#X-Ray Inspection

Explore tagged Tumblr posts

Text

Radiography Test: Key Techniques and Benefits Explained

Radiography test is a non-destructive testing (NDT) method. It uses X-rays or gamma rays to examine the internal structure of materials. This technique is essential for detecting hidden flaws without causing damage, ensuring the integrity and safety of components. Radiography test is widely applied in industries such as manufacturing, construction, and aerospace to inspect welding, castings, and…

#Computed Radiography#Defect Detection#Digital radiography#Gamma-ray Testing#Industrial radiography#NDT Techniques#Non-Destructive Testing (NDT)#Radiographic Evaluation#Radiographic Examination#Radiographic Film Analysis#Radiographic Imaging#Radiographic Interpretation#Weld Defect Identification#Weld Inspection#Weld Integrity Testing#Weld Quality Assessment#Welding Inspection#X-ray Inspection

0 notes

Text

Prosem Technology Private Ltd: Leading the Future of X-Ray Inspection in Industry

Prosem Technology Private Ltd is at the forefront of innovation in the field of X-ray inspection, providing cutting-edge solutions for industries ranging from manufacturing and aerospace to healthcare and automotive. With a strong commitment to advancing non-destructive testing (NDT) technologies, Prosem Technology has established itself as a key player in enhancing the accuracy, reliability, and efficiency of industrial inspections.

At Prosem, the focus is on delivering state-of-the-art X-ray inspection systems that not only ensure the highest quality standards but also improve operational safety. Through their advanced X-ray technologies, Prosem empowers industries to detect even the smallest defects, internal flaws, and structural weaknesses without compromising the integrity of the materials being inspected.

The company’s X-ray inspection solutions are designed to cater to the specific needs of various sectors, offering tailored applications that drive cost savings, optimize performance, and ensure regulatory compliance. By integrating the latest technological advancements, including automation and AI-driven analysis, Prosem is shaping the future of inspection processes, making them faster, more accurate, and more accessible.

With a highly skilled team of engineers and technicians, Prosem Technology Private Ltd continues to push the boundaries of X-ray inspection technology, setting new standards for non-destructive testing across industries. Their commitment to innovation and excellence is reshaping the future of industrial quality assurance and safety protocols, positioning Prosem as a leader in the global X-ray inspection market.

In a world where precision and reliability are crucial, Prosem Technology Private Ltd remains a trusted partner for companies seeking advanced X-ray inspection solutions to enhance their operational efficiency and maintain the highest levels of safety and product quality.

0 notes

Text

Exploring the Dynamics of the X-ray Inspection System Market: Trends, Innovations, and Future Prospects

In today's rapidly evolving industrial landscape, quality control and assurance have become paramount. Manufacturers across various sectors are constantly seeking advanced solutions to ensure the integrity and safety of their products. Among these solutions, X-ray inspection systems have emerged as indispensable tools for non-destructive testing and quality assessment. The X-ray inspection system market is witnessing significant growth, driven by technological advancements, stringent regulatory requirements, and the increasing demand for high-quality products.

One of the key drivers propelling the growth of the X-ray inspection system market is the rising emphasis on product quality and safety. In industries such as automotive, electronics, aerospace, and food processing, the need to detect defects, contaminants, and irregularities in products has never been greater. X-ray inspection systems offer a non-invasive method of inspecting internal structures, ensuring that even the smallest defects are identified with precision. As a result, manufacturers can maintain compliance with industry standards and regulations while safeguarding their reputation and brand integrity.

Moreover, technological advancements have led to the development of more sophisticated X-ray inspection systems with enhanced capabilities. Modern systems are equipped with advanced imaging techniques, such as computed tomography (CT), which provide three-dimensional insights into the internal structures of objects. This enables manufacturers to detect defects hidden within complex assemblies and materials, thereby improving the overall quality and reliability of their products. Additionally, the integration of artificial intelligence and machine learning algorithms has further enhanced the efficiency and accuracy of X-ray inspection systems, allowing for real-time defect detection and analysis.

The X-ray inspection system market is also benefiting from the growing adoption of Industry 4.0 principles in manufacturing processes. As industries embrace automation, connectivity, and data analytics, X-ray inspection systems are being seamlessly integrated into smart production lines. These systems can be networked with other manufacturing equipment, allowing for seamless data exchange and process optimization. Furthermore, the incorporation of IoT-enabled sensors enables remote monitoring and predictive maintenance of X-ray inspection systems, minimizing downtime and maximizing productivity.

