#robot arm 6-axis

Explore tagged Tumblr posts

Text

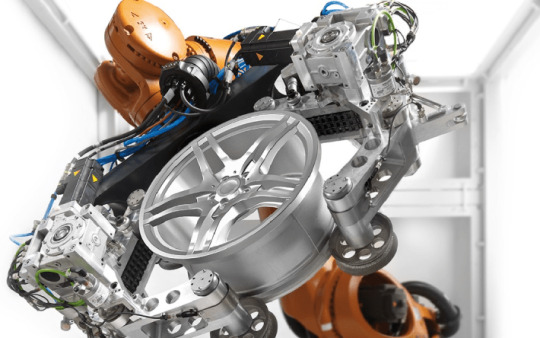

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels Robot Arm 6-axis with special gripper - BarCode inline recognition ISAR image evaluation software - XEye detector X-ray inspection... via HeiDetect HEITEC PTS and MetrologyNews ▸ TAEVision Engineering on Pinterest

Data A006R - Nov 10, 2023

#automation#robot#robotics#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#X-ray Inspection#via HeiDetect#HEITEC PTS#MetrologyNews

1 note

·

View note

Text

Morning Routines and Midnight Cravings

Pairing: Tenya Iida x Fem!Reader

Genre: Fluff / Domestic Life

Word Count: ~1,100

---

The sun hadn’t even crept past the curtains when the nausea hit.

You gripped the edge of the bathroom sink, groaning as your stomach rolled again. It was week 20—supposedly past the worst of the morning sickness—and yet, here you were, face-to-face with the porcelain throne at 6:13 a.m.

Soft footsteps padded down the hall. You heard the familiar cadence—quick and precise—and seconds later, Tenya appeared in the doorway, hair slightly askew from sleep, glasses foggy from the sudden change in temperature.

“Darling,” he said, voice low with concern. “Again?”

You gave him a thumbs up with your eyes closed, cheek pressed to the cool surface of the sink.

Tenya sighed softly, stepping inside. His large hand smoothed over your back, rubbing gentle circles the way he always did when you felt like the room might spin off its axis.

"I'll get you some water and ginger candy," he murmured. "And I already texted your doctor. Just in case."

“You didn’t have to,” you croaked.

“I’m your husband. Of course I did.”

Before you could argue, another pair of footsteps approached—smaller this time, with an eager bounce to them.

“Mama?” your five-year-old son peeked in, his blue eyes wide and worried, clutching a stuffed robot toy in one hand. “Are you sick again?”

You forced a smile for him, reaching out. “Hey, baby. Yeah, a little. But I’m okay.”

Tenya crouched to meet your son’s gaze. “Mama’s tummy is just working very hard. She’s growing your little brother or sister, remember?”

The little boy’s eyes widened. “That sounds hard.”

You chuckled weakly. “It is.”

He scurried away and returned a moment later with a cup of water filled to the brim and a carefully peeled banana.

“For you,” he said, presenting it like a precious artifact.

Tears pricked your eyes. “Thank you, sweetheart. You’re so helpful.”

Tenya kissed the top of your head before lifting you in his arms—like it was nothing, like you didn’t weigh more than ever. “Bed,” he said firmly. “Both of you.”

You didn’t even try to argue this time.

---

Later, you lay tucked into the couch, your son curled up against your side with a coloring book while Tenya returned from the kitchen, balancing a tray with dry toast, peppermint tea, and a tiny cup of applesauce.

“I've reviewed several nutritional recommendations,” he said, adjusting his glasses. “These should help settle your stomach. Unless you prefer pickles and peanut butter again?”

You grimaced. “Only at 2 a.m.”

He chuckled and leaned down to press a kiss to your temple. “You’re doing amazing.”

You sighed, resting your hand on your growing belly. “I feel like I’m failing. I can’t even get through breakfast without—”

“Stop.” Tenya’s tone was firm, loving but certain. “You are creating life. Twice, now. That is the definition of strength.”

Your son looked up from his coloring. “Are you gonna puke again, Mama?”

You and Tenya both burst out laughing.

---

That night, you awoke to find Tenya gently propping your legs up with pillows.

“Sorry,” he whispered. “You were shifting a lot. Thought you’d sleep better this way.”

You blinked at him sleepily. “You’re too good to me.”

