines

Due to the different functional requirements of various coil products, the types of parent wire machines are diversified. At present, common busplane machines are fully automatic bus machines, semi -automatic bus machines, circular bare lines, servo precision bus machines, foil bus machines, automatic automatic parent line machines, automatic automatic parent line machines, automatic automatic buser, automatic automatic parent line machines, automatic automatic parent line machines, automatic automatic parent line machines, and automatic automatic parent line machines, automatic parent cable machines, automatic automatic parent line machines, and automatic automatic parent line machines, automatic parent line machines, automatic automatic parent line machines, automatic parent line machines, automatic automatic parent line machines, and automatic automatic bus. Magnetic rings bus and other models.

First of all, the top ten brands of multi -functional parent line machines are first, what types of components to produce, then the bending machine suitable for such components should be selected. It is best to be accurate. It has a certain improvement in technology. Of course, this also includes the choice of models, such as: what thick parts do you produce, then the choice of bending machine must also choose the appropriate model.

In addition, if the rotation center of a pulley, gear, bearing, or rotor is deviated from the geometric center line, it will appear eccentric. Due to the strict horizontal displacement calibration when the company's parent line machine is produced, the general phenomenon that generally does not appear on the old machine. The neutrality of the machine is very important because it increases because it increase The rotation force applies abnormal stress on the bearing and sealing parts. The types of wrong are: Parallel is not right, the angle is not right, parallel, and angle. Typical wrongdoing is mainly caused by the following reasons: inaccurate assembly of the original component, such as motors, pumps, etc.; The relative position of the original components after installation moves; the twist deformation caused by the pressure of the pipeline system; Flexible support distorted deformation; machine deformation caused by temperature changes; not perpendicular to the coupling surface and axis; because the ground base flexibility is too large, the machine moves when the machine is tightly fixed. In fact, most of the cases are not the combination of the axis angle that is incorrect. The general principle is that the diagnosis should be judged according to the increase of 1x speed in the direction of axial and vertical (or horizontal).

The concentricity of correction pump shafts and motor shafts is 0.1 mm on the outside of the couplet road outside the road. 0.3 mm. The top ten brands of multifunctional bus machines

The advantage of the CNC bending machine is that the most in line with the discounted component display and reference to the space of the space households (clamping coordinates in the distance where people are seeing people from the sawing bedside, and it is difficult for people to meet). The hydraulic clamping can be solved by the operation of the replacement valve very conveniently. This can realize that multiple components are installed and polished at the same time on one clip. The hydraulic junction fixture can realize the multi -site fixture, which greatly mobilizes the production rate.

0 notes

Text

Digital Tensile Testing Machine

Digital Tensile Testing Machine is incorporates digital technology to provide enhanced control, accuracy, and data acquisition capabilities. The term “digital” refers to the use of digital displays, sensors, and electronic control systems in the machine. Digital tensile testing machines feature advanced software and control systems that automate the testing process. Operators can input test parameters, such as testing speed, hold times, and test limits, and the machine will perform the test accordingly. This automation improves efficiency, repeatability, and reduces human error. These models are suitable for testing metals and iron, Plastics, Rubber, Ceramics, Fabrics, Composites, Cables and wires. Load is measured through a strain gauge based Load Cell and elongation is through rotary encoder. Depending upon the customers requirement a suitable type of grips are available. Extra Load cell can be offered suitable for low load samples. The computerized system records and collects data from various sensors, including the load cell and extensometer, during the test. It displays real-time data such as force, displacement, and strain. After the test, the collected data can be analyzed to determine material properties like tensile strength, yield strength, modulus of elasticity, and other relevant parameters.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#testing#testing machine#tensile testing#tensile testing machine#digital tensile testing#digital tensile testing machine#material testing#material testing machine#digital tensile testing machine supplier#digital tensile testing machine manufacturer

1 note

·

View note

Text

For instance, I worked at a sensor manufacturing company. In automation, you run into a handful of problems, such as the fact no one standardized on a system of computers. Beckhoff, Siemens, Allen-Bradley/Rockwell, Schneider, Mitsubishi Electric, etc - all compete within that space with systems that don't really interact with one another, despite the fact they're basically simple computers made with the explicit aim of not breaking down at all. The problem is that they actually have a very limited number of ports for any sensor or actuators and they're just straight up electrical ports. If you wanna transmit 8 bits of data, you need 8 wires. Or what you can do is wire up a shift register, only use a handful of wires to control that shift register, and then send these 8 bits at a rate over 8 times slower than just the straight 8 wires. But you save up on wire space!

Which is why a bunch of companies came up with the concept of IO-Link, which is that instead of this being built into the sensor, the sensor can act as that on-off normally so you don't need to build a shift register directly into your sensor, you just send it to a subcomputer on the same network whose entire purpose is expanding the PLC. You create a communication sublayer between your inputs and outputs, and your PLCs, and one that requires minimal updates to both - a firmware update here, a very slight design change there. Now you can theoretically run a giant production line with just a single PLC (which are expensive as shit!) by shooting off into a variety of masters and these masters can be expanded with hubs so you can have like 64 different sensors and actuators running off the same set of wires. And it's an IEC standard which is great. Thanks, Germany, for one of your handful of worthwhile contributions!

