#accelerated shelf life testing

Explore tagged Tumblr posts

Text

Unlocking the Secrets of Shelf Stability Testing: Ensuring Product Quality and Longevity

Maintaining optimal product quality and longevity is crucial in various industries, such as pharmaceuticals and food production. Among the various processes used for this purpose, “shelf stability testing” is essential.

This vital procedure involves subjecting products to rigorous conditions, simulating environmental factors, and assessing their ability to endure over time. By scrutinizing a product’s stability, industries can ensure compliance with regulations and gain a competitive edge by consistently delivering products that meet or exceed consumer expectations.

Shelf stability testing plays a crucial role in influencing the longevity and reliability of goods in the market across different sectors.

This comprehensive guide will delve into the intricacies of shelf stability testing, exploring its significance, methodologies, and the myriad parameters involved in ensuring the longevity and quality of diverse products.

1 note

·

View note

Text

How Accelerated Shelf Life Testing Supports Dubai’s Food Exporters in Meeting Global Standards? | +971 554747210

Dubai has emerged as a major hub for food exports, connecting global markets with high-quality food products. However, to maintain this status, food exporters must comply with international food safety and quality standards. Accelerated Shelf Life Testing of Food Products plays a crucial role in ensuring that Dubai’s food exports meet the required regulatory and safety standards of different markets worldwide.

What is Accelerated Shelf Life Testing of Food Products?

Accelerated Shelf Life Testing (ASLT) is a scientific method that helps food manufacturers and exporters determine the shelf life of their products in a shorter time frame. By simulating aging conditions, such as increased temperature and humidity, food testing labs can predict how long a product will remain safe and retain its quality under normal storage conditions.

The process involves:

Controlled environmental exposure to heat, light, and humidity

Microbiological and chemical analysis to detect spoilage factors

Sensory evaluations to assess taste, texture, and aroma stability

Predictive modeling to estimate actual shelf life under normal conditions

Why is Accelerated Shelf Life Testing Essential for Dubai’s Food Exporters?

1. Compliance with International Regulations

Global markets impose strict food safety and labeling requirements. Countries such as the United States, the European Union, and China have stringent shelf-life regulations that exporters must meet. Accelerated Shelf Life Testing ensures that food products comply with HACCP, ISO 22000, FDA, and Codex Alimentarius standards, allowing seamless entry into these markets.

2. Reduces Risks of Product Recalls

Food recalls due to incorrect shelf-life labeling can result in financial losses, brand damage, and regulatory penalties. By conducting Accelerated Shelf Life Testing, Dubai’s food exporters can ensure accurate expiration date labeling, minimizing the risk of recalls and legal disputes.

3. Enhances Product Quality and Customer Satisfaction

Global consumers demand high-quality food products with extended freshness and safety. Accelerated Shelf Life Testing helps exporters optimize formulations, preservatives, and packaging to enhance product longevity, ensuring better customer satisfaction.

4. Supports Supply Chain Efficiency

Dubai’s food export industry relies on efficient logistics and distribution channels. Proper shelf-life determination allows businesses to optimize storage, reduce food waste, and ensure that products reach international markets in peak condition.

5. Facilitates Entry into New Markets

Each country has unique regulatory standards for food products. Accelerated Shelf Life Testing helps Dubai’s exporters meet these diverse requirements, opening doors to new markets and business expansion opportunities.

How Dubai’s Food Testing Labs Conduct Accelerated Shelf Life Testing

Dubai is home to ISO 17025-accredited food testing laboratories that specialize in shelf-life studies. These labs follow a scientific approach to determine shelf life accurately:

Step 1: Sample Selection and Preparation

Food samples are carefully chosen to represent the product’s typical composition and packaging conditions.

Step 2: Exposure to Simulated Storage Conditions

Temperature: Increased temperature accelerates chemical and microbial reactions.

Humidity: High humidity levels assess moisture-related spoilage.

Light Exposure: Determines the impact of light on color, flavor, and texture stability.

Step 3: Microbial and Chemical Analysis

Microbial testing: Identifies bacteria, yeast, and mold growth over time.

Chemical stability analysis: Assesses oxidation, pH changes, and nutrient degradation.

Packaging interaction testing: Determines whether packaging materials influence food quality.

Step 4: Sensory Evaluation

Trained experts conduct sensory testing to examine changes in taste, aroma, color, and texture under accelerated aging conditions.

Step 5: Data Interpretation and Shelf Life Estimation

Scientific models are used to extrapolate real-world shelf life based on accelerated testing results. This data is used to determine the ideal expiration date and packaging requirements.

Choosing the Right Lab for Accelerated Shelf Life Testing in Dubai

Selecting the right food testing lab is crucial for obtaining accurate and reliable shelf-life test results. Consider the following factors:

ISO 17025 Accreditation: Ensures credibility and compliance with global food safety standards.

Advanced Testing Equipment: Look for labs with cutting-edge facilities for microbiological, chemical, and sensory analysis.

Expertise in Global Compliance: The lab should have experience in meeting the export standards of different countries.

Comprehensive Reporting: The lab should provide detailed scientific reports and recommendations for improving product shelf life.

Conclusion

Accelerated Shelf Life Testing is an essential tool for Dubai’s food exporters aiming to maintain international compliance, minimize risks, and improve product quality. By leveraging advanced testing methods, food businesses can ensure global market acceptance, reduce food waste, and enhance brand reputation.

#accelerated shelf life testing of food products#shelf life testing of food products#shelf life testing#testing lab near me#testing lab uae

0 notes

Text

Why Food Businesses in Abu Dhabi Need Accelerated Shelf Life Testing for Regulatory Compliance? | +971 554747210

In Abu Dhabi’s fast-growing food industry, ensuring product safety, quality, and longevity is essential for regulatory compliance and consumer trust. Accelerated shelf life testing of food products is a critical process that helps food manufacturers meet stringent safety standards set by local and international regulatory bodies. This scientific method estimates the shelf life of food products in a shorter time frame, allowing businesses to comply with food safety regulations, optimize packaging, and prevent product recalls.

In this blog, we explore why food businesses in Abu Dhabi rely on accelerated shelf life testing (ASLT) to achieve regulatory compliance and maintain product integrity.

Understanding Accelerated Shelf Life Testing

Accelerated shelf life testing is a laboratory process that simulates aging conditions for food products under controlled environmental factors such as temperature, humidity, and oxygen exposure. By doing so, it predicts the product’s longevity and stability under normal storage conditions.

Key Components of Accelerated Shelf Life Testing:

Microbiological Testing: Identifies microbial growth that may cause food spoilage.

Chemical Analysis: Evaluates oxidation, pH balance, and moisture retention.

Sensory Evaluation: Assesses changes in taste, texture, aroma, and appearance.

Packaging Assessment: Determines the effectiveness of packaging materials in preserving product freshness.

Regulatory Compliance in Abu Dhabi’s Food Industry

Food businesses in Abu Dhabi must adhere to strict food safety regulations established by the Abu Dhabi Agriculture and Food Safety Authority (ADAFSA) and international bodies like HACCP, ISO 22000, and Codex Alimentarius.

1. Ensuring Compliance with UAE Food Safety Standards

The UAE Food Code mandates food businesses to conduct stability testing to determine accurate expiration dates. ASLT helps ensure compliance with these regulations by providing scientific validation of product shelf life.

2. Meeting International Export Requirements

Food exporters in Abu Dhabi must comply with global food safety standards, such as the FDA (U.S.), EFSA (Europe), and GSO (Gulf Standards Organization). Accelerated shelf life testing ensures that food products meet these requirements, facilitating smooth entry into international markets.

3. Preventing Product Recalls and Legal Issues

Inaccurate shelf life claims can lead to costly product recalls and legal liabilities. ASLT provides scientific data to back up shelf life claims, reducing the risk of regulatory violations.

4. Ensuring Consumer Safety and Trust

Proper shelf life testing prevents foodborne illnesses and contamination, enhancing consumer confidence in food products.

How Accelerated Shelf Life Testing Helps Abu Dhabi’s Food Businesses

1. Optimizing Packaging and Storage Conditions

ASLT helps determine the best packaging materials and storage conditions to extend product longevity and maintain food freshness.

