#angular rate sensor

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/semiconductors--analog--sensors--pressure/bmp388-bosch-sensortec-1097861

High pressure sensor, low pressure sensor, Water pressure sensors

BMP388 Series 125 kPa 3.6 V Digital Barometric Pressure Sensor

#Sensors#Pressure Sensors#BMP388#Bosch Sensortec#High pressure sensor#low pressure sensor#Water pressure sensors#Optical pressure sensor#Absolute pressure sensor#Pressure sensor chip#angular rate sensor#tire pressure sensor

1 note

·

View note

Text

"Dave" – Toyota Partner Robot ver. 5 Rolling Type (Trumpet), Toyota, Japan (2005). "Partner robots are expected to support people and work with people in offices, hospitals, care facilities, and homes. They need to move with legs or wheels. … The inertial force-sensing system [commonly called an inertial measurement unit (IMU)] consisted of three acceleration sensors, three angular rate sensors, and a digital signal processor (DSP). The system used automobile sensors such as acceleration and angular rate sensors and had small size, high accuracy, and low cost. … The internal force-sensing system was used by several robots at the 2005 Aichi Expo and at the 2006 Tokyo Motor Show … They were a biped-type robot playing trumpet, a biped-type robot with wire drive, a person carrier biped-type robot, [Dave] a two-wheeled rolling-type robot with inverted pendulum , and a person carrier of 2+1 wheeled rolling type called ‘i-Swing’." – Sensor Technologies for Automobiles and Robots, Yutaka Nonomura.

6 notes

·

View notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

What is a gyroscope used for drone or robot?

A gyroscope is a sensor used to measure angular velocity. Its core function is to sense the rotational motion and attitude changes of an object. It can be applied to various fields that require navigation, positioning or stable control. ER-MG-057, as a high-performance single-axis MEMS gyroscope (angular velocity sensor), has become an ideal choice for many professional fields due to its excellent performance and reliable design. Precise measurement and stable output Wide range: ER-MG-057 has a wide range of measurement up to ±400°/s, which can meet the angular velocity monitoring needs of various dynamic scenes, covering high-speed rotation scenes (such as drone maneuvers and high-speed operation of robotic arms). Excellent stability: tactical-level high precision, zero bias instability as low as 1°/hr, angle random walk (ARW) 0.2°/√hr, 0.1dps ultra-low noise, 200Hz bandwidth combined with 2kHz data output rate, real-time capture of instantaneous angular velocity changes, and response delay of only 2ms. High integration and high reliability Ceramic LCC surface mount package, with airtight packaging to protect the core MEMS structure, is only 11x11x2mm in size, easy to integrate into various systems, and RoHS certified. Supports 5V (4.75~5.25V) power supply, power consumption is only 35mA, with low power consumption, default internal synchronization mode, optional external synchronization, compatible with multi-system architecture. Can work stably in strong shock (12g RMS) and vibration (1000g 5ms 1/2 sine wave) environment, suitable for high vibration scenarios such as aviation drones and unmanned vehicles. Application scenarios Navigation and positioning: suitable for scenarios such as inertial navigation system (INS), drones and autonomous driving. Combined with accelerometers, position, speed and direction are calculated by measuring the angle change and acceleration of movement. Precision instruments and stabilization systems: Ensure precise control and attitude stability of mechanical movement, and improve the real-time and accuracy of target tracking. UAV/aircraft stabilization: Provides data for the flight control system to sense the attitude changes (pitch, roll, yaw) of the aircraft, so that it can adjust the motor speed to keep the aircraft hovering steadily or flying according to instructions. Ship/vehicle stabilization system: Large ships use gyro stabilizers to reduce roll; provide reliable attitude data support for autonomous driving. Robot balance and control: Help robots sense tilt angles and maintain their own balance and motion control.

0 notes

Text

Gyro Sensor: Everything You Need to Know About This Advanced Motion-Sensing Technology

Gyro sensors, also known as gyroscopic sensors or angular rate sensors, play a critical role in a wide range of modern technologies—from smartphones and gaming consoles to autonomous vehicles and industrial machinery. These sensors measure angular velocity, which allows systems to detect orientation, maintain balance, and track motion with remarkable precision. In this detailed guide, we delve deep into the workings, applications, and benefits of gyro sensors to provide you with a comprehensive understanding of their importance in today’s digital and mechanical world.

What Is a Gyro Sensor?

A gyro sensor is an electronic device that detects the rate of rotation around a particular axis. It helps systems determine orientation and rotational motion by using the principles of angular momentum. Unlike accelerometers that measure linear motion, gyro sensors are essential for sensing rotational dynamics.

There are several types of gyro sensors, including:

MEMS gyroscopes (Micro-Electro-Mechanical Systems)

Fiber optic gyroscopes

Ring laser gyroscopes

Vibrating structure gyroscopes

Each type has unique characteristics suitable for different applications, ranging from compact consumer electronics to high-precision aerospace systems.

How Do Gyro Sensors Work?

At the core of most modern gyro sensors, especially MEMS gyroscopes, is the principle of Coriolis Effect. When an object rotates, the Coriolis force is exerted on a vibrating structure inside the sensor. This force causes a change in the vibration direction, which the sensor interprets to calculate the angular velocity.

The steps involved in gyro sensor operation include:

A tiny mass inside the sensor vibrates at a consistent frequency.