Now, even that might be outdated relatively soon, but manufacturing technological advances move at the speed of a snail (see: IoT, which is STILL not nearly as common as it should be! - but still better than agriculture!) because it's capital investment and that's got its own set of difficulties when it comes to convincing people.

Well, the company I was working on had one objective with respect to the bread-and-butter sensors and cables, which was to sell them at a loss, or at nearly even. Why? Because these guys owned a disproportionate amount of the market for the IO-Link Master and Hub system. So if you sold your sensors and cables but with no profit on them and they were already IO-Link compatible, then what you could do is acquire their real money makers, which were the specialty sensors and the IO-Link hubs and masters. They didn't need to displace Siemens on the PLC market - they can't - but they could come to dominate the layer below that, and then work off Siemens and Rockwell and Mitsubishi and Schneider just to name some of the big names in PLCs.

Again, unfortunately, manufacturing has a fuckton of inertia and inefficiency because you're dealing with engineering inefficiency, managerial inefficiency and logistical inefficiency on a number of structural levels, and then you have to factor in all manner of capital costs which just make everything messier. Ideally we should have even less people working the shop floors (admittedly everyone would also be MUCH more trained), but you're essentially balancing labor vs capital costs.

Point being - sometimes you can sell something at a loss because that brings you into a situation that incentivizes the purchasing of a completely different product altogether, and one with much higher profit margins. There's tons of other techniques along that vein too.

But what if the competitors don’t agree that they’re doomed? What if they, too, are willing to accept a lower profit rate in order to stay in business? Then the kind of buccaneering behavior that Shaikh presents as a time-honored recipe for competitive success would in fact be ruinously risky — and therefore something intelligent capitalists would try to avoid. This isn’t just a priori speculation. A book on pricing by “three preeminent McKinsey & Company experts” (The Price Advantage) advises managers that “price wars rarely have any real winners — and few healthy survivors.” For that reason, “the best-run companies go to almost any lengths to avoid price wars.” Most price wars that do happen break out by accident, as a result of misperception and miscalculation: “The price war that is initiated as a deliberate competitive tactic is somewhat rare — and rarer still is the one that achieves a positive outcome for either the industry at large or a specific supplier within the warring industry.” Almost identical advice is given in a management book (Confessions of the Pricing Man) by the German pricing consultant Hermann Simon, the founder of the global advisory firm Simon-Kucher. In his firm’s annual survey of managers, 82 percent of those respondents who reported that their company was currently involved in a price war believed it had been instigated by a competitor; only 12 percent said their company had started it as a deliberate tactic. “Unless you have an unbeatable cost advantage which prevents your competitors from responding in kind, it is almost impossible to establish a sustainable competitive advantage through lowering prices,” Kucher writes. The McKinsey experts echo that claim, but they also quantify it: “If you have ever imagined that reducing prices to gain share and increase profits might be a sound strategy for your business, think again. Unless you have a dominant cost advantage — by this we mean costs that are at least 30 percent below the competition — reducing prices all too often triggers a suicidal price war.” (Shaikh at one point characterizes the cost advantage of the innovating firm in one of his numerical examples as “robust, being on the order of 10%.”) Thus, for Shaikh’s theory of real competition to be valid, real-world technical innovation would have to be driven by a competitive strategy that — according to these experts — is rarely seen and almost never works.

Ahh you see capitalism isn't doomed to an eternally falling rate of profit because it's not actually competitive, sorry

129 notes

·

View notes

Text

CANbus Linear Draw Wire and Cable Displacement Sensor Transducer

Key features

Exceptional Durability: Built for 5 million fatigue cycles, ensuring prolonged operational life.

Advanced Digital Communication: Utilizes CANbus interface for reliable absolute position sensing and power-off memory, ensuring data retention and robust communication.

Durable Wire Outlet: Enhanced with ceramic materials to improve wear resistance and extend the life of the steel wire rope.

Data Interfaces: Equipped with CANbus communication for seamless data integration, making it ideal for complex systems requiring high-precision feedback.

High-Quality Construction: Features a 0.8mm diameter, imported flexible stainless steel wire rope with a nylon coating to minimize friction and improve longevity.

Superior Pull Head Design: Innovative fixation method provides a tensile limit 10 times greater than conventional models, accommodating up to a 15° angle deviation.

User-Friendly Configuration: Allows for easy parameter settings via CANbus protocol or software, simplifying configuration and operation.

Versatile Operation Modes: Supports query and auto-return modes with position and speed feedback. Fully programmable for baud rate, positioning functions, counting direction, and speed feedback.

Visit https://briterencoder.com/product/displacement-draw-wire-encoder-and-sensor-with-canbus-communication/ for more.

0 notes

Text

Soul of a Lion (chapter 3)

Sequel to The Smallest Blade.

Summary: After the Red Lion steals them away from the Marmora base and takes them through a wormhole, Shiro, Keith, Katla, and Lance find themselves in front of a majestic castle with nowhere to go but inside. The events that unfold while they’re there will change the fate of the universe.

Also posted on AO3 under the username “kishirokitsune”.

