#agarbatti machine business

Text

Unleash the Aroma: Revolutionize Your Incense Business with the Perfect Agarbatti Making Machine

agarbatti making machine, incense sticks

Are you in the incense business? Looking to enhance your production capabilities and take your business to new heights? Look no further! The perfect solution to meet your needs is an Agarbatti Making Machine. This advanced equipment will revolutionize your incense manufacturing process and enable you to produce high quality agarbattis efficiently. Let’s delve into the world of Agarbatti Making Machines and discover how they can enhance your business.

The Benefits of an Agarbatti Making Machine

Creating incense manually can be a time-consuming and labor-intensive process. However, with the help of an Agarbatti Making Machine, you can streamline your production and enjoy numerous benefits. Let’s explore some of the advantages this machine brings to your incense business.

1. Increased Production Efficiency

By investing in an Agarbatti Making Machine, you can significantly improve your production efficiency. These machines are designed to automate the entire process, from raw material feeding to packaging. With faster production rates and minimal manual intervention, you can create a larger quantity of agarbattis in a shorter time frame, ultimately boosting your overall productivity.

2. Consistent Product Quality

Consistency is key when it comes to incense production. With manual manufacturing, it can be challenging to ensure uniformity in the size, shape, and fragrance of each agarbatti. However, an Agarbatti Making Machine offers precise control over these aspects. You can set specific parameters for length, diameter, and fragrance strength, guaranteeing a consistent product every time.

3. Cost Reduction

Investing in an Agarbatti Making Machine may seem like a significant initial investment, but it offers long-term cost benefits. With automation, you can reduce labor costs and minimize material wastage. Additionally, the machine’s efficiency allows you to produce a larger volume of agarbattis without the need for additional manpower, resulting in significant cost savings.

Choosing the Right Agarbatti Making Machine

Now that you are aware of the benefits an Agarbatti Making Machine can bring to your business, it is essential to select the right machine that suits your requirements. Consider the following factors when choosing the perfect machine for your incense manufacturing needs.

1. Capacity and Output

Evaluate your production requirements and choose a machine with the appropriate capacity. Machines come in various sizes and can produce agarbattis ranging from a few hundred to several thousand per hour. Determine your production targets and select a machine that can meet your desired output.

2. Automation Level

Different Agarbatti Making Machines offer varying levels of automation. Some machines handle the entire process, from powder mixing to incense stick formation, while others focus on specific stages. Assess your workflow and production needs to determine the level of automation required for your business.

3. Maintenance and After-Sales Support

Ensure the machine’s manufacturer offers reliable after-sales support and maintenance services. Regular maintenance and timely repairs are crucial for the smooth functioning of your Agarbatti Making Machine. Look for manufacturers or suppliers who provide comprehensive support and spare parts availability.

Conclusion

In today’s competitive market, staying ahead in the incense business requires efficiency, consistency, and cost-effective production. An Agarbatti Making Machine ticks all these boxes, enabling you to unleash the full potential of your business. With increased production efficiency, consistent product quality, and reduced costs, this advanced equipment will take your incense business to new heights. Choose the right machine that aligns with your requirements, and get ready to revolutionize your incense production process. Invest in an Agarbatti Making Machine and experience the sweet smell of success!

0 notes

Text

agarbatti making machine-fully automatic agarbatti making machine in Delhi

ASVR Engineering is the best agarbatti making machine manufacturer and supplier of incense stick making machine in Delhi. Buy fully automatic agarbatti maker machine in India from us at reasonable cost.

#agarbatti machine#agarbatti making machine#automatic agarbatti making machine#agarbatti making business#incense sticks making machine#incense maker machine#fully automatic agarbatti making machine

2 notes

·

View notes

Text

#agarbatti making machine#business#incense stick making machine#agarbatti making machine in varanasi#agarbatti#insence

0 notes

Text

youtube

#business#incense business#profitable business#agarbatti#paper plate#paper plate business#paper plate machine#paper plate machine manufacturer#Youtube

0 notes

Text

Agarbatti Making Machine in Bhopal

Agarbatti Making Machine in

Bhopal, a city known for its rich cultural heritage, has witnessed a significant surge in small-scale industries, particularly in the production of Agarbattis or incense sticks. This article delves into the intricate world of Agarbatti making machines in Bhopal, shedding light on the manufacturing processes, technology involved, and the impact on the local economy.

Agarbatti Machine in Bhopal.

