#access scaffolding

Explore tagged Tumblr posts

Photo

Without me, who am I (Patreon)

#Doodles#Helix#Max Vyer#Dexter Favin#Vent#More of this#What can we do but pick up the pieces#With a habit that long-running and ingrained it'd be hard to just Stop even if the backlog was destroyed#Not really a choice to Do or Not Do - it's just What One Does whether there's a scaffold to build from or not#The worst part(s) for me really is the memory of people - bringing my ADHD!Max headcanon to the very forefront here haha#To be fair even if he doesn't have That Particular reason to have a shaky hold on his working and/or longterm memory - his drug problem#The idea of not having access to my memories of the people I love/my history/ideas/events or stories that have moved and shaped me#It's probably the scariest thing I can think of#Coupled with the lack of guarantee of tomorrow - that anything that Has existed until now will Continue to exist#And now I don't even have a way to look back to when it did. Total oblivion#Obviously not All of it but I don't even know what I don't know anymore it's just fully gone#So - some more comfort doodles of the boy <3 Shared grief half a grief and all that#He's always lovely and I love him ♥ Important-to-me lad#I'm not sure the last three-set translates exactly - losing your own diary/history/memories can be very self-alienating#No pun intended haha#Max's dream journal was always to do with ZEX and DAX and the Captain once he showed up - a life different from his own#I suppose if you wanted to go really meta with it - since Max is /a/ ZEX and his concept as a character is to be a version of him#Who is he without ZEX? Who are we without our trajectories?#I drew him with his eye there so it's assumed he'd be Max but a Defeated ZEX posing that question to Dex would be interesting too#Changes the ''me'' in question from Max to ZEX - either way their source is the same!#Being actively discouraged from and punished for his creative outlet - different circumstances but a similar sadness I suppose#The Loss and Aimlessness for sure

4 notes

·

View notes

Text

Chemey is preferred Global Supplier of safety railing systems, Hard yet portable Barricades, fall protection solutions and safe access equipment for working at height.

#Chemey#Chemey Mechatronics#Chemey Mechatronics LLP#Industrial Solutions#Industrial Safety#Safety Solutions#Safety Products#Safety Equipments#Industrial Safety Solutions#Industrial Safety Products#Slip-On Fittings#Modular Guard Rail Solution#Tanker Access Platform#Aluminium Slip-On Fittings#Self-Closing Industrial Safety Gates#Osha Safety Gates#Rooftop Guardrails#Skylight Safety Cover#Tanker Truck Access Platform#Aluminium Industrial Floor Grating#Portable Work Platforms#Modular Safety Railing#Mezzanine Safety Barriers#Mobile Tanker Ladder#Self-Closing Safety Gates#Aluminum Structural Fittings#Mezzanine Pallet Gate#Modular Safety Rail Systems#Rooftop Walkway#Scaffold Mobile Tower