In terms of application, the X-ray inspection system market spans a wide range of industries and sectors. In the automotive industry, these systems are used for inspecting welds, castings, and assemblies to ensure structural integrity and safety compliance. In electronics manufacturing, X-ray inspection systems are employed to detect defects such as voids, cracks, and solder joint irregularities in printed circuit boards (PCBs) and semiconductor devices. Similarly, in the food and pharmaceutical industries, these systems play a crucial role in detecting contaminants, foreign objects, and packaging defects, thereby ensuring product safety and regulatory compliance.

Looking ahead, the future of the X-ray inspection system market looks promising, driven by ongoing technological innovations and the increasing adoption of quality control measures across industries. With the continuous evolution of imaging techniques, software algorithms, and hardware components, X-ray inspection systems are expected to become more efficient, reliable, and versatile. Additionally, as industries continue to prioritize sustainability and environmental responsibility, there is a growing demand for X-ray inspection systems that are energy-efficient and eco-friendly.

In conclusion, the X-ray inspection system market is experiencing robust growth driven by the need for advanced quality control solutions across various industries. Technological advancements, regulatory requirements, and the shift towards Industry 4.0 are key factors shaping the market dynamics. As manufacturers strive to maintain high standards of quality and safety, X-ray inspection systems are poised to play a central role in ensuring product integrity and reliability in the years to come.

#X-ray inspection#inspection systems#industrial technology#quality control#non-destructive testing#manufacturing#market trends

0 notes

Text

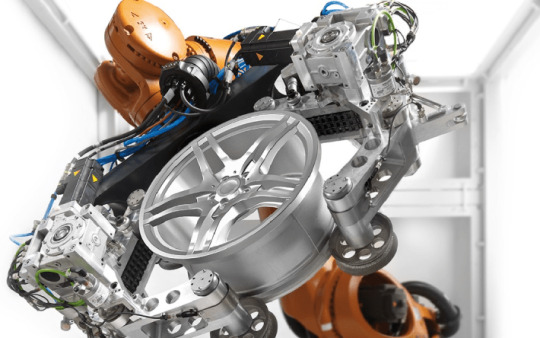

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels Robot Arm 6-axis with special gripper - BarCode inline recognition ISAR image evaluation software - XEye detector X-ray inspection... via HeiDetect HEITEC PTS and MetrologyNews ▸ TAEVision Engineering on Pinterest

Data A006R - Nov 10, 2023

#automation#robot#robotics#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#X-ray Inspection#via HeiDetect#HEITEC PTS#MetrologyNews

1 note

·

View note

Text

What, should I spread my cheeks for you too? — he asked.

4 notes

·

View notes

Text

X-ray Inspection System Market to Reach $1.3 Billion by 2034: Key Growth Trends

The global X-ray inspection system market was valued at US$ 820.0 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2034, reaching approximately US$ 1.3 billion by the end of the forecast period. X-ray inspection systems utilize high-energy electromagnetic radiation to penetrate materials, create detailed images of internal structures and detect foreign objects or defects in finished goods. Widely adopted in food and beverage, pharmaceutical, electronics, aerospace, automotive and security sectors, these systems are prized for their non-destructive testing capability, high throughput and automated data analysis.

Market Drivers & Trends

Food Safety and Compliance: As global regulatory standards tighten (e.g., HACCP, FDA FSMA), food and beverage processors increasingly rely on X-ray inspection to detect contaminants metal, glass, stone and dense organic matter without damaging products or packaging. Non-destructive X-ray scanning helps lower recall risk, reduce waste and maintain brand reputation.

Security Applications: Rising threats from smuggling operations at ports and airports to screening in public buildings are driving demand for advanced X-ray security systems with real-time threat algorithms. Governments worldwide are allocating larger budgets for state-of-the-art X-ray checkpoint scanners.

Technological Advancements: Integration of artificial intelligence (AI) and machine learning (ML) enables automated pattern recognition, reducing false positives and operator intervention. The rise of 3D computed tomography (CT) X-ray systems offers volumetric inspection, delivering a complete internal view for precision industries such as aerospace and semiconductors.

Industry 4.0 Integration: Network-enabled “smart factories” leverage X-ray systems with IoT connectivity for continuous process monitoring, predictive maintenance and centralized quality control dashboards.

Latest Market Trends

3D Imaging Adoption: Leading vendors are rolling out affordable CT-based X-ray scanners that provide layer-by-layer inspection. This trend is particularly strong in electronics and pharmaceutical packaging, where minute defect detection is critical.