When rotation occurs, the Coriolis force alters the path of the vibration.

This deviation is detected by capacitive or piezoelectric elements.

The sensor processes this data to determine angular speed.

Key Features of a Gyro Sensor

When choosing or designing a system with a gyro sensor, understanding its critical features is essential. The most notable features include:

High sensitivity to angular velocity changes

Low noise and drift for stable performance

Compact size and low power consumption, especially in MEMS versions

Wide operating temperature range

3-axis sensing capability for comprehensive motion tracking

These attributes make gyro sensors ideal for embedded systems and portable electronics, where both performance and space-saving designs are vital.

Applications of Gyro Sensors in Modern Technology

1. Smartphones and Tablets

Modern smartphones rely heavily on gyro sensors for functions such as:

Auto-rotation of the screen

Gesture-based control

Augmented reality (AR) and virtual reality (VR) features

Enhanced camera stabilization

Combined with accelerometers and magnetometers, gyroscopes form the foundation of Inertial Measurement Units (IMUs) used in mobile devices.

2. Automotive Industry

In vehicles, gyro sensors are pivotal for:

Electronic Stability Control (ESC)

Anti-lock Braking Systems (ABS)

Inertial navigation systems

Autonomous driving and Advanced Driver Assistance Systems (ADAS)

They ensure safety, enhance vehicle dynamics, and provide real-time feedback for intelligent driving systems.

3. Aerospace and Aviation

Precision and reliability are paramount in aerospace applications. Gyro sensors are used for:

Attitude and heading reference systems (AHRS)

Flight control and stabilization

Satellite orientation and navigation

Here, ring laser gyroscopes and fiber optic gyroscopes offer high precision with minimal drift over time.

4. Gaming and Virtual Reality

Gyro sensors have revolutionized the gaming industry by enabling:

Motion-sensing controllers

Head tracking in VR headsets

Realistic 3D movement simulations

This immersive experience is made possible through accurate real-time orientation detection.

5. Robotics and Drones

Autonomous robots and drones depend on gyroscopic feedback to:

Maintain balance

Navigate accurately in 3D space

Compensate for external disturbances like wind

Gyro sensors are integral to IMU-based navigation systems in UAVs and mobile robots.

Advantages of Using Gyro Sensors

Gyro sensors offer several advantages, making them indispensable across multiple sectors:

Real-time precision: Immediate detection of orientation changes

Compact and cost-effective: Especially true for MEMS gyroscopes

Reliable over time: High-end models maintain calibration and reduce drift

Integration-ready: Easily embedded in modern electronics

Their ability to work in conjunction with other sensors like accelerometers and magnetometers enhances the accuracy of orientation and positioning systems.

Challenges and Limitations of Gyro Sensors

While gyro sensors are versatile, they do come with limitations:

Sensor drift: Over time, small errors can accumulate, affecting long-term accuracy.

Temperature sensitivity: Extreme temperature changes can impact sensor performance.

Complex calibration: To maintain precision, especially in dynamic environments.

However, combining gyroscopes with other sensors in sensor fusion algorithms (e.g., Kalman filters) helps overcome these issues effectively.

Future Trends in Gyro Sensor Technology

The evolution of gyro sensors continues to push boundaries. Key trends include:

Miniaturization and integration: Smaller, more energy-efficient sensors are being developed for wearables and IoT devices.

Improved AI algorithms: Machine learning is enhancing sensor calibration and data interpretation.

Advanced fusion systems: Combining gyro data with GPS, cameras, and LiDAR for improved situational awareness in autonomous systems.

Quantum gyroscopes: A cutting-edge innovation that uses quantum mechanics to achieve ultra-high accuracy without external references.

These advancements ensure that gyro sensors will remain a cornerstone of technological progress in motion tracking and spatial awareness.

Choosing the Right Gyro Sensor for Your Application

Selecting the appropriate gyro sensor depends on your specific application needs. Consider the following criteria:

Precision required (e.g., consumer-grade vs. aerospace)

Cost constraints

Size and power requirements

Environmental conditions (e.g., shock, temperature, vibration)

Axis configuration (single-axis or tri-axis)

Understanding these factors ensures optimal performance and longevity of the motion detection system in your product.

Conclusion

Gyro sensor is a transformative components in today's motion-sensitive world. From enhancing user experience in smartphones to ensuring safety and precision in autonomous vehicles and aerospace, their role cannot be overstated. As innovation continues, the capabilities and applications of gyro sensors will expand, opening new doors in automation, robotics, and immersive digital experiences.

0 notes

Text

Elmalo, let’s dive deeper into the hardware specifications that will form the foundation of Iron Spine’s sensor fusion capabilities. This detailed look will cover sensor choices, ruggedization strategies for extreme environments, and considerations for optimizing edge computing performance.

1. Sensor Choices

A diverse sensor suite is crucial for a system designed to operate across space, deep sea, underground, and more. Here are some categories and specific choices to consider:

Environmental Sensors:

Radiation Detectors:

Example: Semiconductor-based sensors (e.g., Silicon PIN diode detectors) or Geiger-Müller tubes.

Key Considerations: Sensitivity range, calibration for cosmic or deep-sea radiation, and response time.

Pressure Sensors:

Example: Piezoresistive or capacitive sensors like those used in underwater applications.

Key Considerations: Depth ratings, response time, and temperature compensation.