2 notes

·

View notes

Text

Understanding No Go Zones for Scaffolding in Victoria

Understanding No Go Zones for Scaffolding in Victoria https://scaffolding-hire.com.au/understanding-no-go-zones-for-scaffolding-in-victoria/?utm_source=rss&utm_medium=rss&utm_campaign=understanding-no-go-zones-for-scaffolding-in-victoria When it comes to working near powerlines, safety isn’t optional—it’s essential. In Victoria, No Go Zones are designated safety boundaries created to prevent accidents and fatalities involving overhead powerlines. For scaffolders, builders, and site managers, understanding these zones is not just about compliance—it’s about being safe. What Are No Go Zones? No Go Zones are safety areas defined by Energy Safe Victoria (ESV) to mitigate the risk of electrical accidents around powerlines. These zones set strict minimum distances where no work or scaffolding can take place without formal approval. They apply to all kinds of worksites, from construction to agriculture, and are especially relevant in urban settings with dense infrastructure. According to ESV, the key distinctions are: Overhead Distribution Lines (pole-to-pole along streets) Service Lines (from poles to properties) Underground Assets High vs Low Voltage Zones Scaffolding and No Go Zones If scaffolding equipment comes within 5.0 metres vertically or 4.6 metres horizontally of overhead powerlines, you’re in a No Go Zone. In this case, you must obtain a Permit to Work (PTW) from the relevant Victorian power distributor before proceeding. As shown in the graphic above, scaffolding must never be erected above powerlines, regardless of voltage level. Even if your team plans to work near service lines (connecting power from the street to a property), you may require a power shutdown. Spotters may assist during operation, but they are not enough during the erection or dismantling phase due to the unpredictability of scaffold movement. How to Get a Permit to Work (PTW) If your project falls within a No Go Zone, follow these steps: Identify your site’s electricity distributor using the DELWP mapping tool. Contact the distributor (see below) and apply for a PTW. Allow up to two weeks for an inspector to attend your site. If a shutdown is required, plan for up to four weeks for scheduling and execution. Contact details for Victoria’s power distributors: AusNet Services – 1300 360 795 Jemena – 131 626 Powercor / CitiPower – 132 206 / 1300 301 101 United Energy – 1300 131 689 Plan Ahead to Stay Safe Resources like the Look Up and Live app and ESV’s published guidelines help teams identify hazards early. Prior to commencing an inspection, our team will allocate a Licensed Scaffolder individual who will be responsible for the onsite inspection and we will conduct a Safety inspection before scaffolding begins. Starting early not only protects lives but also helps prevent costly delays due to permit wait times or shutdown logistics. If you have any questions or No Go Zones, feel free to reach out to our team directly. The post Understanding No Go Zones for Scaffolding in Victoria appeared first on Reliable Access I Melbourne Scaffolding Hire. via Reliable Access I Melbourne Scaffolding Hire https://scaffolding-hire.com.au May 23, 2025 at 04:31PM

0 notes

Video

youtube

Omega Ladder Access Transom Manufacturing - Wellmade China - Kwikstage ...

0 notes

Text

Discover AARDWOLF QUICKFIT's innovative scaffolding and access solutions. Durable, safe, and versatile products tailored for construction and industrial needs! Ready to elevate your project's safety and efficiency? AARDWOLF QUICKFIT is your trusted partner, redefining scaffolding and access solutions with a commitment to quality, safety, and innovation. Whether for sale or rent, we deliver unparalleled expertise to ensure safer, more efficient operations. Visit www.aqaccess.com or contact us today to take the first step toward excellence!

For more information click here: https://www.mtandt.com/blogs/why-smart-builders-choose-aardwolf-quickfit-for-their-scaffolding-needs

#AARDWOLF QUICKFIT#Scaffolding#access solutions#aluminium towers#aluminium scaffolds#aluminium scaffold#aluminium scaffolding#aluminium ladders

0 notes

Text

How do I use scaffolding safely?

Scaffolding is a necessary tool in building, maintenance, and industrial operations that provides workers a safe platform to complete jobs at heights. Still, improper usage of scaffolding can cause mistakes and injuries. Following safety policies helps you to provide a safe and efficient workplace.

Energy Plus Technical Services W.L., the leading supplier of rope access and scaffolding systems in Qatar, underlines the need of scaffolding safety. This complete guide will enable you to utilize scaffolding safely. Review the scaffolding before usage: List of Objectives Check that every component—including the planks, frames, and braces—is in good form. Check the levelness of the base and the suitable support. Make sure every bracing and locking mechanism is exactly in place. Regular inspections are absolutely vital to prevent problems while in use. 2. Assemble scaffolding correctly. How to Assemble Safely Refer to the manufacturer's directions: As directed by the manufacturer, set up the scaffolding. Use base plates and mud sills to guarantee consistent weight distribution; make sure the base is strong. Put toe boards and guardrails to prevent falls and protect tools and supplies. Both horizontal and diagonal braces help to maintain the stability of the construction. Uncorrect assembly is one of the main causes of scaffolding mishaps. 3. Get on personal protective gear, or PPE. Workers under scaffolding must wear: Hard hats protect one against falling items. Changing to non-slip shoes reduces your risk of slipping. Work at higher altitudes calls for lanyards and harnesses; they should be secured to a sturdy item. Energyplus ensures that every team member has PPE compliant with industry requirements in order for safe operations. 4. Appropriately Load Scaffolding Guidance on Load Management Respect the weight limit of the scaffolding for persons, tools, and supplies to avoid overloading. Distribute weight equally; minimize tipping by not focusing loads in one area. Overloading is one usual mistake that could compromise scaffolding stability. 5. Focus on the surroundings. Guidelines Strong winds could compromise scaffolding, hence avoid operating on it under such situations. Rain or snow: Wait till the temperature rises to avoid slippiness in damp spots. Avoid erecting scaffolding during storms. Monitoring the weather will help you greatly reduce the possibility of mishaps. Six: Keep Access Points Clear Safe access consists of: Safe and handy methods of access are stair towers or ladders. Undirect paths: Clear path from trash and hazards. When access permits, workers can move safely and freely. 7. Try not to improvise. Steer clear of employing homemade materials to alter scaffolding construction. Replace climbing on braces with allowed access points. The structure could weaken and improvisation might lead to unsafe scenarios. 8. Appropriately Instruct Staff Members Training should entail: erecting and dismantling scaffolding. spotting hazards like weak platforms or poor connections. emergency procedures should an accident strike. Energyplus makes a large commitment in extensive training to ensure that its staff members are informed and aware of safety. Why chose Energyplus for Qatar's scaffolding needs? Technical Solutions for Energy Plus W.L.L. is a respected name for scaffolding and rope access solutions in Qatar. Our areas of expertise include: providing excellent scaffolding systems following worldwide safety standards. employing professionals with great training. guaranteeing prompt, secure, efficient project completion. You might be sure Energyplus will precisely and with care handle your scaffolding needs. In summary Responsibilities for scaffolding safety fall to workers, management, and service providers. Following these best standards helps you to create a safe workplace and lower risks. Energy Plus Technical Services W.L.L. is Qatar's most reliable scaffolding and rope access provider. Get in touch right now to learn more!