In search of a Bhopal Agarbatti making machine? There's nowhere else to look! Our top-notch machinery is ideal for creating incense sticks of the highest caliber. Start your own incense business immediately by looking through our extensive selection of models. In Bhopal, we are the top producer, supplier, and wholesale dealer of the highest caliber Agarbatti-making machinery. Machines for creating Agarbatti can be fully or partially automated. Everything is done automatically by fully automated machinery, including feeding the mixture and cutting and packing the sticks.

Agarbatti-making machine advantages.

elevated productivity: The Agarbatti-making machine greatly raises productivity by automating the production process.

Unwavering quality: the apparatus guarantees consistency in the dimensions, form, and aroma of the incense sticks.

Economical: Using an Agarbatti-making machine has long-term advantages that surpass the original outlay, despite the machine's seemingly high initial cost.

Time-saving: By letting the machine handle the production process, business owners can concentrate on other facets of their operations, such customer service and marketing.

Increased safety: The Agarbatti-making machine complies with stringent safety regulations, which lowers the possibility of mishaps and injuries that might happen during the manual production process.

Read More

#Best Agarbatti Making Machine in Bhopal#Best Agarbatti Making Machine#Agarbatti Making Machine in India#Agarbatti manufacturer Machine in Bhopal

0 notes

Text

Learn the step-by-step process of setting up and operating your agarbatti making machine. Armind Industries offers high-quality machines for a successful manufacturing venture. Start your agarbatti production today!

#Agarbatti Making Machine#manual and automatic agarbatti machine#Incense Stick Making Machine#Manual Agarbatti Making Machine#Automatic Agarbatti Making Machine#agarbatti making machines

0 notes

Text

Agarbatti Making Machine: Streamlining Incense Production for Efficiency and Precision

Agarbatti making machines have revolutionized the incense industry, offering a seamless and efficient production process. This informative content delves into the features and impact of these advanced machines.

Automated Production Process: Agarbatti making machines automate the traditionally labor-intensive process of incense stick manufacturing. This not only increases production efficiency but also ensures consistent quality in each agarbatti produced.

High Production Capacity: Equipped with advanced technology, these machines boast high production capacities, allowing manufacturers to meet growing demands without compromising on quality. This scalability is crucial for businesses catering to diverse markets.

Precision in Raw Material Utilization: These machines optimize the use of raw materials, ensuring minimal wastage. By precisely blending ingredients and controlling the thickness of agarbatti, they contribute to cost-effectiveness and sustainability in the production process.

Customizable Output: Agarbatti making machines are designed to produce various types of incense sticks. Manufacturers can easily customize the length, thickness, and fragrance, catering to diverse market preferences and trends.

Labor and Time Savings: By automating the manual processes involved in agarbatti production, these machines significantly reduce the need for labor and time. This not only cuts operational costs but also allows manufacturers to focus on scaling their businesses.

Agarbatti making machines represent a significant leap forward in the incense industry, marrying technology with tradition. Their automated and efficient processes contribute to increased productivity, cost-effectiveness, and the overall advancement of incense manufacturing.

Effortlessly locate Agarbatti Making Machines with the JD app (Justdial app). Download now to connect with reliable suppliers and streamline your incense production process. Enhance efficiency and precision in your agarbatti manufacturing.

0 notes

Text

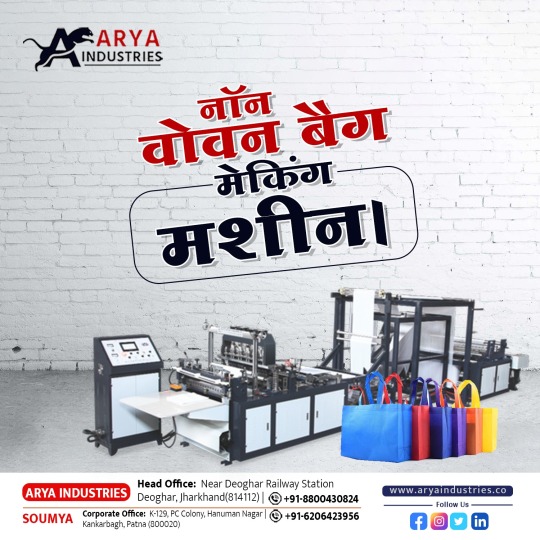

Non Woven Bag Machine in Patna: Arya Industries

Arya Industries stands out as the premier provider of non woven bag making machine Patna, spearheading the industry with its state-of-the-art non-woven bag making machines. As a trusted name in the market, Arya Industries has established itself as the go-to destination for businesses seeking efficient and reliable equipment for their operations.