High-Throughput Lines: To meet the demands of e-commerce and fast-moving consumer goods, manufacturers are deploying multi-lane X-ray conveyors that can inspect hundreds of units per minute.

Compact, Modular Designs: Smaller form-factor X-ray units with quick-swap detectors allow manufacturers to retrofit existing lines with minimal downtime.

Sustainability Focus: New models consume up to 30% less energy and feature advanced shielding materials for safer, eco-friendly operation.

Key Players and Industry Leaders

METTLER TOLEDO

Nordson Corporation

Comet Group

Anritsu

Viscom SE

North Star Imaging Inc.

Nikon Corporation

ISHIDA CO., LTD.

OMRON Corporation

TOSHIBA IT & CONTROL SYSTEMS CORPORATION

3DX-RAY

Sesotec GmbH

Visiconsult GmbH

Scienscope

Recent Developments

July 2023: Nikon Americas Inc. acquired Avonix Imaging LLC to enhance its digital CT inspection portfolio, strengthening its position in industrial metrology.

May 2023: Mettler-Toledo launched the X2 Series, democratizing high-performance X-ray inspection for small and mid-sized food processors with an attractive price-performance ratio and extended service life.

September 2022: Mettler-Toledo introduced a next-generation low-density contaminant detection algorithm, improving identification of plastics and other soft materials in packaged foods.

Other strategic partnerships and product launches throughout 2024 signal an industry pivot toward AI-enabled, cloud-connected X-ray platforms.

Market New Opportunities and Challenges

Opportunities:

Emerging Economies: Rapid expansion of packaged-food and pharmaceutical industries in Asia Pacific and Latin America presents untapped demand for inspection systems.

Custom Solutions: Growing need for tailor-made inspection equipment e.g., for novel packaging formats—creates value-added service opportunities.

After-Sales Services: Predictive maintenance contracts and software upgrades offer recurring revenue streams for OEMs.

Challenges:

High Capital Expense: Initial investment and regulatory approval costs can deter small and medium enterprises.

Technological Complexity: Integrating AI/ML and CT functionality requires specialized expertise, potentially slowing adoption.

Regulatory Variability: Differing international standards necessitate customizable system configurations, complicating product roadmaps.

Future Outlook

Over the next decade, the X-ray inspection market will be defined by deeper AI integration, miniaturized hardware and flexible, plug-and-play architectures. As throughput demands rise particularly in automated e-commerce packing facilities systems capable of inspecting multiple lines simultaneously will gain traction. Continued investments in R&D will lower per-unit cost and enhance detection of low-density contaminants. By 2034, the proliferation of Industry 4.0 ecosystems will position X-ray inspection as a cornerstone technology for end-to-end digital quality control.

Explore core findings and critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=35627

Market Segmentation

Segment

Sub-segments

Type

Digital Imaging, Film-based Imaging

Dimension

2D, 3D

Function

Manual, Automated

End-use

Electronics & Semiconductors; Oil & Gas; Aerospace; Government Infrastructure; Automotive; Power Generation; Food & Pharmaceuticals; Packaging; Others

Region

North America; Europe; Asia Pacific; Middle East & Africa; South America

Regional Insights

Asia Pacific: Held the largest share in 2023, driven by stringent food safety regulations, booming packaged-food consumption and rapid pharmaceutical industry growth in China and India.

North America: Continues to invest heavily in airport/port security and high-tech manufacturing, supporting robust market expansion.

Europe: Emphasizes sustainability and energy efficiency, prompting vendors to introduce eco-friendly X-ray systems.

Middle East & Africa / South America: Emerging security and food safety infrastructure projects are creating early adopter markets.

Why Buy This Report?

Comprehensive Analysis: In-depth coverage of market drivers, restraints, opportunities and emerging trends through 2034.

Strategic Insights: Analyst viewpoints on technology adoption, competitive landscape and regulatory impacts.

Data-Rich: Quantitative forecasts by segment, region and end-use, plus historical data from 2020–2022.

Vendor Profiles: Detailed company overviews, product portfolios, financials and strategic developments of leading players.

Actionable Recommendations: Guidance on market entry, pricing strategies and partnership opportunities for OEMs, investors and end-users.

This electronic (PDF) + Excel package equips decision-makers with the intelligence needed to gain competitive advantage in the dynamic X-ray inspection system market.