2. Reducing Food Waste and Economic Losses

Accurate shelf life testing prevents premature food spoilage, reducing waste and saving costs for food businesses.

3. Supporting Product Development and Innovation

New food formulations require ASLT to ensure stability and safety before entering the market.

4. Improving Supply Chain Management

Food manufacturers and distributors can plan inventory management effectively by understanding product shelf life under different environmental conditions.

Choosing the Right Testing Lab in Abu Dhabi

Factors to Consider:

ISO 17025 Accreditation: Ensure the lab is certified for food testing.

Advanced Testing Equipment: Look for labs with cutting-edge technology such as HPLC and GC-MS.

Comprehensive Testing Services: The lab should offer microbiological, chemical, and sensory testing.

Fast Turnaround Time: Ensure the lab delivers results efficiently to support business operations.

Conclusion

For food businesses in Abu Dhabi, accelerated shelf life testing of food products is an essential tool for regulatory compliance, product safety, and market competitiveness. By working with accredited food testing labs, businesses can ensure their products meet UAE and international food safety standards, prevent costly recalls, and build consumer trust. Investing in ASLT helps businesses achieve long-term success in the competitive food industry of Abu Dhabi.

#accelerated shelf life testing of food products#shelf life testing#testing lab near me#testing lab uae#shelf life testing of food products

0 notes

Text

Herbal Formulations – Food Research Lab

With rising global demand for safe, effective, and clean-label botanical solutions, herbal products have taken center stage. From wellness supplements and functional beverages to skincare and topical formulations, consumers are seeking nature-inspired innovations with scientific backing. At Food Research Lab (FRL), we offer comprehensive herbal product development and innovation services & solutions that blend traditional wisdom with modern formulation expertise. 👉 Discover more: Herbal Formulations – Food Research Lab

Your Partner in Herbal Innovation

Herbal products have gone mainstream across categories including pharmaceuticals, nutraceuticals, cosmeceuticals, and F&B. As experienced herbal product development and innovation consultants, we help brands—from startups to large manufacturers—develop high-performance herbal products with a strong scientific foundation.

Our expertise includes: • Custom herbal blends aligned with target health benefits • Standardization of herbal extracts and bioactives • Clean-label, vegan, and organic formulation design • Phytochemical analysis and botanical sourcing • Regulatory support (FSSAI, AYUSH, EFSA, FDA, and more)

We guide you through every step—from concept development to compliance documentation and shelf-life validation.

End-to-End Herbal Formulation & Scale-Up Services

Translating traditional herbal concepts into commercial-ready products demands technical precision. Our herbal formulation development and scale-up solutions ensure your product is safe, stable, and effective—whether in capsule, powder, liquid, or topical form.

Our capabilities include: • Phytochemical profiling and ingredient compatibility testing • Optimizing dosage and improving bioavailability • Enhancing solubility and choosing the right excipients • Microbial and stability testing under accelerated and real-time conditions • Pilot-scale production, small batch trials, and tech transfer

We deliver lab-proven formulations ready for scale and commercialization.

Herbal Innovation Across Categories

We offer formulation expertise across a wide range of herbal applications, ensuring your products are compliant, stable, and aligned with consumer needs:

• Herbal drinks (detox blends, immunity boosters) • Topical creams, gels, and herbal ointments • Nutraceuticals (capsules, tablets, gummies) • Traditional Ayurvedic products (churnas, arishtas, asavas) • Functional foods enriched with botanicals • Cosmeceuticals with plant-based actives

Our approach fuses botanical heritage with modern formulation technology to deliver distinctive products.

Herbal R&D Services for Outsourcing & Innovation

For companies looking to outsource development, FRL offers specialized herbal product development and innovation contract R&D services with full confidentiality and scalability.

We support you with: • Botanical ingredient sourcing, analysis, and IP consultation • Scientific substantiation of herbal health claims • Custom extraction processes and phytochemical standardization • Advanced delivery formats including nanoformulations and liposomal systems • Preparation of regulatory dossiers for international markets

Our integrated team of botanists, chemists, and regulatory professionals ensures a seamless, end-to-end R&D experience.

Our Scientific Approach to Herbal Formulation

At FRL, we combine ancient herbal knowledge with rigorous scientific methods to create products that meet both traditional and modern expectations.

Our scientific edge includes: • Traceability of herbal raw materials • Advanced analytical tools like HPLC, GC-MS, FTIR, and UV-Vis • Support for clinical studies and documentation of efficacy • Process innovation from decoction to supercritical CO₂ extraction • Global regulatory compliance and documentation readiness

We solve key challenges such as formulation stability, dosage accuracy, and international compliance to help you succeed in the competitive herbal marketplace.

Examples of Herbal Product Success Stories

Here are a few product innovations showcasing our herbal formulation and scale-up expertise: • Stress-relief Ashwagandha gummies • Cognitive boosters with Brahmi extracts • Tulsi and Mulethi-based herbal cough syrup • Anti-acne face cream with Neem and Turmeric • Triphala capsules for digestive wellness • Aloe vera and Hibiscus shampoo with natural preservation

Each formulation is supported by validated botanical science, precise extraction, and regulatory alignment.

Why Partner with Food Research Lab?

FRL is more than just a formulation service—we are herbal product development and innovation consultants dedicated to helping you build impactful, compliant, and market-ready herbal products. Whether launching one SKU or an entire range, we offer:

• Secure and confidential R&D lab services • Scientific validation of herbal ingredients and actives • Category-spanning formulation (topical, ingestible, cosmetic) • Market readiness testing and packaging recommendations • Global scaling solutions with cost-effective sourcing strategies

With our multidisciplinary expertise, your product journey is in trusted hands.

Let’s Build the Future of Herbal Innovation

As botanical products continue to grow in popularity, you need a partner who understands both the roots of tradition and the rigors of modern science. From formulation to scale-up, FRL offers herbal product development and innovation contract R&D services designed to help you succeed.

👉 Ready to bring your herbal vision to life? Explore our capabilities at: Herbal Formulations – Food Research Lab

#Herbal product Development#erbal Formulation Development and Scale-Up Solutions#Herbal product Development and Innovation Contract R&D services & solutions#Herbal product Development and Innovation Consultants services & solutions

0 notes

Text

Gas Chromatography Market: Upcoming Opportunities with SWOT Analysis By 2037

In 2024, the global gas chromatography (GC) market was estimated at USD 4.61 billion and is anticipated to exceed USD 11.66 billion by 2037, growing at a compound annual growth rate (CAGR) of more than 7.4% throughout the forecast period from 2025 to 2037.This robust growth is fueled by rising demand across a broad range of industries including pharmaceuticals, environmental monitoring, petrochemicals, and food safety testing. Increasing regulatory requirements and the need for highly accurate, real-time analysis are accelerating adoption rates globally.

Gas Chromatography Industry Demand

Gas chromatography is an advanced analytical method employed to separate, detect, and measure volatile and semi-volatile substances within complex mixtures.The method relies on the differential distribution of sample components between a stationary phase and a mobile gas phase, offering rapid and precise analytical results.

The��demand for GC technology is primarily driven by its cost-effectiveness, operational simplicity, and long shelf life of consumables. Its widespread applicability in critical sectors—ranging from forensic science to food safety—adds to its increasing adoption. Environmental regulations and public health safety mandates continue to expand the scope and necessity of advanced GC systems.

Gas Chromatography Market: Growth Drivers & Key Restraint

Growth Drivers –

Technological Advancements: Modern gas chromatographs now feature enhanced sensitivity, compact designs, and automated functionalities. Integration with mass spectrometry and AI-powered data analytics is driving higher throughput and better accuracy, spurring market growth.

Outsourcing and CRO Trends: Pharmaceutical and biotech companies increasingly rely on Contract Research Organizations (CROs) for R&D and quality control. This outsourcing trend is amplifying the demand for GC systems in third-party labs worldwide.

Stringent Environmental and Safety Regulations: Rising governmental and international regulations around environmental safety, air pollution, and food quality have pushed industries to adopt more accurate and reliable GC technologies for routine testing and compliance.

Restraint –

High Initial Investment and Skilled Operation Needs: Although gas chromatography is cost-effective in the long term, the initial capital investment and requirement for trained professionals often hinder adoption in small- to mid-sized enterprises, particularly in emerging markets.