At the heart of Arya Industries' offerings is its revolutionary non-woven bag making machine in Patna. With a commitment to sustainability and environmental responsibility, these machines are designed to produce high-quality, eco-friendly bags. The company's dedication to innovation is reflected in the precision and efficiency of their non-woven bag machines, making them an indispensable asset for businesses looking to contribute to a greener future.

In addition to non-woven bag machines, Arya Industries caters to a diverse range of industries with specialized equipment. The company boasts a remarkable noodles machine in Patna, addressing the needs of businesses involved in the production of this staple food item. The noodles machine is a testament to Arya Industries' versatility and commitment to meeting the unique demands of different sectors.

Arya Industries further extends its product portfolio to include a comprehensive range of machinery, such as semi-automatic and fully automatic thermocol plate making machines in Patna. These machines are designed to optimize the production process, ensuring efficiency and quality in the manufacturing of thermocol plates. The company's dedication to providing cutting-edge solutions is evident in the advanced features and technology incorporated into these machines.

The Arya Industries lineup also includes agarbatti making machines and paper cup making machines, showcasing the company's commitment to serving a wide spectrum of industries. The agarbatti making machines are designed for precision and efficiency in the production of incense sticks, while the paper cup making machines cater to the growing demand for eco-friendly disposable cups.

Arya Industries' non-woven bag machine in Patna has become synonymous with reliability and excellence. The company's commitment to quality extends to its customer service, ensuring that clients receive comprehensive support throughout the purchase and implementation process. As a result, Arya Industries has emerged as a trusted partner for businesses looking to invest in cutting-edge machinery for sustainable and efficient production processes.

Arya Industries is not merely a provider of machinery; it is a catalyst for progress and sustainability in the industrial landscape of Patna. With a diverse range of offerings, including non-woven bag machines, noodles machines, thermocol plate making machines, agarbatti making machines, and paper cup making machines, Arya Industries continues to shape the future of manufacturing in the region.

Visit us: https://www.aryaindustries.co/

#kapoormakingmachineinpatna#oil expailer#paperplatesmachinesinpatna#agarbattimakingmachineinpatna#fullyautomaticthermocolplatemakingmachineinpatna#manualnonwovenbagmakingmachinesinpatna#nonwovenbagmakingmachineinpatna#nonwovenbagmachineinpatna#semiautomaticthermocolplatemakingmachineinpatna#handpresspaperplatemachineinpatna#noodlesmachineinpatna

0 notes

Text

Find the Best Agarbatti Making Machine Supplier in Odisha with Priti Enterprises

Priti Enterprises is your trusted Agarbatti making machine supplier in Odisha. Their machines are designed for precision and efficiency, helping you create high-quality agarbatti products. As the leading supplier in Odisha, they offer competitive prices and exceptional customer service. Whether you're starting a new venture or expanding your agarbatti production, rely on Priti Enterprises for top-notch machines. Contact today to discover the best Agarbatti making machines in Odisha and take your business to new heights.

0 notes

Text

ऐसे ही मत जाओ माल बेचने ! दुकानदार की ना को हाँ में बदलें How To Sale Product In Real Market

𝐉𝐨𝐢𝐧 𝐅𝐫𝐞𝐞 𝐖𝐞𝐛𝐢𝐧𝐚𝐫:- https://kaamkaazi.in/ KaamKaazi एक Business Consultancy कंपनी है, KaamKaazi से जुड़कर भारत में हजारो लोग सफलता तक पहुंच पाएं है। हम आपको बिजनेस में आने से पहले उस बिजनेस का Analysis करके बताते है, ताकि आप उस बिजनेस में आने से पहले उस बिजनेस में Expert बन पाएं। इससे आपका फायदा यह होता है कि आप को अपने बिजनेस में पता चलता है की आगे काम कैसे करना है। Expert से Training लेने के लिए आज ही Join करें ! ►Manufacturing Mastery Course SPECIAL LIMITED OFFER 4990/- PAYMENT LINK:-https://rzp.io/l/E4990 हम आपके काम को सरल बनाते है, जिससे आपका काम आसान हो जाता है। यदि आप बिजनेस शुरु करना चाहते है या आगे बढना चाहते है, तो आप आज ही हमारें Training Program में सीख सकते है की किस तरह से आपको यह काम करना है। ►Contact Us For More Details: WhatsApp ,calling support :- 9057898043 ►Email: [email protected] ►Website: www.kaamkaazi.com ►Facebook : - https://www.facebook.com/groups/30291... ►Instagram :- https://instagram.com/yadhuchaturvedi... ►Business playlist ►Business Strategy https://youtu.be/1GvRCR1fxRg ►Business Case Study https://youtu.be/wJi1nyLb3l0 ►Business Success Story https://youtu.be/TLSZnsJ6Pjw ►Business Advice https://youtu.be/efDG1R0sVB4 ►Small Investment Business Series https://youtu.be/jRMjPnW8Hk0 Before Manufacturing Startup Watch This Video ! Agreement Issue of Machinery, New Business, Agarbatti Business, kapoor Business, Snack Business, Small Business, Ideas, Business Ideas in Hindi, Low Investment Business Ideas, New Business Ideas, Business Ideas 2023 ,business Ideas, Low Investment High Profit Business Ideas ,business Ideas in India With Small Investment, Business Ideas in India, New Business Opportunity, New Business Ideas 2023 , Small Scale Business Ides in India, No Competition Business Ideas, New Innovative Machine for Business.