#Rope Access Cleaning company in qatar#Rope Access Qatar#scaffolding company in qatar#scaoffolding cleaning company qatar#scoffolding services qatar

0 notes

Text

Check if You’re Making These 7 Common Mobile Scaffold Mistakes

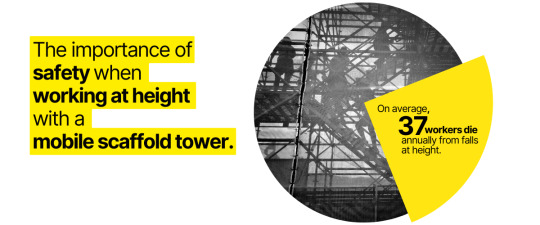

Scaffolds are essential for tasks requiring height access, offering versatility and efficiency. However, improper use can lead to serious accidents. Here are seven common mistakes to avoid to ensure safety and efficiency when using mobile scaffolds.

Contents;

1. Choosing the Wrong Scaffold Tower

2. Failing to Inspect and Secure the Tower

3. Skipping Proper Training

4. Ignoring Assembly Instructions

5. Using Improper Access Methods

6. Overloading the Scaffold

7. Operating in Adverse Weather Conditions

1. Choosing the Wrong Scaffold Tower:

Selecting the right mobile scaffold tower is crucial. Consider your project’s height, load requirements, and working environment. For quick, light-duty tasks, ladder towers are ideal, while stairway towers are better for continuous access. In electrically hazardous areas, fiberglass (FRP) scaffolds provide the safest option. Avoid settling for the wrong type, as it compromises functionality and safety.

Article: 5 Reasons to Avoid Mixing Scaffold Tower Components

2. Failing to Inspect and Secure the Tower:

One of the simplest yet most overlooked steps is inspecting the mobile scaffold before use. Check for damaged or loose parts, as faulty components can lead to catastrophic failures. Additionally, mobile scaffolds must be stabilized to avoid tipping. Use stabilizers or outriggers, and always lock the mobile scaffold wheels once the scaffold is positioned.

Article: How Maruti Suzuki India Achieved 3X Productivity in Height Maintenance

Regular inspections and securing the tower ensure it remains steady and safe during use. These steps, though small, can significantly reduce risks and enhance overall stability on-site.

Read Full Article: Y-Access Manufacturing Blog

#mobile access tower#y access manufacturing#y access scaffold#work at height safety#safety#aluminium scaffold#scaffolding#maintenance and care products#maintenance#high maintenance

0 notes

Text

Are there safety precautions for using scaffolding equipment?