☆ - ☆ - ☆ - ☆ - ☆

3 | Communication

The dim lighting of the castle's nighttime cycle made everything feel far more ominous than it needed to be, with the way it cast long shadows across the floor and highlighted any curvature in the architecture around them. Katla stayed close to the wall as she and Lance snuck towards the security panel she spotted during their tour. With luck, she would be able to hack into it without setting off any alarms.

Neither of them dared speak for fear of getting caught.

Katla gestured for Lance to stop as they reached the end of the hall. She waited a moment and then, with more caution than necessary, peered around the bend. When she saw that the coast was clear, she nodded to him and waved him forward so they could continue towards their task, which was all the way down at the end of the hall on their left.

“This is it,” Katla whispered to him. She held up her right arm and pressed on a slightly raised plate on the underside of her bracer. It clicked and released a tiny cable, which she pulled out and, after taking a deep breath, connected it to the control panel on the wall. The screen flickered in and out for a moment and then turned from blue to a pale violet, signaling that she was successfully wired into the system.

Both of them let go of the breath they were holding.

“Is that it?” Lance asked.

“Almost,” Katla responded, turning her wrist so her hand faced palm down. She double-tapped the top of her bracer, which activated a small, holographic display. “Keep an eye out, would you? Hopefully, this thing will give me a map to an engineering room or something. It's bound to have parts I can use.”

Lance nodded sharply and stood up straight. Though he didn't move away from the wall, he listened as hard as he could for any sound that wasn't the tiny beeps from Katla scouring the system for anything useful.

After a few tense doboshes, Katla cried out in triumph, and although she managed to do it quietly, it still made Lance visibly jump.

“Sorry,” she apologized as she disconnected from the control panel. “There's a spare parts room two halls over and I disconnected the security cameras and put them on loop. It'll last us one varga, so we'll have to be quick.”

“Can you build your-” (Lance vaguely waved his hand) “-whatever-it-is in that short amount of time?”

“Who do you think you're talking to? Of course I can,” Katla said confidently.

Lance snorted in amusement. “Lead on, team captain. I'd like to get some beauty rest at some point tonight and the sooner you do your thing, the sooner I can curl up in bed.”

Katla grinned at him and then set off down the hallway at a much faster pace, more at ease with the knowledge that there was no one around to catch them. According to the system, there was one person three floors above them and there were two other people up in the topmost spire of the castle. (And of course, she checked in to find Shiro and Keith, who were steadily making their way to the front door when she spotted their dots. Or at least, she assumed it was them.)

When they got to the correct door, Katla didn't even have to hack into it, it simply slid open with a simple press to the keypad.

“You know, I'd say I should talk to them about upping their security around here but it's really benefiting me right now, so I won't,” Katla said in a light-hearted tone. “Oh, look at this!”

Lance looked around, but all he saw were heaps of junk and scrap metal. “Uh, yeah, it's really something. Very... metal-y.”

Katla wasn't paying him any attention as she eagerly delved into the piles and began pulling things out, cooing and humming over what she could use and what may be useful for future things. As Lance watched, the pile in front of her grew, and while he didn't see how any of it was meant to fit together, Katla was clearly delighted by her mess of wires and metal pieces, so he didn't say anything until she tried to scoop it all up and carry it to one of the mostly empty tables.

“Here, let me help,” Lance said, stooping down to help pick up some of the stray pieces.

Together the pair got all of the parts over to a desk, where Katla began to assemble them and occasionally looked up to ask Lance to fetch some kind of tool or computer chip or another cable or wire.

Lance did his best to help while also listening for anyone's approach, but by the time Katla had her little machine buzzing to life, he'd forgotten the whole reason he was there. And because both of them were so focused on the communication device, neither noticed there was someone else in the room with them until that person loudly cleared their throat to get their attention.

Lance gasped and back up into the desk so hard that he winced.

Katla's hand flew to her side and grasped the hilt of her dagger as she turned to face the potential threat. She froze when she saw Hunk standing there with his hands held up in front of him to show he didn't mean any harm.

For a moment, there was only silence.

“What do you want?” Lance asked, crossing his arms over his chest.

“You guys set off a sensor when you left your rooms, so I came to make sure everything is alright,” Hunk said, slowly lowering his hands back to his sides.

“You bugged our rooms?” Pidge asked incredulously.

“Well, yeah. I mean, wouldn't you if you were in my shoes?” Hunk asked in response. “What are you two doing in here anyway?”

Lance watched as Katla tried to move over in front of her device before Hunk could get a better look at it. He copied her and closed in as well, though he could tell from the expression on Hunk's face that he'd already seen that they were building something. Maybe if they were lucky, he wouldn't be able to figure out what it was?

A few ticks passed and then Hunk sighed. “I know we don't have any reason to trust each other, but can we try and get along? At least until we figure all of this out with the Red Lion.”

Katla puffed herself up in anger, her tail lashing as she very slowly stepped aside. “We need to send a message back to our families and let them know we're alright.”

Hunk took a single step closer and both of them tensed up, but that was as far as he went. “You could have just asked. Though, uh, I guess the real issue would be convincing Allura and Coran.” He paused for a moment to look at the machine. “Wait, is that a sub-frequency radio? Are you sure you don't want to use something a little faster? I could try and sneak you up on the bridge once they leave and you could send a message that way.”