Request Sample@ https://www.researchnester.com/sample-request-4930

Gas Chromatography Market: Segment Analysis

Segment Analysis by Product Type –

Instruments: Core gas chromatographs are evolving with modular systems, automated injectors, and enhanced detectors.

Accessories & Consumables: Columns, injectors, detectors, vials, and septa fall under this category. High replacement frequency and compatibility with a range of analytical applications ensure consistent demand.

Reagents: Reagents, including carrier gases and derivatization agents, play a critical role in the accuracy and specificity of GC results. Growing application in pharmaceuticals and food safety testing is propelling this segment.

Segment Analysis by End‑User –

Pharmaceuticals & Biotechnology: Used extensively for drug development, quality control, and impurity profiling.

Academic & Research Institutes: Universities and scientific labs utilize GC systems for exploratory research, toxicology studies, and innovation in analytical chemistry.

Oil & Gas: GC is vital in hydrocarbon analysis, process optimization, and environmental monitoring. The sector’s push for refining efficiency and pollution control enhances GC adoption.

Gas Chromatography Market: Regional Insights

North America:

North America remains the dominant region, driven by a well-established pharmaceutical sector, advanced research infrastructure, and strict environmental standards. The U.S. leads in adoption due to consistent government funding and industrial R&D initiatives.

Europe:

Europe follows closely, with significant uptake in environmental testing, food safety, and petrochemical industries. EU regulations on emissions and contamination levels foster strong demand for reliable and high-performance GC systems.

Asia-Pacific (APAC):

APAC is expected to witness the fastest growth, attributed to rapid industrialization, increasing investment in healthcare infrastructure, and the expansion of local pharmaceutical manufacturing. China, India, and Japan are particularly active markets due to rising domestic production and export needs.

Top Players in the Gas Chromatography Market

Leading companies in the gas chromatography market include Waters Corporation, Shimadzu Corporation, Thermo Fisher Scientific, PerkinElmer, Merck KGaA, Phenomenex, Bio-Rad Laboratories, and Cytiva. These organizations are recognized as global providers of analytical instruments, life science tools, and laboratory technologies used extensively in research, diagnostics, quality assurance, and industrial analysis.

Access Detailed Report@ https://www.researchnester.com/reports/gas-chromatography-market/4930

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Trusted Food Product Expiry Testing Services in India — Ensure Quality and Compliance

In the competitive food industry, consumer safety and product quality are non-negotiable. Every food product, whether packed or processed, comes with an expiration date — a crucial factor in maintaining both brand credibility and regulatory compliance. This is where food product expiry testing services in India play a vital role. From shelf-life analysis to microbial stability checks, these services help determine how long a product remains safe and effective under various conditions.

At The Fair Labs, we offer advanced and accredited expiry testing services tailored for India’s food sector. Backed by scientific precision, regulatory expertise, and industry knowledge, our testing solutions help manufacturers, startups, and exporters meet FSSAI and global standards.

What Is Food Product Expiry Testing?

Food product expiry testing, often known as shelf-life testing, is a scientific method of estimating the time during which a food product maintains its desired safety, quality, and nutritional value when stored under recommended conditions.

The test involves:

Microbiological analysis

Physico-chemical stability

Sensory evaluation

Packaging impact analysis

Storage simulation under controlled conditions

Food product expiry testing services in India help businesses determine accurate “Best Before” or “Use By” dates, ensuring both safety and legal compliance.

Why Is Food Product Expiry Testing Important?

Whether you're selling biscuits, juices, ready-to-eat meals, or frozen goods, determining how long your product remains consumable is crucial. Here’s why food expiry testing is essential:

✅ Regulatory Requirement – As per FSSAI and BIS, every food item must carry an accurate expiry date.

✅ Consumer Safety – Prevents consumption of spoiled or contaminated food.

✅ Brand Trust – Enhances credibility and consumer loyalty.

✅ Export Readiness – Meets international safety standards (Codex, ISO, HACCP).

✅ Product Improvement – Helps reformulate products for better longevity.

Our food product expiry testing services in India provide detailed insights to help you make informed labeling and formulation decisions.

Who Needs Expiry Testing Services in India?

Our services cater to a wide spectrum of food-related businesses, including:

✅ Food Startups & MSMEs

✅ Packaged Food Manufacturers

✅ Ready-to-Eat & Frozen Food Brands

✅ Bakeries, Confectioneries, Dairy Units

✅ Cold Chain Operators

✅ Restaurants & Cloud Kitchens (for packaged items)

✅ Exporters & Private Label Owners

✅ FBOs seeking FSSAI approval

Whether you produce in small batches or at industrial scale, food product expiry testing services in India are essential for product success and safety.

What Do We Test at The Fair Labs?

We offer a comprehensive range of tests under expiry analysis to evaluate every parameter impacting food shelf life:

1. Microbiological Testing

We detect and quantify harmful organisms such as:

Total Plate Count (TPC)

Yeast and Moulds

Coliforms

Salmonella

E. coli

Listeria

2. Chemical & Nutritional Testing

Helps identify changes in:

Moisture content

pH levels

Rancidity (in oils and fats)

Preservative effectiveness

Vitamin degradation

Nutritional label validation

3. Sensory Evaluation

Our trained panel checks:

Taste

Odour

Appearance

Texture

Sensory changes often signal spoilage before microbiological issues arise.

4. Packaging Compatibility Testing

Ensures that the packaging used:

Does not react with food

Preserves quality over time

Maintains seal integrity

5. Accelerated & Real-Time Shelf Life Testing

Real-time testing simulates actual market storage conditions.

Accelerated testing uses elevated temperature and humidity to predict shelf life faster.

Both methods are used as per product type and market needs.

Key Industries We Serve

Our food product expiry testing services in India are trusted by a wide variety of food sectors:

Snacks & Namkeens

Bakery & Confectionery

Dairy & Ice Creams

Cold-pressed Juices

Frozen & Ready-to-eat meals

Health Supplements & Nutraceuticals

Pickles, Sauces, and Jams

Beverages (Tea, Coffee, Mocktails)

Edible Oils & Fats

Organic & Ayurvedic Food Products

Whether you’re preparing for product launch, shelf extension, or export approval, The Fair Labs is your reliable testing partner.

Why Choose The Fair Labs for Expiry Testing in India?

At The Fair Labs, we combine technology, compliance, and customer support to deliver end-to-end solutions. Here’s what makes us the go-to provider of food product expiry testing services in India:

✅ NABL Accredited Lab – ISO/IEC 17025 certified for reliable results.

✅ FSSAI Compliance Experts – Testing aligned with Indian & international regulations.

✅ Pan-India Service Coverage – We collect samples from all major cities & rural clusters.

✅ Fast Turnaround Time – Real-time or accelerated reports within 15–45 days (based on protocol).

✅ End-to-End Support – From sample collection to documentation, we handle it all.

✅ Consultation Services – Expert guidance to interpret results and improve shelf life.

We don't just test — we help you improve your product for longer shelf presence and better market performance.

Our Testing Process – Transparent & Efficient

We follow a systematic and documented process to ensure accuracy at every step:

Product Analysis & Objective Discussion

Sample Collection or Courier Coordination

Test Plan Design (Real-Time / Accelerated)

Laboratory Testing with Scheduled Intervals

Observational Reporting (with photos, graphs, data)

Final Expiry Report Issuance

Consultation for Label or Formula Adjustments

All tests are recorded under controlled conditions, in compliance with FSSAI, ISO, and BIS standards.

FSSAI Shelf Life Labeling Compliance – Our Expertise

FSSAI mandates that every food product label must include:

“Best Before” or “Use By” date

Storage conditions

Batch identification

Net weight and ingredient list

Our lab helps ensure that these details are backed by scientifically verified expiry testing data. Exporters can also align with global norms such as:

EU Regulation No. 1169/2011

US FDA Code 21 CFR

Codex Alimentarius guidelines

The Fair Labs empowers you with data-backed confidence in your labeling and market readiness.

How Often Should You Test for Shelf Life?

New Products: Mandatory before launch

Reformulated Products: Test again after any ingredient or process change

Seasonal/Batch Products: Test at least once per year

Export Products: Follow import country protocol (some require testing every batch)

Food product expiry testing services in India are not one-time but an ongoing quality assurance activity.