Frequently Asked Questions

Q1. What is driving the rapid adoption of X-ray inspection in the food industry? A: Stricter food safety regulations (e.g., HACCP, FDA), consumer demand for contaminant-free products and the need to minimize recalls and waste.

Q2. How does 3D CT X-ray inspection improve upon traditional 2D systems? A: 3D CT systems provide volumetric imaging, enabling detection of defects at any depth and offering comprehensive analysis of complex assemblies.

Q3. Which regions offer the highest growth potential through 2034? A: Asia Pacific, driven by rapid urbanization, expansion of packaged-food and pharmaceutical sectors, and government investments in quality infrastructure.

Q4. Are AI and machine learning capabilities standard in modern X-ray inspection systems? A: Leading suppliers now integrate AI/ML for pattern recognition and automated defect classification, though adoption varies by industry and budget.

Q5. What are the key barriers to entry for new players in this market? A: High R&D costs, regulatory approvals and the technical complexity of integrating advanced imaging modalities and analytics.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

https://www.imrmarketreports.com/reports/lithium-battery-x-ray-inspection-systems-market

0 notes

Text

🛠️ X-Ray Inspection Machines for Food Industry Market to Reach $1.77 Billion by 2035 Driven by Safety and Technological Innovations

The X-Ray Inspection Machines for the Food Industry market is set to grow from $823.7 million in 2024 to $1,769.7 million by 2035, marking a CAGR of 7.2% over the forecast period.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/x-ray-inspection-machines-for-food-industry-market-research-report

These machines are integral in ensuring foreign object detection, quality assurance, product integrity, and bone & hard material detection in food products. This report highlights key opportunities for growth in product types, technological advancements, and detection capabilities, along with future revenue projections.

🔍 Industry Leadership & Competitive Landscape

The X-Ray Inspection Machines for Food Industry market is characterized by intense competition, with leading players implementing advanced technologies and automation solutions. Prominent companies in the market include:

Mettler-Toledo International Inc.

Thermo Fisher Scientific Inc.

Anritsu Corporation

Ishida Co. Ltd.

Loma Systems

Eagle Product Inspection

Sesotec GmbH

Mekitec Ltd.

WIPOTEC-OCS GmbH

JBT Corporation

Minebea Intec

Multivac Group

These companies are driving the market’s growth by focusing on safety regulations compliance, enhanced detection technologies, and efficiency improvements in food processing.

🚀 Key Growth Drivers & Opportunities

Several factors are fueling the growth of the X-ray inspection machine market for the food industry, including:

Compliance with stringent food safety regulations across various regions

Technological advancements in X-ray inspection technologies for more efficient and accurate detection

Increased demand for process optimization in food production to reduce waste and increase operational efficiency

Rising automation in food processing plants to enhance product consistency and reduce human error

Key opportunities include tapping into emerging markets in developing countries, along with continued innovation in automation and inspection technologies.

🌍 Regional Trends & Evolving Ecosystems

While North America and Europe lead the market, emerging regions such as Brazil, India, and South Africa present significant growth opportunities. Market players are expanding their presence in these regions to address growing food safety needs and the adoption of advanced inspection equipment.

The market faces challenges such as:

High costs of implementation for advanced machinery

Dependency on skilled labor for machine operation and maintenance

Supply chain complexities in raw materials and distribution channels

As a result, the market ecosystem—from raw material suppliers and equipment manufacturers to distributors and end users—is evolving rapidly to accommodate the growing demand.

🧠 About DataString Consulting

DataString Consulting is a global market research and business intelligence firm that provides bespoke market research, strategic consulting, and insight-driven solutions for both B2B and B2C industries. With more than 30 years of experience, we offer expertise in identifying high-growth opportunities and delivering tailored solutions to meet the strategic needs of businesses.

Our services include:

In-depth market research reports

Comprehensive opportunity assessments

Strategy consulting for market penetration and expansion

Industry trend analysis and forecasting

#X-Ray Inspection for Food Industry#Food Safety Technology#Food Processing Automation#Food Quality Assurance Solutions#Foreign Object Detection Systems#X-Ray Detection Equipment Market#Food Industry Inspection Machines#Technological Advancements in Food Safety#Global X-Ray Inspection Market Growth#Food Industry Regulatory Compliance#Inspection Equipment Market in Food Processing#Emerging Markets for Food Inspection Technology

0 notes

Text

X-ray PCB Inspection Solutions for Quality Assurance

Ensure precision and reliability with Kyoritsu Electric’s cutting-edge X-ray PCB inspection solutions. Our advanced x-ray inspection systems are designed to detect hidden defects in solder joints, BGA, SMT components, and multilayer boards without damaging the product. With decades of expertise, Kyoritsu Electric stands out among x ray manufacturers in India, delivering high-quality x-ray inspection equipment solutions tailored for the electronics manufacturing industry.