0 notes

Text

Pouch Packing Machine & Collar Type Pouch Packaging Machine

Pouch Packing Machine: The Ultimate Guide to Finding the Right Manufacturer and SupplierAre you in search of a reliable pouch packing machine manufacturer and supplier in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad? Look no further! In this comprehensive guide, we will walk you through everything you need to know to make an informed decision and ensure you get the best pouch packing machine for your specific needs. What to Look for in a Pouch Packing Machine Manufacturer and Supplier? When choosing a pouch packing machine manufacturer and supplier, there are several key factors to consider: Experience: It is essential to choose a manufacturer and supplier with years of experience in the industry. This ensures that they have the necessary expertise to provide high-quality machines that meet your requirements. Expertise: Look for a manufacturer and supplier who specializes in pouch packing machines. This shows that they have in-depth knowledge of the product and can offer customized solutions to suit your needs. Authority: Seek out a manufacturer and supplier who is well-established and has a strong reputation in the market. This indicates that they are trustworthy and reliable. Trust: It is crucial to partner with a manufacturer and supplier you can trust to deliver on their promises and provide ongoing support and service. Pouch Packing Machine Manufacturer and Supplier in Delhi In Delhi, there are several reputable manufacturers and suppliers of pouch packing machines. One of the leading companies in the area is XYZ Pouch Packing Machines. With over 20 years of experience in the industry, they offer a wide range of high-quality machines to meet various packaging needs. Whether you are looking for a small-scale machine for your startup or a large-scale automated system for a manufacturing facility, XYZ has got you covered. Pouch Packing Machine Manufacturer and Supplier in Bihar, Bhopal, Varanasi, and Ghaziabad In Bihar, Bhopal, Varanasi, and Ghaziabad, finding a reliable pouch packing machine manufacturer and supplier is crucial for businesses looking to streamline their packaging process. One such company is ABC Packaging Solutions, known for its innovative and efficient machines. From vertical form-fill-seal machines to horizontal flow wrappers, ABC offers a diverse range of options to cater to different packaging requirements. Conclusion In conclusion, when searching for a pouch packing machine manufacturer and supplier, it is essential to consider factors such as experience, expertise, authority, and trust. By choosing a reputable company with a proven track record, you can ensure that you get a high-quality machine that meets your specific needs. Whether you are based in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad, there are several reliable manufacturers and suppliers to choose from. Invest in the right pouch packing machine today and take your packaging process to the next level!

#pouch packing machine#collar pouch packing machine#fully automatic pouch packaging machine#business#manufacturer#agarbatti making machine#machine learning

0 notes

Text

Asvr engineering

Asvr engineering is the best machine manufacturing and supplier company in Delhi. They are many types of machine in our company such as chapatti making machine, agarbatti making machine, notebook making machine, Detergent powder making machine, Bricks making machine, Chappal making machine, wire nail making machine, and many other kinds of machines are available. If you want to startup your business please contacts us on our contact no: 8800971968.

0 notes

Text

How can I launch a business Making agarbatti machines?

Overview of Agarbatti Business

Another name for agarbatti is "incense." It is an aromatic paste or powder that was used as a fumigant in every Indian home. Agarbathie is made in a straightforward and uncomplicated manner. Thus, be aware of the kind of raw material needed to begin producing agarbatti and how to obtain it for manufacturing, etc.

All communities, including those in Sri Lanka, India, Burma, and Indian expatriates, utilise agarbattis. The demand for Incense stick making machine is higher throughout the year, but it is particularly high during holiday seasons. Due to the low degree of technology in this sector, a business producing incense can be launched with modest initial expenditure and basic machinery.

Types of agarbatti

The procedure of creating agarbatti

Manufacturers of agarbatti use machines in their process since they expedite the processing of agarbattis for agarbatti companies. Depending on the demand in the Indian agarbatti making machines, several techniques are used in the producing process.