Pan-India Reach – We Come to You

From Tier-1 cities to remote production units, our logistics and network allow us to serve:

Delhi NCR, Mumbai, Pune, Bengaluru

Ahmedabad, Hyderabad, Chennai, Kolkata

Indore, Jaipur, Nagpur, Kochi, Surat

Export zones, SEZs, rural food clusters

Wherever your food business is located, we bring world-class expiry testing services to your doorstep.

Conclusion: Build Trust with Scientific Expiry Testing

Expiry dates aren’t just labels — they’re a promise of safety and quality. Whether you’re launching a new product or scaling up for global exports, partnering with a reliable testing lab is a strategic necessity.

At The Fair Labs, our food product expiry testing services in India are designed to help your brand comply, compete, and confidently grow. With science-backed data, expert consulting, and pan-India support, we ensure that your product stands the test of time — literally.

0 notes

Text

Why International Cosmetic Brands Choose Testing Labs in Ajman for Product Approval? | +971 554747210

In today’s global beauty market, cosmetic brands are constantly expanding into new territories, and the United Arab Emirates (UAE) is a key destination. With a rapidly growing cosmetics industry, robust regulatory framework, and a consumer base that values both quality and safety, the UAE offers tremendous opportunities for international brands.

However, before cosmetics can be sold in the UAE, they must pass strict product approval and registration processes enforced by authorities such as ESMA (Emirates Authority for Standardization and Metrology) and MOHAP (Ministry of Health and Prevention). This is where a certified Cosmetic Testing Lab becomes essential—and increasingly, international brands are turning to testing labs in Ajman to support this vital step.

In this article, we explore why Ajman has become a go-to destination for international cosmetic companies seeking reliable testing, fast compliance, and successful entry into the UAE market.

The UAE: A Strategic Cosmetics Market

The UAE is a regional hub for the beauty and personal care industry, with a market valued at over $2.7 billion and growing. Consumers in the region demand high-quality, safe, and often Halal-certified cosmetic products. Regulatory authorities in the UAE have established clear guidelines aligned with GCC Standardization Organization (GSO) and UAE.S GSO 1943 for cosmetics, focusing on:

Product safety

Ingredient compliance

Microbiological quality

Accurate labeling

Stability and shelf-life assurance

To meet these requirements, international cosmetic brands must collaborate with locally recognized and accredited testing labs—a niche in which Ajman has emerged as a stronghold.

Why Cosmetic Testing Labs in Ajman Are the Preferred Choice

1. Strategic Location with Growing Infrastructure

Ajman is strategically located within the UAE, close to Dubai and Sharjah, with efficient logistics and accessibility. For international brands shipping samples or setting up regional operations, Ajman offers:

Proximity to major ports and airports

Easy transportation of samples to labs

A growing number of industrial zones and free zones

This infrastructure makes the sample submission and test processing faster, enabling quicker time-to-market.

2. ISO/IEC 17025 Accredited Testing Labs

Most Cosmetic Testing Labs in Ajman are ISO/IEC 17025 accredited, a globally recognized certification that assures:

Valid, accurate, and reproducible test results

Compliance with international testing methods

Credibility with UAE authorities and international partners

International brands trust Ajman labs because the test reports are readily accepted by UAE regulatory bodies, saving them time and cost in repeated testing or documentation.

3. Expertise in UAE and GCC Regulatory Requirements

Ajman labs specialize in cosmetic testing tailored to UAE and GCC regulations. They are well-versed with:

ESMA and MOHAP registration protocols

GSO standards for ingredient restrictions

UAE guidelines for Halal and non-Halal cosmetic certifications

Cosmetic safety assessment procedures

This local regulatory expertise gives international brands a significant advantage in navigating complex approval processes, ensuring that their products are market-ready without delays.

4. Comprehensive Testing Services Under One Roof

Ajman’s testing labs provide end-to-end testing services, which are essential for product approval. These include:

Microbiological Testing: TAMC, TYMC, and pathogen detection (E. coli, P. aeruginosa, S. aureus)

Heavy Metal Analysis: Lead, mercury, arsenic, cadmium

Stability and Shelf-Life Testing: Real-time and accelerated conditions

Preservative Efficacy Testing (PET)

Ingredient Verification and Label Review

pH and Viscosity Testing

Halal Compliance Testing (alcohol, animal derivatives, cross-contamination)

This wide range of services allows international brands to complete all necessary tests in one facility, reducing coordination efforts and accelerating regulatory submissions.

5. Cost-Effective Solutions for Global Brands

Compared to labs in major cities like Dubai or Abu Dhabi, Cosmetic Testing Labs in Ajman often offer more competitive pricing without compromising quality. For international brands operating on tight product launch budgets, this is a compelling reason to choose Ajman.

Services are typically priced in cost-effective bundles and customized packages—especially beneficial for:

New market entrants

Niche or boutique brands

Companies with large portfolios requiring multi-product testing

6. Faster Turnaround Times for Testing and Reporting

Time is critical in the cosmetics industry, especially for seasonal launches and promotional campaigns. Labs in Ajman are known for offering quicker turnaround times than many global alternatives, often delivering:

Microbiological test results in 3–5 days

Stability and PET assessments within defined timelines

Fast-track reporting for urgent submissions

This helps international brands meet launch schedules and avoid supply chain delays.

7. Support with Product Registration and Regulatory Documentation

Beyond testing, many cosmetic testing labs in Ajman offer consulting and documentation support for UAE product registration. This includes:

Preparing Certificates of Analysis (CoA)

Assisting in safety assessment reports

Compiling ingredient declarations and label compliance files

Liaising with local health authorities

Such value-added services are crucial for international brands unfamiliar with local laws, allowing them to confidently navigate the regulatory landscape.

8. Focus on Halal Cosmetics Compliance

With the increasing demand for Halal-certified cosmetics, especially in the Middle East, Ajman labs are equipped to support international brands aiming to enter this segment. They test for:

Presence of alcohol and porcine ingredients

Cross-contamination risks

Verification of Halal-compliant raw materials

Ajman’s cosmetic testing labs often collaborate with Halal certification bodies recognized in the UAE, helping brands align with ESMA’s Halal standards.

Case Study: How a European Skincare Brand Gained UAE Approval via Ajman Lab

A mid-sized skincare brand from France recently entered the UAE market and selected a Cosmetic Testing Lab in Ajman for its regulatory testing. The lab provided:

Full microbiological testing

Stability testing for desert climate conditions

Halal screening for all SKUs

Regulatory consulting for MOHAP approval

The brand successfully registered 18 products within three months and was able to launch ahead of schedule—thanks to the lab’s local insights, cost-effective services, and reliable results.

Conclusion

For international cosmetic brands targeting the UAE and GCC markets, regulatory approval is the first and most critical milestone. Ajman, with its advanced infrastructure, ISO-accredited labs, and regulatory expertise, has quickly become a trusted destination for testing and product compliance.

Whether you're a skincare brand from Europe, a makeup label from Asia, or a haircare innovator from the U.S., choosing a Cosmetic Testing Lab in Ajman can streamline your product approval journey, reduce time to market, and ensure compliance with UAE’s demanding cosmetic safety standards.

#cosmetic testing lab#cosmetic testing#testing lab near me#testing lab uae#cosmetic testing services

0 notes

Text

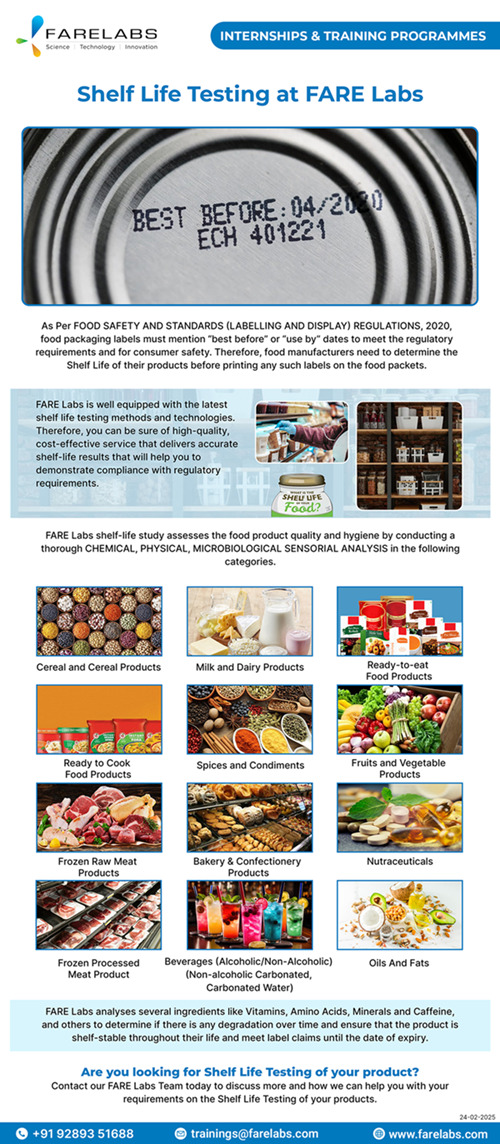

Training in Shelf Life Testing at FARE Labs Pvt. Ltd.