Whether you're looking for detailed fault detection, process control, or quality assurance, our x ray machine PCB inspection technology ensures unmatched accuracy and performance. Trusted by leading electronics and EMS companies, we help you maintain high production standards while reducing rework and failure rates. Discover the power of non-destructive testing and enhance your PCB manufacturing process with Kyoritsu Electric’s reliable and efficient X-ray solutions.

#x ray machine pcb inspection#x-ray inspection systems#x-ray inspection equipment solutions#x ray manufacturers india

0 notes

Text

The XIS-1818DV is an advanced X-Ray Inspection System. The XIS-1818DV utilizes both dual view technology and high powered generators for improved image screening and increased penetration. This advanced x ray inspection system was specifically designed for in-depth screening clarity of customs and military cargo.

0 notes

Text

#electronics manufacturing#electronics manufacturing companies#electronic manufacturers company#X-ray inspection ensures#X-Ray#x ray spex#plastic manufacturers company#X-Ray Technology#PCB Assembly#PCB Assembly India#PCB Assembly Services#pcb manufacturer#pcb

0 notes

Text

Computed Radiography: An Eco-Friendly Inspection Solution

Computed Radiography (CR) is a modern non-destructive testing (NDT) technique that replaces film radiography with a digital imaging process. Computed radiography (CR) does not use traditional X-ray films. Instead, it relies on imaging plates (IPs) to capture high-resolution images. These images are then processed digitally. Consequently, this approach enhances inspection speed, defect detection,…

#CR cassettes#CR imaging accessories#CR readers#CR systems#CR technology#Dental radiography#Digital imaging#Digital radiography#Image processing#Imaging plates#Industrial radiography#Medical diagnostics#Non-Destructive Testing#Photostimulable phosphor#Radiographic inspection#Radiographic testing#Storage phosphor#Veterinary imaging#X-ray imaging

0 notes

Text

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels Robot Arm 6-axis with special gripper - BarCode inline recognition ISAR image evaluation software - XEye detector X-ray inspection... via HeiDetect HEITEC PTS and MetrologyNews ▸ TAEVision Engineering on Pinterest

Data A006R - Jul 24, 2023

#automation#robot#robotics#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#X-ray Inspection#via HeiDetect#HEITEC PTS#MetrologyNews

1 note

·

View note

Text

A Comprehensive Guide to Minimizing Food Contamination and How X-rays are Revolutionizing Food Safety

Food contamination is a significant concern worldwide, affecting public health, economies, and consumer trust. In recent years, technological advancements, such as X-ray inspection systems, have played a pivotal role in enhancing food safety protocols.

Understanding Food Contamination

Food contamination refers to the presence of harmful substances or microorganisms in food, rendering it unsafe for consumption. Contaminants can arise from various sources, including:

Microorganisms: Bacteria, viruses, fungi, and parasites can contaminate food during production, processing, storage, or preparation stages.

Chemicals: Pesticides, heavy metals, cleaning agents, and food additives are potential chemical contaminants that can enter the food chain.

Physical Contaminants: Foreign objects like glass, metal, plastic, or hair can accidentally end up in food during processing or packaging.

Allergens: Ingredients that trigger allergic reactions in susceptible individuals must be carefully monitored and labeled.

Challenges in Minimizing Food Contamination

Despite stringent regulations and industry standards, several challenges persist in ensuring food safety:

Global Supply Chains: With food sourced from various regions globally, maintaining consistent quality control throughout the supply chain is complex.

Emerging Pathogens: New strains of bacteria or viruses continually emerge, necessitating ongoing research and adaptation of safety measures.

Cross-Contamination: Equipment, surfaces, and even personnel can contribute to cross-contamination if proper hygiene practices are not followed rigorously.

Allergen Management: Ensuring accurate labeling and preventing cross-contact of allergens remains a challenge in food processing facilities.

Detection Limitations: Traditional inspection methods may not detect contaminants at microscopic levels, posing risks to consumer health.

The Role of X-ray Inspection Systems

Food X-ray inspection systems have emerged as a cutting-edge technology in food safety, offering several advantages over traditional methods:

Detection Capabilities: X-rays can detect contaminants such as metal, glass, stones, bones, and even dense plastic particles, ensuring comprehensive inspection.