Access to elevated work areas is made possible by scaffolding equipment, which is an essential component of building, maintenance, and industrial operations. Inappropriate usage of scaffolding, on the other hand, poses severe risks to both personnel and construction equipment. It is possible to reduce the severity of these dangers by strictly adhering to safety precautions.Throughout all of their scaffolding operations, Energy Plus Technical Services W.L.L., which is the top provider of rope access and scaffolding services in Qatar, places a strong emphasis on safety. A guide to the most important safety measures to take when utilizing scaffolding equipment is presented here.

1. Carry out initial inspections before use

It is essential to perform a comprehensive inspection before to employing scaffolding.

List of items:

Check that none of the components are broken, deformed, or rusted to ensure that the structure is intact.

In order to provide stability, check that the base plates and mud sills are properly positioned and that they are secure.

Make sure that the guardrails and toe boards are in good condition and that they have been installed correctly.

Be sure to tighten all of the bolts and locking mechanisms on the connections.

Regular inspections help prevent accidents that could have been caused by scaffolding equipment that is either malfunctioning or compromised.

2. Comply with the manufacturer's instructions.

Always be sure to install and utilize scaffolding in accordance with the instructions provided by the manufacturer.

The Most Important Points:

Sequence of Assembly: When assembling and disassembling, make sure to follow the steps that are indicated.

Weight Limits: Ensure that you adhere to the load capacity that has been defined, which includes workers, tools, and supplies.

Approved Accessories: Only use components and accessories that are compatible with the device.

The safety and performance of the scaffolding can be jeopardized if the requirements are not followed completely.

3. Establish a Firm Foundation

For the scaffolding to be stable, a solid base is absolutely necessary.

Exceptional Methods:

Utilize foundation plates and mud sills in order to distribute weight in an even manner.

In order to keep the earth from sinking, make sure that it is level and compacted.

Scaffolding should not be placed on surfaces that are soft or on terrain that is uneven.

When it comes to scaffolding projects around Qatar, Energyplus places a strong emphasis on establishing robust foundations.

4. Always make sure to wear personal protective equipment:

Workers are protected from injuries and falls when they have the appropriate personal protective equipment (PPE).

Necessary Equipment:

Protect yourself from falling items by wearing a hard hat.

Wearing footwear that is non-slip reduces the likelihood of slipping on surfaces that are damp or uneven.

When working at height, harnesses and lanyards are required, and they must be fastened to suitable places.

A non-negotiable safety requirement is the provision of personal protective equipment (PPE) and the enforcement of its use.

5. Ensure that access is kept secure Confirm that workers are able to access and depart the scaffolding in a secure manner.

Stations of Access:

It is recommended to make use of ramps, ladders, or stair towers that are stable and firmly fastened.

Make sure that there are no impediments in the routes and platforms.

Climbing on bracing or routes that have been improvised should be avoided.

Slips, stumbles, and falls can be avoided by ensuring proper access.

6. Take Precautions to Avoid Overloading

Scaffolding that is overloaded might result in the collapse of the structure.

Safety measures:

Spread out the materials and equipment to avoid having a concentrated amount of weight. Distribute the loads evenly.

It is imperative that you do not exceed the load capacity of the scaffolding at any time.

Materials to Be Monitored: When they are not being used, remove any surplus tools and materials.

Ensuring that scaffolding systems are utilized effectively and within safe limits is the responsibility of Energyplus.

7. Pay Attention to the Circumstances of the Environment The weather can have a considerable impact on the safety of scaffolding.

Safety measures:

Securing scaffolding or avoiding its use during periods of high wind speeds is recommended.

Surfaces that are wet: In order to avoid slipping, wait for the rain to finish and make sure that the platforms are dry.

It is imperative that scaffolding not be used during storms or in close proximity to electrical lines.

Keeping an eye on the weather is absolutely necessary for the safety of workers.

8. Provide Workers with Extensive Training

Workers are equipped with the information necessary to properly operate scaffolding when correct training is received.

Emphasis on Training:

There are processes for assembling and disassembling scaffolding.

Hazard identification and risk reduction are both included.

The procedures to follow in the event of an emergency.

In order to guarantee that its employees adhere to the greatest possible safety standards, Energyplus offers them with rigorous ongoing training.

9. Scaffolding should never be altered or improved upon.

Ensure that scaffolding equipment is not subject to any unlawful changes.

Notes of Caution:

It is not acceptable to use homemade materials to repair broken pieces.