Acquire proficiency in assessing product shelf life using accelerated and real-time stability tests. Acquire skills in data analysis, sensory evaluation, and storage testing. Visit-https://farelabs.com/training/shelf-life-of-food-pharma-products-training/

0 notes

Text

Unlocking Food Safety: The Crucial Role of Shelf Stability Assessment

This blog post will delve into the significance of shelf stability assessment and explore the various aspects that make it a cornerstone of food safety. From regulatory compliance to quality control measures, join us on a journey through the intricacies of ensuring the food’s safety.

#Shelf Stability Assessment#accelerated shelf life testing#shelf life testing#food testing labs#air quality testing#air testing at home#air testing#pesticide testing#food testing

0 notes

Text

Antimicrobial packaging additive market Sector Analysis: Technology Trends and Future Outlook 2025–2032

Global antimicrobial packaging additive market continues its upward trajectory, with its valuation reaching USD 673 million in 2024. According to comprehensive industry analysis, the market is projected to grow at a robust CAGR of 6.9%, reaching approximately USD 1.15 billion by 2032. This growth is primarily fueled by increasing demand for food safety, pharmaceutical packaging hygiene, and the rising popularity of active packaging solutions across multiple industries.

Antimicrobial packaging additives represent a critical innovation in material science, designed to inhibit microbial growth on packaging surfaces and within packaged products. These specialized compounds provide extended shelf life while maintaining product quality - particularly crucial for perishable goods and sterile medical products. Their adoption spans diverse sectors including food & beverage, healthcare, and personal care industries where contamination prevention is paramount.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293357/antimicrobial-packaging-additive-market

Market Overview & Regional Analysis

The Asia-Pacific region currently leads the antimicrobial packaging additive market with a 42% revenue share, driven by expanding food processing industries in China and India, coupled with growing pharmaceutical manufacturing in Southeast Asia. Rapid urbanization and increasing middle-class consumption are further accelerating demand for premium packaged goods with extended shelf lives.

North America follows closely, with sophisticated healthcare packaging requirements and stringent food safety regulations pushing innovation. The U.S. FDA's evolving guidelines on food contact materials continue to shape product development strategies for regional players. Meanwhile, Europe maintains technological leadership in sustainable antimicrobial solutions, particularly in silver-ion and natural extract formulations that meet strict EU environmental standards.

Key Market Drivers and Opportunities

The market is experiencing significant growth due to multiple converging factors. The global emphasis on food safety has intensified post-pandemic, with antimicrobial packaging proving essential for minimizing contamination risks in supply chains. Pharmaceutical applications now account for 28% of market value due to sterile packaging requirements for medical devices and temperature-sensitive drugs.

Emerging opportunities lie in developing bio-based antimicrobial agents as sustainability becomes a priority across industries. Plant-derived chitosan and essential oil extracts are gaining traction as effective alternatives to traditional synthetic additives. Furthermore, smart packaging integration presents new avenues, combining antimicrobial properties with freshness indicators and controlled-release mechanisms.

Challenges & Restraints

Despite strong growth prospects, the market faces several challenges. Regulatory complexities create significant barriers, especially for formulations requiring both food safety and biocidal product approvals. Regional variations in testing protocols and acceptable migration limits further complicate market entry strategies for global players.

Cost sensitivity remains a persistent obstacle, particularly in price-driven emerging markets where conventional packaging still dominates. Technical hurdles including additive-polymer compatibility issues and migration concerns continue to demand substantial R&D investments from manufacturers.

Market Segmentation by Type

Inorganic Antimicrobial Agents (Silver, Zinc, Copper)

Organic Antimicrobial Agents (Triclosan, Organic Acids)

Natural Antimicrobial Agents (Chitosan, Essential Oils)

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293357/antimicrobial-packaging-additive-market

Market Segmentation by Application

Food Packaging

Beverage Packaging

Pharmaceutical Packaging

Personal Care Packaging

Industrial Packaging

Market Segmentation and Key Players

BASF SE

PPG Industries

Arkema

AkzoNobel

Evonik Industries

Wacker Chemie

Henkel AG & Co. KGaA

Clariant

Songwon Industrial

Sun Chemical

Lubrizol Corporation

Cytec Solvay Group

Report Scope

This report presents a comprehensive analysis of the global and regional markets for antimicrobial packaging additives, covering the period from 2024 to 2032. It includes detailed insights into the current market status and outlook across various regions and countries, with specific focus on:

Sales, sales volume, and revenue forecasts

Detailed segmentation by type and application

In addition, the report offers in-depth profiles of key industry players, including:

Company profiles

Product specifications

Production capacity and sales

Revenue, pricing, gross margins

Sales performance

It further examines the competitive landscape, highlighting the major vendors and identifying the critical factors expected to challenge market growth.

As part of this research, we surveyed antimicrobial packaging additive companies and industry experts. The survey covered various aspects, including:

Revenue and demand trends

Product types and recent developments

Strategic plans and market drivers

Industry challenges, obstacles, and potential risks

Get Full Report Here: https://www.24chemicalresearch.com/reports/293357/antimicrobial-packaging-additive-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Choosing the Right Testing Lab for Accelerated Shelf Life Testing of Food Products in the UAE | +971 554747210

In the highly regulated food industry of the United Arab Emirates (UAE), ensuring product safety, quality, and compliance is paramount. One critical aspect of food safety and market readiness is Accelerated Shelf Life Testing (ASLT), a scientific method that determines a product’s longevity under simulated conditions. Choosing the right testing laboratory for ASLT is essential to obtaining accurate, reliable, and regulatory-compliant results.

This guide will help food manufacturers, exporters, and retailers identify the best food testing lab in the UAE for Accelerated Shelf Life Testing of Food Products, ensuring their products meet local and international standards.

Understanding Accelerated Shelf Life Testing

Accelerated Shelf Life Testing (ASLT) is a process used to estimate the shelf life of food products by exposing them to controlled environmental conditions, such as:

Increased temperature to simulate long-term storage effects.

Controlled humidity to assess moisture-related deterioration.

Oxygen exposure to evaluate oxidative spoilage.

Microbial analysis to monitor bacterial and fungal growth.

By applying these stress factors, food testing labs can predict how a product will age over time, helping manufacturers establish accurate "best before" or "expiry dates."

Why Choosing the Right Lab Matters

Not all food testing laboratories offer the same level of expertise, technology, or regulatory compliance. Selecting an accredited lab ensures:

Reliable results backed by scientific methods.

Regulatory compliance with UAE’s Emirates Authority for Standardization and Metrology (ESMA) and global bodies like the FDA, EFSA, and Codex Alimentarius.

Faster market access for local and international distribution.

Protection against product recalls due to incorrect labeling or safety concerns.

Key Factors to Consider When Choosing a Testing Lab in the UAE

1. ISO Accreditation and Compliance

A credible ASLT laboratory must be ISO/IEC 17025 accredited, which guarantees:

Accuracy in test results and data validation.

Standardized testing methodologies approved by regulatory agencies.

Competence in shelf life determination using internationally accepted techniques.

In the UAE, regulatory bodies like ESMA and Dubai Municipality require food manufacturers to work with accredited labs for compliance.