“I love you,” he said simply.

You reached for his hand. “Remind me again why we’re doing this?”

He kissed your knuckles. “Because the world needs more heroes with your heart.”

#my hero academia#reader#mha x reader#bhna#fluff#tenya iida#tenya lida#mha tenya#iida tenya x reader#bnha tenya#mha iida#iida x reader#tenya#iida#Iida

163 notes

·

View notes

Text

Ive been going down a rabbit hole of open source robotics and really want to build a 6 axis arm just so I can stick a dildo on the end of it.

On a tangential project, there's a control mechanism that can be theoretically used to control each axis of the arm by using a contraption that looks the same, but has encoders instead of motors for each joint. By moving the end of the arm on the controller, I can move the arm of the robot.

SO, what does this mean? I could hook a fleshlight up to one unit and the dildo up to the other, and experience some odd mechanized sensation of fucking myself in either direction.

That got me thinking about gathering data about how I fuck myself. I could hook up some electrodes and analyze physical response tagged vocally while I use robots to masturbate. I could then analyze the data, pull out movement sequences that I really like, then build a second arm to join the first. With the data I could just sit back and have some automated gooning.

BUT Wait, there's more! With that kind of automation, I could either rig up the program to a model in unreal and fuck a character in VR, or I could add trackers to the physical robots and have the assets rigged to the trackers and if I decide to take manual control, the scene would be dynamic (of course I could close loop my motors and pull that data but that get into a different realm of expense plus a big redesign). Maybe an existing dev would be willing to add trackable characters if I could sell them on gonners wanting to track dolls. Hmmmm...

These aren't even sexy androids, they are automation hardware that I'm trying to use to turn myself into a cum factory. My brain broke. Anyhow, just thought I'd share my day browsing github and Ali express while actively resisting the urge to buy the gyno chair for sale on govdeals.com.

26 notes

·

View notes

Text

youtube

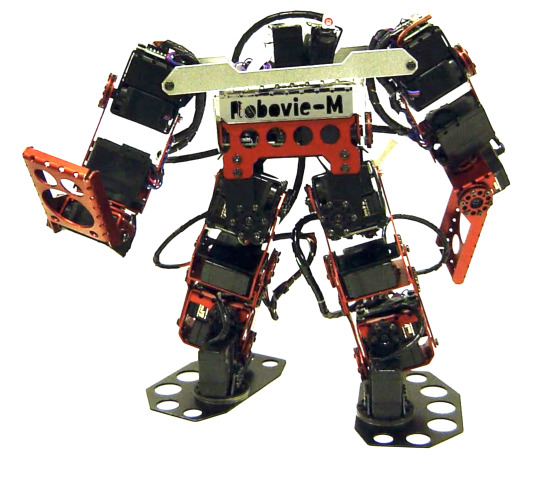

Robovie-M (2003), by ATR and Vstone, Japan. Robovie-M can walk, lie down, perform handstands, and stand up if it falls over.

"Robovie-M is a small humanoid robot that can walk on two legs, developed for students of technical colleges and universities, robot researchers, and engineers who aspire to robot research. It is an assembly teaching material. The hardware is based on the small humanoid robot OmniHead developed by Vstone Co. Ltd., and is small (total height 290mm) but has 22 degrees of freedom (6 degrees of freedom for each leg, 4 degrees of freedom for each arm, 1 degree of freedom for the waist, and 1 degree of freedom for the chest). It has a 2-axis acceleration sensor necessary for attitude control. [Sold] as an assembly kit that allows you to enjoy both hardware and software robot production. Vstone Co., Ltd. will manufacture and sell it." – Robots have become much more familiar!!, ATR, 2003.

22 notes

·

View notes

Text

I decided to make every, single, Axis model. I'm kinda shocked that nobody has done this before lol

Designed by Chujin Ketsukane, this short lived series of bots were designed to help aid in the Underground's Royal Guard. Sadly, none of them could rise to the occasion.

Axis 01 - The Glitchy One - Couldn't go 6 seconds before shutting down.

Axis 02 - The Happy Guy - Actually functioned. A nice and chipper lad, but wasn't very strong or powerful.

Axis 03 - The first one to get arms - He sure does have arms!

Axis 04 - The overconfident one - Launched one his gloves right in the King's face while shouting quirky 90's one liners.