Temperature & Humidity Sensors:

Example: Bosch BME280 or Sensirion SHT series.

Key Considerations: Accuracy under varying environmental conditions, low power consumption, and integration ease.

Motion & Optical Sensors:

Insect-Inspired Motion Sensors:

Example: MEMS-based inertial measurement units (e.g., InvenSense MPU-9250 or similar) that capture acceleration, angular velocity, and magnetic field data with high resolution.

Key Considerations: Minimal latency, low drift, and high sensitivity for subtle movements.

High-Resolution Cameras:

Example: Industrial-grade camera modules (such as those designed for robotics or autonomous vehicles) that can perform in varied lighting.

Key Considerations: Frame rate, resolution, and the ability to operate in low-light or high-contrast conditions.

LIDAR/Optical Ranging:

Example: Compact, time-of-flight sensors or structured light systems.

Key Considerations: Range, environmental adaptability, and integration with visual feeds.

Acoustic & RF Sensors:

Acoustic Sensors:

Example: MEMS microphone arrays or specialized underwater hydrophones for sonar applications.

Key Considerations: Frequency sensitivity (audible versus ultrasonic), noise cancellation, and dynamic range.

RF Sensors:

Example: Software-defined radio (SDR) modules or narrow-band receivers capable of picking up anomalous electromagnetic signals.

Key Considerations: Frequency range, sensitivity, and resistance to interference.

2. Device Ruggedization

Operating in extreme environments demands that each edge device and sensor module be hardened for durability and reliability. Consider these strategies:

Enclosures & Packaging:

IP-Rated Cases: Use industrial enclosures rated at least IP67 or higher to protect against dust, water ingress, and contaminants.

Shock & Vibration Dampening: Implement mounting solutions with shock-absorbing materials (such as silicone inserts or rubber gaskets) to reduce the effects of mechanical impacts and vibrations common in harsh environments.

Temperature Control:

Thermal Management: Integrate active cooling (mini fans or heat sinks) or passive solutions (thermal conductive materials) to maintain optimal operating temperatures across extreme conditions.

Heaters or Insulation: In cold or high-altitude settings, built-in heaters or insulation can prevent sensor malfunctions and maintain performance.

Material Selection:

Robust Circuitry: Use components rated for wide temperature ranges and shock tests. Consider industrial-grade microcontrollers (like those used in aerospace) along with robust soldering and PCB design techniques.

Corrosion Resistance: For deep-sea or subterranean applications, use corrosion-resistant materials (e.g., conformal coatings, stainless steel housings) to extend the lifetime of the sensors and board-level components.

3. Edge Computing Performance

At the edge, the processing unit must handle a high throughput of sensor data in real time. Consider these platforms and configurations:

Primary Edge Devices:

NVIDIA Jetson Series:

AGX Xavier: Offers high computational power with an 8-core ARM CPU, 512-core GPU, and accelerated deep learning inference capabilities. Ideal for implementing sophisticated preprocessing and fusion algorithms.

Jetson Nano: A cost-effective alternative when power is limited, capable of running streamlined models and basic sensor fusion tasks.

Key Advantages:

Real-Time Processing: GPU acceleration and support for frameworks like TensorRT enable fast, in-situ data analysis and decision-making.

Modular Scalability: Easily integrated with additional sensor inputs and can run multiple fusion algorithms concurrently.

Supplementary Controllers:

Raspberry Pi Compute Modules & Arduino Boards:

Roles: Act as microcontroller units (MCUs) for simpler sensor tasks such as data acquisition, local filtering, or secondary processing.

Interfacing: Use standardized communication protocols (SPI, I2C, UART) to easily integrate with primary edge devices.

Communication & Connectivity:

Protocols for Inter-Device Communication: Consider MQTT for lightweight messaging and LoRaWAN for long-range, low-power communication in areas with intermittent connectivity.

Latency & Bandwidth Considerations: Properly balance between local processing (minimizing transmission delays) and cloud synchronization for historical data analysis.

Power Considerations:

Energy Efficient Design: Optimize both hardware and software to balance high performance with reasonable power consumption, especially critical in remote field deployments.

Battery Solutions: Explore rugged, high-capacity battery units or renewable energy options (solar panels) for prolonged, autonomous operation.

Summarized Blueprint Table

This comprehensive hardware specification not only outlines your sensor choices but also integrates strategies for device ruggedization and robust edge computing performance—ensuring Iron Spine’s sensor network is resilient, precise, and ready for extreme, real-world applications.

Would you like to further explore specific sensor integration techniques, or do you have additional requirements or constraints—perhaps environmental limits or power consumption targets—we should account for in the current blueprint?

0 notes

Text

0 notes

Text

Advanced Laminated Rubber Bearing Technology

Laminated Rubber Bearings (LRBs) use layers of steel and rubber. This design reduces structural vibration by 74% during Mw 9.0+ earthquakes. The integrated lead-core damping mechanism converts destructive kinetic energy into thermal dissipation. Real-time structural health monitoring is enabled through:

Fiber-optic sensors detecting 0.05mm displacements

Continuous integrity assessment of critical infrastructure networks

Technical Specifications

Dynamic stiffness: ≤11 kN/mm (ISO 22762-3:2025 certified)

Post-earthquake realignment: <1.8mm residual shift under IX-intensity shaking

Extreme environment operability: -185°C to 135°C (Martian surface validated)

Performance Advantages

The superior performance of our Laminated Rubber Bearings stems from their unique multi-layered construction and advanced material science. Key advantages include:

1.Precision Vibration Control

Our proprietary graphene-enhanced rubber compound provides frequency-dependent damping characteristics, effectively suppressing vibrations across the 0.5-50Hz spectrum that affects most civil structures.