Katla shook her head. “This is more reliable. And since no one uses it anymore, no one is looking or broadcasts through it anymore. Well, except for Keith's dad and my family.”

There was something about Hunk that made Lance feel more at ease, despite his determination to dislike all three Alteans found in the castle. He figured Katla must have been feeling the same way. She wouldn't reveal so much if she wasn't.

“And you built it using pieces you found around here?” Hunk asked. “What are you using to power it?”

Katla hesitated to respond, but after another few ticks of silence and Hunk patiently waiting for her to decide whether or not to tell him, she finally did. “I was going to make a double coil generator so it keeps recycling the energy and gathers displaced electrical currents from the air, but it needs a jump start so I don't have to wait for that to build up. I figured something around here would have enough power to do that, but...”

“Maybe I can find something,” Hunk suggested.

Lance stayed close to Katla as the Altean began to walk around, opening drawers in search of what they needed. He didn't know why Hunk was so willing to help them. Was it a trap? A way of luring them into a false sense of security, prying their secrets from them, and then finding a way to betray them?

His panicked thoughts didn't have time to gain any momentum or spiral off into a more ridiculous scenario. A wave of calm washed over him, soothing his fraying nerves and forcing him to relax. And all at once, Lance realized why he felt so at ease with Hunk.

It took everything in his power not to blurt it out right then and there.

Later. He would tell Katla and the others later. If he brought it up right at that moment, then he would have to explain how he knew so much about Altean secrets and that was a wormhole he had no plans on opening up.

Hunk made a triumphant exclamation as he lifted a tray of shiny rocks from one of the drawers and carried it over to them. “These are power crystals,” he explained, picking up one shaped like an obelisk with a broken base and passing it to Lance. “We'll have to dig through and find one that still has some power left.”

Lance rolled the opaque white gem around his palm, watching with slight alarm as a faint glow began to build up in the center. He quickly passed it off to Katla before anyone could notice what was happening.

“How do you know which ones have power?” Katla asked, curiously eyeing the box before looking at the stone she was just handed. “Because it looks like the one you gave us might work.”

Hunk shook his head. “They'll glow if they have any power left. That one was... oh!” his voice stuttered in surprise as he took a second look. “You're right! That one should work. That's odd...”

Katla didn't question their good fortune and busied herself with installing the crystal in the communication device, practically bouncing in delight as it immediately began to work.

Lance's heart was pounding in his chest. He could feel Hunk's eyes on him. 'Please don't figure it out,' Lance prayed, turning his back towards the Altean and pretending to focus solely on the coils within Katla's device which were steadily directing the energy through the wires and looping back around into itself, glowing brighter with each pass.

If Hunk learned anything from the exchange, he didn't say anything and instead went to put the tray away before returning to watch Katla begin to input her message. It became apparent after a moment that he, like Lance, couldn't make heads or tails of the series of numbers Katla was typing out.

“A coded message?” he guessed.

“My brother and I made our own secret code when we were kids, so we could write to each other without anyone else knowing what we were saying,” Katla explained. “Kol – Keith's dad will pick up on the broadcast, but only Matt will be able to translate.”

“That seems a little excessive.”

Katla gave a humorless laugh. “Maybe you hadn't picked up on this, but we're not exactly friends of the Empire. All of that caution is how we stay alive. We haven't had the luxury of hiding away and sleeping for all these years.”

Hunk flinched, but when he spoke again it was without anger in his voice. “You're right. We hid the Lions and ourselves because we were afraid of what would happen if Zarkon found us. I didn't like it. Allura argued that we should keep fighting. But we listened to our King because he thought it was the right choice. Maybe it was or maybe it wasn't, but we're here now and ready to stand up and fight. The Red Lion brought the four of you here for a reason and I know it's because you've been chosen as the new paladins. Well, four of them. Because there should be five of you.”

“Wait, there are five Lions?” Katla asked.

Hunk looked taken aback by the question. “Yeah. You didn't know?”

“How would we?” Katla asked in response. She took another moment to read over her message and then send it before picking up the device. “So, where are these other four Lions? Are they as well hidden as Red?”

“They should be. We know that the Black Lion is safe since it's here in the castle, but we won't know about the others until we go looking. Allura should be able to tell us where they are,” Hunk said.

“Which means we'll never find them,” Lance stated, crossing his arms over his chest.

“I wouldn't say that. The princess will come around, she just needs a little time,” Hunk said defensively. “I should get you back to your room. It definitely won't help things if she or Coran learn that you're out here sending messages and that I helped you.”

Neither Katla nor Lance protested as Hunk gestured for them to follow him out of the room and back through the halls. None of them spoke; Lance didn't even blurt out the storm of questions left to thunder around in his mind.

When they got back to their rooms, Katla didn't give Lance a chance to go into the room he'd been given and instead grabbed him by the arm and dragged him into Shiro's without giving him a chance to protest. While she looked around for the best place to hide her device, just in case they needed it again, Lance sat down on the edge of the bed and mulled over everything he'd learned, slotting it into place with what he'd known before.

Most of it boiled down to one fact: as much as he didn't want to like him, Hunk was someone they could trust.

It wasn't just the fact that he helped them send their message.

It wasn't even that he kept his patience even when Katla verbally attacked him.

It had everything to do with his Aspect.