Without first consulting a certified supervisor, you should avoid making any changes to the structure.

Use scaffolding in the manner that was intended.

The stability and safety of the equipment can be put in jeopardy if the adjustments are not done correctly.

When it comes to scaffolding services in Qatar, why should you choose Energyplus?

When it comes to scaffolding and rope access solutions, Energy Plus Technical Services W.L.L. is Qatar's reliable partner.

To explain why:

Adherence to the safety standards established internationally.

Excellent scaffolding systems and components of the highest quality.

Professionals with extensive knowledge and experience in the safe use of scaffolding.

We offer individualized solutions for residential, commercial, and industrial construction projects.

When it comes to Energyplus, safety is always the most important concern.

Final Thoughts

The safe utilization of scaffolding necessitates meticulous planning, the utilization of appropriate equipment, and the strict adherence to safety regulations. It is possible for workers and supervisors to establish a safe and productive working environment by adhering to these recommended procedures.

Energy Plus Technical Services W.L.L. is the company to rely on in Qatar for scaffolding and rope access services thanks to their reliability. Get in touch with us right away to see more!

#Access solution provider in qatar#Rope Access Cleaning company in qatar#Rope Access Qatar#scaffolding company in qatar#scaoffolding cleaning company qatar#scoffolding services qatar

0 notes

Text

Scaffolding Barrow

High quality scaffolding services throughout Barrow and the surrounding areas. We provide professional scaffolders throughout Barrow in Furness and the surrounding areas. From Chimney scaffold to Temporary structures, our team of expert scaffolders are keen to take on any request. No job is too big or too small.

Visit Our Website

#Tube Scaffolding Ulverston#Access Scaffolding Ulverston#Tube Scaffolding Dalton-in-Furness#Temporary Roofing Dalton-in-Furness#Commercial Scaffolding Dalton-in-Furness#Commercial Scaffolders Dalton-in-Furness#Scaffolding Dalton-in-Furness#Tube Scaffolding Barrow-in-Furness#Scaffolds Dalton-in-Furness#Temporary Roofing Ulverston

0 notes

Text

J&S Integrated Services

Are you looking for a cherry picker hire in Romford or a temporary boiler hire for your next project in Greater London? At J&S Integrated Services, we specialise in a wide range of plant and machinery hire services, ensuring that your project runs smoothly and efficiently with high-quality equipment such as cherry picker hire, mobile access tower hire, and temporary boiler hire.

We Are Passionate About Cherry Picker Hire and More in Romford, Greater London

At J&S Integrated Services, we are dedicated to delivering top-tier plant and machinery hire services throughout Romford and Greater London. Whether you need to hire a cherry picker, require mobile scaffold tower solutions, or seek temporary boiler hire, our team is committed to meeting your needs. Our expertise spans multiple industries, and we always ensure that all equipment is up-to-date, safe, and ready for use.

Website: https://jandsintegratedservices.co.uk/

Address: Unit 1 Trade Centre, Ashton Rd, Harold Hill, Romford, Greater London, London, RM3 8UJ

Phone Number: 01708 321321

Business Hours: Mon - Fri : 08:00am - 05:00pm Sat - Sun : Closed

#Cherry Picker Hire#Hire A Cherry Picker#Cost of Cherry Picker Hire#Temporary Boilers#Temporary Boiler Hire#Mobile Access Towers#Mobile Access Tower Hire#Mobile Scaffold Tower#Rubbish Removal#Man With Van Rubbish Removal#Garden Rubbish Removal#Garden Clearance#Rubbish Clearance#Diamond Drilling Services#Decorating Services#Property Maintenance

1 note

·

View note

Text

Scaffolding When Is It Necessary?