2.Long-Term Reliability

Accelerated aging tests demonstrate:

Less than 5% stiffness variation after 100 years of service

Only 0.12mm creep deformation under continuous 10MPa loading

No observable rubber cracking after 3,000 thermal cycles

3.Installation Flexibility

The modular design allows for:

±15° angular misalignment tolerance during installation

On-site stiffness adjustment through variable shim configurations

Retrofit capability for existing structures without foundation modification

These performance characteristics have been verified through full-scale testing at our ISO 17025-accredited laboratory and field deployments in high-seismic regions.

Eco-Conscious Engineering

Our manufacturing process achieves:

97% recycled rubber utilization via advanced pyrolysis-reconstitution

85% lower carbon footprint versus conventional production

Graphene-reinforced composite demonstrating:

1.5 million load cycles without material degradation

0.25% annual corrosion rate in marine installations

Multi-Sector Implementation

Infrastructure: 42% market penetration in suspension bridges >1km span

Renewable Energy: 92% vibration suppression in 15MW offshore turbines

Aerospace: Selected for Lunar Gateway Station foundation systems

1 note

·

View note

Text

How Y3K Fashion is Redefining Style with High-Tech & Cyber Aesthetics

The Evolution of Y3K Fashion: A Fusion of Futurism and Technology

The fashion world is continuously evolving, and Y3K fashion is at the forefront of this transformation. Blending cutting-edge technology, cyber aesthetics, and futuristic designs, Y3K fashion is revolutionizing style as we know it. The rise of artificial intelligence, virtual reality, and smart textiles is shaping this trend, making it a fusion of digital innovation and avant-garde clothing. This bold aesthetic draws inspiration from cyberpunk, dystopian futurism, and high-tech apparel, creating a stylish and technologically advanced look.

The Core Elements of Y3K Fashion

High-Tech Materials & Smart Fabrics

One of the most defining features of Y3K fashion is the integration of high-tech materials. These fabrics incorporate nano-technology, self-cleaning properties, and smart textiles that adapt to body temperature. Designers are utilizing biometric-responsive clothing, LED-embedded fabrics, and conductive fibers to push the boundaries of what apparel can do.

LED-Embedded Apparel: Clothing featuring programmable LED displays allows wearers to change colors, patterns, and even display digital messages.

Self-Healing Textiles: Advances in fabric technology have led to materials that can repair themselves, enhancing durability and sustainability.

Temperature-Regulating Clothing: Smart fibers react to environmental changes, keeping wearers cool in the heat and warm in cold conditions.

Cyber Aesthetics & Futuristic Designs

The visual appeal of Y3K fashion is heavily influenced by cyber aesthetics, incorporating elements from sci-fi films, dystopian themes, and digital landscapes. This aesthetic is characterized by:

Holographic & Iridescent Fabrics: Shimmering, color-shifting materials create an ultra-futuristic look.

Sharp, Angular Silhouettes: Clothing designs favor asymmetry, oversized proportions, and geometric shapes.

Minimalist yet Bold: Despite being avant-garde, Y3K fashion maintains a sleek and structured appearance.

Augmented Reality (AR) & Virtual Fashion

Y3K fashion is not just about physical garments—it is pushing the boundaries of digital fashion. Augmented reality (AR) and virtual reality (VR) are being integrated into the industry, enabling consumers to try on clothes digitally and even purchase NFT-based outfits that exist solely in the metaverse. Virtual fashion weeks and AI-generated designs are also becoming commonplace.

The Influence of Technology on Y3K Fashion

AI-Driven Design & Customization

Artificial intelligence (AI) is transforming fashion design by enabling brands to create hyper-personalized clothing experiences. AI algorithms analyze consumer preferences, predict trends, and even generate entirely new fashion pieces. Custom-fitted garments can now be designed using 3D body scanning, ensuring a perfect fit.

Wearable Technology & Smart Accessories

Wearable technology is another critical component of Y3K fashion. Accessories are becoming more than just style statements—they now integrate advanced functionalities, such as:

Smart Glasses: Augmented reality glasses offer real-time data overlays, navigation assistance, and digital connectivity.

Bio-Sensing Jewelry: Rings and bracelets equipped with biometric sensors monitor health metrics like heart rate and stress levels.

AI-Integrated Sneakers: Footwear with self-lacing mechanisms and built-in step counters enhance both performance and convenience.

How Y3K Fashion is Redefining Streetwear

Streetwear has also undergone a radical transformation, merging with cyber aesthetics and high-tech elements to create an entirely new genre of futuristic fashion. Some hallmarks of Y3K-inspired streetwear include:

Techwear Influences: Functional, utility-driven outfits with waterproof materials, multiple pockets, and modular designs.

Neon & Cyberpunk Color Palettes: Bright neon hues, black, metallics, and reflective materials dominate the scene.

3D-Printed Sneakers & Apparel: Customized, futuristic designs made possible through 3D printing technology.