2. Expertise in Food Shelf Life Testing

Shelf life testing is a specialized field that requires expertise in:

Microbiology (bacteria, yeast, and mold analysis).

Chemical stability testing (pH levels, oxidation, and nutrient degradation).

Sensory evaluation (taste, texture, and aroma changes over time).

Choose a food testing lab with a proven track record in Accelerated Shelf Life Testing of Food Products and case studies demonstrating successful results for similar food categories.

3. Advanced Testing Equipment and Facilities

State-of-the-art facilities ensure the most accurate and reproducible ASLT results. The right lab should have:

High-precision environmental chambers to simulate real-world storage conditions.

Microbiological testing labs for pathogen detection.

Gas chromatography and spectroscopy for oxidation and chemical stability analysis.

Texture analyzers and colorimeters for sensory evaluation.

4. Customization of Testing Parameters

Different food products have unique stability challenges. The best food testing lab will customize ASLT conditions based on:

Product composition (dairy, meat, bakery, etc.).

Packaging materials (oxygen barrier, vacuum-sealed, etc.).

Intended storage conditions (ambient, refrigerated, frozen).

Labs offering tailored ASLT protocols help manufacturers optimize packaging and formulations for longer shelf life.

5. Regulatory and Market Compliance Support

Beyond testing, a good ASLT lab helps UAE food manufacturers navigate:

UAE Food Code and ESMA labeling regulations.

GCC food import/export requirements.

International food safety standards for exports to Europe, the US, and Asia.

A lab with regulatory expertise ensures products meet the necessary compliance requirements for local and global market approval.

6. Turnaround Time and Cost-Effectiveness

Speed matters in food production. Select a lab that offers:

Fast turnaround times for ASLT reports.

Affordable pricing for testing packages.

Comprehensive service options (including real-time shelf life studies if needed).

The best labs balance efficiency, affordability, and accuracy to support food businesses effectively.

7. Reputation and Client Feedback

Research the lab’s industry reputation by:

Checking online reviews and testimonials from food manufacturers.

Requesting references from previous clients.

Assessing the lab’s experience with major UAE food brands.

A well-established lab with positive client feedback is more likely to provide dependable ASLT services.

Benefits of Working with a Certified ASLT Lab in the UAE

Partnering with an accredited Accelerated Shelf Life Testing lab in the UAE offers numerous advantages:

✅ Regulatory Compliance: Ensures food products meet ESMA, GSO, and international safety standards.

✅ Market Expansion: Helps food businesses export with confidence, meeting global shelf life labeling laws.

✅ Cost Savings: Prevents unnecessary product recalls, rejections, and food waste.

✅ Product Improvement: Identifies packaging and formulation optimizations to extend shelf life.

✅ Consumer Safety: Confirms food safety by detecting microbial risks, chemical changes, and sensory degradation.

How to Get Started with ASLT in the UAE

If you’re a food manufacturer, distributor, or exporter looking for Accelerated Shelf Life Testing of Food Products, follow these steps:

Identify your product requirements (target shelf life, storage conditions, packaging type).

Shortlist ISO-accredited labs in the UAE with expertise in ASLT.

Request a consultation to discuss customized testing solutions.

Submit food samples for testing based on agreed ASLT parameters.

Review results and recommendations to ensure regulatory compliance and market readiness.

Conclusion

Choosing the right food testing lab for Accelerated Shelf Life Testing in the UAE is crucial for product safety, compliance, and market success. By selecting an ISO-accredited lab with expertise in ASLT, UAE food businesses can ensure their products meet shelf life regulations, minimize waste, and maintain high consumer trust.

#accelerated shelf life testing of food products#shelf life testing#shelf life testing of food products#testing lab near me#testing lab uae

0 notes

Text

Retail Hygiene: Commercial Kitchen Cleaning Essentials

Introduction

In today's hyper-competitive food retail and ecommerce landscape, commercial kitchen cleaning isn't just about compliance—it's a competitive advantage. With consumers increasingly prioritizing food safety and hygiene, retailers that maintain impeccable kitchen standards gain customer trust, reduce waste, and protect their brand reputation.

For ecommerce food brands, the stakes are even higher. Meal kits, prepared foods, and gourmet groceries must arrive in perfect condition, with packaging that reflects quality from the first unboxing. This article explores why commercial kitchen cleaning is essential for retail food businesses, with a special focus on how ecommerce brands benefit from rigorous hygiene practices.

How Ecommerce Food Brands Benefit from Commercial Kitchen Cleaning Ecommerce has revolutionized food retail, but it also introduces unique hygiene challenges. Unlike traditional restaurants where food is served immediately, ecommerce meals must stay fresh through transit, often for days. Here’s how commercial kitchen cleaning directly impacts success for online food businesses.

Extended Shelf Life for Meal Kits & Prepared Foods The cleanliness of your production kitchen directly affects how long your products stay fresh. Poor sanitation introduces bacteria and mold that accelerate spoilage—a disaster for subscription meal services or gourmet grocers shipping perishables.

Reduced Microbial Contamination – Professional commercial kitchen cleaning eliminates Listeria, E. coli, and other pathogens that cause early spoilage.

Optimal Storage Conditions – Regular deep cleaning of refrigeration units prevents cross-contamination and maintains proper temperatures.

Longer Freshness Windows – Cleaner prep areas mean fewer contaminants in vacuum-sealed or modified-atmosphere packaging.

Case Study: A premium meal-kit company reduced product returns by 22% after implementing daily ATP sanitation testing and professional deep-cleaning protocols.

Fewer Customer Complaints & Product Returns Nothing hurts an ecommerce food brand faster than negative reviews about spoiled meals or foreign particles in packaging. Rigorous commercial kitchen cleaning prevents:

Physical contaminants (hair, plastic fragments, dust) in food

Off-flavors from residual grease or cleaning chemicals

Allergen cross-contact (e.g., gluten/nut particles in "free-from" products)

Pro Tip: Implement a "clean-as-you-go" policy for packaging stations, where employees sanitize surfaces between batches to prevent mix-ups.

Instagram-Worthy Packaging Starts with a Clean Kitchen In the age of unboxing videos, your packaging is marketing. But no amount of beautiful branding compensates for:

Grease smudges on meal kit boxes from dirty gloves

Dusty insulation in gourmet food shipments

Condensation stains from improperly cleaned cold packs

Commercial kitchen cleaning ensures: ✔ Hands and surfaces are sanitized before handling packaging ✔ Cold chain items are sealed in contaminant-free environments ✔ Every component (ice packs, liners, labels) is stored hygienically

Example: A direct-to-consumer bakery increased social media shares by 40% after customers noticed their spotless, bakery-fresh packaging.

The Hidden Costs of Poor Kitchen Hygiene in Ecommerce Issue Direct Impact Long-Term Brand Damage Mold in storage 15-30% spoilage rate "Always arrives spoiled" reviews Dirty packaging stations 5% return rate for "foreign objects" Loss of wholesale accounts Grease buildup on equipment 2x more machine downtime Missed subscription delivery windows Essential Commercial Kitchen Cleaning Practices for Ecommerce

Zone-Based Cleaning for Food Prep & Packaging Red Zone (Raw Ingredients): Hourly sanitizing of cutting boards, scales

Green Zone (Packaging): Alcohol wipes for seals, allergen swab testing

Blue Zone (Cold Storage): Weekly defrosting + anti-microbial treatments

Third-Party Audits for Digital Brands Many ecommerce platforms (Amazon Fresh, Thrive Market) now require:

NSF/ANSI 2 certification for kitchen equipment

Documented allergen controls

Microbiological testing results

Training for Remote Teams Since many DTC brands use co-packers, ensure:

Video SOPs for cleaning validation

QR-code checklists at each station

Cloud-based sanitation logs

Conclusion For ecommerce food brands, commercial kitchen cleaning isn’t an overhead cost—it’s the foundation of customer retention and viral marketing. By investing in professional-grade hygiene, you:

✅ Extend product shelf life → Fewer refunds ✅ Create share-worthy unboxings → Free marketing ✅ Pass platform audits → Access premium retailers

Next Step: Download our "Ecommerce Kitchen Hygiene Checklist" to audit your current processes.