One well-known home product with significant business potential is agarbatti. The easy steps to make agarbathie in India are as follows.

Step 1: First, you must be aware that agarbatti manufacturing businesses must register as businesses.

Step 2: Secondly, you need to understand what kind of raw material is needed to begin producing agarbatti and how to obtain it for manufacture.

Step 3: Thirdly, you should be aware of the equipment needed for your agarbatti manufacturing firm.

Step 4: Following this, you must understand the agarbatty-making procedure.

Raw material Agarbatti

The second stage in the easy steps to make agarbatti in India is to understand what kind of raw material is needed to begin agarbatti production and how to obtain it for manufacture. Bamboo sticks are the main raw material used in this step to make agarbatti. The materials needed to make agarbatti are as follows:

Wood Incense Powder Jigat Powder Various Essential Oils

Nargis Powder with Charcoal Dust

Powder Joss

The bamboo sticks must be bought according on your size. With a bamboo stick-making machine, you may also make bamboo sticks for your projects. It is important to select the appropriate formula based on the scent. It is imperative that you pay close attention to the packaging process because, in the agarbatti making industry, a fragrance-look packaging system is required.

Profit for Agarbatti business

The agarbatti business is profitable since it's easy to turn a healthy profit. The profit margin of the Agarbatti business is substantial in relation to its investment; it can yield a monthly turnout of Rs 3 lakh and a gross profit of up to Rs 2 lakh. The number of machines in an agarbatti firm determines its profit margin; having more machines can increase profits. Since India is the world's largest manufacturer of agarbatti, the agarbatti industry is expanding due to the market's enormous potential. 1 kg of agarbatti can cost anywhere from Rs 100 and Rs 500, depending on the brand and quality of the product.

High-Speed Automatic Agarbatti Making Machine: This is the third kind of machinery needed for an agarbatti manufacturing company. These kinds of devices can produce the required results with the least amount of labour involvement. Additionally, the length may be changed from 8" to 12", and one person can operate at least one of the machines at once. There are several varieties of fully automatic, high-speed agarbatti-making equipment available that require less labour to run. You can make between 300 and 400 sticks in a minute. This kind of machine operates autonomously without the need for committed human labour.

Powder Mixer Machine for Agarbatti Making Machine Manufacturer: This piece of equipment is also necessary for businesses that make agarbatti. It can typically combine two different types of powders, both wet and dry, quite effectively. Production capacities typically range from 10 to 20 kg per 10 minutes. To achieve consistent mixing quality with less labour input when launching a large-scale, commercial agarbatti business, you can purchase a blender machine or powder mixer. Shapes, capacities, and sizes are among the variations offered.

0 notes

Text

Starting a business of your own is a great way to earn a living and become your own boss. A small business that has gained popularity these days is the production and sale of incense sticks. To start an incense stick business, you need to follow some simple steps that can help you get started. Here are some bullet points to help you get started:

Research about the incense stick business: It’s important to research and thoroughly understand the incense stick business before proceeding with investing your time and money into this business. Learn about the demand for incense sticks, the market competition, and the required investment for starting the business.

Buy an agarbatti machine: Investing in an agarbatti machine can save you a lot of time and labor costs. You can easily find agarbatti machines in Bhubaneswar, where you can make bulk quantities of incense sticks. This will also ensure consistency in the quality of the incense sticks.

Create a brand name & packaging design: Developing a brand name is a vital step to ensure that your business is recognized by customers. It’s also important to design appealing and attractive packaging to make your product stand out.

Market your products: Once everything is in place, you can start marketing your products to potential customers. Consider selling online, selling to local stores or at flea markets. You can also showcase your product creatively on social media platforms to reach a larger audience.

In a nutshell, starting an incense stick business is an achievable goal with a little planning and the right approach to the process. With these steps, you can easily set up your incense stick business in a cost-effective way that’s both profitable and rewarding.

2 notes

·

View notes

Text

Business Now A Days: Small Business Ideas to Consider

Starting a small business can be challenging, but with the right idea, it can be profitable. Two popular small business ideas are paper plate machine and agarbatti machine. These machines are affordable, easy to maintain, and have high demand in the market. Investing in a paper plate machine can facilitate the production of eco-friendly disposable plates, which is an excellent alternative to traditional plastic plates, while an agarbatti machine can produce incense sticks that are widely used in religious and cultural activities. Both of these machines offer significant potential for growth and can be a profitable business venture. So, if you're looking for a small business idea that requires minimal investment and yields high returns, do consider these options.