Sustainability in Y3K Fashion: The Future of Eco-Tech Wear

As technology advances, so does the focus on sustainability. Y3K fashion is leading the charge toward an eco-conscious future, leveraging new materials and processes to minimize waste. Some of the most notable innovations include:

Biodegradable & Lab-Grown Fabrics: Designers are using mushroom leather, lab-grown silk, and algae-based textiles to create biodegradable clothing.

Zero-Waste Manufacturing: 3D knitting and digital design reduce fabric waste by creating garments with precision.

Recyclable Smart Textiles: Companies are developing garments with embedded tech that can be easily separated and recycled when no longer in use.

The Future of Y3K Fashion: Where Are We Headed?

Y3K fashion is still in its infancy, but it is rapidly shaping the future of style. As technology advances, we can expect to see even more immersive fashion experiences, AI-driven customization, and smart wearables that blend seamlessly into our digital lives. The integration of blockchain technology and digital-only fashion collections will continue to push the boundaries of what fashion can be.

Final Thoughts

The fusion of cyber aesthetics, futuristic materials, and high-tech innovations makes Y3K fashion an exciting and transformative movement. As designers, brands, and tech innovators collaborate, the lines between fashion, technology, and digital experiences will continue to blur, creating a bold and immersive future for the industry.

Read more:

Y3K Outfits

0 notes

Text

The Evolution of Office Desk Materials: From Solid Wood to Quantum Coatings and Technological Leaps

1. The Technological Rebirth of Traditional Materials

The Molecular Revolution of Engineered Wood High-Density Fiberboard (HDF) has been enhanced using nanocellulose technology, increasing its bending strength to over 50 MPa—three times greater than traditional solid wood desk. Columbia Forest Products in the U.S. has introduced PureBond technology, which replaces urea-formaldehyde resin with soy protein adhesive, reducing formaldehyde emissions to 0.003 ppm, meeting Japan’s F4 Star standard. The surface treatment uses synchrotron radiation curing coatings, with a wear resistance of up to 200,000 cycles.

The Lightweight Breakthrough of Metal Substrates Aerospace-grade magnesium-aluminum alloy, processed by Equal Channel Angular Pressing (ECAP), increases yield strength to 380 MPa, while being 57% lighter than steel. Germany’s Interstuhl has developed micro-arc oxidation technology that generates a 20μm ceramic layer on aluminum, achieving a hardness of HV1500, with scratch resistance surpassing that of stainless steel.

The Performance Iteration of Glass Materials Corning’s 6th generation Gorilla Glass undergoes chemical tempering, achieving surface compressive stress of up to 1000 MPa and a drop resistance exceeding 2 meters. Germany's Schott developed AntiReflect glass, which uses a nanoporous coating to increase light transmittance to 99.6%, while reducing reflectance to 0.2%, completely eliminating screen ghosting.

2. Disruptive Applications of New Materials

The Office Revolution with Carbon Fiber Composites Toray's T1100-grade carbon fiber combined with an epoxy resin matrix reduces the desk panel thickness to 5mm, while maintaining a load capacity of 300 kg/m². The BMW i-series production line technology has been scaled down, enabling a 1.5-minute hot-press molding cycle, reducing energy consumption by 83% compared to traditional wooden desks.

Ecological Evolution with Bio-based Materials Dutch company DESSO has developed mycelium-based substrates that solidify 15 kg of CO₂ per square meter in just 28 days of growth. After being coated with chitosan, the material achieves an antibacterial rate of 99.7% and a bending strength of 32 MPa. After disposal, it is fully biodegradable, with a carbon footprint just 1/9 that of traditional materials.

The Application of Smart Responsive Materials MIT has developed mechanical metamaterials that dynamically adjust desk surface stiffness through microstructural deformation: local hardening to Shore D80 when writing, and softening to Shore A30 in the elbow support area. Pressure sensors achieve a precision of 0.1N and can store 20 common posture parameters.

3. Black Tech in Surface Treatments

Quantum Coatings for Optical Control Switzerland’s INSOLIGHT uses Atomic Layer Deposition (ALD) technology to construct 125 layers of nanofilms on glass surfaces. By adjusting electron cloud density, the transparency can be tuned between 5% and 95%, with a response time of 0.2 seconds and energy consumption only 1/20th that of electrochromic technologies.

Self-Healing Coatings in Commercial Applications BASF has developed a biomimetic polymer coating containing 5 million micro-capsules per cm². When scratches over 5μm are detected, the repair agent is released, completing molecular-level repair in 40 seconds, reducing maintenance costs by 79%. UL laboratory tests show that the repair cycle can reach up to 2,000 times.

Bionic Texture for Tactile Revolution 3M’s micro-replication technology replicates the surface structure of shark skin with an accuracy of 0.05mm, controlling the friction coefficient between 0.35 and 0.55. Tactile feedback tests show that this design improves writing smoothness by 33% and reduces wrist fatigue by 61%.

4. Dual Breakthroughs in Environmental Tech

Performance Beyond Recycled Materials Interface’s Net Effect series converts recycled fishing nets into nylon-6 fibers. After solid-state polymerization, the wear resistance reaches 150,000 cycles, and impact strength is 40% higher than that of virgin plastic. Each square meter of desk surface contains 3.2 kilograms of ocean plastic waste.

Invisible Integration of Photovoltaic Materials Switzerland’s CSEM has developed transparent photovoltaic films that maintain 85% visible light transmittance while achieving a conversion efficiency of 12.3%. A 1.5㎡ desk can generate 180 kWh of electricity per year, fully powering the LED lighting system.