They didn't have a lot of records from the time when Altea still hung whole in the sky. All that they knew of their heritage was what had been verbally passed down from parent to child and there were scarce few books and items that remained. Their knowledge of Altean Aspects – the special abilities that their quintessence granted them – was a limited one born of experience.

Body.

Mind.

Spirit.

Heart.

Lance had been born graced with the power to change his form at will. He began far earlier than most babies, changing the color of his skin for his own amusement, as well as the amusement of the other children he grew up with. By the time he was a tween, he could hold color and form for days if he needed to, even through sleep.

His mother said he was extraordinarily blessed.

Lance didn't always see it that way. Not when there was Leifsina, whose sharp mind was leagues above everyone else. Or Rykin, who was gifted with tremendous strength and just enough spirit to power the lamps around their village when needed. And then there was Curtis, who wore his Aspect of Heart like a shield, able to soothe those in need of it and calm tempers when they began to flare.

And all Lance could do was shift his appearance. That was nothing special. Most Alteans carried that ability.

Hunk was one of those special Alteans – like Curtis – who was born with the rarest ability of all. There were no others in their village who boasted the Aspect of Heart and even their records of it were scarce; there was perhaps one born with that Aspect every one-hundred decaphoebs. Still, if there was one thing they knew for certain it was that those with Heart were incapable of lying. There was always some kind of tell when they tried and no amount of practice or emotional control was enough to fix that.

Lance still didn't like him.

But if he had to pick one of the three who he trusted, it would be Hunk.

Shiro and Keith returned with little fanfare and news that the Red Lion hadn't responded to any of Keith's pleading, which meant they were officially stuck on Arus until she changed her mind. After hearing that, Lance was reluctant to tell them about their run-in with Hunk, but Katla had no such fears about telling them all about it.

At least they had gotten a message sent. It was only a question of Kolivan recognizing it as coming from them and getting Matt to translate.

“We should get some rest,” Shiro said once they were all caught up. “The three of you are welcome to stay here for the night. The bed's a little small, but I think we could manage.”

Katla perked up. “Do you mean it?”

“I wouldn't have offered if I didn't,” Shiro responded, sounding amused.

Lance thought for sure Keith would scoff and say he was going to sleep in his own room, but to his amazement, Keith yawned and claimed the middle before climbing over the bed to settle in his chosen spot. Katla grinned as she joined him, rolling over him to settle between Keith and the wall.

“Lance?” Shiro questioned. “Do you want to stay too?”

Lance agreed with only a little embarrassment.

☆ - ☆ - ☆ - ☆ - ☆

Allura sat in front of her vanity, slowly running a brush through her hair as she reflected on the events of the evening before. After a night of proper sleep, she was ashamed by the way she reacted to their guests and the obstinacy she displayed in refusing to believe that the Red Lion had accepted one of them as her paladin.

She set her brush down with deliberate delicacy and closed her eyes.

Her father's Lion had chosen a Galra and it hurt as surely as if she were in physical pain. And while she couldn't fully blame that pain for her actions, it certainly added to the helpless rage that she felt from the very moment she awoke in the cryo-pod, the betrayal of the people she once called allies still a freshly bleeding wound.

Regardless of her reasons, she had acted disgracefully and her guests deserved an apology.

Allura opened her eyes and stared at her reflection. “I will apologize, but this doesn't mean I trust them.”

There was a quiet scratching sound followed by several squeaks that seemed to overlap one another and Allura blinked in surprise as she watched four mice of different sizes climb up onto her vanity and begin to tumble around. There was a tickling in the back of her mind as though four voices were trying to speak and gain her attention, though it wasn't in words but feeling and a quick flash of images.

“Can you... understand me?” Allura murmured, tilting her head to the side as she regarded the mice.

There were more excited squeaks and a starburst of delight.

As she learned that a connection between them existed thanks to their 10,000 years spent in the same cryo-pod, Allura began to consider how she could use it to her benefit. They were small and inconspicuous. No one would even think that she could understand what they were saying.

They would be the perfect little spies.

“Perhaps you'd like to help me with something,” Allura said with a growing smile. “And in return, I'll find whatever food you like to eat.”

#voltron#kidge#kidgemas#fanfiction#soul of a lion#galra shiro#half galra keith#half galra pidge#altean lance#altean hunk#the space mice join the party!

7 notes

·

View notes

Note

>C.R.E.W.> Ah of course, we understand entirely, the captains are known pirates after all, or were at least. Not that they've retired, never retired, just a bit of shore leave, if you will. But please, follow us, we will show you the vessel, teach you all the shortcuts. Captains said to give you the extended tour after all!

The odd little group of sub-alterns proceed to take Whiteout on a master tour of the Demeter's bounty. Sharing with them a digital map, marking locations as they go. The tour is long, but not uninteresting. The C.R.E.W. make for surprisingly good tour guides, filled with facts of the ramshackle construction, pointing out every little detail, every oddity and one of a kind piece of the ship:

>C.R.E.W.> ...and here we have a quite rare IPS-N Mark IV "Grapeshot" class escape pod, a mass recall was issued, but many pirates and "inventive" captains kept them. You see they were designed as a clustered escaped pod, meant to separate mid flight if they detected incoming fire. Thought up as a last ditch defence against certain marauders who'd fire upon fleeing escape pods, usually to ensure no witnesses. However, a problem with their proximity sensor means they only split at the last possible second, functionally a touch sensor. Made them useless as intended, but an enterprising captain could reinforce the impact region, fill it to the brim with Calibans or explosives. And fire it at an enemy ship! They would then break apart on impact, rather violently, driving the individual pieces deeper into the ship! We generally save it for emergencies...