Axis 05 - Big Ol Doofus - Probably the strongest so far but there wasn't a single artificial thought behind those eyes.

Axis 06 - The Pacifist - When he learnt what his purpose was, he was horrified. Decided to become a pacifist. Spouts the words "Peace and Love" every other sentence.

Axis 07 - Walking Axiety - Wouldn't even go in for his demonstration in front of the king. Threw up oil all over the judgement hall's floor on the way out. Chujin decided to stop giving mouths after that.

Axis 08 - The pyromaniac - After how soft the last two were, Chujin decided to give this one more fighting spirit. Unfortunately, 08 developed a love for fire and would commonly burn things just for "the funzies." He was the one who coast Chujin his job.

Axis 09 - The thinker - Chujin made this be a thinker. A strategist, who always thinks through his planes. Unfortunately, he made him too much of a thinker. He would just sit on a stool all day doing nothing but think.

Axis 10 - A wheely bad guard - First to be given straight up wheels. Unfortunately, he was clumsy and would always fall over! He was also just too nice to be in the royal guard lol.

Axis 11 - The jock - A light weight model with much better balance. He was honestly a pretty decent bot, but he kept on calling Chujin "Dude" and "Bro" which made him uncomfortable, and kept on saying pretty misogynistic stuff Chujin did not program him to say. This isn't who you want to represent your career as an engineer.

Axis 12 - The first one to given floating hands - He sure does have floating hands. Pitty they never actually worked...

Axis 13 - The baffled one - Floating hands actually work now, much to the robot's confusion. He kept on staring at them instead of doing what he was to do.

Axis 14 - The best - YOU ALL KNOW HIM!!!

The last few bots were donated to The Steamworks after Chujin's death to guard the premises. Sadly, it wouldn't mean much as the facility would close a few months later.

#undertale yellow#undertale yellow axis#undertale yellow fanart#undertale#undertale art#undertale fanart#fanart#ocs#digital art#character design#goofy

6 notes

·

View notes

Text

i got back from a week long trip so now i've had plenty of time to ruminate on things and im finally ready to see what the fuck this guy has been trying to cook

episode 7 post

ep1 ep2 ep3 ep4 ep5+6

i think i saw a drawing of this guy earlier today except he had boobs

so lion's pretty obviously supposed to be the baby from 19 years ago, right.

ay ay aY AY AY

oh bah, the way it started out as just the last word in caps for a couple lines made me think dlanor was disguised as shannon or something but nah shes just like a robot or possessed for something.

i feel like ive been told explicitly 15 times that beato was the original beatrice's daughter who kinzo believed was her reincarnated, as if this is the first time im being given this information

damn bro you look hideous

alright so we're positing that original beatrice was enough of a fascist that she stuck to mussolini even after the rest of the country gave up? ok.

alright alright alright we're talking about whether the axis were cowards based on whether or not they surrendered and how alright.

REALLY FUNNY FOR THE V/O TO STILL BE FULLY JAPANESE WHEN HE'S SUPPOSED TO BE SPEAKING ENGLISH. OH BUT "I CANNOT SPEAK ENGLISH" IS?

interesting that this beatrice is using the baby beato voice. I've been trying to get the logic of it, and the best I can figure is that its just... to differentiate? differentiate WHAT exactly, whether its between human beatrices or just the humans and the witch im not sure yet. but I miss her other voice :( the flashback we got of her earlier that I didn't mention also used this voice even though im fairly certain the original version didn't.

i get that its for plot contrivances because beatrice had to get here somehow but WHY on EARTH would someone bring their daughter on an armed military vessel in the middle of a massive war. also because i touched on it earlier i'd like to clarify, i get that the participants in war are not necessarily people who agree with any of it. and even then, your circumstances of birth and pressure from your family will put you in situations out of your control (given, thats what this whole thing has Been About). idk i dont want it to come across as i don't get what's going on or like im an idiot or something. i may also be a bit defensive because i haven't really enjoyed the reading process terribly much in a while and didn't appreciate some of the feedback i've gotten in regards to "just keep reading, you'll like it, youll understand" because i dont think its properly come across that i think i Do understand, im just squicked the fuck out by a lot of things in part 6 and so far haven't seen anything that would allegedly turn my opinion around that much. but there's still a lot left in this to go. im just. bored honestly.