Non-Destructive Testing: Unlike physical sampling, X-rays allow for non-destructive testing of packaged and unpackaged food items, preserving product integrity.

High-Speed Inspection: Modern X-ray systems can inspect hundreds of products per minute, making them suitable for high-volume production lines.

Allergen Detection: X-rays can identify allergen traces, helping prevent cross-contamination and ensuring accurate allergen labeling.

Quality Control: X-ray inspection not only detects contaminants but also assesses product quality, including measurements, missing components, and packaging defects.

Implementing X-ray Technology for Food Safety

The adoption of X-ray inspection systems involves several key steps:

Assessment: Conduct a thorough risk assessment to identify potential hazards and determine where X-ray inspection is most beneficial in the production process.

Integration: Integrate X-ray systems seamlessly into existing production lines, ensuring minimal disruption and maximum efficiency.

Training: Train personnel in operating X-ray equipment, interpreting results, and implementing corrective actions when contaminants are detected.

Validation: Validate the effectiveness of X-ray inspection through regular testing, calibration, and comparison with other inspection methods.

Regulatory Compliance: Ensure compliance with local and international food safety regulations regarding X-ray usage, record-keeping, and reporting.

Benefits of X-ray Inspection in Food Safety

The widespread adoption of X-ray inspection systems offers numerous benefits to food manufacturers, consumers, and regulatory bodies:

Enhanced Consumer Safety: By detecting contaminants at microscopic levels, X-rays significantly reduce the risk of consumers ingesting harmful substances.

Brand Protection: Ensuring food safety through advanced technologies like X-rays helps protect brand reputation and build consumer trust.

Regulatory Compliance: Meeting or exceeding food safety standards and regulations is easier with accurate and reliable X-ray inspection data.

Cost-Efficiency: While initial investment in X-ray systems may be substantial, the long-term cost savings from preventing recalls, lawsuits, and brand damage are significant.

Innovation and Sustainability: Embracing technological advancements reflects a commitment to innovation and sustainability in the food industry, attracting eco-conscious consumers.

Future Trends and Challenges

Looking ahead, several trends and challenges will shape the future of food safety and X-ray inspection:

Blockchain Integration: Combining X-ray data with blockchain technology for transparent and traceable supply chains.

Artificial Intelligence: Implementing AI algorithms to enhance detection capabilities and reduce false positives in X-ray inspection.

Sustainability Focus: Developing eco-friendly packaging materials that are compatible with X-ray inspection without compromising safety.

Global Collaboration: Strengthening international collaboration and standards for consistent food safety practices across borders.

Public Awareness: Educating consumers about the role of technology in food safety and empowering them to make informed choices.

Conclusion

Minimizing food contamination is a multifaceted endeavour that requires continuous vigilance, innovation, and collaboration across the food industry. X-ray inspection systems represent a significant leap forward in enhancing food safety, offering unparalleled detection capabilities and contributing to a healthier, more secure food supply chain. By embracing these technologies and best practices, we can pave the way for a future where safe, high-quality food is accessible to all.

0 notes

Text

Food Metal Detection and X-ray Inspection Equipment Market Industry Growth Forecast: Key Drivers and Market Trends to 2033

Food Metal Detection and X-ray Inspection Equipment Market Size

The global food metal detection and X-ray inspection equipment market size was valued at USD 623.45 million in 2024 and is estimated to reach USD 804.26 million by 2033, growing at a CAGR of 2.87% during the forecast period (2025–2033).

Food Metal Detection and X-ray Inspection Equipment Market Overview:

The Food Metal Detection and X-ray Inspection Equipment Market The report provides projections and trend analysis for the years 2024–2033 and offers comprehensive insights into a market that spans several industries. By fusing a wealth of quantitative data with professional judgment, the study explores important topics such product innovation, adoption rates, price strategies, and regional market penetration. Macroeconomic variables like GDP growth and socioeconomic indices are also taken into account in order to put market swings in perspective. Food Metal Detection and X-ray Inspection Equipment are advanced technologies used in the food industry to ensure product safety and quality. Metal detectors identify ferrous, non-ferrous, and stainless-steel contaminants in food, while X-ray inspection systems detect a broader range of foreign materials, including glass, stone, plastic, and bone. The main market participants, the industries that employ the products or services, and shifting consumer tastes are all crucial subjects of conversation. The competitive environments, regulatory effects, and technical advancements that affect the market are all carefully examined in this study. The well-structured Food Metal Detection and X-ray Inspection Equipment Market Report provides stakeholders from a variety of political, cultural, and sectors with useful commercial information.