Scaffolding, When Is It Necessary? https://scaffolding-hire.com.au/scaffolding-when-is-it-necessary/?utm_source=rss&utm_medium=rss&utm_campaign=scaffolding-when-is-it-necessary Deciding between a ladder or scaffolding for your home renovations or roofing project is a common conundrum. Safety and access are key, and knowing when scaffolding is necessary will ensure both. Mobile scaffolding provides stability and support when tasks involve height or more than basic access is required. There are several situations where scaffolding over a ladder might be the way to go. These are projects that require working at heights for long periods or carrying heavy loads that a ladder can’t handle. Knowing these factors will make home renovations safer and more efficient. Assess the Job Before any job begins, most scaffolding suppliers including Reliable Access will want to visit the site to assess the work. We need to see the access points, identify the obstacles and think about all the safety aspects. A site visit provides us with more information than just being told about the job over the phone. After we have assessed the site, we can help you determine what you need to safely and efficiently do the job. So you’re prepared and have a plan. Working at Height When tasks are above ground level safety must be number one. For small jobs like painting a ladder might be enough, although you may need to reposition frequently. Ladders are good for solo jobs but can be limiting. But larger jobs that require more people like painting and gutters might benefit from a more stable platform. A scaffolding solution such as a mobile tower provides a safer environment to store tools and reduce the risk of objects falling. Scaffolding allows workers to move freely and comfortably while doing their job. This structured support helps in managing tools safely and efficiently. So choosing the right equipment is key to safety and efficiency. Job Type and Job Duration Jobs at height often use scaffolding. Instead of investing in big equipment, a mobile scaffold is a practical and cost effective solution. Here are some common jobs that use scaffolding: Painting: Access at elevated levels. Gutter Repairs: Safe and stable work on house exteriors. Roofing: Secure footing on roofs. Window Cleaning: Safe access to high windows. These jobs are safer and more efficient with the right scaffolding equipment, especially from a Melbourne based company such as Reliable Access. Considerations: Safety: Is climbing up and down a ladder repeatedly safe? Efficiency: Would a work platform speed up the job? Using a work platform allows tools to be at the required height, so safety and efficiency is improved by reducing climbs. This job planning approach ensures the job is done with minimal risk and maximum productivity. Workforce When more than one person is working at height it’s important to think about safety. Scaffolding plays a big part here. Not everyone is the same when using a ladder, some are more comfortable or stable than others and carrying tools or materials adds to the challenge. Scaffolding ensures everyone can work safely and comfortably. It provides a more stable and accessible work area than ladders, so the job is more efficient and reduces the risk of falls or injuries on site. The post Scaffolding, When Is It Necessary? appeared first on Reliable Access I Melbourne Scaffolding Hire. via Reliable Access I Melbourne Scaffolding Hire https://scaffolding-hire.com.au January 20, 2025 at 09:14AM

1 note

·

View note

Video

youtube

Ringlock Scaffolding Access Ladder Manufaturing - Wellmade Scaffold China

#youtube#ringlock scaffolding#ringlock scaffold#ring lock scaffold#ringlock system#wellmade scaffold#steel ladder#scaffolding ladder#access ladder

0 notes

Text

https://www.superiorscaffold.com/surprise-surprise-surprise-suspended-scaffold-everywhere-at-400-w-elm-conshohocken-pa/

#construction#nj#de#pa#scaffolding#scaffold#superiorscaffold#suspendedscaffold#access#scaffoldingphilly#gbca#buildingourfuture

0 notes

Text

Why Choose a Suspended Desk System? Overview, Features, and Benefits.

Creating a suspended desk system offers numerous advantages for both residential and commercial spaces. By understanding the features, benefits, and construction process, you can implement a stylish and functional solution that enhances any workspace. Whether for maximizing space, improving aesthetics, or increasing accessibility, a suspended desk system is a modern innovation worth considering.

For more click here: https://bit.ly/3VsuQ7t

#websystems#construction#maintenance#suspended scaffolding#aluminium bridge decking#bridge deck construction#inspection#safety#webcatch#access systems uk

0 notes

Text

Hire Professional Domestic and Commercial Scaffolder in Kent.

We have over years of experience providing scaffolding services to domestic and commercial customers across Scaffolding London area. ✔️01883 330188

#Scaffolder Kent#scaffolding maidstone#scaffold tower hire maidstone#scaffolding medway#scaffolding gravesend#scaffolding companies kent#scaffolding ashford kent#scaffold tower hire kent#all access scaffolding margate#brownes scaffolding ashford#scaffolding hire kent

0 notes

Text

How Maruti Suzuki India Achieved 3X Productivity in Height Maintenance

Client Overview

Maruti Suzuki India Ltd., a leader in the automobile manufacturing sector, is committed to efficiency and innovation. Regular maintenance of EOT cranes, which operate at considerable heights, is critical for ensuring smooth production processes. However, challenges such as dust accumulation, wear on motors and bearings, and the complexities of working at height have made regular maintenance both demanding and essential.