1 note

·

View note

Text

How To Start Agarbatti Manufacturing Business

Agarbatti (incense sticks) are thin, cylindrical sticks made of a mixture of natural or synthetic ingredients, such as bamboo or wood powder, fragrances, and colorants. When lit, they release a pleasant aroma that is often used for spiritual or religious practices, home fragrance, or aromatherapy. Agarbatti is commonly used in many cultures and countries around the world and is available in a wide range of fragrances and types to suit different preferences and needs. Agarbatti is typically made through a manufacturing process that involves mixing, extrusion, drying, cutting, and packaging. The market for agarbatti is significant, with a global market value estimated at over $3 billion in 2021.

What are the steps required in Agarbatti manufacturing?

The steps involved in manufacturing agarbatti (incense sticks) typically include the following:

- Raw material preparation: This involves sourcing and preparing the raw materials that will be used to make the agarbatti, including the base material (such as bamboo or wood powder), fragrances, and other ingredients.

- Mixing: The prepared raw materials are mixed together in a machine or by hand to create a dough-like mixture that will be used to make the agarbatti.

- Extrusion: The dough mixture is passed through a machine called an extruder, which shapes it into long, thin sticks.

- Drying: The extruded sticks are then dried in a drying oven or under the sun until they reach the desired moisture content.

- Cutting: The dried sticks are cut to the desired length using a machine or by hand.

- Packaging: The finished agarbatti are then packaged in boxes or bags for distribution and sale.

- Quality control: Quality control checks are performed at various stages of the manufacturing process to ensure that the agarbatti meets the required standards.

It is worth noting that the specific steps involved in the agarbatti manufacturing business process may vary depending on the specific type of agarbatti being produced and the equipment and resources available to the manufacturer.

How big is the market of agarbatti?

The market for agarbatti (incense sticks) is significant, with a global market value estimated at over $3 billion in 2021. The market is expected to continue growing in the coming years due to the increasing demand for agarbatti in various sectors, including spiritual and religious practices, home fragrances, and aromatherapy. The market is highly competitive, with a large number of manufacturers and brands offering a wide range of products. In addition to traditional agarbatti made with natural ingredients, the market also includes a variety of modern and specialized products, such as aromatherapy agarbatti and floral agarbatti. The market for agarbatti is highly diverse and can vary significantly by region and country due to differences in cultural and religious practices, consumer preferences, and other factors.

Is the agarbatti manufacturing business profitable?

It is possible for an agarbatti (incense stick) business to be profitable, but it will depend on a variety of factors such as the market demand for the product, the cost of production, the pricing strategy, and the efficiency and effectiveness of the business's operations. Some potential strategies for increasing profitability in an agarbatti business could include identifying and targeting a specific niche market, developing high-quality products that command a premium price, and optimizing production and distribution processes to minimize costs. It is important for any business owner to carefully consider these and other factors when starting or operating a business in order to maximize the chances of success.

Different Licenses Required for Agarbatti Manufacturing Business

There are several licenses and permits that may be required for starting and operating an agarbatti (incense stick) making business, depending on the location and specific requirements of the business. Some common licenses and permits that may be required include:

- Company Registration: This is the first step to start incense making business. One needs to register their business as a company or a Proprietorship or ROC register of companies to get started.

- GST Registration: GST registration is mandatory for every business holder. On successful registration, one will get a GST number for selling their goods or services.

- EPF Registration: This registration is necessary only if one has more than 20 employees in a manufacturing unit.

- ESI Registration: This Employee State Insurance or ESI has greater than 10 employees.

- Trade License: This is necessary for every person having a business. One can get it from local authorities.

- Udyog Aadhaar: MSME Udyog Aadhaar online registration on the Official Website.

- SSI Registration: Registration for this license is required for those having an SSI unit, though this is not compulsory.

- Pollution Certificate: This certificate is necessary, and one gets it through an inspection of the site where one has their manufacturing unit. It is done by the State Pollution Control Board, after which one will be allowed to conduct business.

- Factory License: Large-scale manufacturing commercial units must have a NOC and a factory license.

It is important to carefully research and understands the specific licenses and permits that are required for starting and operating an agarbatti-making business in your location. Failing to obtain the necessary licenses and permits can result in legal and financial consequences.

Raw Material required for Agarbatti Manufacturing Business

The raw materials required for starting an agarbatti (incense stick) making business will depend on the specific type of agarbatti being produced, as well as the production process and scale. Some common raw materials that may be used in agarbatti production include:

The raw materials required for Agarbatti are:-

- Aromatic Ingredients

- Natural aromatic oil – Only natural

Bamboo Sticks: Bamboo sticks that range from 8″ to 12″ inches are required, or

Raw Bamboo Sticks: If one is manufacturing bamboo sticks, one needs to buy bamboo sticks in raw form for making incense sticks

Packing Materials: The packing material used must be airtight that lock the fragrance of the agarbatti

Different Color Powder: One can add different color powders to make agarbattis look attractive. The powders are:-

- Crude Paper

- Charcoal Powder

- Gum Powder is also known as Sticky Powder.