Get Sample Research Report: https://marketstrides.com/request-sample/food-metal-detection-and-x-ray-inspection-equipment-market

Food Metal Detection and X-ray Inspection Equipment Market Growth And Trends

Numerous Food Metal Detection and X-ray Inspection Equipment Market breakthroughs are driving a significant shift in the industry, altering its course for the future. Following these important changes is essential because they have the potential to reshape operations and plans. Digital Transformation: Data-driven solutions enhance customer contact and streamline processes as digital technologies develop. Customer Preferences: Businesses are offering customized items as a result of the growing emphasis on convenience and personalization. Regulatory Changes: Companies must quickly adjust in order to stay competitive as compliance standards and rules become more stringent.

Who Are the Key Players in Food Metal Detection and X-ray Inspection Equipment Market , and How Do They Influence the Market?

Mettler-Toledo

Anritsu Infivis

Sesotec GmbH

Ishida

LOMA Systems

CEIA

Eagle PI

WIPOTEC-OCS

Techik

Dylog Hi-Tech

Mekitec

Others

With an emphasis on the top three to five companies, this section offers a SWOT analysis of the major players in the Food Metal Detection and X-ray Inspection Equipment Market market. It highlights their advantages, disadvantages, possibilities, and dangers while examining their main strategies, present priorities, competitive obstacles, and prospective market expansion areas. Additionally, the client's preferences can be accommodated by customizing the company list. We evaluate the top five companies and examine recent events including partnerships, mergers, acquisitions, and product launches in the section on the competitive climate. Using the Ace matrix criteria, their Food Metal Detection and X-ray Inspection Equipment Market market share, growth potential, contributions to total market growth, and geographic presence and market relevance are also analyzed.

Browse Details of Food Metal Detection and X-ray Inspection Equipment Market with TOC: https://marketstrides.com/report/food-metal-detection-and-x-ray-inspection-equipment-market

Food Metal Detection and X-ray Inspection Equipment Market : Segmentation

By Type

Metal Detectors

X-ray Devices

By Applications

Solid Food

Liquid Food

What Makes Our Research Methodology Reliable and Effective?

Data Accuracy & Authenticity – We use verified sources and advanced data validation techniques to ensure accurate and trustworthy insights.

Combination of Primary & Secondary Research – We gather first-hand data through surveys, interviews, and observations while also leveraging existing market reports for a holistic approach.

Industry-Specific Expertise – Our team consists of professionals with deep domain knowledge, ensuring relevant and actionable research outcomes.

Advanced Analytical Tools – We utilize AI-driven analytics, statistical models, and business intelligence tools to derive meaningful insights.

Comprehensive Market Coverage – We study key market players, consumer behavior, trends, and competitive landscapes to provide a 360-degree analysis.

Custom-Tailored Approach – Our research is customized to meet client-specific needs, ensuring relevant and practical recommendations.

Continuous Monitoring & Updates – We track market changes regularly to keep research findings up to date and aligned with the latest trends.

Transparent & Ethical Practices – We adhere to ethical research standards, ensuring unbiased data collection and reporting.

Which Regions Have the Highest Demand for Food Metal Detection and X-ray Inspection Equipment Market?

The Food Metal Detection and X-ray Inspection Equipment Market Research Report provides a detailed examination of the Food Metal Detection and X-ray Inspection Equipment Market across various regions, highlighting the characteristics and opportunities unique to each geographic area.

North America

Europe

Asia-Pacific

Latin America

The Middle East and Africa

Buy Now:https://marketstrides.com/buyNow/food-metal-detection-and-x-ray-inspection-equipment-market

Frequently Asked Questions (FAQs)

What is the expected growth rate of the Food Metal Detection and X-ray Inspection Equipment Market during the forecast period?

What factors are driving the growth of the Food Metal Detection and X-ray Inspection Equipment Market?

What are some challenges faced by the Food Metal Detection and X-ray Inspection Equipment Market ?

How is the global Food Metal Detection and X-ray Inspection Equipment Market segmented?

What regions have the largest market share in the global Food Metal Detection and X-ray Inspection Equipment Market?