REALLY funny how much "bice" comes off sounding like bitch. all my friends at home call me bitch

oh my god also hilarious. the golds in the submarine isnt it.

EVEN IF ITS A TOP SECRET BASE WHY THE FUCK DONT YOU HAVE A DOCTOR?

anybody else have to stop and hold their head for a minute every time wildly specific gun specs are listed for no reason whatsoever

anyways this fight over the gold is fun, i figured something was gonna have to happen that got everyone else off that island and left the gold, so this makes as much sense as anything. and feeling the drive to live despite it all after seeing genuine bloodshed for the first time is a little overdone but just fine.

*curb your enthusiasm theme starts playing* well at least he insisted on taking her to a doctor

ohhhhh we're confirming beato is really and for true kinzo's biological daughter *head in handssss*

PLEASE STOP PINCHING THIS MAN'S ASS!!!

oh my god, first acknowledgement that battler isn't here. i kinda figured since he's always been kinzo's mirror of sorts, he wasn't gonna be here because kinzo was alive. like there's no reason for that to be the case, but to me the logic felt sound. battler and kinzo haven't been in the same place at the same time, at least not in 1986. and it seems that will continue to be the case !!

STOP PINCHING EVERYONES ASSES

lion sucks, actually. wretched personality.

i was holding back on making a joke about how maria talks about beato the way christian billboards exclusively go on about how there's "evidence god exists" or whatever, but now she's reciting the bible word for word so i dont know what to do with my point but i have to share it now. i do like that her point seems to be that because maria doesn't have a father, she is jesus. good for you girl.

BEATOOOOOOOOOOOOOO. and with the voice! ok so definitely that's the witch's voice.

alright this whole scenario can be argued as maria having an imaginary friend about it but if that piece of candy that beato told her to keep as a souvenir and not eat is still in maria's bag, magic is fucking Real.

also beato telling maria to practice basic hygene as her witch traini-- *has a jimmy neutron style brain blast and remembers the 1 (one) shinto shrine i've visited* OH, NO THIS IS A SHINTO THING. OK HELL YEAH. more of beato the "western" witch using japanese magics. i see i see i see.

fellas i may just like witch beato

7 notes

·

View notes

Text

robotic arm cuts rock with surgical precision

Imagine a 2.4-ton robotic arm wielding a six-foot-seven (2-m) circular sawblade with a 12-foot (3.7-m) reach, slung onto a truck-mounted hooklift system for easy transport. It’s as terrifying as it is awe-inspiring. That’s Smart Production’s latest creation, built on the back of Kuka’s KR Fortec 480 Ultra and called the Catonator. It’s a 6-axis, 4,850-lb (2,200-kg) fully electric, battery-powered…

0 notes

Text

Global Articulated Robot Industry Poised for Rapid Transformation

The global articulated robot market is undergoing a dynamic transformation, driven by increased automation across industries and rapid technological advancements. According to the latest market intelligence, the articulated robot market, valued at US$ 17.3 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 8.9% to reach US$ 38.3 billion by 2031.

Market Overview

An articulated robot is an industrial robot equipped with rotary joints, mimicking the motion of a human arm. These robots are highly flexible and are widely adopted in sectors requiring high precision and productivity—such as automotive, electronics, food & beverage, pharmaceuticals, and logistics. Their ability to perform repetitive, complex tasks efficiently is enhancing quality, throughput, and workplace safety.

Market Drivers & Trends

1. Surge in Industrial Automation: Industries are increasingly investing in automation to improve operational efficiency, reduce costs, and address labor shortages. Articulated robots have become central to this trend, especially in manufacturing, where they are used for assembly, painting, welding, and material handling.

2. Workplace Safety Regulations: Governments across the globe are enforcing strict workplace safety laws. Articulated robots minimize the need for human workers in hazardous environments, thereby promoting safety and compliance.

3. Rise of Third-party Logistics (3PL): The booming e-commerce industry is propelling demand for automated 3PL operations. Articulated robots are essential in warehouse automation—streamlining tasks such as sorting, palletizing, and storage.

Latest Market Trends

Miniaturization & Flexibility: Innovations such as ABB's IRB 1010—a compact articulated robot with high payload accuracy—are allowing deployments in constrained spaces and new sectors like wearables manufacturing.