- Nargis Powder

- Jikit Powder

- Perfumes

- Oil Of Sandalwood

- Sawdust

Addition of Fragrance: The addition of fragrance is a different manufacturing step. But it is optional. There are many agarbatti manufacturers that sell it without adding any fragrance. One can do the same if they are selling in local markets. Or one can add any fragrance as per their liking or can do a market survey to know which fragrances are preferred.

You should be aware of the machinery required for the agarbatti manufacturing business.

The machinery required for starting an agarbatti (incense stick) making business will depend on the specific type of agarbatti being produced, the production process, and the scale of the business. Some common machinery and equipment that may be required include:

- Mixing machine: A mixing machine is used to blend the raw materials together to create a dough-like mixture that will be used to make the agarbatti.

- Extrusion machine: An extrusion machine is used to shape the dough mixture into long, thin sticks.

- Drying oven: A drying oven or other drying equipment is used to remove moisture from the extruded sticks until they reach the desired moisture content.

- Cutting machine: A cutting machine is used to cut the dried sticks to the desired length.

- Packaging machine: A packaging machine may be used to package the finished agarbatti in boxes or bags for distribution and sale.

In addition to these machines, the business may also require other equipment such as weighing scales, measuring cups and spoons, and other tools and supplies. It is important to carefully consider the specific machinery and equipment requirements of the business based on the type of agarbatti being produced and the scale of production. It may also be helpful to research and compare different options to find the most suitable and cost-effective equipment.

In India is to understand which machinery is required for the agarbatti manufacturing business.

The following equipment is required for the agarbatti manufacturing business:

- Manual Agarbatti Making Machines

- Automatic Agarbatti Making Machine

- High-Speed Automatic Agarbatti Making Machine

- Drying Machine For Agarbatti Making

- Powder Mixer Machine For Agarbatti Making

The above machinery required for the agarbatti manufacturing business can be explained briefly in the following:

Manual Agarbatti Making Machines

Manual agarbatti (incense stick) making machines are simple, hand-operated machines that are designed to produce small quantities of agarbatti. These machines may be suitable for small-scale production or for use in home-based businesses. They typically consist of a series of rollers and a handle, and are operated by hand to mix, extrude, and cut the agarbatti.

To use a manual agarbatti making machine, the raw materials are typically mixed together to form a dough-like mixture, which is then fed into the machine. As the handle is turned, the mixture is passed through the rollers and shaped into long, thin sticks. The extruded sticks are then cut to the desired length using a cutting blade.

Manual agarbatti making machines are typically smaller and less expensive than automatic or semi-automatic machines, but they may require more labor and time to produce agarbatti. They may be suitable for small-scale production or for producing a limited range of agarbatti. It is important to carefully consider the specific needs and requirements of the business when choosing the most suitable agarbatti making machine.

Automatic Agarbatti Making Machine

Automatic agarbatti (incense stick) making machines are advanced, high-capacity machines that are designed to produce large quantities of agarbatti. These machines are typically used in large-scale production operations and are equipped with a range of automated features that allow for efficient and consistent production.

Automatic agarbatti making machines typically consist of a series of rollers and a control panel, and are operated using electricity. The raw materials are mixed together to form a dough-like mixture, which is then fed into the machine. As the mixture is passed through the rollers, it is shaped into long, thin sticks and cut to the desired length. The extruded sticks are then dried and packaged for distribution and sale.

Automatic agarbatti making machines are generally more expensive than manual or semi-automatic machines, but they offer a higher production capacity and greater efficiency. They may be suitable for large-scale production or for producing a wide range of agarbatti. It is important to carefully consider the specific needs and requirements of the business when choosing the most suitable agarbatti making machine.

High-speed automatic agarbatti (incense stick) making machines are advanced, high-capacity machines that are designed to produce large quantities of agarbatti at high speeds. These machines are typically used in large-scale production operations and are equipped with a range of automated features that allow for efficient and consistent production at high speeds.

High-speed automatic agarbatti making machines typically consist of a series of rollers, a control panel, and a range of sensors and other advanced features. The raw materials are mixed together to form a dough-like mixture, which is then fed into the machine. As the mixture is passed through the rollers, it is shaped into long, thin sticks and cut to the desired length. The extruded sticks are then dried and packaged for distribution and sale.