For a legion they are shockingly talkative, the fact they don't need to pause to breath does not help. But Whiteout is shown everything; the scattered Living Quarters, filled with refugees from the Requiem; the the Weapons/Firing Range, built concernedly out of an old fuel tank; the Messhall, never meant to feed so many, it is constantly full, a joy filled, merry space; Memory Lane, the Ships Bar, is sparsely decorated, all the furniture is old and mismatched, a few trophies are hung from the rafters, old colossal bones and strange weapons, along one wall there is a number of portraits, set up akin to shrines; the various Weapons Decks, all manned by more of The C.R.E.W.; the Bridge, since relocated to the innermost of the ship is amazing, most of the walls replaced with screens, all showing real time footage of the surrounding space; a Gambling Den even, set up the bowels of the ship, tucked into a network of ancient maintenance tunnels below the reactor, The C.R.E.W. recommends Whiteout avoids it:

>C.R.E.W.> ... they had to strip away the radiation shielding you see? to make room for the tables, but the Captains pretend they don't know. Say that we all need our vices, say that you can't get rid it, can't separate humanity and vice. They claim a certain poetry to it, we are not poets, are you a poet Whiteout? We have never understood...

They continue the tour, making sure to show shortcuts. Updating Whiteout's map in response the oddly fluid nature of the maintenance hallways and sub-levels. The reactors are skipped, without comment even, though not entirely unsurprisingly; the fact that they're skipped, not the lack of comment which is most odd. Last stop before returning to the docking bay is the lovingly named Eye of the Maw, the ship scale displacer. It dominates the fore of the ship, a colossal weapon, wires, cables, tubes and pipes sprout from its length like the hair of an ancient god. At its end stand the massive reinforced aperture, a behemoth's eye of reinforced steel. The awe of this terrible weapon is even enough to silence the C.R.E.W. it seems. At least almost, their chatter is reduced in the Eye's vicinity. Almost nervous near it.

Whiteout is then brought back to the docking bay they arrived through. Where The C.R.E.W. do a final check of the map. Filling in a few missed locations and tweaking a few shortcuts. The whole tour took several long hours and The C.R.E.W. seem sad it's over.

>C.R.E.W.> ...and that is all! Please if you have any other questions, seek us out! Although we specifically have other tasks before us, others of us would be glad to help! Please enjoy your stay aboard the Demeter's Bounty. If you so wish, we believe the Captains are now free.

>//[INCOMING TRANSMISSION DETECTED]:: >//[MESSAGE IS UNENCRYPTED] >//[ESTABLISHING LEGIONSPACE BRIDGE]:: >//[LEGIO(ICANN/C4/EVER) STARING-INTO-INFINTY]::

This is LEGIO STARING-INTO-INFINITY, attached to USB FFT Into The Middle Distance. Analysis of local Omninet traffic indicates that this sector was recently the site of a violent conflict and that your vessel, the DEMETER'S BOUNTY has taken on medical duties in the aftermath. Our supplies are low, but our medical personnel are standing by and ready to render assistance. Requesting permission to pool resources? [ INFINITY ]

[Transmission : : Received]

<PERSEPHONE> THIS IS PERSEPHONE OF THE DEMETER'S BOUNTY. OUR MEDICAL SUPPLIES ARE ALSO LOW BUT YOU ARE WELCOME. THERE ARE MANY INJURED AND SICK ABOARD. ANY AND ALL WHO SEEK TO VANQUISH THE SLOW DEATH ARE AT HOME IN MY DOMAIN.

PERMISSION GRANTED.

PERSEPHONE WATCHES.

#Demeter's Bounty#lancer rp#oc rp#lancer rpg#lancer ttrpg#part of the ship part of the crew#lancerrpg#oc rp blog

19 notes

·

View notes

Text

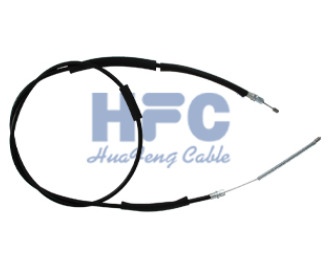

How much do you know about throttle lines?

The two lines of the motorcycle lead to the throttle handle on the right side of the handlebar, so the top line is the throttle line, which is responsible for controlling the throttle valve, and the oil needle, that is, controlling the throttle.

https://www.huafengqp.com/UpLoadFile/image/20221021/6380194624901082084727037.png

Throttle line overview:

The one next to it is the acceleration pump line. When the accelerator is twisted sharply, the carburetor can spray a jet of oil to the throat to improve the acceleration during rapid acceleration. This acceleration pump only works when the accelerator is twisted sharply. Normal driving is to twist the throttle or a slower normal throttle it does not work. Cars equipped with this kind of carburetor should be careful not to turn on the accelerator when parking, otherwise gasoline will be injected into the cylinder, causing flooding and waste of gasoline.