About Us:

Market Strides is an international publisher and compiler of market, equity, economic, and database directories. Almost every industrial sector, as well as every industry category and subclass, is included in our vast collection. Potential futures, growth factors, market sizing, and competition analysis are all included in our market research reports. The company helps customers with due diligence, product expansion, plant setup, acquisition intelligence, and other goals by using data analytics and research.

Contact Us: [email protected]

#Food Metal Detection and X-ray Inspection Equipment Market Size#Food Metal Detection and X-ray Inspection Equipment Market Share#Food Metal Detection and X-ray Inspection Equipment Market Growth#Food Metal Detection and X-ray Inspection Equipment Market Trends#Food Metal Detection and X-ray Inspection Equipment Market Players

0 notes

Text

Why Regular Medical Equipment Inspections and Repairs Matter

In the healthcare industry, the reliability of medical equipment is paramount. Regular inspections and timely repairs ensure that these essential devices function correctly, safeguarding patient health and improving overall operational efficiency. In this blog, we'll explore the importance of medical equipment inspections and repairs, the types of inspections performed, and how partnering with a trusted service provider like OMI MedTech can make a significant difference.

The Importance of Medical Equipment Inspections

Medical equipment inspections involve a systematic evaluation of devices used in healthcare settings. These inspections are crucial for several reasons:

Patient Safety: The primary goal of medical equipment inspections is to ensure patient safety. Faulty equipment can lead to misdiagnosis, improper treatment, or even harm to patients. Regular inspections help identify potential hazards before they escalate into critical issues.

Regulatory Compliance: Healthcare facilities must adhere to strict regulations and standards set by organizations such as the Joint Commission and the FDA. Regular inspections help ensure compliance with these regulations, reducing the risk of penalties or operational disruptions.

Operational Efficiency: Equipment that is regularly inspected is less likely to break down unexpectedly. This leads to fewer disruptions in service and allows healthcare professionals to focus on providing quality care rather than dealing with equipment failures.

Cost Savings: Preventative inspections can save healthcare facilities money in the long run. By identifying and addressing issues early, facilities can avoid costly repairs and replacements, as well as minimize downtime.

Types of Medical Equipment Inspections

Medical equipment inspections typically cover a range of devices, including:

Diagnostic Equipment: This includes imaging devices like X-rays and ultrasounds. Inspections ensure these devices produce accurate results, which are crucial for diagnosis and treatment.

Sterilization Equipment: Autoclaves and other sterilization devices must be regularly checked to ensure they effectively eliminate harmful pathogens. This is vital for infection control in healthcare settings.

Monitoring Devices: Patient monitors, infusion pumps, and ventilators require regular inspections to ensure they function correctly and provide reliable data during treatment.

Surgical Instruments: Tools used in surgical procedures must be regularly inspected for cleanliness, functionality, and safety.

Why Repairs Matter

While inspections are essential, timely repairs are equally important. Here’s why:

Quick Resolution of Issues: When equipment malfunctions, quick repairs are necessary to restore functionality. Delays can lead to service interruptions and impact patient care.

Expertise in Repairs: Specialized medical equipment requires knowledgeable technicians for repairs. Partnering with a reputable service provider ensures that repairs are conducted by experts familiar with the specific devices.

Maintaining Equipment Lifespan: Regular maintenance and prompt repairs can extend the lifespan of medical equipment, maximizing the return on investment for healthcare facilities.

Improved Patient Outcomes: When medical equipment is functioning optimally, it leads to better diagnostic accuracy and treatment efficacy, ultimately improving patient outcomes.

Choosing OMI MedTech for Your Inspection and Repair Needs

At OMI MedTech, we understand the critical role that well-maintained medical equipment plays in healthcare. Our team of experienced technicians specializes in comprehensive inspections and prompt repairs for a wide range of medical devices. We are committed to ensuring your equipment operates at its best, helping you maintain high standards of patient care.

By prioritizing regular medical equipment inspections and timely repairs with OMI MedTech, healthcare facilities can enhance patient safety, ensure compliance with regulations, and improve overall operational efficiency. Don’t wait for a malfunction to disrupt your services—schedule your inspections and repairs today!

Conclusion

Regular medical equipment inspections and repairs are not just good practices—they are essential components of a safe and efficient healthcare environment. By partnering with OMI MedTech, healthcare providers can ensure their equipment is always in optimal condition, leading to improved patient care and safety. Make the smart choice for your facility and invest in regular inspections and repairs today.

#Medical equipment inspection#Autoclave repair service near me#X-ray repair#medical equipment service#autoclave repair#Medical equipment repair

0 notes