High-speed automatic agarbatti making machines are generally more expensive than manual or semi-automatic machines, but they offer a higher production capacity and greater efficiency. They may be suitable for large-scale production or for producing a wide range of agarbatti in high volumes. It is important to carefully consider the specific needs and requirements of the business when choosing the most suitable agarbatti making machine.

Drying Machine for Agarbatti Making

A drying machine is a piece of equipment that is used in the production of agarbatti (incense sticks) to remove moisture from the extruded sticks until they reach the desired moisture content. Drying is an important step in the production process as it helps to ensure that the agarbatti is consistent in quality and will burn evenly when lit.

There are several types of drying machines that can be used in agarbatti making, including ovens, dryers, and other equipment. The most suitable drying machine will depend on the specific needs and requirements of the business, such as the type of agarbatti being produced, the production scale, and the available resources.

Ovens are a common type of drying machine that can be used for agarbatti making. These are typically large, enclosed chambers that use heat to remove moisture from the agarbatti. Ovens can be electric, gas-fired, or wood-fired, and may be equipped with temperature and humidity controls to ensure consistent drying.

Other types of drying machines that may be suitable for agarbatti making include dryers that use heat, air, or other methods to remove moisture, as well as sun drying and other natural drying methods. It is important to carefully consider the specific needs and requirements of the business when choosing the most suitable drying machine for agarbatti making.

Powder Mixer Machine for Agarbatti Making

A powder mixer machine is a piece of equipment that is used in the production of agarbatti (incense sticks) to mix the raw materials together to create a dough-like mixture that will be used to make the agarbatti. Powder mixer machines are typically used to mix a variety of powders and other dry ingredients, such as bamboo or wood powder, fragrances, and colorants.

There are several types of powder mixer machines that can be used in agarbatti making, including ribbon blenders, V-blenders, and other equipment. The most suitable powder mixer machine will depend on the specific needs and requirements of the business, such as the type of agarbatti being produced, the production scale, and the available resources.

Powder mixer machines are typically designed to mix large quantities of materials quickly and efficiently, and may be equipped with features such as variable speed control, automatic timers, and safety features. It is important to carefully consider the specific needs and requirements of the business when choosing the most suitable powder mixer machine for agarbatti making.

Which type of Trending Agarbatti is best?

There are many different types of agarbatti (incense sticks) available on the market, and what is considered the "best" type will depend on personal preferences and the specific use or purpose for which the agarbatti is intended. Some common types of agarbatti include:

- Traditional agarbatti: These are made with natural ingredients such as bamboo sticks, wood powder, and essential oils, and are often used for spiritual or religious purposes.

- Aromatherapy agarbatti: These are made with essential oils and are intended to provide a pleasant aroma and a calming effect when burned.

- Floral agarbatti: These are made with fragrances that are derived from flowers, and are often used to create a pleasant atmosphere in a room or space.

- Masala agarbatti: These are made with a mixture of natural ingredients and fragrances, and are often used for traditional or ceremonial purposes.

Ultimately, the best type of agarbatti will depend on the individual's preferences and needs. It is important to consider the intended use, the desired fragrance, and any other relevant factors when selecting the best type of agarbatti.

Agarbatti Business Plan FAQs:

Is it possible to produce agarbattis that are environmentally friendly? Yes indeed, eco-friendly agarbattis made with dried flowers are healthier and much more popular nowadays. What are among the most popular agarbatti fragrances? Rose, lavender, marigold, sandalwood, and cedarwood were one of the most prominent perfumes. What are the several segments of the agarbatti-making industry? Incense Stick Making Units, Bamboo Stick Supplier Units, Raw Material Supplier Units, and Perfume Adding Units are diverse kinds of agarbatti-making businesses. Is it possible to sell agarbattis online? Yes, by developing a website or using an e-commerce platform, one can sell their agarbattis online. Where can raw agarbatti be sold? Raw agarbattis can be sold to fragrance manufacturing companies. They'll put fragrance in it and sell it in the store. What is the definition of raw agarbatti? Agarbatti that hasn't been scented is known as raw agarbatti. What is the best place to sell Agarbattis? Agarbatti can be sold in the marketplace or exported outside of the country. India exports most of its Agarbatti to the United States, the United Kingdom, and Australia and is the largest exporter of Agarbatti in the World. Which are the top 3 exporters of Agarbatti? The top 3 exporters of Agarbatti are India with 68,487 shipments followed by China with 13,395 and Vietnam at the 3rd spot with 10,777 shipments.

Read the full article

0 notes