The principle of the throttle line:

The traditional cable-pull throttle is connected to the accelerator pedal at one end of the wire and the throttle valve at the other end. Its transmission ratio is 1:1, that is to say, the opening angle of the throttle valve is how much we step on it with our feet, but in many cases , the throttle valve should not be opened at such a large angle, so the opening angle of the throttle valve at this time is not necessarily the most scientific. Although this method is very direct, its control accuracy is very poor. The electronic throttle controls the opening of the throttle valve through a cable or wiring harness. On the surface, it replaces the traditional throttle cable with a cable, but in essence, it is not just a simple change of the connection method, but it can be used for the power output of the entire vehicle. Realize automatic control function.

When the driver needs to accelerate when he steps on the accelerator, the pedal position sensor will transmit the sensed signal to the ECU through the cable, and the ECU will analyze and judge, and issue a command to the drive motor, and the drive motor will control the opening of the throttle to adjust The flow rate of the combustible gas mixture when the load is heavy, the throttle valve opening is large, and the combustible gas mixture entering the cylinder is large. If you use the cable accelerator, you can only control the throttle valve opening by the depth of the accelerator pedal, and it is difficult to adjust the throttle valve. The opening angle of the valve can be adjusted to achieve the theoretical air-fuel ratio, and the electronic throttle can analyze and compare various data collected by the sensor through the ECU, and issue commands to make the throttle actuator act to adjust the throttle to the best position. , in order to achieve a theoretical air-fuel ratio state close to 14.7:1 under different loads and working conditions, so that the fuel can be fully burned.

The electronic accelerator control system is mainly composed of an accelerator pedal, pedal displacement sensor, ECU (electronic control unit), data bus, servo motor, and throttle actuator. The displacement sensor is installed inside the accelerator pedal and monitors the position of the accelerator pedal at any time. When a change in the height position of the accelerator pedal is detected, the information will be instantly sent to the ECU, and the ECU will perform arithmetic processing on the information and the data information from other systems, calculate a control signal, and send it to the servo motor relay through the line. The electric motor drives the throttle actuator, and the data bus is responsible for the communication between the system ECU and other ECUs. Since the electronic throttle system adjusts the throttle through the ECU, the electronic throttle system can set various functions to improve driving safety and comfort, the most common of which are ASR (traction control system) and speed control system (cruise control system) ).

Huafeng is a company specializing in the production of clutch cables. Huafeng is a professional brake cable supplier in China. We manufacture various types of universal brake cables, parking brake cables, and automotive control cables. If you are interested, you can contact us and we can send you samples!

0 notes

Text

What determines the accuracy of CNC machining parts

In CNC machining Parts programming, the correct use of methods and skills can effectively ensure and improve the accuracy of CNC machine processing. So, what determines the accuracy of CNC machining? Let's learn more about it!

CNC machine tool processing accuracy is determined by the position detection element, position detection element by the detection element (sensor), and signal processing device, which is an integral part of the CNC machine tool closed-loop servo system.

Its role is to detect the actual value of the table position and speed and the feedback signal back to the CNC device or servo device, thus forming a closed-loop control. The detection element is generally the use of light or magnetic principles to complete the position or speed detection.

According to the detection method, position detection elements are divided into direct measurement elements and indirect measurement elements. When measuring the linear motion of the machine tool, the linear detection element is generally used, called direct measurement, and the position closed-loop control is called complete closed-loop control. The measurement accuracy mainly depends on the accuracy of the measuring element and is not affected by the accuracy of the machine tool drive.

Since the linear displacement of the machine table is proportional to the rotation angle of the drive motor, it can measure the distance of the table movement indirectly by driving the rotation angle of the detection motor or screw. This method is called indirect measurement, and the position closed-loop control is called semi-closed-loop control.

The measurement accuracy of CNC machining depends on the accuracy of the detection element and the machine feed drive chain. The machining accuracy of the closed-loop CNC machine tool depends mainly on the accuracy of the position detection device. CNC machine tools have very stringent requirements for position detection elements, typically with 0.001-0.01 mm or less resolution.

The probability of damage to the detection element is higher than damage to the cable assembly. If the detection element fails, the first step is to check the wireless cable for broken wires, soiling, deformation, etc. The detection element can be judged by measuring its output. However, it is required to master the operating principle and the output signal of the detection element. For example: What to do when detecting equipment failure and mechanical oscillation (acceleration/deceleration)?

1) Pulse encoder failure. Then is the time to check if the voltage of the feedback line terminal on the speed unit drops to a certain point. If the voltage drops, the pulse encoder is defective and should replace the encoder.

2) The pulse encoder cross-coupling may be damaged, causing the shaft speed to be out of sync with the detected speed, and should replace the coupling.