SEO Keywords Naturally Integrated:

Commercial kitchen cleaning

Ecommerce food safety

Meal kit hygiene

Retail kitchen sanitation

Food packaging cleanliness

HACCP for ecommerce

0 notes

Text

Is There a Perfect Time of Year to Make Pickles?

Pickling is an age-old tradition celebrated in many cultures worldwide, but is there really a perfect season to make pickles? If you’re exploring the best homemade pickles online, understanding the ideal timing for pickling can help you get the freshest, most flavorful results.

🌿 Why Season Matters in Pickling

The quality of your pickle starts with the ingredients. Freshness plays a huge role in the final taste, texture, and shelf life of your homemade pickles. Certain fruits and vegetables are naturally seasonal, and harvesting them at peak ripeness ensures:

Crisp texture

Robust flavor

Maximum nutrient retention

For this reason, the best homemade pickles online often reflect the seasons—using ingredients picked when they’re freshest and most flavorful.

🍅 Ideal Seasons for Popular Pickle Ingredients

Summer: This is prime time for cucumbers, green mangoes, green chilies, and other vegetables commonly used in pickling. The warm weather also helps in natural fermentation and sun-curing processes.

Autumn: Apples, carrots, and beets harvested in fall make excellent pickling candidates. The cooler weather slows fermentation, giving pickles a milder, balanced flavor.

Winter: Root vegetables like turnips and radishes are winter favorites for pickling. Some Indian pickles, like lime or lemon varieties, are traditionally made during winter months for optimal shelf life.

☀️ Sunlight and Temperature: Key to Pickling Success

Many traditional pickles, especially those considered among the best homemade pickles online, rely on sun-curing to develop their signature flavor. Sunlight provides gentle warmth, which aids in:

Drawing out moisture

Activating spices and oils

Accelerating natural fermentation

In colder or rainy seasons, sun-curing becomes challenging, which can affect the final taste and preservation quality.

🧴 Why Homemade Pickling Seasons Still Matter Today

Even with modern refrigeration and preservation methods, many pickle makers prefer to follow seasonal cycles. This respect for nature’s timing preserves tradition, flavor, and authenticity.

Buying the best homemade pickles online that follow seasonal pickling means you're tasting ingredients at their peak, prepared with time-tested methods.

Final Thoughts

While you can make pickles year-round, the perfect time to make pickles aligns with the harvest of fresh, seasonal produce and the availability of warm, sunny days for curing. This ensures vibrant flavors, optimal texture, and longer shelf life.

So whether you’re making your own or choosing from the best homemade pickles online, remember that seasonality is key to the pickle’s perfect bite.

0 notes

Text

How Shelf Life Testing Labs Determine Expiry Dates for Packaged Goods?

In the world of packaged goods, ensuring product safety and quality over time is critical—not just for consumer satisfaction, but also for regulatory compliance. Central to this assurance is the expiry date, which informs consumers about the safe period for using a product. But have you ever wondered how companies accurately determine these expiry dates? The answer lies in the expertise of Shelf Life Testing Lab.

Shelf life testing labs use scientific methods and advanced technologies to evaluate how packaged goods perform under various conditions. This helps manufacturers establish reliable expiry dates, ensuring their products remain safe and effective throughout their marketed lifespan. In this blog, we’ll explore the detailed process of how shelf life testing labs determine expiry dates for packaged goods and why this process is vital for both businesses and consumers.

What Is Shelf Life Testing?

Shelf life testing refers to the series of laboratory tests and analyses designed to assess the stability and longevity of products over time. This process simulates storage conditions such as temperature, humidity, light exposure, and packaging effects to observe how a product’s quality, safety, and performance change.

Shelf life testing is applicable across numerous industries, including food and beverage, cosmetics, pharmaceuticals, and chemicals. The results from these tests help determine the expiry date or best before date printed on packaging.

Why Is Determining Expiry Dates Important?

Expiry dates serve as critical indicators of product safety and quality. Here’s why accurate expiry dating is essential:

Consumer Safety: Using a product beyond its expiry date can pose health risks, especially for consumables and pharmaceuticals.

Regulatory Compliance: Authorities worldwide require accurate expiry dates to ensure products meet safety standards.

Brand Reputation: Reliable expiry dates help maintain consumer trust and reduce the risk of product recalls.

Waste Reduction: Accurate expiry dates prevent premature disposal of safe products and reduce unnecessary waste.

Given these stakes, manufacturers must rely on precise shelf life testing from accredited labs to establish expiry dates scientifically.

How Shelf Life Testing Labs Determine Expiry Dates

Determining expiry dates is a complex process that involves multiple steps, sophisticated testing methods, and careful interpretation of data. Below is an overview of how shelf life testing labs approach this critical task:

1. Initial Product Assessment

The process begins with a thorough assessment of the packaged good. Shelf life testing labs analyze:

Product formulation and ingredients

Packaging materials and sealing methods

Intended storage conditions (e.g., refrigerated, ambient)

Expected distribution and usage timelines

This information guides the design of relevant stability tests to replicate real-world scenarios.

2. Selection of Testing Parameters

Labs identify key parameters to monitor during the testing period. These often include:

Microbial growth: To detect spoilage or contamination.

Chemical stability: Changes in active ingredients or preservatives.

Physical attributes: Texture, color, viscosity, or separation.

Sensory properties: Taste, smell, and appearance.

Packaging integrity: Barrier properties and seal effectiveness.

Choosing appropriate parameters depends on the product type and regulatory requirements.

3. Stability Testing Protocols

Shelf life testing labs follow standardized protocols to evaluate product stability, including:

Real-Time Stability Testing: Products are stored under recommended conditions for the expected shelf life duration. Samples are tested at specific intervals to observe changes.

Accelerated Stability Testing: Products are exposed to elevated stress conditions (higher temperatures, humidity) to speed up degradation processes. Results are extrapolated to predict real-time shelf life.

Stress Testing: Extreme conditions such as freezing, UV exposure, or mechanical stress may be applied to identify vulnerabilities.

These tests provide comprehensive data about how a product’s quality changes over time.

4. Data Analysis and Expiry Date Prediction

Once data is collected, scientists at the testing lab analyze trends in the monitored parameters. Key considerations include:

When do microbial counts exceed safe limits?

At what point do chemical components degrade beyond acceptable thresholds?

Are there significant changes in sensory or physical properties that impact consumer acceptability?

Using statistical models and regulatory guidelines, labs extrapolate the shelf life period during which the product remains safe and retains intended quality. This predicted timeframe forms the basis for the expiry date.

5. Verification and Validation

Before finalizing expiry dates, labs may conduct confirmatory tests or challenge studies to validate the predictions. This ensures that the expiry date is reliable and defensible.

Factors Affecting Expiry Dates in Packaged Goods

Expiry dates depend on multiple variables, including:

Product Composition: Ingredients that are prone to oxidation or microbial growth tend to have shorter shelf lives.

Packaging Type: Barrier properties, oxygen permeability, and sealing quality significantly impact product stability.

Storage Conditions: Temperature fluctuations, humidity, and light exposure accelerate degradation.

Manufacturing Processes: Hygienic practices and preservative efficacy affect shelf life.

Shelf life testing labs evaluate these factors holistically to assign accurate expiry dates.

Role of Packaging in Shelf Life Testing

Packaging plays a crucial role in protecting products and extending shelf life. Testing labs assess:

Barrier Effectiveness: Ability to block moisture, oxygen, and contaminants.

Physical Durability: Resistance to punctures, tears, and seal failures.

Compatibility: Interaction between packaging material and product components.

Results from packaging tests help labs recommend improvements to extend product stability and adjust expiry dates accordingly.

Regulatory Guidelines and Shelf Life Testing

Shelf life testing labs also ensure that expiry dates comply with regulatory standards such as:

FDA (U.S. Food and Drug Administration)

EFSA (European Food Safety Authority)

GCC Standards in the UAE and Middle East

Codex Alimentarius for Food Products

Cosmetic Regulations and Pharmacopeias

Compliance with these regulations is essential for market authorization and consumer safety.

Benefits of Partnering with Accredited Shelf Life Testing Labs

Choosing an accredited Shelf Life Testing Lab offers several advantages:

Reliable and Accurate Results: Labs accredited with ISO 17025 or similar certifications adhere to strict quality standards.

Customized Testing Solutions: Tailored protocols based on product type and market needs.