Existing Work at Height Product and Challenges

Product Used: Scissor Lift

Maintenance Tasks: Conducted at heights of up to 25 feet

Maruti Suzuki’s maintenance team relied on a scissor lift to perform these critical tasks. However, the lift’s limitations led to significant inefficiencies:

Space Consumption: The scissor lift occupied substantial ground space, creating clutter and operational inefficiencies within the plant.

Mobility Issues: Moving the lift was cumbersome, hindering quick repositioning during maintenance tasks.

Power Dependence: The scissor lift required continuous electricity, increasing operational costs.

High Maintenance Costs: Frequent breakdowns and the complexity of repairs made maintenance costly.

Time-Consuming Operations: Slow movement and recurring breakdowns extended maintenance durations.

Productivity Challenges: Inefficient operations led to delays, negatively impacting overall productivity.

Safety and Environmental Concerns: The scissor lift’s design posed safety risks, especially within the enclosed plant environment.

Implications

These challenges had measurable consequences:

Time Wastage: Inefficient equipment prolonged maintenance schedules.

Reduced Productivity: Delays in completing tasks disrupted overall operations.

Inflated Costs: High purchase and upkeep expenses, coupled with energy consumption, strained budgets.

Safety Risks: The unstable nature of the scissor lift increased the likelihood of accidents, compromising worker safety.

Y-Access’s Solution

Product Acquired: Fitout Master with J Hook

To address these challenges, Maruti Suzuki implemented the Y-Access Fitout Master with J Hook, a versatile, efficient, and safety-compliant solution tailored for EOT crane maintenance.

Product Features

Lightweight Construction: Enabled easy setup and dismantling, enhancing mobility and operational efficiency.

Corrosion Resistance: Designed to endure harsh conditions, reducing replacement frequency and costs.

Quick Assembly: No specialized tools were required, saving valuable time.

Enhanced Safety: Stabilizers and a stairway with a J hook ensured a safer work environment.

Compliance: The Fitout Master replaced traditional monkey ladders, which were deemed unsafe by Maruti’s safety team.

Specific Benefits

Improved Accessibility: The J hook and stairway design facilitated easier climbing with tools, streamlining maintenance tasks.

Solution Benefits

Key Advantages

Elimination of Hidden Maintenance Costs: The durable, corrosion-resistant design significantly reduced maintenance and repair needs.

Reduced Maintenance and Breakdown Time: Quick assembly and reliable performance minimized downtime, accelerating task completion.

Enhanced Productivity and Safety: Improved safety features and ease of use created a secure and efficient work environment.

Lower Operational Costs: The lightweight, energy-independent design eliminated reliance on electricity and reduced operational expenses. Simplified maintenance processes further reduced repair costs.

Outcome

The adoption of the Y-Access Fitout Master with J Hook delivered measurable improvements for Maruti Suzuki:

3X Increase in Productivity: Maintenance tasks were completed faster with less downtime, enabling the team to focus on critical operations.

5X Cost Savings: Reduced energy consumption, fewer repairs, and elimination of frequent breakdowns resulted in significant cost efficiencies.

Enhanced Safety and Efficiency: Workers operated in a safer environment with improved tools, contributing to overall operational excellence.

Conclusion

Maruti Suzuki India Ltd.’s transition to the Y-Access Fitout Master with J Hook revolutionized their EOT crane maintenance process. By overcoming the limitations of the previous scissor lift solution, they achieved substantial productivity gains, cost reductions, and enhanced safety standards. This case exemplifies how innovative maintenance solutions can drive operational success in the manufacturing sector.

Case study: Dhamra Port’s HVAC and Electrical Maintenance Streamlined with XO FRP Scaffolds

If you are looking for an access solution to prioritize safety, then check Y-Access Manufacturing’s range of work-at-heigh products. Our products are designed to provide superior protection while ensuring maximum durability and longevity. Don't compromise on safety, choose Y-Access Manufacturing for all your ladder needs.

Reach out to us at: [email protected] or call: +91-9015964626

#scaffolding#work at height safety#high maintenance#aluminium scaffold#safety#Y Access Manufacturing#Fitout master#maintenance#maintenance and care products#engineering#product

1 note

·

View note