AI and IoT Integration: Robotics integrated with artificial intelligence (AI) and Industrial Internet of Things (IIoT) are boosting productivity by enabling predictive maintenance, real-time monitoring, and adaptive task handling.

Customization for SMEs: Manufacturers are tailoring robot solutions to meet the specific needs of small and medium-sized enterprises (SMEs), especially in emerging markets such as Eastern and Central Europe.

Key Players and Industry Leaders

The articulated robot market features prominent players with robust global footprints. Notable companies include:

ABB

FANUC Corporation

YASKAWA Electric Corporation

KUKA AG

Honeywell International Inc.

Mitsubishi Electric Corporation

Kawasaki Heavy Industries Ltd.

Omron Corporation

Schneider Electric

Zebra Technologies

Locus Robotics

JAKA Robotics

These players are continually expanding their product portfolios, investing in R&D, and forming strategic alliances to strengthen their market position.

Download Sample PDF Copy: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=46560

Recent Developments

October 2022: ABB introduced IRB 1010, the smallest articulated robot in its portfolio, targeting wearables and electronic component assembly.

May 2022: KUKA AG entered the medical robotics segment by partnering with Restoration Robotics for the ARTAS iX System, an automated hair restoration platform.

2017: Seiko Epson launched compact 6-axis robots (N6, VT6) and T6 SCARA robots, aimed at compact factory environments.

Market Opportunities

The articulated robot market presents several lucrative opportunities:

Emerging economies such as India, Brazil, and Poland are increasingly investing in manufacturing automation.

Healthcare and food & beverage industries are witnessing significant uptake due to hygiene requirements and labor shortages.

Flexible automation solutions for small-batch manufacturing are opening up new frontiers for robot deployment.

Future Outlook

Analysts forecast sustained growth in the articulated robot market driven by:

Continuous technological advancements in AI-powered robotics

Expanding applications across new verticals like healthcare and agriculture

Government support for automation and digitalization initiatives (e.g., China’s "Made in China 2025")

Asia Pacific is expected to exhibit the fastest growth during the forecast period, thanks to its expanding industrial base, strong government backing, and growing warehouse automation needs.

Market Segmentation

By Offering:

Hardware

Software

Services

By Payload:

Up to 25 Kg

26–50 Kg

51–75 Kg

76–100 Kg

100–200 Kg

Above 200 Kg

By Application:

Palletizing & Depalletizing

Loading & Unloading

Sortation & Storage

Assembly & Dispensing

Others (e.g., Packaging, Replenishment)

By End-use Industry:

Food & Beverage

Automotive

FMCG

Pharmaceuticals

Chemicals

Metal & Machinery

Electronics & Semiconductor

Retail

3PL

Others (Healthcare, Petrochemicals, etc.)

Regional Insights

North America: In 2022, North America held the largest market share (37.72%). The U.S. is spearheading the Fifth Industrial Revolution with significant investments in smart factories and warehouse automation.

Asia Pacific: Expected to register the highest CAGR, driven by strong government support, growing demand in logistics, and local tech innovations. Initiatives like ‘Made in China 2025’ and government subsidies for domestic robotic firms are key growth enablers.

Europe: Countries like Poland are rapidly transforming their manufacturing landscapes, creating fresh demand for robotic automation tailored to SMEs.

Why Buy This Report?

In-depth analysis of market dynamics, trends, and growth drivers

Detailed segmentation and regional breakdown

Competitive landscape featuring leading players and recent developments

Insights into investment opportunities and emerging technologies

Coverage of quantitative and qualitative factors shaping the market

This report serves as a vital resource for investors, manufacturers, distributors, and policy makers seeking actionable insights into the global articulated robot market.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Time-Limited Offer: Free Technical Scheme Design for Precision Servo Planetary Reducer (First 100 Clients)!

Precision servo planetary reducers, core transmission components in industrial automation, robotics, and high-end machine tools, are characterized by high precision, rigidity, and longevity. The global market size reached approximately $4.5 billion in 2024, with China accounting for 30% ($1.35 billion). Dubbed the “golden joints” of industrial equipment, they infuse micron-level precision into every transmission: backlashes as low as 1 arcminute (finer than a hair’s diameter) ensure robotic arms remain steady during nanoscale chip assembly, while high-end CNC machine tools achieve razor-sharp cutting trajectories. With over 97% transmission efficiency, energy loss is minimized, significantly reducing equipment power consumption and extending service life by 3X—saving businesses costs while enhancing durability.