Regulatory Expertise: Labs guide manufacturers on compliance and documentation.

Advanced Technologies: Access to cutting-edge analytical instruments ensures detailed assessments.

Conclusion

Determining expiry dates for packaged goods is a critical step in product development and market launch. Shelf Life Testing Labs use scientific methods, thorough analysis, and regulatory insights to ensure that expiry dates are accurate and reliable. These labs play a vital role in protecting consumers, helping manufacturers comply with regulations, and maintaining brand integrity.

For manufacturers and brands, partnering with a trusted shelf life testing lab is essential to confidently provide safe, high-quality products with trustworthy expiry dates—ultimately fostering consumer trust and business success.

0 notes

Text

Budhan Engineerings: Leading the Future of Cigarette Manufacturing in Indonesia

With decades of engineering excellence and cutting-edge innovation, Budhan Engineerings has emerged as a trusted provider of cigarette machinery in Indonesia. From large-scale factories to agile production units, Budhan delivers precision-driven solutions for every cigarette manufacturer.

Why Budhan Engineerings is the First Choice in Indonesia

✔ Decades of Expertise Budhan Engineering has been manufacturing cigarette machines since 1977, offering tried-and-tested reliability.

✔ Global Technology, Local Focus Their products combine global innovation with the needs of the Indonesian tobacco industry, offering machines tailored for local requirements.

✔ End-to-End Solutions From cigarette making to filter attachment and packaging, Budhan provides all-in-one solutions under one roof.

Innovation That Sets Budhan Apart

Budhan isn't just a machinery manufacturer – it’s a hub of innovation. Here's what makes their products revolutionary:

🔹 Smart Automation Systems Advanced control systems reduce downtime, improve consistency, and lower human error.

🔹 Energy-Efficient Designs Machines are optimized for power efficiency, reducing production costs and environmental impact.

🔹 Modular Components Easily upgradable and serviceable parts help extend machine life and simplify maintenance.

🔹 High-Speed Output Machines like the M2500 produce up to 2,500 cigarettes per minute – ideal for high-volume operations.

🔹 Custom-Tailored Machines Clients can request design tweaks based on their brand specifications, size formats, and packaging types.

Top Models for High-Quality Cigarette Machinery in Indonesia

Budhan M2500 A powerhouse in high-speed cigarette making machines in Indonesia. Output: Up to 2,500 CPM Combines making, tipping & filter joining

Budhan MK8 A classic model known for durability and cost-effectiveness. Mid-speed production Trusted for consistent performance

HLP2 Packer Efficient cigarette box packing with flexible size options. 180 packs/minute Adjustable packet sizes for different markets

Wrapper 300 High-speed cellophane wrapping – sleek, strong, and fast. 300 wraps/minute Perfect finish for product protection and shelf appeal

Why Choose Budhan for Cigarette Manufacturing Machines in Indonesia?

Proven Track Record – 40+ years in global and Indonesian markets

High Quality Machinery – Built to last, perform, and evolve

Best Cigarette Making Machines in Indonesia – Reliable, scalable, and affordable

In-House Manufacturing – From engineering to testing, everything is done under strict quality control

Customer-Centric Approach – Post-sales service, training, and technical assistance available.

Conclusion

For businesses in search of the best cigarette making machine in Indonesia, Budhan Engineerings delivers a perfect blend of tradition and technology. Their range of high-quality cigarette machinery in Indonesia empowers tobacco manufacturers to scale confidently and efficiently. Whether you're a new entrant or an established player, Budhan has the tools, tech, and team to accelerate your growth.

#cigarette machinery in indonesia#best cigarette making machine in indonesia#high quality cigarette machinery in indonesia

0 notes

Text

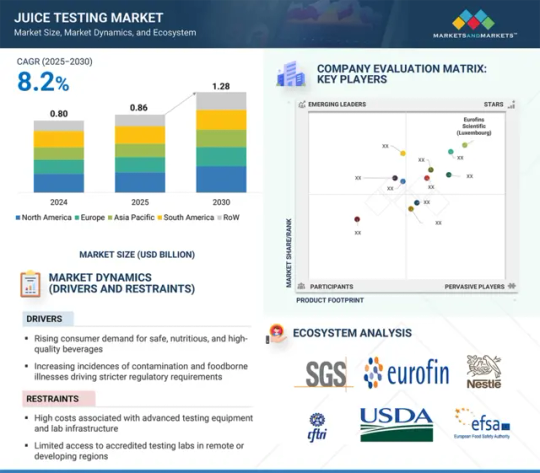

Juice Testing Market Report: Market Size, Share, and Competitive Landscape

The global juice testing market is projected to grow from USD 0.86 billion in 2025 to USD 1.28 billion by 2030, reflecting a CAGR of 8.2% over the forecast period. This growth is fueled by heightened consumer awareness regarding food safety, a rise in contamination cases, and increasingly stringent international regulations. To ensure product integrity, safeguard public health, and protect brand reputation, juice manufacturers are increasingly investing in advanced testing technologies.

The growing diversity of juice products and continuous innovations have amplified the need for rigorous testing. With rising demand for natural and clean-label beverages, producers are under pressure to validate ingredient purity, processing methods, and safety standards through comprehensive testing across microbial, chemical, and sensory parameters.

By Test Type: Chemical Testing Dominates

Chemical testing accounts for a major share of the juice testing market due to its essential role in verifying composition, safety, and regulatory compliance. Manufacturers routinely conduct tests for acidity levels, preservatives, and contaminants to maintain product consistency and meet labeling standards. Increasingly strict global food safety regulations have accelerated the adoption of advanced methods such as chromatography and spectrometry, enabling precise detection of pesticides, heavy metals, and synthetic additives.

The surge in demand for clean-label and functional juices has led to greater investment in additive monitoring and quality control. Additionally, advancements in technology are streamlining workflows and reducing the cost per test, further strengthening the role of chemical testing in the market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=261087115

By Product Type: Mixed Juices Lead the Way

The mixed juice segment holds a substantial market share, driven by growing consumer interest in blended beverages that offer enhanced nutrition and innovative flavors. These products often combine multiple fruit and vegetable extracts, making them more complex to test. As a result, demand for advanced testing solutions that ensure ingredient accuracy, label compliance, and shelf-life stability continues to rise.

The popularity of clean-label, organic, and functional beverages—especially in urban centers—has further intensified the focus on quality assurance. Looking ahead, opportunities exist in rapid testing technologies, AI-driven analytics, and customized protocols tailored to plant-based formulations. Increasing regulatory scrutiny, particularly in export markets, is expected to further drive the adoption of testing practices within this segment.

By Region: Asia Pacific Emerges as the Fastest-Growing Market

The Asia Pacific region is poised for the fastest growth in the juice testing market. Factors such as growing health consciousness, rapid urbanization, and increased consumption of packaged juices are contributing to this surge. Countries including China, India, Japan, and South Korea are experiencing rising demand for both domestic and export-grade juice products, prompting manufacturers to implement stringent testing and quality control measures.

Supportive government policies, evolving food safety frameworks, and advancements in regional testing infrastructure are further enhancing the market landscape. As consumers across the region increasingly prioritize health and safety, demand for reliable juice testing solutions is expected to grow significantly.

Leading Juice Testing Companies:

The report profiles key players such as Eurofins Scientific (Luxembourg), SGS Société Générale de Surveillance SA (Switzerland), ALS (Australia), Intertek Group plc (UK), Mérieux NutriSciences Corporation (France), Certified Group (US), TÜV SÜD (Germany), Symbio Labs (Australia), Alfa Chemistry (US), FoodChain ID (US), AGQ Labs (Spain), Tentamus (Germany), LAUDA DR. R. WOBSER GMBH & CO. KG (Germany), Centre Testing International (China), and Agilent Technologies, Inc. (US).

#Juice Testing Market#Juice Testing#Juice Testing Market Size#Juice Testing Market Share#Juice Testing Market Growth#Juice Testing Market Trends#Juice Testing Market Forecast#Juice Testing Market Analysis#Juice Testing Market Report#Juice Testing Market Scope#Juice Testing Market Overview#Juice Testing Market Outlook#Juice Testing Market Drivers#Juice Testing Industry#Juice Testing Companies

0 notes