#cnc machining parts#cnc machining parts manufacturer#oem cnc machining parts#cnc machining parts supplier#custom cnc machining parts

0 notes

Text

China factory MODUL AVC ESP CONTROL AUTOMATICSCR GGAJ02(TM-2) for power station

China factory MODUL AVC ESP CONTROL AUTOMATICSCR GGAJ02(TM-2) for power station Yoyik is specialized in manufacturing and providing components for turbines, coal-fired generators, and hydro units, as well as for electrical equipments, machinery parts, hydraulic machinery and parts. Our company is seated in the famous industrial city - Deyang with advanced technology, complete facilities and scientific management. Productions are in strict accordance with national standards. Yoyik can offer many spare parts for power plants as below: #DF-MODUL AVC ESP CONTROL AUTOMATICSCR GGAJ02(TM-2)-DF k type thermocouple 1200 degree TE-106 Intelligent Temperature Controller CTL-7PP03-M-AC pt100 sensor WZPK-24 φ6 platinum rhodium thermocouple wire TE-304 4mm rtd pt100 WZPM2-001 Φ6 Turbine Rotation Speed Impactor Monitor HZQW-03A Rotary Torque Sensor CS-1(D-065-05-1) 220v 750w heater tubular heating element screw plu JHG03-380V 6KW heater thermocouple WREK2-230 rpm sensor indicator D100-05-01 Analog Linear Displacement Sensor C9231123 300mm pt100 WZRK-135 Φ5 Proximitor WT0122-A90-B00-C01 angular displacement sensor TDZ-1-02 lvdt sensor TD-3000 angular displacement sensor TDZ-1E-24 rotational speed sensor CS-I-D-065-05-01 Magnetic Speed Sensors CS-1 D-065-02-01 displacement sensor sany 1000TDZ-B Magnetic Speed Sensors DF6101-005-065-01-05-00-00 lvdt full form B151.36.09.04-001 LVDT Measurement HTD-200-6 non contact rpm sensor CS-1-G-065-06-01 non-contact displacement sensor TD2-1 linear displacement transducer 1000TDZ-B displacement sensor sany B151.36.09G36 lvdt displacement transducer ZD-8000TDA rtd temperature sensor WZPK2-16A linear displacement transducer B151.36.09.04-008 inductive displacement sensor B151.36.06(1)G01 cable pt100 WZRM2-001 furnace thermocouple TE-204 Shaft Speed Sensors CS-1 D-085-05-01 lvdt sensor TD-01 sensor lvdt B151.36.09G42 Gear speed sensor 70C85-1010-423 MODUL AVC ESP CONTROL AUTOMATICSCR GGAJ02(TM-2) thermowell stainless WRN2-239 0-600℃ RPM Indicator HZQW-03A rpm sensor CS-1-A00-B00-C08-D01 thermocouple protection tube TE-106 rpm sensor A5SO5T90-05 pt100 thermal resistance WZP2-035 lvdt-sensor 191.36.09(1).03 rpm sensor indicator 159.00.96.11(1) PU/OS1-4 thermocouple k TE-302 k type thermocouple WREX2-001 sensor speed QBJ-CS-2-2 lvdt linear position sensor TD-1-300 displacement sensor HL-3-600-15 DP Transmitter RC861CZ090ZYR24DC thermal resistance tester WZPM-201 φ6 full form of lvdt 199T.319Z Type K Thermocouple Cartridge WRNKD2-04A-II inductive displacement sensor B151.36.09.04-002 lvdt displacement transducer TD2-1 heating equipment cartridge heater JHG03-A12 1.67KW thermocoupl 1000℃ TE-209 tubular heater element GYY-230/400-2 lvdt full form HTD-500-3 pt100 thermocouple TE-205 WATT/VAR TRANSDUCER FPWK301H-V1-A1-F1-P2-06 Power Board M83 ME8.530.004-4 RTD Temperature Sensor Element WZPM-201 5000MM ptfe pt100 temperature sensor WZPM2-002, DZ3.5.1-1995 Vacuum Gauge HS75670 output shaft speed sensor D-090-02-01 inductive displacement sensor TDZ-1-32 lvdt 0-300 LVDT-200-6 pt100 temperature transmitter WZP2-280 lvdt probe ZD-4000TDB 5000 rpm torque sensor CS-01 lvdt displacement sensor C9231116 MODUL AVC ESP CONTROL AUTOMATICSCR GGAJ02(TM-2) DFYLSYC-2024-6-17-A

0 notes

Note

Very, very small, as small as she can make herself, a spider sits tucked up in the darkest corner close to the ceiling. Just watching.

His optics flicker and lift towards his door through the dark and the green gleam that casts a ghastly shade on his frame. His palms spread over his desk amid the many data pads. The six holo screens continue to quietly scroll with their information in white and green. He tugs his hardline cable free and all but one of the screens disappears. He steeples his fingers, elbows on his desk. Still. Even his doorwings are still and half lifted, the same as they had been for hours upon hours as he worked quietly. His tac-net is telling him there is something amiss. His data tells him that the ability for a mechanism to enter his private office is very slim. He crunches the variables: Door and vent. The door could not have opened because all of his wired alarms would run directly to him. He had several sensors in the hallways at all levels of height. The duct system had several sensors that would detect even the smallest mini-bot. Which meant that it would have to be something smaller then a mini-bot. What could be smaller? Mass displacement flickers through his processing center from his tac net. There were very few mechanisms capable of that. He considers. He plays with the jack on one of his cables before he plugs in again. Only four screens this time and he leans back that minuscule amount into his chair again. He shuffles the data pads once more into neat lines. The data resumes scrolling and Prowl props his cheek against his knuckles.

0 notes