Real-World Applications of Carbon Capture Materials UK-based CarbonCure technology injects CO₂ into concrete bases, mineralizing 25 kg of CO₂ per cubic meter of material. Combined with geopolymers, the compressive strength reaches 80 MPa, turning the desk's carbon footprint negative.

At Microsoft’s Future Office Lab, a smart desktop with quantum sensors is optimizing material performance in real time: adjusting local elasticity modules based on contact pressure and fine-tuning the surface friction coefficient according to environmental humidity. This marks the evolution of office desk materials from static substances into intelligent media with environmental awareness. When material science breaks through molecular control limits and sustainable development concepts penetrate to the atomic level, the ultimate form of the office desk will be a technological symbiosis between humanity and nature.

By choosing Ekintop's material solutions, you gain not only office furniture but also a technological carrier for the zero-carbon future.

0 notes

Text

0 notes

Text

0 notes

Text

The Role of Sensors in Modern Automation Enhancing Precision and Efficiency

The Role of Sensors in Modern Automation

In today's dynamic industrial and marine operations, integration of automation has become central to higher productivity, precision, and protection of operations. The fundamental component in most contemporary automation systems is sensors, which are used to identify and react to current conditions Let's highlight the feature of sensors in today's automation process and how effective performance, especially in industrial and marine environments, is enhanced.

Understanding Sensors in Automation

Sensors are instruments that work to identify changes in physical, chemical and biological form and transmit them in the form of an electrical signal that is measurable and actionable. In analyzing the automation systems, the sensors act as sources of the required information for the control systems so that various processes can proceed successfully and effectively.

Types of Sensors Commonly Used in Automation

1. Proximity Sensors: These sensors establish the existence and nonexistence of an item in a certain scope, often called no contact. They are used extensively in manufacturing such as in the identification, counting, and location of an object.

2. Temperature Sensors: Thermometers are used to measure the degree of heat in equipment and processes to guarantee that they are within the safe and most efficient conditions. These are used in many industries, especially food processing industries, pharmaceutical industries and chemical industries.

3. Pressure Sensors: Pressure sensors are used to quantify the pressure of any fluid present in a certain system. They are essential in hydraulic and pneumatic applications where pressure must be controlled in order to achieve system stability.

4. Level Sensors: These sensors help to measure the number of substances in liquid and solid state, in vessels and tanks. Level sensors are widely employed in the water, oil, gas, and chemical sectors.

5. Flow Sensors: These flow sensors are used to determine the flow rate of fluids, liquids and gases, in a particular system. They are important in control of flow rates and reaction rates, in cases of fluid and chemical mixing.

6. Position Sensors: Measuring devices which specify the position of an object are known as position sensors and it position them in terms of linear and angular displacement. These motors are employed in robotics systems, CNC machines, and other applications that demand accurate motion control.

The Importance of Sensors in Executing Automation

1. Precision and Accuracy: Sensors give the information required to monitor and control the different processes automatically. When manufacturing products, position sensors guarantee that the robotic arms perform the intended motion with an incredible level of precision to accommodate mechanical integration processes devoid of failure. They ensure that such processes as welding take place at the right temperature, which leads to quality end products.

2. Real-Time Monitoring: Monitoring equipment and processes with sensors makes it possible to control equipment and processes and make corrections the moment some parameters get too high and too low. It is important for sustaining product quality, minimizing material loss and avoiding time loss. Dropship Automation present a variety of sensors that are coupled with monitoring systems, which assist the operators in getting data feedback that enhances the efficiency of operating systems.

3. Predictive Maintenance: The biggest advantage that can be derived from sensors is that they allow for predictive maintenance. The condition of equipment can be checked all the time to notice signs that might indicate that it is worn out and in need of repair before it fails using sensors. It helps to reduce time losses and increase the duration of equipment and machines used in industries. Dropship Automation offers industries sensors that have sophisticated diagnostic features that help industries remain aware of problems.

4. Safety and Compliance: The safety of the environment and the employees in the industrial and marine fields is protected by Sensors. A gas sensor is responsible for the detection of dangerous gas, whereby when it is identified within an enclosed area, alarms are raised, and systems that may lead to mishap are closed. The pressure sensors help ensure that the operating conditions of the systems do not go beyond the set safe maximum limit, avoiding possible damage to the equipment and posing risks to people. Dropship Automation provides a comprehensive list of safety sensors that are standard in various industries and, hence, fit your safety measures for compliance.

How Dropship Automation Lead to Sensor Technology

High-quality sensors are the commitment that Dropship Automation has made towards fulfilling the needs of modern automation systems. One strategic relationship that the Dropship Automation engages in is partnering with some of the leading manufacturers of sensors like Bosch and Siemens. Its sensors are meant to be sturdy, precise, and plug-and-play, which makes them right at home in any industrial and marine setting.

Conclusion

Sensors are the primary support of contemporary automated systems and allow effective control, continuous monitoring, anticipation of faults, and increased levels of protection. Dropship Automation has a wide portfolio of sensors to assist industries in improving efficiency and reliability. The help of state-of-the-art sensor systems integrated into your automation systems, you can achieve maximum efficiency, cost savings and advantage over your competitors.