Why Choose Qiandeyi ATG Reducers? – 13 Years of Technical Expertise**: Crafted with Taiwanese industrial craftsmanship, meeting European quality standards. – Customization Services: Tailored output shaft dimensions and gear ratios (3–100) for unique applications. – Lifetime Maintenance: 1-year warranty + 24-hour technical support for worry-free operation. – Micron-Level Precision: Backlash ≤3 arcminutes, repeat positioning error ≤0.01mm—ideal for 6-axis robots and machine tool spindles. – Extreme Durability: High-grade alloy steel carburization treatment ensures 20,000-hour lifespan; IP65 protection withstands dust and extreme temperatures (-20°C~90°C). – Modular Compatibility: Standardized interfaces fit Yaskawa, Panasonic, Delta, and other servo motors—plug-and-play for rapid deployment.

★First 100 consulting clients get FREE technical scheme design! Precision drives determine future success. Act now!★

0 notes

Text

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels Robot Arm 6-axis with special gripper - BarCode inline recognition ISAR image evaluation software - XEye detector X-ray inspection... via HeiDetect HEITEC PTS and MetrologyNews ▸ TAEVision Engineering on Pinterest

Data A006R - Jul 24, 2023

#automation#robot#robotics#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#X-ray Inspection#via HeiDetect#HEITEC PTS#MetrologyNews

1 note

·

View note

Text

Challenges and Best Solutions for Deburring Medical Devices: Key Technologies to Enhance Quality and Efficiency

Introduction: The Critical Impact of Burrs in Medical Devices

In medical device manufacturing, even micron-level burrs can pose life-threatening risks—from scratches caused by surgical tools to infection hazards in implants. Burrs directly compromise product safety and compliance (FDA/ISO 13485). However, traditional deburring methods suffer from inefficiency and inconsistency, creating major production bottlenecks.

Three Core Challenges in Medical Device Deburring

1. Balancing Precision and Safety

Issue: Medical device components often use specialized materials like titanium alloys or polymers, with complex burr geometries. Manual grinding risks surface damage or residual debris.

Case Study: A orthopedic screw manufacturer faced over $500,000 in losses due to post-surgical infection complaints linked to burr residue.

2. Efficiency vs. Cost Trade-offs

Data: Traditional manual deburring consumes 30% of production cycles, with yield rates as low as 85-90%.

Pain Point: High labor costs, slow throughput, and scalability issues for mass production.

3. Regulatory Compliance Risks

Requirements: FDA 21 CFR Part 820 mandates "zero burr residue," requiring traceable process validation data.

Industry-Leading Solutions: Innovative Deburring Technologies

Solution 1: Precision Fluid Polishing Technology (Case-Driven)

Principle: Uses customized abrasive media in a sealed chamber for high-frequency冲击 to remove burrs in complex cavities and micro-holes.

Case Study: A cardiovascular stent manufacturer achieved 99.5% yield (up from 88%) and reduced processing time to 2 minutes per part.

Advantages:

Compatible with titanium, PEEK, and other materials;

Surface roughness (Ra) controlled below 0.1μm;

Supports automated batch processing.

Solution 2: Robotic Vision-Guided Deburring Systems

Features:

6-axis robotic arms with AI vision for ±5μm burr detection;

Laser/electrochemical hybrid processes to prevent thermal deformation.

Results: A endoscope component supplier reduced manual intervention by 70% and tripled output.

Solution 3: Closed-Loop Quality Control Systems

Process Integration: Combines SPC (Statistical Process Control) for real-time burr removal monitoring and automated compliance reporting.

Regulatory Value: Meets MDR/CE certification requirements for traceability.

4 Key Criteria for Selecting Deburring Solutions

Material Compatibility: Does it support multi-material production lines?

Process Stability: Is the CPK value ≥1.67?

Compliance Support: Can it provide full validation documentation?

ROI Timeline: Is the payback period within 12 months?