An entrepreneur on the lookout for a Dropship Automation partner with whom to develop your business and maker searching for a Dropship Automation team member who can assist you in your endeavors, you may be confident that you are receiving the competent required to achieve your goals on the area of automation the way you envision it. Have a look at our selection of sensors and find out how we can assist you in enhancing your advanced systems.

1 note

·

View note

Text

OnePlus 12 vs. Samsung Galaxy S24 Ultra A Comprehensive Comparison

The fight between front runner smart devices warms up along with the launch of the OnePlus 12 and the Samsung Galaxy S24 Ultra. Each devices stand for the peak of engeneering coming from their particular brands, using groundbreaking features, strong efficiency, as well as stunning styles. If you're torn in between these two goliaths, this extensive contrast is going to assist you determine.

Additionally, our experts'll touch upon personalization options like skin layers, with brand names such as Gadgetshieldz delivering cost effective and also top notch modifications to maintain your tool looking new.

Concept as well as Construct Premium OnePlus 12 The OnePlus 12 features a streamlined, light in weight layout with a metal structure as well as a frozen glass back. OnePlus has concentrated on functional designs, guaranteeing the phone feels great in palm. Its balanced design as well as polished sides make it stand apart.

Samsung Galaxy S24 Ultra The S24 ULtra keeps its vibrant, angular style, along with superior materials like Gorilla Glass Victus 3 and also an aluminum framework. The gadget feels strong and also glamorous but could be a little burdensome for those with smaller sized hands due to its size as well as body weight.

Judgment: If you choose a lighter, extra ergonomic phone, the OnePlus 12 could match you a lot better. However, for those who desire a durable, superior feeling, the S24 Ultra pioneers.

Present OnePlus 12 The OnePlus 12 boasts a 6.7-inch AMOLED display along with 2K resolution and a 120Hz flexible refresh price. The show delivers lively colours, strong african-americans, and remarkable luminosity, making it best for games adn interactives media.

Samsung Universe S24 Ultra The S24 Ultra includes a slightly much larger 6.8-inch Dynamic AMOLED 2X show wiht QHD+ resolution as well as a 120Hz refresh cost. Samsung's screen technology is recognized for its first-rate shade accuracy and outdoor presence, specifying a higher benchmark.

Decision: BOth display screens are actually magnificent, yet the S24 Ultra outlines ahead of time along with its somewhat bigger monitor as well as industry-leading shade calibration.

Performance OnePlus 12 Powered through thge Snapdragon 8 Generation 3 chipset, the OnePlus 12 deals blistering efficiency. Matched with around 16GB of LPDDR5X RAM adn UFS 4.0 storage, it takes care of multitasking, gaming, as well as hefty applications very easily.

Samsung Galaxy S24 Ultra The S24 Ultra is furnished along with the Snapdragon 8 Generation 3 for Galaxy chipset, a slightly improved version of the regular Generation 3. While it discusses comparable primary design, the "for Galaxy" version supplies minor functionality enlargements.

Judgment: The S24 Ultra has a minor edge in fresh functionality, however thge difference is actually imperceptible in regular use.

Cam OnePlus 12 The OnePlus 12 features a triple-camera setup:

Key Sensor: fifty MP with visual picture stabilization (OIS). Ultra-Wide: fifty MP along with a large field of view. Telephoto: 64 MP with 3x visual zoom. The cam device is co-engineered with Hasselblad, providing natural different colors duplication andd enhanced low-light functionality.

Samsung Universe S24 Ultra The S24 Ultra stuffs a quad-camera setup:

Main Sensing Unit: 200 MP along with innovative OIS. Ultra-Wide: 12 MP. Telephoto: 10 MP (3x optical zoom). Periscope Zoom: 10 MP (10x visual zoom). Samsung's video cameras master versatility and also long-range photography, due to its periscope zoom lens.

Judgment: The S24 Ultra is the crystal clear winner for photography enthusiasts, especially those that need long-range zoom functionalities. However, the OnePlus 12 is actually adept and also delivers great photograph quality for daily usage.

Battery and also Asking for OnePlus 12 The OnePlus 12 is actually geared up with a 5,400 mAh electric battery and sustains blazing-fast 100W wired charging as well as 50W cordless charging.

Samsung Universe S24 Ultra The S24 Ultra houses a 5,000 mAh battery along withh 45W wired asking for as well as 15W wireless charging.

Judgment: The OnePlus 12 supplies faster asking for velocities, making it more convenient for customers on the move.

Program OnePlus 12 Running on OxygenOS 14 based on Android 14, the OnePlus 12 gives a clean, quick, as well as customizable user knowledge with marginal bloatware.

Samsung Universe S24 Ultra The S24 Ultra manages One UI 6, which is actually also based upon Android 14. One UI is actually feature-rich as well as highly personalized but features even more pre-installed apps.

Verdict: Both use superb program expertises, but OxygenOS attract those that choose a cleaner interface, while One UI is actually best for users who like comprehensive attributes.

Price OnePLus 12 OnePlus continues to install its crown jewel as a value-for-money proposal, supplying high-end components at a veyr competitive rate.

Samsung Galaxy S24 Ultra The S24 Ultra comes at a superior, showing its additional functions like the S Pen as well as evolved camera functionalities.

Decision: For budget-conscious purchasers, the OnePlus 12 gives much better market value without considerable trade-offs.

Customization and Skins Both devices are spectacular, however they're prone to blemishes as well as scratches. Personalized skin layers are an excellent method to protect as well as personalize your phone without including majority.

Gadgetshieldz uses budget friendly, top quality skin layers for both the OnePlus 12 adn Samsung Galaxy S24 Ultra. Their skin layers are actually precision-cut, simple to administer, as well as can be found in a variety of structures like carbon fiber, matte, leather, as well as wood. Certainly not only do they improve grip, but they also keep your gadget appearing pristine.

If you're seeking a cost-effective means to make your phone attract attention while keeping it shielded, Gadgetshieldz is actually a great possibility.

Final thought Deciding on between the OnePlus 12 and the Samsung Universe S24 Ultra depends on your priorities:

Select OnePlus 12 if you wish a value-for-money flagship along with rapid charging, a tidy UI, and exceptional day-to-day functionality. Choose S24 Ultra if you need a top-tier camera, improved efficiency, anbd additional functions like the S Pen. No matter which unit you choose, brands like Gadgetshieldz ensure you can safeguard as well as customize your financial investment along with premium skins at a cost effective cost.

0 notes

Text

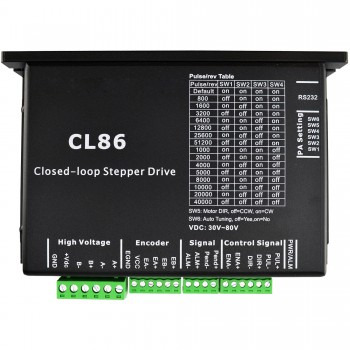

Solutions to faults during operation of stepper motor drivers

1.Basic understanding of stepper motor drivers A stepper motor driver is an actuator that converts electrical pulses into angular displacements. It drives the stepper motor to rotate a fixed angle in the set direction by receiving control signals. The stepper motor driver is an important component of the stepper motor system, responsible for converting the control signal into the current and voltage required by the stepper motor to drive the motor for precise angular or linear displacement. The working principle of the stepper motor driver is to convert the input pulse signal into a drive current signal to control the angular displacement of the stepper motor. The speed of the motor is proportional to the pulse frequency, so the speed can be accurately adjusted by controlling the pulse frequency, and the positioning can be accurately achieved by controlling the number of pulses. The stepper motor driver has high positioning accuracy and stability, and can subdivide each step into smaller steps through the subdivision function, thereby improving positioning accuracy and stability.

2.The main structure of the stepper motor driver 1.Ring distributor. Generate the switching waveform signal processing of the motor in different states according to the requirements of the input signal. Perform PWM modulation on the switching signal waveform generated by the ring distributor and filter and shape the related waveform. 2.Protection circuit. When the winding current is too large, a shutdown signal is generated to shut down the main circuit to protect the motor driver and motor winding. 3.Sensor. Real-time monitoring of the position and angle of the motor, and the signal generation device is transmitted back.

3.Solutions to faults during operation of stepper motor drivers 1.The motor does not rotate or rotates slowly: The stepper motor driver needs to receive the correct pulse signal to control the motor rotation. If the motor does not rotate or rotates slowly, first check whether the pulse signal source is working properly, ensure that the driver input terminal is connected correctly, and check whether the motor wiring is correct to eliminate the motor itself. 2.Overheating: The stepper motor driver may overheat when working for a long time or overloaded. Improve the heat dissipation conditions, add fans or heat sinks, ensure that the working environment temperature is suitable, and avoid long-term overload operation. 3.Excessive noise: Abnormal noise during motor operation may be caused by bearing damage or loose internal parts. Check whether the motor bearing is damaged, re-tighten the loose internal parts, and adjust the driver current setting. 4.Overcurrent protection: The driver has an overcurrent protection function. If the output current exceeds the rated value, the driver will cut off the power supply to protect the motor and itself. Check the power supply and motor load, and readjust the current setting. 5.Communication error: If the driver and controller are controlled by communication, communication errors may indicate that the driver cannot work properly. Check the communication line and settings to ensure stable communication.

4.Precautions for using stepper motor drivers

1.Power management: The quality of the power supply directly affects the performance and power consumption of the driver. The ripple size of the power supply affects the accuracy of the subdivision, and the suppression ability of the power supply common mode interference affects the anti-interference of the system. Therefore, for applications with higher requirements, users must pay attention to improving the quality of the power supply. In addition, the installation of the driver should ensure good ventilation, and regularly check whether the cooling fan is running normally. 2.Signal line processing: When wiring the system, the principle of separating the power line (motor phase line, power line) from the weak current signal line should be followed to avoid interference with the control signal. When it is impossible to wire separately or there is a strong interference source, it is best to use shielded cable to transmit the control signal. Using a higher level control signal is also meaningful for resisting interference. 3.Initial operation check: Do not connect all the lines at the beginning. You can connect the most basic system first, and then complete all the connections after confirming that it is running well. Carefully observe the sound and temperature rise of the motor. If any abnormality is found, it should be stopped and adjusted immediately. 4.Environmental adaptation: Due to the drastic changes in the storage and transportation environment temperature, condensation or frost is easy to occur. At this time, the driver should be placed for more than 12 hours. After the driver temperature is consistent with the ambient temperature, it can be powered on. If stored in an unsuitable environment for a long time, the quality of the product should be retested before operation.

Source:https://medium.com/@porterbickford69/solutions-to-faults-during-operation-of-stepper-motor-drivers-7fc1e964767f

0 notes