Success Story: Transformation in a Global Enterprise

Client: A top 5 surgical robotics company faced joint arm component jamming due to burrs. Solution: Deployed automated magnetic abrasive finishing + AI inspection. Results:

Annual failure rate dropped by 92%;

Per-unit cost reduced by 40%;

Passed FDA unannounced audits.

Technology Adoption is the Sustainable Path Forward

Amid tightening regulations and cost pressures, medical device manufacturers must adopt automated, data-driven deburring solutions. Investing in advanced technologies not only mitigates risks but also delivers over 200% ROI within 3 years through yield improvements and capacity expansion.

Take Action Now: Click below to download the Medical Device Deburring Whitepaper or book a 30-minute customized consultation → [www.hlh-js.com]

0 notes

Text

youtube

Are you curious about how Bonsystems' electric actuators are revolutionizing logistics automation? This video showcases Bonsystems' advanced actuator technology, which boasts high torque and exceptional durability even with its slim design. Applied to AMR robotic and 6-axis robots, this technology opens up new possibilities for logistics automation. It optimizes AMR robotic vehicles and 6-axis robotic arms for heavy-duty logistics systems, enabling them to operate more powerfully, more reliably, and for longer durations. With Bonsystems, you can experience the tangible changes brought by robotic innovation and explore the core technologies driving the future of the logistics industry!

0 notes

Text

High-Precision Smart 6-axis Force Torque Sensor | AIDIN ROBOTICS

Experience cutting-edge precision and control with AIDIN ROBOTICS innovative Smart 6-axis Force Torque Sensor. This advanced sensor technology measures forces and torques in six degrees, delivering high accuracy and reliability.

This Smart 6-axis Force Torque Sensor from AIDIN ROBOTICS is a high-precision device designed to measure forces and torques in three dimensions. It's widely used in various applications in various industrial, robotic, and research applications.

Also, this 6-axis Force Torque Sensor from AIDIN ROBOTICS is based on capacitance. While traditional capacitance techniques had drawbacks in terms of stiffness and measurement sensitivity, AIDIN ROBOTICS successfully implemented high precision comparable to strain gauge methods by modifying the electrode structure based on the fringe effect, thereby reducing costs.

Robotics:

Robot arm control: Precise force control for tasks like assembly, polishing, and grinding.

Human-robot interaction: Ensuring safe and collaborative interactions between humans and robots.

Force feedback: Providing haptic feedback to users for enhanced control and immersion.

Industrial automation:

Quality control: Inspecting products for defects based on force and torque measurements.

Assembly processes: Ensuring parts are assembled with the correct force and torque.

Machine monitoring: Detecting abnormal forces or torques that may indicate equipment malfunctions.

Medical devices:

Surgical robots: Assisting surgeons with precise movements and force control.

Prosthetics: Providing natural and intuitive control for prosthetic limbs.

Rehabilitation devices: Helping patients regain strength and function through force training.

Research and development:

Material testing: Measuring the mechanical properties of materials under various conditions.

Biomechanics: Studying the forces and torques generated by biological systems.

Human-machine interfaces: Investigating the interaction between humans and machines.

Key features and benefits:

High accuracy and resolution: Precise measurements of forces and torques.

Wide measurement range: Capable of measuring a variety of forces and torques.

Compact and lightweight: Easy to integrate into various systems.

Durable and reliable: Built to withstand harsh environments and continuous use.

Easy to install and use: Simple setup and intuitive software interface.

If you are looking for smart 6-axis force torque sensor, you can find it on AIDIN ROBOTICS

Click here to contact AIDIN ROBOTICS

View more: Smart 6-axis Force Torque Sensor

0 notes

Text

Collaborative robot 380V,Six axis, Radius 1400mm Pulse MIG welding

1. The welding machine communicates with the control pad, and all parameters of the welding machine can be set directly on the control pad. 2. The welding trolley can hold gas cylinders. 3. Welding parameters can be saved and called. 4. There are two types of robotic arms, fixed or magnetic. 5. Pulse mode reduces spatter and improves welding quality. 6. The robot arm welding swing mode can be set to improve the weld fusion quality. 7. After the welding gun position path is set, the actual simulation operation can be performed. 8. Automatic welding can be achieved by moving the robot arm to align the points and set the path. 9. The welding point is set directly by moving the robot arm.

0 notes